#Moisture System Installation

Explore tagged Tumblr posts

Text

Moisture Control System Installation | Cotton ginning moisture system in Africa

#Moisture System#Cotton ginning moisture system in Africa#Moisture Control System in Africa#Moisture Monitoring System in Africa#Moisture System Installation#https://mistcoolingsystemsafrica.com/portfolio/moisture-system

0 notes

Text

Moisture Control System Installation | Cotton ginning moisture system in Gulf

#Moisture System#Cotton ginning moisture system in Gulf#Moisture Control System in Gulf#Moisture Monitoring System in Gulf#Moisture System Installation#https://mistcoolingsystemsgulf.com/portfolio/moisture-system

0 notes

Text

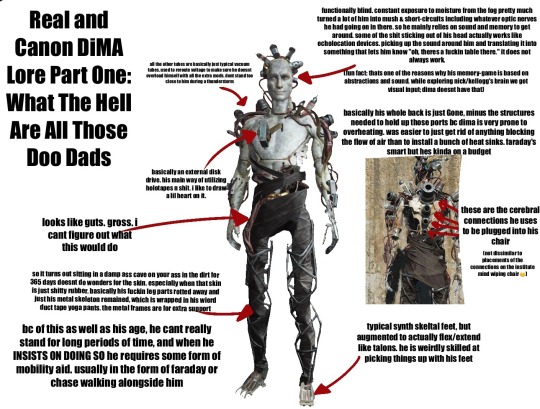

i cannot believe ive never posted this. probably because it looks like shit. anyways heres my pepe silva ass scrawlings about what i think this guy's mods are for.

translation of the nigh unreadable text under the cut

REAL AND CANON DIMA LORE PART ONE: What The Hell Are All Those Doo Dads

(i'll start from the head and go down)

HEAD

functionally blind. constant exposure to moisture from the fog pretty much turned a lot of him into mush and short circuits, including whatever optic nerves he had going on in there. so he mainly relies on sound and memory to get around. some of the shit sticking out of his head actually works like echolocation devices. pickinh up the sound around him and translating it into something that lets him know "oh, theres a fuckin table there. it does not always work. (fun fact: thats the reason why his memory game is based on abstractions and sound. while exploring nick/kellogg's brain we got visual input. dima doesnt have that)

all of the other tubes are basically just typical vacuum tubes. used to reroute voltage to make sure he doesnt overload himself with all the extra mods. make sure you dont stand too close to him during a thunderstorm

TORSO

basically an external disk drive. his main way of utilizing holotapes and shit. i like to draw a lil heart on it

looks like guts. gross. i cant figure out what this would do (i now believe its a liquid cooling system)

LEGS

so it turns out sitting in a damp ass cave on your ass in the dirt for 365 days doesnt do wonders for the skin. especially when that skin is just shitty rubber. basically his fuckin leg parts rotted away and just his metal skeleton remained, which is wrapped in his weird duct tape yoga pants. the metal frames are for extra support. because of this as well as his age he cant really stand for long periods of time (ignore the part where he stands in acadia forever after you get deeper into his questline) and when he INSISTS ON DOING SO he requires some form of mobility aid. usually in the form of faraday or chase walking alongside him

typical synth skeletal feet, but augmented to actually flex/extend like talons. he is weirdly skilled at picking things up with his feet.

BACK

basically his whole back is just Gone, minus the structures needed to hold up those ports because dima is very prone to overheating. was easier to just get rid of anything blocking the flow of air than to install a bunch of heat sinks. faraday's smart but hes on a budget.

these are the cerebral (spinal?) connections he uses to be plugged into his chair (not dissimilar to the placements of the connections in the institute mind wiping chair ☹️)

212 notes

·

View notes

Text

Weep Holes: An Essential Component For Structural Integrity

The world of construction methodologies is vast, dynamic, and continuously evolving. Among the myriad of procedures and mechanisms crucial to the development of robust structures, a particularly crucial yet often overlooked feature is the ‘weep hole.’ In this blog, we delve deeper into what weep holes are, focus mainly on their application in cinder block structures, reasons for their installation near the footing, and the benefits that they provide related to relieving water trapped within a structure.

To begin with, let’s establish what Weep Holes are. Weep holes, as the name suggests give an image of something that exudes, seeps out, or, indeed, weeps. In construction parlance, they are purposely drilled in a structure to allow the movement of water or to let it escape from within.

Though these holes can be integrated into several types of structural system, their use is widely popular in cinder block constructions. Cinder blocks, also known as concrete masonry units, are commonly used in residential as well as commercial construction due to their affordability, strength, and insulation properties. Their design usually involves hollow cores, or cavities, that can unintentionally trap water within. Whether it’s from groundwater, landscape irrigation, or rainfall, the cinder block can host this water, giving birth to many potential issues such as mold, mildew, efflorescence, or even structural failure if water freezes and expands.

Therefore, to alleviate these concerns, weep holes are drilled into the cinder blocks, typically in the bottom row and near the footing. Placed lower down because water tends to flow to the lowest point due to gravity, these openings play a vital role in the overall health and longevity of the structure.

When water is present in the hollow cavities of the cinder block, the weep holes facilitate an escape route. But it isn’t just about aiding drainage; these holes also play an essential part in the structure’s ventilation, helping trapped moisture to dry up more quickly.

One might wonder–why near the footing? The footing of a building is the lowest part of the structure, usually installed below ground level. For blocks near the footing, water accumulation is most likely due to their proximity to the ground. To prevent rising dampness creeping up into the structure and ensure optimal effectiveness, weep holes are strategically drilled near the footing.

One concern that often arises about weep holes is the threat of small creatures or pests entering through them. To prevent this, weep holes are generally covered with plastic, steel, or another type of mesh to allow water escape but deter critters.

