#Monomer capacity

Explore tagged Tumblr posts

Text

PowerAdd 10000 EnergyCell

I have the power!

Are you tired of your devices running out of battery while you’re on the move? The PowerAdd 10000 EnergyCell might just be the solution you’ve been searching for. Today we’re taking a look at the key features, technical specifications and why this pocket-sized powerhouse deserves a place in your essential travel gadgets bag. Product supplied for review purposes PowerAdd 10000 The PowerAdd…

View On WordPress

#Amazon power bank#Battery life extension#Compact size#crazydiscostu#crazydiscostu.com#Energy density#Essential travel gadgets#External battery#Fast charging#geek#High-density battery cell#High-quality battery packs#Holiday power solution#iPhone Xs#Modern travelers#Monomer capacity#Nerd#Pocket-sized powerhouse#Portable charger#Power bank#Power on the go#PowerAdd 10000 EnergyCell#Rapid charging capabilities#review#reviews#Samsung S9#Tech#Tech enthusiasts#tech specs#travel companion

0 notes

Text

Shofu BeautiSealant Pit & Fissure Sealant

BeautiSealant is a fluoride releasing pit and fissure sealant that seals deep grooves and fissures while providing all round protection especially during the caries-prone years through the sustained release and recharge of fluoride. Unlike conventional sealants that require phosphoric acid etching that dehydrates and demineralizes healthy tooth structure BeautiSealant provides a safer, simpler and more predictable option that completely eliminates the need for a conventional phosphoric acid etch

IDEALLY USED FOR:

As a pit & fissure sealant

ADVANTAGES:

Gentle on Enamel:

Conventional sealants require phosphoric acid etching which can dehydrate and demineralize healthy tooth structure. BeautiSealant self-etch primer contains dual adhesive monomers that thoroughly penetrate into deep pits and fissures to prime the tooth surface for an effective chemical bond to the sealant while minimizing any damage to enamel.

This HEMA-free formulation also prevents hydrolysis at the bonding interface for long-term stability and retention. The self-etch primer conditions the enamel surface to make it more reactive that in turn enhances the flow of the sealant paste into the pits and fissures.

Effective Delivery:

An efficient non-drip, fuss-free syringe design and an extra fine 27 gauge needle tip assures precise delivery of the smooth, bubble-free sealant without the hassle of overfilling the grooves, a common problem encountered with conventional delivery systems.

“Giomer Concept”:

A member of the Giomer family of restoratives, BeautiSealant is based on Shofu’s proprietary S-PRG filler technology, where a stable glass ionomer phase is formed to provide the benefits of fluoride. The glass core with glass ionomer phase is protected with a trilaminar surface structure that allows controlled release and recharge of fluoride while maintaining structural integrity.

Remarkable Adhesion:

BeautiSealant with its self-etch primer exhibits an equally durable bond to enamel as other traditional sealants that employ an aggressive phosphoric acid etch. The material surface is optimally cured to guarantee a reliable seal.

Features:

BeautiSealant self-etch primer features dual adhesive monomers to thoroughly prime the tooth surface for an effective chemical bond to the sealant while minimizing any damage to enamel.

The HEMA-free formulation of the primer prevents bond hydrolysis over time.

BeautiSealant paste exhibits a superior surface cure property for a durable seal.

Ideal viscosity and an efficient non-drip, fuss-free syringe design with an extra fine 27 gauge needle tip assures precise delivery of the smooth, bubble-free paste into difficult to reach fissures without the hassle of overfilling grooves.

Exhibits high shear bond strength for long-term durability and retention

Inclusion of S-PRG fillers provides a fluoride rich environment and a unique anti-plaque effect

Fluoride rich environment

Anti-bacterial and anti-cariogenic property

Acid-buffering capacity that neutralizes the effects of acidogenic bacteria

Arrests demineralization and promotes remineralization of enamel

Unique Anti-Plaque effect

Key Specifications:

COMPOSITION:

Paste:

Fluoroboroaluminosilicate glass

UDMA

TEGDMA

Micro fumed silica and others

Primer:

Acetone

Distilled water

Carboxylic acid monomer

Phosphonic acid monomer and others

Packaging:

Shofu BeautiSealant Complete Set:

1 x 1.2g Syringe BeautiSealant Paste

1 x 3ml BeautiSealant Primer

50 x Microbrush Fine (Pink)

25 x V-Dish

Shofu BeautiSealant Refill:

1 x 1.2g Syringe BeautiSealant Paste

Needle Tips

0 notes

Text

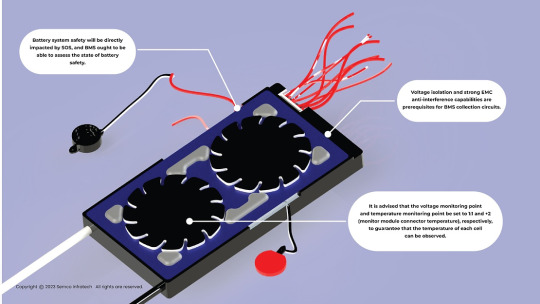

BMS Safety Design: Best Practices for Preventing Battery Hazards

Voltage isolation and strong EMC anti-interference capabilities are prerequisites for BMS collection circuits. Special integrated circuits are generally not advised because they cannot achieve fault diagnosis, accuracy, passive equalization, or high-precision AD conversion. Examples of these circuits include optocoupler relay + external AD, data processing, passive equalization, drop monitoring, and high anti-interference ability. They are hard to guarantee, and they are not very resistant to interference.

It is advised that the voltage and temperature monitoring points be set to 1:1 and +2 (monitor module connector temperature), respectively, to guarantee that the temperature of each cell can be observed. Temperature monitoring points must also be installed on the battery pole to reduce the temperature monitoring delay and increase accuracy. Incorporate temperature monitoring at critical locations that are prone to overheating, like circuit breakers, relays, and power bus connection points.

Battery system safety will be directly impacted by SOS, and BMS ought to be able to assess the state of battery safety. It is impossible to determine the actual temperature inside the battery because temperature monitoring is either not done at this time or is limited to measuring the temperature of the confluence. As a result, there is a serious hidden risk to the battery’s safe operation when the heat inside the battery gets out of control and the rapidly rising temperature is not noticed in time.

Likewise, in the event that both the battery temperature and internal pressure rise too high, the safety valve will open. However, since safety valve monitoring is currently lacking, preventive actions such as shutting off the circuit, halting operation, initiating local cooling, and initiating firefighting cannot be taken in a timely manner. As a result, the two points mentioned above will eventually lead to breakthroughs in BMS security design.

