#Metal 3D Printing Industry

Explore tagged Tumblr posts

Text

Metal 3d Printing Impressively Grow in Future by Top Companies Analysis

Latest Research Report on “Metal 3d Printing Market” | Survey with Valuable Insights

The 2024 market research report for Metal 3d Printing Market offers a comprehensive analysis of the industry, covering key aspects such as trends, opportunities, risks, and drivers. It provides a detailed evaluation of the market's revenue, size, and volume, while also assessing the product portfolios, capacities, and revenues of leading companies. Additionally, the report delves into various industry segments.

According to Straits Research, the global Metal 3d Printing market size was valued at USD 3.3 Billion in 2021. It is projected to reach from USD XX Billion in 2022 to USD 20.96 Billion by 2030, growing at a CAGR of 22.8% during the forecast period (2022–2030). The report places particular emphasis on the Industrial Adhesive market, examining its overall size, segment size (including product type, application, and geography), competitive landscape, current status, and development trends. It also offers strategic insights for companies to navigate the challenges posed by COVID-19.

Get a sample PDF of the report at https://straitsresearch.com/report/metal-3d-printing-market/request-sample

TOP Key Industry Players of the Metal 3d Printing Market

3D Systems Corporation (U.S.)

Stratasys Ltd.

Renishaw plc

General Electric Company

Carpenter Technology Corporation

Materialise NV

Voxeljet AG

Sandvik AB

EOS GmbH Electro Optical Systems

The ExOne Company and Proto LabsInc

Metal 3d Printing Market Segmental Analysis

As a result of the Metal 3d Printing market segmentation, the market is divided into sub-segments based on product type, application, as well as regional and country-level forecasts.

By Components

Hardware

Software

Services

By Technology

Selective Laser Sintering (SLS)

Direct Metal Laser Sintering (DMLS)

Inkjet printing

Electron Beam Melting (EBM)

Laser Metal Deposition (LMD)

Laminated Object Manufacturing (LOM)

Electron-beam Freeform Fabrication (EBF3)

Selective Laser Melting (SLM)

By Software

Design Software

Inspection Software

Printer Software

Scanning Software

By Applications

Prototyping

Tooling

Functional Parts

By Vertical

Automotive

Aerospace and Defense

Healthcare

Consumer Electronics

Powder and Energy

Others

You can check In-depth Segmentation from here: @ https://straitsresearch.com/report/metal-3d-printing-market/request-sample

Regional Analysis Metal 3d Printing Market

The regional analysis section of the report offers a thorough examination of the global Metal 3d Printing market, detailing the sales growth of various regional and country-level markets. It includes precise volume analysis by country and market size analysis by region for both past and future periods. The report provides an in-depth evaluation of the growth trends and other factors impacting the Metal 3d Printing market in key countries, such as the United States, Canada, Mexico, Germany, France, the United Kingdom, Russia, Italy, China, Japan, Korea, India, Southeast Asia, Australia, Brazil, and Saudi Arabia. Moreover, it explores the progress of significant regional markets, including North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

New Additions in the 2024 Report:

Expanded Industry Overview: The report now includes a more comprehensive and detailed industry overview.

In-Depth Company Profiles: Enhanced profiles providing deeper insights into key industry players.

Customized Reports and Analyst Support: Tailored reports and direct access to analyst support available upon request.

Insights on Market Developments: Updated information on recent market trends and future growth opportunities.

Regional/Country-Specific Customization: Reports tailored to specific regions and countries according to your needs.

Key Highlights

Examine the Metal 3d Printing Market: This includes an introduction, analysis of product types and applications, an overview of the market, and a country-by-country market analysis. The study also explores market opportunities, risks, and driving forces.

Profile Manufacturers: The research focuses on manufacturers of Metal 3d Printing, including detailed profiles, primary business activities, recent news, sales, pricing, revenue, and market share.

Competitive Landscape Overview: Provide an overview of the competitive landscape among the world's leading manufacturers, highlighting their sales, revenue, and market share.

Market Segmentation Analysis: Illustrate the market segmented by type and application, with detailed breakdowns of sales, price, revenue, market share, and growth rate for each segment.

Regional Market Analysis: Analyze key regions, including North America, Europe, Asia Pacific, the Middle East, and South America. This includes sales, revenue, and market share data segmented by manufacturers, types, and applications.

Production Cost Investigation: Investigate production costs, essential raw materials, and the production methods used in the industry.

Reasons to Purchase This Report:

Access to Comprehensive Information: Gain access to an extensive collection of analysis, research, and data that would be challenging to acquire independently. This report offers valuable insights, saving you considerable time and effort.

Enhanced Decision-Making: Equip yourself with detailed insights into market trends, consumer behavior, and key industry factors. This report provides essential information for strategic planning, including decisions on investments, product development, and marketing strategies.

Achieving Competitive Advantage: Stay ahead in your industry by understanding market dynamics and competitor strategies. This report delivers deep insights into competitor performance and market trends, enabling you to craft effective business strategies and maintain a competitive edge.

Credibility and Reliability: Trust in the expertise of industry professionals and the accuracy of thoroughly researched data. Authored by experts and grounded in rigorous research and analysis, this report enhances credibility and reliability.

