#Advanced machining cylinder blocks

Explore tagged Tumblr posts

Text

Manufacturer of Premium Cylinder Blocks for Superior Engine Performance: Dasset Engineering

In the competitive world of automotive engineering, the importance of high-quality components cannot be overstated. Among these, cylinder blocks play a crucial role in determining the performance and longevity of an engine. At Dasset Engineering, we specialize in manufacturing premium cylinder blocks that deliver superior engine performance. This blog delves into the significance of cylinder blocks, the attributes of our premium products, and why Dasset Engineering stands out in this industry.

The Importance of Cylinder Blocks

The cylinder block is the backbone of any internal combustion engine. It houses the cylinders, coolant passages, and oil galleries, providing structural integrity and maintaining optimal engine temperature. The performance, efficiency, and durability of an engine largely depend on the quality of the cylinder block. Poorly manufactured blocks can lead to overheating, oil leaks, and ultimately, engine failure.

Attributes of Premium Cylinder Blocks

At Dasset Engineering, we understand that premium cylinder blocks are not just about high-grade materials but also about precision engineering and meticulous craftsmanship. Here are some key attributes that define our premium cylinder blocks:

High-Quality Materials

We use the finest materials, such as cast iron and aluminum alloys, to manufacture our cylinder blocks. These materials offer excellent durability, heat resistance, and strength, ensuring that the engine performs optimally under various conditions.

Precision Engineering

Our cylinder blocks are engineered with precision to meet exact specifications. Advanced machining techniques ensure that each block has the correct dimensions, smooth surfaces, and precise alignment of the cylinders. This precision is crucial for achieving optimal engine performance and efficiency.

Superior Cooling and Lubrication

Efficient cooling and lubrication are vital for engine performance and longevity. Our cylinder blocks feature optimized coolant passages and oil galleries that ensure efficient heat dissipation and lubrication. This reduces the risk of overheating and wear, thereby extending the engine's lifespan.

Rigorous Testing

Every cylinder block manufactured by Dasset Engineering undergoes rigorous testing to ensure it meets the highest standards of quality and performance. We conduct various tests, including pressure testing, thermal cycling, and dimensional inspections, to verify the integrity and reliability of our products.

Why Choose Dasset Engineering?

Dasset Engineering has established itself as a leading manufacturer of premium cylinder blocks, and here's why:

Expertise and Experience

With years of experience in the industry, we possess the technical expertise and knowledge required to produce top-tier cylinder blocks. Our team of skilled engineers and technicians is dedicated to delivering products that exceed customer expectations.

State-of-the-Art Facilities

We operate state-of-the-art manufacturing facilities equipped with the latest machinery and technology. This allows us to maintain strict quality control and produce cylinder blocks that meet the most demanding specifications.

Commitment to Quality

Quality is at the core of everything we do. From sourcing the best materials to implementing stringent quality control measures, we are committed to delivering cylinder blocks that offer unmatched performance and reliability.

Customer-Centric Approach

At Dasset Engineering, we believe in building long-term relationships with our customers. We work closely with them to understand their specific needs and provide customized solutions that cater to their requirements.

Conclusion

The cylinder block is a critical component that significantly impacts an engine's performance, efficiency, and durability. At Dasset Engineering, we take pride in manufacturing premium cylinder blocks that set the benchmark for quality and performance. By choosing our products, you are investing in superior engine performance, reliability, and longevity. Trust Dasset Engineering to be your partner in achieving excellence in automotive engineering.

#High-quality cylinder blocks for engines#Premium engine cylinder block manufacturer#Superior engine performance cylinder blocks#Precision-engineered cylinder blocks#Best materials for cylinder blocks#Advanced machining cylinder blocks#Cylinder blocks with optimized cooling#Durable cylinder blocks for automotive engines#Reliable cylinder blocks for high-performance engines#Custom cylinder block manufacturing#Top-rated cylinder block manufacturers#Cylinder blocks with efficient lubrication#Engine cylinder block quality testing#Benefits of premium cylinder blocks#Engine longevity with high-quality cylinder blocks#Cylinder block structural integrity for engines#Leading cylinder block manufacturers in the industry#State-of-the-art cylinder block production facilities#Expert cylinder block engineering services#Long-lasting cylinder blocks for vehicles

0 notes

Text

1980 Honda CBX 1000

Honda 1047cc Candy Glory Red 6-Cylinder in line road bike with GP racing technology. The CBX's advanced DOHC 24-Valve in line six-cylinder 105Bhp twin-cam engine was its outstanding feature. In many other respects the bike was conventional, having telescopic forks, a tubular frame, twin rear shocks and straight handlebars.

Although bulky, it was only two inches wider than a CB750. The width across the crankshaft was relatively narrow as the CBX had a stacked engine accessory arrangement, whereby the alternator and ignition items were positioned behind the cylinder block. This arrangement produced an acceptable engine width low down and moved critical items out of harm's way in the event of grounding.

This particular machine seen at the Old Brewery Cafe Restaurant in the North Dorset town of Gillingham, UK.

2 notes

·

View notes

Text

youtube

Understanding Nikasil Cylinder Plating: The Gold Standard in Engine Performance and Longevity

When it comes to high-performance engines, Nikasil cylinder plating is a game-changer. Known for its durability, heat resistance, and ability to improve engine efficiency, Nikasil has become a cornerstone in advanced engine technologies. In this blog, we’ll dive into what Nikasil is, why it’s superior, and how it compares to NSC (Nickel Silicon Carbide) plating.

What is Nikasil?

Nikasil, short for Nickel Silicon Carbide, is a proprietary cylinder plating process developed in the late 1960s. It involves coating engine cylinder walls with a thin layer of nickel infused with silicon carbide particles. This coating is applied via an electroplating process, creating an exceptionally hard and wear-resistant surface.

Originally developed for high-performance racing applications, Nikasil has since been adopted for use in motorcycles, aircraft, and high-performance automotive engines, including Porsche engines. Its combination of strength, thermal conductivity, and lightweight properties makes it ideal for aluminum engine blocks.

Benefits of Nikasil Cylinder Plating

Superior Wear Resistance The silicon carbide particles in Nikasil create an incredibly hard surface that can withstand the friction and stress of high-performance engines, reducing wear on piston rings and cylinder walls.

Improved Heat Dissipation Aluminum blocks with Nikasil plating are better at dissipating heat compared to cast iron sleeves. This helps maintain consistent operating temperatures and prevents overheating.

Lightweight Design By eliminating the need for heavy cast iron sleeves, Nikasil allows for the use of lightweight aluminum blocks, reducing the overall weight of the engine.

