#Manufacturing Software Development Services

Explore tagged Tumblr posts

Text

If you're looking to revolutionize your manufacturing operations and stay ahead of the competition, discover how Performix’s cutting-edge AI breakthroughs can elevate your business. Learn more about our recent advancements and how we can help you seamlessly integrate AI and AR into your operations at Performix’s AI Solutions.

#performix#travel and hospitality software solutions#manufacturing software development services#it staff augmentation#web designers near me

0 notes

Text

PhoenixBizz offers custom manufacturing software development services. We design and develop manufacturing software for all your manufacturing needs.

#Manufacturing Software Development Company#Manufacturing Software Development#Manufacturing Software Development Services#Custom Manufacturing Software Development#Manufacturing Software#Manufacturing#Software Development#PhoenixBizz

0 notes

Text

ERP Trends 2024: What Engineering and Manufacturing Industries Need to Know

As we navigate through 2024, the landscape of Enterprise Resource Planning (ERP) systems continues to evolve, presenting both opportunities and challenges for engineering and manufacturing industries. Companies in this sector, especially those in key industrial regions like Maharashtra, Mumbai, Pune, and Gujarat, must stay abreast of the latest ERP trends to maintain competitive advantage and operational efficiency. In this blog, we’ll delve into the significant ERP trends of 2024 and their implications for the engineering and manufacturing sectors.

1. Increased Adoption of Cloud-Based ERP Solutions

One of the most significant trends in ERP software for engineering companies in Maharashtra and across India is the shift towards cloud-based solutions. Cloud ERP offers several advantages over traditional on-premise systems, including lower upfront costs, greater scalability, and enhanced accessibility.

Benefits of Cloud-Based ERP:

Cost Efficiency: Eliminates the need for expensive hardware and reduces IT maintenance costs.

Scalability: Easily adjusts to the growing needs of a manufacturing company in Gujarat or an engineering firm in Mumbai.

Accessibility: Provides access to real-time data from anywhere, facilitating better decision-making.

Leading ERP software companies in Pune are increasingly offering cloud-based solutions tailored to the needs of local engineering and manufacturing businesses. These solutions support remote work and ensure business continuity in an increasingly digital world.

2. Integration of AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing ERP systems by providing intelligent insights and automating routine tasks. For ERP software for engineering companies in Mumbai, integrating AI can enhance predictive maintenance, optimize supply chain management, and improve production planning.

AI and ML Applications in ERP:

Predictive Analytics: Helps foresee equipment failures and reduce downtime.

Supply Chain Optimization: Enhances demand forecasting and inventory management.

Process Automation: Automates repetitive tasks, freeing up human resources for more strategic roles.

ERP solution providers in Pune are at the forefront of integrating AI and ML into their systems, enabling companies to leverage advanced analytics and improve overall operational efficiency.

3. Emphasis on Cybersecurity

With the increasing digitization of manufacturing processes, cybersecurity has become a critical concern. ERP systems, being the backbone of business operations, are prime targets for cyber-attacks. Engineering and manufacturing companies in regions like Gujarat and Maharashtra need robust cybersecurity measures to protect their sensitive data.

Key Cybersecurity Features:

Data Encryption: Protects data during transmission and storage.

Multi-Factor Authentication: Enhances user authentication processes.

Regular Security Audits: Ensures continuous monitoring and improvement of security protocols.

ERP software for engineering companies in Maharashtra must incorporate these advanced security features to safeguard against data breaches and cyber threats.

4. Enhanced User Experience (UX)

User experience has become a critical factor in ERP adoption and utilization. Modern ERP systems are focusing on intuitive interfaces and user-friendly designs to ensure that all employees, regardless of their technical expertise, can effectively use the system.

UX Improvements:

Intuitive Dashboards: Provide real-time insights and easy navigation.

Mobile Accessibility: Ensures that users can access ERP data on-the-go.

Customization Options: Allow users to tailor the system to their specific needs.