Cost-Effective Research: Reduce research expenses by investing in this comprehensive report instead of conducting independent research. It provides a cost-effective means of accessing detailed analysis and insights on a specific topic without requiring extensive resources.

To Understand How Covid-19 Impact Is Covered in This Report - https://straitsresearch.com/report/metal-3d-printing-market/request-sample

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Metal 3d Printing#Metal 3d Printing Industry#Metal 3d Printing Share#Metal 3d Printing Size#Metal 3d Printing Trends#Metal 3d Printing Regional Analysis#Metal 3d Printing Growth Rate

0 notes

Text

Metal 3D Printing Market Size, Trends, Statistics and Analysis 2024 - 2030

The global metal 3D printing market size was valued at USD 7.73 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 24.6% from 2024 to 2030.

Metal 3D printing is one such market that has benefitted significantly from the growing necessity of rapid prototyping and advanced manufacturing practices. The industry is poised to witness unprecedented growth over the forecast period owing to the rising application of additive manufacturing in various industry verticals. The global market is increasingly advancing towards consolidation to stay ahead of the competition. A substantial growth factor for this market is increasing innovation, which is leading to several benefits through the adoption of metal 3D printing across heavy industry applications.

Gather more insights about the market drivers, restrains and growth of the Metal 3D Printing Market

Increasing adoption of metal 3D printers for designing and prototyping products and objects coupled with the reduced manufacturing expenditure and accuracy in the end-product is a key growth proliferating factor. The market is poised to witness high demand arising prominently from the healthcare, automotive, and aerospace & defense sectors. The growing advancements in the healthcare sector to curb physical disabilities and ensure healthy living are influencing the sector to flourish and adopt new innovative methodologies, such as 3D printing.

Additionally, the automotive and aerospace sectors, where prototyping and designing play a vital role in research & development to achieve perfection in their production are leading towards greater opportunities and increasing adoption of the 3D printing process.

However, the prevailing misconceptions concerning the prototyping processes held by small and medium-scale manufacturers are hindering the adoption of additive manufacturing. Companies involved in designing, particularly small-scale and medium-scale enterprises are deliberating before considering investments in prototyping as accountable investments rather than trying to understand the advantages and benefits of prototyping.

The general notion prevailing among these enterprises is that prototyping is merely an expensive phase before manufacturing. Such perceptions regarding prototyping, coupled with the lack of technical knowledge and a looming lack of standard process controls, are expected to hinder the market’s growth.

The outbreak of the COVID-19 pandemic has significantly impacted the overall global economy and, subsequently, the 3D printing industry. Initially, Europe and Asia Pacific were one of the worst affected regions in terms of the number of COVID-19 patients across the globe. Further, the situation worsened in the U.S. as well. Due to the rapid spread of the virus, the government issued an order for the complete lockdown of some key cities.

The complete lockdown affected the production of 3D printing manufacturers. This is attributed to the labor shortage and the complete disruption of logistics and supply chains in the country. The halt in the production of 3D printing adversely impacted the overall market growth in the first and second quarters of 2020.

Metal 3D Printing Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2017 to 2030. For this study, Grand View Research has segmented the global metal 3D printing market report based on component, technology, software, application, printer type, vertical, and region:

Technology Outlook (Revenue, USD Billion, 2017 - 2030)

• Selective Laser Sintering

• Direct Metal Laser Sintering

• Inkjet printing

• Electron Beam Melting

• Laser Metal Deposition

• Laminated Object Manufacturing

• Electron Beam Freeform Fabrication

• Selective Laser Melting

Software Outlook (Revenue, USD Billion, 2017 - 2030)

• Design Software

• Inspection Software

Component Outlook (Revenue, USD Billion, 2017 - 2030)

• Hardware

• Software

• Services

Application Outlook (Revenue, USD Billion, 2017 - 2030)

• Prototyping

• Tooling

• Functional Parts

Printer Type Outlook (Revenue, USD Billion, 2017 - 2030)

• Desktop Metal 3D Printer

• Industrial Metal 3D Printer

Vertical Outlook (Revenue, USD Billion, 2017 - 2030)

• Desktop Vertical

• Industrial Vertical

Regional Outlook (Revenue, USD Billion, 2017 - 2030)

• North America

• Europe

• Asia Pacific

• South America

• Middle East and Africa (MEA)

Browse through Grand View Research's Next Generation Technologies Industry Research Reports.

• The global satellite propulsion system market size was estimated at USD 9.27 billion in 2023 and is expected to grow at a CAGR of 13.2% from 2024 to 2030.

• The global fingerprint access control systems market size was valued at USD 4.29 billion in 2023 and is projected to grow at a CAGR of 12.6% from 2024 to 2030.

Key Metal 3D Printing Company Insights

The ecosystem of the metal 3D printing market comprises an original equipment manufacturer, a network of component manufacturers, system integrators, resellers & distributors, and end users.

Some prominent players in the market include Cognex Corporation (U.S.), Basler AG (Germany), Keyence Corporation (Japan), Sick AG (Germany), and ISRA Vision AG (Germany).

• ISRA VISION GmbH is a manufacturer and provider of surface inspection systems. The company’s products are used for quality and surface inspection, including image processing systems, focused on the arena of metal 3D printing. Its machine vision system comprises lightning components, sensor devices, hardware, software, and mechanical elements such as high-resolution cameras and fast-switching LEDs.

