#Phosphating Tank

Explore tagged Tumblr posts

Text

Phosphating Tank Manufacturers in India

What is a Phosphating Tank?

Phosphating is a vital surface treatment process used to enhance the durability and performance of metal surfaces. It improves corrosion resistance and provides an excellent base for paint adhesion. A Phosphating Tank is an essential component in this process, serving as a container for chemical solutions where metal parts undergo phosphating. Industries such as automotive, construction, and manufacturing rely heavily on these tanks for efficient surface treatment.

Phosphating Tank manufacturers in India

STEP® Techno Solutions LLP is a prominent Phosphating Tank Manufacturer in Gujarat, India, offering innovative solutions for a variety of industrial needs.

Understanding Phosphating

Phosphating involves applying a protective phosphate coating to metal surfaces. This process creates a stable layer that shields metals from corrosion and enhances their ability to hold paint or other coatings. Common applications include treating automobile parts, machinery components, and construction materials.

Phosphating is critical for industries aiming to extend the life of their metal products and improve overall performance. A phosphating tank is essential to the process's efficiency and reliability.

The Role of Phosphating Tanks

A Phosphating Tank is specifically designed to hold the chemical solutions used in phosphating. These tanks are integral to phosphating plants, enabling controlled and efficient surface treatment processes.

There are various types of Phosphating Tanks, each tailored for specific needs:

Immersion Tanks: For dipping metal parts entirely into the solution.

Spray Tanks: For targeted surface treatments.

Multi-stage Tanks: For sequential treatments like cleaning, phosphating, and rinsing.

Choosing the right tank type is essential for achieving the desired treatment results.

Key Features of Quality Phosphating Tanks

A high-quality Phosphating Tank should include:

Durable Material: Resistant to chemical corrosion and high temperatures.

Precision Design: Ensures uniform chemical distribution and efficient treatment.

Customizability: Adaptable to specific industry needs, such as size, shape, and operational features.

Customization allows industries to optimize their phosphating processes for better outcomes.

Overview of STEP® Techno Solutions LLP

STEP® Techno Solutions LLP is a trusted name in phosphating tank manufacturers in India. The company specializes in designing and manufacturing high-performance phosphating tanks for various industries.

Known for their innovation and attention to quality, STEP® Techno Solutions LLP delivers solutions tailored to customer requirements. Their products are durable, efficient, and aligned with industry standards, making them a top choice for businesses across India.

Advantages of Choosing a Top Phosphating Tank

Partnering with a reputable Phosphating Tank Manufacturer like STEP® Techno Solutions LLP offers several benefits:

Enhanced Efficiency: Advanced tank designs ensure optimal chemical usage and faster processing times.

Reliability: High-quality materials and robust construction ensure long-lasting performance.

Excellent Support: Comprehensive after-sales services and technical support help maintain operational efficiency.

For industries seeking reliable surface treatment solutions, choosing a top manufacturer ensures seamless operations.

Customization Options for Phosphating Tanks

Customization is a game-changer for industries with unique requirements. STEP® Techno Solutions LLP offers tailored solutions, including:

Size Adjustments: Tanks designed to fit specific production lines.

Operational Features: Automated systems for improved efficiency.

Material Choices: Selection of materials based on chemical compatibility and durability.

These options enable businesses to maximize productivity and reduce operational costs.

Industry Trends and Innovations

Phosphating technology is constantly evolving. Modern trends include:

Eco-friendly Solutions: Use of non-toxic chemicals for sustainable processing.

Automation: Integration of smart controls for precise treatment.

Compact Designs: Space-saving tanks for small-scale industries.

As one of the leading Phosphating Tank manufacturers in India, STEP® Techno Solutions LLP stays ahead by incorporating these innovations into its products.

Conclusion

A phosphating tank is an essential part of the surface treatment process, assuring durability and efficiency in metal finishing. Industries looking to improve corrosion resistance and coating adhesion can benefit greatly from advanced phosphating tanks.

For reliable and customized solutions, STEP® Techno Solutions LLP stands out as a top Phosphating Tank Manufacturer in India. With their focus on quality and innovation, they deliver products that meet the highest industry standards.

For more information or to inquire about Phosphating Plants, visit our website, call +919898875757, or email at [email protected].

#Phosphating Tank#Phosphating Tank in India#Phosphating Tank Manufacturer#Phosphating Tank manufacturers in India

0 notes

Text

7 Tank Phosphating Demystified: A Journey into Metal Transformation

The 7 Tank Phosphating technique is a respected and transforming approach in the field of metal finishing, allowing a journey into the realm of metal metamorphosis. This sophisticated procedure, which is generally regarded as both an art and a science, is critical in improving the quality, longevity, and look of metal surfaces. Let's go on a voyage to uncover the secrets of 7 Tank Phosphating and see how it revolutionizes metal transformation.

The Fundamentals of 7 Tank Phosphating Process

The 7 tank phosphating method is essentially a succession of precisely controlled chemical baths that a metal substrate goes through. Each of the seven tanks represents a different stage of the transition. Cleaning, rinsing, surface conditioning, phosphating, post-rinsing, passivation, and drying are common steps in the process. The magic happens when these stages work together to create a surface that is not only corrosion-resistant but also favorable to subsequent coatings.

Visit Website: https://officefurnitureindia.in/7-tank-phosphating-process/

The Combination of Art and Science

Knowledge 7 Tank Phosphating necessitates an understanding of the complex balance between art and science. The science is in the chemical processes that are precisely planned to change the metal surface at a tiny level. This modification, known as phosphating, produces a phosphate coating that improves the adherence of future coatings such as paints or lubricants.

The artistry, on the other hand, derives from mastery of the method. Professionals versed in the subtleties of 7 Tank Phosphating may adjust the treatment to particular metals, applications, and desired outputs. The art is in the finesse with which each tank is treated, ensuring that the metal substrate emerges not just altered but also optimized for its intended use.

Decoding the Transformation

Cleaning

The trip starts with a thorough washing of the metal surface. This process eliminates pollutants, oils, and other impurities that may interfere with the future stages.

Rinsing

Following cleaning, the metal is meticulously rinsed to remove any leftover residues from the cleaning stage.

Surface Preparation

The metal surface is prepared for phosphating at this stage. It entails etching or conditioning to improve the phosphate coating's adherence.

