#asphalt production plant

Explore tagged Tumblr posts

Text

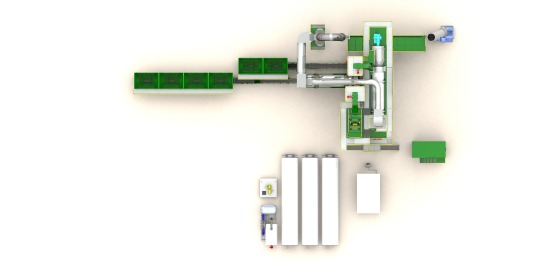

What is Asphalt Recycling Plant?

The use of reclaimed asphalt, or recycling, has become a necessity. Governments increasingly want the reclaimed asphalt from old roads re-used in an effort to be more environmentally friendly. Recycled asphalt also can provide you with cost savings on several fronts.

To use this valuable secondary resource, ZOOMLINE offers the Asphalt Recycling Plants to help your recycling and cost-saving efforts. Regardless of the system you choose, modern ZOOMLINE plant technology will provide a quality recycling process and product.

Asphalt Recycling Plant | Hot & Cold RAP Recycling, RAPpro 100% Recycled Asphalt Hot Mix Plant, Recycled asphalt hot mix plant, RAPpro 100% Recycled Hot Mix Asphalt Production Plant.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#asphalt plant#concrete#heavy equipment#asphaltplant#construction#mobile asphalt drum mix plant#recycling asphalt plant#asphalt recycling plant#recycled asphalt plant#RAP Recycling#recycled asphalt hot mix plant#recycled hot mix asphalt production plant#asphalt production plant

3 notes

·

View notes

Text

Asphalt Drum Mix Plant for Best Road Construction Equipment

The Asphalt Drum Mix Plant is essential for producing high-quality asphalt used in road construction. Designed for efficiency and durability, it ensures consistent mixing at optimal temperatures. This advanced equipment, trusted by professionals, delivers superior performance, making it the best choice for infrastructure projects. It is the Best Road Construction Equipment for reliable, cost-effective operations.

#asphalt drum mix plant#road construction equipment#best road construction equipment#asphalt mixing plant#durable asphalt plant#efficient road construction equipment#high-quality asphalt production#cost-effective road equipment#infrastructure projects equipment#asphalt plant manufacturers

0 notes

Text

Can You Lay Asphalt in Winter? Everything You Need to Know

Learn the essential winter tips for successful asphalt paving on our latest blog at Kaushik Engineering Works. Discover expert insights to ensure your paving projects withstand the challenges of colder seasons. Enhance your knowledge and prepare for winter paving success. Explore the full guide now!

#asphalt paving#asphalt plant manufacturers#asphalt plant manufacturers in India#Construction Equipment Manufacturers#Construction Products

0 notes

Text

In just eight blocks of sidewalk in quiet neighborhood, walking through the not-quite-rain of a sunshower, today I encountered four missing shoe soles. Little pieces of plastic and rubber, detached from pedestrians' shoes, now lonely on the concrete, with the weeds.

No such thing, really, as a "weed", though. "Weed" is not a botanical term. Instead, describes perceived pests, at the discretion of the observer. At the discretion of the authority. Designated as weed by the one with power over that land. The agronomist, the rancher, the plantation manager. The weed wastes space that could otherwise be given to a monoculture cash crop, an "economically significant" plant. The weed interferes with the productivity of the plot of land. The weed interrupts the extraction. The weed diminishes the value. The weed doesn't belong in this place.

People are made to be weeds, too.

Some cities will designate you as a weed, and then they'll take action to pull you out. They'll uproot you. But it's not always explicit, like "we're outlawing loitering" or "we're outlawing taking a nap in the park" or "we're defunding the library". Sometimes it's quite clever, it's written into the physical landscape. Self-congratulatory "progressive" cities learn to co-opt language, to obscure the violence, to use and abuse space.

Thinking about things you might encounter, you might perceive, after you've been destitute, broken, lived at a homeless shelter, for years. Little signs of other peoples' misery. Indicators of desperation that some might overlook. And the way that environment shapes, and is shaped by, these miseries.

A friend asks "why is there always an unusual amount of scuffed detached missing shoe soles on this particular stretch of sidewalk? There are hardly any homes around here, it's all asphalt and empty lots, so where are all these be-shoed people coming from?" Because even though this is a wide expanse without either home residences or any kind of commercial or recreation space someone would want to visit, these blocks are the straight-line direct path between a low-income apartment complex and the cluster of corporate big box stores, and there's no bus line that runs between the two areas. "But don't the vast majority of customers of shopping malls and box stores drive vehicles, hence the obscenely massive parking lots?" Sure, customers drive, but guess who actually has to work at those places? An underclass of people living at that apartment complex with harsh restrictions and cheap amenities, who can't afford car insurance or who might be too physically disabled to bike. And so that apartment complex is a de facto "company town", the residents are essentially in confinement. It is written into that landscape. It can be read. "Why is there always debris, wrappers, coins, etc. in this particular quiet couple of blocks of the boulevard?" Because these blocks are between a thrift store and a same-day drop-in clinic, so many impoverished people will routinely be walking between these two locations. They attend their appointment, and then have forty-five minutes to kill before the bus comes back around, so why not check out the thrift store? The city and county collaborated and placed all the low-income assistance offices on the far side of town, which conveniently forces the poor and disabled to both stay away from the luxurious downtown district and also to waste their time making a four-hour commute, catching various connecting buses or else riding the bikepath, across the city just to attend a ten-minute-long appointment.

