#Plastic processing machine manufacturer

Explore tagged Tumblr posts

Text

Solutions to plastic product mold opening problems (1)

This article mainly introduces problems that arise during mold opening, mold trial and mass production processes after design of plastic parts is completed. It also provides a general understanding of how to solve them. Details are as follows, mainly following points:1. Insufficient filling2. Overflow3.Shrink marks 1. Insufficient filling Underfilling manifests itself as an incomplete injection…

View On WordPress

#Design of plastic parts#injection molded part#injection molded product#injection molding machine#injection molding process#injection pressure#injection speed#Mold clamping force#mold design#mold design and manufacturing#mold parting surface#multi-cavity molds#multi-gate molds#Overflow#plastic parts#product design#Shrink marks#Solutions to plastic product mold opening problems

0 notes

Text

#Non-standard precision machining#precision#cnc swiss#precision parts#cnc turning#Precision machining manufacturer#shaft#The main processing methods of metal parts are: machining#stamping#precision casting (investment casting)#powder metallurgy#metal injection molding. Machining refers to the process of changing the dimensions or properties of a workpiece by means of a mechanical d#Stamping is a forming processing method that relies on press and die to exert external force on plate#strip#pipe and profile to produce plastic deformation or separation#so as to obtain the required shape and size of the workpiece (stamping parts). There are also special processing#laser processing#electric discharge processing#ultrasonic processing#electrolytic processing#particle beam processing and ultra-high speed processing. Turning#milling#forging#casting#grinding#CNC machining#CNC center all belong to machining.

1 note

·

View note

Note

Do you have tips for being able to find affordable clothes without plastic in them? I've found it's hard to find without rayon, specifically.

Rayon is not, in fact, plastic! It's made from processed cellulose- that is, plant fibers -and while the traditional process isn't great environmentally or for the health of the workers...neither are a lot of other Plant Fabric Production Methods. And there are new, better processes being implemented, just like in other avenues of fabric production. I still don't love it, because there's just something great about real silk, but it IS a more affordable/available, technically natural option.

My biggest tip is thrifting. This is becoming less and less the case as the dominance of plastic clothing gets further and further in the past, and things get donated that are from AE (After Enshittification), but you can still find some great things in thrift stores. I've found 100% silk blouses a few times, a LOT of cotton, and even some linen. I know other people who've found wool, but unfortunately I am not one of them. When thrifting online, on Mercari or Depop or eBay or Facebook Marketplace, you can even do keyword searches for "100% [fiber]" or look for photos of the fiber content tag- if you're physically thrifting, that's usually in one of the lower side seams.

People who cut out fiber content tags and then donate clothing to thrift stores without them are on my personal "egg their car" list if I ever find them. If you have sensory issues but also like donating your clothes, for the love of god, keep the tag and safety-pin it to the garment before you donate or something. But I digress

Cotton is your new best friend, by the way. It's the natural fiber you see used the most nowadays, so you will often be able to find SOMETHING cotton even in big box stores.

Also, while this can be more of a Spend More Up-Front To Spend Less In The Long Run, learning to sew can help you have natural-fiber clothing that holds up to mending more than what's mass-manufactured these days. The startup costs are more, but if you can afford them, you'll be better-placed to buy fewer clothes in the future. If you don't have/can't afford a sewing machine, consider looking for an object library near you- they let you "check out" different items an use them for a certain length of time, like the name suggests, and many have sewing machines.

Hope this helps!

82 notes

·

View notes

Text

I've just been thinking a lot about how people like B'Elanna, who have been born into an era (and an area of space) of everyday replicator use, would think about the way we generally manufacture things now especially in a mechanical engineering context, ie mostly via machining it. Making a part with a lathe or a mill, or even something almost magical like electrical discharge machining (EDM), means you have to start with a bigger chunk of material and then work to cut and carve it until you get the part you need. More often than not the largest part of that initial material has been lost in order to get the final result, and it's not easy to get there at all within often very strict tolerances. While a lot of the operations are now done via CNC it still takes a long time, plus studying manuals and accumulating a lot of experience, to become a skilled lathe/mill/EDM technician, not to mention designs that can't be achieved at all through machining and therefore have to be excluded well before a project gets near a lathe. And it is still the most common way we manufacture so many things. Even injection molding for plastic means that you have to have a metal mold to inject your plastic into, and those molds are machined.

And of course the replicators don't work at all like that! They build something by, roughly, adding up building blocks on building blocks, which means very little waste of material in comparison, but most importantly a completely different philosophy of manufacturing and therefore also designing. I started thinking about 3D printers because it's the example of additive manufacturing (versus subtractive manufacturing, like machining) I know best, and one of the things you learn is that you can 3D print things that you would never be able to machine or injection-mold. I'm fascinated by the idea that this is the norm in Star Trek, because I imagine that the replicator, other than making food on demand, would completely revolutionize the industrial manufacturing process.

So I'm wondering how Trek engineers would look at our contemporary machine shops. Quaint, archaic? Like how we watch blacksmiths making Renaissance longswords on youtube? A workflow that would be completely incomprehensible when in your department you don't have to consider the property of every metal alloy not just because of the functionality you want your final part to have, but also how easily (or not) it will machine? Wondering how much time, energy and materials were lost whenever you needed to make even simple nuts and bolts?

I don't know, I just find it interesting to think about.