Phosphating

The process's heart, phosphating, takes place in this tank. When metal reacts with phosphoric acid, a phosphate coating is formed, which enhances corrosion resistance and promotes coating adhesion.

Post-Rinsing

Following the phosphating stage, a thorough washing is performed to remove excess chemicals and ensure the phosphate coating's resilience.

Passivation

Passivation is the process of treating a metal surface to improve corrosion resistance and optimize its chemical state.

Drying

The final process ensures that the metal substrate is properly cured, preparing it for further coatings or applications.

Source URL: https://officefurniturein.wordpress.com/2024/01/08/7-tank-phosphating-demystified-a-journey-into-metal-transformation/

The Magic Unlocked

The results reflect the full brilliance of 7 Tank Phosphating. The improved corrosion resistance, paint adhesion, and overall durability of the altered metal surface. This procedure is widely used in industries ranging from automotive and aerospace to appliances and construction, where metal component quality and lifespan are critical.

Conclusion

In conclusion, 7 Tank Phosphating is a journey into the realm of metal transformation, not merely a method. The delicate ballet of chemical reactions and great craftsmanship results in surfaces that not only stand the test of time but also serve as a blank canvas for future improvements. As we unravel the mysteries of 7 Tank Phosphating, we discover a realm where art and science meet to improve the very essence of metal finishing.

0 notes

Text

Wildfire & Environmental Health

Here's a few interesting studies I read recently at work that were related to wildfire. Y'all know I find wildfire to be an interesting topic, and I'm an environmental scientist who primarily works in the public health sphere, so I thought I would share them!

The first is about metals found in wildfire suppressants. You know, the stuff they drop from planes?

This one immediately caught my interest since I primarily work in theings related to lead, which is a heavy metal. I had not thought about heavy metals in wildfire suppressants before, but it did not suprise me given our track record with fire fighting products in the past (PFAS in fire fighting foam and asbestos as a flame retardant....)

This study looked at fire suppressants approved by the US Forest Service and consumer use to see if it could contribute to increased heavy metals found in soil and water in areas following a wildfire. They looked at vanadium, chromium, manganese, copper, arsenic, cadmium, antimony, barium, thallium, and lead and found councentrations 4–2,880 times greater than drinking water regulatory limit. At least 8, if not all, of the above metals were found in every fire suppressant tested. The products themselves are not meant to be ingested, obviously, but the concern was that if it were many times above the drinking water maximum contaminant level, that it could still be high enough to impact drinking water quality if it ran off into a reservoir used for that. The Forest Service does have buffer zones around bodies of water where fire suppressants should not be dropped, but accidents happen frequently. They estimated that "fire retardant application in the U.S. contributed approximately 380,000 kg of toxic metals to the environment between 2009 and 2021."

All fire suppressants must be tested by the US Forest Service and have their full ingredient list disclosed, but for public facing material safety data sheets up to 20% can be considered "proprietary" and not disclosed. Chromium and cadmium are effective as aluminum corrosion inhibitors, so they have been added to prevent the product from corroding the aircraft's tanks. Chromium, cadmium, lead, copper, manganese, arsenic have all been documented a contaminants in phosphate ores, which could explain some of the heavy metal concentration in fire suppressants that contain phosphates (but not all of them contained phosphates.) Leaching from metal storage/production tanks could also potentially explain some of the metals in the fire suppressants.

This is an interesting article to me. The authors did not mention it, but I want to note that heavy metal contamination can be just as harmful to wildlife as it is to humans, so even if this contamination did not actually enter human drinking water, it could still kill wildlife. This is also just a terrible glimpse into the way we damage ecosystems. Decades of total fire suppression and poor forest management has lead to increasingly worse wildfires with more fuel to burn, and climate change is fueling through hotter and drier seasons, changed weather patterns, and more. Worse wildfires means fires that are harder to control, and thus fires that need increased use of fire suppressants....which are also toxic. Sigh.

The other one is a new study I just saw today, about the potential link between wildfire smoke inhalation and dementia:

This study looked at 1.2 million people in Southern California to see if long term exposure to wildfire fine particulate matter (PM2.5) was associated with dementia diagnosis. PM2.5 exposure is already known to be a risk factor for dementia but wildfire smoke is an increasingly common source of it that can have different chemical and physical properites than other sources of PM2.5. Wildfire-generated PM2.5 now accounts for "over 70% of total PM2.5 exposure on poor air quality days in California."

They found that for every one microgram increase in wildfire PM2.5 per cubic meter of air over the course of 3 years, the odds of dementia diagnosis rose by 18%. For comparison, the odds of dementia diagnosis for the same parameters of non-wildfire PM2.5 only rise by 3%. (This is compared to everyone's baseline risk, so it is still a fairly small risk over the total population.) The difference could because wildfire smoke participles often have higher concentrations of oxidative or inflammatory compounds, have a smaller average particle size, and typically spike intermittently at high levels at certain parts of the year. Low income communities and people of color were noted to be at higher risk—potentialy due to housing quality (air filtration) and systemic discrimination compounding their risks later in life.

This study is very full of statistics and analysis, so in full disclosure some of my summary is also based off a paywalled article I read first on it. It is an intersting study for sure—I would not have guessed that wildfire smoke specifically had so much higher of an impact than other sources of particulate matter.

Uh, happy Wednesday!

#i nearly said happy friday lol <- brain only knows i'm getting off work today. does not comprehend holiday#environmental science#guys i wanna use my professional experience in lead and my laser focused personal interest in wildfire and unite them to study this more#i tried to summarize these the best i could <3 you can probably find like an actual news article on it though that does it better

9 notes

·

View notes

Text

Kit's Aquarium-Keeping Tips!

I'm increasingly frustrated with people not taking the best care of their pets so!! I'm making a little guide for my own sanity. Starting with the big one!

MYTH: Fish grow to the size of their aquarium! FACT: Keeping fish in too-small aquariums will stunt their growth and generally be unhealthy for them!

Fish need room in their aquarium to swim around, and having plenty of space means your tank will overall be cleaner!

Want to get into the hobby but don't know where to start? Get a tank anywhere from 5-20 gallons! That's big enough for most small fish to thrive! Fish bowls are not sustainable for most fish without bio-active set ups because they lack one key component: a proper filter for your beneficial bacteria to grow in! It is one of the worst things to enter main-stream media.

