#Maintenance Software

Explore tagged Tumblr posts

Text

How to Use Maintenance Software to Prevent Equipment Downtime

Equipment downtime is a significant hurdle in construction operations. Unexpected breakdowns can grind projects to a halt, leading to delayed timelines, escalated costs, and disrupted workflows.

In the construction world, minimizing Downtime isn't just a goal it's necessary to maintain productivity and profitability. A well-maintained fleet is the backbone of efficient project execution, and this is where construction equipment maintenance software comes into play.

By proactively managing maintenance through specialized software, companies can drastically reduce equipment downtime and extend the lifespan of their machinery.

This post will explore how to use maintenance software to transition from reactive to preventive maintenance, automate schedules, monitor equipment in real-time, and leverage data-driven insights to boost operations. The results? Increased efficiency, less Downtime, and more profitability.

How Maintenance Software Reduces Equipment Downtime

1.1. Transition from Reactive to Preventive Maintenance

Traditionally, equipment maintenance has been reactive: fix it when it breaks. However, this approach costs time and money, especially in the construction industry, where project delays can result in hefty penalties.

Reactive maintenance tends to increase the chances of complete equipment failure, leading to prolonged Downtime. The alternative is preventive maintenance, which involves identifying issues before they escalate.

Maintenance software is the game-changer that facilitates this transition. It allows you to adopt a proactive approach, where the system monitors equipment performance and sends early warnings when something isn't quite right.

This early detection is vital, preventing minor issues from ballooning into costly breakdowns. The transition from reactive to preventive maintenance has reduced equipment downtime by up to 30%, safeguarding your bottom line and project deadlines.

1.2. Automation of Maintenance Schedules

One of the most impactful features of construction equipment maintenance software is its ability to automate maintenance schedules.

Consistency is vital regarding equipment health, and automation ensures that routine inspections and necessary upkeep are always noticed. Maintenance tasks can be scheduled well in advance, eliminating the risks of human error or forgetfulness.

With automated scheduling, companies can inspect their equipment regularly, reducing the chances of unexpected breakdowns. The software provides timely reminders for essential maintenance tasks, keeping your fleet in optimal condition. This can lead to a 25% increase in equipment uptime, translating into fewer costly delays.

Real-Time Equipment Monitoring and Alerts

2.1. Real-Time Data Collection and Analysis

Modern construction equipment maintenance software offers real-time data collection capabilities, continuously monitoring the health of your equipment.

Sensors embedded in the machinery track various performance metrics such as engine temperature, oil levels, and operational hours and send the data to a centralized platform.

The software then analyzes for immediate detection of performance anomalies. Real-time monitoring is critical because it enables you to act before an issue worsens, which can significantly reduce equipment failure.

By catching problems early, real-time data collection has decreased Downtime by as much as 40%.

2.2. Automated Alerts and Notifications

Another powerful feature of maintenance software is the ability to send automated alerts and notifications. The software will trigger an alert if an equipment component performs below expectations or overheating.

These computerized warnings help prevent catastrophic failures by enabling immediate intervention.

For example, alerts could notify the team when a machine is experiencing low oil pressure or a sudden drop in performance. This kind of timely notification helps crews respond swiftly, scheduling immediate repairs before a complete breakdown occurs. This method minimizes Downtime and Downtime and reduces repair costs by up to 50%.

Centralized Maintenance Records for Optimized Downtime Management

3.1. Streamlining Maintenance Logs and Historical Data

Effective downtime management begins with data. Maintenance software centralizes all equipment maintenance history, ensuring everything gets noticed.

Each piece of equipment has a digital log recording maintenance tasks, repairs, and inspections. This consolidation allows easy access to historical data, invaluable for making informed decisions about equipment health.

When project managers and technicians have access to detailed maintenance records, they can prioritize maintenance tasks more effectively, reducing the likelihood of Downtime.

As Down time maintained log helps pinpoint recurring issues, enabling teams to take proactive measures. Proper data consolidation can lead to a 15% reduction in Downtime to stay ahead of potential failures.

