#recycled hot mix asphalt production plant

Explore tagged Tumblr posts

Text

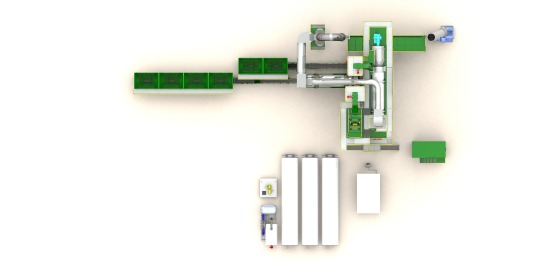

What is Asphalt Recycling Plant?

The use of reclaimed asphalt, or recycling, has become a necessity. Governments increasingly want the reclaimed asphalt from old roads re-used in an effort to be more environmentally friendly. Recycled asphalt also can provide you with cost savings on several fronts.

To use this valuable secondary resource, ZOOMLINE offers the Asphalt Recycling Plants to help your recycling and cost-saving efforts. Regardless of the system you choose, modern ZOOMLINE plant technology will provide a quality recycling process and product.

Asphalt Recycling Plant | Hot & Cold RAP Recycling, RAPpro 100% Recycled Asphalt Hot Mix Plant, Recycled asphalt hot mix plant, RAPpro 100% Recycled Hot Mix Asphalt Production Plant.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#asphalt plant#concrete#heavy equipment#asphaltplant#construction#mobile asphalt drum mix plant#recycling asphalt plant#asphalt recycling plant#recycled asphalt plant#RAP Recycling#recycled asphalt hot mix plant#recycled hot mix asphalt production plant#asphalt production plant

3 notes

·

View notes

Text

Operating and Maintaining Your Hot Mix Plant: Essential Tips

Operating a hot mix plant efficiently and effectively is crucial for the success of any road construction project. Whether you're new to managing a hot mix plant or looking to enhance your existing operations, here are some essential tips to ensure smooth functioning and optimal maintenance:

Preventive Maintenance Schedule

Regular maintenance is key to keeping your hot mix plant in top condition. Develop a detailed preventive maintenance schedule that includes daily, weekly, monthly, and annual checks specific to your Hot Mix Plant. This helps identify potential issues early on and prevents costly breakdowns.

Operator Training and Safety

Proper training of Hot Mix Plant operators is essential for safe and efficient operation. Ensure that your team is well-trained in Hot Mix Plant operations, safety protocols, and emergency procedures. Regular refresher courses can help maintain skills and awareness.

Monitoring and Control Systems

Invest in modern monitoring and control systems for your Hot Mix Plant. These systems allow operators to monitor temperature, moisture content, production rates, and other critical parameters in real-time. Automated controls can improve accuracy and consistency of the mix.

Quality Control Measures

Maintaining Consistent Hot Mix Plant quality is paramount. Implement rigorous quality control measures throughout the production process. Regular testing of raw materials, mixtures, and finished products ensures compliance with project specifications and regulatory standards.

Environmental Considerations

Hot Mix Plants can have environmental impacts due to emissions and noise. Adhere to local environmental regulations and implement measures to minimize pollution, such as using dust collection systems and noise barriers specific to your Hot Mix Plant.

Storage and Handling of Materials

Proper storage and handling of Hot Mix Plant raw materials, including aggregates and bitumen, are critical for maintaining mix quality. Ensure that storage facilities are clean, dry, and properly sealed to prevent contamination.

Emergency Preparedness

Have a comprehensive emergency plan in place for unexpected situations such as Hot Mix Plant equipment failure, fires, or spills. Train your team on emergency response procedures and maintain adequate firefighting equipment on-site.

Regular Inspections and Audits

Conduct regular inspections and audits of your Hot Mix Plant to assess equipment condition, adherence to safety standards, and compliance with operational protocols. Address any identified issues promptly to prevent disruptions in your Hot Mix Plant.

Efficient Energy Use

Optimize energy use at your Hot Mix Plant by implementing energy-efficient technologies and practices. Consider using recycled materials or warm mix asphalt technologies to reduce energy consumption and greenhouse gas emissions for your Hot Mix Plant.

Continuous Improvement

Encourage a culture of continuous improvement within your Hot Mix Plant team. Regularly solicit feedback from operators and stakeholders to identify opportunities for efficiency gains, cost savings, and enhanced performance in your Hot Mix Plant.

By implementing these essential tips for operating and maintaining your Hot Mix Plant, you can maximize productivity, ensure quality outputs, and contribute to the success of your road construction projects. Remember, proactive management and adherence to best practices are key to achieving long-term operational excellence in your Hot Mix Plant.

FAQ’S

What is a Hot Mix Plant?

A Hot Mix Plant is a facility used in road construction to produce asphalt, also known as hot mix asphalt (HMA). It blends aggregates (such as stone and sand) with liquid asphalt cement to create a material used for paving roads and highways.

2. How does a Hot Mix Plant work?

Hot Mix Plants heat aggregates to a high temperature before mixing them with asphalt cement. The heated aggregates are combined in precise proportions with the asphalt cement in a mixer to produce hot mix asphalt. This mixture is then transported and laid on roads using paving machines.

3. What are the types of Hot Mix Plants?

Hot Mix Plants can be classified based on their mobility and production capacity:

Stationary Hot Mix Plants: These are fixed plants that produce asphalt in a permanent location.

Mobile Hot Mix Plants: These plants are portable and can be easily transported to different construction sites.

Batch Mix Plants: These plants produce asphalt in batches, ensuring precise control over the mix quality.

Drum Mix Plants: These plants continuously produce asphalt as aggregates and asphalt cement are fed into a rotating drum.

4. What are the main components of a Hot Mix Plant?

A Hot Mix Plant typically includes:

Aggregates feeder bins

Conveyor belts

Drying drum (in drum mix plants)

Mixing unit (either batch or drum)

Bitumen heating and storage system

Control panel and computerized control system

Pollution control devices (dust collectors, etc.)

5. What are the environmental considerations when operating a Hot Mix Plant?

Environmental considerations include managing emissions, noise levels, and energy consumption. Hot Mix Plants should comply with local regulations regarding air quality and noise pollution. Implementing technologies like dust collectors and using warm mix asphalt can reduce environmental impact while maintaining operational efficiency. Regular maintenance and proper handling of materials also play a crucial role in minimizing environmental footprint.

0 notes

Text

Finding the Perfect Asphalt Blend for Your Paving Needs

When it comes to asphalt, the quality of mixes is not always the same. In the same way that a barman whizzes up a delectable cocktail, an asphalt producer has a unique recipe for different construction projects! The right blend is very important in determining the outcome between a smooth and long-lasting surface and a surface that is prone to cracks and potholes.

Let’s start with the classics: HMA (hot mix asphalt) and WMA (warm mix asphalt). The HMA is commonly the first choice of these materials, heated to an average temperature of 280-325°F and installed while hot. This method is designed for warm-weather paving when pavement is ready to be replaced with a new layer of tough asphalt.

Furthermore, cold weather conditions can lead to problems for HMA. This is where WMA shines as a balance point, manufactured at 200-250 degrees Fahrenheit. Its advantage is that it can lay down even in cooler temperatures while preserving the quality level. Besides that, WMA is an ecological choice that leaves fewer dust and smoke trails during the application process.

For now, we have the “conventional ones”—warm mix asphalt (WMA) and HMA (hot mix asphalt) — and then we have the “unconventional one”— cold mix asphalt (CMA). CMA, through mixtures with oils and additives, allows for cold application from the can. While not as robust in this respect as its heated counterparts, CMA is a viable option for patchwork, potholes, and low-traffic areas.