• Basler AG develops and manufactures digital cameras for medical devices, traffic systems, industrial applications, and video surveillance. The products offered by the company include PowerPack Microscopy equipment; network cameras; 3D cameras for applications in logistics, industrial image processing, imaging, and inspection; area scan cameras for factory automation and traffic monitoring; and line scan cameras for sorting procedures and quality assurance.

• ZRapid Tech specializes in metal 3D printing systems and services, offering a range of additive manufacturing solutions tailored to the needs of different industries. The company focuses on developing advanced metal AM technologies and providing customized solutions for high-performance applications.

• UnionTech is a leading provider of stereolithography (SLA) 3D printing systems, including metal-compatible SLA printers. The company offers a range of high-precision, high-resolution SLA printers that enable the production of intricate metal parts with superior surface quality and dimensional accuracy.

Key Metal 3D Printing Companies:

The following are the leading companies in the metal 3D printing market. These companies collectively hold the largest market share and dictate industry trends. Financials, strategy maps & products of these metal 3D printing companies are analyzed to map the supply network.

• Cognex Corporation

• Keyence Corporation

• Sick AG

• ISRA Vision AG

• Basler AG.

Recent Developments

• In October 2021, 3D Systems announced the acquisition of Volumetric Biotechnologies. Volumetric Biotechnologies is a Huston-based biotech company. The acquisition will help 3D Systems to develop manufacturing capabilities for fully bio-compatible human organs using Additive Manufacturing (AM).

• In November 2019, Renishaw plc announced the collaboration with Sandvik Additive Manufacturing. The collaboration aimed to qualify new additive manufacturing (AM) materials for production applications. This collaboration is expected to help Renishaw plc develop new metal materials for 3D printing.

• In October 2019, GE Additive announced the cooperative research and development agreement (CRADA) with the US Department of Energy’s Oak Ridge National Laboratory (ORNL). The agreement period was for 5 years and focused on processes, materials, and software to increase customer adaptability towards additive manufacturing from conventional manufacturing.

• In July 2019, 3D Systems Corporation, a 3D metal printing solution provider was awarded a contract from the Combat Capabilities Development Command Army Research Laboratory (ARL). The contract valued worth USD 15 million with a focus on creating the fastest, and precise 3D printer.

Order a free sample PDF of the Metal 3D Printing Market Intelligence Study, published by Grand View Research.

#Metal 3D Printing Market#Metal 3D Printing Industry#Metal 3D Printing Market size#Metal 3D Printing Market share

0 notes

Text

Metal 3D Printing Market Segmented On The Basis Of Component, Technology, Software, Application, Printer Type, Vertical, Region And Forecast To 2030: Grand View Research Inc.

San Francisco, 29 Sep 2023: The Report Metal 3D Printing Market Size, Share & Trends Analysis Report By Component (Hardware, Software, Services), By Technology, By Software, By Application, By Printer Type, By Vertical, By Region, And Segment Forecasts, 2023 – 2030 The global metal 3D printing market size is estimated to reach USD 35.33 billion by 2030, according to a new report by Grand View…

View On WordPress

#Metal 3D Printing Industry#Metal 3D Printing Market#Metal 3D Printing Market 2023#Metal 3D Printing Market Revenue#Metal 3D Printing Market Share#Metal 3D Printing Market Size

0 notes

Text

#Metal 3D Printing Market#Metal 3D Printing Report#Metal 3D Printing Industry#Advanced Materials#Bisresearch

0 notes

Text

Metal Additive Manufacturing Market is Estimated to Witness High Growth Owing to Reduced Production Costs

Metal additive manufacturing, also known as 3D metal printing, enables the fabrication of complex metal components using a digital file and successive layering of material under computer control. Manufacturers can produce intricate components with conformal cooling passages, lattice structures, and optimized designs that provide weight savings. As additive manufacturing reduces waste by building only the desired part geometry, it helps lower production costs compared to traditional subtractive methods such as milling and machining. The metal additive manufacturing market encompasses technologies such as direct metal laser sintering, electron beam melting, and binder jetting, among others. Manufacturers across industries adopt these technologies to produce prototypes and end-use products. Due to the potential for mass individualization and supply chain resilience, metal 3D printing demand is growing across automotive, aerospace, healthcare, and industrial equipment verticals.

Global metal additive manufacturing market is estimated to be valued at USD 5.85 Bn in 2024 and is expected to reach USD 14.37 Bn by 2031, exhibiting a compound annual growth rate (CAGR) of 13.7% from 2024 to 2031.

