#Design of demoulding mechanism

Explore tagged Tumblr posts

Text

Design of injection mold for internal thread plastic cover

1 Analysis of plastic part structure Plastic part structure is shown in Figure 1. Size is φ71 mm*47 mm, with a through hole in the middle. There is an internal thread at one end of plastic part. Model of internal thread is M64*3 mm, and its length is 18 mm. There are multiple protrusions on outer surface of plastic part, which can prevent plastic part from rotating with thread core when it…

#Analysis of plastic part structure#Casting system design#Cavity layout design#demoulding mechanism#Design of demoulding mechanism#Design of Injection Mold#injection mold#injection mold for internal thread plastic cover#mold structure#Molding structure design#molding structure of plastic part#plastic part#plastic part structure#two-plate mold

0 notes

Text

Exploring the Benefits of Tilting Table for Precast Concrete Production

Efficiency and precision are essential in the realm of precast concrete manufacturing. One innovative piece of equipment that has revolutionized this process is the tilting table for precast concrete. These specialized platforms are designed to simplify the production of flat concrete elements like walls, slabs, and panels while maintaining high-quality standards. To meet the diverse needs of modern construction projects, leading providers like Moldtech offer cutting-edge tilting tables that combine durability, functionality, and advanced technology.

What is a Tilting Table for Prepared Concrete?

A precast tilting table is a robust, adjustable platform used in precast concrete plants to create flat elements such as slabs and panels. Unlike static moulds, tilting tables offer the unique ability to tilt to a vertical position once the concrete has set. This functionality facilitates the easy removal of the precast element, reducing manual labor and minimizing the risk of damage during demoulding.

Tilting tables are designed with high precision, featuring smooth surfaces to ensure excellent concrete finishes. They often include advanced features such as vibration systems for compacting the concrete and heating systems to accelerate curing.

How Does a Tilting Table Work?

Preparation:

The table is set to its flat position, and the surface is cleaned and treated with a release agent to ensure easy demoulding. Steel reinforcement and concrete column molds edges are added to create the desired shape and thickness of the element.

Concrete Pouring:

Concrete is poured onto the table, and vibration systems are used to compact the material evenly.

Curing:

The concrete is left to cure on the table, sometimes with the aid of integrated heating systems to speed up the process.

Tilting:

Once the concrete has been set, the tilting table for precast concrete is hydraulically tilted to a vertical position, allowing the precast element to be removed safely and efficiently.

Advantages of Using a Tilting Table

1. Improved Efficiency

Tilting tables streamline the production process by making it easier to remove precast elements, reducing the time spent on each piece. This allows plants to achieve higher output without compromising on quality.

2. Enhanced Safety

The tilting mechanism minimizes the need for manual handling during demoulding, significantly reducing the risk of injuries and damage to the precast components.

3. Superior Surface Finish

The smooth, high-precision surface of the table ensures that the finished product has a flawless appearance, making it ideal for projects requiring high aesthetic standards.

4. Versatility

Tilting tables can produce a wide range of flat precast elements, from simple slabs to complex architectural panels. They are adaptable to different shapes and sizes, making them suitable for diverse projects.

A Tilting table for precast concrete is a game-changer in the construction industry, offering unmatched efficiency, precision, and versatility. When it comes to reliable and innovative solutions and moulds for precast concrete products, Moldtech - Equipment for Precast Concrete Plants is a name you can trust. Their advanced tilting tables are designed to optimize your precast concrete production, ensuring durability, safety, and exceptional results. Upgrade your plant with a tilting table today and transform your manufacturing process!

#tilting table for precast concrete#precast tilting table#moulds for precast concrete products#concrete column molds

0 notes

Text

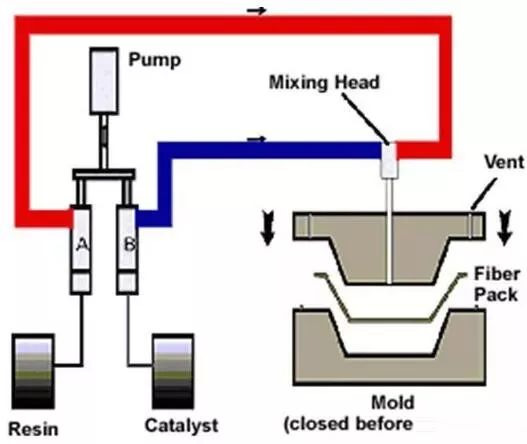

What is the RTM Molding Process for Composite Material?

RTM refers to a process technology in which low-viscosity resin flows in a closed mold, infiltrates reinforced materials and solidifies into shape. It belongs to the category of liquid forming or structural liquid forming technology of composite materials. The specific method is to pre-place reinforced materials that have been rationally designed, cut or mechanized pre-formed into the designed mold. The mold needs to be sealed and tightened around the perimeter to ensure smooth resin flow. After the mold is closed, a certain amount of resin is injected. And after the resin solidifies, the desired product can be obtained by demoulding.

The RTM molding process has the following main characteristics

RTM is a closed mold molding process. The infiltration of the reinforcement and the resin is completed by the rapid flow of pressurized resin in a closed mold cavity, instead of manual infiltration in hand lay-up and spraying processes, nor expensive mechanized infiltration in prepreg and SMC processes. RTM is a low-cost, high-quality semi-mechanized fiber/resin impregnation method.

The RTM molding process uses reinforced material preform technology that is similar to the shape of the product. Once the fiber/resin infiltration is completed, it can be cured, so a low-viscosity fast-curing resin system can be used. It can also heat the RTM mold to further improve production efficiency and product quality.

The reinforced material preform in the RTM molding process can be prepared from chopped strand mat, fiber cloth, wrinkle-free fabric, three-dimensional knitted fabric, three-dimensional braided fabric, etc. And according to the performance requirements, selective reinforcement, local reinforcement, hybrid reinforcement, and embedded and sandwich structures can be used, which can give full play to the performance designability of FRP/composite materials.

