#Mobile asphalt plants

Explore tagged Tumblr posts

Text

Mobile Asphalt Plant - For sale - Asphalt Batch Mix Plants

Explore top-quality portable asphalt plants and mobile drum mix plants crafted by a trusted manufacturer in India. Choose from a variety of mobile asphalt plant and asphalt batch mix plants solutions engineered for durability.

1 note

·

View note

Text

youtube

Mobile asphalt drum mix plant -

Atlas MDM 25 is an ideal small asphalt drum mix plant designed for customers looking for a asphalt plant which can be started in short time and can be shifted frequently. This plant is placed on two chassis (without wet dust collector) or three chassis (with wet dust collector).

0 notes

Text

Asphalt Plant | Bitumen Sprayer Manufacturer in India - S.P. Enterprise

S.P. Enterprise is a manufacturer of road construction machinery like asphalt plant, hot mix plant, asphalt drum mix plant, bitumen sprayer in India. We are exporter and supplier of road construction equipments. Call us on +91-9712583240.

#asphalt plant#bitumen sprayer#mobile asphalt plant#asphalt drum mix plant#asphalt mixing plant#asphalt hot mix plant#bitumen pressure distributor

2 notes

·

View notes

Text

What is Asphalt Recycling Plant?

The use of reclaimed asphalt, or recycling, has become a necessity. Governments increasingly want the reclaimed asphalt from old roads re-used in an effort to be more environmentally friendly. Recycled asphalt also can provide you with cost savings on several fronts.

To use this valuable secondary resource, ZOOMLINE offers the Asphalt Recycling Plants to help your recycling and cost-saving efforts. Regardless of the system you choose, modern ZOOMLINE plant technology will provide a quality recycling process and product.

Asphalt Recycling Plant | Hot & Cold RAP Recycling, RAPpro 100% Recycled Asphalt Hot Mix Plant, Recycled asphalt hot mix plant, RAPpro 100% Recycled Hot Mix Asphalt Production Plant.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#asphalt plant#concrete#heavy equipment#asphaltplant#construction#mobile asphalt drum mix plant#recycling asphalt plant#asphalt recycling plant#recycled asphalt plant#RAP Recycling#recycled asphalt hot mix plant#recycled hot mix asphalt production plant#asphalt production plant

3 notes

·

View notes

Text

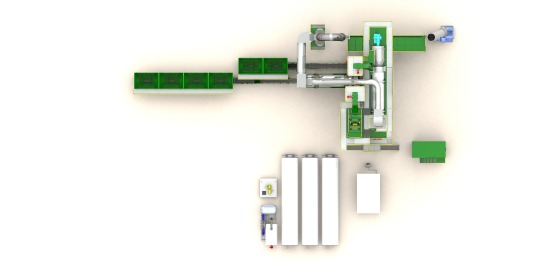

Highly Portable Asphalt Mixing Plant Manufctured By ACE Group, A Jobsite In the Niger

Model:IAP60

Capacity:60 t/h

Highlights: One or two-in-one mobility, quick transfer; reassemble within hours; zero foundation required, water film & cyclone dust filtration techniques

0 notes

Text

Best Manufacturers of Mobile Asphalt Drum Mix Plants in India

Alfa Omega India is recognized as one of the best manufacturers of mobile asphalt drum mix plants in India. We specialize in providing high-quality, durable, and efficient plants designed for superior performance in road construction. Explore our range now!

#construction equipment#mobile asphalt drum mix plant#mobile asphalt drum mix plant manufacturer#road construction equipment manufacturer

0 notes

Text

A Journey of a Laser Cutting Machine and Asphalt Plant Supplier

In the ever-evolving landscape of industrial manufacturing, few industries have experienced such remarkable advancements as laser cutting and asphalt production. At the heart of these transformations lies the dedication and expertise of companies like ours - a laser cutting machine supplier, manufacturer, and wholesaler, along with being an asphalt plant supplier and manufacturer, contributing to the growth of various sectors for over four years.

