#Metal 3d Printing Size

Explore tagged Tumblr posts

Text

Metal 3d Printing Impressively Grow in Future by Top Companies Analysis

Latest Research Report on “Metal 3d Printing Market” | Survey with Valuable Insights

The 2024 market research report for Metal 3d Printing Market offers a comprehensive analysis of the industry, covering key aspects such as trends, opportunities, risks, and drivers. It provides a detailed evaluation of the market's revenue, size, and volume, while also assessing the product portfolios, capacities, and revenues of leading companies. Additionally, the report delves into various industry segments.

According to Straits Research, the global Metal 3d Printing market size was valued at USD 3.3 Billion in 2021. It is projected to reach from USD XX Billion in 2022 to USD 20.96 Billion by 2030, growing at a CAGR of 22.8% during the forecast period (2022–2030). The report places particular emphasis on the Industrial Adhesive market, examining its overall size, segment size (including product type, application, and geography), competitive landscape, current status, and development trends. It also offers strategic insights for companies to navigate the challenges posed by COVID-19.

Get a sample PDF of the report at https://straitsresearch.com/report/metal-3d-printing-market/request-sample

TOP Key Industry Players of the Metal 3d Printing Market

3D Systems Corporation (U.S.)

Stratasys Ltd.

Renishaw plc

General Electric Company

Carpenter Technology Corporation

Materialise NV

Voxeljet AG

Sandvik AB

EOS GmbH Electro Optical Systems

The ExOne Company and Proto LabsInc

Metal 3d Printing Market Segmental Analysis

As a result of the Metal 3d Printing market segmentation, the market is divided into sub-segments based on product type, application, as well as regional and country-level forecasts.

By Components

Hardware

Software

Services

By Technology

Selective Laser Sintering (SLS)

Direct Metal Laser Sintering (DMLS)

Inkjet printing

Electron Beam Melting (EBM)

Laser Metal Deposition (LMD)

Laminated Object Manufacturing (LOM)

Electron-beam Freeform Fabrication (EBF3)

Selective Laser Melting (SLM)

By Software

Design Software

Inspection Software

Printer Software

Scanning Software

By Applications

Prototyping

Tooling

Functional Parts

By Vertical

Automotive

Aerospace and Defense

Healthcare

Consumer Electronics

Powder and Energy

Others

You can check In-depth Segmentation from here: @ https://straitsresearch.com/report/metal-3d-printing-market/request-sample

Regional Analysis Metal 3d Printing Market

The regional analysis section of the report offers a thorough examination of the global Metal 3d Printing market, detailing the sales growth of various regional and country-level markets. It includes precise volume analysis by country and market size analysis by region for both past and future periods. The report provides an in-depth evaluation of the growth trends and other factors impacting the Metal 3d Printing market in key countries, such as the United States, Canada, Mexico, Germany, France, the United Kingdom, Russia, Italy, China, Japan, Korea, India, Southeast Asia, Australia, Brazil, and Saudi Arabia. Moreover, it explores the progress of significant regional markets, including North America, Europe, Asia-Pacific, South America, and the Middle East & Africa.

New Additions in the 2024 Report:

Expanded Industry Overview: The report now includes a more comprehensive and detailed industry overview.

In-Depth Company Profiles: Enhanced profiles providing deeper insights into key industry players.

Customized Reports and Analyst Support: Tailored reports and direct access to analyst support available upon request.

Insights on Market Developments: Updated information on recent market trends and future growth opportunities.

Regional/Country-Specific Customization: Reports tailored to specific regions and countries according to your needs.

Key Highlights

Examine the Metal 3d Printing Market: This includes an introduction, analysis of product types and applications, an overview of the market, and a country-by-country market analysis. The study also explores market opportunities, risks, and driving forces.

Profile Manufacturers: The research focuses on manufacturers of Metal 3d Printing, including detailed profiles, primary business activities, recent news, sales, pricing, revenue, and market share.

Competitive Landscape Overview: Provide an overview of the competitive landscape among the world's leading manufacturers, highlighting their sales, revenue, and market share.

Market Segmentation Analysis: Illustrate the market segmented by type and application, with detailed breakdowns of sales, price, revenue, market share, and growth rate for each segment.

Regional Market Analysis: Analyze key regions, including North America, Europe, Asia Pacific, the Middle East, and South America. This includes sales, revenue, and market share data segmented by manufacturers, types, and applications.

Production Cost Investigation: Investigate production costs, essential raw materials, and the production methods used in the industry.

Reasons to Purchase This Report:

Access to Comprehensive Information: Gain access to an extensive collection of analysis, research, and data that would be challenging to acquire independently. This report offers valuable insights, saving you considerable time and effort.

Enhanced Decision-Making: Equip yourself with detailed insights into market trends, consumer behavior, and key industry factors. This report provides essential information for strategic planning, including decisions on investments, product development, and marketing strategies.

Achieving Competitive Advantage: Stay ahead in your industry by understanding market dynamics and competitor strategies. This report delivers deep insights into competitor performance and market trends, enabling you to craft effective business strategies and maintain a competitive edge.

Credibility and Reliability: Trust in the expertise of industry professionals and the accuracy of thoroughly researched data. Authored by experts and grounded in rigorous research and analysis, this report enhances credibility and reliability.

Cost-Effective Research: Reduce research expenses by investing in this comprehensive report instead of conducting independent research. It provides a cost-effective means of accessing detailed analysis and insights on a specific topic without requiring extensive resources.

To Understand How Covid-19 Impact Is Covered in This Report - https://straitsresearch.com/report/metal-3d-printing-market/request-sample

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Metal 3d Printing#Metal 3d Printing Industry#Metal 3d Printing Share#Metal 3d Printing Size#Metal 3d Printing Trends#Metal 3d Printing Regional Analysis#Metal 3d Printing Growth Rate

0 notes

Text

Metal 3D Printing Market Size, Trends, Statistics and Analysis 2024 - 2030

The global metal 3D printing market size was valued at USD 7.73 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 24.6% from 2024 to 2030.