Key Takeaways Key players operating in the metal additive manufacturing market are GE Additive, 3D Systems, Desktop Metal, EOS GmbH, Renishaw, SLM Solutions, Stratasys, Markforged, Velo3D, DMG Mori, HP Inc., TRUMPF, ExOne (a Desktop Metal company), Materialise, Formlabs, Norsk Titanium, Optomec, Prima Additive, XJet, and VulcanForms. These players focus on expanding their production capacities and service offerings to tap growing metal 3D printing demand. Key opportunities in the Metal Additive Manufacturing Market Trends include leveraging additive manufacturing to produce jigs, fixtures, and tooling for customized production. The technology enables on-demand manufacturing, reducing inventory costs. Further, 3D metal printing facilitates the direct production of end-use implants, prosthetics, and medical devices to improve patient outcomes. Geographically, the metal additive manufacturing market witnesses high growth in North America and Europe due to early technology adoption. However, Asia Pacific is emerging as an attractive market with huge potential, led by government initiatives driving advanced manufacturing. As the technology matures, global metal 3D printing adoption will continue increasing across industries. Market Drivers Reduced production costs with additive manufacturing compared to traditional methods is a key market driver. 3D printing eliminates the need for expensive tooling and reduces waste. It facilitates mass customization by producing different parts using the same production method. Furthermore, additive manufacturing enables the production of complex parts with optimised lightweight designs that provide performance and efficiency benefits. Metal Additive Manufacturing Market Size and Trends technology helps improve design flexibility, reduce lead times, and support supply chain resilience. All these advantages are fueling increased investment in metal 3D printing globally.

PEST Analysis Political: Metal additive manufacturing faces regulations regarding product quality and safety. Regulators aim to establish standards without stifling innovation. Economic: Metal 3D printing reduces waste and improves design flexibility compared to traditional manufacturing. It allows on-demand production and reduces lengthy supply chains. Social: Additive manufacturing increases access to custom-tailored solutions in industries like healthcare, consumer products, and education. It facilitates distributed manufacturing closer to end users. Technological: Advancements in metal powder composition, laser melting techniques, and printer capabilities continue increasing build size and throughput. Computer-aided design tools are optimizing machine parameters for new material formulations. Europe Europe is a major regional market, where aerospace and automotive sectors in Germany, Italy, and UK drive significant adoption of metal 3D printing technology, particularly for prototyping and low-volume production applications. Government support for advanced manufacturing research further boosts the regional market. Asia Pacific The Asia Pacific region is anticipated to witness the fastest growth over the forecast period due to rising focus on industrial modernization across industries in countries such as China, Japan, and South Korea. Establishment of local manufacturing facilities by global players also expands the regional market.

Get more insights on Metal Additive Manufacturing Market

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.

(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/)

#Coherent Market Insights#Metal Additive Manufacturing Market#Metal Additive Manufacturing#Metal AM#3D Printing Metals#Metal Fabrication#Industrial 3D Printing#Metal Prototyping#Metal Additive Processes

0 notes

Text

0 notes

Link

Veer O Metals was established in 1965. We are engaged in the manufacture of Stamped Parts, Precision Sheet Metal Fabrication Parts, Machined Components and Mechanical Assemblies. We have an in-house strong Mechanical Engineering and Manufacturing team for Design and Development, dedicated in providing high end design solutions which are industry specific.

We have established a strong client base at National and International level with our transparent and Global practices, and at the same time retaining robust quality management systems. By developing indigenously designed products of global standards for various sectors, we have added a new dimension to our already existing wide range of product manufacturing and assemblies.

With a core principle of innovation and enhanced technology, Veero always has been at the forefront in embracing the newest trends in the industry. Introducing first of its kind Metal Additive Manufacturing (Metal 3D Printing). Veero has augmented cutting edge manufacturing technology in the field of metal additive manufacturing. It is a Disruptive Technology, which is an automatic process of manufacturing objects (Parts, Prototypes, tools & even assemblies) directly from their CAD models without any cutter, tools and jigs & fixtures.

From inventions to innovations, energy responsibility to environment stewardship, Veer O Metals is well positioned to be a technology leader in manufacturing of sheet metal fabrication parts and mechanical assemblies.

We are proud to mention that we are the most preferred partner for our clients. We have state of the art manufacturing locations in India and Philippines.

Our core activities have been in:

Stamping Components

Precision Sheet Metal Fabrication Parts

Enclosures

Industrial and IT Racks

Mechanical Assemblies

Machined Components

Veer O Products

Metal Additive Manufacturing ( 3D Printing )

Our approach to manufacturing excellence entails stringent quality checks and continual improvements.

#post processing of 3d printed#additive manufacturing company#additive manufacturing application#metal 3d printing companies in bangalore#materials used in additive manufacturing#dmls machine cost in india#3d priniting post processing services#dmls printer manufacturers#metal manufacturers in india#metal 3d printing in chennai#3d metal printing machine manufacturers#metal 3d printing process#3d printing in defence industry#metal companies in india#metal 3d printing in mumbai#metal 3d printing services in india#3d metal printing near me#metal 3d printing materials#additive manufactured products#metal 3d printing manufacturing#metal 3d printing companies in india#metal 3d printing service bangalore#additive manufacturing company in india#additive manufacturing companies in bangalore#additive manufacturing service in india#metal 3d printing bangalore#metal additive manufacturing systems#additive manufacturing metal parts#additive metal 3d printing#metal additive manufacturing machine

0 notes

Note

How significant is powder metallurgy for the use of bastardly-to-machine stuff like inconel these days? it's just i was checking out some quotes for DMLS printing recently and there wasn't *that* much of a price delta between alu and stuff like maraging steel and superalloys

I can’t speak to other industries, but in rocket engineering and fusion engineering it’s huge. Everybody loves to 3D print inconel, as well as funky copper alloys (shoutout to GRCop-84) and steel. It has terrific mechanical properties and you can make almost any arbitrary shape. The hot new thing to do is to 3D print as much of your rocket as possible.