Here's the most common things I come across:

BETTA FISH

These guys are typically kept solitary, but can have friends if you have a big enough tank! Just make sure to have the tankmates in prior and a backup tank if your betta decides it likes being alone, since they get territorial (this is why you notoriously cannot keep two males together) and especially so in smaller tanks.

I recommend getting at LEAST a 5 gallon, you'll see a ton of activity from your little guy! They're best in low-flow tanks with plenty of taller decorations/plants to rest on. NOT shrimp-safe (they WILL eat smaller ones).

GOLDFISH

One of the most iconic fish pets, one of the most abused. Lots of people get these as prizes at fairs and don't realize how massive they get! These are usually feeder/comet goldfish that reach 6 inches in length and require much bigger thanks than the standard fish!

Not compatible with sensitive fish due to the amount of ammonia they produce, best in larger tanks (20+ for even the smaller ones). With proper care, these guys will live SEVERAL years, if not dozens.

COMMUNITY FISH

These guys are usually tetras or other small fish! They like being in SCHOOLS or SHOALS. You know what this means? They like COMPANY! Three is the BARE MINIMUM for these guys. You want to see your little guy out and about? Give him some guys to hang out with for a confidence boost! Want to see them swim around in tighter groups? SIX fish or more will get you there!

ALGAE

The bane of hobbyists everywhere. ALL tanks will grow algae, and this will more often than not require manual removal from YOU! Yes, there ARE algae-eating critters, but they will not keep it at bay forever! Reducing algae growth is a few simple steps even!

Manage how much light your aquarium gets every day! It should be getting 8 hours MAXIMUM. That means after 8 hours, the lights are off COMPLETELY. The blue "night mode" still contributes to algae growth, so make sure to turn this off, too!

Don't overfeed! Most fish will only need to be fed once per day at most, and they only need a small amount of food! Their stomachs and eyes are of comparable size, to put it in perspective.

Test your water for nitrates and phosphates! This is basically fertilizer that algae will feed off of and the main reason why you should be doing water changes. If your nitrates are up, do a water change to bring it down. If your phosphates are up, get a phos-pad to remove it! It's just a sponge you can add to your filter!

For pesky free-floating algae (aka algae blooms), you can simply turn the lights completely off for a couple weeks until it clears up! For planted aquariums, you can either encourage the plants to out-compete the algae with CO2 or add a UV light to your aquarium (either a bulb insert for your filter or a filter with a UV light included). Make sure the bare UV light isn't directly in the tank because it is harmful to both your fish and YOU!

KNOW YOUR TANK

I run into a surprising amount of people who can't tell me the size of their aquarium or what kind of fish they're keeping in it. Some people can't even tell me what kind of water they have! (Hint: It's either freshwater, saltwater, or rarely brackish)

Can't remember? Write it down, take pictures, whatever helps! It makes it much easier to research or get advice with when you have the proper names and sizes of everything!

BE RESPONSIBLE!

Want to get your bestie new fish for their tank as a surprise? Ask them about it!! They'll love to talk about it and you can unwittingly weasel all the information you need to know.

Need to move and can't take them with you? Fish grown way too big for you to feasibly take care of it? Something else? Ask your local fish/pet stores or fish & wildlife rescues if they take donations or will otherwise accept them! Ask around community groups! Whatever you do, just don't dump it outside in a pond/river/etc., ESPECIALLY if it's a species that is non-native to your area! Some places like Florida have a HUGE invasive species problem because of irresponsible (if not illegal) pet dumping!

#[fis]#fishkeeping#aquarium#I probably missed a few points here and there but#this is the culmination of trying to work with a LOT of people#this is more venting than anything else TBH#but I'll be happy if this actually helps anyone

4 notes

·

View notes

Text

🔅ISRAEL REALTIME - Connecting the World to Israel in Realtime

🔻HEZBOLLAH - Anti-Tank Missile(s) - at Margaliot - HIT, 3 farm workers injured.

🔻HEZBOLLAH - Suicide Drones - Beit Hillel, Kfar Yuval, Gonen and many surrounding towns.

▪️HOSTAGE / CEASEFIRE NEGOTIATIONS.. A senior Hamas official who is in Cairo told the Wall Street Journal: "The first week of Ramadan - a realistic target for a deal”.

And a new demand: A report on the Saudi Al-Arabiya channel: Hamas handed the "keys" to the mediators to release the prisoners in exchange for the Israeli hostages. Hamas demands the return of 500 families to the northern Gaza Strip every day of the ceasefire.

▪️GAZA.. Sources in Gaza report that athis morning our forces destroyed several high-rise buildings in the city of Khan Yunis. According to reports - the explosion was also heard throughout the south of the country.

▪️JORDAN.. Jordan is asking for an increased water allocation (Israel provides them a significant amount of water from the Kinneret) after trashing the Israelis for nearly 5 months and downplaying the Oct. 7 massacre - along with arranging threatening along-the-border night exercises of their military.

▪️COUNTER-TERROR BATTLES.. Fatah terrorists shot at security forces this morning in the al-Amri camp near Ramallah, with one of our forces shot and injured. In response the IDF had large forces enter the El Omari camp near Ramallah, the Arabs report at least one terrorist killed.

Tulkarm - IED road mine damaged an armored carrier (a panther).

Tubas - terrorists opened fire from a building at our forces. The building was charged, the force identified the source of the shooting and an exchange of fire began. No casualties.

Shechem - the Shin Bet and the Israel Defense Forces operated tonight in Nablus and destroyed the house of one of the terrorists who carried out the attack in which the members of the Dee family were murdered.

▪️RED SEA - WORLD INTERNET CABLES CUT.. HGC Communications reports 4 of 15 undersea cables in the Red Sea have been cut - reducing their communications by 25%.

▪️RED SEA - GERMAN NAVY SHIP EXPLOSION.. apparently (from grainy video - if real) a failed counter-missile launch that exploded in the tube.

▪️RED SEA - UK SAYS.. The British Embassy in Yemen announced in a statement: The responsibility for the environmental effects caused by the sinking of the ship "MV Rubymar" in the Red Sea lies with the Houthis, and despite international efforts, today the ship "MV Rubymar" has sunk and 41 thousand tons of ammonium phosphate fertilizer and its fuel will leak into the Red Sea.