The closed-mold resin injection method of the RTM molding process can greatly reduce the toxicity of harmful resin components to the human body and the environment, and meet the increasingly stringent restrictions on the volatilization concentration of harmful gases such as styrene in advanced industries.

The RTM molding process generally adopts a low-pressure injection process, which is conducive to the preparation of complex overall structures with large sizes, complex shapes, and two-sided surfaces.

According to the requirements of the production scale, RTM molds can be selected from different grades of molds such as polyester molds, epoxy molds, surface nickel-plated material molds, alloy molds, aluminum molds and steel molds to reduce costs.

Requirements of RTM technology on epoxy resin systems

Epoxy resin has low viscosity at room temperature or lower temperature, and has a certain storage period.

Epoxy resin has good wettability, matching and adhesion to reinforced materials.

The epoxy resin system has good curing reactivity and does not produce volatile matter and other undesirable side reactions during the curing reaction. The curing temperature should not be too high, and the curing speed should be appropriate.

As a high-performance composite material, epoxy resin is also required to have high heat resistance and moisture resistance, excellent mechanical properties, especially toughness. In some special applications, it should also have certain functionalities, such as low dielectric loss, high conductivity, excellent flame retardancy, etc.

High-performance epoxy resin system is still the most widely used high-performance composite matrix. Epoxy resin systems usually used to make prepregs are difficult to mold using the RTM process due to their high viscosity and short storage life. In order to be suitable for RTM molding, YQXPOLYMER launched the 9320A/B epoxy resin curing system. 9320A/B is a special epoxy resin curing system for RTM process. This system product is composed of special epoxy resin and modified amine curing agent. The 9320A/B epoxy resin curing system has the characteristics of fast curing speed, good water resistance, high hardness, good adhesion, mechanical properties of the cured material and high Tg temperature. It can be widely used in automotive composite materials for RTM molding, cultural and sports products (fishing rods, badminton rackets, golf clubs, etc.) and other carbon fiber composite materials. The RTM process has a wide range of advantages. The molded parts have high fiber system content, low porosity, low water absorption, and good mechanical properties. Conventional resins and reinforcing materials can be used in the RTM process.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#bisphenol a type epoxy resin#RTM#RTM molding process#epoxy resin supplier#epoxy resin system#RTM process#resin transfer molding#epoxy composite material#epoxy resin curing system#composite material

0 notes

Text

Design of injection mould for guide vane of curtain bead automatic machine

When designing an injection mold, demolding method affects mold structure. Main manifestation is that selection of parting method needs to consider convenient demoulding of plastic part, simple mechanism and convenient processing of mold parts. When plastic part has multiple characteristics and demolding direction is different, if conventional sliding block, inclined push rod and other mechanisms…

View On WordPress

0 notes

Text

Sculpting Elegance: Bowl Moulds Transformed Through Chemical Etching Brilliance!

In the dynamic world of manufacturing, where form meets function, the artistry of bowl mould design has taken a quantum leap forward with the introduction of chemical etching. This transformative process breathes life into traditional bowl moulds, infusing them with a touch of elegance and precision that was once hard to achieve.

The chemical etching process, also known as chemical milling, has become a cornerstone in the realm of mould transformation. Unlike traditional methods that rely on mechanical force, chemical etching delicately sculpts intricate patterns and textures onto bowl moulds with unparalleled precision. This technique opens up new dimensions of design possibilities, allowing manufacturers to create bowls that not only serve their functional purpose but also stand out as works of art.

One of the standout advantages of chemical etching is its ability to create intricate designs on metal surfaces. In the context of bowl moulds, where metal is a common material, this process offers a level of detail and finesse that traditional methods may struggle to achieve. The precision of chemical etching allows for the reproduction of complex patterns, company logos, and customized designs, transforming bowl moulds into captivating pieces of craftsmanship.

Laser etching on metal has also become an integral part of the chemical etching process. The combination of these advanced technologies results in bowl moulds that boast not only intricate designs but also a sleek and polished finish. Laser etching adds another layer of customization, enabling manufacturers to achieve fine details and sharp lines that contribute to the overall aesthetic appeal of the moulded bowls.

In addition to the visual allure, chemical etching contributes to the functionality and longevity of bowl moulds. The controlled removal of material during the etching process ensures that the surface of the mould is precisely textured, leading to improved release characteristics. This not only enhances the demoulding process but also extends the lifespan of the mould, making it a cost-effective investment for manufacturers in the long run.

Mould polishing is another critical aspect of the chemical etching process, playing a pivotal role in elevating the final product. After the intricate designs are etched onto the bowl mould, polishing adds a finishing touch that enhances the surface quality. This step not only improves the appearance of the moulded bowls but also contributes to the overall tactile experience, creating a product that exudes refinement and elegance.

As manufacturers seek to differentiate their products in a competitive market, the transformative power of chemical etching on bowl moulds has become a game-changer. The marriage of precision, artistry, and functionality makes this process an invaluable tool for those looking to sculpt elegance into their designs. Whether it's for the food industry, hospitality, or home decor, bowl moulds that undergo chemical etching brilliance stand out as not just utilitarian items but as pieces of functional art.

In conclusion, the journey of bowl moulds from functional containers to sculpted works of elegance is paved with the brilliance of chemical etching. This transformative process, complemented by laser etching on metal and meticulous mould polishing, redefines the standards of moulded products. As manufacturers embrace the marriage of art and precision, bowl moulds emerge not just as vessels but as statements of sophistication, setting new benchmarks in the world of manufacturing.

0 notes

Text

What are the essential factors to consider when designing and manufacturing a PP plastic table mould?

Designing and manufacturing a PP plastic table mould is a complex process that demands meticulous attention to detail and a profound understanding of both material properties and manufacturing techniques. PP (polypropylene) plastic tables are widely used in various industries, including hospitality, education, and outdoor events, due to their durability, lightweight nature, and cost-effectiveness. Addressing the intricacies of mould design and production is critical to ensuring the production of high-quality plastic tables that meet the diverse needs of these industries.