Metal 3D printing is one such market that has benefitted significantly from the growing necessity of rapid prototyping and advanced manufacturing practices. The industry is poised to witness unprecedented growth over the forecast period owing to the rising application of additive manufacturing in various industry verticals. The global market is increasingly advancing towards consolidation to stay ahead of the competition. A substantial growth factor for this market is increasing innovation, which is leading to several benefits through the adoption of metal 3D printing across heavy industry applications.

Gather more insights about the market drivers, restrains and growth of the Metal 3D Printing Market

Increasing adoption of metal 3D printers for designing and prototyping products and objects coupled with the reduced manufacturing expenditure and accuracy in the end-product is a key growth proliferating factor. The market is poised to witness high demand arising prominently from the healthcare, automotive, and aerospace & defense sectors. The growing advancements in the healthcare sector to curb physical disabilities and ensure healthy living are influencing the sector to flourish and adopt new innovative methodologies, such as 3D printing.

Additionally, the automotive and aerospace sectors, where prototyping and designing play a vital role in research & development to achieve perfection in their production are leading towards greater opportunities and increasing adoption of the 3D printing process.

However, the prevailing misconceptions concerning the prototyping processes held by small and medium-scale manufacturers are hindering the adoption of additive manufacturing. Companies involved in designing, particularly small-scale and medium-scale enterprises are deliberating before considering investments in prototyping as accountable investments rather than trying to understand the advantages and benefits of prototyping.

The general notion prevailing among these enterprises is that prototyping is merely an expensive phase before manufacturing. Such perceptions regarding prototyping, coupled with the lack of technical knowledge and a looming lack of standard process controls, are expected to hinder the market’s growth.

The outbreak of the COVID-19 pandemic has significantly impacted the overall global economy and, subsequently, the 3D printing industry. Initially, Europe and Asia Pacific were one of the worst affected regions in terms of the number of COVID-19 patients across the globe. Further, the situation worsened in the U.S. as well. Due to the rapid spread of the virus, the government issued an order for the complete lockdown of some key cities.

The complete lockdown affected the production of 3D printing manufacturers. This is attributed to the labor shortage and the complete disruption of logistics and supply chains in the country. The halt in the production of 3D printing adversely impacted the overall market growth in the first and second quarters of 2020.

Metal 3D Printing Market Report Segmentation

This report forecasts revenue growth at global, regional, and country levels and provides an analysis of the latest industry trends in each of the sub-segments from 2017 to 2030. For this study, Grand View Research has segmented the global metal 3D printing market report based on component, technology, software, application, printer type, vertical, and region:

Technology Outlook (Revenue, USD Billion, 2017 - 2030)

• Selective Laser Sintering

• Direct Metal Laser Sintering

• Inkjet printing

• Electron Beam Melting

• Laser Metal Deposition

• Laminated Object Manufacturing

• Electron Beam Freeform Fabrication

• Selective Laser Melting

Software Outlook (Revenue, USD Billion, 2017 - 2030)

• Design Software

• Inspection Software

Component Outlook (Revenue, USD Billion, 2017 - 2030)

• Hardware

• Software

• Services

Application Outlook (Revenue, USD Billion, 2017 - 2030)

• Prototyping

• Tooling

• Functional Parts

Printer Type Outlook (Revenue, USD Billion, 2017 - 2030)

• Desktop Metal 3D Printer

• Industrial Metal 3D Printer

Vertical Outlook (Revenue, USD Billion, 2017 - 2030)

• Desktop Vertical

• Industrial Vertical

Regional Outlook (Revenue, USD Billion, 2017 - 2030)

• North America

• Europe

• Asia Pacific

• South America

• Middle East and Africa (MEA)

Browse through Grand View Research's Next Generation Technologies Industry Research Reports.

• The global satellite propulsion system market size was estimated at USD 9.27 billion in 2023 and is expected to grow at a CAGR of 13.2% from 2024 to 2030.

• The global fingerprint access control systems market size was valued at USD 4.29 billion in 2023 and is projected to grow at a CAGR of 12.6% from 2024 to 2030.

Key Metal 3D Printing Company Insights

The ecosystem of the metal 3D printing market comprises an original equipment manufacturer, a network of component manufacturers, system integrators, resellers & distributors, and end users.

Some prominent players in the market include Cognex Corporation (U.S.), Basler AG (Germany), Keyence Corporation (Japan), Sick AG (Germany), and ISRA Vision AG (Germany).

• ISRA VISION GmbH is a manufacturer and provider of surface inspection systems. The company’s products are used for quality and surface inspection, including image processing systems, focused on the arena of metal 3D printing. Its machine vision system comprises lightning components, sensor devices, hardware, software, and mechanical elements such as high-resolution cameras and fast-switching LEDs.

• Basler AG develops and manufactures digital cameras for medical devices, traffic systems, industrial applications, and video surveillance. The products offered by the company include PowerPack Microscopy equipment; network cameras; 3D cameras for applications in logistics, industrial image processing, imaging, and inspection; area scan cameras for factory automation and traffic monitoring; and line scan cameras for sorting procedures and quality assurance.

• ZRapid Tech specializes in metal 3D printing systems and services, offering a range of additive manufacturing solutions tailored to the needs of different industries. The company focuses on developing advanced metal AM technologies and providing customized solutions for high-performance applications.

• UnionTech is a leading provider of stereolithography (SLA) 3D printing systems, including metal-compatible SLA printers. The company offers a range of high-precision, high-resolution SLA printers that enable the production of intricate metal parts with superior surface quality and dimensional accuracy.

Key Metal 3D Printing Companies:

The following are the leading companies in the metal 3D printing market. These companies collectively hold the largest market share and dictate industry trends. Financials, strategy maps & products of these metal 3D printing companies are analyzed to map the supply network.

• Cognex Corporation

• Keyence Corporation

• Sick AG

• ISRA Vision AG

• Basler AG.

Recent Developments

• In October 2021, 3D Systems announced the acquisition of Volumetric Biotechnologies. Volumetric Biotechnologies is a Huston-based biotech company. The acquisition will help 3D Systems to develop manufacturing capabilities for fully bio-compatible human organs using Additive Manufacturing (AM).