▪️AID DROP MISS.. Gazans show videos of aid drop misses into the sea, a few close and some a significant distance offshore.

19 notes

·

View notes

Note

AAAYYYYEEEE AQUARIUM EMPLOYEE SOLIDARITY!!!! do you work directly with the animals? i’m on the environmental quality team at mine, so i spend the majority of my time up in the lab or down in the pump rooms, and i’m always so envious of our galleries team for getting to have problems like ‘one of the penguins keeps fake sneezing because she loves getting attention from the vet team and wants a checkup every day or she’ll scream at us because she’s a special princess’ and ‘our moray eel found a new hiding place and we’ve yet to figure out where it is so if anyone sees him please email the head aquarist’ as opposed to ‘who the fuck used the last of our phosphate reagents and forgot to order new ones GOD DAMN IT’ and ‘alright who wants to stick their arm into the freshwater sump to retrieve the pH probe we need to calibrate?’ like it must be so wonderful to always be in such close proximity to so many little beasts and creatures. do you have a favorite kind of animal to work with/observe? i’ve always been partial to the tunicates and coldwater soft corals/sponges we pick up whenever we do collections on local coastlines. i ❤️ blob animals

Right now my aquarium is kind of a disaster (middle of massive renovations) and we have as few employees as possible so we all kind of do everything, which is sort of nice because I get to do public education and animal care and behind the scenes stuff and help with research!

I ALSO LOVE TUNICATES!!!!! They’re so cool. I especially love surprising people by telling them that tunicates are chordates that are closer related to them than anything else in the touch tank. Blob animals are the best. You should look through my moon snail tag for the biggest blob you’ll ever see

40 notes

·

View notes

Text

cutting the light levels on the reef tank while i attempt to get a handle on the phosphate induced algae problem but it’s making me sad because i love having fish tank lights illuminating my entire room

9 notes

·

View notes

Text

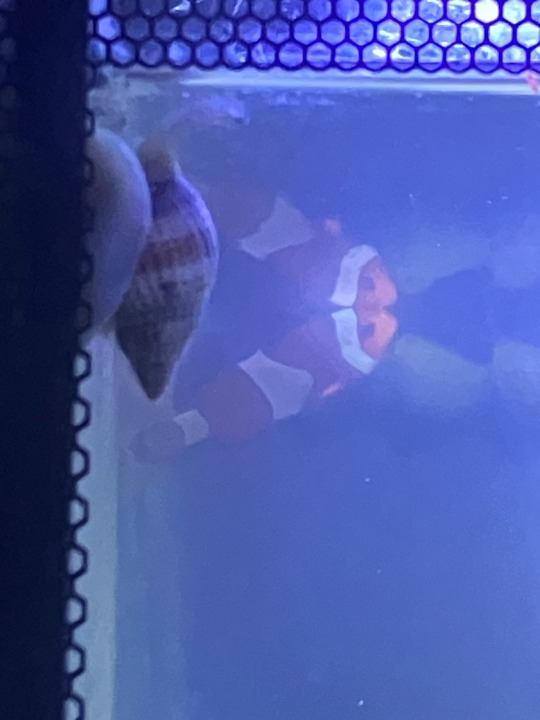

Meet Purrling Reef, aka the 13.5 gallon Fluval Evo reef aquarium that I forgot to tell you all about before: in today's episode: in which Moby scares the sh-! out of me (he's good at that.)

This is Moby, my baby Amphiprion ocellaris clownfish, who, providing that he survives my relative incompetence may live 15+ years. Clownfish are known for being quite hardy fish and people used to use them to cycle their aquariums which is now recognized by many reef aquarists as mild animal cruelty. (Therefore I cycled Purrling Reef using pure ammonia instead.) Along with my (probably female) yellow watchman goby Clyde, Moby has been in Purrling Reef for about a month now.

Things are going well; ammonia is at 0 ppm, nitrates are usually at 0 ppm, phosphates are usually at .25 ppm, salinity is stable at 1.025, and my PH hovers at a somewhat soft but okay 7-7.5. Having at last gotten through the worst of the summer heat and having finally figured out how to set up my inkbird temperature properly, Purrling Reef's waters stay a comfy 25°C (78°F,) all day and night long.

Things are going well, so naturally Moby opted to scare the crap out of me this morning by acting like he was dying.

WTF MOBY.

Terrified for his life I promptly did a water change and dosed the tank with Seachem Prime (which detoxifies ammonia as well as chemicals like chlorine,) then Seachem Stress Guard (which soothes fish.) My ammonia was at zero but I thought that the Prime was a good idea anyway.

Moby promptly stopped looking like he wanted to be crab food, so I went to work; when I came home he was back to his annoying ol' habit of chilling by the filter outflow.

WHY FISH.

After testing all of my water parameters again and finding that all seems well I turned my attention to my newest addition to my reef: Spook the Halloween Hermit crab. I actually call him Captain Spook because he is rather overwhelmingly the least useless member of my cleanup crew. Usually, since I got him he clams up at my approach, sucking as much of his body as he can into the enormous conch snail shell which he adopted as his mobile home.

Chances are he murdered the original inhabitant of this shell.

Today though Spook decided not to spook at my approach which I have two theiries for:

1. The vast anti-Keplar fortifications that I set out around the aquarium double-sided tape traps are working! Yay! (Keplar must not be scaring my aquarium inhabitants as much anymore.)

2. My water is still screwed up so Spook is feeling weird. Given that I have only been at this for like three months... yeah, I can't ignore this possibility.

It was rather remarkable getting to see his white carapace up close for once. While it reminded me that he is in fact a sea bug, but I refuse to hold this against me due to his janitorial awesomeness and the fact that he is much less anxiety inducing than Moby. (Although I live in fear of him eating one of my two puny dwarf hermit crabs.

I can't wait until I can adopt more livestock; Purrling Reef definitely has a job opening available for an emerald crab! (Captain Spook does not like salad.)

Also, here's

Also, here's Clyde the yellow watchman giby who would like me to mention her job a for a pistol shrimp; in the wild watchman gobies live with these shrimp.

If she gets a pistol shrimp friend maybe she'll coe out of her den more often.