One of the primary considerations when creating a PP plastic table mould is the choice of material. Polypropylene is renowned for its excellent balance of properties, including high tensile strength, chemical resistance, and heat resistance. Selecting a high-quality PP material for the mould is essential, as it directly influences the durability and longevity of the mould. A robust and durable mould material ensures that it can withstand the repeated stress and pressure of the injection moulding process, allowing for the production of consistent and defect-free plastic tables.

The design of the mould itself is equally crucial. Precision in mould design is paramount to achieving accurate and intricate table shapes. Utilizing advanced computer-aided design (CAD) software, engineers can create intricate and detailed mould designs that cater to the specific dimensions and features required for the plastic table. The mould design should incorporate elements such as cooling channels, ejector pins, and gating systems, all of which play pivotal roles in the injection moulding process. Proper cooling channel design ensures uniform cooling of the molten PP material, preventing warping or defects in the final product.

Furthermore, the gating system design is instrumental in controlling the flow of molten plastic into the mould cavity. A well-designed gating system ensures that the material flows smoothly and uniformly, preventing air pockets or inconsistencies in the plastic table. Additionally, the placement of ejector pins and the demoulding mechanism must be meticulously planned to avoid damage to the moulded table during the demoulding process.

The precision and quality of the PP plastic table mould have a direct impact on the final production of plastic tables. A well-designed and precisely manufactured mould results in plastic tables with smooth surfaces, sharp edges, and consistent dimensions. These high-quality tables not only enhance the visual appeal but also ensure functional excellence. Smooth surfaces are crucial for easy cleaning and maintenance, making the tables suitable for various environments, including restaurants, schools, and outdoor venues.

Moreover, the precision of the mould directly influences the structural integrity of the plastic tables. Tables manufactured from moulds with precise dimensions and intricate details exhibit superior strength and stability. Whether the tables are designed for heavy-duty use in commercial spaces or for lightweight and portable applications, the quality of the mould determines the resilience of the final product. High-quality moulds produce tables that can withstand various loads, ensuring durability and longevity even in demanding environments.

In addition to structural integrity, the precision of the mould significantly impacts the assembly and fitting of different components. For instance, moulds designed for tables with detachable legs or additional accessories must ensure precise alignment and compatibility. A meticulously crafted mould guarantees that all components fit together seamlessly, eliminating gaps or misalignments in the assembled table. This attention to detail enhances the user experience, allowing for easy assembly and disassembly as needed.

Furthermore, the quality of the mould influences the production efficiency and cost-effectiveness of plastic table manufacturing. A high-quality mould with precise dimensions and features facilitates faster production cycles and reduces the occurrence of defects. Minimizing defects not only reduces material wastage but also decreases the need for secondary processes, such as trimming or finishing, optimizing the overall production cost. Additionally, the longevity of a quality mould ensures consistent production over an extended period, maximizing the return on investment for manufacturers.

In conclusion, the design and manufacturing of a PP plastic table mould requires a comprehensive understanding of material properties, precision engineering, and moulding techniques. The careful selection of high-quality materials, coupled with meticulous mould design and manufacturing processes, results in moulds that produce plastic tables of exceptional quality, durability, and functionality. The precision and quality impact the final product, influencing aspects such as surface finish, structural integrity, assembly precision, production efficiency, and overall cost-effectiveness. By investing in top-quality PP Plastic Table Mould Company and adhering to stringent manufacturing standards, industries can produce plastic tables that meet the diverse needs of consumers across various sectors, ensuring satisfaction and reliability in every application.

#High Quality PP Plastic Table Mould#PP Plastic Table Mould Manufacturers#PP Plastic Table Mould Company

0 notes

Text

What Are the Classification of Injection Mold Processing?

https://www.gmmoldtech.com/what-are-the-classification-of-injection-mold-processing.html

What Are the Classification of Injection Mold Processing?

Ⅰ. The plastic injection mold processing

Injection molding is a relatively common manufacturing method of industrial products in machining processing. This processing technology obtains the required shape by processing rubber and plastic. There are many types of injection mold processing. In the process of processing, the processing technology should be selected according to the requirements of the injection product.

Ⅱ. The classification of plastic injection mold processing

1. Single parting surface injection mold

When the mold is opened, the movable mold and the fixed mold are separated, so that the plastic part is taken out, which is called a single parting surface mold. This processing method is the simplest of the plastic injection mold and molding. It can be divided into single-cavity injection molds or multi-cavity injection molds according to the design. It is widely used in today's production.

2. Double parting surface injection mold

Double parting surface injection molding has two parting surfaces. Compared with single parting surface injection molds, double parting surface injection molds have a movable intermediate plate in the fixed mold part, so this type of injection mold is called three-plate injection mold. It is most commonly used for single-cavity or multi-cavity molds with point gate feeding.

3. Injection mold with lateral parting and core pulling mechanism

When the plastic part has a side hole or a side depression, it needs to be formed with a core or slider that can move laterally. After injection molding, the movable mold will move down for a certain distance, and then the inclined surface of the bending pin fixed on the fixed template forces the slider to move outwards. At this time, the push rod of the ejection mechanism pushes the plastic part to take off from the core.

4. Injection mold with movable forming parts

Due to some special structures of plastic parts, injection molding will be required to be set into movable injection molded parts, such as movable punches, dies, movable inserts, movable threaded cores or shaped rings. During demolding, it can be moved out of the mold together with the plastic part and separated from the plastic part.

5. Automatic thread unloading injection mold

For plastic parts with threads, when automatic demolding is required, a freely rotatable thread core or ring can be set on the mold, and the mold opening action or the rotation mechanism of the injection molding machine can be used to drive the thread core or the threaded ring rotates and the plastic part comes out.