HOWEVER, in nuclear fusion, inconel in general is kind of going out of fashion. For those of you in the room who aren't familiar, inconel refers to a class of "superalloys," structural metals that can retain their strength while very close to their melting point. One would think this would be a super useful property in a fusion reactor, and one would be absolutely correct. JET in the UK went hog-wild with inconel, as did TFTR at Princeton.

But, depending on the alloy, inconel is anywhere from 50% to 70% nickel. Nickel is particularly problematic in areas of high neutron flux (like, say, in a fusion reactor), where it captures neutrons and "activates." Almost every element does this to one extent or another, but it's real bad when it happens to nickel.

I'm not a neutronics person, but from what they tell me, the various transmutation reactions give you both radioactive byproducts with annoyingly long half-lives, and pockets of helium that lead to severe embrittlement. A nickel-rich alloy is just not going to have a good time in a fusion power plant, long term.

96 notes

·

View notes

Text

Researchers at Tohoku University's Institute for Materials Research and New Industry Creation Hatchery Center have made a breakthrough in a multi-material 3D printing technique, demonstrating the process for creating a lightweight yet durable automobile part. The process of metal 3D printing involves building objects by depositing metals layer by layer, using heat to bind them together. The precision of 3D printing allows for the production of unique, highly customizable shapes that often create less wasteful byproducts than traditional manufacturing methods. "Multi-material structures" which strategically combine different materials for optimal performance of a component can also be created via 3D printing. For example, steel automobile parts can be made more lightweight by combining them with aluminum. Due to these benefits, mastering such 3D printing techniques is garnering considerable attention from researchers. However, this technique does come with some challenges.

Read more.

7 notes

·

View notes

Text

new bucket list attempt everything on this list at least once

Master list of creative hobbies

Art creative hobbies

1. Botanical illustration

2. Architectural drawing

3. Urban sketching

4. Comic and manga illustration

5. Children’s book illustration

6. Digital art and design

7. Figure drawing

8. Fashion illustration

9. Mapmaking

10. Doodling and zentangle

11. Sticker making

12. Coloring books (for adults)

13. Paint by numbers

14. Diamond painting

DIY creative hobbies and crafts

15. Soap making

16. Resin molding

17. Button making

18. Candle making

19. Basket weaving

20. Terrazzo

21. Sand art bottles

22. String art

23. Perler beads

24. Seed beading

25. Wreath making

Industrial creative hobbies

26. Woodworking

27. Woodturning

28. Wood burning (pyrography)

29. Glass blowing

30. Glass etching

31. Stained glass art

32. Concrete molds

33. Jewelry making

34. Leather working

35. Metalworking and welding

36. Metal embossing

37. Mosaics

Sculpting and carving hobbies

38. Sculpting

39. Ice sculpting

40. Wood carving

41. Pottery

42. Soap carving

43. Sand sculptures and sandcastle building

Printmaking creative hobbies

44. Linocut printmaking

45. Woodcut printmaking

46. Screen printing

47. Rubber stamping

Needlecraft creative hobbies

48. Sewing

49. Cosplay

50. Embroidery

51. Cross-stitching

52. Crewel

53. Needle felting

54. Quilting

55. Crochet

56. Amigurumi

57. Knitting

58. Arm knitting

59. Needlepoint

Fiber arts hobbies

60. Visible mending

61. Macrame

62. Weaving

63. Rug tufting

64. Punch needle

65. Latch hook

66. Lace making

67. Dreamcatchers

Miniature creative hobbies

68. Model building

69. Painting miniatures

70. Dollhouses

71. Fairy gardens

72. Bonkei

73. Diorama making

74. Putz houses and nativity scenes

75. Lego MOC

Stationery and lettering hobbies

76. Calligraphy

77. Hand lettering

78. Art journaling

79. Bullet journaling

80. Card making

81. Scrapbooking

Papercraft creative hobbies

82. Origami

83. Papercraft modeling

84. Paper quilling

85. Collage art

86. Paper making

87. Bookbinding

88. Pop-up making

89. Paper mache

Digital creative hobbies

90. 3D printing

91. Stop motion animation

92. Graphic design

93. Photo manipulation

94. Game development

95. Raspberry Pi

Plant-related creative hobbies

96. Bonsai

97. Tree shaping (Pooktre)

98. Terrariums

99. Aquascaping

100. Flower pressing

101. Flower arranging

102. Topiary gardening

103. Seed art

104. Rock gardening

Other creative hobbies and crafts

105. Puzzles

106. Sudoku

107. Crossword puzzles

108. Writing

109. Learning a foreign language

110. Cooking

111. Music

112. Photography

113. Dancing

114. Sports

115. Improv

116. Nail art

117. Baking

118. Magic

119. Tarot cards

120. Card stacking

121. Collecting

8 notes

·

View notes

Text

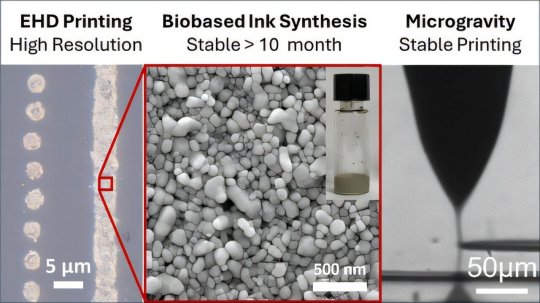

Nanoink and printing technologies could enable electronics repairs, production in space

An Iowa State University engineer floats in the air while other researchers hang tight to a metal frame surrounding and supporting their special printer. It's not the usual photo you see in a research paper. Tests aboard microgravity flights aren't your typical materials experiments, either.