Energy Storage BMS Development Trend

As monomer battery capacity increases, battery imbalance becomes more severe.

Passive equalization technology is no longer sufficient to balance battery systems and extend battery life.

Active equalization technology is an inevitable trend in the development of energy storage BMS.

Active equalization can extend battery life by 20%, which has high economic benefits.

Development Trend of Energy Storage BMS Battery Sensing Technology

The development of battery sensors and wireless BMS has become a priority due to the swift advancement of this technology. Future research and discussion on BMS are critically needed.

Problems with the technology of the current battery management system. There are obstacles in the way of technological advancement for the current battery management system:

1. There are two unsolvable issues because the voltage and temperature recorded by the current battery management system are the external parameters of the cell.

(a) Because the battery’s internal temperature cannot be measured, it is impossible to accurately determine how hot it gets inside. As a result, in the event of a small internal short circuit or thermal runaway cell, prompt safety warning and protection are not possible. This is a really big issue. The temperature inside the battery can be used to predict the thermal runaway of the battery in advance, preventing many combustion and explosion accidents that have happened in electric cars and energy storage power plants.

However, the system has experienced thermal runaway precisely as a result of the temperature gradient’s influence and the delay in temperature sampling. It’s too late to issue warnings and safeguards. This problem, which must be resolved immediately, is connected to the battery system’s safety.

(b) It is impossible to precisely determine the true state of the battery, including its capacity, health, attenuation, safety status, etc., since the real temperature and other state parameters inside the battery cannot be obtained.

2.The current battery management system must gather wire harness data to gather parameters like voltage, temperature, and other data. Numerous failure hazards, including poor contact, will arise because of the numerous geranium beams, sampling points, and connectors attached to the wire harness. In addition, it will result in production issues, insulation deterioration, and power leaks brought on by wire harness aging, damage, or extrusion. The system’s potential safety risk.

3. Since wire harness installation is typically done by hand, production and installation costs will inevitably rise.

4. Ineffective cell detection in the absence of installation and operation; damage to the battery; and thermal runaway safety.

Energy storage BMS development is moving in the direction of active equalization technology. This is because active equalization, particularly for large-capacity battery systems, can more successfully balance battery systems and increase battery life. Because active equalization technology can increase battery life by up to 20%, it offers significant economic benefits.

Since batteries account for a large portion of the cost of energy storage systems, this represents substantial savings for users of energy storage. Active equalization technology is where energy storage BMS development is trending. This trend is advantageous since it will result in energy storage systems that are more dependable and efficient.

#Battery Hazard Prevention#Battery Management System (BMS) Safety#Battery Safety Hazards#BMS Best Practices#BMS Safety Design

0 notes

Text

Polyethyleneimine: An Important Building Block in Various Applications In Industry

What is Polyethyleneimine?

Polyethyleneimine (PEI) is a polymeric compound composed of repeating units of ethyleneimine monomers. It is a white solid polymer that is soluble in water. PEI is classified as a branched or linear cationic polymer that is formulated through the polymerization of aziridine. The polymer's molecular weight can range from 300 to over 10,000 Daltons depending on its intended use. Properties and Structure of PEI

PEI is a polymer that contains secondary nitrogen atoms along its backbone that provide cationic charge centers. These nitrogen atoms can interact and form electrostatic bonds with negatively charged macromolecules or surfaces. The cationic nature of PEI allows it to act as a polycation and complex or condense with negatively charged substances like DNA or RNA. PEI is also very hygroscopic due to its numerous amine groups that attract water molecules. Its branched structure provides greater buffering capacity and DNA condensation ability compared to the linear form of PEI. Uses in Gene Delivery

One of the most important uses of Polyethyleneimine is in non-viral gene delivery applications. Its cationic charge allows it to efficiently bind and compact negatively charged nucleic acids like plasmids, forming nano-sized polyplexes that can transfect cells. The polyplexes are effectively endocytosed by cells and the low pH of endosomes triggers PEI to buffer the compartment, releasing the DNA from the complex. This "proton sponge" mechanism of PEI facilitates effective intracellular delivery and expression of the gene of interest. It is commonly used as a transfection agent for in vitro studies as well as in vivo gene therapies and vaccines. Role in Biomaterials and Tissue Engineering

Given its favorable properties, PEI also finds extensive use as biomaterials for tissue engineering applications. Its cationic nature permits binding of PEI to negatively charged components of the extracellular matrix like glycosaminoglycans. This helps direct cell adhesion, growth, and function. PEI can act as a coating onto implants and scaffolds, promoting their integration with surrounding tissues. It allows bioconjugation of signaling cues to influence cell behavior in regenerative therapies as well. The tunable properties of PEI through controlling its molecular weight or branching also expand its utility in the design of biomaterials.

In addition to the major uses mentioned above, PEI has applications in many other fields due to its versatile characteristics. It acts as a flocculating agent in wastewater treatment processes to remove pollutants and purify water. PEI finds increasing importance as a hardener in epoxy resins used in manufacturing infrastructure and electronics. Its buffering ability makes it valuable as a non-corrosive alternative to replace hazardous chemicals in industrial cleaning agents as well. Overall, the unique polymeric structure and properties of PEI designate it as an essential building block material with myriad applications.

Get more insights on Polyethyleneimine

Unlock More Insights—Explore the Report in the Language You Prefer

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

Alice Mutum is a seasoned senior content editor at Coherent Market Insights, leveraging extensive expertise gained from her previous role as a content writer. With seven years in content development, Alice masterfully employs SEO best practices and cutting-edge digital marketing strategies to craft high-ranking, impactful content. As an editor, she meticulously ensures flawless grammar and punctuation, precise data accuracy, and perfect alignment with audience needs in every research report. Alice's dedication to excellence and her strategic approach to content make her an invaluable asset in the world of market insights.

(LinkedIn: www.linkedin.com/in/alice-mutum-3b247b137 )

#Polyethyleneimine#Aliphatic Carbon#Versatile Polymer#PEI#Linear Polymer#Cyclic Amine#Cationic Polymer#Biopolymer#Flocculant#Emulsifier#Nanoparticle Synthesis

0 notes

Text

Acetic Acid Products: Analyzing Current Size, Share, and Growth Trends

The global acetic acid market size is expected to reach USD 23.02 billion by 2030, growing at a CAGR of 7.6% from 2024 to 2030, as per the new report by Grand View Research, Inc. The growth of the market can be attributed to the rising demand for the product in industries such as construction, pharmaceuticals, and textiles. Acetic acid is widely used in the production of paints and coatings, which are in high demand due to the increasing desire to elevate the aesthetics of houses worldwide. The paints and coatings market are expected to grow significantly in the coming years, driven by factors such as increasing demand from various end-use industries, rising construction activities, and growing urbanization.