6. Runnerless injection mold

Runnerless injection mold refers to the method of adiabatic heating of the runner to keep the plastic between the nozzle and the cavity of the injection molding machine in a molten state, so that there is no condensate in the pouring system when the mold is opened and the plastic part is taken out.

7. The injection mold of the demoulding mechanism on the fixed mold

In the injection mold, the demolding device is installed on the side of the movable mold, which is of great help to the ejector device in the opening and closing system of the injection molding machine. In actual production, because of the shape limitation of some plastic parts, leaving the plastic parts on the side of the fixed mold is more helpful for forming.

0 notes

Photo

Apeeling Design

Channels, tunnels and tubes – life relies on vessels to move fluids around, with our circulatory system transporting cells, chemicals and warmth all over the body. Biomedical engineers often mimic this pipework to learn about the physics involved, but also to watch commuting cells adapting to travel inside. Here researchers overcome a hurdle to more ambitious 3D designs for their networks of microchannels. First, they allow a plastic material to set around wire-like templates of soft resin. Once set, they pull out the templates which become thinner as they stretch, peeling away from the inside of each tube gently, where a solid wire might split or crack the design. They are left with these networks of channels – examples of how this 'soft demoulding' process could be adapted for microfluidic devices, or even used in the pneumatic systems of soft robots designed to help around the body.

Written by John Ankers

Image from work by Dongliang Fan and colleagues

Shenzhen Key Laboratory of Biomimetic Robotics and Intelligent Systems, Department of Mechanical and Energy Engineering, Southern University of Science and Technology, Shenzhen, Guangdong, China

Image originally published with a Creative Commons Attribution 4.0 International (CC BY 4.0)

Published in Nature Communications, August 2022

You can also follow BPoD on Instagram, Twitter and Facebook

21 notes

·

View notes

Text

Problems that cause PVC pipe failure and its solutions

Excessive daylight exposure. Once the sun beats down on unprotected PVC pipe for associate degree extended amount of your time, dangerous things will happen, Water speed. If water travels through PVC too quickly, conditions like clap and surge pressure will develop, Soil and trash, Installation problems.

It is seen that PVC pipe fittings can turn out numerous issues throughout the process, however all the issues square measure caused by instrumentality, process, mold, formula, etc. As long as there square measure excellent instrumentality and molds, affordable formula and method will avoid issues. within the actual production method, such issues square measure typically generated, or issues square measure generated and also the causes and solutions aren't better-known. Therefore, made operative expertise is additionally a condition for guaranteeing excellent product.

The design has an unreasonable undercut, the demoulding structure is unreasonable or the position is improper, and desires to be corrected.

The mold isn't enough within the mold, modify the mold and increase the angle. The surface of the mold is damaged and damaged or the surface of the cavity is rough and desires to be polished. The extremely polished mold surface makes it troublesome for the injection formed half to be formed beneath vacuum negative pressure. The ejector mechanism isn't applicable and desires to be revised.

NewTech-Pipes is simplest the largest Pipe makers in Islamic Republic of Pakistan and produces premium level quality of pipes and fittings services in Pakistan like HDPE Pipes, PVC Pipe, PVC Pipes, MDPE Pipes, highest quality MDPE Pipe, EC Pipe, EC Pipes, highest quality global organization Pipe, top quality MDPE Pipes, UPP Pipes, UPP Pipes, top quality PPRC Pipe, top quality PVC Pipe, UPP bedded Pipe

2 notes

·

View notes

Text

This design uses a cylindrical jack

In summary, the gate position is set at the intersection of the outer circle of 72 and the bottom surface of the plastic part, which is not only conducive to shortening the shunt, but also saves materials, simplifies the mold structure, and is also conducive to the design requirements of one mold and two parts .2 Selection of parting surface The choice of parting surface is one of the difficulties in the design of injection molds. 1. widely. The uniform ejection force of the push plate does not affect the appearance quality of the plastic parts, but the plastic parts have a slope transition, making the push plate difficult to manufacture.

2 Overall mold structure and working principle

2. Although it will produce shallow ejection marks in the plastic parts during the introduction, but does not affect the overall appearance, it can be sanded to eliminate the ejection marks [3]. Based on the analysis of the dimensional accuracy, surface quality, and structural manufacturability of the plastic parts, the parting surface, gate position, core, cavity In the design of molds and other structures, computer-aided mold design is used in the design process, which greatly shortens the development cycle and reduces production costs. 4. Its structure is simple, and the quality of the molded product is good. With the parting surface closed, the reset lever is also right.1 Overall mold structure The overall mold structure of the plastic part is shown in Figure 6. The push rod has a simple pushing structure, smooth and reliable pushing. After the mold is closed, the plastic is first heated and melted in the heating barrel of the injection molding machine, and then the injection machine fills the cavity with the melt through the main channel through the nozzle.

Author: Li Runjuan PROCEEDINGS: Henan Broadcasting Dianshitaixue

Send feedback

History

Saved

Community. This design uses a cylindrical jack, which has a simple structure, is easy to process, and can meet the requirements of use. The jack is reset, and then the next working cycle is performed. It also reduces assembly errors and is not easy to deform. The reasonable selection of parting surface has an impact on the forming, demoulding, mold structure and manufacturing cost of plastic parts.2 The working principle of the mold The mold is installed on the injection molding machine, the fixed mold is installed on the fixed mold wrench of the injection molding machine, and the movable mold is fixed on the movable template. Figure 3 is a schematic diagram of the gate position of the plastic part. From the above analysis, it can be concluded that the plastic part adopts a push-rod pushing mechanism.3 The structural design of the mold core and cavity Because of the uniform wall thickness of the plastic parts and the simple structure, considering the principle of economy and practicability, the single-split injection mold is used. Under the action of the injection molding machine, the ejector is pushed to push the plastic part out, and then the mold is closed.