ERP software companies in Pune are prioritizing user experience in their solutions, making it easier for engineering and manufacturing firms to train their staff and increase productivity.

5. Internet of Things (IoT) Integration

The integration of IoT with ERP systems is another trend transforming the manufacturing industry. IoT devices collect vast amounts of data from production lines, equipment, and other operational areas, which can be analyzed by the ERP system to optimize performance.

IoT Benefits in ERP:

Real-Time Monitoring: Provides immediate insights into production processes.

Predictive Maintenance: Schedules maintenance activities based on equipment condition rather than time intervals.

Enhanced Quality Control: Monitors product quality throughout the manufacturing process.

For ERP for manufacturing companies in Gujarat, IoT integration offers a significant advantage by improving efficiency and reducing operational costs.

6. Sustainability and Green Manufacturing

Sustainability is becoming a critical focus for manufacturing companies worldwide. ERP systems are evolving to support green manufacturing practices by tracking and optimizing resource usage, reducing waste, and ensuring compliance with environmental regulations.

Sustainable ERP Features:

Resource Management: Tracks energy and material usage to minimize waste.

Regulatory Compliance: Ensures adherence to environmental laws and standards.

Sustainability Reporting: Provides detailed reports on sustainability metrics.

Engineering and manufacturing companies in regions like Mumbai and Maharashtra can benefit from ERP solutions that incorporate sustainability features, helping them achieve their environmental goals and enhance their corporate reputation.

7. Modular and Flexible ERP Solutions

In response to the diverse needs of engineering and manufacturing firms, ERP solution providers in Pune are developing more modular and flexible ERP systems. These systems allow companies to select and implement only the modules they need, which can be easily scaled and customized as their business grows.

Advantages of Modular ERP:

Cost-Effective: Pay only for the features you need.

Scalability: Easily add new modules as your business requirements evolve.

Customization: Tailor the system to fit specific operational needs.

This trend is particularly beneficial for small to medium-sized enterprises (SMEs) in the engineering and manufacturing sectors, enabling them to adopt ERP systems without the burden of high costs or complexity.

8. Focus on Customer-Centric Manufacturing

ERP systems are increasingly supporting customer-centric manufacturing practices, where production processes are aligned with customer needs and preferences. This approach enhances customer satisfaction and drives business growth.

Customer-Centric ERP Features:

Custom Order Management: Handles unique customer requirements and specifications.

Enhanced CRM Integration: Integrates with customer relationship management (CRM) systems for a holistic view of customer interactions.

Real-Time Order Tracking: Provides customers with real-time updates on their orders.

Manufacturing companies in Gujarat and engineering firms in Maharashtra are leveraging these customer-centric ERP features to improve their service levels and build stronger customer relationships.

9. Advanced Analytics and Business Intelligence (BI)

Advanced analytics and BI are becoming integral components of modern ERP systems. These tools provide deep insights into business operations, helping companies make data-driven decisions and improve performance.

Key BI Features:

Data Visualization: Converts complex data into easy-to-understand charts and graphs.

Dashboards: Offer a real-time overview of key performance indicators (KPIs).

Predictive Analytics: Forecasts future trends based on historical data.

ERP software companies in Pune are incorporating advanced analytics and BI capabilities into their systems, empowering engineering and manufacturing firms to gain a competitive edge through better insights and informed decision-making.

10. Globalization and Localization Support

As engineering and manufacturing companies expand their operations globally, ERP systems must support multiple languages, currencies, and regulatory requirements. Globalization and localization features are essential for companies operating in diverse markets.

Globalization Features:

Multi-Language Support: Accommodates users from different regions.

Multi-Currency Handling: Manages transactions in various currencies.

Compliance with Local Regulations: Ensures adherence to regional laws and standards.

ERP solution providers in Pune and other industrial hubs are enhancing their systems to support global operations, enabling companies to seamlessly manage their international business processes.