Pioneering Laser Cutting Technology: Our journey began with a vision to revolutionize the metalworking and fabrication industries by introducing cutting-edge laser cutting machines. As a supplier, we sought to source and provide the latest technology to our clients, ensuring they stay at the forefront of efficiency and precision. As a manufacturer, we took great pride in designing and producing cutting machines that could cater to diverse needs and surpass industry standards. And as a wholesaler, we endeavored to reach out to businesses of all sizes, ensuring accessibility to this game-changing technology.

Over the years, our dedication to quality, innovation, and customer satisfaction enabled us to build a strong reputation in the market. Collaborating with various industries, including automotive, aerospace, construction, and more, we witnessed firsthand the transformative impact of laser cutting technology. Manufacturers embraced the newfound capabilities, achieving higher productivity, reduced waste, and unmatched precision in their operations.

Empowering Asphalt Industry with Cutting-Edge Solutions: In parallel to our journey in laser cutting, we recognized the tremendous potential of the asphalt industry. To meet the growing demands for high-quality road construction, we ventured into supplying and manufacturing asphalt plants. With a focus on mobile asphalt plants and recycling asphalt plants (RAP), we sought to provide eco-friendly and cost-efficient solutions.

As a mobile asphalt plant manufacturer, we understood the need for flexibility and portability in road construction projects. Our plants empowered contractors to produce asphalt directly at the site, minimizing transportation costs and time. Additionally, our RAP asphalt plant offered a sustainable approach by recycling reclaimed asphalt, reducing waste, and conserving valuable resources.

Building Strong Relationships: Our success story is not just about machines and technology; it's about the relationships we built along the way. We took immense pride in being more than just suppliers and manufacturers - we became partners in our clients' growth. Understanding their unique requirements, providing tailored solutions, and offering comprehensive after-sales support became the cornerstones of our business philosophy.

Adapting to Changing Landscapes: As technology continued to advance and industries evolved, we remained committed to staying at the forefront of innovation. Regularly updating our laser cutting machines to incorporate the latest advancements and optimizing our asphalt plants for enhanced efficiency became an integral part of our journey.

Looking Ahead: With four years of experience as a laser cutting machine supplier, manufacturer, and wholesaler, alongside being an asphalt plant supplier and manufacturer, we take pride in our contributions to industrial progress. However, our journey doesn't end here. As we look ahead, we envision further advancements, expanding our product lines, and empowering more industries with cutting-edge technology.

Our dedication to excellence remains unwavering as we continue to partner with businesses worldwide, fueling progress, and transforming industries through the power of innovation. The journey has been exhilarating so far, and we eagerly embrace the exciting road ahead.

1 note

·

View note

Text

Mobile Asphalt Drum Mix Plant - Atlas Industries

Atlas is manufacturers of mobile drum mix plant. We are supplier and exporters of mini asphalt plant with low price. Buy high quality of portable mixing plants.

0 notes

Text

A Happy Origin

A scrawny girl with dirt covered blond hair, squeezed through a previously boarded up window. She muffled her grunts, trying to stay as quiet as possible as she wiggled out into a dingy alleyway. The ruckus coming from the building behind her told her that she had enough time to get far enough away from the building without her captors noticing. Once free, she quietly jogged down the dark alleyway; nights smoggy skies and the murky stank of molding trash and piss accompanying her on her walk home.

This wasn’t a new development in her life, no, the whole kidnapping scenario was oddly reoccurring. Different groups of scumbags every time but the same lousy routines. They’d grab her, intimidate her, throw her in some moldy room, and check on her occasionally. She stopped being scared after the fourth or fifth time this had taken place and since then it had been a regular, yet annoying, routine in her life.

She made her way through the labyrinth of streets and alleyways to a backpack she had planted behind a large trash bin; thank God it hadn’t been stolen and that this time she had enough of a heads up to plant it. She took a seat beside the pile and methodically stripped away her disguise. Dirty golden hair pulled away to reveal fiery red locks and makeup wiped away to reveal skin that had been mauled. She peered into a small handheld mirror and scoffed at the woman peering back at her. She snapped the small mirror closed and chucked it back into the backpack, she would take off the latex that smoothed her features into a younger and less scarred face when she got home. She pulled out a jacket and sweatpants she had stashed in the bag and shimmied them over the leggings and long-sleeved shirt she wore. Once the wig was stuffed into the bag and the makeup wipes were disposed of, she flipped up the hood of her jacket and made her way to the closest bus station. It was a quiet ride home on the buses, small victories for the late routes.