1 Mold structure design

1.4 The design of the ejector mechanism Because the mold cavity is in the fixed mold part and the core is in the moving mold part, the plastic part is wrapped around the core and left in the moving mold part after the mold is opened, so the mechanism needs to be pushed out to place the plastic part Out of the mold, the pushing mechanism can be pushed out by push plate or push rod. In consideration of the processing feasibility and economic principle, the core and the movable template are connected by steps, as shown in Figure 5. 1. When the mold is opened, the moving mold part follows the template to open the parting surface. According to the inner shape of the plastic part, the integral mosaic core can be used for the structure of the core. It has a simple structure, strong adaptability and application. 2. Since tangential feed for circular plastic parts can reduce welding marks, improve the strength of the welded joint, and facilitate exhaust, it is preferred to use tangential feed.

During design, the diameter of the ejector rod should not be too small, and it should have sufficient rigidity to withstand the ejection force, so as not to bend or break during ejection. Its structural schematic diagram is shown in FIG. Combined with the shape of the plastic part, the integral cavity is used. 1. From the analysis of the plastic parts diagram, it can be seen that the structure of the plastic parts is simple, the wall thickness is uniform, and it is a regular circular distribution. The cavity of the injection mold with a single parting surface is set in the fixed mold, the core is set in the moving mold, and a pushing mechanism on one side of the moving mold is used to push out the plastic parts and the runner condensate. According to the selection principle of the parting surface and the shape of the actual plastic part, the parting surface is selected on the bottom surface of the large end jar bottle blowing machine of the water cup cover, so that the plastic part can be demolded smoothly.1 The choice of gate position The choice of gate position has a great influence on the quality of plastic products [2].

3 Conclusion

Using the UG software, the three-dimensional modeling of the plastic water cup cover was carried out

1 note

·

View note

Text

The mold design task book is proposed by the plastic parts craftsman according

According to the specific requirements and functions of the whole product of plastic products, which kind of external quality and specific size are determined: plastic products with higher appearance quality requirements and lower dimensional accuracy, such as toys; functional plastic products, size requirements Strict; plastic products that require strict appearance and size, such as cameras. If these problems are solved, the structural form of the mold will naturally be solved.04 is 0. The draft angle is directly related to the release and quality of the plastic products, that is, whether the injection can be carried out smoothly during the injection process: the draft angle is sufficient; the slope should be in the form of the part or the part of the molded part of the plastic product. The amount of plastic products produced is far beyond the reach of other molding methods. The number of cavities and their arrangement are determined according to the geometrical features of the plastic parts, the dimensional accuracy requirements, the batch size, the difficulty in mold manufacturing, and the cost of the mold.

Under a small injection pressure, a shorter molding time, a better product than the general injection molding system is injected. When using the gate, To ensure the shedding of the runner, attention should also be paid to the design of the degasser and the nine-gate mechanism of the demister. The economic requirement of production is to make the cost of plastic parts low, the production efficiency is high, the mold can work continuously, the service life is long, and labor is saved. Stamping die - computer panel D. Smooth inflow; 4 gate position should be opened at the thickest part of the plastic part; 5 to avoid the plastic straight into the cavity wall, core or insert when flowing down the cavity, so that the plastic can flow into the cavity as soon as possible, and avoid The core or insert is deformed; 6 try to avoid causing the product to have weld marks, or make the weld mark appear in the unimportant part of the product; 7 the gate position and the plastic inflow direction should be such that the plastic can flow along the cavity when flowing into the cavity The parallel flow of the cavity in a uniform direction facilitates the discharge of gas in the cavity; 8 the gate should be placed on the most easily removed part of the product without affecting the appearance of the product as much as possible. Generally, it depends on the product requirements.

The design is exquisite, diverse, easy to use, and stable and reliable. 2. Compression molding die - Bakelite switch, scientific porcelain dishes D. The hot runner system, also known as the hot runner system, is mainly composed of a hot sprue bush, a hot runner plate, and a temperature-controlled electric box. Thermoforming mold - transparent molded packaging shell G. For example, ABS 0. When continuing to increase the weight of plastic parts, multi-cavity molds are rarely used. Low, so more people use the large nozzle system to work. This system is also called the waterless mouth system, which can save raw materials, is suitable for the case where the raw materials are expensive and the product requirements are high, the design and processing are difficult, and the mold cost is high. Determine whether the molding method uses direct pressure method, casting pressure method or injection method.02 mm or less. The mold design personnel design the mold based on the molded plastic parts task book and the mold design task book. For example, for the injection machine, the following should be understood in terms of specifications: injection capacity, mold clamping pressure, injection pressure, mold mounting size, ejection device and size, nozzle hole diameter and nozzle spherical radius, gate sleeve positioning ring size, The maximum thickness and minimum thickness of the mold, the stroke of the template, etc. Blowing mold - beverage bottle C. General definition of mold: In industrial production, various kinds of presses and special tools mounted on the press are used to produce metal or non-metal materials by pressure to produce parts or products of the desired shape. The shape, position, and mounting location of the heating element of the cooling, heating, and heating cooling grooves are determined. It consists of several sets of parts with a molded cavity. For example, what are the requirements for the appearance, color transparency, and performance of plastic parts, whether the geometrical structure, slope, inserts, etc. (2) Thermal radiation is difficult to control. Die-casting mold - super alloy, cylinder block (2) plastic mold is divided into different according to the production process and production products: A. The choice of gate location should follow the following principles: 1 The gate location should be selected on the parting surface to facilitate the processing and use of the gate. Determine the parting surface. The mouth is directly on the product, so the flow channel does not need to be demoulded. Adaptation; whether it will affect the accuracy of the appearance and wall thickness; whether it will affect the strength of a certain part of the plastic product. proposed in the process task book, whether it can be implemented. The depth of the venting groove varies depending on the plastic, and is basically determined by the maximum allowable gap in which the plastic does not generate a flash. Injection molding process description: Plastic mold is a tool for producing plastic products. (2) Sluice nozzle: The runner and gate are not on the parting line, generally directly on the product, so it is necessary to design a set of nozzle parting lines. Tools are collectively referred to as molds. Our common hot runner systems are available in single-point hot gates and multi-point hot gates. 4.