Then this spatial layout, this city's physical environment, will shape the physical body. This violence writes itself into the flesh. The way the denim is chafed and discolored on the left shoulder of someone's jacket from carrying a small backpack around by foot, day after day after day. The way someone's heart rate increases when they see a white and black vehicle in the periphery of their vision, subconsciously recollecting institutionalization and institutional abuse, or fearing what a ticket fee would mean for their budget (they might not be able to afford rent). The way someone develops a painful limp, maybe occasionally depends on a cane, because they had to walk great distances every day to get to work and their shoe sole fell off on the sidewalk, but they can't replace the shoes because their employer is underpaying them, and they're forced to stand all day at work anyway, and they already had some modest nerve damage in their foot because they've been rationing their insulin and can't afford their prescriptions, and federal medical insurance keeps denying them because their physical letters in the mail always show up too late or not at all, and groceries are too expensive so it's hard to get good nutrition to heal, but the diabetic nerve damage has by now damaged their digestive tract too so they have a strictly limited bland diet and can't enjoy the simple pleasure of a home-cooked meal (if they can even afford a home, at this point), and all those "little" miseries add up, and now they're hungry, and in pain, because they were forced to walk kinda funny for a long time over all those decaying sidewalks with all those other weeds.

642 notes

·

View notes

Text

In most city builders the unofficial (sometimes, explicit) goal is to grow your city - get a large amount of money, a large population and large tax income, unlock cool buildings, etc - and, while you can play it that way, the real unofficial goal of Workers & Resources is self-sufficiency.

While in the early game you're necessarily reliant on foreign trade to purchase raw materials, even hire foreign skilled labourers, and depend on exports to make up your currency deficit, the excitement of the game comes about once you fully control all steps of a given production process. You go from importing electricity - to mining, transporting, and refining coal for your own domestic power plants. And that applies to every single resource chain in the game, from bread, to concrete, to railway carriages.

What really sells me on the whole thing is this - in 'realistic' mode, the ability to construct buildings purely from money is removed. You can still import materials and labour, but you need to actually get them there. The process for starting out your city goes like this:

Set up mud tracks (the only free road type) from a border customs office. Build the free versions (which is to say, designated dirt lots) of a construction office, a fuel depot, and a road logistics office. From the border, buy vehicles with cash - cement mixers, dump trucks, asphalt pavers and steamrollers, a bus to bring foreign workers to your construction site, and don't forget a fuel tanker to supply your fuel depot. At this point you have a muddy construction site with some cars parked on it. Start construction on worker housing, the electrical substation for the housing, a water pump and water treatment plant (or, just a water tower to import water into), a small store to feed them - and hopefully it's not cold enough that you need a central heating block. Congrats, now get your construction offices carrying out each individual stage of construction in turn, requiring different resources and vehicles at each part, until, over dozens and dozens of workdays, you've finally built a single worker accomodation. Take in some workers, who are probably a bit annoyed that there aren't any bars or sports complexes around, and you've finally, after months of construction works, got your first residents. Now they need an actual workplace - and, luckily, you've now got a local workforce to construct it. Give it time, and this remote patch of dirt will be constructing nuclear power stations.

I feel like, in the way games like Banished (or, more topically, Manor Lords, I think? I've never played it) turn city-building into a survival game, by just semi-accurately portraying the precarity of a peasant economy, Workers & Resources definitely makes you feel like a stressed planner fighting against production itself, rather than your own citizens, like in Cities Skylines or the like.

290 notes

·

View notes

Text

the AU where Prime Torino time-travels to the Advent of Quirks era (a time period he did not study for) and picks up two street babies after recognizing one as a miniature AfO

context: Sorahiko's been in the past for less than year. He's been preventing AfO from picking up new Quirks for maybe two weeks, and has dropped off food for the twins a couple of times.

wc: ~1.1k

//

The children stared at Sorahiko with wary eyes, eerily alike for all that they differed in stature and eye color. He didn’t let himself move, save for a tip of his head. The bigger child, the one Sorahiko thought was a young All for One, mimicked him; the smaller boy said in a faltering voice, “Who are you?”

“Call me Torino,” he said. “How about you?”

The smaller boy bit his lip and gave his brother a nervous side-eye. Chibi-AFO ignored him; he only had an unblinking stare for Sorahiko, and truth be told, it was getting irritating. Don’t raise your voice, he heard Shimura chide.

He sighed, then changed tack. “Did you like the food?” At the clear brightening of the smaller boy’s expression, Sorahiko lifted the plastic bag. The boys were younger than Kotarou, but he had vague memories of Shimura feeding her son soft foods before he turned a year old. Surely steamed vegetables and (slightly) overcooked rice was fine.

Chibi-AFO lurched forward without a sound, one hand outstretched, the other still holding tight to his brother’s wrist.

A curse slipped through Sorahiko’s filter; he dropped the bag and Jetted himself backwards, out of reach but not out of sight. The last thing he wanted was to be chased blindly by some murderous toddler.

The showing of his Quirk, however, sparked something in Chibi-AFO’s eyes. A different kind of hunger--one that apparently required both hands now, as he unceremoniously dropped his brother and doubled down on trying to grab Sorahiko. The smaller boy yelped as spikes burst from Chibi-AFO’s skin, and then showed an incredible lack of self-preservation by trying to intervene.

“No!” he cried. “No, don’t! He’s nice!”

Sorahiko dodged another lunge for his neck. Can I hit him now? he begged the Shimura on his shoulder. I’m justified in knocking him out for his own good, right? That’s how this works?

You can’t hit a baby! Shimura scolded. He doesn’t know any better!

Chibi-AFO, as if to refute Shimura’s sympathies, finally opened his mouth to screech, “GIVE!” He kept springing for Sorahiko with his tiny palms thrust outwards; the spikes on his body rushed unerringly for Sorahiko’s limbs. “GIVE IT!”

“Stop it! Stop!”

How much stamina could a toddler have? More importantly, how long did Sorahiko have until the civilians he’d ushered off the street rang the local police station? Sorahiko, out of sheer curiosity, started leading Chibi-AFO in a circle. It felt criminally easy to maintain a generous distance between himself and the toddler, even as Chibi-AFO grew more desperate and enraged at not having easy prey.

“IT’S MINE!” the toddler snarled, out of breath. “MINE! MINE!”