46 notes

·

View notes

Text

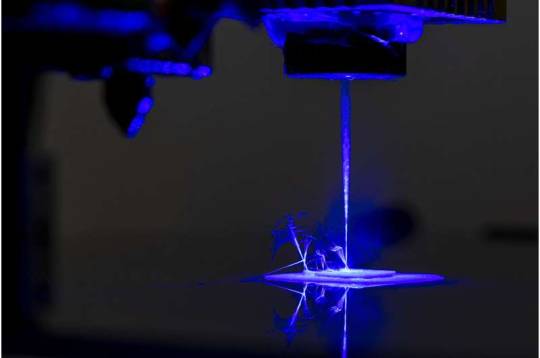

No assembly required: Innovative 3D printing method streamlines multi-materials manufacturing

University of Missouri researchers have developed a way to create complex devices with multiple materials—including plastics, metals and semiconductors—all with a single machine. The research, which was recently published in Nature Communications, outlines a novel 3D printing and laser process to manufacture multi-material, multi-layered sensors, circuit boards and even textiles with electronic components. It's called the Freeform Multi-material Assembly Process, and it promises to revolutionize the fabrication of new products. By printing sensors embedded within a structure, the machine can make things that can sense environmental conditions, including temperature and pressure. For other researchers, that could mean having a natural-looking object such as a rock or seashell that could measure the movement of ocean water. For the public, applications could include wearable devices that monitor blood pressure and other vital signs.

Read more.

17 notes

·

View notes

Text

Restoring a 1930s Typewriter + Some Scattered Thoughts

There’s something so magical about holding something this old in one’s hands. Who used it before? What feelings had it translated into words? How many families did it watch grow and scatter? How many houses has it survived?

A couple of months ago I set out to fulfill a lifelong dream of mine to have a vintage typewriter. One evening, I found a listing for this gorgeous piece for relatively cheap. I didn’t know much about the world of manual typewriters but I was eager to learn. And just like that, I was knee deep in a new hobby.

As soon as I got the machine, I went to work. I used cheap toothbrushes and Waschbenzin to clean the slugs. As it is really quite old, some gunk in between the characters were not lifting. I had to improvise and use a sewing needle to scrape the caked ink. I then removed the tattered old ribbon and replaced it with a new one.

I still have the task of cleaning and doing some small repairs on its leather case. And while the platen itself is still in really good condition the feed rollers have flat spots making it a bit temperamental when advancing the paper. I will have to find a specialty store that can replace them in the future. There are areas of chipped paint which should be quick enough to address with some black nail polish. And then for a final touch, it needs to be polished with car wax. But these tasks are secondary. The typewriter is fully working despite its age. It was incredible seeing it come to life the first time I used it. It felt like a fantasy, like time travel.

Throughout the whole process of cleaning and repairing my typewriter, I was constantly reminded that this machine is 87 years old. The curved cover, the font on the decal and the simplicity encapsulates the art deco style from that era. WWII was just starting when this was manufactured. My grandfather wasn’t even born yet. Working with this typewriter was a meditative experience but it also brought on a lot of melancholy thoughts on existence, technology, consumerism.

You can just tell how much thought and care was put into building this typewriter. It’s innovation with purpose, not solely for profit. This machine’s ribbons feed from right to left. Once it is completely wound to one side, there is a button that reverses the gears and the ribbon will then feed from left to right, ensuring that the ink in the ribbon is used up without any waste. There is a button that allows you to type beyond your set margins in case it’s necessary. There is a lever that centers the platen and disengages the margin bell in order to prevent it from jiggling around and breaking while in transport. There is a self-starter key which is practically a tab button. The case comes with clamps that keep the typewriter from moving around. It also allows you to type with the case attached.

The manufacturers and innovators of that time thought about everything. Technology is meant to last. It is meant to address as many problems as possible, and meant to stand alone without needing more attachments. Back in the day, when you purchase something, it’s meant to last your lifetime, if not beyond. Just the fact that it still works after all this time is a testament to the integrity of its creation.

87 years from now, what will our era have left for the future? What will be left of our time when iPhones self destruct every two years to force purchase of the newest model? What will the future generation seek out to repair and refurbish from our time that isn’t made of plastic? What would be “vintage” to them when everything is made to break?