Let’s sum up the importance of weep holes: They are not a construction afterthought but an essential design feature engineered to prolong and conserve the structural integrity of cinder block structures, whether they be a garden wall, chicken coop, house, or commercial building. By simultaneously promoting ventilation and facilitating the drainage of trapped water within the cinder blocks’ hollow cavities, weep holes help to prevent the onset of undesirable moisture issues, water damage, and structural instability.

So the next time you come across some random, small holes in a structure, remember, they aren’t gaps in design or construction; they’re mitigating water damage one drop at a time. This is the importance of an often overlooked, yet vital construction element – the weep hole.

Tagged Essential Component For Structural Integrity, Structural Integrity

#Essential Component For Structural Integrity#Structural Integrity#foundation repair#foundation solutions#foundation contractor#foundation experts#foundation repair solutions#foundation services#residential foundation repair services#foundation repair near me#foundation solution#signs of foundation problems

7 notes

·

View notes

Text

"Confederate monuments bear what the anthropological theorist Michael Taussig would call a public secret: something that is privately known but collectively denied. It does no good to simply reveal the secret — in this case, to tell people that most of the Confederate monuments were erected not at the end of the Civil War, to honor those who fought, but at the height of Jim Crow, to entrench a system of racial hierarchy. That’s already part of their appeal. Dr. Taussig has argued that public secrets don’t lose their power unless they are transformed in a manner that does justice to the scale of the secret. He compares the process to desecration. How can you expect people to stop believing in their gods without providing some other way of making sense of this world and our future?

Swords Into Plowshares might have been the first to propose melting, but other communities are working out their own creative visions for Lee’s afterlife. One of the biggest changes so far has been at Arlington House, the historic plantation mansion at the center of Arlington National Cemetery, which is the official national Robert E. Lee Memorial. In 2021, Arlington House reopened with displays not only about Lee’s family, who lived there after they inherited it from Lee’s father-in-law, but also about the lives of the families enslaved there. Even Lee’s burial site at Washington and Lee University in Lexington, Va. — where he served as president after the war — has changed. The university decided to focus on Lee the civilian rather than Lee the general, for example by moving a prominent portrait of him in uniform. And it constructed a wall to enclose the large sculpture of Lee that once claimed an insistent place in the university’s chapel.

Covering this story over the past few years, I’ve come to realize two things. First, when a monument disappears without a ceremony to mark why it is coming down, a community has no chance to recognize that it has itself changed. (Ideally the ceremony is public, but because of safety concerns, the melting I attended was not.) Second, if you are outraged that something’s happening to your community’s heroic statue of Lee, you’re not going to be any less outraged if the statue is moved to some hidden storeroom than if it’s thrown into a landfill. So if all changes, large or small, will be resisted, why not go for the ones with the most symbolic resonance?

That’s why the idea to melt Lee down, as violent as it might initially seem, struck me as so apt. Confederate monuments went up with rich, emotional ceremonies that created historical memory and solidified group identity. The way we remove them should be just as emotional, striking and memorable. Instead of quietly tucking statues away, we can use monuments one final time to bind ourselves together into new communities.

...

When the remaining legal barriers were cleared (including a last-minute lawsuit that sought to have the statue reassembled), Lee was finally ready to surrender to the furnace. The foundryman turned on the propane supply and laid Lee’s sword across the hole in the lid. He told the spectators that the metal had to get hot enough to release any moisture before he maneuvered it down through the hole into the crucible.

When he did, its blade stuck up out of the furnace for a moment, then melted down “like a stick of butter,” as Dr. Schmidt put it.

Lee’s face was the last piece to go into the crucible. Given how often the monument and its ideals were celebrated with flames — from Klansmen’s torches to the tiki torches of white nationalists in 2017 — it seemed fitting for flames to close over the monument.

...

Dr. Douglas, Swords Into Plowshares’ other co-founder, apologized that the ceremony could not be public. She thanked those in attendance, telling us we were witnessing it on behalf of Charlottesville’s residents, including those long gone who lived under slavery. Someday, she said, when we think of Civil War heroes, we will imagine not Lee but, instead, those who fought for their freedom against him.

The man in the protective visor dropped the red-hot piece of metal that once represented Lee on the ground. It fell to pieces, which he fed into the crucible. A line of cameras faced him, making new images of history as the old image finally disappeared in flames.

- Erin Thompson, "The Most Controversial Statue in America Surrenders to the Furnace." New York Times. October 24, 2023. Photo by Eze Amos.

#swords into plougshares#confederate monuments#robert e. lee#tear them down#historical monuments#american civil war#historical memory#united states history#united states politics

18 notes

·

View notes

Note

Congratulations on the follower milestone, so well-deserved! 🎉

May I humbly suggest Codywan + love language as a prompt? 🧡

Grow Old (Codywan, 738w)

Rating: G

Tags: Established Relationship, Tatooine Husbands, Past Trauma, Recovery

Summary: A small Tatooine Husbands vignette.

Author’s Note: This is the third ficlet for my follower celebration on Tumblr, in response to the wonderful Codywan prompts provided by @goldleaf-art and @oathkeeperoxas: “love languages” and “silent devotion,” respectively. Thank you so much to goldleaf and Serie for the incredible inspiration (in the prompts and in your gorgeous stories): for the two of you, I knew I had to do Tatooine husbands, so this is part gift, part tribute. <3<3<3

Ficlet below the cut - or you can read it on AO3

"Cody?”

It was Obi-Wan’s voice, drifting out from the hut and still stretching through the last cracks of his sleep. The call was curious but not concerned - Cody had left his vibroblade next to the bed as a sign that he’d felt safe when he left - so he waited a beat before responding, giving himself time to savor the experience of hearing his own name, the way its syllables sounded through the dry stillness of the desert morning and the filter of Obi-Wan’s weathering accent.