Corrosion Resistance Nikasil's nickel layer provides excellent protection against corrosion, even when exposed to ethanol-blended fuels.

Enhanced Engine Efficiency The smooth, hard surface created by Nikasil reduces friction, improving engine efficiency and performance.

Nikasil vs. NSC (Nickel Silicon Carbide)

While Nikasil and NSC are often used interchangeably, NSC is an evolution of the original Nikasil process. Both involve Nickel Silicon Carbide coatings, but modern NSC processes are refined to improve consistency and performance further. These advancements ensure better adhesion and even greater durability, making NSC a preferred choice for modern engines.

Key Differences:

Application Improvements: NSC utilizes updated electroplating techniques for better precision and uniformity.

Environmental Considerations: Modern NSC processes are designed to be more environmentally friendly, addressing concerns associated with older Nikasil plating techniques.

Performance Edge: NSC offers marginally better thermal and wear properties, making it ideal for the most demanding applications.

Nikasil and Porsche Engines

Porsche has been a pioneer in adopting Nikasil and NSC cylinder technologies. High-performance models, including the iconic 911, have utilized Nikasil to achieve unmatched reliability and performance. Engines equipped with Nikasil cylinder liners are known for their longevity and ability to withstand extreme conditions, making them a favorite among enthusiasts and professionals alike.

LN Engineering offers its billet aluminum NSC plated aluminum Porsche cylinders for Porsche engines, whose benefits include:

Greater Surface Area and Thermal Conductivity

Nickies have more surface area and up to twice the thermal conductivity of factory Mahle cast aluminum cylinders.

Nickies have as much as four times the thermal conductivity of cast iron or ductile iron cylinders.

Superior Strength and Durability

Nickies have up to 50% greater tensile and ultimate yield strength than OEM Porsche cast aluminum cylinders.

Nickies are stronger and more ductile than any cast iron, ductile iron, or aluminum OEM or aftermarket cylinders.

Expanded Sizing Options

Nickies allow for larger slip-fit and machine-in sizes than previously available with cast iron or aluminum cylinders.

Improved Performance Features

Most Nickies cylinders for Porsche applications come half-mooned for improved crankcase windage, providing a performance boost of approximately 8-10hp over factory Mahle non-half-mooned cylinders.

Compliance and Manufacturing Excellence

Nickies are SCCA legal.

Nickies are 100% made in the USA.

Maintaining Nikasil-Plated Cylinders

To maximize the lifespan and performance of Nikasil cylinders:

Use High-Quality Oils: Always use oils formulated for high-performance engines to ensure proper lubrication and prevent premature wear.

Regular Maintenance: Keep your engine in top condition by following recommended service intervals.

Avoid Abrasive Cleaners: When cleaning Nikasil-plated cylinders, avoid using abrasives that could damage the plating.

Conclusion

Nikasil plating has revolutionized the way high-performance engines are built and maintained. Its exceptional wear resistance, heat dissipation, and lightweight properties make it the ideal solution for modern engines. Whether in motorsport or daily driving, Nikasil ensures your engine performs at its peak for years to come. As technologies like NSC refine and build upon the original process, the future of cylinder plating looks even brighter.

0 notes

Text

Best Reasons to Choose Ductile Iron Casting for Your Business

Ductile iron casting has become a staple within businesses regardless of the industry since it combines durability, flexibility, and cost-effectiveness. Whether from the perspective of manufacturing, construction or automotive companies, ductile iron casting will bring you crucial benefits and support operational performance as well as product excellence.

What is Ductile Cast Iron Casting?

Ductile Iron casting is a special alloy of iron used to provide more strength along with a more flexible material. This cast iron differs from the traditional ones since it contains small traces of magnesium that changes its internal microstructure and allows the material to possess excellent ductility properties. That is, the ability to resist high stress or strain without cracking makes the material superior for demanding applications.

Major Benefits of Cast Ductile Iron

1. Strength and Toughness

Cast ductile iron does not break under extreme pressure and weight. This is long-lasting, thereby ensuring proper performance in challenging environments. Hence, it is a good choice for many components like gears, pipes, and auto parts.

2. Cost-Effective

Quality Iron Solutions is very valuable for firms that wish to optimize their budgets. It is less expensive than other strength materials like steel, but its performance equals that. Its long life cuts back on the cost of replacements, making it more cost-efficient.

3. Cross-Industry Flexibility

Quality Iron Solutions, in its versatility, can be highly used in different applications. The material will be excellent for use in machinery parts of subtle detail to large-scale construction, and even various shapes and sizes suited to special business needs.

4. Resistance to Corrosion

The first important advantage of Quality Iron Solutions is its corrosion resistance. Such an important feature is necessary when components need to be in an environment that consistently exposes them to moisture and chemical substances, for instance, industries involved in the water supply and management of sewage.

5. Machinability

High-Strength Iron Casting can be machined compared to other materials. Thus, in the production process, time and cost are reduced. High machinability assists to produce accurate designs and specifications without losing the material's integrity.

Applications of Ductile Iron Casting

Ductile iron casting has a great demand due to its good properties. There are several common applications.

Automotive: Engine blocks, crankshafts, suspension systems

Construction: Pipes, fittings, maintenance hole covers

Industrial machine parts: gearboxes, pump housings, hydraulic cylinders

Agriculture: tractor parts, plough parts, irrigation systems

Why Choose Advanced Iron Casting for Your Business?

If you are looking for a material that is both strong, affordable, and versatile, cast ductile iron will stand out as an excellent choice because it adapts to any industrial requirements while maintaining superior performance that guarantees your investment.

At AKP Ferrocast, we specialize in high-quality Advanced Iron Casting that matches your business needs. Our people ensure that every product is of good quality, meeting the toughest industry demands for performance and value.

Conclusion

Add ductile iron casting to your business by identifying the parts or products you need. Partner with a reliable supplier such as AKP Ferrocast to get the best material and know-how at every stage of production. Add more efficiency and savings with better quality to your products by investing in Advanced Iron Casting today.

Advanced Iron Casting offers unrivalled benefits to businesses looking for dependable, economical and versatile material solutions. Strength is one of the superior strength profiles, and it has a very high corrosion resistance profile. Due to these features, many industries have shown inclination towards it. With Quality Iron Solutions, new innovations and efficiency opportunities are opened for businesses. Optimize your processes with Quality Iron Solutions-step into a smarter tomorrow-a stronger future.

0 notes

Text

Why Barium and Calcium Inoculants Are Crucial for Superior Metal Production!