• In November 2019, Renishaw plc announced the collaboration with Sandvik Additive Manufacturing. The collaboration aimed to qualify new additive manufacturing (AM) materials for production applications. This collaboration is expected to help Renishaw plc develop new metal materials for 3D printing.

• In October 2019, GE Additive announced the cooperative research and development agreement (CRADA) with the US Department of Energy’s Oak Ridge National Laboratory (ORNL). The agreement period was for 5 years and focused on processes, materials, and software to increase customer adaptability towards additive manufacturing from conventional manufacturing.

• In July 2019, 3D Systems Corporation, a 3D metal printing solution provider was awarded a contract from the Combat Capabilities Development Command Army Research Laboratory (ARL). The contract valued worth USD 15 million with a focus on creating the fastest, and precise 3D printer.

Order a free sample PDF of the Metal 3D Printing Market Intelligence Study, published by Grand View Research.

#Metal 3D Printing Market#Metal 3D Printing Industry#Metal 3D Printing Market size#Metal 3D Printing Market share

0 notes

Text

3D Printing Metals Market

3D Printing Metals Market size is forecast to reach $2.9 Billion by 2030, after growing at a CAGR of 18.6% during 2024-2030. This growth is driven by a significant trend in the industrial metal additive manufacturing market is poised for sustained growth, fueled by increasing demand from key sectors such as aerospace, military, and automotive.

0 notes

Note

whats your favorite math. have u worked with matrices i like matrices barely remember em tho

oUh i- i don't- I DOMT KNOW ENOUHG MATH FALLOW OAUAHHhGhahHhagahjdkgmvkdl😭 LITERALLY i dropped out of year 12 i don't know enough about anything to be able to say i have a favourite😭😭😭

oouhhh. i will say matrices are pretty cool though, they're related to vector maths which is fun and intuitive! half the time! and vectors can be very related to complex numbers again too ^^

i couldn't even decide on a least favourite. like if i don't think something's cool and awesome then clearly i don't know enough about that thing to be having an opinion y'know?? fjhdjsks

#oaUhagh i gotta get back to UNI but i stood up the other day and my heart hit 140bpm and i still have issues with my executive function. so.#kfjdldkfk oH i actually have an MRI scheduled on the 27 of this month!!! hopefully then let me take a copy of all the data for myself#i wanna make a life size 3d printed copy of my brain#also it's terrifying they ask you if you're ''MRI safe'' which is basically like. oh you don't have any metal in your body?#no pacemaker or bone screws or anything? and it's like. no i dont but also do i??? what if i did and i didn't know it????#cause obviously it works with a ton of magnets so if you say you're safe but you're not then you get rent asunder 🤷 fjhdjsks#rambling in the tags again fjdjsn ok ok#askmuck

1 note

·

View note

Text

Metal 3D Printing Market Segmented On The Basis Of Component, Technology, Software, Application, Printer Type, Vertical, Region And Forecast To 2030: Grand View Research Inc.

San Francisco, 29 Sep 2023: The Report Metal 3D Printing Market Size, Share & Trends Analysis Report By Component (Hardware, Software, Services), By Technology, By Software, By Application, By Printer Type, By Vertical, By Region, And Segment Forecasts, 2023 – 2030 The global metal 3D printing market size is estimated to reach USD 35.33 billion by 2030, according to a new report by Grand View…

View On WordPress

#Metal 3D Printing Industry#Metal 3D Printing Market#Metal 3D Printing Market 2023#Metal 3D Printing Market Revenue#Metal 3D Printing Market Share#Metal 3D Printing Market Size

0 notes

Text

0 notes

Text

T4TM (Theseus4TheMinotaur)

lost wax cast bronze, patina & paste wax

2023

(process photos & info under cut <3)

my minotaur boy!! pls click on the photos for higher res! my thesis is focusing on trans men and creatures (how original ik) and this was last semester's final. i spent a lot of time looking at sculptures of the theseus/minotaur story, and yknow? a LOT of them are erotic! i'm pretty sure i saw some of them on tumblr a decade ago, and that's led to this now!

as you'll notice, the minotaur has a big t-dick! i wanted to give him breasts and an enlarged clitoris to present a very masculine trans figure. the boy on the bottom is also trans because i say so . the piece is about looking up to older, bigger, hairier trans men and seeing something awe-inspiring and beautiful. the minotaur was locked up by a cruel father for being different, and i think modern adaptations tend towards a sympathetic asterion (his name in one version)

making this piece was. so much effort. it took me about 3 months to get it all together - from clay model (plasticine) to 3D print to silicone mold to wax cast, and finally bronze pour into the shell mold. and then a TON of filing, sanding, dremel-ing, and various other metalworking techniques that probably took years off my life.

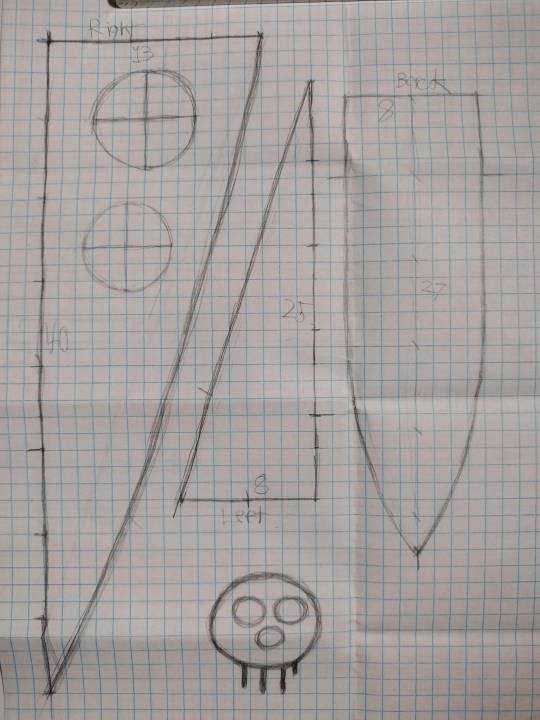

i started with sketches and made theeeeeee ugliest model ever:

then used a 3D scanner to get it digital, then spent a goooood month or two making him pretty in blender! then i spent an agonizing few weeks trying to get it print-ready, and fiiiiiinally did

