#Maintenance Management

Explore tagged Tumblr posts

Text

A Comprehensive Guide to Production and Operations Management

#Production and Operations Management#Production Management#Operations Management#Supply Chain Management#PGDM in Production#PGDM in Operations#Maintenance Management

1 note

·

View note

Text

Achieve Maintenance Excellence with Lean Six Sigma.

Isn't it time your business looked into how to achieve maintenance excellence in its maintenance department by incorporating Lean Six Sigma principles?

Lean Six Sigma is an amalgam of two methodologies: Six Sigma, which strives to decrease variation and enhance quality, and Lean, which concentrates on eliminating waste.

Organisations can improve efficiency, optimise resource allocation, and streamline processes by implementing these principles.

Discover the essential elements of Lean Six Sigma, such as the pursuit of perfection, value stream mapping, employee engagement, data-driven decision-making, and a focus on customer needs.

All of these elements work together to create a culture of continuous improvement, which is necessary to achieve excellence in maintenance.

Improved process efficiency, enhanced predictive maintenance, standardised procedures, lower maintenance costs, and higher equipment uptime are some of the advantages of applying Lean Six Sigma to maintenance.

Lean Six Sigma also helps sustainability initiatives, promotes data-driven decision-making, and builds team collaboration.

However, putting Lean Six Sigma into practice may present difficulties for organisations. Change aversion, a lack of leadership support, inadequate training, poor data quality, and cultural misalignment are typical roadblocks.

Addressing these issues requires continual training, clear communication, and efficient change management.

In order to maintain the advantages of Lean Six Sigma, you might want to think about creating a maintenance performance dashboard with CorVu or Power BI.

Key performance indicators (KPIs) pertaining to maintenance operations should be tracked by this dashboard to facilitate real-time monitoring and well-informed decision-making.

Lean Six Sigma has a lot of potential to improve maintenance procedures and be successfully implemented, but it also needs leadership commitment, a clear vision, and a continuous improvement-oriented culture.

Maintenance managers can proactively use Lean Six Sigma principles to drive operational excellence by identifying indicators such as high maintenance costs or frequent equipment downtime.

Lean Six Sigma is an effective framework for attaining maintenance excellence, which raises reliability, lowers costs, and improves efficiency in maintenance operations.

Below is the table of contents from my latest article on this subject:

1.0 Introduction to Lean Six Sigma In Maintenance

1.1 Historical Context.

1.2 Lean Six Sigma in Maintenance.

1.3 Global Adoption and Thought Leadership.

1.4 The Unique Landscape of Maintenance.

1.5 The Path to Maintenance Excellence.

2.0 Key Components of Lean Six Sigma in Maintenance Excellence.

3.0 Benefits of Implementing Lean Six Sigma in Maintenance.

4.0 Implementing Lean Six Sigma.

5.0 Overcoming Challenges in Lean Six Sigma Implementation.

6.0 Real-World Applications of Lean Six Sigma.

7.0 Principles of Lean Six Sigma.

8.0 Integrating and Implementing Lean Six Sigma.

9.0 Future Trends and Developments in Lean Six Sigma.

10.0 Lean Six Sigma Certification and Training.

11.0 Impact of Lean Six Sigma on Organizational Culture.

12.0 Global Impact and Future Potential of Lean Six Sigma.

13.0 Applying Lean Six Sigma to CMMS Data Management.

14.0 Why Important Initiatives Sometimes Fail and How to Succeed.

15.0 Conclusion.

To learn more and read my article in full, here is the link: Maintenance Excellence with Lean Six Sigma - CMMS Success

#asset management#maintenance management#six sigma#lean six sigma#lean six sigma maintenance#maintenance excellence#achieve maintenance excellence#sustain maintenance excellence#maintenance continuous improvement#better maintenance performance

0 notes

Text

Utilize VLC Maintenance Management to streamline your maintenance administration. Our solutions optimize workflows, leading to unified and effective maintenance operations. Organize and execute routine plant maintenance effortlessly, ensuring efficient operations. With VLC, you can enhance maintenance management and boost productivity!

0 notes

Text

What are the Most Utilized Maintenance Strategies?

Unveiling the secrets to machinery longevity and optimal performance! Dive into our latest infographic on the 'Most Utilized Maintenance Strategies' and discover the key approaches that top industries swear by. Equip yourself with the knowledge to enhance efficiency and reduce costs. Now, with Cryotos Maintenance Management Software, you can harness the power of the most utilized maintenance strategies right at your fingertips.