#reefing#saltwater#saltwater aquarium#yellow watchman goby#ocellaris clownfish#clownfish#hermit crab#halloween hernit crab

8 notes

·

View notes

Text

cyanobacteria is kicking my ass again so here are some PRO TIPS‼️ for dealing with it:

if you smell the Cyanobacteria Smell then take care of it soon!! do a water change and check your plants!! don’t ignore it just because it’s hard to see!

if there’s mats of it, it can usually be siphoned off easily. trying to swipe it off with your fingers is futile just use a hose.

it mainly shows up when the water has consistently low nitrates and high phosphates. i think that generally happens in heavily planted tanks with lots of decaying material (plants, food, dead things etc) and infrequent water changes

the way i’ve dealt with it then is by doing more water changes, heavily trimming plants, & over-dosing liquid fertilizer to keep the nitrates above 0. i’ve read some people add straight nitrate, but i’m not sure how happy shrimp would be with that..

a way to tell if it’s growing is if all the worms disappear. the cyanotoxins it puts out are ruthless to them, even when there’s only a bit of it!! the smaller crustaceans are always fine, im not sure about shrimp. fish get lethargic and stressed from it (and die if there’s a lot).

IF YOU HAVE DUCKWEED AND GET CYANOBACTERIA. TAKE THE DUCKWEED OUUUUUUUUUT

or any floating plant that covers a lot of the surface really!! i had water lettuce before and it was a nightmare, because right at the top of the water near the light & tucked into roots is the perfect place for cyanobacteria to be. duckweed is the main thing though, since if it builds a layer & then dies off, that can cause a bloom.

its a really cool bacteria, it’s been on earth for 3.5 billion years, it was the first thing to photosynthesize and it’s still around, it’s just that adaptable, and it’s awesome. unfortunately it also sucks for fish tanks. 💔

2 notes

·

View notes

Text

1‑Year‑Old 40‑Gallon Jungle Aquarium Transformation 🌿🐠

Checkout the full long form YouTube video here - https://www.youtube.com/watch?v=Nh2Jz5VCBdU

Welcome to my living jungle: a 40 gallon tank that has grown from bare glass into a lush Planted aquarium over the last twelve months. I set out to prove you can build a gorgeous community fish tank without pressurised CO₂ or stadium lighting, and this diary is the proof. Every branch, root and leaf went in slowly, with long pauses for biology to catch up; if you enjoy the slow‑motion drama of a Planted tank settling into balance, read on.

I laid Fluval Stratum for long‑term nutrients and gentle buffering, then bonded spider wood together with tissue‑and‑glue tricks before locking the structure with black lava rock and Seiryu stone. A few weeks of “dark‑start” cycling let good bacteria thrive so their colonies could support the tanks bioload. Lights stayed off and livestock stayed out, so no fish or plant ever saw a toxic spike.

When the water cleared I planted a carpet of Helanthium tenellum ‘Green’, attached Java fern, Anubias, Bucephalandra to the wood, and let Rotala rotundifolia climb into the skyline while planting Echinodorus plants in the substrate. Duckweed and water lettuce now raft across the top, soaking up stray nutrients.

First onto the payroll came the clean‑up crew: Amano shrimp that bulldoze filament algae, horned nerite snails that polish glass, and a mixed colony of orange, yellow and red cherry shrimp that patrol for every crumb.

For schooling movement I added fifteen Cardinal tetras, fifteen harlequin rasbora and three Pearl Gourami. The gourami were rowdy, so I re‑homed them and brought in honey gourami—calmer, smaller and shrimp‑safe. A squad of cory catfish (Corydoras) now sweeps the substrate, while a flash of neon tetra and tiny chili rasbora glitter mid‑water. One juvenile Siamese algae eater joined but quickly developed a taste for Cory eggs instead of algae.

Month four brought the Black Beard Algae Apocalypse. Amanos and nerites ignored the coarse tufts and my tests showed phosphate off the charts. The culprit: a clogged canister filter packed with six months of mulm. A deep clean, a shorter photoperiod and lighter feeding starved the BBA; within three weeks the tufts turned pink, then ghost‑white, then vanished as shrimp finally found them chewable.

With nutrients balanced, life exploded. Corydoras now spawn almost weekly, rasboras scatter eggs at dawn, and the shrimp colony has multiplied into a shuffling confetti storm. A short potassium dip punched pinholes in the Java fern; a potassium supplement and the occasional spinach leaf fixed that in days.

One year in, this 40 gallon tank practically runs itself. I feed twice a day, trim Rotala tops fortnightly, and spend more time day‑dreaming than working. Visitors lose track of minutes watching neon tetra shimmer through red Rotala leaves or cory catfish kick sand into tiny dunes while the cherry shrimp clean up the mess.

If you’re tempted by a community aquarium on a budget, let this setup be your green‑lit go‑ahead. Start slow, cycle thoroughly, pick hardy species, feed lightly, honour your water changes and the tank will answer with colour, movement and endless moments of calm. Drop questions below and bookmark this clip—I’ll be back at the two‑year mark with another deep dive into my underwater forest.

1 note

·

View note

Text

Thermal Runaway in Batteries

Thermal runaway in batteries causes, safety solutions

Electric vehicles (EVs) have revolutionized transportation by offering an environmentally friendly alternative to gasoline-powered cars. However, concerns regarding battery safety, particularly thermal runaway, remain a critical challenge for manufacturers and consumers alike. Thermal runaway is a dangerous phenomenon that can lead to battery fires and explosions if not properly managed. This article delves into the science behind thermal runaway, its causes, effects, and the strategies used to mitigate this risk in EVs.

What is thermal runaway in batteries?

Thermal runaway occurs when a battery cell enters an uncontrollable self-heating state, leading to rapid temperature escalation. In lithium-ion batteries, this happens when the internal temperature of a cell exceeds a critical threshold (typically around 60-100°C), causing an exothermic reaction. This reaction generates additional heat, leading to a vicious cycle of temperature increase, which can eventually result in fire or explosion.

What causes thermal runaway in batteries?

Poor thermal management:

Inefficient cooling systems may fail to dissipate heat effectively, allowing temperature to rise uncontrollably within battery cells.