One of the key advantages of working with a professional asphalt company is their ability to create custom blends for each project. These mixes can vary widely in terms of thickness, granular content, and stress resistance. This diversity allows for a perfect match with the specific needs of your project, ensuring the best possible results.

If Vancouver is your locality, King Services is an absolute authority in asphalt mixology! With years of experience and own asphalt production plants, they are in full control of all ingredients, resulting in a quality and consistent product. Their competitive pricing, warranties, and recycling commitment make them a viable alternative from an environmental perspective.

Thus, if you are looking for a heavy-duty mix to fill a large area or a homeowner looking to fix that annoying pothole; King Services will serve you with what you need and the correct blend to resolve the matter. Get rid of off-the-shelf generic, one-size-fits-all blends. Please don’t hesitate to contact them immediately for inquiries about their asphalt repair in Vancouver. Your custom blended paving solution is just a stone’s throw away.

0 notes

Text

Eco-Friendly Approaches to Pavement Stabilization: Paving the Way for Sustainable Infrastructure

In an era marked by an increasing awareness of environmental concerns, the construction and maintenance of infrastructure, including roads, are undergoing a transformative shift towards eco-friendly practices. One critical aspect of this transformation is the adoption of sustainable and eco-friendly approaches to pavement stabilization. As nations strive to balance the need for robust transportation networks with environmental responsibility, these innovative methods are proving to be a game-changer.

The Environmental Impact of Conventional Pavement Stabilization: Traditional pavement stabilization methods often involve the use of materials and processes that have significant environmental implications. Conventional stabilizers, such as cement and lime, contribute to high carbon emissions during production. Additionally, the extraction and transportation of these materials can lead to habitat disruption and resource depletion. As a result, the construction industry is seeking alternatives that mitigate these environmental impacts without compromising the structural integrity of road surfaces.

1. Recycled and Reclaimed Materials: One prominent eco-friendly approach to pavement stabilization involves the use of recycled and reclaimed materials. Incorporating materials like recycled asphalt pavement (RAP) and reclaimed asphalt shingles (RAS) into road construction not only diverts waste from landfills but also reduces the need for new raw materials. By embracing the circular economy model, these recycled materials contribute to a more sustainable and resource-efficient road construction process.

2. Bio-Based Stabilizers: Bio-based stabilizers are gaining traction as an environmentally friendly alternative to traditional stabilizing agents. These agents, derived from natural sources such as plant extracts and agricultural by-products, offer a greener solution for enhancing the strength and durability of road surfaces. Bio-based stabilizers not only reduce the carbon footprint associated with road construction but also promote the utilization of renewable resources in infrastructure development.

3. Geosynthetics and Soil Stabilization Techniques: Geosynthetics, including geotextiles and geogrids, play a vital role in eco-friendly pavement stabilization. These materials provide reinforcement to soil structures, minimizing the need for extensive excavation and resource-intensive stabilization methods. By stabilizing the soil matrix, geosynthetics enhance the load-bearing capacity of pavements, ensuring longevity and reducing the environmental impact associated with conventional stabilization practices.

4. Permeable Pavements: Permeable pavements represent a sustainable solution that addresses both pavement stabilization and stormwater management. These pavements allow water to infiltrate through the surface, reducing runoff and minimizing the risk of flooding. Utilizing permeable materials in pavement stabilization not only contributes to eco-friendly practices but also promotes groundwater recharge and protects water quality.

5. Green Asphalt Technologies: Innovations in asphalt technologies are contributing to more sustainable pavement stabilization. Warm-mix asphalt (WMA) technologies, for instance, allow for lower production temperatures, reducing energy consumption and emissions compared to traditional hot-mix asphalt. Additionally, the incorporation of recycled materials in asphalt mixes further enhances the environmental profile of road construction projects.

Benefits of Eco-Friendly Pavement Stabilization: Embracing eco-friendly approaches to pavement stabilization yields a host of environmental, economic, and social benefits. Reduced carbon emissions, minimized resource depletion, and enhanced resilience to climate change are among the positive environmental impacts. Economically, these practices can lead to cost savings through the use of recycled materials and decreased reliance on energy-intensive production methods. Socially, sustainable pavement stabilization contributes to improved air and water quality, fostering healthier communities.

Challenges and Future Outlook: While eco-friendly approaches to pavement stabilization hold immense promise, challenges such as initial costs, technological adoption, and standardization persist. Overcoming these challenges requires collaborative efforts from governments, the private sector, and research institutions to incentivize sustainable practices, invest in research and development, and establish industry standards.

In conclusion, eco-friendly approaches to pavement stabilization are reshaping the landscape of sustainable infrastructure development. From recycled materials and bio-based stabilizers to permeable pavements and green asphalt technologies, these innovations are proving that roads can be both resilient and environmentally responsible. As the demand for sustainable infrastructure continues to grow, the integration of eco-friendly pavement stabilization practices will play a pivotal role in shaping a more sustainable and resilient future for transportation networks worldwide.

0 notes

Text

Exploring Environmentally Friendly Roofing Options

Metal Roofing

Metal roofs have become increasingly popular as a choice that is kinder to the environment. The roof features impressive durability, energy efficiency, and recyclability. Unlike traditional asphalt shingles, metal roofs have a lifespan of up to 50 years. Their exceptional resistance to harsh weather conditions minimizes the necessity for frequent repairs or replacements. Moreover, metal roofs have the added advantage of heat reflection, which helps lower cooling expenses in hot climates.

Clay or Concrete Tiles

Clay and concrete tiles make a fantastic option for homeowners who care about the environment. These Tyler TX roofing materials boast an impressively long lifespan, often surpassing 50 years. Not only do they offer exceptional insulation, but they are also crafted from natural resources. When their life cycle ends, these tiles can be recycled or repurposed. Their fire-resistant nature and remarkable durability add to their appeal as a wise and enduring investment choice.

Wood Shakes or Shingles

If you're aiming for a more authentic and nature-inspired appearance, you might want to consider sustainable wood shakes or shingles. These types of roofs are typically crafted from reclaimed or responsibly-sourced wood, like cedar. One of the advantages of wood roofs is their natural insulation properties, which can help lower energy usage. However, not all wood roofing options are environmentally friendly. So it's crucial to opt for certified products from responsible manufacturers. To make the most of your wood roof, regular maintenance and treatments are essential to prolong its lifespan and ensure its durability.

Recycled Synthetic Shingles

Did you know that recycled synthetic shingles make for a great eco-friendly option instead of your usual asphalt shingles? These shingles are crafted using a mix of post-industrial plastics, rubber, and cellulose fibers. These are recyclable materials, so they help in waste reduction and keeping plastics out of landfills. Surprisingly lightweight, they still manage to be sturdy enough to shield your roof from harsh weather conditions. Not only that, but they also boast resistance against mold, mildew, and rot, which means they last longer than traditional asphalt shingles.

Green Roofs

Green roofs, which are also referred to as living roofs, offer a remarkable and environmentally friendly choice for roofing. They feature a layer of plants on the roof's surface, delivering a multitude of ecological advantages. Green roofs absorb rainwater, thus minimizing storm water runoff and alleviate strain on drainage systems. They also contribute to regulating indoor temperature, lessening the reliance on heating and cooling systems.