Acetic Acid Market Report Highlights

Based on application, the vinyl acetate monomer segment is expected to witness the fastest growth rate with a CAGR of 7.8% globally. This is attributed to its wide utilization in the paints & coating industry. Acetic acid is an essential raw material for the production of vinyl acetate monomers. Hence, the increasing demand for vinyl acetate monomer is directly influencing the product demand

Asia Pacific dominated the market with a revenue share of 33.9% in 2023 and is predicted to remain on top over the forecast period. This is attributed to the rising demand for the product in the pharmaceutical industry. Acetic acid is widely consumed in the development of medicinal drugs such as aspirins to cure headaches. Increasing number of patients in the region is driving demand for medicines, which is directly impacting the product demand in the industry

North America is the second largest region and captured 21.2% of the market in 2023. This is attributed to the increased demand for the product in the food & beverage industry in the region. Acetic acid is a less toxic and low-cost chemical that is widely used in the food industry. The market is anticipated to see significant growth owing to its increased demand in the food industry over the predicted years

In September 2023, INEOS announced the acquisition of Eastman Chemical Company's Eastman Texas city site which also includes an acetic acid plant of 600 kilotons

In January 2023, Kingboard Holdings Limited announced that its subsidiary, Hebei Kingboard Energy Development Co., Ltd., plans to submit the "Environmental Impact Report of Hebei Kingboard Energy Development Co., Ltd. Acetic Acid Expansion and Transformation Project" for approval

For More Details or Sample Copy please visit link @: Acetic Acid Market Report

The demand for vinyl acetate monomers is rising in industries such as paints and coatings, paper coatings, and printed products. The market has considered an essential raw material for the production of vinyl acetate monomer, directly increasing the demand for the product. Acetic acid is widely used in the food and beverage industry in North America, where the increasing consumption of food directly influences the demand for the product. The region's demand for acetic acid is driven by its various applications in the food and beverage sector.

In the global product industry, competition is fierce due to the presence of multinational corporations. Eastman Chemical Company, SABIC, HELM AG, and Indian Oil corporations are among the prominent players in this industry. These companies are committed to continuous research and development efforts in order to improve their operational efficiency. Additionally, they actively pursue joint ventures and expand their production capacities to gain a competitive advantage.

List of major companies in the Acetic Acid Market

Eastman Chemical Company

Celanese Corporation

LynodellBasell Industries Holding B.V.

SABIC

HELM AG

Indian Oil Corporation Ltd

Gujrat Narmada Valley Fertilizers & Chemicals Limited

DAICEL CORPORATION

Dow

INEOS

Gain deeper insights on the market and receive your free copy with TOC now @: Acetic Acid Market Analysis Report

We have segmented the global acetic acid market based on application and region.

#AceticAcidMarket#GlacialAceticAcid#TerephthalicAcid#EthanoicAcid#CarboxylicAcid#Polymers#Paints&Coatings#FoodAndBeverage#MedicinalDrugs#FoodAdditive

1 note

·

View note

Text

The Ultimate Guide to Rubber Gaskets for Industrial Use

In the realm of industrial usage, the HUMBLE rubber gasket remains a critical element that ensures reliability as well as efficiency in machinery and equipment. Manufacturing, maintenance or engineering personnel can have great influence on their operational success by getting to know rubber gaskets better. This complete guide will help you make informed choices about your industrial needs by discussing important aspects of rubber gaskets like different types, benefits, and applications.

What is a Rubber Gasket?

Rubber gaskets are sealing elements manufactured from diverse types of rubber materials. Their purpose is to seal off spaces between two surfaces so that both fluids and gases do not leak out. They are indispensable in maintaining connections and joints’ integrity on machinery, pipes among other industrial systems.

Types of Rubber Gaskets

Different types of rubber gaskets are designed for certain applications and conditions. Some common ones include the following:

Neoprene Gaskets: For their excellent resistance against weathering, ozone degradation as well as ageing effects, neoprene gaskets are widely used in automobile and refrigeration sectors.

EPDM Gaskets: Automotive and industrial applications find ethylene propylene diene monomer (EPDM) gaskets ideal owing to their high resistance to steam, heat and chemicals.

Nitrile Gaskets: Nitrile rubber gaskets are at the same time highly resistant to oils, fuels, and other petroleum-based matters due to this they are commonly used in the oil and automotive industries.

Silicone Gaskets: Silicone gaskets have the ability to withstand high heat and the flexibility that makes them suitable for use in extreme temperature applications.

Viton Gaskets: Viton gaskets possess excellent capacity of high temperature resistance, chemicals as well as fluids. In such a way they are best suited for tough industrial settings.

Benefits of Rubber Gaskets

Rubber is very useful in industry because:

Leak Prevention: One of the key characteristic of rubber gasket is its ability to prevent leaks which is vital for maintaining machine/system safety and efficiency.

Flexibility: Rubber gasket can mold itself into irregular surfaces hence providing a tight seal even under less-than-ideal conditions.

Durability: Withstand hostile environmental conditions including temperature changes, chemical attacks and physical stresses

Cost effectiveness: A good number of applications use cheap-rubber gasket material compared to others sealing materials available on the market today. Hence cost effective for large number of users

Ease of Installation: This makes installation fast and reduces downtimes thus reducing costs associated with maintenance.

Applications of Rubber Gaskets

Rubber gaskets are used across many industries because they are versatile:

Automotive Industry: In automobiles, rubber gaskets are employed in the engines, transmissions and cooling systems to prevent leaks and ensure smooth running.

Industrial Machinery: These are required in industrial machinery to seal joints and connections, thus preventing leakages of fluids and gases.

Construction: In construction, rubber gaskets maintain energy efficiency in HVAC systems, plumbing and other applications hence avoiding any leaks.

Aerospace: They require high-performance gasket materials for aerospace uses, which can endure harsh conditions hence making rubber gaskets an essential part of aircraft systems.

Oil and Gas: Rubber gaskets are vital in oil and gas where they seal pipelines and equipment ensuring safety as well as efficiency of activities.

Choosing the Right Rubber Gasket

Several factors come into play while selecting the right rubber gasket:

Material Compatibility: Make sure that you use a type of rubber that is compatible with the liquid or gas it comes into contact with.

Temperature Range: Therefore, select a material for your gasket that can survive your application’s operating temperatures.

Chemical Resistance: For applications that include chemicals, choose a suitable material based on its chemical resistance.