19 notes

·

View notes

Text

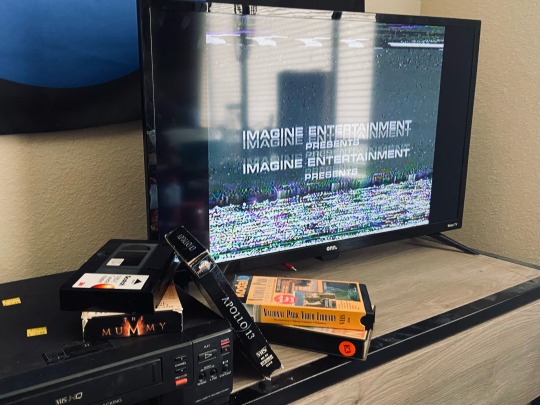

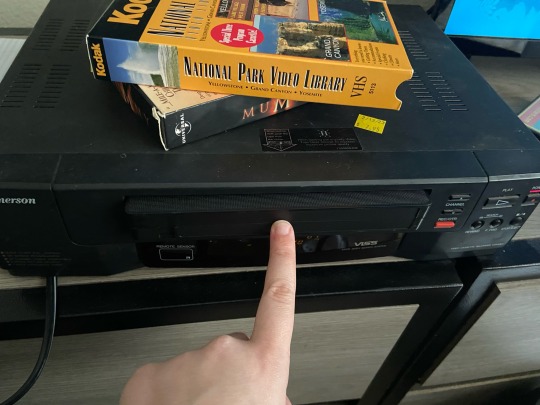

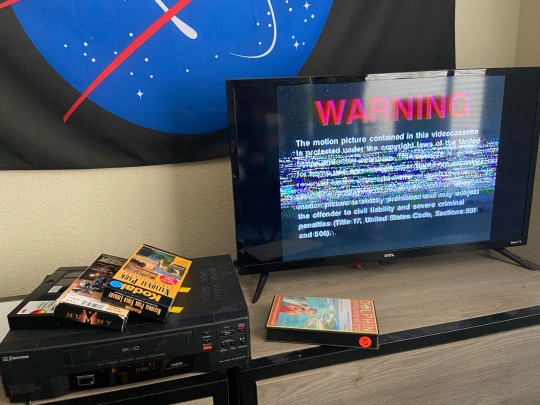

Hey, do you want to learn how to play VHS tapes in the year 202X?

I know this is my art blog, but it has come to my attention that some of you are too young to have experienced the joys of the Video Home System in its prime. Come hither so I can teach you and we can embrace the beauty of physical media together. If you have a thrift store and a TV, this process should work for you.

Step 1: Get a VCR ($4-$15)

DO NOT BUY EXPENSIVE VCR/COMBO SETS FROM THE INTERNET!

The ones you find on sites like eBay and Etsy are insanely overpriced and might not even work. Instead, find a Goodwill, Savers, or independent thrift store near you and go to the electronics section. There’s a good chance they’ll have at least one VCR. If they don’t, try a different shop. You can also check local online marketplaces, yard sales, etc.

Good things to look for:

4 (or more) Heads — Heads are the things that actually read the tape. The more heads you have, the better your picture is going to be.

Auto Tracking — Poor tracking can create a rolling picture, which is a pain to fix. An auto tracking VCR does that work for you.

Pre-2000 — After 2000, electronics started being mass produced with plastic casings and cheap parts. VCRs made after this time are a whole lot easier to break. Ideally, you want something from the late 80s to mid 90s.

Well-known brands — Sony, Toshiba, etc. Japanese manufacturers tend to have the best quality. Early Emersons are nice too.

Generally good condition — If there’s a bullet hole in the case, it’s probably best to pass on. A bit of dust isn’t an issue, but major damage isn’t a good sign. If you can, plug the machine into a power outlet in the store and see if it even turns on.

Head cleaning indicator — Not something you *need*, but I find it nice to have. You’ll want to use a head cleaning tape when the indicator starts flashing.

This is the one I’ll be using for the sake of this guide. This is an old Emerson that I picked up from Goodwill for $7.95. (Notice the five price tags they slapped on top.)

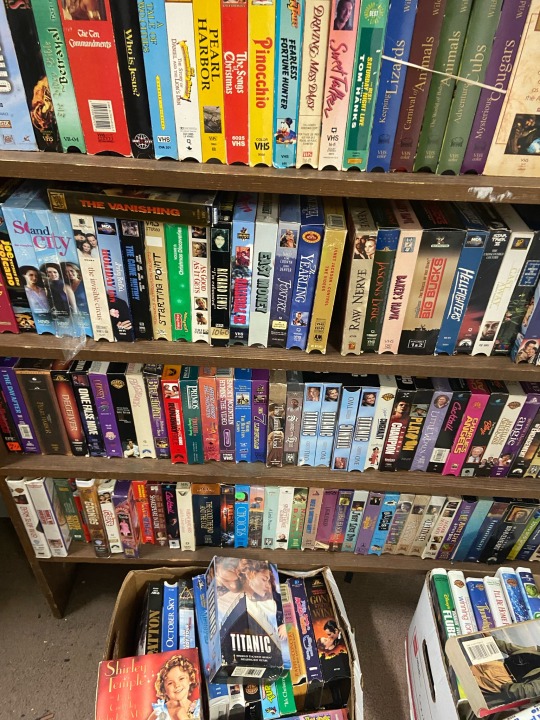

Step 2: Get Some Tapes (¢10-$1)

This is the fun part. Almost every thrift store will have some VHS tapes, usually near the books/DVDs/records. I’ve seen them as expensive as a dollar, but some stores will just give them away for free. I suggest buying a few movies you like, plus one or two shitty tapes to test out your VCR with.

You may also find 20 different copies of Titanic in every store. This is a normal occurance.

Remember to check the condition of any tape you plan on putting in your machine. If the spool looks moldy, you *can* try to clean it, but you’ll need another VCR to do so. If the tape looks wrinkled or otherwise damaged, you can still probably play it, but it will look and sound a lot rougher than you should expect. If the casing is damaged, I wouldn’t risk trying to put it in your VCR at all.

Remember: VHS tapes stopped being produced commercially in 2006. Most tapes you find aren’t going to be in the best shape, because they’re all a few decades old. (Sometimes, though, you will come across a tape with an excellent picture, good sound quality, and subtitles! The Mummy tape that I own is near perfect.)

Step 3: Connecting the VCR to Your TV

For this step, you’re going to want a coaxial cable and a set of RCA cables (the red, yellow, and white ones). If your TV doesn’t have an RCA input, you’ll also need an RCA-to-HDMI converter. If your TV also doesn’t have an HDMI input for whatever reason, you’re shit out of luck.