Conclusion

The ERP landscape for engineering and manufacturing industries is rapidly evolving, driven by advancements in technology and changing business needs. Companies in Maharashtra, Mumbai, Pune, and Gujarat must stay informed about these trends to leverage the full potential of ERP systems. By adopting cloud-based solutions, integrating AI and IoT, prioritizing cybersecurity, and focusing on sustainability, businesses can achieve greater efficiency, competitiveness, and growth in 2024 and beyond.

For engineering and manufacturing firms looking for the best ERP software for engineering companies in Maharashtra or ERP for manufacturing companies in Gujarat, it is crucial to partner with leading ERP solution providers in Pune who understand the unique challenges and opportunities in this sector. Embracing these trends will not only enhance operational efficiency but also drive innovation and sustainability in the engineering and manufacturing industries.

By staying ahead of these ERP trends, companies can position themselves for success in an increasingly digital and interconnected world. Whether you are an engineering firm in Mumbai or a manufacturing company in Gujarat, the right ERP system can transform your operations and pave the way for a prosperous future.

#ERP software in Vadodara#Manufacturing ERP software in Gujarat#ERP software companies in Vadodara#ERP software providers in Vadodara#ERP for manufacturing company in Gujarat#ERP software#ERP system#cloud ERP#ERP solutions#software development#engineering ERP#management software#engineering services#engineering industry

5 notes

·

View notes

Text

#erp software#cloud erp#erp application#erp consulting services#erp development company#erp development services#erp for small business#erp system#erp integration#crm software#erp for manufacturing

1 note

·

View note

Text

Choosing the right ERP is crucial for business growth. Odoo and SAP are top contenders, but which one suits your needs best? Our in-depth comparison explores key features, pricing, scalability, and industry suitability to help you make an informed decision. Whether you're a small business or an enterprise, discover the pros and cons of each system and find the perfect fit for your operations. Don’t invest blindly—read our expert guide now and choose the best ERP for your business success! To Read More click here

#erp#erp software#erp solution bd#erpsoftware#erp system#odoo development#odoo development company#odoo#odoo development services#odoo erp#dubai#dublin#software development#web development#development#technologies#developer#software#services#united states#america#united states of america#england#united kingdom#london#scotland#wales#businesssuccess#business#manufacturing

0 notes

Text

Shape Your Cloud Business with Surfytech!

Manufacturers & Exporters – Maximize Your Product Visibility!

Struggling to get your products in front of the right buyers? Surfytech helps manufacturers, suppliers and Exporters:

- Showcase products with SEO-friendly listings

- Optimize search rankings to increase visibility

- Target the right customers via AI-driven social media marketing

- Boost engagement & conversions with data-backed strategies

Let’s take your business global! Contact us today.

#manufacturer#exporter#supplier#software development#website#web design#search engine optimization#seo services#social media

0 notes

Text

How to Build an Online Marketplace? 8 Steps from an Idea to Launch

AI and ML development company eCommerce development company Hire Shopify developers Custom software development company

#app development cost#ios application development services#app development#website#ai in manufacturing#ai development solutions#saas software solutions#AI in agriculture#AI development solutions#AI/ML development service#Custom AI development solutions#online marketplace development#ecommerce development company

1 note

·

View note

Text

Make manufacturing simple with SAP Business One Cloud! 🌟 Plan and track your work, check for missing materials, and keep everything running smoothly. It's like having a smart helper to make sure you finish on time and save money too

#sap b1#cloud erp#sap erp#clouderp#sap business one#erpsolutions#erp software#erp for small business#sapbusinessone#cloud partner#manufacturing erp#manufacturing industries#manufacturing erp software#manufacturing with netsuite#services#industry#industries#manufacturing supply company#warehouse#development#manufacturing consent

0 notes

Text

#technews#Enterprise Resource Planning (ERP)#ERP Solutions#Business Management Software#Integrated Business Applications#Supply Chain Management#Customer Relationship Management (CRM)#Financial Management Systems#Human Resources Management#Inventory Management Software#Manufacturing Resource Planning#Cloud ERP Solutions#On-Premise ERP Systems#ERP Implementation Services#ERP Consulting#ERP Software for Small Business#ERP Software for Manufacturing#ERP System Integration#ERP Software Development#ERP Customization Services#ERP Training and Support