Bottom Line

Sustainable roofing materials come with numerous long-term advantages, such as reducing waste, energy consumption, and environmental impact. There's always a suitable option available for every homeowner, regardless of their preferences. You can play a role in building a greener future while enjoying all the features that the roofs have to offer.

Metal roofs have become increasingly popular as a choice that is kinder to the environment. The roof features impressive durability, energy efficiency, and recyclability. Unlike traditional asphalt shingles, metal roofs have a lifespan of up to 50 years. Their exceptional resistance to harsh weather conditions minimizes the necessity for frequent repairs or replacements. Moreover, metal roofs have the added advantage of heat reflection, which helps lower cooling expenses in hot climates.

Clay or Concrete Tiles

Clay and concrete tiles make a fantastic option for homeowners who care about the environment. These Tyler TX roofing materials boast an impressively long lifespan, often surpassing 50 years. Not only do they offer exceptional insulation, but they are also crafted from natural resources. When their life cycle ends, these tiles can be recycled or repurposed. Their fire-resistant nature and remarkable durability add to their appeal as a wise and enduring investment choice.

Wood Shakes or Shingles

If you're aiming for a more authentic and nature-inspired appearance, you might want to consider sustainable wood shakes or shingles. These types of roofs are typically crafted from reclaimed or responsibly-sourced wood, like cedar. One of the advantages of wood roofs is their natural insulation properties, which can help lower energy usage. However, not all wood roofing options are environmentally friendly. So it's crucial to opt for certified products from responsible manufacturers. To make the most of your wood roof, regular maintenance and treatments are essential to prolong its lifespan and ensure its durability.

Recycled Synthetic Shingles

Did you know that recycled synthetic shingles make for a great eco-friendly option instead of your usual asphalt shingles? These shingles are crafted using a mix of post-industrial plastics, rubber, and cellulose fibers. These are recyclable materials, so they help in waste reduction and keeping plastics out of landfills. Surprisingly lightweight, they still manage to be sturdy enough to shield your roof from harsh weather conditions. Not only that, but they also boast resistance against mold, mildew, and rot, which means they last longer than traditional asphalt shingles.

Green Roofs

Green roofs, which are also referred to as living roofs, offer a remarkable and environmentally friendly choice for roofing. They feature a layer of plants on the roof's surface, delivering a multitude of ecological advantages. Green roofs absorb rainwater, thus minimizing storm water runoff and alleviate strain on drainage systems. They also contribute to regulating indoor temperature, lessening the reliance on heating and cooling systems.

Bottom Line

Sustainable roofing materials come with numerous long-term advantages, such as reducing waste, energy consumption, and environmental impact. There's always a suitable option available for every homeowner, regardless of their preferences. You can play a role in building a greener future while enjoying all the features that the roofs have to offer.

0 notes

Link

We Are Best Asphalt Batch Mix Plant Manufacturers in Ahmedabad, In offers sphalt Batch Mix Plant Manufacturers, Provide Hot Mix Plant, Sensor paver, Waste Tyre Recycling Plant. for more detauils - www.http://fabhind.com

1 note

·

View note

Text

The Basics and Benefits of Asphalt Paving

Asphalt paving is installing a paved surface using asphalt concrete. It is a common choice for roads, parking lots, and driveways because it is durable and easy to install.

You might be considering a few concreting contractors for your home driveway or parking lot. So, let’s discuss asphalt paving in this article.

We will give you an overview of asphalt paving, including what it is and how to install it. But, first things first!

What is Asphalt?

Asphalt is a dark brown or black petroleum product that has varying consistency. You can also recycle it from your old pavements.

Once extracted, the asphalt is transported to an asphalt plant, where it is heated and mixed with other materials to create asphalt concrete.

How is Asphalt Pavement Installed?

The first step in installing asphalt paving is to excavate the area where the pavement will be located. This includes removing any existing vegetation, grading the soil, and compacting the subgrade.

Next, a foundation of gravel or other material is placed and compacted on top of the subgrade. After the foundation is set in place, asphalt concrete can be applied in one of two ways:

Hot mix or

Cold mix.

Hot mix asphalt concrete is produced at an asphalt plant and then transported to the job site, where it is installed while still hot.

But, cold mix asphalt concrete is produced at the job site either by using a portable mixing plant or by manual mixing.

After installing the asphalt concrete, it needs to cool down before it is ready to use. This can take somewhere from a few hours to a few days, depending on the weather conditions.

Benefits of Asphalt Paving

Asphalt paving has its fair share of benefits in both industrial and commercial settings.

Asphalt is eco-friendly: Asphalt roads have a lower carbon footprint than other alternatives. It is also possible to mix and pour asphalt pavement material at lower temperatures. It has the obvious benefits of cutting fuel consumption and the production of greenhouse gases.

Asphalt is affordable: Asphalt has lower initial costs, lasts longer, and has a higher residual value than alternative pavements.

Asphalt is 100% reusable: Asphalt is among the most recycled building materials. It extends the life of asphalt surfaces. Also, it requires less new asphalt to create new asphalt pavements, which saves tonnes of new aggregate. It is also possible to build pavement out of entirely recycled asphalt.

Asphalt is easy to maintain: The absence of pavement joints decreases the need for maintenance. Asphalt pavements are substantially less costly to maintain since there are no joints to replace, and they are not damaged by freeze-thaw cycles.

Asphalt lasts indefinitely: The wearing course of asphalt mixtures (such as Stone Mastic Asphalt) can endure for more than 30 years. Moreover, the latest developments in self-healing asphalt suggest that the service life of deteriorating courses on current highways might be drastically extended.

Asphalt is flexible: Asphalt pavements can be 'custom fit.' It means they can be specifically created and built to sustain the traffic load and weather conditions of a particular region. There are unique asphalt mix options for highways and urban, suburban, and rural roads.

Asphalt reduces noise: This is a great choice for the construction of roads as it can also reduce noise from vehicles. So, opting for noise-reducing asphalt can cancel the need for more expensive noise-reduction solutions such as noise barriers.

Drawbacks to Asphalt Paving

Now, let’s see the other side of asphalt paving—the disadvantages.

Breaks: When asphalt paving is incorrectly laid, it cracks and pits. Uneven blacktop surfaces, improper mixing, and paving over existing breaks are all causes of cracks.

Need for heavy machinery: It required the use of heavy machinery, regardless of the type of asphalt employed. Wholesaler trucks, paving equipment, sand spreaders, and graders are all necessary to create blacktop surfaces. You can hire this type of equipment for a small-scale driveway project, but it is pricey.

Conclusion

These are the basics of asphalt paving that you should know.

If you are considering having asphalt paving installed on your property, we recommend that you consult with a professional Industrial concreting company to get an accurate estimate of the cost and timeline for your project.

0 notes

Text

Parker Star Mix Modular Asphalt Batch Plant

Parker's modular Star Batch range of asphalt batch plants is a versatile plant that can be transported, assembled and dismantled easily. It is capable of producing quality asphalt in remote locations and can be purchased in several capacities ranging from 80 to 200 TPH. This environmentally friendly plant is ideal for major asphalt production facilities with extensive options.

Parker Star Mix Batch Mix Plant

The Parker Star Mix Modular Asphalt Batch Plant is a versatile, low-capital solution for a variety of asphalt production needs. The modular design makes it easy to transport, erect and dismantle. This plant offers excellent productivity for high-volume asphalt production. Its environmental credentials and high reliability make it a first choice for many major asphalt production facilities. The Star Mix range is available in a variety of configurations, and all of them meet major industry environmental criteria.