You’ll plug these cables into the “out” or “out to tv” connection on your VCR, then plug the other end into the back of your TV.

Note: Not all VCRs have right audio (the red one)! That’s fine. Just leave it hanging free. The left audio (white) is your mono audio, so you’ll just have that instead.

Lastly, put the channel switch on the back of your VCR on 3 or 4. I keep mine on 3. This is the number for the channel you’ll go to on your TV to actually see what the VCR is playing.

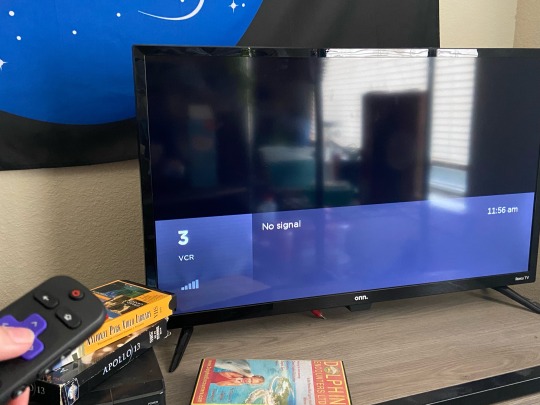

Step 4: Setting up the TV

I use a little Roku TV, which is surprisingly steady to set up for VCR input:

Settings ➡️ TV Inputs ➡️ Live TV

From here, you’ll either be prompted to scan for channels OR you’ll have to select “scan for antenna channels”. It will ask you if you want to have channels 3 and 4, to which you’ll say “yeah, I do want channels 3 and 4” and click the button that lets you have channels 3 and 4. If you don’t have an antenna, you can skip the other prompts.

I haven’t done this on any other type of TV, but the process should be pretty similar: get yourself to channels 3 and 4 through whatever means necessary.

Once you’re there, it should look like this. Sad, blank, and lonely. But not for long.

Step 5: Playing Your Tapes

This is where things can go really really well or really really wrong. If everything is hooked up, you can grab your shitty tape and insert it into the VCR.

(Make sure there isn’t anything else in there first, though. Some people don’t remove their precious Titanic copies before donating these things.)

You’ll want a tape that’s fairly clean, with no casing damage, and already rewound (black tape in the left window). To insert the tape into a front-loading VCR, slowly and firmly slide it into the slot. Once it’s most of the way in, the machine should “grab” it and pull it all the way inside. You’ll hear the machine make some noises.

(If those noises are really crunchy, that’s probably not a good thing. Troubleshoot with your favorite search engine or head over to r/VHS to see if anyone can help you.)

Once your machine is only making some clunky whirring sounds, it should be safe to press the play button. Enjoy watching your favorite films in the least pleasant format possible. Don’t forget to rewind em when you’re done.

If you have issues, the freaks over at r/VHS tend to be really helpful, but you can also find decade-old YouTube videos that might answer your questions too.

183 notes

·

View notes

Text

OEM precision machining

#design#autos#business#cnc machining#prototyping#precision machining#prototype#prototype machining#rapid prototyping#machining parts#cnc part#cnc precision machining#high precision#cnc manufacturing#cnc processing#plastic machining#metal machining

1 note

·

View note

Text

Mobile phone shell injection mold design and moldflow

1 Preliminary preparation 1.1 Overview Mobile phone products have huge market development space. At the same time, market is also in a stage of rapid development. This is an extremely important development stage for manufacturers, distributors and retailers, and is a stage where market structure is gradually taking shape. Therefore, in next few decades, design and processing of mobile phone…

View On WordPress

#barrel temperature#Cold material well design#cooling system design#Design of demoulding mechanism#design of mold base#design of molded part#Design of molding parts#design of plastic molded parts#Exhaust system design#Flow analysis#Gate design#Gate location selection#gating system design#Grid connectivity diagnosis#Grid related analysis#Guide mechanism design#injection mold design#injection molding machine#large and medium-sized molds#Mesh thickness diagnosis#mobile phone case injection mold#Mobile phone shell injection mold design#mold design#mold manufacturing#mold manufacturing and assembly#Mold temperature#molded parts of injection mold#Moldflow#molding process#multi-cavity mold

0 notes

Text

the conceit of the dream btw was that inside of a mall there was a venue containing some kind of mysterious supernatural process and if you went into it you would die and then like 2-3 days later you would be reconstituted and show up outside the venue. appearancewise it was like.. ok this is a very clear image in my head but i dont know how to describe it... like the entrance of a museum exhibit where everything is hastily erected particleboard dividers with black fabric over them? that kind of slightly forboding manufactured non-space. very liminal in the original sense of the word before the aesthetes got to it. obviously because this was a dream the geometry of the place wasnt super clear but there was an entry line and an exit line and they both had plastic clipboards with paper for people to sign in and out of the Death Mechanism. the entry line had sharp turns so a person going through it was immediately out of sight. the whole place was totally silent and empty and motionless and constructed out of shades of black but not in a mystical way i mean it was all extremely practical and realistic. if youve seen after last season you can probably understand the vibe. anyway . nobody knew how the death and resurrection mechanism worked but it was understood to be painful and you were fully aware that you were dying and it took at least a couple minutes. and then you woke up 36 hours later in the exit line. it was never addressed where this thing came from or who owned it, it was just established as a thing that exists in the mall. and not like an anchor store either, it was the size of like, spencers. or one of those shoe stores no one is ever in. in the dream before i actually got to the death machine i was just talking to some people on an escalator going down towards it, there were two women one of whom had done it before and one who was going for the first time and we were discussing why people would do it. for both of the women it was like a hardcore kink thing but there was also some religious aspect to it for some people, like specifically some christian denominations were really into it and by dream logic this was totally self evident like Ohhhh yeah of course the jesuits are fans of the death machine. obviously. i dont know anything about jesuits for the record. and some people did it for obtuse artistic reasons or like extreme adrenaline junkies who were bored of cave diving and free soloing. because despite the conceit of it being a temporary death there was still some small but not insignificant chance that you wouldnt come out, like 1 in 5000 or something. i did not personally enter the death machine i just looked around the outside. and then i either woke up or went on to another dream plot i dont remember. anticlimactic!