3.2. Using Analytics to Predict and Prevent Downtime

Maintenance Downtime has potent analytics tools that allow companies to predict when equipment will likely fail. The software can analyze historical data using machine learning and predictive analytics to identify patterns or recurring issues.

This predictive maintenance approach enables teams to anticipate equipment failures before they happen, preventing costly breakdowns and optimizing equipment usage. Companies implementing predictive maintenance can reduce Downtime by 30% while decreasing equipment life by 20%.

Scheduling Preventive Maintenance Using Maintenance Software

4.1. Creating Efficient Maintenance Schedules

Preventive maintenance is only as good as its consistency. Maintenance software helps create efficient schedules that ensure every piece of equipment is serviced at the right time.

Companies can avoid unnecessary Downtime by following best practices for scheduling preventive maintenance.

The software also allows for flexibility, letting teams adjust schedules based on real-time data and current project needs. This flexibility ensures that preventive maintenance happens without causing delays to project timelines.

Properly scheduling maintenance tasks can boost overall equipment uptime by 22%, leading to smoother project execution.

4.2. The Impact of Preventive Maintenance on Equipment Lifespan

Preventive maintenance prevents Downtime and eliminates The lifespan of downtime equipment. By addressing issues before they lead to significant breakdowns, companies can reduce wear and tear on their machines.

This prolongs the operational life of the equipment, resulting in fewer replacements and lower overall costs.

Scheduled interventions have been shown to reduce unexpected downtimes by 35%.

Equipment that undergoes regular preventive maintenance is also far less likely to suffer from catastrophic failures, thus saving companies millions in repair and replacement costs.

Managing Spare Parts and Inventory to Prevent Delays

5.1. Integrating Inventory Management with Maintenance Software

Tracking spare parts availability is crucial to minimizing Downtime. If Downtime breaks Downtime, the necessary parts aren't available, and delays can stretch over days or weeks.

Maintenance software integrates with inventory management systems, allowing companies to track spare parts in real-time.

By knowing what parts are available and when they need to be ordered, companies can avoid delays caused by part shortages.

5.2. Optimizing Spare Parts Procurement Based on Maintenance Data

Maintenance data can also be used to optimize spare parts procurement. For example, if the software detects that a specific part is frequently causing issues, you can prioritize its procurement before it leads to a critical failure.

Real-time tracking ensures that you always have the right parts on hand, preventing costly repair delays.

This data-driven inventory management approach can reduce parts-related downtimes by 15%, improving operational efficiency and project profitability.

Data-Driven Decision-Making to Minimize Downtime

6.1. Leveraging Equipment Performance Data

Companies can use performance data to identify patterns that suggest potential risks for Downtime. This Downtime allows downtime decision-makers to act on historical metrics, whether adjusting maintenance schedules or investing in better equipment.

This proactive, data-driven approach has been shown to reduce downtime risk by as much as 35%, leading to more efficient, profitable operations.

6.2. Predictive Maintenance with Maintenance Software

Predictive maintenance tools built into the software give actionable insights into which equipment will likely fail soon. By identifying potential problems early, companies can take immediate action, preventing unforeseen breakdowns and keeping equipment running smoothly.

This predictive capability reduces unexpected equipment failures by up to 40%, making Downtime a rare rather than a routine issue.

Conclusion

In summary, using construction equipment maintenance software is critical to preventing equipment downtime. From automating maintenance schedules to leveraging real-time data and predictive analytics, maintenance software can make a measurable difference.

By embracing a preventive maintenance strategy, you minimize and extend your equipment downtime, driving productivity and profitability. Make the switch today and see how maintenance software can boost your construction operations by 40% or more!

1 note

·

View note

Text

Equipr: Australia's Leading Construction Scheduler

Boost site productivity with Equipr software —Australia's top construction scheduler. Manage crews, equipment & timelines with ease.