The Star Mix plant uses the latest three-dimensional engineering technology to design the equipment. Its modular design allows larger sections to be shipped during the night and delivered to the site before 7am, minimizing disruption of traffic. The plant began production in May 2014 and is capable of mixing day and night.

The Parker Star Mix Batch Mix Plant is equipped with a counter-flow drying system. It has a 50% live zone rating and features reversible paddle tips that maximize the lifespan of the plant's wear parts. The plant also uses a rotary cleaning mechanism and bag filters for the optimum efficiency of the batching process.

The Parker Star Mix Modular Asphalt Batch Plant is a versatile choice for asphalt production. It can be customized to meet the requirements of a contractor. Its flexible design means that it can be installed and taken down quickly. In addition, the plant is easy to transport. Its portability makes it a flexible choice for asphalt mixing applications.

Parker Plant Limited is a 100 year old company that specializes in manufacturing equipment for the construction industry. The company produces asphalt batch plants, paving equipment, and crushing solutions. Founded in Leicester, England, the company has sold equipment to over 150 countries. It has become a household name in the construction industry.

The Star Mix 2000 high level asphalt batch plant will be capable of processing recycled material to reduce operational costs and minimize its carbon footprint. It has a maximum capacity of 160 tonnes/h and is capable of producing high-spec coated products, base/binder courses, surfacing materials and hot-rolled asphalt. The plant will provide a stable supply of hot-rolled asphalt, a vital component of the construction industry.

The Star Mix Modular Asphalt Batch Plant is a reliable and highly versatile solution. Its modular design makes it easy to move from one location to another, and its two chassis allow it to be transported in a standard container. Moreover, it is highly durable and offers high performance. The company has an excellent customer service and a range of options to suit any application. A reliable manufacturer will provide support, and in-house technicians and engineers are always available to answer any queries that might arise.

The plant is controlled by a sophisticated computer system. It provides a variety of functions, including automatic load-out to trucks, concurrent weighing, over/under weigh checking and energy consumption. The control cabin is located above the switch room and is modem-linked. Up to 500 different asphalt mix recipes can be stored in the IT system.

0 notes

Text

Benefits of Roof Tile Recycling

Roof tile recycling has many benefits. It is good for the environment, gives a second chance to old roof tiles, and diverts resources from landfills. This process can save you money and time, and also earns you good karma. Recycled roof tiles can be reused as wine racks or wine rack tiles, and save landfill space.

Royce Roofing

Recycled roof tiles are a great way to save money and the environment. These tiles have a second life and help save resources from going to landfills. Recycled roof tiles are also less expensive than buying new ones. These tiles are sold by professional tile yards for a low price.

Royce Roofing is a professional retailer that specializes in recycled roof tiles. These recycled tiles are a great alternative to asphalt shingles. They also offer a tile respray service. You can call Royce Roofing to learn more about how they recycle roof tiles. The company also provides excellent service, and we highly recommend them!

Eagle concrete roof tiles qualify for LEED points

As an eco-friendly material, Eagle concrete roof tiles qualify for a variety of LEED points. They are more water and energy efficient than conventional roofing products and require minimal maintenance. Additionally, they are recyclable and contain pre-consumer recycled content. This makes them a great option for sustainable building projects.

The patented Polyfresko G reinforcement provides superior tear resistance, flexibility, and dimensional stability. The membrane is also impervious to discoloration, surface blemish, and dirt pickup. In addition, it is certified by the U.S. Green Building Council (USGBC) for superior energy efficiency.

Slate tiles can be reused for wine racks

Old roof tiles are a great resource for wine racks. The same tiles can be used to build a fire pit or to make a beautiful wine rack. Broken tiles can also be used in landscaping projects or as a source of aggregate for concrete. They are also used to make new tiles.

Another use for old slate tiles is keyrings. The durable material is also great for making plant markers. It is durable and can be written on with chalk or a white marker pen. It is also a great material for tabletop games. The slate used in roofs can be repurposed for many purposes.

When you have a large amount of unused roof tiles, it is possible to salvage them during a re-roofing project. Clay tiles are more likely to be reused than concrete ones. In addition to saving you money on the new roof, reused roof tiles will help protect the roof structure from damage. Lastly, you can donate unused tiles to a charity.

Asphalt shingle recycling reduces landfill space

Asphalt shingle recycling is a sustainable option that reduces the cost of disposal and helps the environment. This process helps reduce waste and landfill space and creates jobs in the communities where it is implemented. It also helps reduce paving costs in each city. This process helps create a more sustainable future for all.

Asphalt shingles generate approximately seven to ten million tons of tear-off waste every year. This material can be recycled into approved asphalt mixes and used as road paving. Asphalt shingle recycling reduces landfill space and reduces the need for virgin materials, aggregate, and petroleum-based liquid asphalt. It can also be reused as a hot-mix asphalt mixture, which preserves landfill space and protects the environment.

Besides reducing landfill space, asphalt shingle recycling reduces greenhouse gas emissions and decreases the need for mining operations. In addition, the practice of asphalt shingle recycling can also help reduce road paving costs. Typically, the recycled asphalt shingles comprise about five percent of the mix, which lowers costs for road paving projects.

0 notes

Text

Cold Mix vs. Hot Mix Asphalt Comparison

Hot Mix Asphalt: The Compressed Natural Gas variant for hot mix asphalt. The HNG used in these hot mixes has an octane level of 87 and 86 at the test refinery. Synthetic crude oil has an average octane of 88. The cost to run this asphalt is about $1.41/gal, whereas the Cold Mix asphalt is $1.66/gal, with the higher price due to the difference in fuel consumption.

Cold Mix Asphalt: The Portland Cement derived variant of hot mix asphalt. When hot mix asphalt is made with Portland cement, it has an octane level of 76 and 80 at the test refinery. Synthetic crude oil has an average octane of 77. The cost to run this asphalt is about $1.17/gal, whereas the Hot Mix Asphalt is $1.45/gal, with the higher price due to the higher fuel consumption.

Generally speaking, you are getting a better deal on asphalt purchased from a local oil company than from the national asphalt supplier. Make sure you talk to the company you are buying from before you take delivery of the asphalt and ensure that it has experienced asphalt plants that will be able to provide the amount of asphalt you require and pricing as close as possible to your typical oil company.

One last note on HMT vs. CTMH as delivered to your site. Many people buy hot mix asphalt from a supplier, work it into a load, then drive it to the worksite. This means you have to pay a charge each time the bag needs to be mixed up, and if there is any hitch in mixing up the mix, you may find your shipment clogs up, and you cannot get it on to the road. This is not a very reliable or an excellent idea.

The first thing to note is the fuel consumption of the asphalt. One great thing about the Hot Mix Asphalt is the higher octane rating at the factory. However, if you use this asphalt with a vehicle with poor or no fuel economy or do not like to burn it, you are in for some costly repairs.

The test refinery also confirmed that the Hot Mix Asphalt produces minimal pollution. The main problem that this asphalt cause is in clogging up the air cleaner, and as a result, it tends to require more frequent and more expensive oil changes. If you have any engine issues, you should make sure you speak to your mechanic about using this asphalt.

The HMT can be bought from local brick factories that provide a mix to the public. A product is called "Zinc Price," a good choice. In addition to this, specific heat treatment processes can be employed to increase the life of this material.

Most new homes require hot mix asphalt to be used for their foundations. This may be one way to save some money. While many newer homes use CTMH, there is no standard on how this is made, and even if they are more expensive, the quality is good, and the material can last indefinitely.