The woman made her way back to the same shady trailer park that she’d lived in for 15 years now. The rows of mobile homes were lined with weathered asphalt and the neighborhood sandwiched between the main city and woods. This place never truly felt special to her but it was the closest thing to home she had. She stopped in front of a lime house, the paint long faded and vines started to creep up the sides of it. She didn’t bother trying the front door, just made her way straight to the back door. It opened with a creak into a dead silent main room, she didn’t dare bother calling out, just quietly moved through the musty house towards her room.

Her room was the same pale eggshell color as the rest of the house’s interior but far minimally decorated. She flopped onto a small stool sat in front of a dirty desk and dust covered mirror; the imprint of a hand routinely wiping away the specs that settled on it gave her a clear spot to view her own reflection. She peeled away the latex that hid an ugly acid scar that ran the expanse of her right cheek and down the right side of her body. Then she carefully popped out the contacts that changed her eyes from a subtle green to one dark brown left eye and one milky white right eye. When her disguise was successfully removed and her face was once again her own, she threw herself back onto her bed. She only had a few hours to sleep but she took this moment to simply breathe before falling into the comforting arms of a dreamless sleep.

This was the life of Maxine Auclair, 25-year-old, French American, scam artist and high school dropout extraordinaire.

Aren’t you tired, Maxine?

Maxine woke up with a gasp. Her peace disturbed by slamming doors, screams, and burning eggs. She sighed and got out of bed, showering, getting dressed, and finally putting on a new disguise. This one was one she was much more familiar with. Today, and every other time that daylight hit her hemisphere, she was Bridget Laurent. Bridget worked at the corner store. She had unmarred flesh, brown hair, brown eyes, and always wore a gentle smile when checking out the greasy low lives who asked what she was up to when her shift ended.

She took a deep breath and slipped out of her room. She made brief eye contact with her father and offered him a lazy wave, one that went unreciprocated as he continued to yell at her mother.

“Stupide pute, QU'EST-CE QUE C'EST!?” The graying and lean man screamed with a thick Brooklyn accent. His taunting parroted by the equally thick French accent of her mother.

Max walked over to the stove, flicking off the burner and scooped some of the now partially charred eggs onto a plate, then moved the skillet to a cool burner. She slumped into an empty chair at their dining table and watched the two adults continue their verbal war. To say she resented the pair would be an understatement, after all their bad decisions were directly responsible for the misery that her life is full of. The reason her skin was marred with scars, the reason she had no further education than a GED, the reason she lived a life of fake identities, and oh yes, of course, the reason she often found herself blindfolded and gagged in the back of shady vans.

Are you not craving freedom, Maxine?

She was snapped from her thoughts by a crooked hand firmly clasping her shoulder, “Good to see you made it back, girl. Try and be a little quieter coming in next time? Your mother is a she-devil when she doesn’t get her “beauty rest.””

Mr. and Mrs. Auclair had the unmistakable talent of doing business with the absolute worst kind of people but at Maxs young age of 16 they developed the incredible strategy to scam the low lives they borrowed money from. Most parents wouldn’t take pride in routinely selling their daughter, but the Auclair’s certainly did. They were tight on cash and out of things to barter so they traded her to a shady group. To their surprise, Max showed back up at their door a few days later, shaking with tears streaming down her cheeks. With a dog so loyal their next steps were a no brainer; sell her again and again and she would just come right back. But eventually they ran out of groups to deal with, so she took up new identities to scam the same groups again and again. All of this resulted in losing her true identity along the way. By day she was Bridget, by night she was anyone they needed her to be. This cycle resulted in a terribly miserable and lonely life; one she had no relief from, not as she kept living a complete and total lie.

You could live your own life, Maxine.