#cmms#cmms software#maintenance management#maintenance software#preventive maintenance#predictive maintenance#facility management software#work order

0 notes

Text

Reduce operating costs and increase the efficiency of the entire downstream production process. Get AI/ ML & IoT Integrated https://apple.co/3TZocCJ iFactory mobile app solution for inline & above line 100% inspection. Read More https://bit.ly/ifactoryindustrialassetmaintenance

Android- https://bit.ly/plantinspectionmaintenance

iOS- https://apple.co/3TZocCJ

#maintenance#inspection#plant maintenance#software#predictive maintenance#safetymaintenance#ai#ml#ifactory#factoryautomation#maintenance management#digital transformation#plant optimization#usa cement#indiacement#leanmanufacturing#production#manufacturing#cementindustry#cementmanufacturing#cement#cementplant#digital solution#foodmanufacturing#foodplant#pharma industry#manufacturingindustry

0 notes

Text

😐 a little late to finally start having grounds keeping on site when the fucking complex is being SHUT DOWN aint it

#cliffnotes/.txt#if u havent been here: gotta move. entire apt complex being shut down for violating safety codes#terrible short notice to leave but also good riddance this place fucking sucks#maintenance is never here the main office is never cooperative....hell if there weven was anyone in the office#its changed management companies like 3 times since we've been here. and wt one point they didnt even have a contract for trash collection.

124 notes

·

View notes

Text

#renting issues#bad landlords#tenant rights#rental problems#landlord disputes#housing justice#tenant advocacy#rental market#housing inequality#tenant protection#property management#landlord accountability#rental discrimination#tenant harassment#lease agreements#housing affordability#security deposit disputes#eviction processes#maintenance neglect#housing crisis#rent control#renters' rights#substandard housing#tenant organizing

220 notes

·

View notes

Text

💪😼

#ffxiv#wolgraha#g'raha tia#Arsay Nun#managed to not get dc'd for the 30 minutes it took to take this bless#did immediately get kicked for maintenance though#buff g'raha appreciation hours !!!#wanted to do this all weekend its so important!#she love him big arms 🥰#graharsay

77 notes

·

View notes

Text

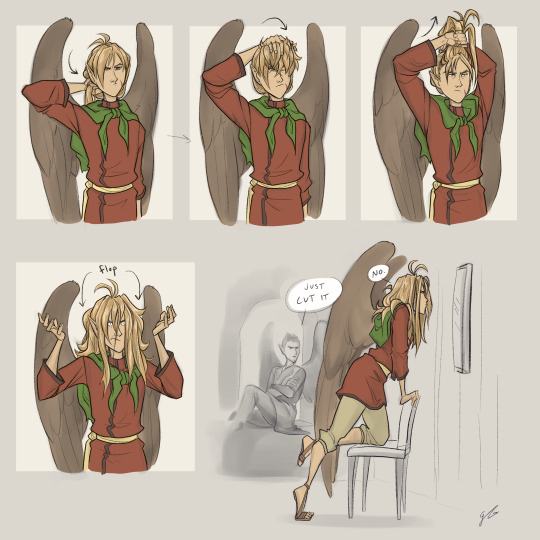

I forgot to share FETransExchange janaff on here. twt post @ my person gakufigure, who requested transmasc janaff trying different hairstyles. you know this fool is high maintenance and indecisive as hell

#you know this fool is high maintenance as hell and will be indecisive and complain about everything#enjoyed the opportunity to play w my headcanon that 1) janaff has a lot of hair#2) it is of a type that is very difficult to manage#3) he will complain about it constantly and never change anything#tellius#fire emblem#janaff#fe9#fe10#fe janaff#janaff fire emblem#ulki#fe#fanart#my art

88 notes

·

View notes

Text

UB Sovereign. my special little guy :-)

#my art#pokemon#calyrex#blacephalon#i was about to put it on artfight but as soon as i finished typing up all its lore and hit submit#the site went down 4 maintenance . soooooo#if ur interested in its whole deal well. can scope it on artfight whenever i manage to get it up on there#update: it’s on there now :-)

245 notes

·

View notes

Text

Hear me out:

Try calling house cleaning,

Entropy management.

Heh? Eh? It gets me past the IDONWANNAS

System maintenance 🏋🏻♀️

Is remembering to eat and bathe, exercise and take my meds 💊, sleep, doctor 🩺 and dentist 🦷 appointments, etc.

Welcome to my ADHD brain where I gotta do irregular end-runs around my executive dysfunction...

83 notes

·

View notes

Text

Rhea BaD, she sends junk emails to encourage people to do sports

Fodlan AU : Garreg Mach tries this "sports festival" thing with some macguffin to limit the influence of crusts for people who have them, so everyone can participate "equally" (Nabateans are banned from participation, which makes Flayn very upset).

However, without her dual crusts, Supreme Leader, who boasted about her "unparalleled" ability at shot put got a low score. Blaming cruel beasts subjugating humanity, she called this thing rigged when the barbarian commoner got a better score than her.