Pressure Requirements: The pressure conditions that will ensure the gasket can hold out properly under different pressures should be considered.

Size and Shape: To create an effective seal, the gasket must fit accurately into its place of service.

Conclusion

Rubber gaskets are critical components in several industrial processes offering a range of benefits including leak prevention, ability to accommodate movement and withstand huge variations in temperature. Better understanding of rubber gasket types and their application will enable you make inform choices for improved system efficiency and safety. If you want to find more about these materials, check out other resources like Sealmax where you can find a wide range of solutions tailored to meet your specific requirements.

Resource: https://justpaste.it/aoc2p

0 notes

Text

What is PVP K30 Used for in Pharma?

Polyvinylpyrrolidone is one of the important excipients advocated internationally. PVP is a white to milky white powder. Easily soluble in water, alcohol, amines and halogenated hydrocarbons, but insoluble in acetone, ether, etc.

Povidone K30 is a combination of pyrrolidone and ethylene under pressure to form vinylpyrrolidone monomer. It is a homopolymer of 1-vinyl-2-pyrrolidone obtained by polymerization under the action of a catalyst. The molecular formula is (C6H9NO)n, where n represents the average number of 1-vinyl-2-pyrrolidone chain units. Calculated based on anhydrous matter, the nitrogen (N) content should be 11.5%~12.8%. Povidone K30 (K30 is named based on its K value) is an important product in the povidone series.

Povidone K30 is mainly used in the pharmaceutical industry. As one of the three new pharmaceutical excipients advocated internationally, it is mainly used as a binder for tablets and granules, as a flow aid for capsules, as a detoxifier and lubricant for eye drops. , cosolvents for injections, dispersants for liquid preparations, enzymes and heat-sensitive drugs.

It can be used as a stabilizer for chemicals, synthesized with iodine as PVP-I disinfectant, and can also be used as a low-temperature storage agent.

Unilong Industry Co., Ltd. Supply different grades of PVP K30 like USP26 and USP43 to meet your application. Our production capacity can reach 4000tons per year. Our product has a very wide range of uses in the field of pharmaceutical preparations and is one of the three new pharmaceutical excipients advocated internationally.

#UNILONG #PVP #9003-39-8

0 notes

Text

Innovations and Opportunities in the Super Absorbent Polymers Market

Super Absorbent Polymers: Revolutionary Materials Absorbing Liquids Introduction Super absorbent polymers (SAPs), as the name suggests, are advanced materials with an extraordinarily strong ability to absorb and retain liquids. When immersed in water or other aqueous solutions, SAPs can soak up hundreds of times their own weight in liquid within seconds through a process called gel blocking. This unparalleled absorbency property stems from SAPs' porous, three-dimensional network structure at the molecular level. Common Applications of SAPs Despite being relatively new materials, SAPs have carved out an important place for themselves in several industries through their unique water retention qualities. Some of their most widespread applications include: - Disposable Diapers and Sanitary Pads: SAPs allow diapers and pads to absorb large amounts of urine and other fluids without leakage. They help keep babies and adults dry for longer. - Agriculture: When mixed with soil, SAPs aid water retention for crops in arid environments. They reduce irrigation needs by absorbing and storing water in the root zone. - Construction: Sealants, caulks, and other fillers containing SAPs don't crack in the presence of water. This protects buildings from moisture damage. - Medicine: Wound dressings featuring SAP technology pull liquids away from injury sites. They also maintain a moist healing environment. - Packaging: Absorbent pads and liners with SAPs soak up meat juices and other liquids in food packaging. This prevents leaks and increases shelf life. How are SAPs Manufactured? Most commercially available SAPs are produced through a process of crosslinking polyacrylate or polyacrylamide polymers. These watersoluble polymers are mixed with a crosslinking agent, usually an acrylate or multifunctional monomer. Upon addition of the crosslinker and initiation via heat or radiation, covalent bonds form between the polymer chains. This crosslinking process transforms the disorganized linear or branched starting polymers into an interconnected three-dimensional network structure with countless pores and interstitial spaces. The surface chemical groups along the polymeric network readily interact with water molecules through hydrogen bonding. Capillary forces then draw liquid into the porous matrix where it gets trapped and retained without draining away. Properties and Performance Some key properties of SAPs that impart their super absorbency include: - Absorption Capacity: Modern SAPs can absorb 100-1000 times their own weight in aqueous solutions within a short time. Laboratory samples have touched absorption ratios of over 2000. - Gel Strength: The crosslinked network structure provides SAP hydrogels with high gel strength even when fully swollen with liquid. This prevents leakage. - Swelling Speed: SAPs take only seconds to absorb fluid through their porous morphology. The rapid gel blocking prevents fluids from emerging. - Return Flow Pressure: Absorbed liquids remain immobilized against external pressures like gravity, movement, or compression during use. - Salt Tolerance: Absorption is efficient even in solutions with dissolved salts and minerals, unlike many other absorbent materials. Super Absorbent Polymers of the Future

0 notes

Text

Itaconic Acid Market Analysis: Key Insights and Future Outlook

Introduction Methylenesuccinic acid is an organic dicarboxylic acid produced as an intermediate metabolite by certain fungi during glucose fermentation. With the chemical formula C5H6O4, methylenesuccinic acid has two carboxyl groups that make it highly reactive and versatile for chemical applications. Its production from renewable biomass via fermentation also makes methylenesuccinic acid attractive as a sustainable building block. Applications in Specialty Polymers One major use of itaconic acid is in the production of specialty polymers. Its two carboxyl groups allow it to act as a comonomer in polymerization reactions. When copolymerized with acrylic acid or other monomers, methylenesuccinic acid introduces desirable properties like hydrophilicity, permeability, and acidity into the final polymers. Such methylenesuccinic acid copolymers find widespread use as superabsorbents in hygiene products, thickeners in industrial applications, and biodegradable materials. They are also being explored for new applications in fuel cells, adhesives, coatings and ion-exchange resins. Intermediate for Synthetic RESINS Besides direct applications, methylenesuccinic acid also enables the production of many important intermediates and final products. It undergoes thermal decarboxylation to form styrene, a precursor to polystyrene plastics. Via acidolysis with polyols, methylenesuccinic acid can make reactive polyester resins used as binders, coatings or matrices. Dimerization to produce citraconic anhydride opens new routes for epoxy and alkyd resins essential to paints, varnishes and construction materials. With techniques like selective hydrogenation, methylenesuccinic acid can even yield substituted furan derivatives and other platform chemicals with wide scope in the agrochemical and pharmaceutical industries. Sustainable Chemical Building Block As industries transition towards renewable, sustainable bio-based options, itaconic acid displays immense potential. It serves as an ideal building block - with its versatile functional groups, biodegradability, and production from abundant biomass. Global production capacities are scaling up to serve diversifying applications. Meanwhile, metabolic engineering pushes yields and titers higher. Methylenesuccinic acid exemplifies how sustainable biomanufacturing and green chemistry principles can yield platform chemicals previously derived from petrochemicals. This opens up new pathways for more environmentally benign products meeting society's needs well into the future.