In the world of metallurgy, achieving superior metal quality is an ongoing challenge. Foundries and metal production facilities rely on advanced technologies and materials to optimize the characteristics of metals. Among these materials, barium inoculant and calcium inoculant stand out as crucial agents for improving the microstructure and mechanical properties of metals. These inoculants play a significant role in enhancing casting performance, reducing defects, and ensuring high-quality production. Let’s delve deeper into why these inoculants are indispensable in metal production.

The Role of Inoculants in Metallurgy

Inoculants are substances added to molten metal to influence its solidification process. Their primary function is to refine the grain structure, promote uniformity, and reduce casting defects such as porosity and shrinkage. This ensures that the final product meets stringent quality standards required in various industries, including automotive, aerospace, and construction.

Among the wide range of inoculants available, barium and calcium-based inoculants have gained prominence due to their unique properties and effectiveness in enhancing metal quality.

Barium Inoculant: Key Benefits

Barium inoculant is widely used in the production of gray iron and ductile iron. Its addition to molten metal provides several benefits:

Refined Grain Structure: This inoculant promotes the formation of fine, evenly distributed graphite flakes in gray iron and nodules in ductile iron. This leads to improved mechanical properties, including strength and durability.

Reduction of Chill Formation: In iron casting, chill is the formation of hard carbides, which can compromise machinability and toughness. Its minimizes chill, ensuring a smoother and more consistent casting surface.

Improved Fluidity: Barium enhances the fluidity of molten metal, making it easier to fill molds completely. This reduces the likelihood of defects and ensures intricate designs can be cast effectively.

Stabilization of Graphite Formation: Barium inoculant ensures consistent graphite precipitation during solidification, preventing the formation of irregular structures.

Calcium Inoculant: Key Benefits

Calcium inoculants are another essential component in high-quality metal production. They are particularly effective in cast iron and steel manufacturing processes. Here are the key points on how they contribute to superior metal quality:

Nucleation Sites for Graphite: these inoculants provide nucleation sites for graphite precipitation, resulting in a refined and uniform microstructure. This enhances the mechanical and thermal properties of the metal.

Reduction of Sulfur Content: Calcium reacts with sulfur in molten metal to form calcium sulfide, which prevents the formation of harmful sulfides that can weaken the metal’s structure. This makes These type of inoculants particularly useful in applications requiring high ductility and toughness.

Prevention of Carbide Formation: Like Ba, Ca inoculants inhibit the formation of carbides, which can negatively impact machinability and overall metal performance.

Improved Surface Finish: (Ca) inoculants help achieve a smoother casting surface by promoting uniform solidification, which is critical in industries requiring precise and aesthetic components.

Applications of Barium and Calcium Inoculants

The versatility of (Ba and Ca) inoculants makes them valuable in various applications. Here are some of the common uses:

Automotive Industry: Inoculants are crucial in the production of engine blocks, cylinder heads, and brake components, where strength, durability, and machinability are paramount.

Aerospace Industry: High-performance materials with refined microstructures are essential in aerospace applications. (Ba and Ca) inoculants ensure the reliability of critical components.

Construction Equipment: Heavy machinery and construction tools require robust and defect-free components. These inoculants help achieve the necessary quality standards.

Piping and Fittings: Cast iron pipes and fittings benefit from the enhanced properties imparted by these inoculants, including resistance to pressure and corrosion.

Choosing the Right Inoculant

The choice between inoculants depends on the specific requirements of the metal production process. Factors such as the type of alloy, desired mechanical properties, and casting conditions play a role in determining the most suitable inoculant.

Barium inoculant is often preferred for applications where the elimination of chill and improved graphite morphology are critical.

Calcium inoculants are ideal for reducing sulfur content and preventing carbide formation, making them indispensable in processes requiring high ductility and machinability.

Conclusion

In the quest for superior metal production, the importance of barium and calcium inoculants cannot be overstated. These materials not only enhance the physical and mechanical properties of metals but also ensure consistency and reliability in casting processes. By refining microstructures, reducing defects, and improving overall performance, (Ba and Ca) inoculants contribute significantly to the advancement of the metallurgy industry.

For foundries and metal production facilities aiming to achieve excellence, investing in high-quality inoculants is a strategic decision. Whether Ba inoculant can prevent chill formation or Ca inoculant’s sulfur-reducing properties, these agents are indispensable tools for producing metals that meet the highest standards of quality and performance.

#inouclant #bariuminouclant #calciuminoculant

0 notes

Text

Essential Everyday Applications of Rubber O-Rings

In industries where precision and reliability are essential, rubber o-ring manufacturers components are critical. From household appliances to sophisticated machinery, these vital parts ensure tight seals, preventing leaks and maintaining optimal performance.

As industry demands evolve, O-ring manufacturers continue to advance their products and technologies. Understanding both basic and advanced applications of rubber O-rings is crucial for making informed decisions when selecting the right products for business needs.

What Are O-Rings?

Rubber O-rings are circular, doughnut-shaped seals that fit into grooves to form a tight seal between two parts. Made from various rubber compounds, these O-rings are precisely crafted to meet the demands of specific applications. They are used in both dynamic and static sealing scenarios: in static applications, they maintain a seal between non-moving components, while in dynamic applications, they prevent leaks in moving parts like hydraulic cylinders.

The flexibility and durability of rubber O-rings make them essential for systems that require airtight or fluid-tight seals. Their primary role is to prevent gas or liquid leaks while blocking external contaminants, making them vital in automotive, plumbing, and industrial machinery applications, where even small leaks can lead to costly failures.

As demand for high-performance seals increases, rubber compound manufacturers are developing materials with superior resistance to extreme temperatures, pressures, and chemicals.

Basic Applications of Rubber O-Rings

Rubber O-rings are utilized in a wide range of everyday applications, ensuring smooth and efficient operations. Here are some key uses:

Household Appliances:

Washing Machines & Dishwashers: O-rings prevent water leakage from pipes and joints, ensuring efficient operation and avoiding water damage.

Plumbing Systems:

Faucets, Pipes, and Valves: O-rings maintain seals between components, preventing leaks and ensuring the integrity of plumbing systems.

Door Locks and Hinges:

O-rings are commonly used in door locks and high-end door hinges to ensure smooth movement and prevent wear.

Automotive Industry:

Engine Systems: O-rings are crucial in engine systems, maintaining proper seals and ensuring smooth engine performance.

Braking Systems: They help manage pressure and maintain critical seals to ensure braking efficiency and safety.