^^^ an early resin printed draft of the model - you can see in the final that i added lots to theseus after some feedback, but sadly the nosering broke off every time i cast it so i just. let that be <3

then came the moldmaking, and then the wax dipping!! the yellow stuff is shell mold (ground up ceramic bits and algae soup, sticks to the wax, then silica sand in varying sizes on top) which gets the wax melted out, and bronze poured in!

then it's all metalworking, cutting stuff off, and working with hot metal. they don't tell you about all the bronze dust and how annoying it gets wearing a respirator AND goggles. but it is for me health, me boy. here's him all cleaned up before the patina:

and then i spray him down with various chemicals to make it "patina" (aka rust) in pretty colors. wait a few days, then apply paste wax to seal it and give it that shine!

then we get what you see above!!! the blue was actually unintentional, and i'm still not super sure why it looks that way.. but it's pretty so idc <3

thanks for reading!! if you ever have any bronze/casting questions, don't hesitate to message me! <3

#artists on tumblr#bronze sculpture#sculpture#greek myth art#queer artwork#jays0n arts#trans ftm#thanks for reading if you did! i put a lot of work into this project#it's defffff not perfect but i'm proud of what i did!!#if ur curious: my next one is a werewolf w his pussy out :)

8K notes

·

View notes

Text

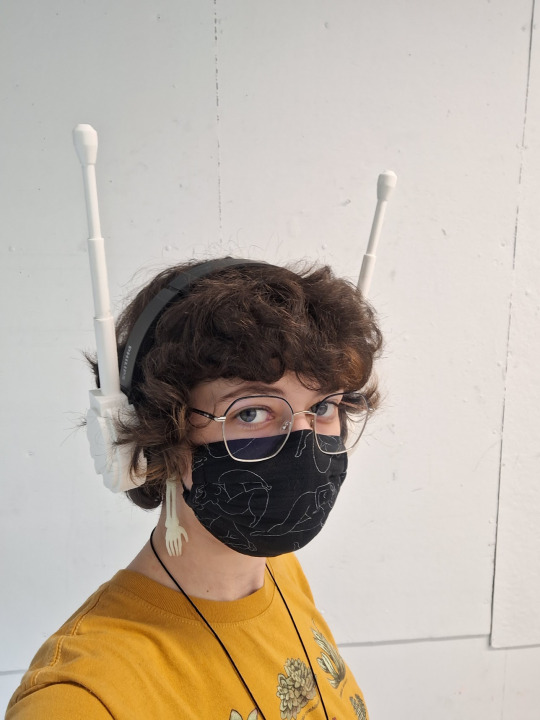

I have been so excited about this project!! 3D printed a pair of iterator antennae headphone attachments :D

The size is measured to my Philips TAH4205 headphones so they clip on without any glue or tape, .STL files and .UFP files (formatted for Ultimaker S3 printers through Cura) are included here!

These are fresh off the 3D printer, I plan to paint them silver tonight to seem more metallic >:]

PART 2 is in reblogs! Fully painted/sealed + bonus WIP stages :]

#rain world#rw iterator#rain world iterator#3d printing#personal project#my art#five pebbles rw#im so so happy with these this is one of the most fun projects ive ever done#3d model#fanart kinda?#face reveal#almost lol

986 notes

·

View notes

Text

I thought that I would post about my Abhorsen bell progress since I haven't mentioned it at all here. Oops!

My friend 3d printed me 2 sets of the bells that I think you can find on thingiverse. One at 100% and the second at 75% since I am small and the largest bell at 100% is roughly the size of my torso and that just won't do. 😂 Thankfully, since I have 2 sets, the bigger set is my tester set, pictured.

Currently I'm in the process of painting them. I used some Rustoleum sanding/fillable grey primer and then spray painted the bases Krylon's metallic aluminum spray once the primer had dried and I sanded the bumps. I then taped the bells once the paint had dried with Krylon's espresso brown.

I definitely plan on painting a darker brown on the handles to make them look more like wood and a darker metallic to make the "metal" base details pop more. I also need to go back over some areas where the brown bled through onto the silver bases of my tester set (specifically Kibeth, the trickster bell), but that will have to be for later--now to move onto my final

126 notes

·

View notes

Text

Bug toys I would try to crowdfund if I had the right connections to produce original *cheap, bulk* rubber or plastic objects (which is still seemingly unattainable compared to having pins or plushes made)

Rubber ducky isopod that works as a rubber ducky

translucent ticks and fleas with fake blood sloshing around inside

Extremely simple big floppy rubbery bugs like any cheap toy spider but of lesser known things like whip spiders and scorpionflies

Bendy velvet worm

Fish that when you squeeze it the tongue biter pops out of its mouth

Clear plastic planktonic crustaceans and brine shrimp that really float in water

Little accurate figures of different insects after their parasitic mushrooms sprouted

Shiny metallic silverfish roughly the size of typical fake roaches

Cheap rubber roaches but of more exotic species

Just a bouncy rubber ball modeled like a curled up isopod

Various things with accurate mandibles or pincers that work like clips so you can clip them on your clothes or hair

People always suggest 3d printing and casting and stuff but Im already getting into that, the problem is I dream of being able to have thousands made so everyone can have one for just a few bucks rather than a $30 limited edition Etsy art piece. I wouldn't even copyright these kinds of things or at least not for long, I'd want them to multiply freely across toy and novelty markets

608 notes

·

View notes

Text

Acht (Dedf1sh) Cosplay Rundown

feel free to copy or take inspiration :]

assembly instructions and print settings/materials for 3d printed parts are on thingiverse (headphones) (other parts)

models designed by me are in brackets in the materials list

Hat/Tentacles

black trucker hat with blank white front panel

[dedstencil.stl]

fabric paint

shiny indigo fabric

less shiny white fabric

glow-in-the-dark pigment powder

polyfill

metal marbles (to weight the ends so they hang properly)

two of [octosucc.obj] in different sizes

acrylic paint

conveniently enough i've had this hat hanging on my door for years. i got it with N from pokemon in mind but i never actually did that cosplay ¯\_(ツ)_/¯

here are the sketches i based my patterns on (1 square=1 cm). don't forget to add seam tolerances