0 notes

Text

Acrylonitrile Styrene Acrylate (ASA) Prices, News, Trend, Graph, Chart, Forecast and Historical

Acrylonitrile Styrene Acrylate (ASA) is a high-performance thermoplastic polymer known for its exceptional properties, including UV resistance, impact strength, and weatherability, making it widely used in industries such as automotive, construction, and electronics. ASA is often considered a superior alternative to other thermoplastics due to its ability to withstand harsh environmental conditions, ensuring its longevity in both outdoor and indoor applications. The global ASA market has witnessed significant growth in recent years, driven by the increasing demand for durable and high-quality materials in various sectors. ASA's versatility allows it to be molded into a range of products, from automotive parts to consumer goods, which further contributes to its growing popularity.

The pricing of ASA is influenced by several factors, including raw material costs, production processes, and supply chain dynamics. The primary raw materials used in the production of ASA are acrylonitrile, styrene, and acrylic monomers, all of which have fluctuating prices based on global market conditions. Acrylonitrile, for example, is derived from natural gas and petroleum, so any changes in the prices of crude oil can directly impact ASA pricing. The volatility of crude oil prices, therefore, plays a pivotal role in determining the cost of ASA production. Additionally, styrene and acrylic monomers are also subject to market forces, with their prices influenced by factors such as production capacity, availability of raw materials, and global demand. As a result, ASA manufacturers must carefully monitor these raw material price trends to effectively manage production costs and maintain competitive pricing in the market.

Get Real time Prices for Acrylonitrile Styrene Acrylate (ASA): https://www.chemanalyst.com/Pricing-data/acrylonitrile-styrene-acrylate-asa-1265

In addition to raw material costs, the production capacity and technological advancements in ASA manufacturing also have a significant impact on pricing. As the demand for ASA continues to rise, manufacturers are investing in more advanced production techniques and increasing their capacity to meet market needs. Innovations in production processes, such as the development of more energy-efficient methods and the use of sustainable raw materials, have the potential to reduce production costs and, in turn, stabilize ASA prices. However, the initial investment in new technologies and the scaling up of production can lead to temporary price fluctuations as manufacturers adjust to changing market conditions and production capacities. This dynamic creates a level of uncertainty in the ASA pricing market, which can affect buyers' purchasing decisions and manufacturers' profitability.

Geographical factors also play a crucial role in determining the pricing trends of ASA. The global market for ASA is highly fragmented, with significant demand from regions such as North America, Europe, Asia-Pacific, and Latin America. In North America and Europe, the demand for ASA is primarily driven by the automotive and construction sectors, which require durable and weather-resistant materials for components like exterior parts, roofing systems, and building facades. In contrast, the Asia-Pacific region is experiencing rapid industrialization and urbanization, resulting in increased demand for ASA in sectors such as electronics, packaging, and consumer goods. As a result, regional differences in supply and demand patterns can lead to varying price trends across different markets. The competition among ASA manufacturers in these regions also influences pricing strategies, as companies seek to capture market share and respond to fluctuations in demand.

The impact of global trade policies and supply chain disruptions further complicates the ASA pricing market. The recent COVID-19 pandemic has highlighted the vulnerability of global supply chains, with disruptions in the transportation of raw materials, labor shortages, and factory shutdowns leading to delays in ASA production and delivery. These disruptions have, in many cases, resulted in increased production costs and higher prices for ASA. Furthermore, trade policies such as tariffs and export restrictions can exacerbate these challenges, especially in regions that rely heavily on imported raw materials or finished ASA products. Manufacturers and consumers alike are forced to adapt to these changing conditions, which may result in short-term price increases until the supply chain stabilizes.

Market trends indicate that the ASA market will continue to grow in the coming years, albeit with some volatility in pricing. The increasing adoption of ASA in industries like automotive, construction, and electronics, combined with advancements in production technologies, suggests a steady rise in demand. However, raw material price fluctuations, geopolitical uncertainties, and supply chain issues may continue to influence pricing trends. To navigate this complex market, both manufacturers and consumers must stay informed about global economic conditions, technological advancements, and regional demand shifts to make well-informed decisions. As the market for ASA evolves, pricing strategies will remain a crucial factor in determining the profitability of manufacturers and the affordability of ASA products for end-users. The balance between supply and demand, along with external market factors, will shape the future of ASA pricing in the global market.

Get Real time Prices for Acrylonitrile Styrene Acrylate (ASA): https://www.chemanalyst.com/Pricing-data/acrylonitrile-styrene-acrylate-asa-1265

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Acrylonitrile Styrene Acrylate#Acrylonitrile Styrene Acrylate Prices#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

0 notes

Text

Unlocking Potential: How Technology is Transforming the Global Sphingolipids Market

The global sphingolipid market is on track for remarkable growth, poised to exceed a valuation of USD 564.0 million in 2021 and projected to achieve a Compound Annual Growth Rate (CAGR) of 5.1% by the end of 2032, reaching an estimated value of around USD 991.8 million.

Sphingolipids are essential for the creation and function of cell membranes, and lipid-based drug delivery methods greatly benefit from their special qualities. Sphingolipids present versatile strategies for augmenting drug solubility and stability, as well as enabling targeted administration and controlled release, in an array of therapeutic applications.

Because of its special qualities and potential for therapeutic uses, the broad family of lipids known as sphingolipids is showing up more and more in pharmaceutical formulations. They are essential for cell signaling and structure. Due to the rising need for both natural and synthetic sphingolipids and monomers in the production of numerous medicinal goods, sphingolipid sales are expected to rise.

Gain a Competitive Edge: Request Your Sample: https://www.futuremarketinsights.com/reports/sample/rep-gb-15713

This factor might significantly improve the adoption and consumption of pharmaceutical sphingolipids. The rising product launches and approvals are expected to contribute to the market growth over the forecast period too.

Key Takeaways from Market Study:

Sphingomyelin is the leading segment as a product and holds approximately 0% market share in 2021, due to its anti-cancer, bacteriostatic, and cholesterol-lowering characteristics.

Synthetic sphingolipids are the leading segment by source, and held about 4% market share in 2021, owing to their potential as therapeutic prospects for treating a range of medical problems.