During injection molding, the mold is clamped on the injection molding machine, the molten plastic is injected into the molding cavity, and is processing of plastic products factory cooled and shaped in the cavity, and then the upper and lower molds are separated, and the product is ejected from the cavity from the cavity through the ejection system, and finally the mold is closed. Wait. The hot runner temperature is equal to the temperature of the injection molding machine nozzle, which avoids the surface condensation of the raw material in the runner and the injection pressure loss is small. (2) The pressure loss is small. Digestion process data, analysis of the requirements of the molding method, equipment model, material specifications, mold structure type, etc. Sluice system. A. The hot runner is re-entered into the cavity, which is suitable for single-cavity multi-point feeding or multi-cavity molds.. (3) Hot runner mold: This type of mold structure is basically the same as the fine water nozzle. (4) The cost of mold manufacturing is increased, and the price of standard accessories for hot runner systems is high, which affects the popularity of hot runner molds. Rotating Molding - Soft Plastic Doll Toys ◆ Injection molding is the most commonly used method in plastic processing. The arrangement of the cooling system and the specific form of the cooling system; the specific location and size of the cooling system; the cooling of key parts such as moving molds or inserts; the cooling of side slides and side cores; the design and cooling standards of cooling components Selection of components; sealing structure design. Digest the plastic parts drawing, understand the use of the parts, analyze the technical requirements of the plastic parts, dimensional accuracy and other technical requirements

1 note

·

View note

Text

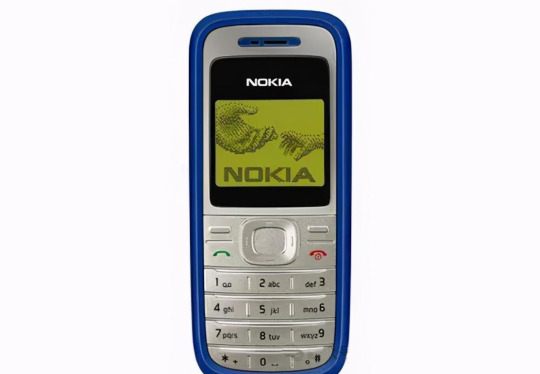

Mobile phone shell injection mold design and moldflow

1 Preliminary preparation 1.1 Overview Mobile phone products have huge market development space. At the same time, market is also in a stage of rapid development. This is an extremely important development stage for manufacturers, distributors and retailers, and is a stage where market structure is gradually taking shape. Therefore, in next few decades, design and processing of mobile phone…

View On WordPress

#barrel temperature#Cold material well design#cooling system design#Design of demoulding mechanism#design of mold base#design of molded part#Design of molding parts#design of plastic molded parts#Exhaust system design#Flow analysis#Gate design#Gate location selection#gating system design#Grid connectivity diagnosis#Grid related analysis#Guide mechanism design#injection mold design#injection molding machine#large and medium-sized molds#Mesh thickness diagnosis#mobile phone case injection mold#Mobile phone shell injection mold design#mold design#mold manufacturing#mold manufacturing and assembly#Mold temperature#molded parts of injection mold#Moldflow#molding process#multi-cavity mold

0 notes

Text

What are the main components of an plastic injection mold?

Injection mold is a kind of mold that must be made before producing plastic products. Each plastic product design has its own mold. Injection molding refers to the injection of heated and melted plastic materials into the mold cavity at high pressure and high speed by an injection molding machine, and after cooling and solidification, a molded product is obtained.

Although the structure of the injection mold varies due to the type of plastic, performance, shape and structure of the plastic product, and the type of injection equipment, but the basic structure is the same.

The basic structure of the injection mold can be divided into seven parts: molding parts, gating system, guiding mechanism, ejector device, lateral parting and core pulling mechanism, cooling and heating system and exhaust system.

1, Molding parts

It refers to the parts that constitute the mold cavity, mainly including: punch, die, core, forming rod, forming ring and inserts and other parts.

2, Gating system

It refers to the plastic flow channel in the mold from the injection molding machine nozzle to the cavity, which ensures the appearance and internal quality of the plastic part, improves the molding speed and shortens the molding cycle. Ordinary gating system is composed of main runner, branch runner, gate, cold material hole and so on.

1) Definition of the main channel: The main channel refers to the section from the contact between the nozzle of the injection machine and the mold to the runner.

2) Definition of branch runner: the section between the main runner and the gate, it is the transition section where the molten plastic flows from the main runner into the cavity, and it is also the transition section in the gating system through the change of cross-sectional area and the plastic turning, which can make the plastic get smoothly

3) Gate definition: Gate is also called feed port or inner runner. It is the narrow part between the runner and the plastic part, also known as the shortest part of the gating system.

4) Cold material hole structure: The cold material hole is used to store the cold material head generated during the injection interval, to prevent the cold material from entering the cavity and affecting the quality of the plastic parts, and to enable the molten material to fill the cavity smoothly. The hole is also called the cold material well.

3, Guiding mechanism

In the plastic mold, the main function of the guiding mechanism is to guide, to ensure the normal closing and separation of the movable and fixed molds, to avoid the collision between the movable and fixed molds, and to ensure the accurate clamping of the movable and fixed molds. The mold will generate lateral pressure during molding, which will cause dislocation of the movable and fixed molds. Especially in large-scale, thin-walled plastic parts or molds with asymmetric shapes of plastic parts that require high injection molding accuracy, when the sides of the cavity and core are subject to greater pressure, it is easy to cause the cavity or core to be offset. In order to ensure the relative position accuracy of the movable and fixed molds during injection molding, and to prevent lateral displacement of the movable, fixed molds and molding parts; Both the movable and fixed molds must have a positioning structure, and their functions are as follows:

1) Positioning function: maintain a certain orientation between the movable and fixed molds when the mold is closed, and maintain the correct shape of the mold cavity after the mold is closed.