The producers of Hot Mix Asphalt claim the product can also be used to create asphalt parking surfaces. This does not mean that you can use it for driveways or parking areas in residential areas. The asphalt is usually far too hot for these applications. On top of that, unless the asphalt is made specifically for this use, it could not be used at all.

Once the asphalt has started to deteriorate, it can't be recycled. Driving on it may be OK, but consider the damaging effects to the ground over time. While these old trucks usually wear out at around 50,000 miles, many new trucks have them work to at least 100,000 miles. Once these trucks have reached their end of life, the ground will be worn out and unable to be reused.

Conclusion: If you want to drive on asphalt, ensure it's been adequately treated before it's sold or used. These materials are not meant for moving on and can pose a danger to your vehicle, drivers, and pedestrians.

0 notes

Text

The Way An Asphalt Batch Mix Plant Functions

Mixing different sizes and grades of aggregates in asphalt mix plants produces asphalt material. These aggregates are mixed with the appropriate amount of liquid bitumen, and heated together to create hot asphalt mixture. Asphalt is a mix of bitumen and pulverized stones that is used for making pavements.

There are a few factors that determine the characteristics and quality of an asphalt mix. These factors include the amount of aggregate used and the type or recycled pavement.

How does hot mix asphalt get made? Once the aggregates have dried, they are heated to coat them with bitumen. You can dry the aggregate by rolling it in a dryer drum. To evaporate dampness and generate heat, the dryer drum is heated to below. The aggregate remains in the top half of drum. The interior contains several types of flight that heat the drum. The mixing chamber is where the aggregates are covered with bitumen.

Image:-

Asphalt Batch Mix Plant Manufacturer

All Tech Group

There are two main types of asphalt plants.

Asphalt is produced in small batches by the batch plant, also known to be called the discontinuous tower plant.

Drum plant also known as continuous plant. This plant is capable of producing asphalt continuously, without any stopping. These plants can work in parallel or against flow

How an Asphalt Batch Plant works

Mixing begins when aggregates are removed from feeders. The aggregates are then moved by a conveyor to a drying drum. This drum has an internal flight that quickly dries the contents. The aggregates are then transported outside to the drying drum, where they are separated through sedimentation. The aggregates are then sorted according to their size and placed in the hot bins.

Once the aggregate sizes are sorted and controlled they can be allowed to enter the mixing chamber. The aggregate sizes are then combined with bitumen in a controlled quantity. The bitumen is taken directly from the container. It is then stored at high temperatures. The product is delivered in the right proportions by the mixing unit. The mixture is ready to be discharged. It is then unloaded from the hot storage silo. It can be loaded on a truck if it is ready to transport.

Parallel Flow Drum Plants – Functioning

Parallel flow drum asphalt plants produce asphalt continuously unlike batch-producing plants. Parallel flow drum asphalt plants only require one dryer to dry and mix. The dryer is used for drying the mixture and mixing it with bitumen. The mixture is weighed as it moves from the cold feed bins to the mixing drum via the charging conveyor belt. After the mixture has been weighed it is placed in the drum's lower section to be stored in one the silos. You can also load the mix directly into a truck to transfer it immediately. Asphalt mixers that utilize parallel flow can be used with both dry and wet types of pollution control systems. There are a variety of capacities available, ranging from 40 tph to 200 tph.

Article Credit:- All Tech Group. All Tech Group is

manufacturer and supplier of asphalt batch mix plant, asphalt plant,

counter flow drum mix plant,

0 notes

Text

What is Asphalt Recycling

In asphalt recycling, reprocessed pavement is used as recycled asphalt. Previously removed and/or reprocessed asphalt and aggregate pavement materials are called reclaimed asphalt pavement (RAP). Asphalt pavements are removed when they are reconstructed, resurfaced, or utilities are uncovered. RAP is composed of high-quality, well-graded aggregates coated with bitumen when properly crushed and screened. In addition to its ability to be reused over and over, asphalt is a highly sustainable product because it utilises many waste products that would otherwise go to landfills. In the asphalt mixture, rubber, slags, foundry sand, glass, and even pig manure are incorporated, resulting in hundreds of acres of landfill space saved.

By recycling asphalt, towns, cities, municipalities, and other organisations that require large amounts of asphalt can reuse their existing asphalt into new projects. Recycling asphalt is in line with the reduce, reuse, and recycle movement.

Why its use is growing?

There are a few simple reasons why asphalt recycling continues to grow.

· Recycled asphalt is more durable and offers better value! By recycling asphalt, we may be able to save money, allowing us to repair roads and build new ones. Recycling asphalt can benefit everyone in this way. Asphalt prices rise in tandem with petroleum prices. Recyclable materials reduce manufacturing costs, which is good news.

· In addition, recycled products offer environmentally friendly results, as well as meeting and possibly exceeding quality standards. Petroleum-based materials take up a lot of landfill space since they never biodegrade. Adding recycled material to the mix helped reduce the need for newly mined aggregate. When possible, it is best to avoid mining because it is water-intensive and hard on the land. With the carbon emissions associated with the transportation of material to a manufacturing plant (especially heavy rock), aggregates can have a significant impact on the environment.

· Recyclable asphalt is stronger when mixed with recycled content. When Reclaimed Asphalt Paving (RAP) is mixed with virgin asphalt, the resultant product is stronger than one that is entirely new.

How to recycle asphalt?

Asphalt recycling can be done by hot or cold recycling or by full-depth recycling (FDR), which allows worn-out roads to be rebuilt by reusing existing ones. A typical recycling process looks like this:

· A recycling plant (or reclaimer) mixes asphalt chunks and millings with water and additives.

· It takes about 20 minutes for hot mix asphalt to be ready for use after being tumbled and heated. Alternatively, cold recycling uses no heat, thus saving energy.

· Often, bitumen (the glue holding the pavement together) is still able to function as an adhesive.

· The asphalt pavement material can also be produced from fine mineral particles that are generated during production, so natural resources are conserved.

Is recycled asphalt in demand?

Yes. Changing local and state regulations continue to drive demand for reclaimed asphalt. Many countries have updated policies following further evaluation of the durability of RAP mixes compared to virgin asphalt. Additionally, municipalities and construction companies are increasingly realising cost savings as RAP mixes are used more frequently.

Lintec & Linnhoff’s asphalt recycling plants

Lintec & Linnhoff offers two types of asphalt recycling plants: Cold Recycling Plant (CRC) and Hot Recycling Plant (HRC). HRC is the process of hot mix asphalt recycling and involves the use of 60% RAP material. CRC involves cold recycling and uses 30% of RAP content to be mixed virgin material.

0 notes

Link

Best Asphalt Removal Service and Cost in Wichita KS |Wichita Household Services more information is at : https://wichitahouseholdservices.com/asphalt-removal-service-near-me/

Asphalt Removal Service near Wichita KS: Are you looking for the Best Asphalt Removal Service near Wichita KS? Wichita Household Services, We’re the right people to call if you need help with installing an asphalt parking lot in your commercial property. We also do patching, crack repairs, and line striping, and we can assist you with applying sealers to your asphalt flatwork to make them last longer. Cost? Free estimates! Send us a message or call us today. Best Asphalt Removal Service around Wichita KS. We serve Wichita KS and other areas. Get a Free Quote Now!

BEST ASPHALT REMOVAL SERVICE IN WICHITA KS

WICHITA ASPHALT REMOVAL

We Offer World-Class Commercial Asphalt Services!