Conventional lipid-based drug delivery systems (LBDDS) is the leading segment in terms of application holding about 9% of the market share, as compared to traditional tablets or powder-filled capsules, as they can improve bioavailability and reduce dissolving rate-limited absorption because of their pharmacological composition in a solubilized condition.

Semi-solid form of sphingolipids is the leading form as of 2021, withholding about 3% of the global market share, owing to the property of reduced adverse side effects when a high drug load is applied to the area where the medication is actually required.

Pharmaceutical companies are the leading end users of the global market as of 2021, withholding about 5% of the market share, because of increased outsourcing, innovative modalities, and creative patient outreach tactics.

By region, North America is leading in the global sphingolipids market and is expected to continue to do so with a projected CAGR of 4% during the forecasted years.

“Rising initiatives to promote health benefits of sphingolipids products, as well as the increasing ongoing research and development in modifying novel sphingolipids formulations is set to propel the market of sphingolipids across the globe,” says an analyst of Future Market Insights.

Market Competition

Companies are actively working to increase their market share in this industry by forming strategic agreements to diversify their respective service offerings and sphingolipid production capacities.

In January 2022, Pfizer and Acuitas Therapeutics reached an agreement on Lipid Nanoparticle Delivery System for mRNA vaccines and therapeutics.

June 2022: To support customers’ scientific research, CD Bioparticles, enlarged its lipid system portfolio and introduced a number of Sphingolipids products. With the addition of Phosphosphingolipids, Ceramides, Sphingolipid Metabolism, Sphingosines, Glycosphingolipids, Phytosphingosine, and Sphingomyelin, researchers now have more options to choose from and employ in lipid system applications.

Key Companies Profiled

Merck KGaA

CordenPharma International

Lipoid GmbH

LARODAN AB

Croda International Plc.

Biosynth, Santa Cruz Biotechnology, Inc.

Creative Enzymes

CD Bioparticles

Cayman Chemical Company

Biosolve BV

Key Segments Covered In Sphingolipids Industry Research

By Product:

Ceramide

Sphingomyelin

Glucosylceramide (GlcCer)

Lactosylceramide (LacCer)

Ganglioside GM3

Other

By Source:

Synthetic

Semi-synthetic

Natural

By Application:

Conventional Lipid-based Drug Delivery Systems (LBDDS)

Self-Emulsifying Drug Delivery Systems (SEDDS)

Self-Microemulsifying Drug Delivery Systems (SMEDDS)

Liposomes

Solid Lipid Nanoparticles

Nanostructured Lipid Carriers

Others

By Form:

Liquid

Semi-solid

Solid

By End User:

Pharmaceutical Companies

Biopharmaceutical Companies

Academics and Research Institutes

Others

0 notes

Text

Understanding Lithium Battery Cell OCV Testing

Lithium-ion batteries are at the heart of modern technology, powering everything from smartphones to electric vehicles. Ensuring the health and performance of these batteries is of paramount importance. One valuable tool in assessing the state of lithium battery cells is the Open Circuit Voltage (OCV) test. In this article, we'll explore the principles, parameters, and precautions associated with lithium battery cell OCV testing.

I. OCV Test Principles

The OCV test is a method used to estimate the state of battery cells. It involves measuring the open circuit voltage, AC internal resistance, and housing voltage of individual battery monomers. By assessing the voltage of the battery under open circuit conditions, valuable insights into the battery's remaining capacity and overall health can be obtained.

Remaining Capacity Estimation: The core principle of the OCV test is to gauge the relationship between a battery's open circuit voltage and its remaining capacity. As a battery discharges, its open circuit voltage decreases. By measuring the voltage at different states of charge, a curve can be established, allowing for the estimation of remaining capacity.

Termination Voltage: During discharge, the open circuit voltage of a battery steadily decreases with diminishing capacity. At a certain point, often referred to as the termination voltage, the voltage drop becomes significant. This critical voltage level signifies that the battery is nearly depleted.

Calibration and Modelling: Real-world application of the OCV test typically requires calibration and modeling based on historical data and battery characteristics. This process involves measuring the open circuit voltage of the battery at various states of charge and leveraging existing models and calibration data to infer remaining capacity or health status.

II. Parameters Involved in Lithium Battery Cell OCV Testing

To gain a comprehensive understanding of lithium battery cell OCV testing, it's essential to be familiar with the key parameters involved:

Open Circuit Voltage: This is the voltage measured when the battery has no external load after resting for a specific period. It serves as a valuable indicator for estimating the battery's remaining capacity and overall health.

Cut-off Voltage: The cut-off voltage is the voltage at which a battery is considered discharged. It is a crucial parameter for determining the end of a battery's discharge cycle.

Battery Characteristic Curve: By measuring the open circuit voltage of a battery at various states of charge, a characteristic curve can be established, showing the relationship between open circuit voltage and remaining capacity.

Calibration Data: Calibration involves refining test results based on historical battery data and characteristics. Calibration enhances the accuracy and reliability of OCV tests.

Estimation Algorithm: Estimation algorithms use the open circuit voltage of the battery, combined with existing models or calibration data, to infer the remaining capacity or health status of the battery through a defined mathematical algorithm.

III. Precautions in Lithium Battery Cell OCV Testing

While the OCV test is a valuable tool, its accuracy and reliability can be influenced by various factors, including changes in battery characteristics, temperature variations, and usage conditions. Therefore, it is essential to exercise caution and consider the following precautions:

Environmental Factors: Factors such as temperature and usage conditions can significantly impact the accuracy of OCV tests. Be mindful of these variables during testing.

Comprehensive Assessment: Recognize that the OCV test is just one method of estimating a battery's state. For a comprehensive evaluation, it's often necessary to combine multiple test methods and algorithms.

Conclusion

In conclusion, the Open Circuit Voltage (OCV) test is a vital tool for assessing the state of lithium battery cells. By measuring the voltage at different states of charge and utilizing calibration data and estimation algorithms, valuable insights into a battery's remaining capacity and health can be obtained. However, it's crucial to exercise caution and consider various factors to ensure accurate and reliable results when conducting OCV tests.

#Battery OCV and SOC relationship#Battery open circuit voltage (OCV) testing#Importance of OCV in lithium batteries#Lithium battery cell OCV testing#Lithium battery testing methods#Lithium-ion battery OCV analysis#OCV measurement for lithium-ion cells#Open circuit voltage testing for batteries#Testing lithium battery health with OCV

0 notes

Text

How to choose copper ore beneficiation equipment

Copper ore beneficiation is a process in which copper ore is processed through crushing, grinding, flotation and other processes to extract high-grade copper minerals. In this process, mineral processing equipment is a key link. It can effectively separate metal minerals and waste rocks through physical mineral processing technology. Choosing appropriate mineral processing equipment can improve mineral processing efficiency and ore recovery rate, thereby reducing production costs. Next, let’s briefly analyze the crushing, grinding and flotation equipment needed in the copper ore beneficiation process.