0 notes

Text

Why Attending Tech Expo Gujarat 2024 is a Must for MSMEs and Businesses

Tech Expo Gujarat AI development service

AI/ML development solutions

Hire AI developers

Hire Chatbot developers

Hire LLM developers

Hire neo4j develoeprs

#tech expo gujarat#tech news#tech expo ahmedabad#biggest tech expo Gujarat#ai in manufacturing#ai development solutions#saas software solutions#AI in agriculture#AI development solutions#AI/ML development service#Custom AI development solutions

1 note

·

View note

Text

Partner with Performix today to transform your logistics operations with cutting-edge technology designed specifically for trucking and dispatch needs. With our expertise in logistics software development services tailored to the industry’s unique requirements, we are here to help you succeed in this competitive landscape.

#performix#manufacturing software development company#manufacturing software development services#web designers near me#software companies near me

0 notes

Text

Accelerate Manufacturing Growth with NetSuite Industry Activation by OpenTeQ Consultant

Leveraging the appropriate tools is crucial to staying ahead in a competitive market in the industrial sector where accuracy and efficiency are what drive success. With its powerful features designed to improve productivity, cut expenses, and streamline operations, NetSuite has become a game-changer for manufacturers. End-to-end NetSuite services that enable manufacturers to efficiently optimize their operations are the specialty of OpenTeQ, a Certified NetSuite Partner.

Why Choose NetSuite for Manufacturing?

Tight profit margins, intricate production cycles, and shifting supplier chains are some of the difficulties faced by manufacturers. These issues are resolved by a comprehensive solution such as NetSuite Manufacturing ERP & Management Software, which improves visibility, automates processes, and facilitates improved decision-making.

NetSuite easily connects with all facets of manufacturing, from shop floor operations to inventory management. Businesses can save a lot of money by using its sophisticated capabilities to better schedule production, keep track of resources, and guarantee constant product quality.

Unlocking the Power of NetSuite Industry Activation

NetSuite Industry Activation is an essential tool for manufacturers looking for industry-specific customizations. It enables companies to modify their ERP systems to satisfy the particular requirements of the manufacturing industry. With capabilities like enhanced material planning, production monitoring, and demand forecasting, OpenTeQ makes sure producers can benefit fully from this activation.

Businesses can easily integrate NetSuite into their current systems with OpenTeQ's expertise, opening the door to improved operational management and less downtime.

Top NetSuite Services Provider for Manufacturing

The secret to maximizing NetSuite's potential is selecting the appropriate installation partner. OpenTeQ stands out as a Top NetSuite Services Provider because of its unique strategy for manufacturing companies. OpenTeQ guarantees that manufacturers receive customized solutions that optimize return on investment from the first consultation through deployment and beyond.

By fusing extensive understanding of NetSuite Development with industry experience, OpenTeQ assists manufacturers in streamlining reporting, automating procedures, and customizing workflows to meet their unique objectives.

Reduce Costs with Custom Development

NetSuite's versatility is one of its best qualities. Manufacturers can improve their ERP capabilities by utilizing bespoke development. The NetSuite Development team at OpenTeQ is very skilled at developing solutions that smoothly mesh with corporate processes.

Manufacturers benefit from customizations that reduce human labor and prevent expensive mistakes, such as automated quality checks, thorough resource tracking, and sophisticated reporting capabilities. These developments ensure businesses not only reduce operational costs but also improve overall efficiency.

Partnering with a Certified NetSuite Partner

OpenTeQ, a Certified NetSuite Partner, offers manufacturers unparalleled experience in NetSuite implementation and optimization. Our team of professionals is dedicated to comprehending the particular needs of every company and making sure that each solution is tailored to produce quantifiable results.

