#Machine Lubrication

Explore tagged Tumblr posts

Text

Machine Lubrication: Ensuring Efficiency and Longevity

Machine lubrication is a cornerstone of efficient industrial operations. Proper lubrication minimizes wear, reduces friction, and prevents costly breakdowns. At Harvard Filtration, we understand the importance of effective machine lubrication and offer solutions to optimize performance and extend equipment life.

What is Machine Lubrication?

Machine lubrication involves applying lubricants such as oils or greases to mechanical components to reduce friction, dissipate heat, and protect against corrosion. It ensures smooth functioning of machinery, which is essential for consistent productivity in industries like manufacturing, construction, and energy.

Types of Machine Lubrication Systems

Modern industries utilize a range of machine lubrication systems to meet diverse requirements:

Manual Lubrication: Operators apply lubricants manually to specific parts. Suitable for smaller machines, but labor-intensive.

Automatic Lubrication Systems: These systems deliver precise amounts of lubricant at regular intervals, minimizing human intervention.

Single-Line Systems: Ideal for small to medium machines with fewer lubrication points.

Multi-Line Systems: Designed for larger machinery with multiple components.

Progressive Systems: Sequentially lubricate complex systems with interconnected components.

Mist Lubrication Systems: Used for high-speed applications, this system disperses lubricants in the form of a fine mist.

Importance of Machine Lubrication Maintenance

Even the best lubrication system requires regular maintenance to function effectively. Machine lubrication maintenance includes:

Inspecting Lubricant Levels: Ensuring the system has adequate lubricant for continuous operation.

Analyzing Lubricant Quality: Checking for contamination or degradation that may reduce effectiveness.

Cleaning Lubrication Lines: Removing blockages for smooth lubricant flow.

Regular System Audits: Identifying potential issues early to prevent system failure.

Benefits of Effective Machine Lubrication

Reduced Downtime: Prevents unexpected breakdowns, ensuring seamless operations.

Enhanced Equipment Life: Reduces wear and tear, extending the lifespan of machinery.

Cost Savings: Minimizes repair and replacement costs by maintaining optimal system performance.

Improved Efficiency: Lowers energy consumption by reducing friction between components.

Harvard Filtration: Your Partner in Machine Lubrication

At Harvard Filtration, we specialize in providing advanced lubrication systems and maintenance solutions tailored to your industrial needs. Explore our detailed blog, Machine Lubrication & Its Types, for deeper insights into lubrication technologies and best practices.

Ensure your machinery operates at peak performance—contact Harvard Filtration today for expert guidance on machine lubrication systems and maintenance.

#Machine Lubrication#Machine Lubrication Systems#Machine Lubrication Maintenance#machine lubrication advantages

0 notes

Text

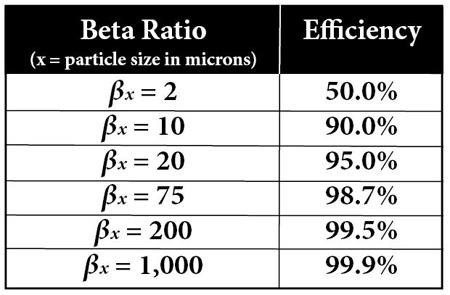

Understanding of the BETA factor

What is the Beta Ratio?

The beta ratio refers to the efficiency in which a given filter element removes the particle of a given size. The Beta Ratio is calculated using the ISO multi-pass test standard 16889:1999.

How is it measured?

Get your filter check today, Call +91 7030901266

So, to purchase a filter with a beta ratio of 2-10 is considered poor, it is advised to use filters with at least a Beta factor of 75 and 98.7% effectiveness. High quality, efficient filter assemblies can achieve 200 to 2000 Beta Ratio for given particle size and should be ideal to achieve a low level of contamination.

Also read: https://www.linkedin.com/pulse/you-buying-right-oil-filter-anshuman-agrawal-mlt-1-/

We at Minimac Systems Pvt Ltd. provide services of Total Lubrication Management and Lubrication Consulting that helps you optimize your Lubrication needs. Minimac stands for MINImum MAChinery Maintenance.

