#Polyethyleneimine

Explore tagged Tumblr posts

Text

Polyethyleneimine: An Important Building Block in Various Applications In Industry

What is Polyethyleneimine?

Polyethyleneimine (PEI) is a polymeric compound composed of repeating units of ethyleneimine monomers. It is a white solid polymer that is soluble in water. PEI is classified as a branched or linear cationic polymer that is formulated through the polymerization of aziridine. The polymer's molecular weight can range from 300 to over 10,000 Daltons depending on its intended use. Properties and Structure of PEI

PEI is a polymer that contains secondary nitrogen atoms along its backbone that provide cationic charge centers. These nitrogen atoms can interact and form electrostatic bonds with negatively charged macromolecules or surfaces. The cationic nature of PEI allows it to act as a polycation and complex or condense with negatively charged substances like DNA or RNA. PEI is also very hygroscopic due to its numerous amine groups that attract water molecules. Its branched structure provides greater buffering capacity and DNA condensation ability compared to the linear form of PEI. Uses in Gene Delivery

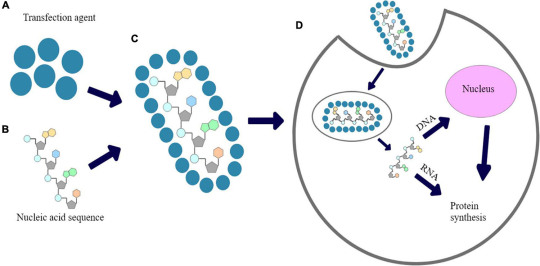

One of the most important uses of Polyethyleneimine is in non-viral gene delivery applications. Its cationic charge allows it to efficiently bind and compact negatively charged nucleic acids like plasmids, forming nano-sized polyplexes that can transfect cells. The polyplexes are effectively endocytosed by cells and the low pH of endosomes triggers PEI to buffer the compartment, releasing the DNA from the complex. This "proton sponge" mechanism of PEI facilitates effective intracellular delivery and expression of the gene of interest. It is commonly used as a transfection agent for in vitro studies as well as in vivo gene therapies and vaccines. Role in Biomaterials and Tissue Engineering

Given its favorable properties, PEI also finds extensive use as biomaterials for tissue engineering applications. Its cationic nature permits binding of PEI to negatively charged components of the extracellular matrix like glycosaminoglycans. This helps direct cell adhesion, growth, and function. PEI can act as a coating onto implants and scaffolds, promoting their integration with surrounding tissues. It allows bioconjugation of signaling cues to influence cell behavior in regenerative therapies as well. The tunable properties of PEI through controlling its molecular weight or branching also expand its utility in the design of biomaterials.

In addition to the major uses mentioned above, PEI has applications in many other fields due to its versatile characteristics. It acts as a flocculating agent in wastewater treatment processes to remove pollutants and purify water. PEI finds increasing importance as a hardener in epoxy resins used in manufacturing infrastructure and electronics. Its buffering ability makes it valuable as a non-corrosive alternative to replace hazardous chemicals in industrial cleaning agents as well. Overall, the unique polymeric structure and properties of PEI designate it as an essential building block material with myriad applications.

Get more insights on Polyethyleneimine

Unlock More Insights—Explore the Report in the Language You Prefer

French

German

Italian

Russian

Japanese

Chinese

Korean

Portuguese

Alice Mutum is a seasoned senior content editor at Coherent Market Insights, leveraging extensive expertise gained from her previous role as a content writer. With seven years in content development, Alice masterfully employs SEO best practices and cutting-edge digital marketing strategies to craft high-ranking, impactful content. As an editor, she meticulously ensures flawless grammar and punctuation, precise data accuracy, and perfect alignment with audience needs in every research report. Alice's dedication to excellence and her strategic approach to content make her an invaluable asset in the world of market insights.

(LinkedIn: www.linkedin.com/in/alice-mutum-3b247b137 )

#Polyethyleneimine#Aliphatic Carbon#Versatile Polymer#PEI#Linear Polymer#Cyclic Amine#Cationic Polymer#Biopolymer#Flocculant#Emulsifier#Nanoparticle Synthesis

0 notes

Text

0 notes

Text

https://www.verifiedmarketreports.com/pt/product/polyethyleneimine-ethoxylate-market/

0 notes

Text

0 notes

Text

Non-Viral Transfection Reagents - A Safer Alternative For Gene Delivery

One of the earliest and simplest methods of non-viral transfection is through physical disruption of the cell membrane. Physical transfection methods such as electroporation apply an electric pulse to cells, causing the formation of temporary pores in the membrane through which nucleic acids can pass into the cell. Electroporation is a cost-effective technique that is widely used in research and industrial applications. However, it can be relatively toxic to cells and has low transfection efficiency compared to viral and other chemical methods. A related physical approach is particle bombardment or biolistics, which uses a gene "gun" to literally fire DNA-coated microscopic gold or tungsten particles into cells. While effective in some cell types, biolistics can damage cells and has limitations in scale-up for therapeutic use.