“Out here,” he called back, unbending from his crouch next to the garden beds with a few syncopated pops in his knees and a mostly smothered wince.

Obi-Wan must have sensed Cody's lack of urgency, because when he appeared at the doorway to their hut he had two mugs in hand: one for his own tea and a second for the caff that Cody liked a little on the milky side these days.

“You’re up early,” Obi-Wan observed - the words neutral but the tone probing - and it was true. Cody was usually the later riser.

It was also true, in this case, that he'd barely gone down at all. The two of them had gotten into a - well, Cody supposed most people would call it a fight, though Obi-Wan rarely let Cody engage him directly enough for it to feel like that’s what it was. Not like the fights Cody had gotten into with Rex or Fox or Alpha. And not like the arguments he turned on himself when he thought of his brothers either: a tissue-deep burn in his chest that could simulate fullness, at least for a little while.

He and Obi-Wan were more careful with each other’s anger now, and Cody knew the reasons why. He still started most days by picking his way around the half-obliterated nightmares and scraps of memory the reasons left littered around his mind. But there were times when he missed the blows he and his general had traded on the sparring mat - even the sharp words they’d sometimes yelled across the battlefield.

Or maybe he just missed the old lie: that when he was in a position to shatter the ground beneath their feet, he would know it.

“I fixed the irrigation issue,” he said, taking his caff as Obi-Wan joined him by the edge of their fledgling garden. “Since you were so put out last night about the black melon leaves wilting.”

Obi-Wan made a noise of protest, slightly muffled by the sip he’d just taken from his mug.

“I do not,” he said, sounding decidedly put out, “get put out.”

“My mistake,” Cody replied mildly. “Must have picked the wrong word. You know I have trouble remembering things these days.”

He made a show of tapping his finger to his temple, and Obi-Wan graced him with a theatrical roll of his eyes. But the lines on Obi-Wan’s face were a little looser by the time he turned to stare back down at the beds. He took his time observing the changes, his gaze moving over the new system of moisture spikes and buried clay pots that Cody had installed around the rows of seedlings.

“This is a very sensible arrangement,” he offered at last. Primly, some might say.

“I know it is,” Cody responded, letting the smallest hint of a smile tug at the corner of his lips. He bumped his shoulder against Obi-Wan’s. “It’s just a garden, you know. It doesn’t have to mean anything more than that.”

Obi-Wan grimaced before smoothing out his expression again.

“Am I that obvious?”

It was a question meant to sound tossed off, and Cody recognized the pattern of the delivery from memory: the sly lilts and tonal feints that had made Obi-Wan’s voice such a precision weapon for so long. But it came out sharper than it would have then - more raw, the patches of erosion showing through around the edges.

“You’re not as good at masking it anymore,” Cody replied, taking a long drag from his caff before adding: “I don’t mind that part, actually.”

Obi-Wan bumped his shoulder back against Cody’s and then stayed there, resting his weight on Cody’s arm as they contemplated the prospect before them: the crawl of flat heat across the sand, the spindly tendrils of green at their feet.

“It’s just a garden,” Obi-Wan repeated.

“Not a test,” Cody agreed. “An experiment. We’re just seeing what can grow.”

#codywan#commander cody#obi wan kenobi#tatooine husbands#tumblr celebration#my fics#thank you goldleaf and serie!!!

76 notes

·

View notes

Text

How to Build a Container Home Step by Step in 2025

Container homes have become a groundbreaking trend in sustainable architecture, offering affordability, eco-friendliness, and versatility. In 2025, the process of building a container home has become even more streamlined, thanks to advanced materials and innovative designs. This comprehensive guide outlines every step to create your dream container home while ensuring compliance with modern standards.

Step 1: Planning and Design

Define Your Goals and Budget

Before starting, determine your purpose for the container home. Is it a permanent residence, a vacation property, or an investment rental? Establish a realistic budget, considering land acquisition, permits, materials, labor, and unforeseen costs.

Research Local Building Codes

Container homes must comply with local regulations, including zoning laws and building permits. Research thoroughly or consult a professional to avoid legal issues later.

Select the Right Design

Modern container homes range from minimalist single-container structures to luxurious multi-container designs. Collaborate with an architect experienced in container home construction to optimize space utilization and aesthetics.

Step 2: Choosing and Preparing Containers

Select High-Quality Containers

Opt for ISO-certified shipping containers to ensure structural integrity. Containers come in two standard sizes: 20 feet and 40 feet. Choose new or lightly used containers to avoid dealing with rust and damage.

Inspect and Clean the Containers

Thoroughly inspect the containers for dents, corrosion, or chemical residues. Once inspected, clean them using pressure washers and non-toxic cleaning solutions to eliminate contaminants.

Modify Containers for Your Design

Cut openings for windows, doors, and ventilation according to your design. Reinforce edges with steel beams to maintain structural strength during modifications.

Step 3: Securing the Foundation

Choose the Right Foundation

The type of foundation depends on your site conditions and budget. Common options include:

Concrete slab foundation for flat surfaces.

Pier foundation for uneven or sloped land.

Crawl space foundation for additional storage or ventilation.

Prepare the Site

Level the ground, remove debris, and compact the soil. Install drainage systems to prevent water pooling, which could compromise the foundation over time.

Step 4: Assembling the Structure

Position the Containers

Using cranes or heavy equipment, place the containers on the foundation as per your design. Align them carefully to ensure structural stability.

Weld and Secure Containers

Weld the containers together for a unified structure. Seal any gaps to improve insulation and prevent water leaks.

Install Structural Reinforcements

For multi-story container homes, add steel columns or beams to support the weight of the upper containers. Reinforce the roof if necessary for load-bearing purposes, such as solar panels or rooftop gardens.