#frf#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#hydraulic oil filter#contamination#oil purification system#oil purification machine#oil contamination#oil purification#oil testing#oil filter machine#oil filter systems#oil filters#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical bre#turbinemaintenance#wind turbines#gas turbine#steam turbine#steel#metal#mining#oil dehydration systems

2 notes

·

View notes

Text

The bones are in a particular state of dismay this morning and I don’t know why

#The temp dropped another degree? Who knows#inflammatory hell#sometimes I feel like I need to directly inject lubricant/painkiller into each joint#Failing machine of fragile meat#Usually I can track it back to like drinking or jogging or having an eggplant or something but not today

5 notes

·

View notes

Text

Do y’all crave the strength and certainty of steel like, platonically, or y’know. Carnally

#the eroticism of the machine#yk that phrase and ‘this is a girl to me’ have played havoc with me working on cars#lubricating an oil filter by making it kiss the old one. this is indeed yuri

3 notes

·

View notes

Text

#LUBRICANT OIL FILLING MACHINE#Robotic Lubricant Oil Filling Line#LUBE OIL FILLING MACHINE#Lube Oil Filling Process Machines#AUTOMATIC HIGH SPEED LUBE OIL FILLING MACHINE#lubeoilblendingplant#lubeoilblendingmachinery#lubeoilblendingindustry#lubeoilblendingplantfillingline#lubricatingoilblendingproject#AUTOMATIC 6 HEAD CAPPING MACHINE

0 notes

Text

Enhancing Metalwork: The Role of Wire Drawing Oils

#WireDrawing#WireDrawingOil#Lubricants#Metalworking#Manufacturing#IndustrialLubricants#WireManufacturing#MetalForming#Machining#HighPerformanceLubricants#DrawingOils#MetalProcessing#CoolingLubricants#PrecisionEngineering#WireProduction

0 notes

Note

V2 NO!!! YOUR OIL WILL CATCH FIRE AND BLOW UP!! NO!!!

V2 and Mirage on a date..? (I JUST REALLY LOVE HOW YOU DRAW THEM I NEED MORE SORRY,,)

Why is it now a running gag that V2 smokes in my drawings

Anyway here you go dear anon

#wait do the machines use oil?#im pretty sure v1 uses blood as lubricant or something but idk about v2

836 notes

·

View notes

Text

Lubricant filling machines are essential for automating the precise dispensing of lubricants into containers, optimizing industrial processes across various sectors such as automotive, manufacturing, and chemicals. These Lubricant filling machines offer high-speed operation, accuracy, scalability, and versatility, adapting to different container sizes and oil types. They feature advanced components like filling nozzles, conveyor systems, and control panels to ensure efficient and spill-free filling .Modern technologies, including programmable logic controllers (PLCs) and touchscreen interfaces, enhance the machines' functionality, while safety features and regular maintenance are crucial for their operation.Investment in these machines leads to increased production efficiency, reduced labor costs, and minimal wastage, contributing to a quick return on investment.

0 notes

Text

Manufacturer of Premium Cylinder Blocks for Superior Engine Performance: Dasset Engineering

In the competitive world of automotive engineering, the importance of high-quality components cannot be overstated. Among these, cylinder blocks play a crucial role in determining the performance and longevity of an engine. At Dasset Engineering, we specialize in manufacturing premium cylinder blocks that deliver superior engine performance. This blog delves into the significance of cylinder blocks, the attributes of our premium products, and why Dasset Engineering stands out in this industry.

The Importance of Cylinder Blocks

The cylinder block is the backbone of any internal combustion engine. It houses the cylinders, coolant passages, and oil galleries, providing structural integrity and maintaining optimal engine temperature. The performance, efficiency, and durability of an engine largely depend on the quality of the cylinder block. Poorly manufactured blocks can lead to overheating, oil leaks, and ultimately, engine failure.

Attributes of Premium Cylinder Blocks

At Dasset Engineering, we understand that premium cylinder blocks are not just about high-grade materials but also about precision engineering and meticulous craftsmanship. Here are some key attributes that define our premium cylinder blocks:

High-Quality Materials

We use the finest materials, such as cast iron and aluminum alloys, to manufacture our cylinder blocks. These materials offer excellent durability, heat resistance, and strength, ensuring that the engine performs optimally under various conditions.