The chain reaction of thermal runaway in batteries:

Once thermal runaway begins, it can quickly spread from one cell to adjacent cells, escalating into a battery pack fire. The process follows these stages. First, initiation occurs when a single cell experiences excessive heating due to one of the causes mentioned above. Then, propagation happens when neighboring cells absorb heat from the failing cell, causing their own temperatures to rise and triggering further breakdown. Finally, explosion or fire may result as temperatures exceed critical levels, electrolyte decomposition and gas buildup can lead to combustion or explosion.

Solutions of thermal runaway in batteries

How to solve thermal runaway risks:

To enhance battery safety and prevent thermal runaway, EV manufacturers implement several mitigation strategies, including battery management systems, advanced cooling systems, cell and pack-level safety designs, safer battery chemistries and smart charging technologies.

Battery management systems:

Battery management system continuously monitors voltage, temperature, charge levels, ensuring safe operating conditions and cutting off power in case of anomalies.

Advanced cooling systems:

Liquid cooling systems use coolant to dissipate heat efficiency, maintaining optimal battery temperatures. Some EVs rely on air cooling systems with forced air circulation to regulate temperature.

Cell and pack-level safety designs:

Thermal batteries with fire-resistant materials are placed between cells o slow heat propagation. Modular battery design separates battery modules with insulation, reducing the likelihood of a chain reaction.

Safer battery chemistries:

Lithium-iron-phosphate (LFP) batteries are more thermally stable and less prone to thermal runaway compared to traditional nickel-manganese-cobalt (NMC) batteries. Solid-state batteries, still in development, promise improved thermal stability by replacing flammable liquid electrolytes with solid materials.

Smart charging technologies:

Algorithms optimize charging cycles to prevent overcharging and overheating. Wireless charging solutions may offer safer alternatives by reducing heat generation during power transfer.

Emergency response to EV battery fires:

Despite advanced safety measures, EV fires still occur and they present unique challenges to first responders. Unlike gasoline fires, lithium-ion battery fires burn hotter, release toxic fumes, and can reignite hours after being extinguished. Firefighters use several techniques to combat these fires. Large amounts of water help cool the battery and prevent further thermal runaway. Some fire departments submerge burning EVs in water tanks to eliminate residual heat. Fire blankets help contain flames and prevent oxygen from fueling the fire. Research is also focused on developing fire suppressants specifically designed for lithium-ion battery fires.

Future of battery safety:

The global electric vehicle (EV) market is projected to grow from USD 396.49 billion in 2024 to USD 620.33 billion by 2030 at a CAGR of 7.7%. Many factors are collectively driving the electric vehicle market. The most important of these is the reduction of the total cost of ownership through lower fuel and maintenance costs than traditional internal combustion engine (ICE) vehicles. The energy density has significantly improved while the cost has substantially decreased, thereby enabling electric vehicles to have larger driving ranges and yet be cheaper at the same time.

As EV adoption grows, researchers and manufacturers continue to enhance battery safety. Innovations in solid-state batteries, AI-powered battery monitoring, new fire-resistant materials promise a future where EV fires become even rarer. Regulators worldwide are also implementing stricter safety standards to ensure battery reliability and consumer protection.

Conclusion:

As the innovation and technology have been shaping the automobile industry, especially to the EVs to a state of wonder day by day, there is no doubt that battery safety is becoming a greater concern to the manufacturers. Automobile industry is focusing on the proper management system of batteries, safer chemistries, smart charging equipment and process to minimize the risks of thermal runaway in batteries. Implementing strict safety standards can also ensure the battery reliability and protection of thermal runaway in batteries.

Read More:

gyanfactory.com

0 notes

Text

Conveyorized Powder coating Plant Manufacturer in India

Are you searching for the best Conveyorized Powder Coating Plant Manufacturer in India? We offer cutting-edge automated powder coating plants designed for high productivity, superior finishing, and cost efficiency.

Swift Scientific Works, Powder Coating Booth, liquid Painting Booth, Hot Water Generator, PP Tank, Diesel Fired Oven, LPG Fired Oven, Electrical Oven, Over Head Conveyor, PLC Based Transporter, Powder Coating Plant, Phosphating Plant, Liquid Painting Plant, Hot Water Generator, PLC Based Transporter, Powder Coating Plant, Diesel / Lpg Fired Oven, Liquid Painting Plant on turnkey basis. Customer requirements , lower running cost, and less maintenance are kept in view while designing the plants.

Website: https://sswovenbooth.com/conveyorized-powder-coating-plant-manufacturer/

0 notes

Text

Unlocking the Secrets of the 7 Tank Process for Powder Coating Success

Powder coating has become a popular finishing method due to its durability, aesthetics, and environmental benefits. The 7-tank procedure stands out among the many ways as a thorough and effective approach to achieving exceptional powder coating outcomes. In this blog, we'll delve into the complexities of the 7-tank process, revealing the secrets that contribute to its success in producing high-quality, long-lasting coated products.

Learning the 7-Tank Process:

The 7-tank process is a precisely constructed approach that consists of seven separate steps, each of which is critical in preparing the substrate and guaranteeing optimal powder coating adhesion and endurance.

Visit Website: https://officefurnitureindia.in/7-tank-phosphating-process/

Pre-treatment:

The procedure begins with pre-treatment, which involves thoroughly cleaning the substrate to eliminate impurities such as oils, grease, and rust. This step is critical in achieving a clean surface that facilitates good powder adherence.

Rinsing:

The substrate is rinsed after pre-treatment to remove any leftover cleaning agents. This ensures a clean surface for the powder coating process's future steps.

Phosphating:

Phosphating is a chemical process that coats the substrate with phosphate. This coating improves powder adherence and adds corrosion resistance, making the completed product more durable.

The Second Rinsing:

A second rinse cycle is used after phosphating to eliminate any surplus chemicals and by-products. This thorough rinse is required to prepare the substrate for the subsequent phases of the process.

Drying:

The substrate is then completely dried to remove any remaining moisture. A totally dry surface is necessary for proper powder adherence and the prevention of flaws in the finished coating.

Application of Powder Coating:

The powder coating procedure begins once the substrate has been thoroughly prepared. Powder particles that are electrostatically charged stick to the substrate, resulting in a uniform and robust covering.