Step 5: Insulation and Weatherproofing

Insulate for Comfort

Steel containers are excellent conductors of heat and cold, making insulation crucial. Popular options include:

Spray foam insulation for superior thermal performance.

Rigid foam panels for cost-effective solutions.

Natural materials like wool for eco-friendly insulation.

Weatherproof the Exterior

Apply anti-corrosion coatings to the steel surface. Seal joints with waterproof caulking to protect against moisture. Add cladding or siding for aesthetics and additional protection.

Step 6: Installing Utilities

Electrical Systems

Hire a licensed electrician to install wiring, outlets, and circuit breakers. Plan for energy-efficient systems, such as LED lighting and solar panels, to reduce your carbon footprint.

Plumbing Systems

Install water supply lines, drainage systems, and sewage connections. Consider using a tankless water heater or rainwater harvesting system for efficiency.

HVAC Systems

Choose compact and efficient heating, ventilation, and air conditioning systems to maintain comfort throughout the year.

Step 7: Interior Finishing

Walls, Floors, and Ceilings

Walls: Cover the interior with drywall, plywood, or reclaimed wood for a polished look.

Floors: Install durable flooring materials such as vinyl, laminate, or bamboo.

Ceilings: Use suspended ceilings to conceal wiring and ductwork while adding insulation.

Furniture and Fixtures

Optimize space with built-in furniture and multi-functional designs. Use modular kitchen units and compact bathroom fixtures for maximum efficiency.

Step 8: Exterior Enhancements

Landscaping

Enhance your container home’s surroundings with landscaping features such as pathways, gardens, and outdoor seating areas.

Decks and Patios

Extend your living space with a deck or patio. Use reclaimed wood or composite materials for sustainability.

Solar and Energy Systems

Install solar panels, wind turbines, or battery storage systems to power your home sustainably.

Step 9: Final Inspections and Permits

Conduct Professional Inspections

Before moving in, have professionals inspect the structure, electrical systems, plumbing, and overall safety. Address any deficiencies to ensure compliance with building codes.

Obtain Occupancy Permits

Submit all necessary documentation to local authorities and secure an occupancy permit to finalize the project.

Step 10: Maintenance and Upgrades

Regular Maintenance

Inspect your container home periodically for rust, leaks, or structural issues. Repaint and reseal the exterior as needed to maintain its durability.

Future Upgrades

Consider adding features like rainwater harvesting systems, additional solar panels, or a green roof to enhance sustainability.

Building a container home is an exciting and rewarding endeavor that combines functionality, sustainability, and modern design. By following these detailed steps, you can create a comfortable and eco-friendly living space tailored to your needs.

Tags:

2 notes

·

View notes

Text

SS 304 Blind Flange | Best Deals at Lowest Price

SS 304 Blind Flanges are an essential component for sealing off pipelines and preventing the flow of liquids or gases in various industrial systems. Known for their exceptional corrosion resistance, strength, and durability, SS 304 Blind Flanges are widely used in industries like oil and gas, chemical processing, water treatment, and more. Finding the best deals at the lowest price for SS 304 Blind Flanges is key to optimizing your operational costs while maintaining the quality and performance you need.

In this article, we'll explore the benefits of SS 304 Blind Flanges, their industrial applications, and how you can find the best deals online.

Why Choose SS 304 Blind Flange?

SS 304, a grade of stainless steel, is one of the most popular and versatile alloys used in various industrial components, including flanges. It contains 18% chromium and 8% nickel, which makes it highly resistant to corrosion, even in harsh environments where moisture, chemicals, and high temperatures are present. Here’s why SS 304 Blind Flanges stand out as a top choice for industrial use:

1. Exceptional Corrosion Resistance: One of the main reasons why SS 304 Blind Flanges are favored across multiple industries is their corrosion resistance. The chromium content in the stainless steel creates a passive oxide layer on the surface of the flange, preventing it from rusting. This makes it ideal for use in environments exposed to moisture, chemicals, or high humidity.

2. High Durability and Strength: SS 304 Blind Flanges are known for their strength and ability to withstand high pressures and temperatures. Whether you're dealing with high-pressure pipelines or industrial systems that operate in extreme temperatures, SS 304 Blind Flanges provide the durability needed to keep your systems running smoothly.

3. Low Maintenance: Because of their corrosion resistance and strength, SS 304 Blind Flanges require minimal maintenance, which reduces the need for frequent replacements or repairs. This makes them a cost-effective solution for industrial applications where reliability and long-term performance are essential.

4. Easy Installation: SS 304 Blind Flanges are designed for easy installation, making them a convenient option for industrial systems that need to be sealed off temporarily or permanently. They can be quickly bolted into place, ensuring a tight seal that prevents leakage or contamination.

5. Versatile Use Across Industries: SS 304 Blind Flanges are used in a wide range of industries, from oil and gas to food processing and water treatment. Their versatility makes them a reliable choice for various applications, ensuring that they meet the needs of different industrial environments.

Applications of SS 304 Blind Flanges

SS 304 Blind Flanges are used in several industries for their ability to seal off piping systems. Common applications include:

Oil and Gas Pipelines: SS 304 Blind Flanges are used to close off pipeline sections during repairs, testing, or maintenance. Their corrosion resistance makes them suitable for handling hydrocarbons and other chemicals typically found in the oil and gas industry.

Chemical Processing Plants: In chemical plants, where pipelines carry corrosive fluids, SS 304 Blind Flanges are a reliable option for sealing pipes during system shutoffs or maintenance periods. They prevent leaks and ensure the integrity of the system.

Water Treatment Facilities: In water treatment plants, SS 304 Blind Flanges are used to block off sections of water pipelines, ensuring that the water remains uncontaminated and the system remains functional during maintenance.