2) Guiding function: When the mold is closed, the movable mold is guided to close in sequence to prevent damage to the core and to bear a certain lateral force.

3) Bearing effect: The ejector plate is used for demoulding or the three-plate mold structure, and the guide post can bear the heavy load of the pusher plate and the fixed mold cavity plate.

4) The function of maintaining smooth movement: For the demolding mechanism of large and medium-sized molds, it has the function of keeping the movement of the mechanism flexible and stable.

4, The ejector device

It mainly plays the role of ejecting the parts from the mold, and is composed of ejector rod or ejector pipe or push plate, ejector plate, ejector pin fixing plate, reset rod and pulling rod.

The ejection mechanism of the injection mold is also called the demoulding mechanism. In each cycle of injection molding, the plastic part must be taken out from the mold cavity, and the mechanism that completes the action of taking out the plastic part is the ejector mechanism.

The main function has the following two points

When the mold is opened, it ensures that the plastic parts and the pouring system condensate can be smoothly released from the mold without deformation; The mechanism resets correctly.

After the plastic parts and condensate are taken out from the mold, make sure that the ejector mechanism is correctly reset when the mold is closed.

5, Lateral parting and core pulling mechanism

The function of the lateral parting and core-pulling mechanism is to release the lateral punch or extract the lateral core, which usually includes inclined guide posts, bent pins, inclined guide grooves, wedge blocks, inclined sliders, and inclined guides. slots, gear racks and other parts.

6, Cooling and heating system

It consists of cooling system (cooling water hole, cooling water tank, copper pipe) or heating system. The function is to adjust the temperature of the mold process, and the temperature of the mold directly affects the quality and efficiency of the molding of plastic parts.

Plastic parts with low melting point and good fluidity can be cooled to shorten the production cycle. For some plastics with poor fluidity, in order to improve the fluidity, the mold can be heated.

7, Exhaust system

Its function is to remove the gas in the cavity, which is mainly composed of exhaust grooves and matching gaps.

In some large plastic parts or plastic parts with a relatively large injection volume, the injection mold is closed because there is air in the mold cavity. In the injection plastic, the pressure generated inside the cavity is too large, which will cause some parts of the plastic part to be damaged. The effect of air pressure causes the incomplete plastic parts to be missing. At this time, exhaust devices should be made at these corresponding positions to facilitate the removal of air!

Guangzhou Yijiada Plastic Products Co., Ltd. is a professional plastic mold design and production factory, dedicated to the design, development and production of molds for plastic parts, plastic packaging containers, electronic products, household appliances, household products, industrial applications, agriculture, medical equipment and other products. For a long time, we have won unanimous praise from customers at home and abroad by providing customers with services of low price, good quality and fast delivery. You can contact us to inquire about mold opening and product production for your custom molds such as plastic mold products, plastic injection molding products, plastic blow molding products, etc.

#plastic injection mould#plastic blow mould#plastic container#plastic bottle#cosmeticpackaging#airless pump bottle#PET bottle#PE bottle

0 notes

Text

Design experience points for injection mold slider and lifter

Design experience points for injection mold slider and lifter

Due to special requirements of product, stripping direction of a certain part is inconsistent with mold opening direction of injection machine, side splitting and core pulling are required to smoothly eject product. There are two types of side splitting and core pulling mechanism: slider and lifter. First, slider 1. Slider calculation (example below):In order to ensure smooth demould of…

View On WordPress

0 notes

Text

carbon fiber roller production and processing

Conventional roll shaft production consists of roller body initial rolling, initial static balancing, shaft head assembly, finishing rolling and dynamic balancing. After the roller is formed, the surface treatment or coating, such as painting, galvanizing, TEFLON spraying, rubber coating, chrome plating, ceramic spraying and oxidation, is also needed for rust prevention, corrosion resistance, wear resistance and support. Carbon fiber roller axes are generally used in high-precision instruments, which have high requirements in balance accuracy and other aspects. In terms of production and manufacturing, they generally include the following aspects:

Carbon fiber roller rough production

Carbon fiber roller is usually made of carbon fiber pipe by winding molding process. Carbon fiber winding molding process is the continuous fiber (or cloth tape, pre-soaked yarn) soaked in resin glue solution is wound to the core mold according to a certain law, and then cured, demoulding, products.

According to the physical and chemical state of resin matrix during fiber winding forming, it can be divided into dry winding, wet winding and semi-dry winding. Dry winding adopts prepreg yarn or tape, which is heated and softened to viscous state on the winding machine and then wound to the core mold. Wet winding is the fiber bundle (yarn belt) after dipping glue, under tension control directly wound to the core mold; Semi-dry winding is after fiber dipping, a drying equipment is added on the way of winding to the core mold to remove the solvent in the dipping yarn. Compared with dry method, the pre-dipping process and equipment are saved. Compared with wet method, the bubble content in the products can be reduced. Among the three winding methods, wet winding is the most widely used, while dry winding is only used in high performance and high precision cutting-edge technology fields.

The carbon fiber tube using the winding molding process can design the winding law according to the force of the product, and give full play to the strength of the fiber. Compared with the metal tube with the same volume and pressure, the weight can be reduced by 40%-60%. At present, this process has realized mechanization and automatic production, product quality is stable, accurate, high labor productivity, can be made into different lengths, diameters and wall thickness of carbon fiber pipe.

The processing of the outer circle and section of carbon fiber roller

For the processing of the outer circle and section of the carbon fiber roller, the program is divided very carefully, including rough turning, semi-finishing turning, finishing turning, rough grinding, fine grinding, grinding, ultra-finishing, fine turning, etc. Each program has different indexes in economic accuracy and surface roughness. The processing of the outer circle and section of the carbon fiber roller is summarized as three stages below:

Roughing stage: mainly to efficiently remove most of the allowance on various machined surfaces and provide a benchmark for semi-finishing. Rough machining is carried out on machine tools with high power, low precision and high productivity as far as possible, so as to give full play to the potential of equipment and improve production efficiency. In this stage, it is necessary to find and deal with the blank defects in time and correct the position errors of the previous process in time, such as bending, displacement, eccentricity, deviation, non-parallel, non-vertical and so on. If the error can not be corrected, it will be marked as invalid, so as not to continue processing waste time.