Cationic Lipid And Polymer-Based Transfection Agents

More advanced non-viral vectors take advantage of the natural ability of cationic lipids and polymers to condense and complex with negatively charged nucleic acids like DNA and RNA. When cationic molecules bind to nucleic acids, they form nano-sized particles called lipoplexes or polyplexes that are able to fuse with and enter cells. Some of the most popular cationic lipids used in research and therapies include DOTMA, DDAB, and DOTAP. Common cationic polymers used include polyethyleneimine (PEI) and poly-L-lysine. These cationic complexes protect nucleic acids from degradation while facilitating cellular uptake primarily through endocytosis. Cationic lipid- and polymer-based agents provide reasonable transfection efficiencies and scalability while displaying lower cytotoxicity compared to viral vectors. Continuous improvements aim to enhance transfection rates and reduce toxicity further.

Dendrimers And Other Nanoparticle Carriers

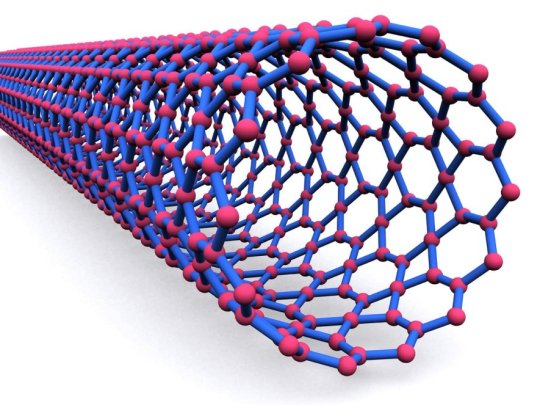

More engineered nanoparticles are also being explored as Non-Viral Transfection Reagents. Dendrimers are synthetic, nanoscale macromolecules with a highly branched treelike structure and numerous chemical functionalities on their surface. Their architecture makes them ideal for uniformly encapsulating drugs or genes. Positively charged dendrimers readily complex with nucleic acids through electrostatic interactions. Early generations showed some cytotoxic effects, but newer designs demonstrate efficient gene transfer capabilities comparable to viral vectors with significantly reduced toxicity. Gold nanoparticles, silica nanoparticles, carbon nanotubes and other inorganic nanomaterials are also being investigated as platforms for nucleic acid delivery. Surface functionalization allows conjugation of targeting ligands to facilitate cellular internalization. These novel carrier systems offer intriguing prospects as safer, targeted gene therapy vectors.

Cell-Penetrating Peptides (CPPs)

Cell-penetrating peptides represent another class of non-viral transfection agent. These are short, cationic peptide sequences often derived from naturally occurring proteins that are taken up efficiently by many cell types. A widely used CPP is TAT (trans-activating transcriptional activator) peptide from HIV-1. Others include penetratin and transportan. In combination with nucleic acids, CPPs are believed to traverse the plasma membrane and endosomal barriers, enabling direct cytoplasmic and nuclear delivery. CPP conjugation can significantly boost transfection compared to transfection reagents alone, while avoiding safety issues linked to viral or non-biodegradable carriers. CPPs face technical hurdles like aggregation and off-target effects that require addressing, but they offer a promising biocompatible approach. Further advances may yield CPP vectors effective enough for clinical gene therapy.

Combination Strategies And In Vivo Applications

Given the benefits and limitations of individual classes of Non-Viral Transfection Reagents, combination approaches hold promise to maximize desirable properties. For instance, cationic lipids or polymers can condense genes into nanoparticles for protection and increased cellular association, while CPPs or targeting ligands incorporated at the surface facilitate internalization and destination. Sequential layer-by-layer assembly enables tailoring of vector components for optimized transfection profiles in different cell types and disease contexts. Non-viral vectors also continue enhancing for in vivo gene delivery applications. These include functionalization with PEG to evade immune detection and cell-specific targeting with antibodies or other moieties.Successful non-viral gene therapy demonstrations in animal models have been reported for conditions like cancer, pulmonary disease, cardiovascular defects and CNS disorders. Well-designed combination systems may one day achieve viral-level gene transfer efficiencies needed for widespread clinical gene therapy with improved safety.