Marine Industry: The saltwater environment can be particularly corrosive, but SS 304 Blind Flanges are resistant to seawater corrosion. This makes them ideal for use in shipbuilding, offshore platforms, and other marine-related industries.

Food and Beverage Industry: The non-reactive properties of SS 304 make it a preferred material in industries that require high hygiene standards, such as food processing and beverage production. SS 304 Blind Flanges ensure a safe, clean, and durable seal in these environments.

Tips for Finding the Best Deals on SS 304 Blind Flanges

Finding SS 304 Blind Flanges at the lowest price doesn't mean compromising on quality. With a bit of research and strategy, you can secure the best deals on high-quality flanges. Here are a few tips to help you get the most value for your money:

1. Compare Prices from Multiple Suppliers: To find the best deals, it's important to compare prices from several suppliers. With the availability of online platforms, you can easily compare pricing, shipping options, and customer reviews. Be sure to check if the supplier offers any promotions or discounts that could further lower the price.

2. Look for Bulk Purchase Discounts: If your project requires a large number of SS 304 Blind Flanges, buying in bulk can significantly reduce the cost per unit. Many suppliers offer discounts on bulk purchases, which can help you save money in the long run, especially for large-scale projects.

3. Check for Seasonal Promotions: Some suppliers offer seasonal discounts, promotional offers, or clearance sales. These can be a great opportunity to buy SS 304 Blind Flanges at reduced prices. Keep an eye on major online marketplaces and industrial suppliers for these kinds of offers.

4. Verify Product Quality and Certifications: While getting a good deal is important, ensuring product quality is equally crucial. Make sure the SS 304 Blind Flanges you’re purchasing meet international standards such as ASTM, ASME, or DIN certifications. This ensures that the product has been manufactured to meet rigorous quality control and safety standards.

5. Negotiate with Suppliers: Don't hesitate to negotiate with suppliers, especially if you’re placing a large order or planning a long-term partnership. Many suppliers are willing to offer discounts or better pricing for repeat business, so it’s worth asking for a better deal.

Advantages of Buying SS 304 Blind Flanges Online

Purchasing SS 304 Blind Flanges online offers several benefits:

Convenience: Online platforms make it easy to browse, compare, and purchase products from the comfort of your office or home. You can explore a wide range of suppliers, products, and prices in just a few clicks.

Wide Selection: Online suppliers often offer a greater variety of SS 304 Blind Flanges in different sizes and specifications, ensuring that you find the exact product to meet your requirements.

Fast Shipping: Many online suppliers provide fast delivery options, ensuring that you receive your SS 304 Blind Flanges when you need them, helping to keep your project on schedule.

Customer Reviews: Reading reviews from other customers can give you insight into the quality of the product and the reliability of the supplier, helping you make an informed decision before making a purchase.

#SS304BlindFlange#BestDealsFlanges#LowestPriceFlange#StainlessSteelFlange#IndustrialFlanges#BuyNow#CorrosionResistantFlange#OilAndGasFlange#WaterTreatmentFlange#PipelineSolutions#BulkOrderFlanges#ChemicalProcessingFlange

6 notes

·

View notes

Text

my bathroom was not a bathroom originally so the shower has a regular window in it, with a wooden sill on the inside, at chest-and-head height so i am daily showing people across the street my tits, and the bathroom is at an angle because the floor beneath it is sinking so the water from the shower does not run off the windowsill like it's supposed to and instead pools in one corner against the windowframe, and because the bathroom was not at first a bathroom there isn't a fan or ventilation system either so the windowsill puddle after every shower sits and develops an ecosystem over the course of the next day as it sinks into the softly rotting wood, and i noticed this too late to begin wiping it down with a towel after every shower because the water sitting on the wood made the wood Moldy and i didn't want to christen a dedicated Mold Towel when i only had three towels to begin with, but the mold apart from just like being mold also made showering unpleasant because it was like Right There the entire time and i couldn't stop thinking about its proximity and trying to avoid it so after several short-term-solution cullings i finally this last weekend really went to town on the situation, bleach and two toothbrushes and other chemicals and objects i won't list in full here except to say that one of the objects was a second shower curtain liner, which i hung over the entire window and sill and most of the width of that wall of the shower so that the water just mechanically cannot Get to the newly sanitized and dehumidified sill at all, which worked splendidly when i tried it out tonight except i kept the window open to aid the general moisture status of the room and both the plastic liner on my shower curtain and the one over the window billowed inward, trapping me and the water in a gently heaving crevice, like someone's art installation of the vaginal canal through which visitors can walk to reexperience the moment of birth

5 notes

·

View notes

Text

Key Design Considerations for Pantograph Support Insulators in High-Speed Rail Systems

In the realm of high-speed rail systems, every component plays a crucial role in ensuring safe and efficient operations. Among these components, pantograph support insulators stand out as critical elements that facilitate the seamless transmission of power from overhead lines to the train's electrical system. As a leading pantograph insulator manufacturer in India, Radiant Enterprises recognizes the importance of meticulous design considerations in crafting reliable and durable insulators. In this blog post, we'll explore the key design considerations essential for pantograph support insulators in 25 KV high-speed rail systems, shedding light on Radiant Enterprises' commitment to excellence in manufacturing.

Understanding Pantograph Support Insulators

Pantograph support insulators are integral components of the overhead electrification system in high-speed rail networks. These insulators provide electrical isolation and mechanical support for the pantograph, which is the apparatus mounted on the train's roof responsible for collecting electricity from the overhead wires (catenary). In 25 KV high-speed rail systems, where trains operate at exceptionally high speeds, the performance and reliability of pantograph support insulators are paramount.

Design Considerations for Pantograph Support Insulators

Material Selection: The choice of materials significantly influences the performance and longevity of pantograph support insulators. At Radiant Enterprises, we utilize high-quality, durable materials such as silicone rubber or composite polymers that exhibit excellent electrical insulation properties, mechanical strength, and resistance to environmental factors such as UV radiation, pollution, and temperature variations.