8 notes

·

View notes

Text

Effervescent tubes have revolutionised the pharmaceutical and nutraceutical industries, becoming the go-to solution for packaging effervescent tablets. As a prominent name in the sector, NBZ Healthcare, located in Mumbai, stands at the forefront of exceptionally effervescent tube manufacturing, ensuring quality and innovation.

In this article, we delve deep into the manufacturing of effervescent tubes, their applications, benefits, and the unparalleled expertise of NBZ Healthcare in this domain.

Understanding Effervescent Tubes

Effervescent tubes are specialised containers designed to store and preserve effervescent tablets. These tablets, when exposed to moisture or air, tend to lose their potency, necessitating robust, moisture-resistant packaging. Effervescent tubes, often crafted with airtight and tamper-proof caps, provide the ideal solution to ensure the longevity and effectiveness of these tablets.

Importance of Effervescent Tubes

Effervescent tubes are more than just packaging; they play a crucial role in the pharmaceutical and nutraceutical industries by:

1. Protecting Product Integrity:

- Shielding tablets from moisture and air.

- Preventing degradation of active ingredients.

2. Enhancing Consumer Experience:

- Easy to open and reseal.

- Portable and convenient for on-the-go consumption.

3. Ensuring Regulatory Compliance:

- Meeting stringent health and safety standards for pharmaceutical products.

4. Sustainability:

- With increasing focus on eco-friendly materials, many effervescent tubes are now designed to be recyclable or biodegradable.

Effervescent Tube Manufacturing Process

Effervescent tube manufacturing is a precise and technologically driven process. At NBZ Healthcare, we combine state-of-the-art machinery with strict quality control measures to produce exceptional effervescent tubes. Here’s an overview of the key stages:

1. Material Selection

- High-grade plastic materials such as polypropylene (PP) or polyethylene (PE) are used.

- Materials are selected based on moisture resistance, durability, and eco-friendliness.

2. Tube Extrusion

- Plastic granules are melted and extruded into tube-like shapes using extrusion machines.

- The dimensions and thickness are carefully controlled to meet industry standards.

3. Moulding

- Injection moulding is used to form the caps and closures of the tubes.

- Caps are designed to ensure an airtight seal and tamper resistance.

4. Printing and Branding

- Tubes are labelled or printed with product details, branding, and regulatory information.

- Advanced printing techniques ensure durability and clarity.

5. Quality Control

- Rigorous testing for moisture resistance, durability, and compatibility with effervescent tablets.

- Each tube undergoes inspection to ensure zero defects.

NBZ Healthcare: Redefining Effervescent Tube Manufacturing

As a leader in exceptionally effervescent tube manufacturing, NBZ Healthcare sets the benchmark for quality and innovation. Based in Mumbai, our facility is equipped with cutting-edge machinery and a dedicated team of professionals who prioritise precision and excellence.

What Sets NBZ Healthcare Apart?

1. Advanced Manufacturing Capabilities

- NBZ Healthcare utilises the latest extrusion and moulding technologies to produce high-quality tubes.

2. Customisation Options

- We offer custom designs, sizes, and branding options to cater to the unique needs of our clients.

3. Sustainable Practices

- Focused on reducing environmental impact, we incorporate eco-friendly materials and processes wherever possible.

4. Regulatory Compliance

- Our manufacturing processes comply with international standards, including ISO and FDA regulations.

5. Global Reach

- While based in Mumbai, NBZ Healthcare serves clients across India and internationally, ensuring timely delivery and exceptional service.

Applications of Effervescent Tubes

Effervescent tubes find applications in various sectors, including:

1. Pharmaceuticals:

- Storage of vitamins, supplements, and medications in effervescent tablet form.

2. Nutraceuticals:

- Packaging for dietary supplements and health-boosting effervescent tablets.

3. Food and Beverage:

- Containment of flavour-enhancing or health-focused effervescent powders and tablets.

4. Personal Care:

- Packaging for effervescent bath tablets or other similar products.

Innovations in Effervescent Tube Manufacturing

At NBZ Healthcare, innovation is at the heart of our operations. Here are some of the cutting-edge advancements we incorporate:

1. Smart Packaging Solutions

- Tubes embedded with QR codes or NFC tags for enhanced consumer engagement and traceability.

2. Enhanced Moisture Resistance

- Using desiccant-lined caps and advanced sealing technologies to further improve moisture protection.

3. Eco-Friendly Materials

- Transitioning to biodegradable plastics and exploring sustainable alternatives like biopolymers.

4. Automation and AI Integration

- Automated production lines ensure consistency and reduce manufacturing errors.

- AI systems monitor quality in real-time for enhanced accuracy.

Challenges in Effervescent Tube Manufacturing

While effervescent tube manufacturing offers immense potential, it comes with its own set of challenges, such as:

1. Material Costs:

- Balancing quality and affordability when sourcing raw materials.