She finished her eggs, cleaned her plate, then grabbed her bag and headed out for the day. Mornings were a lot nicer without all the screaming so generally, she enjoyed her commute to work. Work itself was about as good as it could be when you work at a gas station. The weathered eggshell walls, grime covered tile floors, and bright LEDs was the perfect environment to attract all sorts of folks. Funny enough, she recognized some of her captors from her “adventures” as they stopped in. She always took a little bit of pride in charging the lowlifes for items they most certainly didn’t buy, after all nobody looked close enough at their receipts to call her out. Day in and day out this was the cycle, one that she couldn’t escape. Go to work, go home, see if she had any “surprises” waiting for her, escape, go to bed, rinse and repeat. The monotony killed her but it’s hard to realize that when your whole life has been the same routine, running and hiding for survival.

That is, until the cycle was broken by her parents flying too close to the sun in their scams and greed.

It was a quiet evening, so she had no greasy lowlifes to escape and no late-night busses to catch. No screams filled the house, which meant her parents were in a good mood. Unfortunately for Maxine that was a good indicator that tomorrow would bring more problems for her; they were only this quiet and content after getting the money for whatever they needed it for. Tonight though, Maxine let herself breath, quietly drifting off to the muffled sounds of some late-night sitcoms laugh tracks and the smell of nicotine gently rotting the walls.

Loud banging and the shrieks of her mother filled the air, startling Maxine awake. She didn’t think, just sprinted to her door and threw it open. She was barely two steps passed the threshold of her room when hands gloved in leather yanked her back. A strong arm wrapped around her waist, pinning her arms to her side and her body against their own. Her captor’s other hand slapped against her mouth, effectively silencing her.

Maxine was dragged into the living room, her heart pounding in her ears. Fear and adrenaline mixed into an ugly, sickening concoction in her stomach. Her eye landed on her mother and father, screaming and pleading down on their knees. Then her eye landed on two men who stood in front of them. One was tall and big like the man that held her, and the other was lean and weaselly. She didn’t get long to process the scene before she was unceremoniously thrown to the floor in front of her parents.

“Now that we got the whole family here let’s discuss our little problem Mr. and Mrs. Alarie or maybe Blanchet is what you’d prefer?” a man spoke. When she lifted her head, she noted that it was the weaselly man.

“You see you lot owe us a hefty price. Those two different deals under two different names sure didn’t make the boss all that happy when he found out he had been swindled. Especially when your payment has trouble staying in her cage, so the boss sent me to collect,” he squatted down and yanked Maxines head back by her hair, “Huh, ugly little mouse, aren’t you?”

“We didn’t mean any harm, honest, you see our daughter has always been a basket case ha-ha- We had no clue that she’d come crawling back, but we obviously tried to return her with our second dealings. I know-” her father’s desperate ramblings were silenced by the weaselly mans gloved hand raising. The man slammed Maxines head down and stood up, wiping his hands on his coat.

“Hush hush Mr. Blanchet. It’s no sweat off our back; the boss is a forgiving man. You just have to give us the total you owe us to clear up this misunderstanding, with interest of course.” A wry smirk sat on the weaselly man’s lips as he spoke.

“We- how much do we owe your boss?” Her father sighed, anxiety in his tone drawled out by his thick accent.

“$78,000”

“$78,000! You can’t possibly be serious- we borrowed no more than 40- 48- 56k from you guys. No one has that sort of money on hand!”

The weaselly man ran a hand through his hair with a mocking sigh. The two larger men went behind Maxines mother and father, kneeling down and restraining the couple.

“Not to worry, you can buy an extension of… oh well, how about a month?” His words were punctuated by the gun aimed directly at Maxines head.

Maxines breath and heart quickened as she looked down the barrel of her death. No, surely her work escaping and being traded around was too valuable to give up. Her parents wouldn’t trade her life like this. Her demise would surely spell their doom, they had to have money somewhere, especially since they just traded her for some more.

Are you ready, Maxine?

Maxines thoughts stilled as her mother’s voice cut through the tension like a butcher’s knife and landed in her back.

“Oui, oui, s'il vous plaît. Nous accepterons l'affaire, nous aurons votre argent dans un mois.” The woman pleaded through anxious sobs.

“Maman?” Maxine whispered looking back at her mother.