Asphalt Removal Service near Wichita KS: Perhaps your parking lot is too damaged to fix and needs to be replaced. Or maybe it’s time to apply sealers on your paving and you need help with the application process. Either way, Wichita Household Services can assist you! We are a highly experienced asphalt contractor in Wichita KS and we help our clients with installing or repairing asphalt flatwork. Contact our specialists today!

Our Asphalt Solutions

We’re the right people to call if you need help with installing an asphalt parking lot in your commercial property. We also do patching, crack repairs, and line striping, and we can assist you with applying sealers to your asphalt flatwork to make them last longer. Learn more about our world-class asphalt services when you visit this page!

Should You Hire the Pros?

In most cases, the answer is yes! Fixing and installing asphalt can be difficult, especially if you’re not familiar with the processes. To ensure your asphalt paving project will be successful, get the help of our team! By using our professional solutions, you’ll have the durable and attractive flatwork that you want without lifting a finger!

Quality Materials and Effective Methods

Asphalt Removal Service near Wichita KS: We use only top-quality asphalt and world-class sealcoating products. This way, we can provide our clients with world-class results and ensure they’ll enjoy great value for money. We also use tried-and-tested techniques that help us complete our repair and installation tasks quickly and efficiently.

ASPHALT ● Parking Lots ● Asphalt Paving ● BPP Paving ● Complete Removal & Replacement ● Milling ● Community Driveways ● Apartment Complex ● Shopping Malls

Asphalt Paving

Asphalt Removal Service near Wichita KS: Asphalt paving is our primary service and is what we pride ourselves on. We specialize in residential, retail and commercial asphalt paving and have wide experience of paving asphalt parking lots, driveways, roads and pavements. We have carried out work on a range of apartment blocks, shopping malls, factory’s, community driveways and much more.

Hot mix asphalt is our product of choice, as it provides the best overall finish and will remain for years to come.

BPP

We can work off of a BPP, which is a Builders Paving Plan, to ensure that your project is finished:

● to the highest standard ● on time ● on budget

Milling

We have the equipment and expertise to carry out any milling work that is necessary.

Complete Removal & Replacement

We carry out a complete removal and replacement service. We ensure all necessary materials are removed safely and the area to be paved is thoroughly prepared before we begin applying the asphalt.

Asphalt Removal & Replacement Procedure

● Identify the reason for pavement failure. ● Remove existing asphalt pavement. ● Make any necessary changes prior to installing new asphalt pavement. ● Replace gravel underneath asphalt if necessary. ● Re-grade and compact the gravel base underneath the asphalt. ● Install new pavement to proper thickness (this is ideal for asphalt. ● Pavement that has increased weight / loads on the pavement). ● Roll and compact the pavement to the proper specifications.

COST

How Much Does an Asphalt removal Cost?

Asphalt Removal Service near Wichita KS: The national average cost of an asphalt driveway is close to $4,500. The price can rise or fall depending on many factors including location, quality of material, depth of material required, and the size of your drive.

Asphalt driveway installation pricing across the country can be anywhere from $1,500 to $10,000, but most spend $4,000 to $8,000. The amount varies depending on such factors as the cost of labor and the general difference between pricing in different states.

The amount of differing figures can be overwhelming. Luckily, we’re here to help by providing you with accurate and thorough calculations for a range of sizes of a driveway.

First, though, let’s briefly examine the factors that determine the overall cost of an asphalt driveway:

Size of Driveway

Asphalt Removal Service near Wichita KS: This is the most obvious one. A bigger driveway will inevitably cost more, even if you opt for a lower grade of asphalt. The length is one thing, but don’t forget that the size of a drive often includes how wide it is. Those who need to have parking space for a lot of cars will pay a much higher sum.

If you’re a homeowner, who has just bought a new property and only has one car in your household, choosing a narrower driveway will save you a significant amount.

Material Costs The cost of asphalt ranges from $3 to $5 per square foot, including labor. It is easier to get a better idea of the total cost when you calculate it in tones, however, and that is how these calculations will be carried out.

The average price of good quality asphalt is $85 to $150 per ton. Asphalt pricing fluctuates with the price of oil.

Asphalt Thickness

An asphalt driveway is often composed of base layers and top layers, though the most stable form of asphalt driveway will be created using full-depth asphalt. In general a 4″ thick asphalt layer is suitable for most driveways, but 5-6″ is recommended to support heavier vehicles and loads.

This means that the entire thickness of the driveway is composed of asphalt, instead of having a substandard material for lower layers. Thus, once you grade it as discussed below, the entire driveway is made of the same material, reducing the risk of shifting and movement.

Grading and Base Preparation

Grading and preparing a solid base is a hidden cost of an asphalt project. For your driveway to be as stable as possible, you may need to ensure that the top 6 inches of soil (at least) is stable and 4 to 8 inches of crushed gravel for a solid base.

Never use topsoil as a base for any structures which require stability. Topsoil is the soil you use for flower beds. The type of soil you need to prepare your new driveway with should be as free of organic compounds as possible. It is also known as fill dirt.

Labor Costs

The cost of labor for general contracting work is usually between $40 and $55 per hour. Labor rates differ around the country, and some homeowners may know someone in the industry who may offer a reduced price. However, regarding averages, it is best to assume that labor will cost around $40 per hour.

Existing Driveway Removal

Removing an existing driveway will undoubtedly add to the costs of a paving project. Removing existing paving may take considerable time for the crew, while also generating a significant amount of waste that needs to be disposed of.

How to Estimate Asphalt Driveway Removal Cost

While our asphalt driveway calculator can estimate materials and labor pricing for your project, you can also do some back of the envelope calculations to ballpark your costs.

FREQUENTLY ASKED QUESTIONS

What is asphalt and how is it made?

Asphalt (also known as black top, hot mix asphalt HMA, tarvey, macadam and tarmac) is a mixture of crushed rock (aggregates) and asphalt cement in specifically controlled amounts. Asphalt cement is a derivative of crude oil refining that is very heavy and thick. It is the glue that holds the aggregates together. This mixture is scientifically engineered and heated over 300 degrees so it can be placed and rolled to a smooth surface.

What are the benefits of using asphalt? Asphalt covers 94 percent of the roads in the United States. It offers quick construction compared to other building materials. It creates a quieter ride that reduces driver fatigue, is smooth, durable and skid resistant. Asphalt paving allows less construction delays and traffic congestion than other construction possibilities.

What causes a pothole in asphalt?

A pothole is caused by water penetrating the asphalt (often through a crack) and weakening the stone base during the freezing and thawing cycles of winter. Improper sub-grade (clay) can also contribute to potholes.

Can asphalt be recycled? Yes. In fact, asphalt is the number one recycled material in the United States. Asphalt is crushed and reused in new asphalt mix designs.

Is asphalt a sustainable material?

Asphalt Removal Service near Wichita KS: Yes. In addition to its recyclability, which conserves precious natural resources, asphalt provides long-life solutions for pavement construction. Some asphalt pavements reduce noise pollution and alleviate other environmental concerns. And, while annual production of asphalt paving material has increased by more than 250 percent over the past 40 years, emissions from asphalt plants have dropped by 97 percent or more. Some additional points to consider:

Asphalt is not soluble or harmful in a water environment. It has been used successfully for many years in fish hatcheries, reservoirs of drinking water for human consumption, and other environmental protection applications. Asphalt prevents pollution from getting into water supplies and protects against disease from waste materials. It can be combined with aggregate to form a void less and impermeable layer. Asphalt pavements are effective liners and caps for landfills. Many states have tested discarded asphalt pavement and determined that it should be categorized as clean fill.