Granted, the Blue Lion's victory was short lived when they discovered that their prize was a golden zanado fruit - sure it's edible but, uh... It's the gesture that counts?

(They gave it to Billy, who ate it in 2 bites saying they never had something that tasty before)

#fodlan nonsense#Rhea caca#ça fait des spams maintenant!#BL class got more medals than the others#that's why they won?#all those efforts for a golden zanado fruit#Ingrid was so disappointed but since they still got to eat normal food after it everything ended well#Flayn tried this shot put thing but only managed to break Hanneman's window#of course he blamed Manu

12 notes

·

View notes

Text

Defect Elimination Management And Bad Actor Analysis.

Maintaining asset integrity, maximising performance, and reaching peak production outcomes all depend on effective defect elimination management.

The difficulties of locating, comprehending, and resolving asset flaws will be examined in this article, with a focus on the significance of having a complete awareness of their nature, implications, and possible outcomes.

The significance of maintenance departments creating a framework for integrating defect elimination and bad actor analysis into their proactive maintenance strategies, enabling them to make more informed decisions, becomes clear when we delve into the subtleties of defect analysis.

Defects in an asset are characterised as flaws, inadequacies, or departures from standard operating characteristics or design specifications.

The kind of defect, where it is located on the assembly of the asset, and what happens when it exists determine how one defect impacts the performance of the asset as a whole.

For example, a minor corrosion patch on a panel that is readily replaceable and does not pose a structural risk to the asset overall is unlikely to have an adverse effect on the asset's longevity, performance, or safety.

Effective Defect Elimination Management is critical for maintaining asset integrity, optimizing performance, and achieving peak production results. It involves identifying, understanding, and addressing asset defects systematically.

Understanding asset defects requires accurate identification and comprehensive documentation in the CMMS, including risk assessments that evaluate both the consequence and likelihood of defects leading to failures.

Defect Elimination Management (DEM) is a comprehensive approach that goes beyond traditional maintenance practices, focusing on root cause analysis and implementing long-term solutions to prevent defect recurrence.

"Bad Actors" in defect elimination refer to equipment, systems, or components that consistently underperform, require frequent maintenance, or cause repeated operational reliability or quality issues.

Advanced diagnostic tools and technologies, such as vibration analysis systems, infrared thermography, and AI-based analytics, have transformed the way asset defects are identified and managed.

Quality and timely repairs and clear business processes for managing defects are crucial, along with maintaining quality maintenance history data to provide valuable insights for future defect elimination processes.

To learn more, you can read my article via this link: Defect Elimination Management - CMMS Success

#defect elimination#defect management#bad actor analysis#maintenance management#asset reliability#asset performance#value driven maintenance#asset analysis

0 notes

Text

Mr. Laundry went home a couple days ago and I already miss his squishy face.

#dogblr#the man the legend: laundry#i do not miss his leash walking (lack of) or the amount of drool he left whole drinking from a bowl#but he was a really really sweet dog who adapted really well to life in a tiny apartment with a pinecone#and that really says something about Carla's dogs so#im so glad she lent him to me#it was a great reminder why im going with a slightly lower maintenance breed#i was feeling nostalgic and thinking i wanted to stay in britts and luckily laundry fixed that for me#he needed A LOT of management#(the same way mav did at a similar age tbh)#and it was a really good thing to keep me out of my head for a month#but not what im looking for in a permanent dog right now#he played so well with pike though 😭❤#she was so happy to have a friend

87 notes

·

View notes

Text

Why Does A Manufacturing Industry Require Asset Management Software?

Manufacturing industries are complex ecosystems with numerous assets, from machinery to human resources. Asset management software streamlines the tracking, utilization, and maintenance of these assets. By providing real-time insights into asset performance, lifespan, and potential issues, such software ensures optimal productivity, reduces operational costs, and minimizes unplanned downtimes. In an era where efficiency and timely delivery are crucial, asset management software becomes an indispensable tool for manufacturing industries, ensuring they operate at peak performance and remain competitive in the global market.

#cmms#cmms software#maintenance management#maintenance software#predictive maintenance#preventive maintenance#facility management software#work order

0 notes

Text

Me, panicking about breaking the lease: Maybe the mold and air quality problems in the apartment weren’t as bad as I thought they were. Maybe it was all in my head. Maybe I was wrong to listen to my instincts and my body, and—

*panic interrupted by an asthma attack triggered by my picking up an item we had forgotten to decontaminate from the Mold Apartment *

Me: Ah. Nope, fleeing was actually the right choice. Never mind.

#about me#Jfc maybe one day I will stop unintentionally gaslighting myself#and will actually stop second guessing things#at least my inhaler works well!#fuck MCAS#Fuck our property management company#and the maintenance people who kept screwing us over#and fuck the contractors who cut corners and turned our new apartment building into a toxic hell hole

9 notes

·

View notes