#construction scheduling software#crane rental software#crane scheduling software#allocation software#equipr software#urban cranes#mobile dockets#construction management software#maintenance software#mobile crane hire

0 notes

Text

How Maintenance Teams Can Reduce Production Costs and Material Waste in 2025?

Is your equipment constantly breaking down? Are unexpected repairs eating into your productivity? It’s time to take control with effective maintenance strategies. But how do you reduce costs and material waste while maximizing efficiency with a solid maintenance management system?

Our comprehensive guide offers actionable steps to help you minimize waste and reduce production costs in 2025. By optimizing your maintenance workflows, inventory, and predictive maintenance, you can stay ahead of potential issues and boost operational efficiency—all with the right maintenance management system in place.

With Cryotos, you can streamline your maintenance processes, automate routine tasks, and make data-driven decisions to improve asset reliability and performance.

#Maintenance Management#Maintenance Software#Maintenance Startegy#Maintenance Management System#Maintenance Management Software

0 notes

Text

AntMyERP's blog on enhancing highway equipment maintenance management shares smart strategies for better maintenance. It highlights the need for a proactive maintenance schedule and using advanced tracking systems. By integrating technology, businesses can analyze data in real time, reducing downtime and improving safety. These steps help extend the life of highway equipment and ensure everything runs smoothly.

#saas technology#field service software#equipment maintenance#heavy equipment#highway and road equipment#maintenance software

0 notes

Text

Thinking about Shadow and Metadow and Metamyadow

#Thinking about Shadow and Neo rn!!!#Shadows system are like. SUPER outdated. His hardware cant keep up with his software#<- (He overheats a lot which is a cause for more organic body language like blushing and having a reason to breathe)#Neo doesn't understand why he doesn't update his hardware. Neo has a much more efficient processor so she never overheats.#Shadow is afraid to go under such a big change. 1.) Nine PTSD. he gets squeamish about getting unnecessary maintenance.#2.) He prefers to feel organic by slowly updating hardware to mimick aging. 3.) His hardware has Black Arms tech in it!!#His hardware is super adaptive and can't be irreparably damaged because it can heal itself#also he doesn't know if that contributes to his variety of emotions and sentience. so he is NOT gambling that.#Shadow needs to feel like he's organic. Neo doesn't. Neo doesn't understand why he'd choose an old flawed system.#Neo still respects his decision. it actually makes her more curious because be can have such physical responses to stimuli.#ALSO HEHEHE#they bond over having free will stripped from them!#scariest experience of Shadows existence is basically how Neo felt for YEARS. She's desensitized but hes very sensitive about it.#‼️bonus bc cute‼️#they bond over liking Amy! theyd both die for her and Shadow jokes about her messing up their systems#robotfucker amy /j#Metamyadow is in my brain i need to draw them more