2. Environmental Concerns:

- Reducing the carbon footprint of manufacturing processes.

3. Regulatory Compliance:

- Adhering to diverse regulatory standards across different markets.

4. Consumer Expectations:

- Meeting the growing demand for sustainable and innovative packaging solutions.

The Future of Effervescent Tube Manufacturing

The demand for effervescent tubes is expected to rise significantly as more consumers turn to effervescent products for their convenience and efficiency. NBZ Healthcare is well-positioned to lead this growth, with a focus on:

1. Sustainability Initiatives

- Introducing greener manufacturing processes and materials.

2. Global Expansion

- Reaching untapped markets to provide high-quality effervescent tubes worldwide.

3. Product Diversification

- Expanding into new applications and industries beyond pharmaceuticals and nutraceuticals.

4. Technological Upgrades

- Adopting emerging technologies to enhance efficiency and product quality.

Why Choose NBZ Healthcare for Effervescent Tubes?

At NBZ Healthcare, we combine years of expertise with a commitment to innovation and customer satisfaction. When you partner with us, you’re choosing:

- Unmatched Quality: Every tube is crafted with precision and care.

- Custom Solutions: Tailored to your product’s specific needs.

- Reliable Service: Consistent and timely delivery of all orders.

- Sustainable Values: Supporting environmentally responsible practices.

Conclusion

Effervescent tubes play a pivotal role in preserving the efficacy and quality of effervescent tablets. With NBZ Healthcare’s expertise in exceptionally effervescent tube manufacturing, businesses can rely on robust, high-quality packaging solutions tailored to their needs.

As a Mumbai-based pioneer in the industry, NBZ Healthcare continues to set the standard for excellence, innovation, and sustainability. Whether you’re in the pharmaceutical, nutraceutical, or any related industry, NBZ Healthcare is your trusted partner for exceptional effervescent tube solutions.

Reach out to us today and experience the difference in quality and service!

2 notes

·

View notes

Text

Elevating Precision Manufacturing: The Role of Mekalite’s CNC Machining Service

In today’s competitive manufacturing landscape, precision, efficiency, and adaptability are key to staying ahead. CNC machining has emerged as a vital technology, enabling manufacturers to produce complex and high-precision parts consistently. At Mekalite, we are redefining excellence in CNC machining services by combining advanced technology, a skilled workforce, and a commitment to quality.

https://mekalite.com/

What is CNC Machining?

CNC (Computer Numerical Control) machining is a process that uses computerized controls to operate machinery and tools with high accuracy. This enables the production of intricate parts from a variety of materials, including metals and plastics, while maintaining tight tolerances. CNC machining is critical in industries such as aerospace, automotive, medical devices, and electronics.

Why Choose Mekalite for CNC Machining?

Mekalite sets itself apart by offering a comprehensive approach to CNC machining, ensuring every project is handled with precision and care.

Advanced Machinery and Capabilities Our cutting-edge, multi-axis CNC machines allow us to handle even the most complex designs with precision and consistency. Whether you need rapid prototyping, low-volume manufacturing, or full-scale production, Mekalite’s technology enables us to meet your unique needs.

Customized Solutions We understand that every project is different. Mekalite works closely with each client to understand their specific requirements, delivering tailored solutions that align with their design and functionality goals.

Strict Quality Assurance At Mekalite, quality is our top priority. Our rigorous quality control protocols cover every step of the production process, from material selection to final inspection. This commitment ensures every part meets the industry’s highest standards.

Industries Served by Mekalite

Mekalite’s CNC machining services support a diverse range of industries, including:

Aerospace: High-precision components for engines, structural parts, and aircraft interiors.

Automotive: Custom engine parts, suspension components, and detailed bodywork.

Medical: Surgical instruments, implants, and diagnostic equipment requiring tight tolerances.

Electronics: Housing frames, connectors, and precision parts for delicate devices.

Benefits of Partnering with Mekalite

Choosing Mekalite as your CNC machining service provider offers numerous advantages:

High Precision and Accuracy Our state-of-the-art CNC machines, combined with skilled operators, enable us to achieve exceptional accuracy and repeatability across all projects.

Wide Range of Materials Mekalite’s expertise spans across various materials, from metals like stainless steel and aluminum to specialized plastics. This flexibility allows for innovative product designs and customized applications.

Cost Efficiency and Scalability With automated processes and minimal manual intervention, CNC machining reduces labor costs while enhancing efficiency. Whether you need a single prototype or a large production run, Mekalite’s scalable services can adapt to your requirements.

Timely Deliveries Time is crucial in manufacturing. Our efficient workflows and commitment to meeting deadlines ensure that your projects are completed on schedule, every time.

Looking Ahead: Mekalite’s Commitment to Innovation

Mekalite is committed to staying ahead of industry trends and technological advancements. By continually investing in the latest CNC machinery and refining our processes, we aim to provide even more innovative and reliable solutions to our clients. Our vision is to be a trusted partner in helping businesses achieve new levels of success through precision manufacturing.

Conclusion

CNC machining is revolutionizing the manufacturing industry, and Mekalite is at the forefront of this transformation. Our combination of cutting-edge technology, tailored solutions, and a dedication to quality makes us a preferred partner for businesses across various sectors.