Because Sorahiko wasn’t above taunting a baby, he upped the speed on his Jet. Chibi-AFO’s reliance on his spikes to propel him was the toddler’s downfall; as the chase continued, the production output and quality of the spikes diminished, until it was pure spite that powered Chibi-AFO’s bare feet.

The smaller boy had collapsed long ago by the food, gasping, but he seemed like he registered that Sorahiko wasn’t about to die, because he was now spectating with awe-struck eyes.

“Are you done?” said Sorahiko mildly, continuing to deny the toddler any hope of closing the gap. The boy’s face was getting redder, and scrunched-up, and then the funniest thing happened: Chibi-AFO tripped on his makeshift robe, face-planting into the asphalt.

Don’t laugh, Shimura said, in a long ago memory about Kotarou colliding into a glass door.

Chibi-AFO was trembling, every limb shaking. The smaller boy had shot up, renewed concern pushing him to his brother’s side and babbling something unintelligible. Sorahiko stifled the bark of laughter as Chibi-AFO gingerly lifted his head and goggled at the ground, like he couldn’t believe he’d fallen.

“Be nice,” the smaller boy pleaded, frantically patting Chibi-AFO’s shoulders. “Don’t, don’t, be nice.”

A tiny, minuscule drop of pity collected at the pit of his stomach. Sorahiko made the executive decision to sacrifice his cape, unpinning it from his suit and dropping the heavy fabric onto the boys before going to fetch the food. They startled at the sudden weight, but the smaller boy could only squeak and Chibi-AFO, thoroughly exhausted, could only twitch.

“Let’s try this again,” said Sorahiko dryly. He popped the plastic lids of the styrofoam containers and stuck spoons into two of them, situated both in front of the children, and took his own seat a full meter away. “I’m Torino. How’s the food?”

Huddled under his cape, the smaller boy looked bewilderedly from him to the food, and back again. “Um…!”

“Not hungry,” said Chibi-AFO.

“... Alright. You two have names?”

“No,” said Chibi-AFO, sullen. “Go ‘way.”

As tempting as it was, Sorahiko took a measured breath and let out a controlled exhale. “No. You’re hurting people being out here, and I can help you. Food, and a place to sleep. Do you understand me?”

The smaller boy fiddled with a handful of Sorahiko’s cape. Tentatively, he asked, “Safe?”

Chibi-AFO repeated, in the same tone as before, “No.”

At some point, Sorahiko thought, you really couldn’t justify letting a toddler steer the conversation. He considered his options, and responded to the smaller boy first. “Yes, it’s safe. I won’t hurt you, or him. I just can’t let him hurt anyone else.”

A small hum, and then: “Okay. We go.”

“No!” Chibi-AFO protested, and finally pushed himself up, wincing. Tears pooled at the corners of his eyes, but Sorahiko would place a bet that they were purely reflexive. “No, I’m safe! He’s bad! He hurt me!”

“You hurt you,” the smaller boy sniffed.

The murderous intent flashed on Chibi-AFO’s face again, and Sorahiko hastily stepped in before more blood was shed. He snapped his fingers in front of the toddler. A malformed spike, sloppy in execution and sluggish in timing, tried to pierce Sorahiko’s hand and dissipated before he could even recoil. Exhaustion! Finally!

“Go ‘way,” the toddler demanded.

Sorahiko simply leaned his cheek against his fist, propping his elbow on his knee. Either Chibi-AFO would recover and try for a second time to steal Jet, or he would pass out. There wasn’t any point trying to reason with the brat.

The smaller boy patted Chibi-AFO’s shoulders, but he too went quiet. Eventually, Chibi-AFO slumped flat to the ground again, and his slurred orders dwindled to a faint burbling snore. That was Sorahiko’s cue to creak upright, crouch down, and ask the smaller boy in a serious tone, “Can I pick you up?”

The kid looked at the food.

“I have more at home.”

“... Okay,” he said softly, and in swift order, Sorahiko resituated his cape so it swaddled Chibi-AFO, took him up on one arm, and hoisted the smaller boy in his other arm. There was that squeak again, and a nervous clutching at his flight suit, but Sorahiko’s attention was on thinking about the route back to his apartment.

It would be easier on the kid’s nerves if he walked, but the Meta X gangs were too troublesome to bother with tonight.

“Hold tight,” Sorahiko muttered, and Jetted for the rooftops.

#bnha#gran torino#torino sorahiko#all for one#shigaraki yoichi#shih.txt#d-december#i still don't know what to call this#okay stand in tag:#sorahiko and his shigaraki adoptees au#the names are truly the worst part about this#because sorahiko's not going to bother naming them#they don't even know to call each other brother yet until sorahiko's like 'go tell your older/younger brother'#and then he pauses like 'wait. who's older'#chibi afo senses a power play and lunges for it. 'I AM I AM'#god. sorahiko won't even know about the rats. get ready for b+ parenting

124 notes

·

View notes

Text

Making my own post to respond to this, because the point is pretty tangential:

When I first played stardew valley there was something I found really dissonant. You start in this shitty company that's implied to be cold and isolating and treats you as a a cog in a machine, and you inherit this idyllic and pastoral farm. So far so good. But then immediately you set about on trying to upgrade the farm and make it efficient and extract as much value from the land as quickly as you can. You clear cutt large sections of land and replace them with cash crops. You turn the land and the town into a well-oiled machine, just as your previous job had done to you. This process of upgrading and increasing efficiency is the central form of progress in the game.

Obviously the game never really addresses dissonance, but I really wish there was a game that did. I wish that the back half of the game turned into something like Factorio as you seek to automate more and more of your production so you can buy the late-game upgrades. Gradually these changes affect the town as well, people start to move away because of the smog, and you can buy up their land to have a place to put your new combine harvester.