Whether it’s implementing NetSuite Manufacturing ERP & Management Software or activating industry-specific functionalities, OpenTeQ guides manufacturers through every step of the journey to achieve their operational goals.

Conclusion

For manufacturers looking to stay competitive, increasing productivity and cutting expenses are essential. Businesses may successfully reduce expenses, increase productivity, and streamline operations using NetSuite's extensive toolkit and OpenTeQ's experience as a Top NetSuite Services Provider.

OpenTeQ can assist you whether you're prepared to work with a reputable Certified NetSuite Partner, deploy potent NetSuite Development solutions, or unleash the full potential of NetSuite Industry Activation. To advance your manufacturing company, get in touch with us right now.

Reach out to OpenTeQ for expert NetSuite services tailored to your business needs. [email protected], +1-469 623 5106.

#NetSuite Industry Activation#NetSuite Manufacturing ERP & Management Software#Top NetSuite Services Provider#NetSuite Development#Certified NetSuite Partner#Industry Activation NetSuite#NetSuite ERP Software for Manufacturing Companies#NetSuite for Manufacturers#NetSuite ERP for Manufacturers#Manufacturing with NetSuite#NetSuite Solutions for Manufacturing#NetSuite Portals for Manufacturing#NetSuite Services#NetSuite Services Company#NetSuite Support Services#NetSuite Development Company

0 notes

Text

Simulanis is an Augmented Reality Company in India that stands at the forefront of the Augmented Reality Companies in India sector. As a leader in the AR space, Simulanis is helping businesses across industries leverage the power of augmented reality to transform their operations, enhance customer experiences, and foster innovation. With a focus on creating cutting-edge augmented reality app development solutions, Simulanis delivers customized AR solutions that cater to various sectors, including healthcare, education, manufacturing, retail, and more

#simulanissolutions#Augmented Reality Company India#Augmented Reality Companies in India#Augmented Reality Company#Augmented Reality Companies#Augmented Reality in India#augmented reality app development company in india#augmented reality india#best augmented reality company india#listed virtual reality companies in india#top arvr companies in india#R Development India#Augmented Reality Solutions#AR App Development India#AR Software India#Augmented Reality for Business#AR Innovation in India#AR Experience Design#Virtual and Augmented Reality#AR for E-commerce India#AR for Education India#Augmented Reality Platform India#AR Content Creation#AR in Retail India#AR Technology Company India#Augmented Reality Services#AR for Marketing India#Custom AR Solutions India#AR-Based Training Solutions#AR in Manufacturing India

0 notes

Text

OpenTeQ: Streamlined NetSuite Solutions Provider for Every Industry

NetSuite, the world’s leading cloud ERP solution, is revolutionizing the way businesses operate by providing robust tools to manage financials, customer relationships, and operations. For manufacturing companies and other industries, leveraging the capabilities of NetSuite requires the support of experienced solution providers and development companies. This article delves into the pivotal roles of NetSuite Solution Providers, top NetSuite services, NetSuite development expertise, consultation offerings, and specialized NetSuite portals for manufacturing businesses.

NetSuite Solutions Provider: Your Strategic ERP Partner

NetSuite Solution Providers play an essential role in delivering tailored ERP solutions that address diverse business needs. These providers offer everything from system evaluation to implementation, customization, and long-term support. By aligning NetSuite’s capabilities with organizational objectives, solution providers enable businesses to achieve seamless operations, enhance decision-making, and improve productivity.

NetSuite Development Company: Crafting Tailored Solutions

A NetSuite Development Company specializes in creating bespoke solutions that extend NetSuite’s core functionalities. From building custom workflows to integrating industry-specific modules, these companies ensure that businesses can address unique challenges and streamline their operations. NetSuite Development company also focus on enhancing user experience and creating applications that leverage NetSuite’s powerful API capabilities.