25 notes

·

View notes

Text

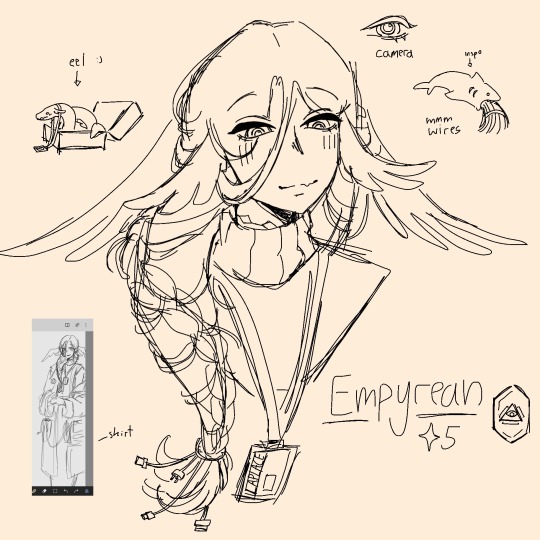

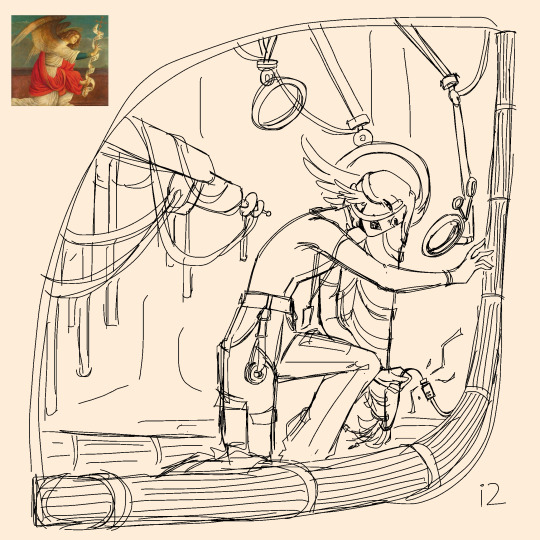

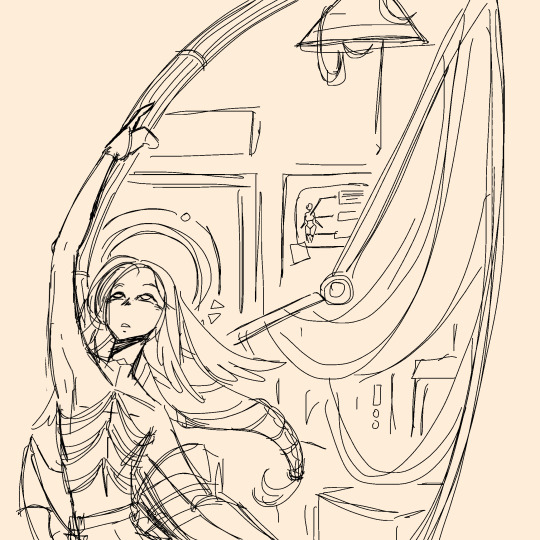

Happy Fibre Optic Friday!!! Say hi to Empyrean (she/they/it)

Also a scrapped i2 concept:

#while Lamont’s schtick is being both a force of entropy + repair — Empyrean is all about maintenance#she is an anxious little ball of sea creature who can’t stand it when her robot/machine friends aren’t in a pristine state#has a special connection with machines and electricity but cannot utilize arcanum#which puts her out of the categorization of ‘arcanist’#she’s a beyond creature :)))#her lack of abilities in arcanum is compensated by her weapon mastery#she can practically make an electric weapon live forever as long as it is charged to her#can also manipulate its software by connecting it to her cables#silly little goober#oc - empyrean#reverse 1999 oc#oc#mochadoodles#so far i have no new ocs without sharp teeth deal with it#oh she may be a literal angel (alien?) but i think thats obvious 😭#I MADE THEM TO ROMANCE LUCY#SHUT UP#her i2 art makes it look like shes fucking the cables and maybe thats okay#ACCIDENTAL OBJECTUM?! Perhaps. Perhaps not so accidental either…

28 notes

·

View notes

Text

2 notes

·

View notes

Text

Trusted outsource software development teams - SSTech System

Outsource software development is the practice of relinquishing software-related duties to outside singularities or organizations. Outsourcing is used by firms to acquire software services and products from outside firms that do not have direct employees or employees under contract to the business entity that is outsourcing.

Infect, the outsourcing market worldwide is projected to grow by 8.28% (2025-2029) resulting in a market volume of US$812.70bn in 2029. This model is highly versatile and suits businesses of all sizes.

Start-ups often use outsourcing to develop MVPs quickly, while established companies might seek custom software development services or AI outsourcing services to address complex challenges. Outsourcing can include working with offshore development teams, global software development partners, or local experts like Australian software development experts for specific projects.

The benefits of outsourcing software development

Outsourcing has become a cornerstone for modern businesses due to its numerous advantages. Here’s a closer look at the key benefits:

1. Cost efficiency

Perhaps the biggest incentive for sourcing solutions from outsourcing service providers is the cost cutting factor. For instance, offshore software development in India provides expertise services at comparatively lower cost than that of in-house developed services in Western countries. This efficiency enable the enactments of cost savings in some other strategic sectors of the organization.