The flight path to these experiments began when a research team led by Iowa State's Shan Jiang, an associate professor of materials science and engineering, and Hantang Qin, formerly of Iowa State who's now an assistant professor of industrial and systems engineering at the University of Wisconsin-Madison, wondered if their ink and printer technologies would work in the zero gravity of space.

The ink features silver nanoparticles synthesized with biobased polymers. After heat treatment, the ink can conduct electricity and can therefore print electric circuits. The printer uses electrohydrodynamic printing, or 3D printing that jets ink under an electric field at resolutions of millionths of a meter. The electric field could eliminate the need for gravity to help deposit ink.

If the technologies work together in zero gravity, astronauts could use them to make electric circuits for spacecraft or equipment repairs. And astronauts might manufacture high-value electronic components in the special, zero-gravity environment of space.

NASA wondered if it would work, too.

Diving into microgravity

Researchers bolted the printer to the floor of a jet and prepared for a "roller coaster, basically," Jiang said.

The NASA plane would continuously climb and dive, going in cycles from about 24,000 feet over Florida to 32,000 feet, then back to 24,000. The dive phase produced about 10 seconds of pure zero gravity.

"It was exciting and new," Jiang said.

Motion sickness was a problem for some. Others enjoyed the thrill of it. Jiang felt "frozen" the first time he experienced microgravity. "I was blank."

But that didn't last. "There was so much time and investment in this project. We wanted to achieve good results."

But printing for a few seconds at a time on a microgravity flight "is a very challenging experiment," Jiang said. "It's so easy on the ground where everything is stable. But if anything gets loose during the flight, you lose your printing."

The first microgravity flight was a good example. The printer wasn't adequately secured against the plane's shakes and vibrations.

"These are very intense experiments that require a lot of teamwork and preparation," Jiang said.

So, the team went back to work, made some changes, made more test flights and produced better results.

"This proof-of-concept microgravity experiment proves the unique capability of (electrohydrodynamic) printing under zero-gravity conditions and opens a new venue for future on-demand manufacturing in space," the researchers wrote in a paper published in Applied Materials & Interfaces.

Making a new nanoink

The key innovation by Jiang's research group was developing a new laboratory method to synthesize the ink with its silver nanoparticles.

"This is a new combination of materials and so we needed a new recipe to make the ink," Jiang said.

Both programs "strive to support innovative and leading research in Iowa," said Sara Nelson, director of the programs and an Iowa State adjunct assistant professor of aerospace engineering. "We are thrilled to have supported Dr. Jiang's research. His work has helped to build Iowa's research infrastructure and is an important part of NASA's strategic mission."

The project also makes use of an abundant Iowa resource, plant biomass.

The ink includes a biobased polymer called 2-hydroxyethyl cellulose, which is typically used as a thickening agent. But it is also a cost-effective, biocompatible, versatile and stable material for the inks necessary for high-resolution ink jet printing under an electric field.

"There is a lot of biomass in Iowa," Jiang said. "So, we're always trying to use these biobased molecules. They make a wonderful polymer that does all the tricks for us."

Jiang called that "the biggest surprise of this research. We didn't know that before. Now we know what we can do with these biobased polymers."

The Iowa State University Research Foundation has filed a patent on the new nanoink and the technology is currently available for licensing.

"This success is really just the beginning," Jiang said. "As humanity ventures deeper into space, the need for on-demand manufacturing of electronics in orbit is no longer science fiction; it is a necessity."

Next up for the researchers could be the development of 3D space printing for other electronic components such as semiconductors.

After all, Jiang said, "You can't just make one component and assemble an electronic device."

TOP IMAGE: Researchers—as well as a toy Cy the Cyclone—test their nanoink and printer technologies during a NASA microgravity flight. Pictured, left to right, are: Fei Liu, Yanhua Huang, Matthew Marander, Xuepeng Jiang and Pavithra Premaratne. Credit: Shan Jiang

LOWER IMAGE: Credit: ACS Applied Materials & Interfaces (2024). DOI: 10.1021/acsami.4c07592

6 notes

·

View notes

Text

FAC 86: "The 1987 Factory Christmas gift sent out to industry figures, contacts and friends was a make-it-yourself 3D card model of the Manchester club The Haçienda. Presented as 5 flat colour card sheets with metallic silver to the rear, wrapped in a white printed band and signed by Factory Records staff. When combined, the sections made up the 3D model."

pictures from here and here

#MERRY CHRISTMAS TO MEEEEEEEEE#ive been looking for high quality scans/pictures of this kit for so long omg#this is so awesome. wish that i had access to my printer rn to actually print it -_-#my post#factory records#the haçienda

3 notes

·

View notes

Text

The Commonly Used Metal 3D Printing Materials

Metal 3D printing uses a variety of metal powders, wires, and even liquid resins infused with metal. Almost any metal can be 3D printed, from stainless steel to nickel-based alloys, and in practice, about 8 are most commonly used. The most common question about metal 3D printing is: Will the final part have the same mechanical properties as a machined, moulded or forged metal part? The answer is yes, and sometimes even better mechanical quality, but it depends a lot on the metal 3D printing technology you use, the type of feedstock used, post-processing and the shape of the part. In addition, the comparison depends on the aspects you are concerned about: for example, tensile strength, static load strength, high cycle fatigue, and so on.