Air Conditioning Units: O-rings prevent leaks, manage pressure, and keep contaminants like dust from entering the system, ensuring the longevity of the air conditioning unit.

Advanced Applications of Rubber O-Rings in Industry

While O-rings are crucial for basic mechanical functions, their importance grows in more advanced industrial applications. Sectors like aerospace, chemical processing, and oil & gas require components that can endure extreme conditions. O-rings are designed to perform reliably under high temperatures, pressures, and exposure to aggressive chemicals.

At GB Rubber, we provide solutions that ensure the integrity of O-rings in harsh environments, meeting the performance and safety needs of industries like aerospace, chemical processing, and oil & gas.

For example, in aerospace, O-rings are used in fuel systems, landing gear, and hydraulic systems, where they must endure drastic temperature changes and high altitudes while maintaining perfect seals. In chemical processing plants, O-rings must withstand corrosive chemicals, requiring materials that resist chemical degradation. Similarly, in oil & gas, O-rings prevent leaks in pipelines and drilling equipment, where failure is not an option.

Custom Rubber O-Rings: Tailoring Solutions for Specialized Needs

While standard O-rings suit many applications, specialized industries often require custom solutions for more complex functions. Custom O-rings are designed to meet precise specifications, especially in fields like medical devices, pharmaceutical equipment, and food processing.

O-ring manufacturers collaborate closely with engineers to create O-rings that meet exacting requirements for pressure, size, and material composition. For instance, in the medical industry, O-rings used in devices like pumps, valves, and respiratory equipment must be made from biocompatible materials that can withstand sterilization without degrading. In food processing, O-rings must resist both high temperatures and the chemicals used in cleaning, with suppliers offering FDA-approved materials safe for food contact.

Custom O-rings enable companies to meet specific needs in these industries, ensuring reliability, safety, and optimal performance, which ultimately improves product quality and operational efficiency.

Final Thoughts

Rubber O-ring components are a cornerstone of sealing technology, offering reliable and cost-effective solutions across a broad range of industries. Their versatility, durability, and sealing efficiency make them indispensable in maintaining equipment functionality and safety. As industry needs evolve, the demand for advanced, customized solutions continues to grow.

By partnering with trusted manufacturers like GB Rubber, companies can secure high-quality O-rings for their operations. Whether standard or custom-made, our durable, reliable, and precise rubber products supplier serves a wide range of industries. Visit our website to learn more about our offerings or reach out to our experts.

0 notes

Text

USD 110,203.8 Million in Milling Machine Market by 2033

By 2023, the worldwide milling machine market is anticipated to be valued at $68,303.3 million. Between 2023 and 2033, the market is expected to grow at a sluggish but consistent CAGR of 4.9%. The market value is expected to rise to US$ 110,203.8 million by 2033.

Milling machines are the workhorses of metalworking, capable of carving, drilling, and shaping various metals with precise control. From crafting intricate parts for aerospace components to machining engine blocks for automobiles, milling machines play a vital role in numerous industries. Let's delve into the diverse applications of milling machines and explore the trends propelling this important market forward.

Applications of Milling Machines

Milling machines offer a range of functionalities across various metalworking applications:

Machining Complex Parts: With their ability to move a cutting tool along multiple axes, milling machines can create intricate three-dimensional shapes in metal components. This is crucial for industries like aerospace, where lightweight and high-precision parts are needed.

Die and Mold Making: The ability to create precise and polished surfaces makes milling machines ideal for manufacturing dies and molds used in various forming and casting processes.

Engine Component Production: From machining cylinder heads and engine blocks to creating intricate channels for oil and coolant flow, milling machines are essential for engine manufacturing.

Job Shops and Contract Manufacturing: Milling machines offer versatility for small-batch production or one-off projects. Job shops and contract manufacturers rely on them to fulfill diverse customer requirements.

Maintenance and Repair: Machine shops and repair facilities utilize milling machines for machining replacement parts, modifying components, or repairing damaged metal parts.

Get Exclusive Sample Copy of the Report: https://www.fmisamplereport.com/sample/rep-gb-16589

A Market Fueled by Progress: Growth Factors Shaping the Future

The milling machine market is driven by several key trends:

Growth in Automotive and Aerospace Industries: The increasing demand for lightweight, high-performance vehicles and complex aerospace components necessitates the use of advanced milling machines for precise part creation.

Rise of Automation and CNC Technology: The integration of Computer Numerical Control (CNC) technology into milling machines allows for automated and highly precise machining processes, improving efficiency and productivity.

Demand for Shorter Production Cycles: Manufacturers are constantly striving to reduce time-to-market for new products. Milling machines, with their ability to produce complex parts quickly and accurately, contribute to achieving this goal.

Growing Focus on Advanced Materials: The increasing use of hard-to-machine materials like titanium alloys and composites in various industries necessitates the development of more powerful and versatile milling machines.

Skilled Labor Shortage: The growing demand for skilled machinists is a challenge. Milling machines with user-friendly interfaces and automation capabilities can help address this gap to some extent.

The global milling machine market is poised to reach a significant valuation of USD 68,303.3 million by 2023, with an expected CAGR of 4.9% from 2023 to 2033. By the end of the forecast period, the market is anticipated to surge to USD 110,203.8 million.

Challenges and Considerations

While offering significant advantages, the milling machine market faces some challenges:

High Initial Investment: CNC milling machines, particularly those with advanced features, can involve a significant upfront investment. This can be a barrier for smaller workshops or businesses with limited budgets.

Skilled Workforce Requirements: Operating and programming CNC milling machines effectively requires a skilled workforce with a strong understanding of machining principles and CNC programming languages.

Rapid Technological Advancements: The milling machine market is constantly evolving with new technologies and features. Keeping pace with these advancements can be challenging for manufacturers and machining professionals.

0 notes

Text

WIDMA: A Leader in Precision Machining Solutions

In the world of advanced manufacturing, precision and reliability are key. WIDMA, a division of Kennametal, has established itself as a trusted name in the machining industry, delivering innovative solutions for complex requirements. From deep hole drilling machine manufacturers to state-of-the-art grinding and boring machines, WIDMA offers a diverse range of products that cater to the evolving needs of industries like automotive, aerospace and energy.

Excellence in Deep Hole Drilling Machines

When it comes to precision drilling, WIDMA stands out as one of the top deep-hole drilling machine manufacturers. Their machines are engineered to handle operations like gundrilling, BTA drilling, counter boring, skiving and roller burnishing with unmatched accuracy. These machines are ideal for industries requiring high precision in manufacturing components such as crankshafts, fuel injectors and hydraulic cylinders. With a focus on efficiency, WIDMA ensures that their machines are built for durability and optimal performance, making them a preferred choice for global manufacturers.