Semi-finishing stage: finishing the secondary surface and preparing for finishing the main surface. Through manual cleaning, careful inspection of the surface found problems, such as pores, white spots, pits, etc., the production process caused by uneven distribution of resin defects for timely repair or treatment.

Finishing stage: Using high precision lathe and grinder on the roller body surface finishing processing, to remove excess resin layer, from the artifacts to polishing of aluminum alloy pieces at the ends of the roll shaft, improve workpiece surface finish and overall uniformity, guarantee form tolerance elements such as roundness and cylindricity and straightness is conform to the requirements of the drawings, and according to the dynamic balance test data, adjust the direction of the finishing and strength.

Surface treatment of carbon fiber roller

The most common surface treatment method of carbon fiber roller is spray painting, and the spray painting link should be constantly inserted in the above coarse and finishing processing procedures, generally in accordance with the order of spray painting (the first time), rough grinding, spray painting (the second time), rough grinding, fine car, fine grinding.

In the process of painting, the metal turnbuckle is used to fix both ends of the carbon fiber roller on the inner core of the metal roller, which is completed by automatic painting equipment and manual operation. After spraying paint to go through 15 to 20 minutes of leveling before entering the drying room drying. The paint surface surface of the initial spray is unsmooth, rich in volatile components, liquidity is strong, after a certain period of static, paint surface through micro flow and become smooth, the volatile components in the whole layer to a large number of, even volatile, can prevent paint bubble, flow away deformation. After the paint leveling, the carbon fiber roller is baked at different temperatures and at different times according to the actual situation of the product. As the carbon fiber roller has a very high precision requirement, any fine dust may cause a significant impact, so the whole painting and leveling process needs to be carried out in a dust-free room.

Roller made traditional materials in the actual use process, the metal properties and bearing impact resistant ability is poorer, runtime has neck size, the influence of such factors as often cause shaft wear and tear, thus appeared the roll shaft vibration increase, cause bigger noise, vibration, instability, and so on and so forth, caused more serious shaft fracture, damage equipment and other parts, It will even lead to major accidents and seriously affect the normal production of enterprises. However, with the performance advantages of raw materials and high manufacturing level, carbon fiber roller shaft can show the advantages of high strength, light weight, long life, low noise, corrosion resistance, no friction, maintenance-free, low energy consumption, optimal system layout, etc., and become the priority choice of more precision instruments.

0 notes

Text

Are you looking for a wide variety of stainless steel castings & high-quality Stainless steel casting manufacturers in India?

If you are looking for an extensive variety and high-quality stainless steel casting manufacturers in India, Sujan Industries have got you covered. We are one of the very few renowned class A certified stainless casting steel companies that produce and deliver premium quality steel and ductile iron casting material to the core industries across the world.

Also, we have gained broad expertise in producing casting materials for railway applications, general engineering applications, valves, pumps etc. All our materials meet global quality requirements in various MOC like alloy steel, plain steel carbon, stainless steel, high nickel alloys, super duplex steel, duplex steel, ADI, ductile iron in the weight range of 5 kgs to 1000 kgs every piece.

Stainless steel casting making procedure

The in-house manufacturing plant we have is situated around a 50,000 sq. ft area and is assembled with cutting-edge technology instruments. We also have the capacity to produce 300 MT premium casting products every month. The casting production procedure we follow is the project, design, moulding, core making, melting, casting, demoulding, shot-blasting, sleeves-feeders cutting, heat treatment, fettling, quality control, inspection, machining etc.

The furnace we have at the top stainless steel casting manufacturers in India, Sujan Industries is furnished with containers that can hold 1000 kgs and 500 kgs of liquid metal. Also, we execute the tea spout and leap pouring methods for accuracy. Our temperature control furnace is equipped with a duly regulated pyrometer. To get the fluid steel, we melt the scraps and ferroalloys in an electric oven. We keep medium frequency in the melting section.

Then based on the steel alloy we want to produce, like stainless steels, carbon steel, corrosion-resistant steels, heat resistant steels, high nickel alloy steel etc, we set the temperature between 1450 degrees Celsius to 1650 degrees Celsius so the steel can melt well.

Also, the fettling workshop we have is equipped with a hanger type KSBM that makes the shot blasting instruments hold 300 kgs of metal per batch. The cast then endures a special heat treatment to acquire the mechanical features like hardness, strength, toughness etc. our internal facilities for standard annealing, heat treatment, tempering, normalizing, solution annealing etc.

Our heat treatment shop has a gas-fired HT oven that has a 3 MT capacity to hold metals, and a rapid quench facility with a 30,000 litres capacity to hold metals. We can also regulate the furnace as per API 6A standard. Not only that, our gas-fired salt bath furnaces can hold tempering 1 MT and austempering 2.5 MT.

The entire stainless steel casting production process in our workshop finishes with the machining of the castings so that they get the best shape and tolerances as per the demands of our customers. In the machining section, we execute milling, turning, drilling, and balancing operations. In our internal machining shop, there are cutting-edge instruments with optimum capacity like VMC machine, CNC machine, Drill machine, Lathe machine etc.

Quality control and Testing facilities at Sujan Industries

At Sujan Industries we have chemical testing and physical testing facilities in our internal workshop. So based on the chemical composition and heat treatment, we take the physical features of the cast steel through significant changes. As per the required application, the features are picked to meet the performance necessities. The features are hardness, strength, toughness, corrosion resistance, ductility, wear resistance, weldability, machinability, low-temperature properties, high-temperature properties etc. At present we are delivering quality stainless steel castings product to the Indian Railway industries and are looking to expand our business to the global market. So if you are interested in growing your business, get in touch with us.

0 notes