#Polycarbonate

Explore tagged Tumblr posts

Text

Jorba Castle Works, Puig de la Guàrdia, Spain - Carles Enrich

#Carles Enrich#architecture#design#building#modern architecture#modern#minimal#old and new#history#ruin#old building#historical#historical sites#castle#shelter#archaeology#spain#spanish architecture#cool design#beautiful places#landscape#slopes#timber#wood architecture#timber frame#joinery#polycarbonate#lightweight#architectural photography#stone

224 notes

·

View notes

Text

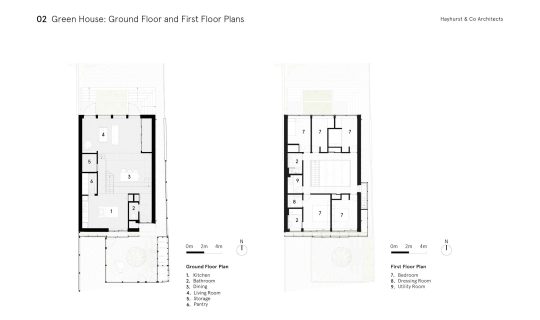

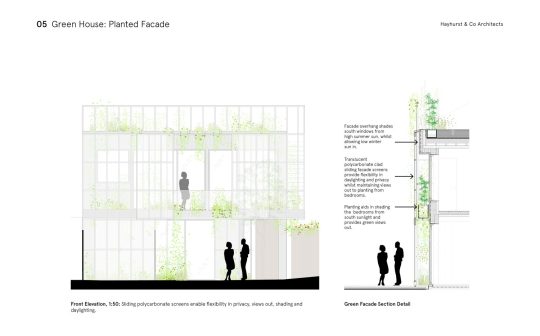

Green House, Tottenham, London, United Kingdom,

Hayhurst and Co

#art#design#architecture#minimal#nature#interior design#minimalism#green house#london#tottenham#hayburst & Co#bamboo#polycarbonate#screen#facade#low cost#lost energy#eco-friendly#sustainability#sustainable architecture#gif#architecture gif

346 notes

·

View notes

Text

Android Tissue Sheathing Sheathing is the skin encasement around the android’s body and face — at least where obvious cybernetic implants are not affixed. A unique android might start game play with the most advanced alloy cladding, a more typical plastic sheathing, or be unlucky and have no covering at all and all its servo motors, wiring, pistons and underlying skeletal frame exposed. Androids start with a base defense value of 0 (zero) just like a human character, however apply any agility modifiers, sheathing mods, or skill-based changes after the character is created.

Sheathing, or a lack thereof, also affects the endurance trait of the android so record any endurance amount added or subtracted when establishing a sheathing type, as this amount can change when skin is added or removed. Only one sheathing type can be adhered to the android at any given time. Ink illustration for page 46 of The Mutant Epoch RPGs Expansion Rules Book. See a commentary here: https://swordsandstitchery.blogspot.com/2024/10/review-commentary-on-mutant-epoch.html

#skin#sheathing#skinned#tissue#skeleton#android#noai#noaiart#ink#rpg#ttrpg#scifi#playercharacter#mutantepoch#expansionrules#tme#postapocalyptic#themutantepoch#roleplayinggame#apocalyptic#outlandsystem#outlandarts#mutants#mutant#epoch#tabletoprpg like#gammaworld or#fallout or#mcc#Polycarbonate

7 notes

·

View notes

Text

Using pyrolysis for high-quality recycled plastics

Plastics made of polycarbonate are sought-after materials in industrial applications thanks to their versatility and high quality. However, recycling of plastic waste is still running up against limits these days, as mechanical recycling methods do not produce adequate qualities of recycled material for all applications. Together with chemical company Covestro Deutschland AG, Fraunhofer researchers have now developed a method that makes it possible to reclaim the substances originally used to make the polycarbonates. In catalytic pyrolysis, a controlled process of heating in an oxygen-free environment, plastic waste breaks down into its components. Manufacturers can then use the raw materials to produce new plastics.

Read more.