One of the characters is a philosophy grad student studying Heidegger who's home for the summer, and she talks to the player about his theory of technology. Where modern technology is powerful enough that it's actually feasible to use of 100% of an existing resource, and so we start thinking about that resource in terms of how to most efficiently extract value from it. We objectify it, in a sense -- a river can't be a beautiful ribbon of blue stretching across the countryside, because we can only think of it in terms of "the thing that powers hydroelectric plant" and think about how to maximally utilize it. And the player slowly realizes that they've carried this mindset back with them from the city. That the dehumanizing aspects of their old life were never about the skyscrapers and asphalt, but about the way that their superiors viewed them as a resource, and the way that their environment facilitating efficient use of them as a resource. And that they've carried this attitude back to the idyllic country town where it's now spread like a virus, destroying all the things that drew them to the farm in the first place, and that they now live in a hell of their own making. They restore the community center, but they've destroyed the community it was made for. The only way to avoid this ending is to deliberately refuse to upgrade past a certain point. To accept that certain end-game content is forever out of reach, and to be okay with that.

now to be clear, I don't actually endorse all the politics implied by this. But I think it would be interesting for a game to actually grapple with the kind of pastoralism thats common in this genre. This flavor of pastoralism has fundamental tradeoffs against efficiency and reduction of labor. And I think if you want to endorse this ideal, that's a bullet you have to bite.

342 notes

·

View notes

Text

“Dirty hands, clean money”

Organic farmers in Altamira are working to change the culture of a region where many people think nothing of using pesticides to kill weeds and insects. As well as the fight against entrenched attitudes, they face economic and climate challenges

Organic farmers in Altamira are working to change the culture of a region where many people think nothing of using pesticides to kill weeds and insects. As well as the fight against entrenched attitudes, they face economic and climate challenges

Sebastião Heraldo Lira Gomes has done a bit of everything, from soiling his hands in the yellow mud of Brazil’s gold-mining regions to digging in the black soil of a vegetable garden. In his 45 years, he has worked for construction and asphalting companies, at brick plants, and even as a gold prospector. In the mines, his life once hung by a thread when he was digging branches out of the mud to clean off material to be mined. An alarmed co-worker pointed to a mountain of tailings and shouted a warning: “The barrier is going to collapse.” It did, and Sebastião narrowly escaped. He told this story while planting a row of lettuce seedlings in his organic garden in Altamira, a city in southwestern Pará.

“Mining is an adventure. You head out not knowing whether you’ll come back,” Sebastião says. He survived the dangers but never returned to the mines. Born on a small farm on Bacabal, an island in the Xingu River, Sebastião grew up helping his family plant rice, beans, corn, and cassava. Until the age of 25, he followed in his parents’ footsteps, but then he moved to Altamira, where he held a number of jobs. In 2021, at the suggestion of his wife, Alderene, 51, he left mining and decided to make farming a source of income, hoping to enjoy the security of working on his own land while being close to his family.

When he contacted the Pará state rural extension agency Emater, the agent Joabe dos Santos asked him, “Why don’t you plant organic produce?” Sebastião didn’t even know what organic food was. His family had never used pesticides on their crops. Indigenous peoples, Beiradeiros, and other traditional communities in the Amazon have always planted without relying on these poisons.

Organic farming emerged as a response to the growing application of pesticides and fertilizers on European crops following World War I (1914-1918). The practice aims to keep agricultural activities in balance with Nature through the adoption of modern production techniques and the responsible use of water and soil. Organic farming rejects chemical fertilizers and transgenic seeds, which have been modified to resist drought, pests, and pesticides. This approach to agriculture also strives to forge an environment of social justice and respect for both human labor and the more-than-human world.

Continue reading.

#brazil#brazilian politics#politics#environmentalism#farming#image description in alt#mod nise da silveira

3 notes

·

View notes

Text

this morning i saw the city.

i was walking to the bus stop, eyes half-closed against the driving rain and endless too-bright headlights, when i accidentally looked sideways through a crack in the pavement.

for a moment i could see it all.

the city's skin was made of asphalt, with folds where it went over hills, dry and cracking in some places, newly healed in others. the roadworkers up ahead were part of the immune system, putting stitches in the city's skin, leaving pebbled scabs and painted line scars behind.

the houses and shops, rising tall or short and squat, were tiny hairs, sensitive to the slightest movement. the larger structures, the bridges and arenas and skyscrapers, were moles and callouses. the fences and streetlamps formed the little textured dots and pores that i could feel when i ran the pad of my index finger down the inside of my arm.

and the humans, well — the humans and other animals were the lifeblood of the city, moving water and oxygen and hemoglobin from place to place in each day-long heartbeat, releasing waste products into the air and waters and streets to be carried away by the cleaners and garbage collectors of the city's gastrointestinal system.

i stood there, staring, until my eyes began to hurt with the effort of seeing, and i blinked, and the vision disappeared.

i could still see it, though, behind my eyes, as i walked along the footpath stretch mark, and past the textured pores of street signs, and waited under the shelter of the hair follicle of a bus stop. beside the bus stop, I saw a little patch of yellow dandelions, barely staying alive despite the rain.

they were just plants, rooted in a dirty smudge upon the city's skin. nothing more.

i felt immensely sad all of a sudden, and i tried to look sideways at the dirt, too, from a different angle. i couldn't work it out, and then my bus arrived, and i lost the vision entirely. perhaps, though, that was for the best.