If you’re looking for a reliable CNC machining service provider that delivers precision and value, Mekalite is here to help. Contact us today to discuss your next project!

https://mekalite.com/

2 notes

·

View notes

Text

while im ranting about stupidly written gun restrictions, the fact that the striker 12 and cobray street sweeper (same thing, different company) are still considered a class 3 destructive device is absolutely absurd. they come in at least 1 configuration that is not a sbs (short barrel shotgun) and is just a 12 gauge semiautomatic shotgun with a 12 round non removable drum magazine. You can get more capacity on pretty much any modern magazine fed semi auto shotgun, plus it will be removable so you don't have to deal with an inefficient and fiddly reloading process.

The fact that the striker 12 remains sharing the classification for bombs and machine guns (on top of being a SBS if you don't get the >18" barrel) on a technicality about bore diameter just goes to show that nobody ever goes back to clean this shit up.

the more you learn about gun laws the more you realize just how bass-ackward and poorly written most of them really are. But if you own a gun you do need to know them lest you acidentally commit a felony because you didnt realize cutting the barrel of your rifle to performatively destroy it is actually manufacturing a SBR legally speaking (a problem that usually crops up with grass roots "gun buybacks" ironically enough), or that putting a $10 piece of vertical plastic on the front of a pistol makes it a super illegal unless you paid for your permission slip from the atf

2 notes

·

View notes

Text

Rotary CNC Router Machine

At GK Laser Enterprises, we pride ourselves on delivering cutting-edge solutions to meet the evolving needs of the manufacturing and fabrication industries. One such innovation that has gained popularity for its versatility and precision is the Rotary CNC Router Machine. As a leader in CNC technologies, we offer a range of advanced CNC machines, and today we dive deep into how a rotary CNC router machine can revolutionize your operations.

What is a Rotary CNC Router Machine? A Rotary CNC Router Machine is a computer-controlled cutting machine that uses rotary tools to carve, cut, or engrave materials in three dimensions. The term “rotary” refers to its ability to rotate the material around an axis while it works, providing access to all sides of the material. This capability enables intricate detailing, sculpting, and shaping of cylindrical or irregularly shaped materials.

Unlike traditional CNC routers that work on flat surfaces, rotary CNC routers can handle 3D shapes, making them ideal for creating complex, multi-faceted designs.

How Does a Rotary CNC Router Machine Work? The Rotary CNC Router works by rotating the material, typically using a rotary axis attachment, while the cutting tool precisely follows the programmed paths. Here’s a breakdown of the process:

Material Preparation: A workpiece, such as wood, metal, or plastic, is mounted on the rotary axis, which allows it to rotate. Programming: A computer-aided design (CAD) program creates a digital blueprint of the desired outcome. This is then converted into machine-readable code using computer-aided manufacturing (CAM) software. Cutting Process: The router uses its rotary axis to rotate the material while the cutting tool moves along the X, Y, and Z axes to carve, cut, or engrave the material into the desired shape. Finishing: Once the operation is complete, the workpiece is inspected and may require minimal finishing, thanks to the machine’s precision.

Key Features of a Rotary CNC Router Machine High Precision and Accuracy: Rotary CNC routers are known for their precision in handling complex designs, offering high accuracy even in detailed cuts and engravings. Versatility: Whether you’re working with wood, metal, plastic, or composites, the rotary CNC router can handle a wide range of materials. This versatility makes it invaluable for industries such as furniture design, sculpture, and sign-making. 3D Carving and Engraving: With the ability to rotate the material, rotary CNC routers are ideal for creating 3D objects like sculptures, chair legs, moldings, and even complex cylindrical designs. Automation and Efficiency: The CNC aspect automates the cutting process, ensuring uniformity in production and reducing the need for manual labor. This enhances efficiency and speeds up production time.

Why Choose a Rotary CNC Router Machine for Your Business? If your business requires precision, complexity, and scalability, a rotary CNC router is a wise investment. At GK Laser Enterprises, we emphasize the value it can bring to industries like:

Furniture Manufacturing: Intricate 3D carvings and details for chair legs, columns, and sculptures can be easily achieved using rotary CNC routers. Sign Making and Woodworking: From large signs to ornate wood designs, rotary CNC routers deliver exceptional precision that elevates your craftsmanship. Sculpture and Artwork Creation: Artists and designers benefit from the ability to craft complex shapes and details, providing unmatched creativity. Metal and Plastic Fabrication: Industrial manufacturers who work with metals and plastics can create custom parts, components, and molds with great precision.

Benefits of Using a Rotary CNC Router Machine Enhanced Productivity: With automated processes, your business can take on more projects with faster turnaround times, maximizing profitability. Cost Efficiency: Despite the upfront investment, the long-term savings on labor, material waste, and improved product quality make it a highly cost-effective solution. Precision and Consistency: The automation ensures that each piece you produce is identical in quality and detail, improving overall consistency. Flexibility: Whether you’re producing one-of-a-kind custom pieces or bulk products, the rotary CNC router offers the flexibility to handle both with ease. Lower Material Waste: Precision machining ensures that there is minimal waste, reducing the cost of raw materials and promoting sustainable practices.

Why Buy From GK Laser Enterprises? At GK Laser Enterprises, we provide high-quality rotary CNC router machines tailored to meet the unique needs of businesses across industries. With our deep industry expertise, we ensure that you get the most suitable machine for your applications, ensuring optimal performance and cost-efficiency.

We also offer:

Comprehensive Training and Support: Our team will provide full training on how to operate and maintain your CNC router machine. Maintenance Services: Regular servicing to keep your machine running smoothly, ensuring minimal downtime and maximum output. Custom Solutions: We understand that every business has different requirements, so we provide customized solutions that best fit your needs.