2. Access to global talent

Outsourcing can help to discover the wealth of new talents as well as the skills of professionals from other countries. No matter Whether it’s AI and machine learning integration, web application development in Australia, or outsourced healthcare software development, businesses can find experts in virtually any domain.

3. Scalability and flexibility

Outsourcing offers flexibility that is unparalleled in many organizations today. This is because; firms are able to expand and contract particular teams depending on the specific demand in projects. For example, outsourced IT solutions help business organizations prepare for different conditions while not having to employ permanent workers.

4. Faster time-to-market

With reliable software development teams in Australia or offshore development teams in India, businesses can speed up their project timelines. This helps innovations to make it through to the market early enough, which is useful for companies.

5. Focus on core activities

By delegating tasks like software maintenance and support or cloud software development in Australia to outsourcing partners, businesses can focus on their core competencies and strategic goals.

6. Reduced risk

In-house staff and trained outsourcing partners come with best practices, methods and procedures which when implemented reduce the chances of project hitch. Working with the top-rated IT outsourcing companies in Australia gives you confidence that your project is in safe hands.

Choosing the right outsourced software development partner

In the period from 2023 to 2027, the revenue of software outsourcing is forecasted to thrive at a CAGR of 7.54%. So, outsourcing partner selection is one of the most vital components since it determines the success of a given venture. Here are essential factors to consider:

1. Technical expertise

Check the partner’s competency and his knowledge of the field. For instance, SSTech System Outsourcing offers comprehensive solutions, from AI development services in India to mobile app development outsourcing in Australia.

2. Proven track record

Look for partners with a strong portfolio and positive client testimonials. A proven track record in delivering custom software development services or managing outsourcing software development contracts is a good indicator of reliability.

3. Effective communication

Effective and open communication is extremely important if the project is to be successful. Work with people who give frequent reports and employ efficient media to overcome the differences in time areas.

4. Cultural compatibility

There has to be a cultural match or at least appreciation for each other’s customs for there to be harmony in the working relationship. As such, staffed with proficient Australia software development experts or offshore development teams, whose experience is to work on global markets can coordinate and blend well with your work culture.

5. Security and compliance

You have to make sure that your partner complies with the standards and the policies that are in the industry. This is especially substantial for all information-sensitive projects such as outsourced healthcare software development or cloud software development in Australia.

6. Scalable infrastructure

Choose a partner capable of scaling their resources and infrastructure to meet your project’s evolving needs. This is crucial for long-term collaborations, especially with global software development partners.

AI-powered tools for outsourced development teams

According to a report from the US Bureau of Labor Statistics, software development ranks among the most sought-after professions. Hence, AI is at the forefront of reshaping the outsourcing industry. Therefore, the implementation of artificial intelligence will add value to business processes, make workflow easier, and boost the results of projects. Here are some examples:

1. Automated code reviews

Tools like DeepCode and SonarQube assist outsourced teams in detecting whether errors reside in the code line or not, and whether code needs to be enriched or not. This is particularly accurate concerning AI outsourcing and in-house development industries.

2. Predictive analytics

Automated analytics tools can predict such things as the time it will take to complete the project, how much money it will cost, and what risks are possible in a software development outsourcing scenario.

3. Smart project management

Tools and platforms such as Jira and Monday.com, when empowered with AI, allow the coordination of tasks and the tracking of progress and resource allocation.

4. AI collaboration tools

Communication and collaboration with internal members and offshore software development Australia partners get facilitated through applications that include, Slack, Microsoft Teams, and zoom with integrated AI functions.

5. Natural Language Processing (NLP)

AI-powered chatbots and virtual assistants simplify communication and issue resolution, making them valuable for managing outsourced IT solutions.

Best practices for managing outsourced development teams

Outsourced teams should be mandated and coordinated following a number of recommendations to ensure the efficiency of the entirety of the outsourcing process.