Crushing equipment

Crushing technology is an important front-end process in a copper ore dressing plant. Only by crushing large pieces of copper ore to the required particle size through crushing equipment can the grinding efficiency be improved and high-grade copper minerals extracted.

When selecting crushing equipment, factors such as the hardness and crushing ratio of the ore need to be considered. Although jaw crushers, vertical shaft impact crushers, cone crushers, etc. can be used to crush copper ores, different crushing methods are suitable for copper ores of different properties. , it is necessary to choose the appropriate crushing method according to the actual situation. For example, for harder ores, you can choose to use a jaw crusher, and for medium-hard ores, you can choose to use a cone crusher or vertical shaft impact crusher.

Grinding equipment

Ore grinding technology is to roll, impact and grind the ore particles processed by the crushing equipment under high pressure, and further grind them to achieve the dissociation of copper mineral monomers, thereby facilitating the subsequent mineral processing process. Commonly used grinding equipment includes ball mills, rod mills, etc. When selecting grinding equipment, you also need to consider the hardness of the ore, grinding efficiency and other factors. For harder ores, you need to choose a ball mill that can withstand greater pressure. For heavier ores, you need to choose a ball mill that can withstand greater pressure. For soft or brittle ores, you can choose to use a rod mill; depending on the production capacity, you need to choose different specifications of ball mills or rod mills.

0 notes

Text

Propylene Glycol Production Cost Analysis: A Complete Overview

The latest report titled “Propylene Glycol Production Analysis Report” by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of Propylene Glycol.

Procurement Resource study is based on the latest prices and other economic data available. It also offers additional analysis of the report with detailed breakdown of all cost components (capital investment details, production cost details, economics for another plant location, dynamic cost model). In addition, the report incorporates the production process with detailed process and material flow, capital investment, operating costs along with financial expenses and depreciation charges.

Request For Free Sample: https://procurementresource.com/production-cost-report-store/propylene-glycol/request-sample

Procurement Resource’s detailed report describes the stepwise consumption of material and utilities along with a detailed process flow diagram. Furthermore, the study assesses the latest developments within the industry that might influence Propylene Glycol production cost, looking into capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Procurement Resource Assessment of Propylene Glycol Production Process:

1. Propylene Glycol Production Cost Via Direct Hydrolysis: This report presents the detailed production methodology and cost analysis of propylene glycol industrial production across propylene glycol manufacturing plants. In this process, propylene oxide undergoes direct hydrolysis with water to produce propylene glycol.

Request For Free Sample: https://procurementresource.com/cost-analysis/propylene-glycol-production-via-peroxidation/requestsample

2. Propylene Glycol Production Cost Via Chlorohydrin process: This report provides the thorough economics of propylene glycol industrial production across propylene glycol manufacturing plants. In this process, propylene monomer reacts with hypochlorous acid, resulting in propylene chlorohydrin. Subsequently, the propylene chlorohydrin reacts with sodium hydroxide to produce propylene glycol.

Request For Free Sample: https://procurementresource.com/cost-analysis/propylene-glycol-production-via-direct-hydrolysis/requestsample

3. Propylene Glycol Production Cost Via Peroxidation: This report presents the extensive cost requirement of propylene glycol industrial production across propylene glycol manufacturing plants. In this process, hydrogen peroxide and propylene monomer undergo a reaction to produce propylene oxide. Subsequently, the resulting propylene oxide is subjected to a hydration process to form propylene glycol.

Request For Free Sample: https://procurementresource.com/cost-analysis/propylene-glycol-production-via-chlorohydrin-process/requestsample

Product Definition:

Propylene Glycol (PG) is a synthetic, odorless, and colorless organic compound with the chemical formula C3H8O2. It is a viscous liquid that belongs to the family of diols, also known as glycols. Propylene Glycol is produced through the hydration of propylene oxide, a petrochemical derivative. It finds widespread use across various industries due to its versatile properties. In the food and pharmaceutical sectors, PG serves as a safe and effective additive, functioning as a humectant, solvent, and preservative. It is also commonly utilized in cosmetics and personal care products to improve texture and stability. Moreover, Propylene Glycol has a lower freezing point than water, making it a valuable ingredient in antifreeze solutions and de-icing products. Additionally, its ability to absorb and retain moisture makes it a preferred component in air humidifiers and e-cigarette liquids. However, due to its potential health risks when ingested in large quantities, PG must be used responsibly and within established safety guidelines.

Market Drivers:

The market drivers for Propylene Glycol (PG) are primarily influenced by its versatile applications across diverse industries. One of the key drivers is the growing demand in the food and pharmaceutical sectors, where PG serves as a safe and effective additive, contributing to increased consumption. In the cosmetics and personal care industry, PG's role as a humectant and stabilizer fuels its market growth. The automotive sector also drives demand, as PG's antifreeze properties make it a crucial component in coolants and de-icing products. Moreover, the expanding e-cigarette market has led to a surge in PG usage in e-liquids due to its ability to create vapor and enhance flavors. Additionally, PG's presence in air humidifiers, solvent formulations, and industrial applications further boosts its market demand. As sustainability and environmental concerns grow, PG's eco-friendly nature acts as an additional driver, attracting eco-conscious industries seeking greener alternatives. These factors collectively contribute to the steady expansion of the Propylene Glycol market.

Looking for an exhaustive and personalised report that could significantly substantiate your business?

Although Procurement Resource leaves no page unfurled in terms of the rigorous research for the commodities that make the heftiest base of your business, we incline more towards tailoring the reports per your specificities. All you need is one-to-one consulting with our seasoned consultants to comprehend the prime parameters you are looking to pin your research on.

Some of the common requests we receive from our clients include:

Adapting the report to the country/region where you intend to establish your plant.

Adjusting the manufacturing capacity of the plant according to your needs

Customizing machinery suppliers and costs to meet your requirements.

Providing additional information to the existing scope based on your needs.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertakes extensive research to provide our customers with the latest and up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele.

Procurement Resource work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. As a team of experts, we also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with updated and reliable data.

We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate so that they can form strategies that ensure their optimum growth.