NetSuite Consultation: Expertise for Strategic Decisions

NetSuite consultation services guide businesses in making informed decisions about their ERP strategies. Experienced consultants analyze current processes, identify inefficiencies, and recommend the best NetSuite solutions to drive growth. From initial assessments to implementation roadmaps, NetSuite consultation services ensure businesses get the most out of their ERP investment.

NetSuite Portals for Manufacturing: A Game-Changer for Efficiency

For manufacturing companies, NetSuite portals offer unparalleled visibility and control over production workflows, inventory, and supply chain management. These portals provide real-time insights into every aspect of the manufacturing process, enabling businesses to reduce lead times, minimize costs, and ensure product quality. NetSuite’s ability to integrate with other systems and provide a unified platform makes it an indispensable tool for manufacturers aiming for operational excellence.

Conclusion

OpenTeQ is a trusted NetSuite Solutions Provider, offering end-to-end services to empower businesses with seamless ERP integration and customization. As a Top NetSuite Services Provider, OpenTeQ specializes in delivering tailored solutions, ensuring maximum efficiency and ROI for diverse industries. As a leading NetSuite Development Company, OpenTeQ provides advanced development expertise, creating custom workflows, integrations, and automation to meet unique business needs.

Through comprehensive NetSuite Consultation, OpenTeQ’s experts guide organizations from strategy formulation to post-deployment optimization, ensuring smooth transitions and enhanced productivity. With specialized NetSuite Portals for Manufacturing, OpenTeQ enables manufacturers to streamline operations, improve supply chain coordination, and achieve real-time visibility, driving innovation and operational excellence. Partner with OpenTeQ to unlock the full potential of NetSuite and achieve long-term business success.

#IndustryActivation#Industry Activation NetSuite#NetSuite Industry Activation#NetSuite for Manufacturing#Manufacturing ERP & Management Software#NetSuite ERP Software for Manufacturing Companies#NetSuite for Manufacturers#NetSuite ERP for Manufacturers#Manufacturing with NetSuite#NetSuite Solutions for Manufacturing#NetSuite Portals for Manufacturing#NetSuite Services#NetSuite Services Company#Top NetSuite Services Provider#NetSuite Support Services#NetSuite Solutions Provider#NetSuite Development Company#NetSuite Development#NetSuite Developer#NetSuite Consultation#NetSuite Consulting Services#NetSuite Accounting Services#NetSuite Financial Software#NetSuite BPO Accounting Services

0 notes

Text

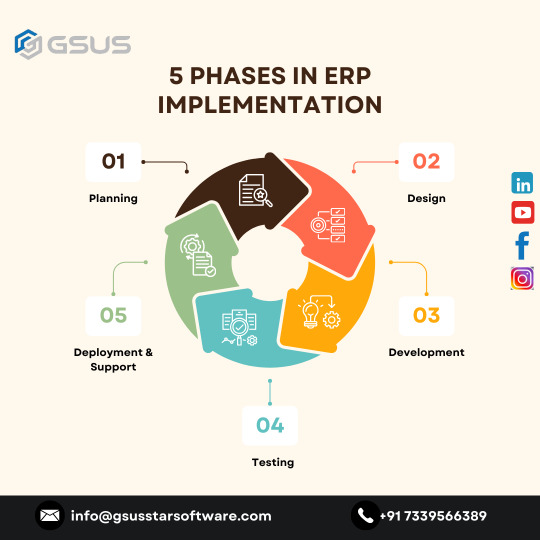

Kickstart your ERP journey with these essential phases: Planning, Design, Development, Testing, and Deployment. Each step is crucial for a seamless transition and maximizing your system’s potential. 1️⃣ Planning: Set clear goals and assemble your team. 2️⃣ Design: Map your processes and customize the system. 3️⃣ Development: Build and integrate features tailored to your needs. 4️⃣ Testing: Ensure everything works smoothly with thorough testing. 5️⃣ Deployment: Go live and provide support for a seamless transition! Transform your business operations and drive efficiency today! www.gsussoftware.in