2. Electrical Insulation: Ensuring reliable electrical insulation is paramount to prevent electrical arcing and ensure the safe transmission of power. Our pantograph support insulators are engineered to withstand high voltage levels (25 KV) and exhibit low electrical conductivity to minimize power losses and mitigate the risk of electrical faults.

3. Mechanical Strength: Pantograph support insulators are subjected to mechanical stresses induced by the pantograph's movement and external forces such as wind loads and vibrations. Therefore, our insulators undergo rigorous mechanical testing to ensure they can withstand these forces without deformation or failure, ensuring uninterrupted operation and minimal maintenance requirements.

4. Corrosion Resistance: In outdoor environments exposed to moisture, pollution, and corrosive agents, corrosion resistance is essential to maintain the structural integrity of pantograph support insulators over their operational lifespan. Our insulators are engineered with corrosion-resistant materials and undergo surface treatments to enhance their resistance to rust and degradation, ensuring long-term reliability and performance.

5. Dimensional Accuracy: Precision engineering is critical to ensure proper fit and alignment of pantograph support insulators with the overhead wires and the train's pantograph. Our insulators are manufactured with tight tolerances and undergo strict quality control measures to guarantee dimensional accuracy and compatibility with the rail infrastructure, minimizing installation challenges and optimizing performance.

6. UV Stability: Exposure to ultraviolet (UV) radiation can degrade insulator materials over time, compromising their electrical and mechanical properties. Therefore, our pantograph support insulators are formulated with UV-stabilized materials that withstand prolonged exposure to sunlight without degradation, ensuring reliable performance and longevity in outdoor applications.

Radiant Enterprises: Your Trusted Pantograph Insulator Manufacturer in India

As a leading manufacturer of pantograph support insulators in India, Radiant Enterprises is committed to delivering superior quality products that meet the stringent requirements of high-speed rail systems. Our state-of-the-art manufacturing facilities, coupled with a team of experienced engineers and quality assurance experts, enable us to design and produce pantograph insulators that excel in performance, reliability, and durability.

Conclusion

In the dynamic world of high-speed rail systems, the reliability and performance of pantograph support insulators are critical for ensuring safe and efficient operations. By adhering to meticulous design considerations such as material selection, electrical insulation, mechanical strength, corrosion resistance, dimensional accuracy, and UV stability, manufacturers like Radiant Enterprises can deliver pantograph insulators that meet the demanding requirements of 25 KV high-speed rail systems. As a trusted pantograph insulator manufacturer in India, Radiant Enterprises is committed to providing innovative solutions that contribute to the advancement of railway electrification technology and the seamless operation of high-speed rail networks.

#Customised epoxy insulators manufacturer in India#Pantograph insulator manufacturer in India#25 KV pantograph support insulators manufacturers in India#25 KV roof busbar support insulator manufacturers in India#Solid third rail insulator#Customized Powerrail Epoxy Insulators#Epoxy Insulators#Epoxy insulator manufacturers in India

7 notes

·

View notes

Text

Moisture Control System Installation | Cotton ginning moisture system in Africa

#Moisture System#Cotton ginning moisture system in Africa#Moisture Control System in Africa#Moisture Monitoring System in Africa#Moisture System Installation#https://mistcoolingsystemsafrica.com/portfolio/moisture-system

0 notes

Text

Retro computer emulation/virtualization resources

Not too long ago, it was one of my hobbies to recreate and emulate old machines and try to use them in a somewhat 'legit' way in order to experience how using them in an accurate time-period might have felt like. While it's always better to use a real machine, it's also important to note that time-accurate machines are essentially a 'ticking bomb'. Some of the electronics inside can go bad at any given time, like capacitors, and other critical components might also go bad due to humidity, moisture in the air, changes in temperature, etc. Plus, they are not always cheap and they take space that you might not have.

This is why I prefer using emulators and virtualization software in order to virtualize a time-period accurate machine that I can use. This is the software I found that I like the most, and what systems I use them for.

DOSbox-X

This is a modified version of DOSBox that includes support for multiple video devices including 3dfx emulation (Voodoo), networking, and even printer support (emulated, but AFAIK it only prints in black and white). It's perfect for MS-DOS and Windows (1-3.11) emulation. Technically you could even install Windows 95 in it.

86-box

This is the way to go if you want to emulate old retro systems. No questions. The best part of it is how flexible it is. You can select the motherboard, the processor you want to emulate, the video card, you can also enable 3dfx support up to the Voodoo 2 (but it also emulates a Voodoo3 and the Banshee), sound card, literally every detail. It's like building a PC, but virtually. And it has hardware from the old 8086 IBM PCs to more modern Pentium 2 machines. It also has network and printer support.

The downside is that since it's low-level emulation, you need a 'beefy' CPU with very good single thread performance in order for more modern systems like Windows 9x and ME to run more smoothly. Another flaw is that for some reason the FP emulation for older processors doesn't work properly for some reason, so you might prefer to use DOSBox-X if you want DOS emulation. The 3dfx emulation is also 'so-so' and not very great, but it works.

It also requires valid ROMs, but you can search for a valid ROMset online (check Github) if you want to use it. For legal reasons, I can't provide links to them, but they are not hard to find.

VMWare Workstation Player

I choose VMWare over other virtualization solutions because of it's graphic drivers capable of running relatively new games from the mid 2000s, and because unlike VirtualBox (since version 6) it still supports old Windows versions, including XP, 9x, ME and old NT systems.

Broadcom wants you to buy a license for the Pro version so they hide the links to the free Workstation Player version. But they are still available and they even release updates once in a while (yes, it's free of charge).