Headphones

full details on thingiverse (mudmouth not included)

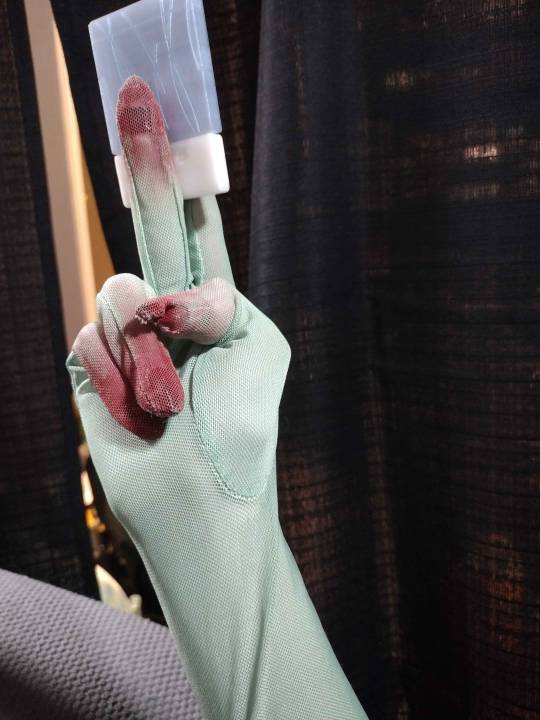

Arms

mesh bolero with built-in gloves

rit dye

fabric paint

10 of [finger_claw_vase.stl] in varying sizes

i wear claws under the gloves, but sometimes i'll wind up taking them off after a while since they can get uncomfortable and they make it hard to use my phone :/

Bracelet

[acht_bangle_vase.stl]

acrylic paint

glow-in-the-dark pigment powder

glossy clear coat

a cut up mello yello bottle

packing tape

eva foam

Misc. Doodads

red mirror shades

color chips

necklace chain

[acht_tag_jelleton.stl]

[acht_tag_ident.stl]

[acht_tag_hook.obj]

did you know that acht gives eight a mobility chip in the trailer but a power chip in the actual game? bc i didn't notice until after i'd already finished making the mobility one. so i've got a spare chip i guess

the dogtags were kind of a spur-of-the-moment creative liberty. i had the jelleton one sitting around from some experiments with composite filaments, and while i was brainstorming a way to incorporate acht's cool fish hook into the cosplay without needing to actually get my ears pierced it all sorta clicked together. i made the ident tag shortly afterwards and swiftly forgot what the text says :P

the rest of it

dress tunic thingy

metal eyelets

red string

camo pants

combat boots

i skimped on accuracy in favor of comfort for the lower half ¯\_(ツ)_/¯ the dress is more of a shirt, i added comfy pants bc i hate wearing colored tights (or god forbid painting my thighs green), and shorter boots bc more accurate ones are expensive as hell. plus any heel higher than this makes walking feel like playing qwop (skill issue). speaking of which does it bug anybody else how long acht's feet are on their in-game model or is that just me

idk if it counts as part of the cosplay but i also add a leather jacket when my arms get cold. i think it goes hard

To-Do:

ink the shaved streaks onto the hairnet

swap out the red leather cord for something less stiff

see if beans would work better than marbles

hand bandages?

single pointy tooth?

make a pre-sanitized version so i don't have to scrub off face paint every time

#i'll probably make more posts like this for other cosplays as i pull them out for cons#this time it's acht. because they're the one i'm the most autistic about rn. insert achtism_creature.jpg here#cosplay reference#splatoon#dedf1sh#acht mizuta#colossalcon#hewk babbles

29 notes

·

View notes

Text

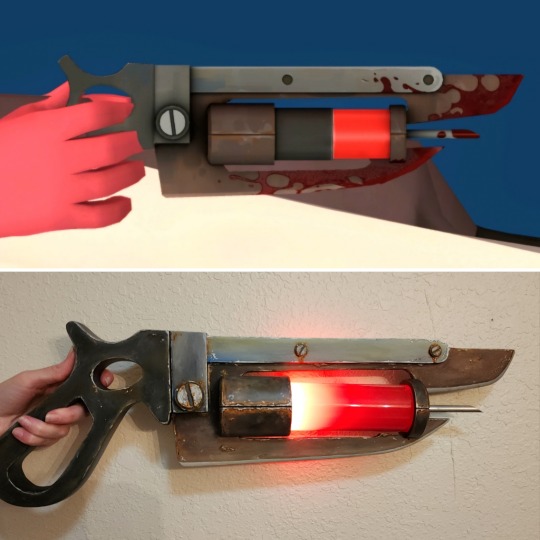

The Übersaw build breakdown, Part 1: (enjoy!)

Note: I'm more than happy to answer any and all questions about this build. Want me to breakdown a specific step or detail, please ask!

From top reference, to bottom complete, this build was a challenge from start to finish and required me to learn a ton of new skills, and reach out to a variety of people for help/advice/brainstorming! But when I decided I was finally going to make my dream cosplay of Medic, I knew this is the saw I wanted to make along with it.

Every piece was made from scratch, and includes sintra, pla 3d printing, resin printing, acrylic tubes, a straw, bondo, E6000, hex bolts, led ring light, arduino trinket, metal switch, aaa battery pack, misc. wiring, spray paint, acrylic paint, and a whole lot of sanding sanding sanding!

I always wanted to stay as true to the original design as possible, but knew adjustments would have to be made, moving a model from a game to real life. Some details I wanted to keep a true as possible, such as the base shape and size. Some aspects were modified deliberately to fit better with the overall aesthetic of the specific version of Medic I was creating; such as smoothing out the edges of the handle, rather than keeping them sharp like in the game. (Something that would make it more realistic overall, a goal I kept in mind through every piece of the costume.)