Here are the best practices to ensure your project’s success:

1. Set clear objectives

Make it clear to your project team, stakeholders, and other relevant parties what the parameters of the project are, what it is that you expect out of it, and what you expect to get from it in return. This fostaines consistency between your team and the outsourcing partner to increase efficiency in service delivery.

2. Choose the right tools

Use project tracking and collaboration software approaches to track and evaluate progress and meet regular informality and collaboration targets.

3. Foster a collaborative environment

It is worthy of note that constant communication is key to ensuring that your outsourcing team is on the same page with you. Fresh produce and feedback mechanisms need to be provided in order for there to be trust as is needed in project management.

4. Draft comprehensive contracts

There should be a comprehensive outsourcing software development contract. It should address issues to do with confidentiality, ownership of ideas and concepts, plea structure and mode of handling disputes.

5. Focus on long-term relationships

Building a long-term partnership with trusted providers like SSTech System Solutions can lead to consistent quality and better project outcomes.

Conclusion

To keep up with technology, outsourcing software development offers businesses solutions and support that can enable the creation of complex solutions out of mere ideas. Outsourcing has the benefits of minute overhead cost and is also a rich source of globally talented employees, and it offers the advantage of early time to market. Whether you’re looking for mobile app development outsourcing in Australia or seeking offshore software development in India or opting for AI outsourcing services, the potential is huge.

Such companies can only benefit from opting for reliable outsourcing companies such as SSTech System Outsourcing and embracing industry best practices to promote the success of business project implementations while enhancing market relevance. As technologies like AI and cloud computing are still changing the face of the outsourcing market, software development outsourcing will still be important for any company that wants to survive in a digital world.

Take the first step today—partner with global software development partners and unlock the full potential of your ideas with the power of outsourcing.

#SSTech System Outsourcing#SSTech System Solutions#AI outsourcing services#cloud computing#offshore software development#Outsource software development#AI outsourcing#web application development in Australia#custom software development services#mobile app development#outsourced IT solutions#cloud software development#IT Support & Maintenance Services

4 notes

·

View notes

Text

Unmaintained dependencies

A recent online discussion made me think about all the open-source software (OSS) I use regularly and in particular how much of it might be no longer maintained.

My curiosity was piqued. I decided to list my software dependencies with the dates their last-known releases. Here are the ones that are more than a year old:

2010-05-20 jmf v2.1.1e 2012-01-11 imgscalr-lib v4.2 2013-01-25 org.apache.commons.io v2.4 2021-02-13 junit4 v4.13.2 2022-01-11 jcommander v1.82 2022-04-05 lemur v1.16.0 2022-04-05 lemur-props v1.2.0 2022-04-05 lemur-proto v1.13.0 2022-04-24 Bullet v3.2.5 2023-01-26 sim-math v1.6.0 2023-11-02 jmh v0.7.2 2024-01-01 commons-exec v1.4.0 2024-01-28 jinput v2.0.10 2024-02-29 de.undercouch.download v5.6.0 2024-04-08 actions-gh-pages v4.0.0

While there are many reasons a project might not publish a release for 12 months, it seems to me a valid cause for concern.

#lists#open source#software development#software maintenance#release#should i be concerned#curiosity#dependencies

2 notes

·

View notes

Text

I have worked 24 of the last 48 hours. I stopped counting the number of prod breaking issues after number 13. and somehow the netapp crashed corrupting a bunch of stuff. and we lost an entire datacenter for like 4 hours.

basically, its been a loooong past 2 days

8 notes

·

View notes

Text

Next-Level Crane & Plant Ops Made Simple

In today's high-pressure construction world, delays, inefficiencies, and communication breakdowns can cripple productivity. That's where Equipr Software becomes a game-changer. Built for modern crane hire, plant hire, and civil construction operations, Equipr's intelligent platform integrates crane rental software, crane scheduling software, and allocation software into a single, intuitive system.

What Is Equipr Software?

Equipr is a cloud-based construction management software purpose-built to handle complex jobs like mobile crane hire, plant and equipment hire, and operated plant hire. From automated equipment scheduling software to real-time mobile dockets and operator timesheets, Equipr removes paperwork, cuts downtime, and streamlines dispatch.