In the link I'm providing, go to the 'player' folder and select the latest version (higher number, now it's 17.6.1) and your system to download VMWare Workstation Player. Then go to the 'ws' folder and select the same version and system, but then select 'packages' to download a matching copy of vmware tools.

Finding software

If you need software, there are three places you need to look for. One is archive.org, the other is WinWorld PC, and the other is Vetusware (requires an account). I can't provide links so search for them on your own. I also browse sites like oldversion.com, but I don't trust these too much, so go at your own risk (or better yet, don't). Naturally you should always buy the software you use, whenever it's possible, and use backups of your legally owned software.

Did you like this post?

I will make more posts in the future about how to set up these emulated machines and how I work with them.

2 notes

·

View notes

Text

youtube

Jude constructs a hot compost bay layered with the perfect ingredients to feed a productive patch.

On a sloping block in the Blue Mountains, Jude has many projects on the go. To keep the garden cranking, Jude’s been learning a lot about compost. “This stuff is gold,” says Jude, “it adds nutrients, water and is the life of the soil.” Here’s how to construct a hot compost bay to feed a productive patch.

The Built Structure:

Jude’s two-bay compost system can house about two cubic metres and was constructed with the help of a mate. They’ve used recycled pallets which are heat treated to make sure the compost is safe to put on edible produce. It has gates at the front, low enough for a wheelbarrow, and is clad with corrugated iron. Jude says the corrugated iron “makes a really good backing when you're digging into the compost, and they also heat it up.” It’s a good idea to install a chicken-wire tube in the centre of the bay for airflow.

Compost is broken down organic matter and is full of nutrients that plants thrive on. Organic matter is anything that was once alive, like plants, animals, and even manures. This material can be broken down slowly by worms in a cool compost system, but in a hot compost system, it’s broken down by millions of micro-organisms and fungi. A big mass of material paired with a lot of microbial action generates a lot of heat. Jude says, “hot compost is a great way to get a lot of compost in a very short amount of time.”

Hot compost needs to be built it all in one go, at least one cubic metre in size. Jude says smaller composts “won't generate the heat required to breakdown the organic matter.” The ideal temperature for hot compost is 60°C, anything higher is way too hot to support the microbes. Regular turning for airflow will help manage the temperature. Jude’s got the perfect ingredients for a healthy hot compost habitat to provide these critters food, air and moisture.

Green & Brown Materials:

Good compost has “a mix of greens and browns,” says Jude. Brown layers are carbon-rich material such as cardboard, sticks, newspaper and straw. These offer energy to the microbes, absorb moisture and improve airflow. Green layers are not always green in colour. Greens are nitrogen-rich materials such as grass clippings, coffee grounds and food scraps. Jude says, “as a general rule of thumb, you want at least twice as much of the carbon-rich material as the nitrogen-rich green stuff.”

Layer #1: Brown:

Cover the base with a carbon layer of sticks and twigs. The rough textures allow excess water to drain, will bulk out the base and help oxygen get into the pile. Jude says, “when I'm adding a layer of carbon, I'm watering it in. I'm aiming for a pile that's moist but not soaking wet.” A layer of wet newspaper on top of the twigs will help create this environment.

Layer #2: Green:

Repurpose your old kitchen scraps and leafy garden waste. Jude says, “avoid meat, bread and dairy” to keep rodents away, and make sure you’re “not adding any weeds with seeds, bulbs or runners.” Break big sections up with a spade to help it breakdown faster. Jude says, “adding diverse nutrients like comfrey will help fire up microbial life.”

Layer #3: Brown:

A thick layer of straw mulch will act as a blanket for all that heating mass underneath. In two weeks, this pile can be lifted and moved into the second bay and turned every few weeks. Check the pile regularly to see if it needs more water or aeration.

You’ll know it's ready when it begins to look like yummy crumbly chocolate cake. Like the one Jude’s brother Charlie was inspired to make - what a team!

#gardening australia#solarpunk#compost#how to#how to make compost#diy#do it yourself#hot compost#hot compost system#Youtube

4 notes

·

View notes

Text

Wood Foundation Repair: Ensuring Longevity and Stability with Foundation Solutions

Wood foundations, though less common than concrete or brick, are a viable option for many homes due to their cost-effectiveness and ease of construction. However, like any other type of foundation, wood foundations can experience issues that compromise the stability and safety of your property. At Foundation Solutions, we specialize in wood foundation repair, offering expert services to address and resolve these problems. In this blog post, we will explore the common issues associated with wood foundations, the benefits of timely repairs, and why Foundation Solutions is your best choice for wood foundation repair services.

Common Issues with Wood Foundations

Wood foundations can face several challenges due to their material properties and environmental exposure. Understanding these issues can help in identifying problems early and seeking appropriate repairs:

Moisture Damage: Wood is susceptible to rot, mold, and mildew when exposed to excessive moisture, compromising its structural integrity.

Termite Infestation: Termites can cause significant damage to wood foundations, leading to weakened structural support.

Soil Movement: Changes in soil moisture levels can cause the ground to expand and contract, leading to foundation shifts and cracks.

Poor Drainage: Inadequate drainage systems can lead to water accumulation around the foundation, causing erosion and weakening the wood.

Aging and Wear: Over time, wood foundations can deteriorate due to natural aging and wear, necessitating repairs or replacement.

Signs of Wood Foundation Issues

Identifying the early signs of wood foundation problems can help prevent more extensive damage. Look out for the following indicators:

Visible Rot or Decay: Check for any visible signs of wood rot or decay, especially near the ground level.

Mold and Mildew: The presence of mold or mildew indicates moisture problems that need to be addressed.

Termite Damage: Look for termite tunnels or damaged wood that may indicate an infestation.

Cracks in Walls or Floors: Foundation shifts can cause cracks in the walls or floors of your home.