Advanced Tool Grinding Machines

In today’s competitive market, high-quality tools are essential for achieving superior machining results. WIDMA’s tool grinding machine solutions are designed to manufacture and regrind complex geometry tools such as shaper cutters, hobs and round tools. These machines use advanced software and automation technology to deliver precision and consistency, ensuring that manufacturers meet their production goals with ease. Whether it’s creating new tools or reconditioning existing ones, WIDMA’s grinding machines provide unparalleled performance and reliability.

Precision with Fine Boring Machines

WIDMA also excels in delivering fine boring machines for applications that demand high accuracy. These machines are perfect for machining components like engine blocks, cylinder heads and gear housings. Built to achieve tight tolerances, WIDMA’s boring machines are equipped with advanced controls and tooling options that make them a valuable asset for manufacturers. Their fine boring solutions not only enhance productivity but also ensure superior surface finish and dimensional accuracy.

Why Choose WIDMA?

WIDMA’s reputation as a leader in precision machining solutions is built on decades of expertise, state-of-the-art manufacturing facilities and a customer-centric approach. Based in Bengaluru, India, their 75,000-square-foot facility is equipped with the latest technology to design, develop and deliver customized solutions. Their products are trusted globally and their commitment to innovation has made them a pioneer in the industry.

Industries Served

WIDMA caters to a wide range of industries, including:

Automotive: Solutions for machining engine components, gear systems and more.

Aerospace: High-precision machines for critical aerospace parts.

Energy: Custom solutions for turbines, oil & gas equipment and wind energy components.

General Engineering: Versatile machines for diverse engineering applications.

Conclusion

WIDMA continues to set benchmarks in the machining industry with its advanced solutions. Whether you’re looking for a reliable deep hole drilling machine manufacturer, a high-performance tool grinding machine, or a precision fine boring machine, WIDMA has the expertise and technology to deliver. With a legacy of innovation and quality, WIDMA remains a trusted partner for industries worldwide, driving efficiency and excellence in modern manufacturing.

0 notes

Text

Cylinder Head Repair and Reconditioning: Breathing New Life into Your Engine

Introduction:

The engine is the heart of any vehicle, and the cylinder head plays a crucial role in optimal functioning. Over time, wear and tear can take a toll on the cylinder head, leading to decreased performance and efficiency. In this article, we will delve into the importance of Cylinder Head Repair and explore the benefits of cylinder head reconditioning.

Repair of Cylinder Heads:

The cylinder head is a critical component that houses the intake and exhaust valves and the combustion chamber. When issues arise, such as cracks, warping, or damaged valves, it's essential to address them promptly through cylinder head repair.

One common problem is the development of cracks in the cylinder head. These cracks can lead to coolant leaks, combustion issues, and reduced engine performance. Skilled technicians use advanced techniques like welding or cold stitching to repair these cracks, restoring the structural integrity of the cylinder head.

Warping is another concern due to overheating or other stress factors. In the Repair of Cylinder Heads, professionals use precision machining to restore the flatness of the head surface. This ensures proper sealing and prevents further damage to the engine.

Valve problems, such as bent or burnt valves, are also addressed during the repair process. Technicians inspect, repair, or replace damaged valves to ensure smooth airflow and optimal combustion within the engine.

Reconditioning Cylinder Heads:

Cylinder head reconditioning goes beyond basic repairs, aiming to restore the entire component to like-new condition. This process involves a comprehensive inspection and refurbishment of the cylinder head, often including cleaning, resurfacing, and replacing worn-out components.

The cylinder head is thoroughly cleaned during reconditioning to remove carbon deposits, rust, and other contaminants. This not only improves performance but also extends the lifespan of the engine.

Precision machining is a crucial aspect of Cylinder Head Reconditioning. Technicians use state-of-the-art equipment to resurface the head, ensuring a perfect fit with the engine block. This promotes optimal compression and combustion, enhancing overall engine efficiency.

The valve seats and guides are also examined and replaced if necessary during reconditioning. This attention to detail ensures proper valve function, preventing issues like misfires and loss of power.

Conclusion:

Both cylinder head repair and reconditioning are vital processes that can breathe new life into your engine. Whether addressing specific issues or opting for a comprehensive overhaul, these services improve performance, fuel efficiency, and overall vehicle longevity.

For reliable cylinder head repair and reconditioning services, consider contacting ARA Engine Reconditioning. Their skilled technicians and advanced facilities ensure top-notch quality and precision in every job. Visit their website at araenginereconditioning.com.au to learn more about how they can keep your engine running at its best.

0 notes

Text

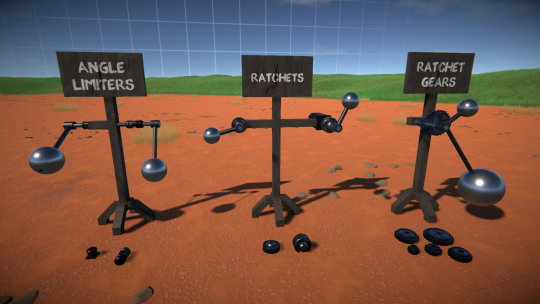

Hey everyone, after taking a much needed break, I'm back to work on the game!

The next major task to tackle is "logic" (switches, sensors, control modules, etc.) which will involve some experimentation and iteration to figure out how it should all work. This will take a little while, so in the meantime here's a small update with a selection of new parts and other improvements.

Angle limiters

These parts connect to an axle via a rotary bearing, and restrict rotation between a minimum and maximum angle that you can specify.

Ratchets

These also connect to an axle via a rotary bearing, and allow for rotation in only one direction. You can configure the number of ratchet locking "steps", set the locking direction, and optionally bind a key to temporarily release the ratchet lock.

There are also gears of various sizes with the ratchet mechanism built in.

Other parts

Speaking of gears, I've added a couple more spur gear size variations, and worm gears with the opposite thread direction. You'll also find some new blocks and connectors…

…including a universal joint "yoke" that can be combined with the "Angle Axle 4 x 90" connector to build universal joints.

There a few more improvements too, check out the full release notes for details:-

New parts:-

Block, resizable in all three axes (and hollow, like the sphere and cylinder).

U-Plate block.

Offset tile 1x2 and 2x2 blocks.

Spur gears 28T and 36T.

Worm gears x1, x3, and x7 with opposite thread direction.

Ratchets (axle-to-axle & block-to-axle).

Ratchet gears x1 to x3.

Angle limiters (axle-to-axle & block-to-axle).