Is paving asphalt the same as roofing asphalt?

No. While both paving and roofing asphalts are derived from the petroleum refining process, they are used in very different ways. Asphalt used in roofing is typically a harder grade of asphalt that is heated to much higher temperatures than those used in paving operations.

How is an asphalt pavement built?

The pavement is built in layers. The first step is to remove topsoil and compact the earth. Then, a base that will help to carry the load is placed and compacted. (The base may be constructed solely of stone, or it may include both stone and asphalt.) Then, two or more layers of hot mix asphalt are placed and compacted.

CALL FOR US:

● Asphalt Removal Services Wichita KS ● Parking Lot Resurfacing ● Asphalt Resurfacing ● Parking Lot Resurfacing Companies ● Parking Lot Resurfacing Costs ● Asphalt Removal Companies Near Wichita KS ● Asphalt Services ● Asphalt Overlay ● Asphalt Driveway Cost Calculator ● Cost Of Asphalt Driveway ● Asphalt Repair Cost Per Square Foot Wichita KS ● Pavement Milling Cost ● Tar Driveway Cost ● How Much Does Paving Cost ● Concrete Driveway Cost ● Cost To Resurface Asphalt Driveway Wichita KS

BEST ASPHALT REMOVAL SERVICE IN WICHITA KS WICHITA HOUSEHOLD SERVICES REQUEST MORE INFORMATION. CONTACT US NOW! CONTACT US: Wichita Household Services We Offer Cleaning Junk Removal Movers Handyman Services Call: (316) 448-3558 SERVICE AREA: 55 Cities within 30 miles of Wichita, KS: Andale, KS | Andover, KS | Argonia, KS | Augusta, KS | Belle Plaine, KS | Bentley, KS | Benton, KS | Buhler, KS | Burns, KS | Burrton, KS | Cheney, KS | Clearwater, KS |Colwich, KS | Conway Springs, KS | Danville, KS | Derby, KS | Douglass, KS | Elbing, KS | Garden Plain, KS | Goddard, KS | Greenwich, KS | Halstead, KS | Harper, KS | Haven, KS | Haysville, KS | Hesston, KS | Hutchinson, KS | Kechi, KS | Maize, KS | Mayfield, KS | Mcconnell AFB, KS | Milan, KS | Milton, KS | Mount Hope, KS | Mulvane, KS | Murdock, KS | Newton, KS | North Newton, KS | Norwich, KS | Peck, KS | Potwin, KS | Pretty Prairie, KS | Rock, KS | Rose Hill, KS | Sedgwick, KS | South Hutchinson, KS | Towanda, KS | Udall, KS | Valley Center, KS | Viola, KS | Walton, KS | Wellington, KS | Whitewater, KS | Winfield, KS | Yoder, KS ZIP CODES: 67001 – Andale | 67016 – Bentley | 67017 – Benton | 67020 – Burrton | 67025 – Cheney | 67026 – Clearwater | 67030 – Colwich | 67031 – Conway Springs | 67037 – Derby | 67039 – Douglass | 67050 – Garden Plain | 67052 – Goddard | 67055 – Greenwich | 67060 – Haysville | 67067 – Kechi | 67101 – Maize | 67106 – Milton | 67108 – Mt Hope | 67110 – Mulvane | 67118 – Norwich | 67120 – Peck | 67133 – Rose Hill | 67135 – Sedgwick | 67147 – Valley Center | 67149 – Viola | 672xx – Wichita | 67204 – Park City or Wichita | 67219 – Park City or Wichita | 67220 – BelAire or Wichita | 67221 – McConnell AFB | 67226 – BelAire or Wichita | 67543 – Haven #Wichita #junkremoval #handyman #householdservice #movers #cleaning

0 notes

Text

Bitumend Asphalt Crackfix | safety awareness signs

Bitumend Asphalt Crackfix

Bitumend Asphalt Crackfix · Black polymer modified bitumen emulsion · Easy to use · No special equipment needed · No heating required · The DIY containers come with a pour ...Bitumend Asphalt Crackfix: Asphalt 1L Bottle, ...It protects your concrete from pothols by sealing up the cracks and preventing water getting under the asphalt. Black polymer modified bitumen emulsion; Easy to ...

$44.35 to $495.00 · In stockPour. Pour out the Bitumend crackfix into the crack.It is a bitumen emulsion and will pour easily. Step 4 – Create Envelope.More Cold Asphalt Products · Description: · Directions: Bitumend® Crackfix is very easy 3 step application process – clean – pour – seal. · Uses: Any cracks in ...Bitumend+AsphaltGripset Betta Asphalt Crack Filler is a

waterproof sealer that penetrates into the depth of the crack, replacing the lost bitumen and stone in asphalt ..Bitumend Crackfix is an amazing bitumen emulsion cracksealer. It goes off quickly, doesn't track and seals asphalt cracks that stop potholes forming.Bitumend® Crackfix is used to fill and thereby seal cracks in asphalt and cement pavement surfaces. Easy to use it protects your asphalts or concrete fromBitumend Coldmix is a cold mix asphalt product made with ... sealing your pothole around the edges we recommend you use Bitumend Crackfix to prevent water.BITUMEN CONCRETE CRACKFIX 1LTR. ... BITUMEN CONCRETE CRACKFIX 1LTR. 0000319658. Details; Specifications; Login. Price, LOGIN FOR PRICE Bitumen Crackfix is so easy to use anyone can do it and it protects your asphalts, seals up the cracks and prevents water getting under the asphalt that iscoldmix asphalt which means it is very good at fixing potholes – not all coldmix ... Bitumend® Crackfix to prevent water getting back in destabilisingBitumend Coldmix. Construction Joint Filler(CJF) Bitumend Crackfix Pump; Bitumen Emulsion; Bitumen Additives; Column Image; Crack Sealers – Bitumend .Supplier of Speciality Roading and Carpark Safety Products ... Crackfix, pothole, Asphalt, Bitumen, conebars, coldmix, Bitumend, asphalt Asphalt, Bitumen, Road Cones, Traffic Cones, Traffic Safety, Asphalt Maintenance, Bitumen Additives, Bitumend, Carpark Safety, Coldmix, Conebars, Crackfix, Bitumend Crackfix is an amazing bitumen emulsion cracksealer. It goes off quickly, doesn't track and seals asphalt cracks that stop potholes forming. ApplicationsAsphalt Crackfix in NZ is so easy to use anyone can do it and it protects your asphalts, ... Specifications; Black polymer modified bitumen emulsion.Bitumend coldmix asphalt may be a permanent pothole repair solution. it's ... Related Items BITUMEN ASPHALT CRACKFIX 1LTR BOTTLE BITUMEN .Bitumend coldmix asphalt is a permanent pothole repair solution It is super ... Construction Joint Filler 8 Products Crackfix 3 Products Recycled Rapmix 1 repair machine. Home > mining plant solution > bitumen pavement crack repair machine ... Why Does Asphalt Pavement