Uneven Floors: Sloping or uneven floors are a sign of foundation settling or shifting.

The Benefits of Timely Wood Foundation Repair

Addressing wood foundation issues promptly offers several benefits, including:

Preventing Further Damage: Early intervention can stop minor issues from escalating into major structural problems.

Maintaining Property Value: A stable foundation preserves your property’s market value and aesthetic appeal.

Ensuring Safety: Timely repairs protect your family or occupants from potential hazards caused by a compromised foundation.

Reducing Repair Costs: Addressing problems early can save you from more expensive repairs in the future.

Our Wood Foundation Repair Process

At Foundation Solutions, we follow a comprehensive and meticulous process to ensure effective wood foundation repairs. Here’s how we do it:

Inspection and Assessment: Our experts conduct a thorough inspection to identify the root cause and extent of the foundation damage.

Customized Repair Plan: Based on the assessment, we develop a tailored repair plan that addresses the specific issues affecting your foundation.

Moisture Control: We implement moisture control measures to prevent further damage, including improving drainage and installing vapor barriers.

Rot and Decay Repair: Using high-quality materials and advanced techniques, we replace or reinforce damaged wood to restore structural integrity.

Termite Treatment: We provide termite treatment solutions to eliminate infestations and protect against future damage.

Waterproofing: To prevent future moisture-related problems, we implement effective waterproofing solutions around the foundation.

Final Inspection: We conduct a final inspection to ensure all repairs meet our high standards of quality and durability.

Why Choose Foundation Solutions?

Selecting the right company for your wood foundation repair needs is crucial. Here’s why Foundation Solutions is the best choice:

Experience and Expertise: With years of experience, our team has the knowledge and skills to handle any foundation issue.

Customer Satisfaction: We prioritize customer satisfaction, delivering high-quality results that meet your expectations.

Advanced Technology: We use the latest equipment and techniques to ensure precise and efficient repairs.

Transparent Pricing: Our pricing is clear and upfront, with no hidden fees, so you know exactly what to expect.

Guaranteed Results: Our work comes with a guarantee, giving you peace of mind that your foundation is built to last.

Case Study: Successful Wood Foundation Repair

Recently, we completed a project for a homeowner whose wood foundation had significant rot and termite damage due to poor drainage and moisture exposure. Our team conducted a comprehensive assessment and implemented a customized repair plan, which included moisture control measures, replacing damaged wood, and providing termite treatment. The result was a stable and secure foundation that restored the integrity of the home and prevented further damage.

Contact Us Today

If you’re experiencing issues with your wood foundation, don’t wait for the problem to worsen. Contact Foundation Solutions today for expert advice and professional wood foundation repair services. Let us help you maintain a strong, stable, and safe foundation for your property.

At Foundation Solutions, we are dedicated to providing top-quality wood foundation repair services that exceed your expectations. Trust us to deliver the strength and stability your property needs, ensuring long-term safety and reliability.

Tagged Foundation Repair, Foundation Solutions, Wood Foundation Repair

#Wood Foundation Repair#Foundation Repair#Foundation#Foundation Solutions#Wood Foundation#foundation contractor#foundation experts#foundation repair solutions#foundation services#residential foundation repair services#foundation repair near me#foundation solution#signs of foundation problems

2 notes

·

View notes

Text

On June 13, 2022, the licensee notified the Agency that on Friday, June 10, 2022, a truck containing a Insto Tek 3500 moisture density gauge was stolen. The gauge contained a 44 millicurie americium-241 source, and an 11 millicurie cesium-137 source. The licensee reported that the technician had stopped at a convenience store to buy some items and when they came back out the truck was missing. The licensee stated the gauge was locked in the back of the truck but was unsure if the keys to the locks were also taken. The licensee stated the gauge has an old Global Positioning System tracking device that was inactive. The licensee stated they had contacted the GPS service company to see if the tracking device was still active and the gauge tracked that way. * * * UPDATE ON 2/22/2023 AT 1048 EST * * * The truck was recovered and was partially stripped for parts. The gauge was missing. The source was locked, however, the keys to the gauge were in the pickup truck. The licensee conducted training on security of the gauge and not leaving trucks running even if the gauge is properly secured. The company is purchasing GPS tracking units to install on the gauges. On Feb 21, 2023, the licensee reported to the Agency that the gauge was found on February 20, 2023, in the back of a stolen U-Haul truck. The licensee has the gauge in their possession and the gauge is in good condition.

which one of you fuckers stole a truck containing an infinitesimally radioactive moisture sensor gauge and left it in the back of a uhaul 8 months later. in texas. because you're in a nuclear regulatory commission event report

58 notes

·

View notes

Photo

Metropolis Poster Paris GLASS IS INCLUDED THOUGH NOT SHOWN IN THE PHOTOGRAPHS TO AVOID THE GLARE EFFECT OF THE FLASH. Double Mated Around Print Molding: Wooden Flat Top Design with Black Finish Includes Glass and Metal Wire Hooks Installed Ready For Hanging Dry Mounted High Quality Print Bonded to Foam Core, Will never fold or fade. . The double mat adds depth giving the display a unique "looking through a window'' appearance. The calendar print is bonded to foam core on a hot vacuum press. This bonding gives the print a perfect flat and smooth texture. This process also insures the print will never fold or fade with age or moisture. This wonderful display makes a thoughtful and original gift containing a classic vintage touch yet modern design, allowing it to fit alongside both modern and classic decor. BID WITH CONFIDENCE. ALL OF MY DELICATE ITEMS ARE SHIPPED WITH A SPECIAL 3 LAYER PROTECTION SYSTEM.

#metropolis poster#fritz lang#1936#science fiction#sci fi#fantasy#futuristic#vintage ad#robot poster#robots#robotics#wall art#moebius art

2 notes

·

View notes