“What was that? Sorry, didn’t quite catch that.” The weaselly man replied with a chuckle.

“Yes, we will accept your deal,” her father doubled down.

Everything was happening in the matter of a few moments for Maxine. She faced her twilight, the final act of a life she had had no control over, an itch for freedom left unscratched by the hateful maws of those that drowned her. She turned her gaze to the man, noting his smile.

“Good choice.”

Fight, Maxine.

She didn’t think, just acted. Her hands shot out and grabbed the gun, a loud bang rang out as she wrestled the weapon from his hand. She howled in pain as a bullet buried itself into her thigh but something louder in her howled. The ugly concoction of fear and adrenaline mixed into something new under her skin. She pried the gun from the man, pressed it to his chest and pulled the trigger.

She didn’t even watch him drop as she spun to face the rest of the people in the room. Maxine briefly stumbled as she aimed the weapon at the big guy that restrained her mother. She shot twice, one bullet lodging itself into her mother while the other hit its mark in the man’s chest. She didn’t notice the other man already reaching for his own gun, just pivoting and firing. As Maxines own gun went off, another bang echoed, its bullet lodging in her shoulder. She let out a shrill scream but watched as the behemoth fell.

Silence enveloped the house as she panted. Finally looking at the carnage in the room. Cold filled her veins as the adrenaline of the moment washed over her. Her eye flickered over the corpses of the three strangers bleeding out in the greasy living room. Her mother’s body was draped over one of them as well. Her eye then landed on a figure in the middle; her father getting off the floor and approaching her with his arms out.

“Maxine! You did so good, girl!” Her father’s voice drew her out of her thoughts and back into reality.

She was aware of everything at that moment. The smell and slight tang of copper mixing with the lingering smell of nicotine, the sharp pain in her shoulder and thigh, and the gun that felt heavy in her hand. Her eye drifted to the weapon, sleek and covered in splatters of crimson that extended to her scarred hand. She was shaking but not from fear or regret, no, she was shaking from the aftermath of the rush she just felt.

Her father’s voice was drowned out by the roar of her heartbeat as he pulled her into a tight hug, her gaze still trained on the gun in her hand. Its weight felt like liberation. Her gaze rose back to her father who limped to go pick up his cane from the floor, still rambling nonsense that was lost on her. Her hand stopped shaking as she raised the gun again. Her eye locking with his as horror flashed over his face. Some part of her delighted in the look he gave her as his mouth started to move again. She didn’t have to be a good shot; he was close enough.

A small smile made its way to her lips as she pulled the trigger one last time.

Sirens started to fill in the silence, with all the commotion, of course police would be called. She picked up her father’s cane and hauled out the door. Her eye landed on the forest at the end of the street and she took off. She ran as fast as she could with a bullet hole in her leg and another oozing blood out of her shoulder. Using her dads old cane as a crutch, Maxine thumped down the trailer parks roads. Sirens drew closer but her attention was on the woods, the sound of the wind in her ears, and the freedom that she now possessed. She huffed, bare feet meeting broken asphalt, fiery red locks catching the light of half burnt out streetlights, a wide grin on her face as the woods in front of her drew ever nearer.

Maxine reached the threshold of the woods as the sirens started to pour into the trailer park. She dodged and weaved through the large trees, trying not to draw any attention to her as she made her escape in the dead of night.

Sharp rocks and thrones embedded themselves into her skin, causing her to wince and cry but she pressed on. She began to feel faint from blood loss, but she forced herself to stay conscious. It was only a matter of time before people came looking but she wanted to get a little further into the woods. She stumbled into a patch of Aspen trees. By now her balance faltered as her end approached fast.

Maxine knew that she would die but at least she would die knowing that she was finally free. She would not die as Bridget Laurent, or Blanchet, or Alarie, not even Auclair. Tonight, she would die as Maxine, just Maxine.

She tripped and caught herself on one of the pale trees. She slid down the bark of the tree, her vision blurring in her one good eye. Her body hit the forest floor with a thud, but she managed to prop herself up. She threw her head back and looked at the stars, huffing for air as she bled out. A small laugh leaving the normally quiet and stale woman.