Curing:

The powder-coated substrate is then baked to cure in the final stage. The heat causes a chemical reaction, causing the powder to melt, flow, and cure into a long-lasting finish. Curing is critical for getting the desired coating qualities, such as hardness and chemical resistance.

The 7-Tank Process Success Secrets:

Surface Preparation is Critical:

The thorough preparation of the substrate is what makes the 7-tank procedure so effective. Thorough cleaning and pre-treatment guarantee that the surface is clean and free of impurities, resulting in a perfect canvas for powder coating.

Chemical Accuracy:

Accurate chemical formulations in each stage, particularly phosphating, contribute to the process's effectiveness. Exact chemical treatments improve adhesion and corrosion resistance, raising the overall quality of the powder-coated product.

Timing and Temperature:

It is critical to maintain strict control over the curing process. The proper curing temperature and duration ensure that the powder coating reaches maximum hardness and endurance. Deviations from these specifications can result in coating problems.

Source URL: https://theomnibuzz.com/unlocking-the-secrets-of-the-7-tank-process-for-powder-coating-success/

Powder Coating Materials of High Quality:

It is critical to use high-quality powder coating materials. The selection of powders with the proper composition and properties is critical in obtaining the required finish and durability.

Conclusion:

The 7-tank process for powder coating success displays the value of accuracy, thoroughness, and attention to detail in surface preparation and finishing. Uncovering the secrets of each stage enables manufacturers and finishers to create powder-coated goods that meet high quality, durability, and aesthetic appeal on a consistent basis. Businesses can upgrade their powder coating processes and assure customer satisfaction with goods that stand the test of time by learning and adopting these secrets.

#7-tank process for Powder Coating#7 tank process in powder coating#7 tank process for painting#7 tank pretreatment process#7 tank phosphating process

0 notes

Text

With any substrate, things like phosphates, iron, and ammonia come to be gradually and naturally concentrated at the bottom. This is why reddish cyanobacterial blooms happen on the substrate, sometimes, in even marine tanks with perfect water parameters. Its also why the sudden, physical stirring of an established substrate, can rapidly affect the water chemistry as reported by test kits; when 'bad stuff' is immediately sent upwards in the water column, and thus back into solution, because formerly percolated chemicals and particles have been disturbed.

The way in which the saturated substrate has different chemical parameters to the water column up above, means that - for example - the phisphate levels of the aquarium water can suddenly (and negatively) be affected, should the substrate become disturbed, usually by the activities of the aquarist. Needless to say, any such stirring of the substrate must be regular and small scale, for example through the activities of 'live sand' infauna, and those of larger, burrowing ornamental animals, such as shrimp, gobies, echinoderms, and gastropods.

A similar misunderstanding of a substrate involves freshwater tanks, and the fear that 'muck' or detritus in the substrate makes undergravel filtration ineffective. In reality such detritus holds well the beneficial nutrients, that plants require and are able to access with their root systems. Dirty gravel or sand is thus excellent for plant growth, and coarser grains trap more wholesome muck. As with marine tanks, and for the same reason as described above, substrates should not be disturbed large scale if it can be avoided, whether or not an undergravel filter happens to be employed in the tank.

The accumulation of detritus within a gravel or sand substrate, and the processes and products of its decomposition, are (as they say) a rather integral working or feature, and not at all a ‘bug’ to be avoided. Aquaria cannot be spotless, and vacuuming activities should only ever be done lightly, or not at all - and if done at all, then only lightly spruced, and only from the surface of the sand or gravel. It is important that only the surface of the gravel should be disturbed if at all, or its utility for natural biofiltration will be compromised.

Returning to the subject of substrates and filtration; in marine aquariums, but rarely in freshwater tanks, people sometimes advocate what are called 'anoxic plenums' beneath the substrate - the so-called 'Monaco method'. The whole point is that, unlike the workings of undergravel filtration systems, water is not at all pumped through the space, making it a stable volume or 'void space' of water, that is deprived of dissolved oxygen - constituting a plenum. Plenums were once a huge idea in reefkeeping, following the famous aquarium scientist, Jean Jaubert.

However, it seems that the idea of the often imitated Monaco system, is actually based on misunderstood observations of phenomena taking place in aquariums, that have other scientific explanations. Related to the facts and fallacies surrounding the dubious plenum method, is the popular notion that sufficiently deep beds of sand used as a substrate, are in themselves similarly beneficial, thus rendering the creation of a plenum superfluous. Typically associated with marine and especially reef aquaria, these methods have some advocates as regards freshwater tanks.

Where water flow is absent throughout the substrate, there is a risk, however slim, that organic material might end up decomposing deep in the substrate, in a way producing accumulations of bacterial toxins alongside noxious smells - and a possibility that there could be mortalities should this filth be released unto desirable organisms. I have only ever experienced such smells after disturbing a settled substrate, and yet fortunately, there were no mortalities despite a sudden and downward shift in my water quality, that distressed the fish - you should get the picture by now, not to disturb the substrate, wether it is being used as a filter medium or not.

Now returning to the subject of plants in freshwater aquaria. Vascular plants (or tracheophytes) access nutrients via their roots, and natural selection has furnished different plants with different root systems for this purpose. Plants such as Echinodorus and Cryptocoryne are heavy root feeders, equipped with long and deeply penetrating roots, Such plants do better when they are planted in gravel than on sand, because gravel traps detritus better. A reverse flow variant of the undergravel system, would actually help to bring nutrients to the living and feeding plant roots.

#substrate#water chemistry#undergravel filtration#biofiltration#planted tanks#aquarium plants#cyanobacteria#detritus#deep sand beds#plenums#monaco method#gravel vacuums#decomposition

1 note

·

View note

Text

Choosing the Right Antifreeze for Your Audi A5: A Complete Guide

The Audi A5 is a luxury vehicle that requires proper maintenance to ensure longevity and peak performance. One crucial aspect of maintenance is selecting the right antifreeze (coolant). Antifreeze is essential for regulating the engine temperature, preventing freezing in cold weather, and avoiding overheating in hot conditions. Using the wrong antifreeze can lead to serious engine damage, including corrosion and overheating issues. In this guide, we’ll discuss the types of antifreeze for audi a5 suitable for an Audi A5, how to check and replace it, and key maintenance tips.