Precision Engineering

Our cylinder blocks are engineered with precision to meet exact specifications. Advanced machining techniques ensure that each block has the correct dimensions, smooth surfaces, and precise alignment of the cylinders. This precision is crucial for achieving optimal engine performance and efficiency.

Superior Cooling and Lubrication

Efficient cooling and lubrication are vital for engine performance and longevity. Our cylinder blocks feature optimized coolant passages and oil galleries that ensure efficient heat dissipation and lubrication. This reduces the risk of overheating and wear, thereby extending the engine's lifespan.

Rigorous Testing

Every cylinder block manufactured by Dasset Engineering undergoes rigorous testing to ensure it meets the highest standards of quality and performance. We conduct various tests, including pressure testing, thermal cycling, and dimensional inspections, to verify the integrity and reliability of our products.

Why Choose Dasset Engineering?

Dasset Engineering has established itself as a leading manufacturer of premium cylinder blocks, and here's why:

Expertise and Experience

With years of experience in the industry, we possess the technical expertise and knowledge required to produce top-tier cylinder blocks. Our team of skilled engineers and technicians is dedicated to delivering products that exceed customer expectations.

State-of-the-Art Facilities

We operate state-of-the-art manufacturing facilities equipped with the latest machinery and technology. This allows us to maintain strict quality control and produce cylinder blocks that meet the most demanding specifications.

Commitment to Quality

Quality is at the core of everything we do. From sourcing the best materials to implementing stringent quality control measures, we are committed to delivering cylinder blocks that offer unmatched performance and reliability.

Customer-Centric Approach

At Dasset Engineering, we believe in building long-term relationships with our customers. We work closely with them to understand their specific needs and provide customized solutions that cater to their requirements.

Conclusion

The cylinder block is a critical component that significantly impacts an engine's performance, efficiency, and durability. At Dasset Engineering, we take pride in manufacturing premium cylinder blocks that set the benchmark for quality and performance. By choosing our products, you are investing in superior engine performance, reliability, and longevity. Trust Dasset Engineering to be your partner in achieving excellence in automotive engineering.

#High-quality cylinder blocks for engines#Premium engine cylinder block manufacturer#Superior engine performance cylinder blocks#Precision-engineered cylinder blocks#Best materials for cylinder blocks#Advanced machining cylinder blocks#Cylinder blocks with optimized cooling#Durable cylinder blocks for automotive engines#Reliable cylinder blocks for high-performance engines#Custom cylinder block manufacturing#Top-rated cylinder block manufacturers#Cylinder blocks with efficient lubrication#Engine cylinder block quality testing#Benefits of premium cylinder blocks#Engine longevity with high-quality cylinder blocks#Cylinder block structural integrity for engines#Leading cylinder block manufacturers in the industry#State-of-the-art cylinder block production facilities#Expert cylinder block engineering services#Long-lasting cylinder blocks for vehicles

0 notes

Text

Explore Molygraph's BRB 100, the premier moly grease designed for outstanding lubrication and protection. Formulated with molybdenum disulfide, this high-performance grease excels in heavy-duty industrial applications, offering superior resistance to wear, extreme pressure, and corrosion. BRB 100 ensures long-lasting equipment performance by reducing friction and extending the lifespan of components. Trust Molygraph's advanced moly grease to maintain the reliability and efficiency of your machinery in the most demanding environments.

0 notes

Text

Reclamation of FRF

A 1200 MW coal-fired thermal power plant using Indo-Chinese Turbine EHC System in Southern India

Synopsis

Problems

Failure of Moog valve: This was the main reason for the trip of the turbine and breakdown in the power plant.

Poor Oil Analysis Program: An oil analysis is supposed to be done monthly for Particle count & TAN (weekly if the trend is negative) and weekly test for water content but the customer has scheduled these indefinitely.

Inadequate Operation Practices: The solenoid valve of the LVDH (oil purification machine) vacuum line was only 20% closed which failed to generate vacuum.

Solutions

Benefits

1) Extended oil life 2) Reduced TAN value 3) Elimination of oil Replacement cost 4) Protection of Turbine against hunting 5) Increased Turbine reliability.