She looked at her surroundings, her freedom and grave, with a smile, life fading fast from her. In her delirium or so she thought, her eye landed on a tall figure. The watching eyes of the aspens melding into the form of a man, no he was too tall to be a man, perhaps a monster. Her thoughts didn’t linger on him much more though as her vision fell to black and she slumped over.

Before eternity took her gracefully one last thought wiggled its way into her fading mind.

You are not done yet. Don’t you want more than a lick of freedom?

“Yes” she whispered with her last breath.

Then so be it, Happy.

So began the life of Happy, 25-year-old, French American, murderer extraordinaire.

Hi Hi!!! So erm I am slowly rewriting everything, its going to be posted here and AO3 but I hope yall enjoy. Ill probably have more shitposts here over the weeks. Also! Like the official chapter 1 should come out soon so there wont (hopefully) be more multi month waits. Enjoy!!!!

#creepypasta#oc#original character#happypasta#splendorman#happy the proxy#fanart#original art#drawing#artists on tumblr#original writing#writing

3 notes

·

View notes

Text

What's the Functions of Asphalt Plant Dryer Drum?

The asphalt plant dryer drum is to preheat the cold aggregate, dry and heat it up to ensure that discharge temperature meets the requirements.

Drying drum is one of the core components of asphalt mixing plant. The performance of drying drum directly determine the production of a complete set of asphalt mixing plant.

The Advantages of Drying Drum: Long service life Energy saving Low emission Low fuel cost

ZOOMLINE provide stationary and mobile type drying drums for choice.

#dryer drum#drying drum#asphalt plant dryer#asphalt dryer drum#asphalt drum mix plant#asphalt mixing plant#road construction#asphalt plant#construction#asphaltplant#mobile asphalt drum mix plant#heavy equipment#concrete#bitumen#dryer#dryer drum mix

2 notes

·

View notes

Text

Shower thoughts on power generation

Starting assumptions:

The current generation of Small Modular Reactors has never been small enough to containerize, but there are small thermoelectric containerizable power plants without proliferation concerns: see the Mars rovers

Gigascale nuclear is still cheaper per MWh than SMR

But solar and wind are cheaper than gigascale nuclear

But solar and wind aren't 100% availability

Batteries are somewhat expensive

Flywheels are already containerized (see Kodiak, Alaska)

Terraform Industries would be stupid if their plants weren't containerized, and they don't seem stupid. Their rollout starts in 2024.

Carbon-neutral and carbon-negative don't mean "no carbon-based fuels"; just "no fossil fuels".

How do I see the near future playing out, say by 2050?

Containerized nuclear thermoelectric batteries are used for low-load low-sunlight high-impact postings, as a form of set-and-forget critical infrastructure. This is the most-wishful item on my list.

Maybe there's some geothermal in the mix, but it remains high cost to site and construct relative to other forms of power, and has limited geographic availability.

Gigascale nuclear gets built when your consumption density is higher than available solar/wind generation density, so long as it remains infeasible to build new long-distance power transmission lines.

Solar/wind fields power containerized electricity-to-CH4 plants as a source of carbon for carboniferous fuels. This fuels non-electrified mobile sources and, directly fuels demand-responsive gas turbines for The Grid when the sun don't shine/the wind don't blow. Your renewables overproduce electricity, beyond what The Grid needs? Make CH4. Don't want to deal with permitting for a thousand-mile-long transmission pipeline? Don't. Colocate CH4 generation with CH4 use.

Need a microgrid for a Burning Man, a FEMA camp, or Palestine? Unload a containerized 1MWh solar/flywheel/battery/CH4 setup, with 5 acres' worth of containerized solar panels to back it up. Knock out the temporary panels on the containers and convert them to modular buildings. Need more MWh? More containers, more acres. Or just truck in a couple tankers of methane and a generator.

Applications requiring high energy density switch to CH4, or use the cheapest solar/wind electricity to turn CH4 to propane/kerosene/gasoline as needed. Aircraft and many ground vehicles will still emit CO2, but it's CO2 that was sucked from the sky: Net Zero is achieved.