#business central#cloud erp#erp#app development#erp for manufacturing#erp development company#erp integration#erp software#sap#sap business one#sap s/4hana#sap solutions#sap services

0 notes

Text

OpenTeQ NetSuite Developer: Driving Customization and Integration

A NetSuite Developer plays a crucial role in tailoring NetSuite, an advanced cloud ERP platform, to meet specific business needs. Whether it's customizing dashboards, building workflows, or integrating third-party applications, these developers bring unmatched flexibility to NetSuite's already robust suite of tools. By leveraging SuiteScript, SuiteFlow, and SuiteTalk APIs, developers enhance NetSuite's core functionalities, ensuring seamless operations across various business units. From automating financial processes to creating custom reports, NetSuite Developers are vital in shaping the platform to align with organizational goals.

NetSuite Consultation: Strategic Guidance for Business Transformation

The role of NetSuite Consultation cannot be overstated, especially for businesses seeking to transition to or optimize NetSuite. Expert consultants help organizations assess their current processes, identify pain points, and implement NetSuite solutions that drive efficiency and scalability. With a focus on cloud-based ERP, NetSuite Consultation provides guidance on system configuration, data migration, process optimization, and user training. By working closely with internal teams, consultants ensure that NetSuite implementation aligns with the company’s long-term goals, ultimately delivering higher productivity and cost savings.

NetSuite Financial Software: Simplifying Complex Financial Management

NetSuite Financial Software is a comprehensive solution designed to streamline financial operations, from basic accounting to advanced financial planning. It offers real-time insights into financial performance, automates routine accounting tasks, and supports multi-currency, multi-subsidiary management. With features such as general ledger, accounts receivable/payable, tax management, and revenue recognition, businesses can gain control over their financials with increased accuracy and compliance. NetSuite’s cloud-based architecture allows for real-time collaboration, making financial reporting and auditing faster and more transparent, thus simplifying complex financial management processes.

NetSuite Support Services: Ensuring Seamless Operations and Continuous Improvement

NetSuite Support Services offer the technical expertise needed to maintain and optimize your ERP system after implementation. Whether it’s troubleshooting errors, upgrading the system, or optimizing performance, these NetSuite Support services ensure that the platform runs smoothly, allowing businesses to focus on their core operations. Support teams also help with system customization, patch updates, and new feature implementation, ensuring that the software adapts to evolving business needs. Continuous support can reduce downtime, enhance system performance, and ensure a seamless user experience.

NetSuite for Manufacturers: Revolutionizing the Manufacturing Process

NetSuite for Manufacturers is designed to address the specific needs of the manufacturing industry, offering solutions for managing production processes, inventory control, and supply chain operations. With real-time visibility into inventory levels, order management, and production schedules, manufacturers can reduce waste, improve efficiency, and deliver products faster. NetSuite’s built-in manufacturing modules support make-to-order, make-to-stock, and engineer-to-order processes, helping manufacturers adapt to changing market demands while maintaining profitability. This holistic approach ensures that manufacturers can streamline operations, reduce costs, and maintain a competitive edge in the market.

Conclusion

OpenTeQ Technologies stands as a reliable partner for businesses seeking to maximize the potential of NetSuite solutions. With a dedicated team of NetSuite Developers, OpenTeQ offers tailored customization and seamless integration to meet unique business needs. Through expert NetSuite Consultation, the company ensures that organizations implement the platform effectively, optimizing processes and aligning it with their strategic goals. OpenTeQ’s proficiency in NetSuite Financial Software simplifies complex financial management, while its comprehensive NetSuite Support Services ensure uninterrupted operations and continuous improvement.

For the manufacturing sector, NetSuite for Manufacturers empowers businesses to streamline production, inventory control, and supply chain management, driving efficiency and profitability. OpenTeQ Technologies delivers holistic NetSuite solutions that enable businesses to thrive in today’s competitive landscape.

#NetSuite Developer#NetSuite Consultation#NetSuite Financial Software#NetSuite Support Services#NetSuite for Manufacturers

0 notes