7 notes

·

View notes

Photo

Beomseok Chae

24 notes

·

View notes

Text

RYDER, BASIC PLUS RANGE

RYDER, BASIC PLUS RANGE Anti-Scratch, Anti UV Light, POLYCARBONATE Scratch-resistant, hard coated polycarbonate lens filters out more than 99.9% of harmful UV light. Snug-fitting wrap around lens provides perfect impact protection around the eyes. Close-fitting unitary front with dual 9.75 base curvature offers wide and unobstructed vision

NOSE Piece : Universal, Integral to lens TEMPLE : Modern Temple Design and Spatula type SCREW : Stainless Steel Standard Hinge screw Spec Pouch & Cord (Optional)

2 notes

·

View notes

Text

Transform Your Space with Versatile Polycarbonate Roofing Options

Polycarbonate roofing has become a popular choice for homeowners and businesses looking for durable, stylish, and practical roofing solutions. Known for its strength, versatility, and transparency, this roofing material is ideal for a wide range of applications. Whether you're upgrading your outdoor patio, building a greenhouse, or creating a modern office space, polycarbonate roofing offers the perfect balance of form and function.

What is Polycarbonate Roofing?

Polycarbonate roofing is made from a thermoplastic material that is lightweight yet incredibly strong. It is designed to withstand extreme weather conditions, including intense sunlight, heavy rain, and even hail. Its UV-resistant properties make it an excellent choice for areas with high exposure to the sun, as it blocks harmful rays while allowing natural light to filter through.

Benefits of Polycarbonate Roofing

Polycarbonate roofing offers numerous benefits that make it a versatile option for various spaces:

Durability: This roofing material is highly resistant to impact and can last for years with minimal maintenance.

Transparency: Polycarbonate sheets allow natural light to pass through, creating bright and welcoming spaces.

Lightweight: Despite its strength, polycarbonate is easy to handle and install, reducing labor costs.

Weather Resistance: It can withstand harsh weather conditions without cracking, fading, or warping.

Energy Efficiency: By allowing natural light in, polycarbonate roofing reduces the need for artificial lighting, helping you save on energy bills.

Applications of Polycarbonate Roofing

The versatility of polycarbonate roofing makes it suitable for a variety of applications:

Residential Spaces: Use polycarbonate roofing for patios, carports, or pergolas to create shaded, comfortable outdoor areas while maintaining a stylish aesthetic.

Commercial Spaces: Businesses can use this material for canopies, skylights, or covered walkways, providing functional yet visually appealing structures.

Greenhouses: Its transparency and UV-blocking properties make it perfect for creating greenhouses that promote healthy plant growth.

Industrial Use: Factories and warehouses can benefit from polycarbonate roofing to allow natural light into workspaces, enhancing productivity.

Choosing the Right Polycarbonate Roofing

When selecting polycarbonate roofing, consider these factors to ensure you get the best solution for your needs:

Thickness: Thicker sheets provide greater durability and insulation, making them suitable for heavy-duty applications.

Color: Clear sheets allow maximum light, while tinted or frosted options provide additional privacy and shade.

Type: Polycarbonate roofing is available in solid, corrugated, or multi-wall designs, each offering unique benefits.

Caring for Your Polycarbonate Roof

Polycarbonate roofing requires minimal maintenance to retain its appearance and functionality. Here are some tips:

Regular Cleaning: Use a soft cloth, mild soap, and water to clean the surface, avoiding abrasive materials that could scratch it.

Check for Damage: Inspect for cracks or loose fittings, especially after extreme weather.

UV Coating Maintenance: Ensure the UV coating remains intact to prolong the roof’s lifespan.

Conclusion

Polycarbonate roofing is an excellent investment for anyone seeking a versatile, durable, and aesthetically pleasing roofing option. Its ability to adapt to various applications—residential, commercial, and industrial—makes it a standout choice. By selecting high-quality materials and proper installation, you can enjoy the benefits of polycarbonate roofing for years to come.

Transform your space with this innovative roofing solution and experience the perfect blend of practicality and style.

0 notes

Text

🌿 Elevate Your Greenhouse Construction with PC Roofing Sheets! 🌿

🔍 Polycarbonate (PC) roofing sheets offer exceptional durability, UV protection, and thermal insulation, making them ideal for greenhouse applications. Our latest blog post provides an in-depth guide on utilizing PC sheets to enhance your greenhouse projects. Explore our custom processing services tailored for large-scale plastic procurement and OEM needs.