6 notes

·

View notes

Text

Let's appreciate some cases of Xinyiguang's LED floor screen

Stay at home, go shopping, and walk on the road. Our common floor materials include carpet, wood plank, marble, cement road, asphalt and other types, but no matter how fancy, pattern, and color change, they all have a common feature-slightly "dull". Some people say that it is fun and convenient, just change it frequently. It sounds very embarrassing, you can change the carpet every day, but you can't pry the floor every day. Have you heard of Xinyiguang LED floor tile screen? Through the LED display, the visual interactive experience is immersive, giving people: the indoor floor tile screen with the experience of "sitting at home, the world is under the feet"; stepping and jumping, and the intelligent interaction of playing and dancing floor tile screen; waterproof and dustproof, super heavy outdoor floor tile screen. It can be tiled on the ground and displayed slowly, or it can be used to create a dreamy and flashing stair screen that climbs up the steps. Onlooker No. 1: It sounds amazing, do floor tile screens with so many functions really exist? Onlooker No. 2: Need to be powered on? Is it safe? Onlooker No. 3: Will it be crushed? Yes, yes, all of the above! Chinese people don’t lie to Chinese people. The editor of Digital Audio-Video Engineering Network couldn’t stand everyone’s urging, and decided to go to Xinyiguang with everyone to learn about it. It was an eye-opener. Experience the fun of "seeing is owning". 2022 CCTV Spring Festival Opera Gala-P2.976-300 square meters

Shenyang-TV Station-106.25 square meters

Yinchuan-Planning Pavilion-330 square meters

Xinjiang-Museum-P3.91-250 square meters

Zhejiang - Qiandao Lake Tourist Attraction - 240 square meters

Shanghai-Audi Flagship Store-P3.91

Russia - Stavropol - P2.976-288 square meters

Wuhan K11-P6.25 Indoor - 280 square meters

Q&A session

1. Is it safe? Quiet heat dissipation The power box of the LED intelligent interactive floor tile screen box adopts a die-cast aluminum box with good heat dissipation, and a special heat dissipation device is designed by a professional R&D team to achieve a better silent heat dissipation function. 2. Is it waterproof? The bottom case, mask, power cord and signal line of the waterproof and moisture-proof LED floor tile screen module are specially designed and equipped with waterproof and moisture-proof materials. They are made of raw materials with low moisture absorption coefficient. The front and back of the body can reach the waterproof level of IP45. 3. Is it reliable? The anti-slip and wear-resistant LED intelligent interactive floor tile screen mask is made of imported PC materials, which has high wear resistance and flexibility, and good high and low temperature resistance. And designed according to the principle of mechanics, Xinyiguang mask has good anti-slip and load-bearing functions. 4. Is it hard? Super load-bearing Each component of Yiguang LED intelligent interactive floor tile screen, according to different mechanical designs, has an ultimate load-bearing capacity of up to 3 tons per square meter. Onlookers 1, 2, and 3: Awesome! Is that brand okay? Editor: Founded in 2012, Xinyiguang is a professional supplier of global application products and solutions. Xinyiguang has a modern manufacturing plant of 8,000 square meters. The core R&D team has more than 20 years of experience in professional research and development. The company has obtained a number of valid patent certificates and a number of test reports to provide users with high-quality products and services. And in December 2021, it was awarded the "2021 Famous Brand of LED Floor Tile Screen" by Digital Audio Video Engineering Network. The trophy is still warming up, what do you think? Onlooker No. 1: Wow, it's so powerful, I will arrange a basketball court with LED floor tiles for the village immediately, the cubs in our village must not lose to the next village! Low-key arrangement... Onlooker No. 2: I heard it a long time ago! We have 4 in our village, 1 each in the east, west, north, and south. Onlooker No. 3: Tsk tsk tsk, you guys are so naive. I want to arrange a big floor tile screen for the entrance of my house, so that everyone will envy my house! The indoor LED floor tile screens, intelligent interactive floor tile screens, and outdoor LED floor tile screens developed and produced by Xinyiguang have various installation styles of floor tile screens and stair screens. The product cabinets are made of hard materials such as die-casting aluminum, aluminum plates, and iron. Increase the strength of the box, strong and wear-resistant. It's really good, the boss remembers to stock up for the New Year, because it will be a big hit in 2022! Read the full article

2 notes

·

View notes

Text

A Comprehensive Guide to Starting an Asphalt Plant for the First Time

Looking to start an asphalt plant? Get a comprehensive guide from Kaushik Engineering Works, leading asphalt plant manufacturers. Learn the essential steps, tips, and expert advice for successfully setting up and operating an asphalt plant. From site selection to equipment installation and production optimization, this guide covers all aspects to help you kickstart your asphalt plant project with confidence. Explore our informative blog now!

#asphalt plant manufacturers#Construction Equipment Manufacturers#Construction Products#asphalt construction product

0 notes

Text

Why Rajasthan Tops as the Best Hydrated Lime Manufacturer in India

Introduction

Rajasthan, often referred to as the land of minerals, has carved a unique identity in India's lime industry. As demand grows for quality hydrated lime in infrastructure, metallurgy, and chemical sectors, Rajasthan emerges as the frontrunner, thanks to its abundant natural resources and advanced manufacturing capabilities. This blog delves into the reasons why Rajasthan dominates as the hub of hydrated lime manufacturers in India, with a special focus on industries seeking premium lime for asphalt and the role of the best limestone manufacturers in powering this growth.

1. Geographical Advantage and Rich Mineral Deposits

One of the primary reasons Rajasthan is a leader in hydrated lime production is its vast natural limestone reserves. Districts such as Nagaur, Jodhpur, and Udaipur are known for their high-purity limestone, which forms the foundation for producing top-grade hydrated lime.

The availability of raw material in close proximity not only reduces transportation costs but also allows manufacturers to maintain consistent quality—a critical requirement for industries relying on premium lime for asphalt or chemical processing.

2. Advanced Manufacturing Infrastructure

Over the years, Rajasthan has witnessed rapid industrial development, especially in the lime sector. Many of the best limestone manufacturers in the country have set up cutting-edge production facilities here. These plants are equipped with modern kilns, automated hydration systems, and quality control labs that ensure superior product consistency.

Companies in Rajasthan adopt environmentally friendly practices and energy-efficient technologies, helping them stay compliant with both Indian and international standards. This focus on quality makes Rajasthan a go-to destination for hydrated lime manufacturers in India blog searches.

3. Skilled Workforce and Industrial Experience

With decades of experience in lime production, Rajasthan's workforce has become highly skilled in the processes of calcination and hydration. From quarry management to final packaging, every step is handled by professionals trained to meet the stringent demands of industries like asphalt mixing, construction, and metallurgy.