Discover the platform at equiprsoftware.com.

Key Features Driving Real Results

Smart Crane Scheduling – Crane scheduling software lets you plan lifts, allocate crews, and prevent double-bookings.

Crane Dispatch & Rigging Management – Easily manage rigging, prep work, and site allocations with crane rigging software.

QR Code System – Track plant, crew, and gear with precision using QR codes for plants.

Service & Maintenance Tracking – Log inspections and plan downtime with operations and maintenance software.

Mobile Tools for Field Teams – Log hours and jobs with mobile dockets & operator timesheets.

Why Equipr Outperforms Traditional Tools

Legacy systems and spreadsheets can't keep up with today's dynamic, fast-paced project needs. Equipr offers real-time insights and flexibility across all your plant hire or crane rental workflows. Whether you manage urban cranes, long-haul equipment dispatch, or site prep, Equipr reduces friction between the field and office.

Check out Equipr's value-driven use cases:

Mobile Crane Rental Software

Crane Resource Management

Operated Plant Hire Scheduling

Industry-Proven – Trusted Across Regions

From Riverina Crane Services to Top Gun Cranes and Bebrok Excavations, Equipr is trusted by industry leaders seeking greater control, improved forecasting, and scalable project oversight.

Want to know what sets Equipr apart? Read more here.

Your Next Step to Smarter Construction Ops

Whether you're managing mobile crane hire in the suburbs or large-scale civil construction operations, Equipr's operations software ensures you're always ahead. Start planning smarter with Plan Better or request a live walkthrough today.

👉 Book a Demo Now

👉 Contact the Equipr Team

Equipr is not just another tool—it's your edge in competitive, time-critical environments.

Relevant Solutions & Pages:

Crane Hire Software

Plant Hire Software

Civil Construction Software

News & Updates

Expansion News EU/UK

Hawkes Bay Crane Platform

Streamline your business. Simplify your day. Scale without chaos. That's the Equipr promise.

#construction scheduling software#crane rental software#crane scheduling software#equipr software#allocation software#mobile dockets#urban cranes#construction management software#maintenance software#mobile crane hire

0 notes

Text

2025 Maintenance Trends: Why AI is the Key to Operational Success

Is your maintenance strategy ready for 2025? Traditional methods are quickly becoming obsolete, leading to costly downtime and unnecessary expenses. The future is intelligent, predictive, and automated.

This essential guide to the "2025 Maintenance Trends" explores how AI is transforming the industry. We move beyond the hype to show you real-world results and what’s coming next. Equip your team with the knowledge to build a robust, future-proof maintenance strategy.

Ready to stop talking about the future and start building it? Cryotos AI-Powered Maintenance Management is the tool designed to bring these 2025 trends to your facility now.

#Maintenance Management#Maintenance Software#Maintenance Startegy#Maintenance Management System#Maintenance Management Software

0 notes

Text

AntMyERP's office equipment maintenance software automates tasks to prevent breakdowns, reduce downtime, and save money. Its mobile accessibility enhances team productivity, while predictive maintenance spots issues early. Manage equipment from purchase to disposal, making informed decisions and maximizing lifespan. Ideal for the office equipment industry. Request a free demo to know more !

0 notes

Text

Discover how software maintenance and support services can enhance security, ensure adaptability, and boost user satisfaction. Learn why it's a strategic investment for business growth.

1 note

·

View note

Note

about ur uncanny valley post, are there moments where meiko and kaito kinda forget theyre robots sometimes?

Probably! Especially as the CVs grow more and more "humanlike" as their adventures continue. I think that they'd be less prone to it than say, Miku's classmates, though, given that as their overseers they get a lot more reminders that the kids are androids.

#asks#vocal android verse#like...they get software maintenance every week and hardware maintenance every month#not including whatever happens as a consequence of their getting into fights against supervillains#so mei and kai see their insides a lot. (weird phrasing ik but you get what i mean)

8 notes

·

View notes