Subscribe to our WhatsApp Community and be a part of our Journey - Click Here

#frf#oil filtration machine#oil flushing#minimac systems#power#minimac#oil & gas#hydraulic oil#lube oil filter#contamination#hydraulic oil filter#oil filtration systems#oil testing#oil analysis#oil filters#oil industry#oil and gas#turbine oilanalysis maintenance lubrication reliability contaminationcontrol oil powerplants oilfiltration rotatingequipment mechanical#turbinemaintenance#gas turbine market trends#power industry#metal#mining#oil purification system#oil purification machine#oil filtration system#transformer oil#transformer oil cleaning#transformation oil purification#transformer oil filtration

0 notes

Text

Online Training on machine maintenance

Our Training on Machine Maintenance are the first of their kind in India. By using a hands-on approach, we seek to educate people on the practical aspects of machine maintenance usually not covered in theory, or hard to understand without some demonstration, or doing.

These training on Machine Maintenance can be held in-house or off-site and are suitable for a wide variety of people. Depending on your requirement, we can tailor-make a one-day or multiple-day course for you and your team.

#training on machine maintenance#bearings services#lube management#bearing failure analysis report#bearing lubrication methods#bearing training course#bearing maintenance#bearing and lubricant maintenance#thermography service#bearing maintenance training#bearing reliability

0 notes

Text

#Skid Mounted Lube Oil Blending Plant#Skid Mounted Lube Oil Blending Machinery#lubeoilblendingplant#lubeoilblendingmachinery#lubricatingoilblendingproject#lubeoilblendingindustry#Lubricant Oil Blending Process#Lube Oil Blending Project#Lube Oil Blending Machine

0 notes

Text

What is ultrasound condition monitoring?

Caravan Reliability Services Provide Best bearing maintenance training and preventive and predictive maintenance for the Industries.

What if we could monitor the condition of the machine on a regular schedule without stopping the machine?

The advantages of regular condition monitoring are:

Reduction of the Duration of Scheduled Maintenance: As the condition of the machine will be known well before the machine is stopped for maintenance, lesser time can be spent in visually inspecting components.

Reduction in the number of Unplanned Stops: Regular condition monitoring will reduce the number of unplanned stops as the condition and life of the various components can be predicted and a plan can be put in place to replace or repair them.

ABOUT US

Caravan Oil Suppliers has been offering solutions in lubrication of machines for the past 40+ years. It is with this experience that we have launched our new division; Caravan Reliability Services.Through Caravan Reliability Services, we aim to give our customers proactive technical maintenance for their machines using the latest technology which allows the machine to continue operation while being analysed. We also provide training on effective continued bearing and lubricant maintenance.

Our expert, Pratap Kemble, is a professional mechanical engineer with over 25 years of experience in the field of bearing technology, bearing maintenance, bearing lubrication, bearing lubrication methods. centralized lubrication systems, bearing failure analysis, and Ultrasound condition monitoring.. He and our team can not only analyses the condition of the machines but interpret the results and give a comprehensive report that helps customers make a more informed decision.

Ultrasound Condition Monitoring (Predictive Machine Maintenance):-

We can provide predictive machine maintenance . We can help you plan repairs ahead of time and increase machine life by accurately predicting the condition of machine components using our ultrasonic listening device.

CONTACT US

Address

106 Road Number 4, 2nd Phase, Jigani Industrial Area, Anekal Taluk, Bangalore Disctrict 562102

Call Us

+91 99728 10317

Email

#ultrasound condition monitoring#shell high temp grease#shell hydraulic oil 68#lubricant oil suppliers#lubricants distributorship#lubricant suppliers#3m tape distributors in bangalore#shell lubricants#lubricant oil distributor#shell lubricants distributors#grease distributor#machine bearing#root cause analysis tools#thermography testing#lubricating oil uses#maintenance services#laser alignment tool#bearing lubricant#industrial maintenance#preventive maintenance#predictive maintenance#preventive and predictive maintenance#machine preventive maintenance#bearing maintenance#mounting of bearing#bearing guide#training on machine maintenance#Bearing Training Course#lube management#machine maintenance

0 notes

Video

youtube

Machine Maintenance/How Protect Your Roll Forming Machine

#youtube#grez grease#machine#protectmachine maintenance#roll forming machine maintenance#video#cable#lubrication

0 notes

Text

0 notes