Conclusion The Rotary CNC Router Machine offers unparalleled precision and flexibility, making it an essential tool for businesses involved in woodworking, metalworking, and creative design. At GK Laser Enterprises, we’re committed to providing top-tier CNC solutions that enhance productivity and reduce costs. By investing in a rotary CNC router, your business can stay ahead of the competition while delivering superior quality products. Contact us today to learn more about our CNC machines and how they can benefit your operations!

2 notes

·

View notes

Text

Maximize Efficiency in Pressure Die Casting with Our High-Quality Steel!

At Virat Special Steels, we specialize in supplying high-quality tool and die steels to the pressure die casting industry.

Our comprehensive range includes: DIN 1.2344 (#H13), DIN 1.2343 (#H11), DIN 1.2581 (#H21)

Pressure die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process.

DIN 1.2344 (H13) is a hot work tool steel that has excellent machinability and polishability, good high toughness and plasticity, high wear resistance at high and low temperatures and overall hardening performance. It is widely used for aluminum, magnesium and zinc die casting, as well as metal extrusion tools, shear knives, and hot forging dies.

DIN 1.2343 (H11) is also a hot work tool steel that has similar properties to DIN 1.2344 (H13), but with less vanadium content, which gives it higher toughness and lower wear resistance. It is suitable for die casting molds for light metal processing, cylinders and pistons on cold chamber machines, and hot forming tools.

DIN 1.2581 (H21) is a tungsten-chrome-vanadium steel for hardening in oil and possibly in air with very good hardenability, very high firmness during the heat and resistance to the tempering, high resistance to the hot tempering and good toughness. It is mainly used for hot-working dies and tooling, such as extrusion, die casting and hot-forming of parts.

Virat Special Steels is one of the largest importer, exporter and stockist of die blocks, tool steels, die steels, special steels and alloy steels in various grades in India. The company maintains a high level of inventory of special steels from the world’s leading manufacturers and provides technical advice and support to its customers.

Choose VIRAT SPECIAL STEELS for a seamless blend of quality, variety, and reliability in every steel grade.

Learn more : https://www.viratsteels.com/hot-work-steel.html https://www.viratsteel.in/materials/hot-work-steel-supplier-in-india/

Any queries feel free to contact us : [email protected] or Call on mobile number +91-9814021775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#DieCasting#PressureDieCasting#DieCastingProcess#CastingIndustry#AluminumCasting#MoldMaking#hot work steel#h11steel#h13steel#h21steel#din 2344#din2343

2 notes

·

View notes

Text

so i watch manufacturing videos on youtube sometimes right? and the Algorithm has been recommending me ones with. the funniest AI-generated thumbnails. here follows a running commentary

This machine seems to be multitasking to an incredible degree. Taking whole animals to fully-cured meat products in one invisible process, presumably occurring in the Pit at the center of the processing line, with the only human input being buckets of the all-important Pink Slop. Truly ingenious.

Ah, the banana belt. Where stacks of single fruits (known to be the most popular method of purchasing bananas) are passed through the ceremonial halo of their brethren to be deposited on the laundry room counter. An essential process as it instills within the fruits a sense of dread and resignation of their place in the world which increases their potassium content.

Time for some life-changing DIY innovations! For instance, inspire your fan to greater heights by weighing it down with ceremonially-prepared symbols of unfulfilled purpose! The ice and tinfoil filling these plastic bottles reminds the fan of what happens to useless objects, filling it with a sense of panic and driving it to do better. And, of course, we need no reminder of that classic trick of using last week's Shein haul as fuel for cooking your dinner. It probably costs less than a natural gas stove at this point.

Ah yes, the Pit That Boils Workers Alive. A necessary evil. As we all know, there is no way to cool down 6-ton blocks of superheated steel without a human sacrifice guiding them into the baptismal font with a folding chair. Depending on the quality of ventilation in the room above, perhaps several other humans will experience the divine sensation of being steamed like dumplings.

Welcome to the Infinite Avenue of Bamboo! Begin your pilgrimage by amputating both legs at the knee and grabbing your trusty ladder, then simply stumble your way forward through shifting poles of endless length. The grove around you creaks and groans, the outer stalks inevitably succumbing to their place upon the piles surrounding you and stacking them ever higher. You do not know where the infinite poles below you grow from. More seem to push up from underneath the pile you pull yourself through. You cannot see the end. How long have you been moving? When can you rest?

This aesthetic bricklayer has made the classic mistake of "painting oneself into a corner", i.e. surrounding oneself with completed work that one should not walk on for fear of ruining it. The cat does not seem to mind this. Additionally, our unfortunate worker has not accounted for the inevitable path of water in her plans and may find all her hard work sadly destroyed by her lovely aesthetic waterfall within an hour or so.

Once you claw your way free of the Infinite Avenue of Bamboo, you may find yourself in the Infinite Mushroom Warehouse. These fungi range from the size of your head to the size of a large SUV and flow in endless waterfalls from the Vat, despite workers' best efforts to stem the flood. Grab a pallet, friend, for if these malevolent invaders are not stored away hastily, they may seek out your flesh and add you to their numbers.

#what the hell do i tag this.#youtube#creative writing#i guess. it sort of got away from me. in my defense it is very funny#good luck escaping the Infinite Mushroom Warehouse. do not eat them

2 notes

·

View notes