One such change was adding liquid to the Übersaw core and an led light that pulses red. Looking at the base design, and the color palette the original creators used, they intrinsically translated in my mind to "liquid" and "light" rather than just a flat color. Thinking about Medic and his designs, I figured an ominous, pulsing red would be perfect for when the Übersaw was fully charged. (Plus it would look really cool, so... that definitely influenced my decisions!)

I mixed up a concoction of distilled water, red and silver mica powder, and filled an acrylic tube with the mixture. There's actually two tubes, the smaller inside one helps reduce water weight on this already hefty prop.

Of course, these changes also meant I needed to learning how to code an arduino trinket (which ended up being a lot of fun!), and create a special holder at the base of the Übersaw to hold the ring light, trinket, switch, battery pack and wiring. Not to mention it had to be accessible so I could change the batteries out when needed. That's when it was time to ask for help from some talented friends!

Here's what the resulting holder ended up looking like! (Not pictured is the ring the light sits on) It was 3d modeled and printed in PLA by my friend with some imput by me, but he knows so much more about this stuff I was happy to let him take the lead! The design includes hex bolts to secure the light holder to the Übersaw like a clamp, but also allows it to be opened in half for easy access to the batteries/any electronics that are having issues.

The base of the whole saw is sintra (pvc board), in many layers. The layers were then blended with Bondo and SO MUCH SANDING. After the piece looked like a cohesive whole, rather than 8 layers of plastic board, it was base coated with spraypaint and detail painted with acrylics. (I say this as though it was a simple task, but the spraypaint fought me every step of the way, had to be constantly re-sanded, and some layers refused to dry at all and had to be varnished to remove the tackiness. It was a trial to be sure!)

But after all was said and done, it was finally time for detail painting: My favorite part of any project! (Continued in part 2)

#cosplay#team fortress 2#tf2#tf2 medic#medic#ubersaw#cosplay wip#sisu squid stuff#tf2 cosplay#tutorial

46 notes

·

View notes

Text

Lancer mech license idea

Lore:the license company Name is Magpie arms company,they're a weapons production company originating from Nova Australis (an Australian colony if the name wasn't obvious) comprising of 2 men who,surprised that their design for an asteroid field clearing shotgun managed to be highly profitable,decided to branch out into mechs.

Mechs: for actual mechs we have

Pixie,a size 1/2 mech that makes up for its low armor by being incredibly fast on top of being able to teleport

Kookaburra,a size 2 mech that comes with a sonic Canon that can stun enemies temporarily

Funnelweb: a size 1 mech that can repeatedly infect another mech with computer viruses once in meele range

Bunnings (name pending since that's an actual company still in business):size 2 mech that 3d prints ammo as well as being able to do light repairs on ally mechs

GeeBeeR(Great Barrier Reef): size 3 mech that can create a giant wall of metal branches.

I'm kinda new to lancer as a whole bit I hope you find this interesting.

12 notes

·

View notes

Text

Fun terms i’m picking up from trawling japanese nail art instagrams:

“Full order” vs “size order” - full orders are fully custom for a single client, size orders are part of the artist’s predetermined standard styles but made to order in custom size/shape

“Furisode” and “wagara” - a furisode is a fancy, young woman’s kimono with long sleeves and elaborate prints/painting etc. Furisode nail sets are meant to emulate the aesthetic of and coordinate with such a kimono and usually feature at least 1-2 “wagara” style nails. Wagara refers to aesthetic typical of the kimono prints and will typically be a floral design outlined in shiny metallic or white. A lot of these furisode sets will also have a knot-shaped charm to emulate an obi!

“Nuance” - a watercolory, abstract nail aesthetic characterized by a lack of any figural elements (no florals, animals, etc). Usually in muted and/or pastel tones. Sometimes will employ abstract 3D elements and metallic or glitter accents.

18 notes

·

View notes

Text

RG Nano Review: The Only Device Worse Than Not Having One

It's been a while since I bought this device and even longer since Anbernic released the RG Nano. It's been about a year and a half since it came out so you can't really accuse me of being an early adopter. But I've been spending a lot of time with this device testing everything that I could and it's not great. I won't pretend there isn't anything good about it but I will tell you now that this device is near 100% novelty with 0% practicality.

The RG Nano for those that don't know if an emulation handheld made to play a myriad of emulators and their game files. In this regard the RG nano is actually very impressive capable of playing everything up to and including the PS1 with minimal to no issues. Which is beyond impressive for a device that is shorter than a cotton swab. But as is standard with Anbernic, and other companies producing these devices, they have long since given up on making the perfect device and have opted for making nearly perfect devices with several drawbacks. After all, if they sold you the perfect device what reason would you have to buy the one they release a month later? In the year since this device was made we've seen over 10 devices made from the same XX family of devices that all have the same internals with the only differences being the shell shape. I'm someone who has been a long time supporter of Anbernic but this past year and this device has made me change my mind. Enough about my growing discontent though, let's actually review it.

The Shape

There are several important factors that come in when designing a gaming device, especially a handheld. You need to account for screen size, portability, and comfort. The RG Nano is what happens when all of that is thrown out the window. The nano opted for the form factor of the DMG gameboy but with baxy buttons and two bumpers. The shell is metal with grooves for grip. The dpad is a single unit with sharp corners, the baxy buttons are incredibly small and hurt the thumb, the bumpers feel cheap and clicky similar to a 3d printed material, and I have no complaints about Start and Select. The top of the shell is a usb C out for power and data transfer, and it lights up when plugged in, very cool. The power button is small and sits almost flush with system in a receded pit in the device. This also functions as your menu. It's a single boot sd card slot, speaker on the bottom, and fake speaker lines on the bottom right of the device. No headphone jack but it came with a USB to headphone jack dongle.

Anbernic created this device during the peak of Mini emulator handhelds. The Funkey S had come out, a small clamshell emulator.