Net CO2 reduction comes from diverting air-sourced carbon to fixation: plastics, paints, asphalt, concrete, diamonds.

The Haber-Bosch process uses air-sourced hydrogen or desalination-sourced hydrogen instead of fossil hydrogen to make ammonia.

6 notes

·

View notes

Photo

Hi! Local archaeologist here!

This story involves a place just north of Mobile, Alabama, called Africatown, so named by the above mentioned Cudjo Lewis (also known as Kossola before he took an American name) and the other survivors of the Clotilda, the last slave ship to ferry enslaved Africans into the United States. The Clotilda was smuggled in to Mobile Bay one night in 1860 (already illegal in the U.S. at the time), where it's cargo of 110 West Africans from Dahomey and the surrounding region was offloaded in secret and divided amongst the wealthy white slave-owners that commissioned and ran the voyage, namely Timothy Meaher and William Foster. With Emancipation in 1863 and the end of the Civil War (Mobile briefly being occupied with Union troops) in 1865/66, the Clotilda survivors found themselves free people. They joined together and saved up $1000 to charter voyage back to West Africa before being told by their former masters that a voyage back would be much more expensive and not at all profitable. So instead, Cudjo and the others used that money and more to purchase land, establishing their community of Africatown, where they could speak their own language, live under their own local government, farm and have children, and eventually become americanized.

Africatown still exists today, but it has had a very tragic history of environmental and racial injustice. It is overwhelmed with industry (chemical refineries, asphalt plants, pipe and metal manufacturers, paper mills, and more), which has caused a serious health and cancer epidemic. MUCH OF THE LAND HERE IS STILL OWNED BY DESCENDANTS OF THE MEAHER FAMILY. Yet, the town is revitalizing its own culture history with the rediscovery of the Clotilda's remains, including the construction of a new heritage center and archaeological work. If you're at all interested in this story, then read the book published from Zora Neale Hurston's work called Barracoon or Nick Tabor's Africatown: America's Last Slave Ship and the Community It Created. Consider visiting these sites and others to lend your support.

Cudjo Lewis, the last surviving captive of the last slave ship to bring Africans to the U.S.

https://www.history.com/news/zora-neale-hurston-barracoon-slave-clotilda-survivor?utm_campaign=Echobox&utm_medium=Social&utm_source=Twitter#link_time=1525373347

156K notes

·

View notes

Text

Revolutionizing Road Construction with Mobile Asphalt Drum Mix Plants

In the ever-evolving landscape of road construction, Mobile Asphalt Drum Mix Plants have emerged as a game-changer. These compact and efficient plants offer unparalleled flexibility, enabling seamless on-site production of high-quality asphalt mixes. Mobile Drum Mix Plants have revolutionized project timelines, eliminating the need for transportation delays and ensuring a continuous and reliable supply of asphalt. Their portability and quick setup make them ideal for remote locations, reducing overall project costs. Embracing innovation, these plants embody efficiency, environmental consciousness, and durability. As the construction industry adapts to changing demands, Mobile Asphalt Drum Mix Plants stand as a beacon of progress, redefining the future of road infrastructure.

For More details, Kindly contact us at 90999 41311 this Number and visit our site:https://www.coninfra.in/

0 notes

Text

Advantages of Mobile Asphalt Drum Mix Plant - Atlas Technologies

Mobile asphalt plants come with some inherent advantages over their stationary counterpart and size and features like additional portability are not the only ones.With mobile drum mix plants, the components are preassembled on a maximum of three or four chassis.

0 notes

Text

Hotmixplant Manufacturer in Delhi NCR

S.K. Engineering is a renowned manufacturer of high-quality road construction machinery, specializing in Hot Mix Plants, Asphalt Hot Mix Plants, Asphalt Drum Mix Plants, and Mobile Asphalt Drum Mix Plants. With a focus on innovation, durability, and performance, our equipment is designed to meet the diverse needs of modern infrastructure projects. We are committed to delivering reliable and efficient solutions, ensuring the highest standards of quality and customer satisfaction. Backed by years of industry expertise, S.K. Engineering continues to be a trusted partner for businesses worldwide, contributing to the success of road construction projects of all scales.

1 note

·

View note