This experience adds another layer of reliability, particularly when supplying premium lime for asphalt, where precision in chemical composition and particle size is vital for road durability and strength.

4. Quality That Meets Global Standards

Hydrated lime from Rajasthan is well-regarded for its high calcium content, low impurities, and fine texture. This makes it suitable for a wide range of industrial applications including water treatment, flue gas desulfurization, steel manufacturing, and road construction.

Many hydrated lime manufacturers in India, particularly from Rajasthan, now export to markets in the Middle East, Southeast Asia, and Africa. The reputation for high-quality products has been a game-changer for buyers seeking consistent and reliable supply.

5. Strategic Location and Excellent Logistics

Rajasthan’s location provides easy access to both northern and western parts of India. The robust road and rail connectivity ensure faster delivery times and reduced transit damage. For industries relying on bulk supplies of hydrated lime—such as cement, steel, or asphalt contractors—this logistical convenience adds immense value.

Leading hydrated lime manufacturers in India from Rajasthan also offer customized packaging and bulk delivery services, further cementing their reputation among national and international clients.

6. Application of Premium Lime in Asphalt

One of the fastest-growing applications of hydrated lime is in asphalt road construction. Premium lime for asphalt is used to enhance adhesion, reduce stripping, and improve durability of pavements. Rajasthan-based manufacturers offer hydrated lime with ideal moisture content and chemical purity tailored for this specific application.

Their lime acts as an anti-stripping agent, binding the bitumen to the aggregate more effectively and significantly extending the life of roads—especially in India’s extreme weather conditions.

7. Supportive Government Policies

Rajasthan’s state government has long supported the growth of the lime industry by offering incentives like subsidies on equipment, access to mineral leases, and streamlined licensing processes. These policies have helped local businesses scale their operations and invest in research and development.

As a result, manufacturers in the state continue to innovate and diversify their offerings to cater to evolving industry needs—from construction-grade lime to high-end applications such as food processing and pharmaceuticals.

8. Rising Export Opportunities

With India being a cost-effective manufacturing destination, Rajasthan-based hydrated lime companies are increasingly looking beyond domestic markets. Thanks to their scale, quality, and pricing, these companies are becoming preferred partners for international buyers looking for large volumes of premium lime for asphalt and other industrial applications.

Customs-friendly policies at ports like Kandla and Mundra—both easily accessible from Rajasthan—further facilitate smooth exports.

9. Sustainability and Eco-Friendly Practices

Environmental sustainability is a growing concern across industries. Many best limestone manufacturers in Rajasthan are now adopting sustainable mining techniques and carbon capture technologies in their lime kilns.

They also invest in water recycling, dust management, and tree plantation efforts around mining sites. These steps not only make the production eco-friendly but also align with global buyers’ expectations on sustainable sourcing.

10. Rajasthan's Reputation and Industry Leadership

The sheer number of lime manufacturers in Rajasthan, coupled with decades of consistent supply and product excellence, has given the state a near-monopoly in India’s hydrated lime market. It has become the first name that comes to mind when one thinks of hydrated lime manufacturers in India blog topics, thanks to the state's comprehensive ecosystem.

Buyers across industries—from road construction to water purification—prefer Rajasthan for its trustworthiness, volume capabilities, and innovation-driven mindset.

Conclusion

Rajasthan’s dominance in hydrated lime manufacturing isn’t a coincidence—it’s the result of geological blessings, industrial foresight, and a commitment to quality. From being home to the best limestone manufacturers to becoming the preferred source of premium lime for asphalt, the state offers unmatched advantages for industries across India and abroad.

Whether you're sourcing lime for a government road project or a high-precision industrial process, Rajasthan remains the top choice. As the market grows and evolves, Rajasthan is poised to lead from the front, maintaining its stature as the heart of India’s lime industry.

#limestone suppliers in india#hydrated lime manufacturers in jodhpur#quick lime manufacturers in india

0 notes

Text

Conveyor Belt Tensioner Manufacturer in Ahmedabad, India

Introduction

Established in 1994, Nisuka Industries has been a name synonymous with quality and innovation in industrial components. Located in Ahmedabad, Gujarat, India, we have grown steadily over the years to become one of the most respected manufacturers of conveyor accessories in the country. Our expertise extends to a wide range of products including SMSR gearboxes, pulleys, plummer blocks, gear oil pumps, suspension magnets, metal detectors, and of course, conveyor belt tensioners.

Our commitment to high-quality manufacturing, precision engineering, and customer satisfaction has made us a preferred supplier for various industries such as cement, mining, aggregate, stone crushing, asphalt, and coal handling.

What is a Conveyor Belt Tensioner?

A conveyor belt tensioner is a mechanical device used to maintain the proper tension in a conveyor belt system. It ensures that the belt remains aligned and tight enough to transmit power effectively without slipping or sagging. Proper tensioning not only increases the efficiency of the system but also significantly extends the life of the belt and associated components.

Whether your conveyor operates under heavy load or at high speeds, an effective tensioning system is vital to prevent downtime, reduce wear and tear, and maintain consistent material flow.

Why Choose Nisuka as Your Conveyor Belt Tensioner Manufacturer?

As a leading Conveyor Belt Tensioner Manufacturer in Ahmedabad, India, Nisuka Industries delivers solutions that combine durability, efficiency, and innovation. Here's why businesses across India and abroad trust us:

1. Precision Engineering

Each tension unit is manufactured using advanced CNC machinery and top-grade raw materials to ensure precision and long service life.

2. Tailored Solutions

We offer standard as well as customized tensioners tailored to the specific requirements of your conveyor system, including load type, belt width, and environmental conditions.

3. Low Maintenance Design

Our tensioners are designed for ease of installation and minimal maintenance, helping reduce your operational costs and downtime.

4. Consistent Performance

Built to perform under heavy-duty conditions, Nisuka’s tensioners maintain stable belt alignment and prevent belt slippage, even in harsh industrial environments.

5. Expert Support

Our engineering team works closely with clients to provide the right tensioning solutions for their applications, offering technical assistance from selection to installation.