Small corner 90 and tee 90 pipes.

"2-Hole & Axle (Perp)" and "2-Plate & Axle" connectors.

Universal joint "yoke" connector.

Stepper motors now have optional angle limits.

Added colliders to gear and pulley "hubs".

Added option to simulation settings to disable physics force range limit.

Added option to builder tool "advanced options" to adjust part highlighting brightness.

Added option to ConstructionDebug script mod for showing part colliders.

Added option to game settings to disable cloud diagnostics crash and exception reporting.

Updated localised strings.

Bug fixes.

Upgraded to Unity 2021.3.45.

1 note

·

View note

Text

Dasset Engineering: Your Partner in Automotive Spare Parts Excellence

For superior engine performance and reliable fastening solutions, Dasset Engineering is a trusted manufacturer, supplier, and wholesaler of automotive spares across India. Specializing in automotive spare parts manufacture, exporter, and supplier, Dasset Engineering delivers premium cylinder liners, cylinder blocks, crankshafts, connecting rods, pistons, and high-quality stainless-steel screws.

Premium Engine Components for Superior Performance

We manufacture premium cylinder liners designed to enhance engine efficiency and durability. Our product range includes cylinder blocks, crankshafts, connecting rods, and pistons, crafted with high-grade materials and advanced technology to meet modern engine demands.

Our cylinder liners ensure excellent heat dissipation, wear resistance, and longevity, making them ideal for industrial and automotive applications. From heavy machinery to performance engines, Dasset Engineering has you covered.

High-Quality Stainless-Steel Screws

Dasset Engineering also offers a diverse range of machine screws, self-tapping screws, self-drilling screws, and other specialized fasteners under the "Dasset Engineering" brand.

Made from 202, 304, and 316-grade stainless steel, these screws provide outstanding corrosion resistance and strength, suitable for industrial, construction, and domestic use.

Advanced Manufacturing and Quality Assurance

We use cutting-edge techniques and equipment in our manufacturing processes, ensuring every product meets the highest standards. Our quality control team conducts stringent checks at every stage to deliver flawless performance. Premium materials like 202, 304, and 316-grade stainless steel guarantee durability and reliability.

Why Choose Dasset Engineering?

Extensive Product Range: From engine components to fasteners, we cater to diverse needs.

Top Quality: Rigorous quality checks ensure outstanding performance.

Industry Expertise: Advanced manufacturing processes and a skilled team set us apart.

Trusted Wholesaler: Renowned for reliability and excellence across India.

Conclusion

Dasset Engineering is your go-to partner for automotive spare parts manufacture, exporter, and supplier in India. Whether you need durable engine parts or reliable fastening solutions, our products deliver unmatched quality and performance.

Trust Dasset Engineering to elevate your projects with premium components and fasteners - because quality isn’t just a promise, it’s our commitment.

#Dasset Engineering#Automotive spare parts manufacturer in India#Trusted wholesaler of automobile spares#Automotive spare parts exporting and supplying#High-quality connecting rods and pistons#Advanced engine components manufacturing

0 notes

Text

Components- The Building Blocks of Your Motorcycle

Motorcycles are intricate machines made up of various components that work together to deliver optimal performance, speed, and handling. Professional motorcycle racers and enthusiasts understand the importance of each component in enhancing the overall performance and experience of riding a motorcycle. Let’s delve into the essential building blocks of a motorcycle, as seen from the perspective of professional motorcycle racers or racing enthusiasts.

Chassis- The Foundation of a Motorcycle

The chassis serves as the backbone of a motorcycle, providing structural integrity and support for other components. Typically made from welded aluminum or steel struts, the chassis includes the frame and suspension. The frame houses the engine and rear suspension, with components like carbon fiber, titanium, and magnesium used in high-performance custom frames. The suspension system, consisting of front forks and the swingarm connected to the rear wheel, plays a crucial role in ensuring stability and handling during rides.

Engine- The Heart of Performance

The engine is undoubtedly the most critical component of a motorcycle, dictating its power, speed, and efficiency. Most motorcycles are fueled by internal combustion engines, ranging in size from less than 50cc in small scooters to over 5000cc in high-performance cruiser motorcycles. Different engine configurations, such as single-cylinder, twin-cylinder, V-twin, and inline four, offer varying levels of power, smoothness, and reliability. Motorcycle engines can be air-cooled or liquid-cooled, each with its advantages in terms of performance and maintenance.

Transmission- Shifting Gears for Control

The transmission system on a motorcycle allows riders to shift gears and control power delivery to the rear wheel. Most motorcycles come equipped with a sequential manual transmission operated by a foot lever. Additionally, some motorcycles feature continuously variable transmissions or hydraulic automatic transmissions for smoother and easier gear changes. The clutch, housed within the transmission system, engages or interrupts power transfer from the engine to the rear wheel, impacting acceleration and speed.

Wheels and Tires- Connecting to the Road

The wheels and tires of a motorcycle are essential for traction, stability, and handling. Different types of wheels, such as steel, aluminum, or magnesium, paired with pneumatic tires designed for various riding conditions, impact the overall performance of the motorcycle. Racing bikes often utilize advanced wheel designs, such as carbon-fiber wheels, to reduce weight and improve agility on the motorcycle track.

Braking System- Ensuring Safety and Control

The braking system on a motorcycle comprises front and rear brakes that are crucial for safety and control during rides. Modern motorcycles feature disc brakes or cantilever brakes, each offering unique advantages in terms of stopping power and reliability. Disc brakes, in particular, provide immediate stopping ability and are commonly used in high-performance racing motorcycles for enhanced safety and precision.

Importance of Component Integration in Racing Bikes

In the realm of motorcycle racing, the integration and synergy of various components are paramount in achieving optimal performance and competitive edge. Components such as high-performance wheels, advanced transmission units, and precision braking systems work together to deliver speed, agility, and control on the racetrack. Professional motorcycle racers understand the significance of selecting the best components for their bikes to maximize performance and achieve success in challenging race conditions.

Conclusion

Professional motorcycle racers and enthusiasts recognize the intricate interplay of components within a motorcycle and the significant impact each part has on the overall performance, handling, and safety of the bike. By prioritizing the selection of high-quality components and ensuring seamless integration among them, riders can experience heightened performance, precision, and enjoyment while riding their motorcycles. Ultimately, understanding the building blocks of a motorcycle and their roles is essential for enhancing the riding experience and achieving success in the competitive world of motorcycle racing.If you want to improve your motorcycle riding experience, book your schedule with us.