In general, the material properties of metal parts made by metal bond jetting are equivalent to those of metal parts produced by metal injection moulding, and it is one of the most widely used manufacturing methods for the mass production of metal parts. These 8 metal alloys below are just the beginning of what is possible today as metal material producers continue to push the boundaries and customize metal alloys for specific needs using specific metal 3D printing technologies.

1.Stainless Steel Feature: All-round Stainless steel is not the material most commonly used in 3D printing, but many alloy varieties. The first two are 316L and 17-4 PH, but also 304L, 15-5 PH, 420, 254, PH1, GP1, 630, and 410 can be printed, as well as custom blends produced by material manufacturer. These steels are specifically designed to resist corrosion. They are a lightweight and affordable metal that is ideal for 3D printing. This is because it is faster and cheaper than traditional methods and can print small batches and complex parts. 3D printing is the preferred option for companies that need a single tool or several replacement parts. Stainless steel can be used in almost any type of 3D printing, from economical wire for extruded 3D printing on benchtop machines to powder for binder jetting and laser powder bed fusion, and even resin.

2.Tool Steel Feature: High hardness, good wear resistance Tool steels, like stainless steels, come in different varieties with different tensile strengths, ductility, hardness and other properties. Tool steels are a variety of alloy steels designed specifically for the manufacture of tools. They are known for their hardness, wear resistance and ability to hold a cutting edge at high temperatures. This 3D printing steel is commonly used in the manufacture of injection mould inserts, aerospace components, military applications, manufacturing tools, as well as construction and architecture. The main advantage of 3D printed tool steel is not only its strength, but also its unique ability to create parts with internal channels (e.g. cooling channels in moulding tools) and lattice fillings that cannot be manufactured by traditional methods.

3.Low-Alloy Steel All 3D printing steels are alloys, but this category includes steels with low or less than 5 per cent of other elements. These low alloy steels are designed to have higher mechanical properties and greater resistance to wear and corrosion than other steels which are commonly used in automotive, aerospace and structural applications.

4.Aluminum Feature: Lightweight and corrosion resistant For aerospace, automotive and industry, the design freedom and cost efficiency of 3D printing further enhances the lightweight and chemical resistance of aluminum components. The use of aluminum and aluminum alloys in 3D printing is surging because the metal is economical and easy to 3D print. Like most metals, aluminum can be used as wire or powder for a variety of 3D printing techniques. Aluminium has good chemical resistance, is very light and has one of the best strength-to-weight ratios of any metal. Combined with silicon and magnesium, it is the choice of many in the aerospace and automotive industries because of its ability to withstand harsh conditions.

5.Titanium Feature: Lightweight and biocompatible As strong as steel but half the weight, titanium is a complex metal that is practically made for 3D printing. Titanium has become one of the most commonly used metals in additive manufacturing, with a wide range of applications in aerospace, joint replacement and surgical tools, racing car and bicycle frames, electronics and other high-performance products. Titanium and titanium-based alloys offer high mechanical strength, high strength-to-weight ratios and better corrosion resistance than stainless steel. It makes rockets and aircraft lighter, thus saving fuel and increasing payload capacity. In the medical industry, 3D printed titanium implants have been successfully used in the spine, hips, knees and extremities due to the inherent biocompatibility and good mechanical properties of the metal, coupled with the ability to customize porous structures with 3D printing, allowing for osseointegration and mass customization for better patient outcomes.

6.Copper Feature: Electrical and thermal conductivity 3D printing using pure copper and space-age copper alloys is available with a range of metal 3D printers and services. You can create rapid copper prototypes using copper filament on an FDM 3D printer and large copper rocket boosters using copper alloys on a laser powder bed fusion 3D printer. There is also copper wire and copper resin for micro 3D printing. In fact, copper plays a huge role in the global sustainable development goals as a key component of electric motors, charging infrastructure, solar energy and batteries.

7.Nickel Alloy Feature: Extreme environments resistant Nickel-based alloys and "high-temperature alloys" are known for their excellent high-temperature strength, corrosion and oxidation resistance. These alloys retain their strength and mechanical properties at high temperatures. They are commonly used in demanding applications such as aerospace, gas turbines, chemical processing and marine environments. In recent years, these alloys have also become increasingly popular in 3D printing, especially in the aerospace and automotive industries. When referring to nickel alloys, you may hear the term inconel. Inconel is the trade name for a range of nickel-chromium-based high-temperature alloys, including IN625, IN718 and IN939. Nickel alloys are generally more expensive than other materials such as steel and aluminium and may not be suitable for low temperature applications.