The q36 was a small game gear mini like device. Sega released its game gear minis, and the pocket sprite had released. All of these small devices did similar, they offered a wide suite of emulation tools made in the most portable form factors possible. Each one choosing a different shape. Technically the Funkey S was the smallest, followed by pocketsprite, rg nano, and then q36, and GKD Pixel. The main difference between each was mostly the shape and who was offering them.

When comparing the RG nano to its peers you can see one thing in common. All of them have better more comfortable shapes and bigger buttons. Playing on the nano is like repeatedly pressing on the end of a push pin. Sessions longer than 30 minutes will result in pain in your thumb and just a minute of play puts a tiny button indent in your thumb. Anbernic was concerned with going as small as possible and congrats, because there is 0 wasted space in its shell. This is the most cramped board I've ever seen and I worked in mobile device repair before becoming a YouTuber.

How this thing doesn't overheat is a mystery to me, I'm guessing the metal shell doubles as a heat sink. Anyway, since they opted for the smallest possible design they went with a square screen, and a vertical form factor. The q36 has the same screen size, but because it went vertical it's overall a much more comfortable shape. The buttons are bigger and every thumb has room to breathe and you have a better grip. Neither handheld is ideal for comfort but q36 is an example of Powkiddy doing the best with the assignment. Anbernic went with sacrificing comfort for novelty. Which is definitely an option. Don't worry though, give them a bit and I'm sure we'll get a nano H for horizontal.

Now about that screen, it's 1:1 square ratio. This square ratio can work great on larger devices like the RG Cube. Having a square screen means every system gets similar accommodations for it's shape. So everyone gets screwed over a little and results in a handheld that is horizontally smaller making it more portable. On smaller devices this means that anything with less than a square aspect ratio is going to be made even smaller. This means only Gameboy, Gameboy Color, NES, and SNES are going to fill out that screen nicely.

Meanwhile everything else is 4:3 or 3:2, leaving massive black bars at the top and bottom with the gameplay being shrunken even further than it's already miniscule monitor. You can choose to stretch the scaling but this will leave many characters look like they went through a taffy puller. 4:3 stretching isn't too bad, but 3:2 like the gameboy advance is horrendous. So despite being made for portability the GBA looks bad or just too small. You can optionally zoom with the shortcut select + right on d pad but this cuts off the edges. Other than that the screen is perfectly legible on emulators for handheld devices. But home systems had smaller sprites intended to be seen on TVs. So it's a big time squint fest. The brightness on the screen is great, maybe too high. The pictures I've shown have all been at 0% brightness but I wish it still went lower. I've been using this as a portable flashlight more than a gaming system because it's brighter than my phone.

The Firmware

Anbernic is as popular as it is because of how easy it is to set up out of the box. Most of the time these devices come loaded with thousands of games with emulators already set up. But these games are usually in Chinese, and they're numbered but not in alphabetical order making it impossible to find games on it. On this device that's pretty bad as in list view you can only see 4 game titles at a time. Have fun. But the firmware for this one is problematic. First issue is Anbernic used Funkey's open source operating system, fun key has said they're fine with that. But Anbernic didn't publicly release their version after which is scummy.

Anbernic has a long history of their OS' being outdone almost immediately after release by the community. This has led to anbernic getting lazy in recent years releasing devices with bad or buggy operating systems. In the Nano's case it boots to a clock first every time before booting into a launcher menu. This launcher menu looks like something you'd see on a nokia flip phone. Thankfully it has an alternate launcher you can get to by pressing power then going to "Set Launcher". Confirm with A then restart the device and you get something that looks more like their usual emulation station style launcher.

Now mine looks a little different, that's because I changed my OS to Funkey OS by Drum76. This is an OS that is much closer to Funkey's and is available for many mini devices. I don't normally switch my OS because before this Anbernic's Stock OS' have been fine. But on the Nano that annoying clock on every launch was annoying, but more annoying was my games wouldn't launch and sometimes my device wouldn't power on without multiple on/offs. I changed my OS to Drum's and everything works now. Sort of, now I get occasional flickering. Well, flickering is a step up from not turning on or launching. But now you can see where my title is starting to make a bit of sense. It gets worse though.

The Sound

Nothing major of note here, I'm not an audiophile but I'm not tone deaf. I prefer my music on vinyl, but at the same time I don't notice audio unless it's really bad. That said the speaker isn't the worst but there may be some latency on the sound. When playing Rhythm Tengoku Silver, a fan translation of the Rhythm Tengoku GBA. I'm pretty good at guitar hero, I can't play on expert but I can beat the majority of songs on hard. But on RTS I noticed my timing was worse than on my preferred device my Retroid Pocket 3+. On RP3 I was finishing Karate Man on first try, but on the nano I had to try multiple times. It wasn't until I plugged in my headphones that I was able to get almost a perfect. This could be blamed on the small buttons, the speaker, emulation, any number of things. Whatever it was, I wasn't playing my best. It was possibly the emulation as there is some pixelation when playing.

The Emulation

At first I thought this handheld was great. I tried the classic Yoshi's Island test and it worked fine despite the CPU being at 83% nearly the whole time. Double of what I was getting on PS1 emulation. But it ran fine, maybe it stutters aren't as noticeable on a small screen? What's the Yoshi's Island Test? This is a test Bob on Wulffden does. Yoshi's Island and some other select SNES games had a built in Super FX chip. This chip let Nintendo squeeze some extra power out of their SNES games. This let them do 3d. Yoshi's Island despite displaying minimal 3d absolutely makes the most of this chip. Maybe because so few games used it or maybe it really is that hard to emulate, either way many emulator handhelds can't run Yoshi's Island well. This is kind of common knowledge because many emulator handhelds that typically come with thousands of games seem to always forget Yoshi's Island. It was even able to run Goodboy Galaxy and that's a very recent GBA game made in 2023.

Anyway, it passed the YIT for me. So I decided to roll the dice and play random games. I got a game gear one, Sonic Chaos and started getting frequent slowdowns despite it being an 8 bit console. But everything runs pretty great or normally. Some ps1 games run at 30 fps but it's a consistent 30 and isn't as noticeable on the Squint Master.