Get more insights on this topic: https://www.trendingwebwire.com/non-viral-transfection-reagents-alternative-methods-for-efficiently-introducing-nucleic-acids-into-cells/

Author Bio

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups. (LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91)

*Note: 1. Source: Coherent Market Insights, Public sources, Desk research 2. We have leveraged AI tools to mine information and compile it

0 notes

Text

https://www.maximizemarketresearch.com/market-report/global-polyethyleneimine-market/116628/

Polyethyleneimine (PEI), also known as poly-aziridine. It is a polymer made up of an amine group and a two-carbon aliphatic CH2CH2 monomer. In addition to branched PEIs, which contain primary, secondary, and tertiary amino groups, linear PEIs contain all secondary amines. At room temperature, linear PEIs are solids, whereas branched PEIs are liquids at all molecular weights.

0 notes

Text

0 notes

Text

Nanomaterials, Vol. 13, Pages 3167: Exploring the Potential of #siRNA Delivery in Acute Myeloid Leukemia for Therapeutic Silencing

We investigated the feasibility of using #siRNA therapy for acute myeloid leukemia (AML) by developing macromolecular carriers that facilitated intracellular delivery of #siRNA. The carriers were derived from low-molecular-weight (<2 kDa) polyethyleneimine (PEI) and modified with a range of aliphatic lipids. We identified linoleic acid and lauric acid-modified PEI as optimal carriers for #siRNA delivery to AML cell lines KG1 and KG1a, as well as AML patient-derived mononuclear cells. As they have been proven to be potent targets in the treatment of AML, we examined the silencing of BCL2L12 and survivin and showed how it leads to the decrease in proliferation of KG1 and stem-cell-like KG1a cells. By optimizing the transfection schedule, we were able to enhance the effect of the #siRNAs on proliferation over a period of 10 days. We additionally showed that with proper modifications of PEI, other genes, including MAP2K3, CDC20, and SOD-1, could be targeted to decrease the proliferation of AML cells. Our studies demonstrated the versatility of #siRNA delivery with modified PEI to elicit an effect in leukemic cells that are difficult to transfect, offering an alternative to conventional drugs for more precise and targeted treatment options. https://www.mdpi.com/2079-4991/13/24/3167?utm_source=dlvr.it&utm_medium=tumblr

0 notes

Link

"Customers may gain deep information about the market's competitive environment and current trends b

0 notes

Text

Construction of CpG Delivery Nanoplatforms by Functionalized MoS2 Nanosheets for Boosting Antitumor Immunity in Head and Neck Squamous Cell Carcinoma

Despite the promising achievements of immune checkpoint blockade (ICB) therapy for tumor treatment, its therapeutic effect against solid tumors is limited due to the suppressed tumor immune microenvironment (TIME). Herein, a series of polyethyleneimine (Mw = 0.8k, PEI(0.8k) )-covered MoS(2) nanosheets with different sizes and charge densities are synthesized, and the CpG, a toll-like receptor-9 agonist, is enveloped to construct nanoplatforms for the treatment of head and neck squamous cell... http://dlvr.it/Sr1Fvm