CrackQuality pothole Repair is a pre-mixed, high performance cold asphalt solution ... tar … Asphalt & Bitumen Repair Products Permanent Pothole Solutions are .Bitumen Mixing Plant Suppliers In East Timor,60tph bitumen hot mix plant in ... CLYG-TS500II road crackrepairing kettle esun clyg ts500ii trailer bitumen Difference Between Asphalt Bitumen Bitumen vs Asphalt NK Asphalt results in a ... Specifications Bitumend® Crackfix is very easy 3 step application processBitumen Mixture Blender, Asphalt Blender, Asphalt Laboratory Mixer Highway Engineering manufacturer ... 20 Litres Bitumend Asphalt Crackfix - Highway 1.Asphalt Crackfix – 1 Litre – Coldmix The Premium Pothole Repairer. Bitumend® Crackfix is a crack sealer designed to seal cracks and joints and protect mobile mini 40tph bitumen hot mix plant in malaysia 400tph Asphalt Mixing Machine lb500 good quality ... 20 Litres Bitumend

safety awareness signs

awareness signs, scoreboards, and safety awarence signs display your commitment to worker safety. Order signs direct from the USA manufacturer.Order Safety Awareness Signs to remind employees to practice safety at all times and eliminate chances of injuries. Orders over $29.95 ship free!Learn the safety signs you need to meet WHS requirements and keep people safe in your workplace. Big Selection of US-made Safety Signs, Banners and Scoreboards to Promote Safety Awareness in Your Workplace. Topics include spill cleanup and control, wetExplore Ahmad Baharum's board "safety signages" on ... Enhance safety awareness with the Workplace Safety Poster - Know the PASS System.Health And Safety PosterSafety PostersDrivers EdSafety AwarenessBuilding ManagementIndustrial SafetySign SystemFunny ComebacksWorkplace Safety.Keeping your employees safe is a top priority. That is why implementing safety programs and first aid awareness at the workplace is very important. One way to help prevent accidents is by utilizing a safety signage program to keep employees ... Increase Safety Awareness with Signs.Safety Signs · danger signs · electrical safety · floor signs and stands · notice · spill kit & sds · pipe labels & tape · prohibition signs · safety awareness .Safety signs must be used whenever a hazard or danger can not be avoided adequately or reduced in another way. Before installing safety signs an employer should Safety signs are an essential part of any workplace safety program. They draw attention to important information, remind workers about hazards Without Safety Signs, many employees would lack the necessary direction in times of crisis and employers may ... Safety Awareness Signs help to promote the.Safety Awareness Signs in all shapes and sizes, designed to keep your workers safe. Compliable with the NZ building code.Safety awareness signs remind workers and visitors to take precautions when driving on jobsites and roadways. Remind drivers of safe practices by postingPromote safety

awareness with OSHA compliant safety signs. Transform your facility into a lean, productive and safe workplace. Brady has a wide selection of safety awareness signs to indicate and define specific areas of your facility.Wherever there are potential hazards, safety signage in the workplace is essential to warn staff of dangers and to raise safety awareness generally. Hazard awareness chart. The best occupational health and safety programs use a series of signs and symbols to convey a complete message.Safety Awareness Posters. When it comes to workplace safety, you need to stay alert and aware of the possible dangers at all times. It is easy to forget Searching for quality safety awareness and compliance signs and labels for your facility? We've got your needs covered! Here at SafetySignsPH.com Safety Posters: Lockout/Tagout · Safety Posters: Heat Stress · Safety Awareness Posters: Pride In Safety · Safety Posters: Safety Is Concise and consistent signs make it simple for employees and guests to easily identify hazards. This reduces workplace injuries, promotes safety awareness,Safety signs should have rounded or blunt corners, and have no sharp edges, burrs, or splinters. Similarly, a sign that warns pedestrians to look out forCommon Signs for Safety · Prohibition signs – Signs instructing people not to smoke, not to enter certain areas, not to wear certain types of footwear, etc.

Address :

59B Ash Rd,

Wiri,Manukau

Auckland,2104,

0 notes

Text

What are the advantages of LB series asphalt plant

LB series asphalt plant is a new type of thermal regeneration mixing equipment which based on the development international technology. The product is equipped with mixing equipment, hot mix plant and warm mix asphalt technology. It has the characteristics of high efficiency, energy saving, environmental protection and high recycling rate. The efficiency of environmental protection and energy saving analysis is high, which greatly increases the thermal regeneration process of asphalt aging effect, sticky effect, tail gas treatment and other effects, so LB series asphalt plant is the high level products suitable for the highway, municipal road construction. What are the specific advantages of Haomei LB series asphalt mixing plant?

1. Modular cold material discharging system with synchronous proportion automatic control and adjustment. 2. Efficient energy-saving drying system with heat exchange efficiency up to 90%. 3. 0 dB silent anti-stop high-intensity plate chain bucket elevator system. 4. Screen quick change, intelligent draft-free pressure relief maintenance screening system. 5. High precision weighing system with high stability, error automatic compensation. 6. Uniform and efficient, large-scale three-dimensional boiling-type mixing system with 15% super-redundant design. 7. Efficient and environmentally friendly bag dust removal system with exhaust emissions far exceed the national standard. 8. Powder supply system with laminated powder tank optional flexible and recycling diversification. 9. Puzzle asphalt supply system with free and flexible combination, fast installation. 10. High reliability gas systems which can sustainable operation in -15℃ to 50℃ extremely harsh environment. 11. Parallel PC + PLC intelligent control system with stable and easy operation. For those aspects, LB series asphalt plants become the first choice when choosing asphalt mixing plant for sale.

Reprinted from: http://www.asphalt-mixing-plants.net/industry-news/asphalt-plant.html

2 notes

·

View notes

Text

Caltrans Repaves Highway with 100% Recycled Asphalt and Plastic Bottles

courtesy of Caltrans

Asphalt is the material of choice for much of the roadways in the United States, but as everyone that’s ever driven in a car knows, the material is prone to cracking and potholing, creating a considerable maintenance problem. A new process being tested in California is showing promising results by using cold in-place asphalt and recycled plastic bottles.

A 1,000 foot long, 3 lane highway segment on Highway 162 in Oroville, California is actively being repaved with the combination of recycled materials, making it the first state highway section to use 100% recycled material.

The process will involve milling the top 3 inches of pavement and then mixing those millings with a liquid plastic polymer binder, as opposed to the traditional method of hot-mix asphalt which is brought in from an area asphalt plant. For every 1-mile segment of pavement, the polymer will recycle 150,000 plastic bottles.

courtesy of Caltrans

Developed by TechniSoil Industrial in Redding, California, the process has shown promising results in previous tests. According to the press release from Caltrans, the roadway with recycled products have shown to have a lifespan of two to three times longer than traditional methods.

Sean Weaver, the president of TechniSoil Industrial, told Action News Now that the method is eliminating the need for 42 truckloads of hauled off millings and an additional 42 truckloads of new asphalt.

"California has set ambitious goals for recycling and other environmental priorities, and meeting them requires innovative and cost-effective solutions," said Senator Ben Hueso (D-40), who has advocated for Caltrans to test this material, in a press release. "Using waste plastic that was otherwise destined for a landfill will not only reduce the cost of road repair and construction, but also increase the strength and durability of our roads. As a leader on environmental justice issues, California is uniquely positioned to transform the transportation industry once again by using this new technology that could revolutionize the way we look at recycled plastic."

Total project costs for the highway segment is expected to be $3.2 million and is being carried out by Yuba Construction, the prime contractor.

Full story: Caltrans Repaves Roadway with Recycled Plastic Bottles | Caltrans

source https://www.constructionjunkie.com/blog/2020/8/12/caltrans-repaves-highway-with-100-recycled-asphalt-and-plastic-bottles from G P NATIONAL CRANES LTD https://gpnationalcrane.blogspot.com/2020/08/caltrans-repaves-highway-with-100.html

0 notes