Applications of Conveyor Belt Tensioners

Nisuka’s conveyor tensioners are used across a wide range of sectors, including:

Mining & Quarrying

Cement Plants

Stone Crushing Units

Asphalt Mixing Plants

Fertilizer & Chemical Industries

Coal & Sand Processing

Bulk Material Handling Systems

By maintaining optimal belt tension, our tension units play a critical role in reducing belt misalignment, increasing efficiency, and ensuring continuous material flow.

Our Product Range

In addition to being a trusted manufacturer of conveyor tension units, Nisuka Industries is proud to offer a comprehensive portfolio of conveyor system components and industrial gear units:

SMSR Gearboxes: As a shaft mounted gearbox manufacturer in India, we provide reliable gearboxes suitable for heavy-load conveyors and crushers.

Conveyor Gearboxes: We are also recognized as a conveyor gearbox manufacturer in India, offering robust gear systems for industrial material handling.

Plummer Blocks: Rigid and corrosion-resistant blocks designed to support rotating shafts and reduce vibration.

Permanent Magnetic Drum Pulleys: High-performance magnetic pulleys for ferrous metal separation from conveyor materials.

Suspension Magnets: For over-belt removal of metal contaminants to protect crushers and other downstream equipment.

Metal Detectors: Industrial-grade sensors to detect and prevent unwanted metal in product streams.

Gear Oil Pumps: Efficient and durable gear pumps designed for lubricant circulation in heavy-duty machines.

Every product is engineered with precision and built to deliver unmatched reliability in demanding industrial environments.

Serving Industries Across India and Beyond

With a well-equipped manufacturing facility in Ahmedabad and a network of distributors across India, we supply our products to various sectors, including:

Cement & Concrete Plants

Quarry and Mining Operations

Aggregate and Sand Processing

Steel and Power Plants

Waste and Recycling Facilities

Our reputation as a trusted manufacturer stems from our focus on delivering quality, customization, and customer satisfaction with every unit we supply.

Quality Assurance

At Nisuka Industries, we never compromise on quality. Our in-house testing facilities and strict quality control processes ensure that every conveyor belt tensioner and other product leaving our factory meets international standards. Our dedication to continuous improvement and investment in R&D keeps us at the forefront of innovation.

Conclusion

If you are looking for a reliable Conveyor Belt Tensioner Manufacturer in Ahmedabad, India, look no further than Nisuka Industries. With decades of experience, cutting-edge technology, and a wide range of industry-proven solutions, we have what it takes to support your conveyor operations efficiently and affordably.

From shaft mounted gearboxes to magnetic drum pulleys, and from conveyor gearboxes to belt tensioning units, Nisuka Industries offers complete solutions under one roof. We invite you to explore our product range and get in touch with our team to discuss your specific requirements.

#Conveyor Belt Tensioner Manufacturer in Ahmedabad#Conveyor Belt Tensioner supplier in Ahmedabad#Conveyor Belt Tensioner exporter in Ahmedabad

0 notes

Text

What are the application scenarios for using industrial tire shredders in the circular economy?

keyword:industrial tire shredders

link:https://www.shred-waste.com/rubber-tire-shredder-machine/

Industrial tire shreddersplay a crucial role in the circular economy by transforming waste tires into reusable resources across various application scenarios. Here are some key areas where industrial tire shredders are applied:

1. Building materials and engineering applications

Rubber asphalt mixture:Shredded tire particles can be mixed with asphalt to improve the elasticity, wear resistance and noise reduction of the road surface, and are widely used in the paving of highways and high-grade roads.

Cushion and anti-skid materials:Rubber crumbs are used in sports venues (such as plastic tracks, football fields), sidewalks, gyms and other scenes to provide cushioning and anti-skid functions.

Rubber bricks and floors:Floors and bricks made of recycled rubber have sound insulation and wear resistance, and are suitable for industrial plants, public places and home decoration.

2. Rubber product recycling and industrial raw materials

Recycled rubber production:Shredded rubber particles can be processed into recycled rubber, which is used to manufacture tire retreading, sealing strips, brake pads, soles and other products, reducing the consumption of virgin rubber (80% of China's annual demand relies on imports).

Rubber powder application:Fine rubber powder (50-80 mesh) is used in industrial fields such as waterproof coils, coatings, and rubber tubes. The cost is only 1/4 of that of virgin rubber, and the market demand is strong.

Metal and fiber recycling:After sorting, the steel wire and nylon fiber in the tire can be used as spring steel raw materials or plastic product substrates to achieve full resource utilization.

3. Energy substitution and industrial fuel

Tire-derived fuel (TDF):Shredded tire fragments can be used as high calorific value fuel to replace coal in industrial combustion scenarios such as cement kilns and power plants. For example, in one case, 500,000 tons of coal can be replaced each year, significantly reducing carbon emissions.

Pyrolysis oil production:Tires are converted into fuel oil or carbon black through chemical processing for industrial energy supplementation.

4. Agriculture and public facility innovation

Water conservancy engineering materials:Waste tires are processed into irrigation pipes or flood control equipment, which have both corrosion resistance and low cost advantages.

Environmental protection facilities:Recycled rubber is made into public facilities such as trash cans and park fitness equipment, which have both durability and environmental protection properties.

5. Landfill reduction and pollution prevention and control

Volume reduction:The volume of shredded tires is reduced by 70%, significantly alleviating the space pressure of landfills.

Pollution prevention and control:Avoid soil and water pollution caused by open-air burning or random stacking, and reduce harmful gas emissions.

Industry drive and policy support

Policy incentives:China's "Catalogue of Comprehensive Utilization of Resources" clearly supports the recycling of waste tires, and enterprises can enjoy tax incentives. Regulations such as the EU "ELT Directive" also promote global market growth.

Economic advantages:The price of recycled rubber powder is only 1/4 of that of virgin rubber, and market demand continues to grow (the global annual scrap tires exceed 1.5 billion), forming a market scale of hundreds of billions.