Original Source - https://evolvegt.com/components-the-building-blocks-of-your-motorcycle

0 notes

Text

Unlock Exceptional Lifting Capabilities with Advanced Excavators

In today’s construction landscape, Australian contractors are looking for ways to enhance productivity and efficiency, especially when it comes to heavy-duty lifting operations. One of the most versatile and essential pieces of equipment in the industry is the excavator.

Advanced excavators have revolutionised the construction world, providing unmatched power, precision, and control. Whether you’re working on a small project or a massive infrastructure job, the right excavator can help unlock exceptional lifting capabilities that simplify your tasks and maximise results.

Why Advanced Excavators Matter for Lifting Capabilities

Excavators have always been known for their digging capabilities, but modern advancements have transformed them into multi-functional machines. Equipped with advanced hydraulic systems, smart technologies, and reinforced structures, today’s excavators offer excellent lifting capacities, making them invaluable in a range of industries, from construction to mining and beyond.

The importance of lifting in various construction tasks cannot be overstated, especially when it comes to handling heavy materials like steel beams, concrete blocks, or large pipes. The ability to safely and efficiently move these materials with precision can drastically reduce project timelines, minimise labour costs, and improve overall project safety. Advanced excavators, designed for lifting, are built to handle these demands and provide operators with the confidence needed to complete challenging tasks.

Key Features of Modern Excavators for Lifting Operations

Modern excavators are designed with features that enhance lifting capabilities, focusing on stability, control, and power. These features allow operators to perform even the most challenging lifts with ease and accuracy.

Hydraulic Power

The core of an excavator’s lifting ability lies in its hydraulic system. High-quality hydraulic pumps and cylinders generate enormous lifting forces, allowing the excavator to handle substantial loads. Advanced hydraulic systems are optimised for precision, making it easier for operators to lift and manoeuvre heavy objects with confidence.

Stability and Balance

When lifting heavy loads, stability is crucial. Excavators are engineered with wide tracks, low centres of gravity, and counterweights that ensure the machine remains stable even when handling maximum loads. Additionally, the cab’s design enhances visibility, enabling the operator to maintain better control and balance during lifting operations.

Intelligent Control Systems

Many advanced excavators come equipped with intelligent control systems that help operators monitor and adjust the machine’s performance in real-time. These systems can automatically adjust the hydraulic flow to maintain lifting precision and stability. Some machines also feature load-lifting charts displayed in the cab, helping operators gauge their lifting limits to prevent accidents.

Boom and Arm Strength

The boom and arm components of an excavator are designed to withstand high stress levels, allowing them to handle heavy loads without compromising performance. Reinforced booms and arms, built with high-grade steel, provide the strength and durability necessary for consistent, high-capacity lifting.

Featured Products

PC88MR-11 Excavator

The PC88MR-11 Excavator is a compact and versatile machine ideal for working in tight spaces, offering exceptional performance and durability for urban, residential, and commercial projects. PC88MR-11 combines power with efficiency, making it suitable for various applications like digging, trenching, and lifting. Its advanced hydraulic system ensures smooth operation, while the compact tail swing design allows for better maneuverability in confined areas.

Key Features:

Compact Tail Swing Design: Perfect for tight job sites, improving accessibility and reducing the risk of damage to nearby structures.

Fuel-Efficient Engine: Complies with the latest emission standards while delivering high performance with lower fuel consumption.

Advanced Hydraulic System: Provides smooth, precise control and enhances operator efficiency.

Operator Comfort: Equipped with a spacious, ergonomic cab that includes climate control, an adjustable seat, and an intuitive control panel.

Reduced Maintenance Requirements: With extended service intervals and easy access to maintenance points, downtime is minimized.

Durability: Designed with reinforced structures and components to withstand tough job site conditions.

PC130-8 Excavator

The PC130-8 Excavator is a mid-sized excavator designed for productivity and versatility across a wide range of tasks. PC130-8 provides powerful performance in earthmoving, demolition, and material handling, making it suitable for both heavy-duty construction and smaller projects. With its robust design and user-friendly features, this machine ensures efficient and reliable operation.

Key Features:

Powerful Engine: Delivers optimal power for high-performance digging and lifting, while maintaining fuel efficiency.

Efficient Hydraulic System: Ensures smooth and precise movements, improving productivity and control during complex tasks.

Durable Components: Built to last with reinforced structures and high-quality materials, reducing the likelihood of wear and tear.

Spacious Cabin: Offers a comfortable and quiet working environment with excellent visibility, ergonomic controls, and climate control.

Easy Maintenance: Simplified access to key components and extended service intervals reduce operational downtime.

Enhanced Safety Features: Equipped with safety systems, including advanced monitoring and alarms to keep operators secure.

Importance of Safety During Lifting Operations

Safety is always the top priority during any lifting operation. Modern excavators are designed with built-in safety features to help operators perform tasks safely and efficiently. Operator training is equally important, as understanding the machine’s limits, stability dynamics, and proper use of control systems can prevent accidents and equipment damage.

Investing in advanced excavators not only enhances your lifting capabilities but also improves job site safety, helping you avoid costly downtime and injury.

FAQs

How does hydraulic power affect lifting capacity?

Hydraulic power is crucial for lifting heavy loads. The hydraulic system generates the force needed to raise, lower, and manoeuvre loads. A more powerful hydraulic system enables the excavator to lift heavier materials with greater ease and control.

Why is stability important during lifting operations?

Stability ensures that the excavator remains balanced and secure while lifting heavy loads. Without proper stability, the machine could tip or shift, which could result in accidents or damage to the equipment and materials.

Can advanced excavators be used for tasks beyond lifting?

Yes, modern excavators are multi-functional. While they are highly effective for lifting, they can also perform tasks like digging, grading, and demolition, making them versatile machines for construction projects.

What safety features are available in advanced excavators?

Advanced excavators come equipped with features like intelligent control systems, load monitoring, and stability assist systems. These features help operators maintain control and work within the safe lifting limits of the machine.

How do I choose the right excavator for my lifting needs?

Choosing the right excavator depends on the scale of your project, the type of materials you need to lift, and the environment you are working in. Consider the lifting capacity, hydraulic power, and stability features when making your decision.

Conclusion

Advanced excavators are key to unlocking exceptional lifting capabilities in the construction industry. With the right excavator, you can enhance efficiency, improve safety, and tackle even the toughest lifting operations with ease. By selecting the best excavaotrs for your needs, your Australian construction projects will benefit from smoother operations and superior results.