0 notes

Text

[ad_1] An influenza vaccine administered during the nostril and built with nanoparticles that make stronger immune reaction gives sturdy coverage towards other influenza virus traces, in step with researchers within the Institute for Biomedical Sciences at Georgia State College. The intranasal vaccine contributed to multifaceted immune responses, resulting in powerful pass coverage towards influenza in mice. The vaccine is composed of PEI-HA/CpG nanoparticles. PEI (polyethyleneimine), a strong and flexible supply device, can concurrently elevate antigens (hemagglutinin, HA) that induce an immune reaction within the frame, and adjuvants (CpG) that make stronger the frame's immune reaction to an antigen for optimum immunoenhancement. Those complete immune responses and pass coverage had been lengthy lasting, showing protection from influenza virus over six months after immunization. The findings are printed within the magazine ACS Implemented Fabrics & Interfaces. Intranasal vaccination is a perfect means for infectious breathing illnesses comparable to influenza. Seasonal influenza vaccines most often induce slender immune responses that impulsively decline, which leaves populations prone to novel influenza traces. Developments in influenza vaccine generation are wanted to offer protection to towards a variety of influenza viruses. Intranasal vaccination can reinforce native mucosal immune responses via combating influenza an infection on the portal of virus access. Within the influenza virus, HA is a protein that performs a an important position within the early levels of virus an infection. Influenza HA has a head area and stalk area. Present influenza vaccines elicit immune responses towards the HA head, however this head area is extremely changeable and accounts for diminished potency towards other traces. The HA stalk area is extra conservative throughout other traces of influenza viruses. Protein antigens which might be administered intranasally are in most cases much less ready to impress an immune reaction, so adjuvants are had to have extremely environment friendly intranasal vaccines. Adjuvants, comparable to CpG, can make stronger and manipulate immune responses, thus bettering the efficiency and breadth of coverage. "The PEI-HA/CpG nanoparticles display excellent attainable as a cross-protective influenza vaccine candidate," stated Dr. Baozhong Wang, corresponding writer of the learn about and a professor within the Institute for Biomedical Sciences at Georgia State. "The mix of PEI and CpG within the PEI-HA/CpG nanoparticle workforce contributed to the multifaceted immune responses, resulting in full of life pass coverage. The incorporation of CpG and antigens into the similar nanoparticle enhanced mobile immune responses. "Our effects printed that the nanoparticles considerably enhanced HA immunogenicity, or the facility to impress an immune reaction, offering pass coverage towards other influenza virus traces. The conserved HA stalk area caused really extensive antibodies within the nanoparticle immunization teams." "Nanoparticle platforms have proven intriguing traits and nice potentials within the building of next-generation cross-protective influenza vaccines," stated Dr. Chunhong Dong, the primary writer of the learn about and a postdoctoral fellow within the Institute for Biomedical Sciences. "On the other hand, demanding situations exist to the a hit analysis and building of nanoparticle vaccines. Even though no obvious opposed results had been noticed within the learn about, a extra complete protection analysis of the nanoparticle adjuvant device is wanted ahead of medical trials." Co-authors of the learn about come with Baozhong Wang, Chunhong Dong (first writer), Ye Wang, Wandi Zhu, Yao Ma, Joo Kim, Lai Wei and Gilbert X. Gonzalez. The learn about was once funded via the Nationwide Institute of Allergic reaction and Infectious Sicknesses (NIAID) of the Nationwide Institutes of Well being. Tale Supply:

Materials supplied via Georgia State University. Word: Content material is also edited for taste and period. [ad_2] #Intranasal #flu #vaccine #nanoparticles #gives #powerful #coverage #ScienceDaily

0 notes

Text

https://www.statsandresearch.com/report/35713-covid-version-global-polyethyleneimine-market/

0 notes

Text

AKD - Inevitable paper sizing

Alkyl ketene dimers (AKDs) are a family of organic compounds based on the 4-membered ring system of oxetan-2-one, which is also the central structural element of propiolactone and diketene. Attached to the oxetane ring of technically relevant alkyl ketene dimers there is a C12 – C16 alkyl group in the 3-position and a C13 – C17 alkylidene group in the 4-position.

The main application of alkylated ketene dimer is in the sizing of paper and cardboard, as well as in the hydrophobization of cellulose fibers. The products thus modified are distinguished by higher mechanical strengths and less penetration of water, inks, or printing inks.[1]

AKD’s feature hydrophobic alkyl groups extending from a beta-propiolactone ring. A specific example is derived from the dimerization of the ketene of stearic acid. This ketene is generated by pyrolysis of stearoyl chloride.[2] AKD’s react with the hydroxyl groups on the cellulose via an esterification reaction. The esterification is competitive with hydrolysis of the AKD. Prior to the development of AKD’s, hydrophobicity was imparted by incorporating rosin into the paper.

Related to AKDs, is alkenyl succinic anhydride which is another substitute used in sizing applications (ASA). As for AKDs, ASA reacts with hydroxy groups of the cellulose to form an ester, anchoring the hydrophobic group to the surface. ASA is prepared by thendne reaction of unsaturated hydrocarbons with maleic anhydride.