#polycarbonate#greenhouseconstruction#pcroofingsheets#customprocessing#engineering#oem#plastic products#innovation#materialscience#sustainability#industrial design#technology#futuretech#ecoideas

0 notes

Text

Nightlight Shed, Akaroa, New Zealand - Fabric

#Fabric#architecture#design#building#modern architecture#interiors#minimal#modern#contemporary#contemporary design#contemporary architecture#structure#hut#shed#timber#wood#wood architecture#low cost#reuse#polycarbonate#light#tools#workshop#studio#garden studio#garden#cool design#small#new zealand#design blog

254 notes

·

View notes

Text

Glass House, Uckermark, Germany,

The wooden structure of the roof forms a wind protected space on the first floor. Towards west, the entire roof surface is glass so the view over the green valley and sunset can be experienced from inside.

The eastern slope of the roof is polycarbonate that creates a spectacular play with light, shadow and changing colors as the sun moves over the house. Every day is a new experience.

Sigurd Larsen Architect

#art#design#architecture#minimal#nature#interior design#minimalism#interiors#glass#glasshouse#germany#millwork#uckermark#sigurd larsen#weekend house#retreat#polycarbonate#shadows#light

232 notes

·

View notes

Text

Polycarbonate Sheath Skin While still flexible like skin, this covering is hard to mistake as anything natural, and while it hugs the contours of the body shape within, and seems to pronounce any gender identifying physical attributes, the skin itself is not warm, exhibits little subtleness or responsiveness despite any amatory capabilities the android might have. This skin is usually of some unnatural color, and like ballistic mesh, is exhibits a grid or diamond shaped pattern which sometimes reflects light almost like fish scales. Ink illustration for page 47 of The Mutant Epoch RPGs Expansion Rules Book. Learn about this game book at https://www.outlandarts.com/expansionrules.htm

#polycarbonate#skin#amatory#skintype#plasticskin#fake#silicon#polysheathed#android#noai#noaiart#ink#rpg#ttrpg#scifi#playercharacter#mutantepoch#expansionrules#tme#postapocalyptic#themutantepoch#roleplayinggame#apocalyptic#outlandsystem#outlandarts#mutants#mutant#epoch#tabletoprpg like#gammaworld or

4 notes

·

View notes

Text

High-performance Polycarbonate Sheets: The Smart Choice for Builders and Designers

At Kapoor Plastics, we are committed to providing high-quality polycarbonate solutions to meet your unique project needs.

0 notes

Text

Lightweight yet incredibly strong our Polycarbonate Shades offer the perfect balance of durability and design. Engineered to withstand the elements while reducing structural load, these shades provide reliable protection without compromising on style.

Visit our website for more information - https://www.buildmatt.net/product/poly-carbonates

#BuildMattLtd#polycarbonate#polycarbonateroofing#PolycarbonateShades#PolyCarbonateShadeSheet#pchollowsheet#TweenWallPolycarbonateSheet#Uganda

0 notes

Text

𝐕𝐢𝐬𝐭𝐚 𝟗𝟗.𝟗𝟗% 𝐔𝐕 𝐩𝐫𝐨𝐭𝐞𝐜𝐭𝐢𝐨𝐧

Optically correct

High velocity impact & high mass resistant

Meets ANSI Z87.1 & CE EN166 standards

Features

* Sunglasses style with metal hinge structure creates premium look for safety glasses

* Full eye coverage, permanent side protection, resistant against high impact

Soft nose piece & soft temple tips generate the comfort & soft cushions to wearer for long time use

Optical Class 1 polycarbonate lens which provides 99.9% of UV protection

visit : https://sams-solutions.com/collect.../eye-protection-premium

to place your order online :https://www.ppe-online.com/products/vista-premium-range

#empiral#vista#sunglassesstyle#uvprotection#polycarbonate#eyeprotection#safetyglasses#manufacturing#highquality#hilights#safety#safetyfirst#safetyequipment

0 notes

Text

In a world where security concerns are constantly rising, choosing the right materials for protection is more crucial than ever. Public spaces like banks, schools, and commercial buildings face threats that demand enhanced security measures. Enter polycarbonate solid sheets—a modern solution to age-old security challenges.

0 notes

Text

Choosing the Right Awning in Singapore: A Comprehensive Guide

In Singapore, where the tropical climate brings intense sunlight and frequent rain, awnings have become a must-have feature for residential and commercial properties. A well-designed awning enhances outdoor spaces, offering shade, protection, and aesthetic appeal. Whether you’re upgrading your home or enhancing your business facade, choosing the right awning Singapore requires careful consideration.