Typical cases and future trends

China's Shengzhong tire shredder processes 50,000 tons of waste tires annually, which is equivalent to saving 16,000 tons of virgin rubber, with significant economic and environmental benefits.

Industrial tire shredders not only address environmental challenges like "black pollution" but also generate substantial economic value, crucial in the circular economy framework.

0 notes

Text

Here’s your next SEO blog using the keyword tyre recycling machine, with a focus on eco-friendly construction using recycled tyre products:

Building a Greener World: Eco-Friendly Construction Using Products from Tyre Recycling Machines

As sustainable building practices rise globally, the construction industry is turning to recycled materials to reduce its carbon footprint. One surprising contributor? The tyre recycling machine. This powerful tool transforms old tyres into materials that are not only cost-effective but also eco-friendly and highly durable.

In this blog, we’ll explore how construction companies can use outputs from tyre recycling machines in building greener structures and infrastructure.

How Tyre Recycling Machines Support Green Construction

A tyre recycling machine breaks down scrap tyres into:

Rubber granules

Rubber powder

Steel wire

Tyre-derived fuel (TDF)

Carbon black (if pyrolysis is used)

These outputs are then used in various construction applications, promoting sustainability and innovation.

Eco-Friendly Construction Materials from Tyre Recycling

✅ Rubberized Concrete

Rubber powder is mixed into concrete to improve:

Flexibility

Shock resistance

Durability under temperature changes

Used in pavements, lightweight structures, and parking lots.

✅ Rubber Paver Tiles & Interlocking Mats

Rubber granules are molded into:

Anti-slip tiles for walkways

Outdoor playground mats

Gym and warehouse flooring

Noise-reducing underlays

These tiles are widely used in urban landscaping and public infrastructure.

✅ Rubber-Modified Asphalt for Roads

One of the most impactful uses — rubberized asphalt made with tyre-derived rubber lasts longer and:

Reduces road noise

Minimizes cracks from temperature shifts

Requires less maintenance

✅ Many smart cities and highways in India now use this method.

✅ Green Roofing Systems

Some green buildings use rubber layers under rooftop gardens or water tanks to:

Reduce heat

Prevent leakage

Act as anti-vibration pads

Rubber sheets made from tyre recycling machine outputs are affordable and durable.

Supportive Technology to Scale Construction Materials

You can expand your output using:

👉 Tyre to Fuel Oil Machine – Produce fuel for factory operations 👉 Continuous Pyrolysis Plant – Convert large volumes of tyre waste 👉 Waste Oil Distillation Machine – Refine pyrolysis oil for generator and machinery use

Why Construction Firms Prefer Recycled Tyre Materials

Cost-effective vs traditional materials

Lightweight yet strong

Environmentally certified

Eligible for green building credits (IGBC, LEED)

Easy to transport and install

Case Studies of Tyre-Based Green Projects

Kolkata Smart City Roads – Rubberized asphalt roads made using recycled tyre rubber

Green School Playgrounds – Built with shock-absorbing recycled rubber mats

Private Villas in Bengaluru – Use rubber powder in driveway pavers

Conclusion

With rising demand for green infrastructure, the tyre recycling machine offers a golden opportunity for construction companies to adopt sustainable practices while reducing costs. From roads and rooftops to tiles and flooring — tyre waste is reshaping the future of eco-friendly building.

👉 Want to start producing rubber-based construction materials? Connect with Veera Group for tyre recycling machines, plant setup, and product guidance.

Reply “give another blog” to keep the series going strong!

0 notes

Text

Responsible Disposal of Tyres: Sustainable Solutions for Tyre Recycling

The disposal of tyres is a critical environmental issue worldwide. Millions of used tyres are discarded each year, contributing to pollution and waste buildup. Improper tyre disposal can lead to severe environmental consequences, including soil contamination, fire hazards, and breeding grounds for disease-carrying pests.

To combat these issues, tyre recycling has become a key solution for reducing waste and promoting sustainability. By adopting responsible disposal methods, individuals and businesses can contribute to a cleaner and greener environment.

Why Proper Tyre Disposal Matters

The improper disposal of tyres poses several environmental and health risks:

Landfill Overload: Tyres take up significant space in landfills and decompose very slowly.

Fire Hazards: Stockpiled tyres are highly flammable and can burn for long periods, releasing toxic fumes.

Pest Breeding Grounds: Water trapped inside discarded tyres creates an ideal breeding ground for mosquitoes and other pests.

Responsible tyre disposal and recycling help minimize these risks and turn waste into valuable resources.

Sustainable Tyre Recycling Methods

Tyre Retreading Retreading extends the life of tyres by replacing the worn-out tread with new rubber. This process is cost-effective and environmentally friendly, reducing the demand for new tyres.

Crumb Rubber Production Old tyres can be shredded into small granules known as crumb rubber, which is used in various applications such as playground surfaces, athletic tracks, and rubberized asphalt.

Tyre-Derived Fuel (TDF) Shredded tyres can be used as an alternative fuel source in cement kilns, paper mills, and power plants. Tyre recycling into fuel helps reduce reliance on fossil fuels.

Upcycling into New Products Recycled tyre materials are repurposed into new products, such as:

Flooring materials

Artificial turf infill

Rubberized railway sleepers

Garden mulch and pathways

Legal and Eco-Friendly Disposal Services

Many countries have strict regulations regarding tyre disposal. Licensed recycling facilities and collection centers ensure that tyres are processed in an environmentally responsible manner. Businesses and individuals should use certified services to dispose of their tyres properly. Read Full Article From Here: https://medium.com/@apsrecycling1/responsible-disposal-of-tyres-sustainable-solutions-for-tyre-recycling-2bb566e5d874

#tyre rubber recycling#tyre recycling#Tyre recycling process#Waste Tyre Collection Service#Scrap Tyre Collection#Scrap Tire Recycling#disposal of tyres#waste disposal recycling#tyre recycling solutions#sustainable waste disposal#Recycling products

0 notes