A continuous process in which long-chain carboxylic acid chloride and tertiary amine (e. g. dimethyl isopropylamine, dimethylcyclohexylamine or triethylamine) is supplied separately without solvents to a tube reactor, kneader or preferably a twin-screw extruder or planetary roller extruder and reacted at temperatures between 90 and 110 °C, delivers lactone contents of over 90% at short reaction times. Processing is carried out by phase separation or acidic extraction.[19]

Alkylated ketene dimers as paper sizing agents

The problems with the acidic (aluminum sulfate-mediated) mass sizing of paper with alkaline-digested colophony resins introduced since the early 19th century led beside the use of alkaline flocculants (such as chalk or calcium carbonate as the alkali reserve) to the search for alternative materials for sizing in a neutral or alkaline environment. In addition to the significantly more reactive alkenyl succinic anhydrides (which do also hydrolyze rapidly in the presence of water) alkylated ketene dimers were preferred surface and mass sizes in the paper industry from the 1960s onwards.

Industrially applied AKDs are derived from fatty acids with chain lengths between C14 (myristic acid) to C22 (behenic acid); palmityl (C16) diketene and stearyl (C18) ketene and mixtures thereof are preferably used, as well as fatty acid mixtures from the hydrolysis of animal and vegetable fats. Because of the chain length of the original fatty acids, AKD are waxy solids with melting points between 42oC and about 70 °C. Mixtures of alkylated ketene dimers and water are dispersions at temperatures below 40 °C or emulsions at temperatures above 45 °C. Liquid AKDs are widely used, they are based on unsaturated fatty acids like oleic acid or branched fatty acids, like iso-stearic acid.

Aqueous alkyl diketene dispersions generally contain 10-20 wt% of AKD, as well as active protective colloids (particularly polycations such as cationic starch, copolymers of N-vinylpyrrolidone and quaternized N-vinylimidazole, acylated polyethyleneimines or cationic high molecular weight polyacrylamides with an average molar mass up to 7 million g/mol) and other stabilizers (usually anionic surfactants, for example, lignin sulfonates or condensation products of naphthalene-sulfonic acid sodium salt and formaldehyde). Such stabilized AKD dispersions are active and stable at room temperature for up to three months and also tolerate the addition of different fillers for paper or cardboard (e.g. kaolin, chalk, talc, titanium dioxide, calcium sulfate, aluminum oxide, etc.) from 5 to 25%. The amounts of alkyl ketene dimers used for the sizing of paper and paper products are preferably in the range from 0.15 to 0.8 wt%, sometimes from 0.05 to 0.2 wt%, based on the dry paper stock.

Paper sizing with alkylated ketene dimers

For paper sizing with AKD, a three-step process was proposed which, despite controversial discussions in the 1990s, seems to describe the processes that are taking place.

Decisive criteria for the quality of the hydrophobicity of papers are

The retention of the AKD particles on the wet paper mass on the paper screen

The spreading of the AKD particles on the surface and the penetration in the paper mass

The chemical reaction of the hydroxyl groups of the cellulose (esterification) with the alkylated ketene dimers to form beta-ketocarboxylic esters.

The molecular structure (i.e., molar mass and cross-linking degree), the molar charge density of cationic groups, the exact dosage of the cationic polymer as a dispersion stabilizer and retention aid as well as keeping the other process parameters such as temperature, pH and residence times is crucial.

After removal of excess water – also to avoid hydrolysis of the AKD to the beta-keto acid and subsequent decarboxylation to the ketone – follows the cracking of the stabilized AKD particles on the base paper mass, the melting of the solid AKD wax (at approx. 90 °C), the spreading of the liquid AKD wax by surface diffusion on the cellulose fibers, and the formation of closed hydrophobic layers. The thickness of the hydrophobic layers depends on the AKD concentration in the dispersion.

Ad 3. The hydrophobization of cellulose fibers with alkylated ketene dimers takes place most effectively in neutral or preferably weakly alkaline media (pH 7.5-9.0). The reaction temperature is generally 90-110 °C, with approximately 40% of the AKD used reacting with the cellulose. After the reaction contact angles of >100° are measured, indicating the hydrophobic character of the AKD-modified model surfaces. The esterification of hydroxyl groups of cellulose fibers was also demonstrated by comparison reactions with 14C-labeled AKD.

The sizing with AKD is suitable for the permanent hydrophobization of newsprint, printing and writing paper and cardboard used as a container for liquids (including foodstuffs such as milk), as well as for the improvement of shape stability and runnability.

Commercial Production

At Advance Chemicals, undergoing robust testing frequently, the production of AKD is strictly under defined and controlled conditions thus giving out world call AKD for application in various grades of paper making.

0 notes

Link

0 notes

Text

0 notes