Contact Us:

Company Name: Procurement Resource Contact Person: Chris Byrd Email: [email protected] Toll-Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500 Address: 30 North Gould Street, Sheridan, WY 82801, USA

#PropyleneGlycolProductionCost#PropyleneGlycolProduction#PropyleneGlycol#PropyleneGlycolProductionReport

1 note

·

View note

Text

Neoprene Rubber Prices Trend, Monitor, News, Analytics & Forecast | ChemAnalyst

Neoprene rubber prices, reflective of the cost of this versatile synthetic rubber material, are subject to fluctuations influenced by various factors such as global market dynamics, industrial demand, and production costs. Understanding these price movements entails a comprehensive analysis of supply and demand dynamics, raw material availability, and macroeconomic indicators.

The pricing of neoprene rubber is significantly influenced by the balance between supply and demand within industries such as automotive, construction, marine, and sports equipment manufacturing. Neoprene rubber, prized for its excellent resistance to oils, chemicals, and extreme temperatures, finds widespread application in products ranging from automotive seals and gaskets to wetsuits, hoses, and roofing materials. Disruptions in the supply chain, such as fluctuations in raw material availability, production capacity, or transportation logistics, can impact the availability and cost of neoprene rubber, thereby influencing its market price.

Get Real-TimeNeoprene Rubber Prices: https://www.chemanalyst.com/Pricing-data/neoprene-rubber-1309

Industrial demand plays a crucial role in determining neoprene rubber prices. Industries such as automotive and construction rely heavily on neoprene rubber for its durability and weather resistance, while the marine and sports equipment sectors utilize it for its waterproofing and shock-absorption properties. Fluctuations in demand from these sectors, influenced by factors such as construction activity, consumer spending, and sporting events, can lead to price volatility for neoprene rubber.

Raw material costs significantly impact neoprene rubber prices. The price of raw materials such as chloroprene monomer, which is used in neoprene rubber production, can fluctuate due to changes in global supply and demand dynamics, feedstock availability, and energy costs. Any significant increase in raw material costs can translate into higher production costs for neoprene rubber manufacturers, thereby exerting upward pressure on prices.

Macroeconomic indicators, such as GDP growth, industrial output, and consumer spending, can indirectly affect neoprene rubber prices by influencing over all demand for products containing neoprene rubber. Economic expansions tend to drive demand for neoprene rubber-intensive products such as automotive components, construction materials, and sporting goods, thereby supporting higher prices. Conversely, economic downturns or uncertainties may lead to reduced demand and downward pressure on neoprene rubber prices.

Regulatory changes and quality standards also play a role in shaping neoprene rubber prices. Government regulations on product safety, environmental standards, and manufacturing practices can impact production costs and market access for neoprene rubber manufacturers. Compliance with these regulations may require investments in research, testing, and quality control measures, influencing pricing dynamics.

Looking ahead, several factors are expected to continue influencing neoprene rubber prices. Continued growth in sectors such as automotive, construction, and sports equipment manufacturing, coupled with increasing demand for durable and weather-resistant materials, is likely to drive sustained demand for neoprene rubber. Moreover, advancements in material science and engineering, as well as changes in global trade dynamics, could lead to changes in market dynamics and price levels for neoprene rubber.

In conclusion, neoprene rubber prices are subject to a complex interplay of factors including supply and demand dynamics, industrial trends, raw material costs, regulatory changes, and macroeconomic indicators. Stakeholders in industries reliant on neoprene rubber, such as automotive, construction, marine, and sports equipment manufacturing, must closely monitor these factors to anticipate price movements and make informed decisions. As industries evolve and technology advances, navigating the dynamic landscape of neoprene rubber pricing will remain a key challenge for industry participants.

Get Real-TimeNeoprene Rubber Prices: https://www.chemanalyst.com/Pricing-data/neoprene-rubber-1309

GmbH — S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49–221–6505–8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Acroleic Acid Production Cost, Manufacturing Process, Raw Materials Requirements, Costs and Key Process Information

The latest report titled Acroleic Acid Production Cost by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the manufacturing process of Acrylic Acid.

Procurement Resource study is based on the latest prices and other economic data available. It also offers additional analysis of the report with detailed breakdown of all cost components (capital investment details, manufacturing cost details, economics for another plant location, dynamic cost model). In addition, the report incorporates the manufacturing process with detailed process and material flow, capital investment, operating costs along with financial expenses and depreciation charges.

Request Free Sample – https://www.procurementresource.com/production-cost-report-store/acrylic-acid/request-sample

Procurement Resource’s detailed report describes the stepwise consumption of material and utilities along with a detailed process flow diagram. Furthermore, the study assesses the latest developments within the industry, including Acrylic Acid manufacturing process, that might influence Acrylic Acid manufacturing cost, looking into capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Product Definition:

Acrylic Acid or Acroleic Acid (C3H4O2) is an alpha, beta-unsaturated monocarboxylic acid in which ethene is substituted by a carboxy group. The organic compound looks colourless with a tart/acrid odour and has the role of a metabolite and the conjugate acid of an acrylate. It is soluble in water and extremely corrosive to metals and tissue. Its respective melting, boiling, and flash point is 141.0°C, 14.0°C and 68°C. Its molecular mass is 72.06 g/mol, and its density is 1.0511 at 20°C.

Market Drivers:

The Acrylic Acid market is being driven by the growing usage of the acid for producing an extensive product range. It is used to make acrylic esters and resins, which are employed further to make adhesives and coatings, which boost the market growth further. In addition, it is used in oil and water treatment chemicals, water-absorbent polyacrylic acid polymers, and detergent intermediates. Owing to its ability to polymerize upon being heated, it is employed in the production of polyacrylates and as works as a monomer for polyacrylic and polymethacrylic acids. Also, it finds use in the production of plastics, flocculants, tackifiers, water-soluble resins and salts, etc., which in turn boosts the market expansion.

Looking for an exhaustive and personalised report that could significantly substantiate your business?

Although Procurement Resource leaves no page unfurled in terms of the rigorous research for the commodities that make the heftiest base of your business, we incline more towards tailoring the reports per your specificities. All you need is one-to-one consulting with our seasoned consultants to comprehend the prime parameters you are looking to pin your research on.

Some of the common requests we receive from our clients include:

Adapting the report to the country/region where you intend to establish your plant.

Adjusting the manufacturing capacity of the plant according to your needs.

Customizing machinery suppliers and costs to meet your requirements.

Providing additional information to the existing scope based on your needs.

Contact Us

Company Name: Procurement Resource Contact Person: Leo Frank Email: [email protected] Toll-Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537 132103 | Asia-Pacific (APAC) - Phone no: +91 1203185500 Address: 30 North Gould Street, Sheridan, WY 82801, USA

0 notes