The Game Feel

This is in it's own section because even devices that all run the same hardware and software can still handle games differently than others. The Retroid 2 is comparable to many devices but struggles with Dreamcast when others in it's price range don't for example. Probably because it's an Android device. But a lot of factors go into game feel, the hardware, firmware, the emulators, frame rate, the system size, buttons, individual taste, and yeah the RG nano may nail emulation for the most part but it is genuinely terrible to play on.

The screen is too small the majority of the systems it runs well play bad because of the added shrink from small aspect ratios. GBA suffering the most. Gameboy and GBC are great, perfect fits. But even the NES and SNES with their 10:9 screens are still terrible to play because their sprites are smaller. But they control poorly too as systems like PS1 and SNES have a lot of buttons. Yoshi's island runs but the sprites are so small and the buttons too. So it's hard to see but hard to platform too since the dpad is too small for previse movement. When playing Sonic Chaos I frequently had to try and jump to grab rings. One ring took me 5 jumps because I kept barely moving too much.

The machine is perfect for RPGs because they don't require precise controls and if they have a lot of buttons you at least have plenty of time to press it. Playing PS1 is nearly off limits as the nano lacks analog sticks, and L2 and R2 buttons. You can press Select + R to get R2. But say you're playing Chocobo's Dungeon 2, select is the map. So press R2 means opening your map first and then r2 not doing anything because you're on the map. Ps1 doesn't play too bad with a stretched resolution though.

There is only one use case I can think of that this is a good system. You really like Pokemon. It's turn based, clean text, doesn't require precise inputs, uses few buttons, it's a Pokemon machine. But anything else I played all had drawbacks.

Overall

The RG Nano is a perfect example of "Just because you can do something, doesn't mean you should." Anbernic didn't need to ask "Why don't people make systems this small?" Because the answer is obvious, it's a terrible way to play. Now what I meant by the title. Playing this device made me want to play the other systems I own. Every game I thought "This would be better on the rg28xx" or "I miss my RP3". If I had to play nothing but this, I'd choose to not play anything. I'm not even joking. I'll go outside over playing this.

Get Literally Anything Else

Even if you account for it being the most portable handheld it's still pretty terrible because of its other issues.

RG28XX above, RG35XX H below

I'd recommend getting an RG28xx it's $30 and goes on sale frequently, the New model has wifi so you can use Retro Achievements. The rg28xx is also only slightly bigger than a micro but still much smaller than a GBA. Better D Pad, bigger buttons, has an r2 and l2, no analog though. The RG35xx H is a better 28xx with analog sticks but and both have hdmi out. Make sure you get the ones that say "New" in their name as they have Wifi.

The Miyoo Mini Plus is recommended by so many people and it's just 50 bucks.

Retroid Pocket 3+, my emu handheld of choice. Android based OS, touchscreen, plays everything from the DS and PSP and earlier. I've even played some Wii and Gamecube on it. But if you want 3ds, Gamecube, Wii U, Wii, and PS2 get RP4 Pro or 5.

If you're willing to go expensive get a Retroid system, they run on Android and it has quickly replaced my phone. When checking social media I don't even reach for my phone anymore. It just needs a camera and a sim slot. If you have literally any other emulation handheld the RG Nano feels like some obscure torture method by comparison. I can confidently say, if the RG Nano is the only emu handheld you can get then maybe it's time for a new hobby. Pick up hiking, rollerblading, skateboarding, boardgames or tabletops.

#gaming#retro#retrocollection#retrocollector#retrogaming#retrocollecting#gamecollecting#gamecollection#emulation#emulator#rg nano#anbernic#miyoo mini#retroid#powkiddy#gba#gbc#gameboy#nes#snes#ps1#playstation#nintendo

13 notes

·

View notes

Text

COMMISSIONS

TEMPORARILY CLOSED. i hope to be back in early 2025.

if you want to get your hands on one of my critters, a few options are available:

1) prints of existing bjd models starting at 60€ + shipping. if you want any creature posted in the catalog tag, this option is for you. mini catalog contains simple tiny sculpts that cost 15€. we can discuss size, color, and paint options, or you can have a blank base. eyes and hair are included, clothing and accessories are not. if the post indicates there are fixes i need to make to the prototype, those fixes will be made before your doll is printed. price is determined by how much post-print painting and other customization work you want; i will give you an exact quote when the details have been fully hashed out. the starting price includes a simple paint job & faceup.

2) custom bjd 200€ + shipping. a fully unique sculpt made to your specifications, printed and painted. can include hair and eyes, does not include clothing. i can make clothes for an extra fee, see this & this for some examples. a custom sculpt that involves your design [oc references etc] will not be sold to anyone else.

the maximum height for full dolls is 35cm. bigger prints cost extra, depending on size.

3) floating heads from any sculpt in the catalog tag 25€ + shipping, unique custom heads 50€ + shipping. includes faceup and eyes. can be any size, up to 1/3 scale.

4) familiars/other metal armature art dolls 70€, or 100€ with wings. art dolls can be mixed&matched from all parts i've made, and colors can be whatever i happen to have on hand/am able to find. the tag for familiars is here. if you need a custom head/paws/other parts, i can also do that.

all dolls are fdm 3d-printed in PLA. this means the following things:

they are very lightweight and reasonably sturdy.

there will be layer lines and imperfections. i check the quality of every doll, but a 3d print will never be as flawlessly smooth as a resin doll or a mass-produced plastic doll.

they are non-toxic, though should not be given to children to chew on because they're entirely made of small parts strung together with elastic cord.

i'm not currently selling any digital files.

turnaround time is 2-8 weeks. keep in mind i am one person with one printer, so technical problems can cause delays. payments via paypal invoice when i'm ready to start working. bank transfer and mobilepay are also ok for finnish customers. i ship worldwide, cost depends on location; starting at around 20€ for eu, 45€ for usa, and somewhere in-between for the rest of the world. let me know where you live and i'll give you an exact shipping quote.

no returns or refunds & i can't take responsibility for any problems during shipping. if a part of your doll breaks (in transit or after), i will replace it at the cost of shipping for the new part.

shoot me a chat message to get started!

86 notes

·

View notes