This guide explores the benefits of awnings, factors to consider when selecting one, and tips for finding the best contractor in Singapore.

Why Invest in an Awning in Singapore?

Awnings provide numerous advantages for properties in Singapore’s climate:

Protection from the Elements: Awnings shield outdoor areas from intense sunlight and sudden rain showers, making them perfect for patios, balconies, and storefronts.

Energy Efficiency: By blocking heat from entering your property, awnings help reduce air-conditioning costs and improve energy efficiency.

Enhanced Outdoor Living: With the added shade, you can transform your outdoor space into a comfortable area for relaxing, dining, or entertaining.

Aesthetic Appeal: Awnings come in various designs, colors, and materials, allowing you to customize them to match your property’s style.

Increased Property Value: A functional and stylish awning can enhance your property’s overall appeal and value.

Types of Awnings Available in Singapore

When selecting an awning, consider the following popular options:

Retractable Awnings

Ideal for those seeking flexibility.

Can be extended or retracted based on weather conditions.

Available in motorized or manual systems.

Fixed Awnings

A permanent solution for consistent shade and protection.

Suitable for storefronts and residential patios.

Canopy Awnings

Stylish designs that add a decorative touch.

Often used for entrances or walkways.

Pergola Awnings

Provide partial shade while allowing airflow.

Popular for gardens and patios.

Key Factors to Consider When Choosing an Awning in Singapore

Material Quality Opt for weather-resistant materials that can withstand Singapore’s humid and rainy climate. Look for:

Fabrics: UV-resistant, waterproof, and mold-proof materials.

Frames: Rust-proof aluminum or galvanized steel for durability.

Customization Options Awnings should blend seamlessly with your property’s design. Choose contractors that offer a wide range of colors, patterns, and styles to match your aesthetic preferences.

Space and Functionality Assess the area where the awning will be installed to determine the right type and size. Consider retractable awnings for versatility or fixed awnings for consistent coverage.

Energy Efficiency Features Choose awnings that reduce heat absorption and promote ventilation, helping to lower indoor temperatures and energy consumption.

Contractor Reputation Partner with an experienced contractor who understands Singapore’s climate and regulations. Check reviews, portfolios, and testimonials to ensure quality work.

Benefits of Professional Awning Installation

Hiring a professional contractor for your awning installation ensures:

Proper Assessment: Contractors evaluate your property and recommend the best awning type for your needs.

Precision Installation: Secure and accurate installation minimizes risks like sagging or poor alignment.

Compliance with Local Standards: Professionals ensure your awning adheres to building codes and safety regulations.

Maintenance Services: Many contractors offer cleaning, repairs, and adjustments to prolong the lifespan of your awning.

Common Mistakes to Avoid

Compromising on Quality Low-cost options may save money initially but often lead to higher maintenance costs due to inferior materials or poor workmanship.

Neglecting Local Climate Ensure the awning materials are suitable for Singapore’s tropical weather, particularly its high humidity and frequent rain.

Skipping Reviews Always check online reviews or request references to verify the contractor’s reliability and expertise.

Overlooking After-Sales Support Choose a contractor who provides warranties and maintenance services for long-term satisfaction.

Shade Times: The Trusted Name for Awnings in Singapore

For high-quality awnings in Singapore, Shade Times is the name you can rely on. With years of experience, we specialize in crafting custom awning solutions tailored to meet the unique needs of our clients.

Our range of products includes retractable, fixed, and canopy awnings, all made with premium materials that can withstand Singapore’s tropical climate. Whether you’re a homeowner looking to enhance your patio or a business owner wanting to attract more customers, we offer solutions that blend functionality with style.

Shade Times provides:

Professional Installation: Ensuring secure and efficient setup.

Durable Materials: UV-resistant fabrics and rust-proof frames for long-lasting performance.

Custom Designs: Tailored options to match your property’s aesthetics.

After-Sales Support: Maintenance and repair services to keep your awning in top condition.

Final Thoughts

An awning is a valuable addition to any property in Singapore, offering shade, weather protection, and a boost in curb appeal. By considering factors like material quality, design options, and contractor reputation, you can find the perfect awning to suit your needs.

Shade Times is committed to delivering top-notch products and services, ensuring your awning provides long-lasting comfort and style. Contact us today for a free consultation and discover how we can enhance your outdoor space with a premium awning in Singapore!

0 notes