Understanding Antifreeze for the Audi A5 Antifreeze is a liquid coolant that mixes with water to regulate the temperature of your engine. It prevents freezing in cold weather and boiling over in extreme heat. The Audi A5, like other modern vehicles, uses a specific type of antifreeze formulated to protect the engine and radiator from corrosion.

Recommended Antifreeze for Audi A5 Audi vehicles, including the A5, use a specific coolant type that meets Volkswagen Group’s G12, G13, or newer specifications. These coolants are formulated with organic additives that prevent rust and corrosion in aluminum and other engine components.

G12 (Red or Pink Coolant): Older Audi A5 models may use G12 coolant, which is phosphate- and silicate-free. It offers long-lasting protection but should not be mixed with other types of antifreeze. G12+ and G12++ (Pink or Purple Coolant): These upgraded versions of G12 offer enhanced corrosion protection and longer service life. G13 (Purple Coolant): The latest formulation, G13, is designed with environmentally friendly additives while providing excellent cooling performance. It is compatible with G12++ but should not be mixed with non-approved antifreeze types. Using generic or incompatible antifreeze can cause deposits to build up in the cooling system, reducing efficiency and potentially damaging your engine. Always check your owner's manual or consult a certified Audi service center to ensure you use the right coolant.

How to Check and Refill Antifreeze in an Audi A5 Regularly checking and maintaining the coolant level in your Audi A5 is essential for preventing engine problems. Follow these steps to check and refill antifreeze properly:

Park the Vehicle on a Level Surface: Ensure the engine is cool before opening the coolant reservoir to prevent burns from hot steam or fluid. Locate the Coolant Reservoir: The coolant expansion tank is usually marked with a pink or purple coolant warning symbol under the hood. Check the Coolant Level: The coolant should be between the “MIN” and “MAX” markers on the reservoir. If it is low, a refill is needed. Use the Correct Coolant: Mix the correct antifreeze with distilled water if required (check the product instructions). Some coolants come pre-mixed and do not require dilution. Fill Slowly: Pour the coolant into the reservoir gradually to avoid overfilling. Secure the Cap: Tighten the coolant cap securely to prevent leaks. Run the Engine: Start the car and let it idle for a few minutes to circulate the coolant. Monitor the temperature gauge to ensure proper operation. Signs of Coolant Issues If your Audi A5 is experiencing cooling system issues, you may notice:

Overheating engine Coolant leaks under the vehicle Low coolant warning light on the dashboard Heater not working properly in cold weather If you encounter these issues, check the coolant level and consult a mechanic if necessary.

Coolant Maintenance Tips for Audi A5 Check the coolant level every few months and before long trips. Flush and replace coolant every 3-5 years or as specified in the owner’s manual. Avoid mixing different coolant types unless they are specifically compatible. Inspect for leaks around hoses, the radiator, and the water pump. Conclusion Using the correct antifreeze in your Audi A5 is vital for engine performance and longevity. Stick to Audi-approved coolants like G12, G12+, or G13, and follow proper maintenance procedures to ensure a reliable cooling system. Regular checks and timely replacements will keep your Audi A5 running smoothly for years to come.

0 notes

Text

Corrosion Inhibitors: We use corrosion inhibitors to defend our industrial equipment and physical structures from damage.

Corrosion stands as the top reason materials break down and brings big problems to our built environment and equipment operations. Many industries today protect their assets through using corrosion inhibitors. By using these chemical compounds we help metal equipment and structures stay strong and run better over time.

What does a Corrosion Inhibitor do?

When you put corrosion inhibitors into a damaging environment they help metals resist oxidation and decay. These inhibitors create a safe cover on metal surfaces or they adjust the chemical setting to reduce its corrosion potential. Most industries need to protect metals from severe environments that contain water, salt, and chemical substances.

Types of Corrosion Inhibitors

Anodic Inhibitors: These inhibitors prevent metal decay by creating a shielding oxide film over the metal surface during the anodic reaction.

Catholic Inhibitors: Reduce the catholic reaction rate through surface barrier formation.

Mixed Inhibitors: Mix anodic and catholic inhibitor elements to secure full protection of the material.

Volatile Corrosion Inhibitors (VCIs): The chemical moves from vapor back to solid to build up a shield on metal parts.

Organic Inhibitors: The compounds amines and phosphates in these inhibitors build water-repelling protective layers.

Different industries apply Corrosion Inhibitors in several ways.

Corrosion inhibitors are indispensable in various industries, including:

Construction: We need to prevent corrosion of steel supports in concrete buildings by shielding them from chloride damage.

Oil and Gas: Special protection must be applied to pipelines, storage tanks and offshore platforms facing extreme environmental pressures.

Automotive: The coatings preserve radiators and exhaust systems to last longer in vehicles.

Water Treatment: Add corrosion inhibitors to save boilers, cooling systems and water pipes from rust damage.

Marine: Use inhibitors to defend ships docks and sea hardware from saltwater harm.

Using corrosion inhibitors produces several advantageous results for metal infrastructure.

Enhanced Durability: Metal parts in industrial machines and buildings work longer with appropriate protection.

Cost Savings: Consistent inhibitor usage cuts down costs for fixing and replacing corroded equipment.

Improved Safety: The use of inhibitors reduces the chance that rust will break metal structures.

Environmental Protection: The substances help to keep rust and corrosion byproducts from entering our natural surroundings.

Efficiency: Industrial equipment and infrastructure function at their best when protected with corrosion inhibitors.

Effectively matching corrosion protection solutions with your needs begins with proper inhibitor selection.

The selection of a suitable corrosion inhibitor depends on several factors:

Type of Metal: Each metal type needs its own special protective chemical.

Environment: Study the materials around your equipment that cause corrosion such as wetness, salt crystals or chemical substances.

Application Method: You can protect metals through surface treatment, direct submersion or by mixing inhibitors into your process fluid.

Regulatory Compliance: Test the inhibitor according to accepted protection and environmental rules.

Cost-Effectiveness: Seek the best results by planning your budget carefully.

Conclusion

Corrosion inhibitors help all industries protect their assets from rust damage in known and reliable ways. These inhibitors defend metal assets by making protective surfaces and changing their surrounding environments. Because industries aim to become more sustainable and economical corrosion inhibitors will see increasing demand to help preserve physical assets against natural damage.

0 notes