8.Cobalt Chrome Feature: High temperature and corrosion resistance 3D printed cobalt chrome has a high strength-to-weight ratio and excellent corrosion resistance, making it a good material choice for aerospace components and industrial machinery. It is also biocompatible and is often used in orthopaedic implants, dental prosthetics and medical devices that require long-term contact with biological tissue. Cobalt-chromium alloys can be processed using additive manufacturing techniques such as selective laser melting (SLM) or electron beam melting (EBM). This allows complex geometries and customized parts to be produced with minimal material waste, making it attractive to industries adopting advanced manufacturing techniques.

To sum up, metal 3D printing uses a wide range of metal powders and wires, including stainless steel, tool steel, etc. to print complex parts with superior mechanical properties. Commonly used metals in 3D printing include aluminum, titanium, copper, nickel alloys, tool steel, cobalt-chromium alloys, stainless steel for aerospace, medical and jewellery applications and more.

#design#business#autos#prototype#prototyping#prototype machining#rapid prototyping#3d printed#3d printing#3d printing services#sls#slm

2 notes

·

View notes

Text

Unlocking the Potential of 3D Printing: A Guide to PrintPrizm3D

Welcome to the world of 3D printing with PrintPrizm3D! Whether you’re a hobbyist, a small business owner, or an innovator looking to turn your ideas into reality, 3D printing offers limitless possibilities. At PrintPrizm3D, we specialize in providing high-quality 3D printing services that cater to a wide range of needs. Discover how our services can help you bring your visions to life and explore the benefits of incorporating 3D printing into your projects.

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. By layering materials such as plastic, metal, or resin, 3D printers can produce complex shapes and intricate designs with precision and accuracy. This technology has revolutionized industries, including aerospace, automotive, healthcare, and fashion, by offering rapid prototyping, custom manufacturing, and cost-effective production.

Why Choose PrintPrizm3D?

At PrintPrizm3D, we pride ourselves on delivering top-notch 3D printing services. Here’s why you should choose us for your next project:

High-Quality Prints: We use advanced 3D printers and materials to ensure your prints are of the highest quality. Whether you need a prototype, a functional part, or a decorative item, we’ve got you covered.

Expertise and Experience: Our team has extensive experience in 3D printing and design, enabling us to handle a variety of projects with skill and efficiency.

Customer Satisfaction: We are committed to providing exceptional customer service. From the initial consultation to the final product, we work closely with you to meet your specific needs and expectations.

Our Services

PrintPrizm3D offers a comprehensive range of 3D printing services to cater to various requirements:

Prototyping: Quickly and accurately create prototypes to test and refine your designs.

Custom Manufacturing: Produce custom parts and products tailored to your specifications.

Design Services: Our expert designers can help you create and optimize your 3D models for printing.

Educational Workshops: Learn about 3D printing technology and its applications through our informative workshops.

Visit Our Online Stores

Explore our wide range of 3D printed products and services on our online platforms:

PrintPrizm3D Website: PrintPrizm3D Website

PrintPrizm3D eBay Store: PrintPrizm3D eBay Store

Connect with Us on Social Media

Stay updated with our latest projects, promotions, and 3D printing tips by following us on social media:

Facebook: PrintPrizm3D Facebook Page

Instagram: PrintPrizm3D Instagram

Rippin-R-Us Instagram: Rippin-R-Us Instagram

Rippin-R-Us Facebook: Rippin-R-Us Facebook

Get in Touch

Have questions or need assistance with your 3D printing project? Contact us at [email protected]. We’re here to help you every step of the way!

Conclusion

3D printing is transforming the way we create and innovate. At PrintPrizm3D, we’re dedicated to providing high-quality 3D printing services that help you turn your ideas into reality. Visit our online stores, connect with us on social media, and discover how we can assist you with your next project. Embrace the future of manufacturing with PrintPrizm3D!

For further insights and tips on 3D printing, subscribe to our blog and stay tuned for more updates. Happy printing!

#ShopNow#OrderNow#BuyNow#LimitedEdition#NewArrival#3DPrinting#AdditiveManufacturing#3DPrint#3DPrintingCommunity#3DPrintingTechnology#3DPrinted#3DPrinter#3DPrintingService#Prototyping#ProductDesign#CustomManufacturing#RapidPrototyping#Engineering#ProductDevelopment#TechInnovation#eBayStore#eBayDeals#ShopOnEbay#EbayFinds#EbaySeller#FacebookMakers#3DPrintingFB#MakerSpace#Insta3DPrinting#3DPrintingArt

2 notes

·

View notes

Text

Are you looking for a reliable and precise low-volume manufacturing service?

Look no further! 🌟

At ProtoTech Machining, we are not just a manufacturer; we innovate with precision.🛠️

Our company specializes in top-notch low-volume manufacturing services that are tailored to various industry needs such as aerospace, medical, automotive, robotics, and many other sectors. From CNC machining to Rapid prototyping and Sheet Metal Fabrication, our expert team can leverage cutting-edge technologies to turn complex designs into reality. 🚀

Plus, whether you need 3D printing, 5-axis, or Swiss CNC machining, we have the best capabilities to provide innovative and cost-effective solutions without compromising quality. ✨

So don’t wait any longer! Contact us now and let us be your partner in all your manufacturing needs. 📞

Browse https://prototech-machining.com/low-volume-manufacturing/ to learn more.

#prototechmachining#3dprinting#cncmachining#technologies#swisscncmachining#manufacturing#innovative#metalfabrication#aerospace#medical#automative#robotics

2 notes

·

View notes