0 notes

Text

Machine Shops in Jamaica

Jamaica's automotive industry relies heavily on the expertise of local machine shops to keep vehicles running smoothly. These specialized facilities play a crucial role in repairing and refurbishing essential engine components. Among the reputable establishments in Kingston, AC's Engineering Ltd stands out for its comprehensive range of services and state-of-the-art equipment.

Located at 13 Lyndhurst Road in Kingston, AC's Engineering Ltd has established itself as a go-to destination for automotive repair and maintenance. With a team of skilled technicians and a commitment to quality, they offer a wide array of machining services to meet the diverse needs of Jamaica's motorists.

Cylinder Head Decking

Cylinder head decking is a critical process in engine repair and maintenance. At AC's Engineering Ltd, this service is performed with precision to ensure optimal engine performance. The process involves machining the bottom surface of the cylinder head to create a smooth, flat surface that forms a perfect seal with the engine block.

The importance of proper cylinder head decking cannot be overstated. It helps to:

Restore compression ratios

Improve engine efficiency

Prevent coolant and oil leaks

Ensure even distribution of pressure across the head gasket

AC's Engineering Ltd employs advanced CNC machinery to achieve the highest level of accuracy in cylinder head decking. Their technicians are trained to handle a variety of cylinder head materials, including cast iron and aluminum, ensuring that each job is completed to manufacturer specifications.

Cylinder Block Boring in Jamaica

Cylinder block boring is another essential service offered by machine shops in Jamaica. This process is necessary when cylinder walls become worn or damaged, leading to loss of compression and increased oil consumption. AC's Engineering Ltd specializes in precision cylinder boring to restore engine blocks to their original specifications or to accommodate oversized pistons.

The cylinder block boring process at AC's Engineering Ltd involves:

Thorough inspection of the cylinder block

Precise measurement of cylinder wear

Use of computer-controlled boring machines for accuracy

Honing of the bored cylinders for optimal surface finish

By offering this service, AC's Engineering Ltd helps Jamaican vehicle owners extend the life of their engines and avoid costly replacements. Their expertise in cylinder block boring covers a wide range of vehicle makes and models, from compact cars to heavy-duty trucks.

Crankshaft Regrinding

Crankshaft regrinding is a specialized service that requires both skill and precision. AC's Engineering Ltd has invested in advanced grinding equipment to provide top-quality crankshaft regrinding services to the Jamaican automotive market. This process is essential for restoring worn crankshafts, which are critical to the smooth operation of an engine.

The crankshaft regrinding process at AC's Engineering Ltd includes:

Thorough inspection for cracks and other damage

Precision grinding of main and rod journals

Polishing to achieve the required surface finish

Balancing to ensure smooth engine operation

With their expertise in crankshaft regrinding, AC's Engineering Ltd helps Jamaican motorists avoid the high cost of crankshaft replacement. Their service ensures that reground crankshafts meet or exceed OEM specifications, providing reliable performance and longevity.

In conclusion, machine shops like AC's Engineering Ltd play a vital role in maintaining and repairing Jamaica's vehicle fleet. Their specialized services in cylinder head decking, cylinder block boring, and crankshaft regrinding contribute significantly to the longevity and performance of engines across the island. For those in need of professional machining services in Jamaica, AC's Engineering Ltd can be reached at 876-927-7929, offering expert solutions for a wide range of automotive machining needs.

https://machineshopsinjamaica.blogspot.com/2024/09/machine-shops-in-jamaica.html https://docs.google.com/document/d/1PlDLMasooYTrirq8zjYqIeL1LluHJtdAiXn1rtiyxh8/edit?usp=sharing https://docs.google.com/document/d/1_Nimd-KgURVxitRF4MmkoPdPYpHtfw9eeybd7MyD8LE/edit?usp=sharing https://docs.google.com/document/d/1Mpae_6v2519w4J7JRFjxbEqZTGQ9v8E5jqrsO6icWJU/edit?usp=sharing https://persianrugrestorationlamesa.blogspot.com/2024/09/implant-teeth-procedure-oceanside.html https://www.tumblr.com/jeremymcdo/761265630602280960 https://www.tumblr.com/juliannacastroverde/761242511210577920 https://massagecareertraining294.blogspot.com/ https://carrepairvista.blogspot.com/2024/09/massage-career-training.html

0 notes

Text

What Is Included In The Reconditioning Service For A Range Rover 2.0 Engine?

The Range Rover 2.0 engine is a high-performance unit, delivering power, efficiency, and versatility. However, like any engine, wear and tear can lead to decreased performance over time. Rather than opting for an entirely new engine, reconditioning is an increasingly popular option. This process revives the engine's operational abilities while providing a cost-effective solution. Whether you are considering engine replacement or simply wish to enhance the performance of your current engine, understanding the reconditioning process is crucial. Inspection and Diagnostics: The First Step The reconditioning process for a Range Rover 2.0 engines begins with a detailed inspection and diagnostics phase. During this step, the engine is removed from the vehicle and thoroughly examined. Technicians utilize advanced diagnostic tools to identify specific issues like leaks, worn-out components, and performance irregularities. A comprehensive assessment of the engine block, pistons, crankshaft, and other integral parts is conducted. The goal here is to identify which parts require replacement and which can be restored. This phase also includes running tests to detect potential problems related to fuel systems, cooling systems, and electrical connections. Whether the engine is being reconditioned for general maintenance or complete engine replacement, diagnostics are vital to ensuring efficiency. Cleaning and Stripping Down the Engine Once the diagnostics are complete, the engine is stripped down to its basic components. Every part, from the cylinder head to the pistons, is disassembled and removed. After disassembly, the parts are subjected to thorough cleaning. High-pressure washing systems and industrial-grade chemicals are often used to clean every component. Cleaning removes all accumulated grime, carbon deposits, and oil residue that can hinder performance. This step is crucial in ensuring the engine’s reconditioned components work optimally. The thorough cleaning process can be considered as resetting the engine, providing a clean slate before reassembly. At this point, parts that need replacement are set aside, awaiting supply and fit services. Replacing Worn-Out Components with New Parts Replacing worn or damaged parts is a core element of the reconditioning service for a Range Rover 2.0 engine. After disassembly and cleaning, components like pistons, piston rings, bearings, gaskets, and timing belts are carefully inspected. If these parts do not meet the required standards, they are replaced with high-quality replacements. Choosing the right replacement parts ensures that the engine runs smoothly post-reconditioning. Parts that show signs of excessive wear or are beyond repair are immediately replaced. The focus is to achieve optimal performance while preventing future breakdowns. Engine replacement services that include supply and fit ensure the installation of new parts with precision. Reconditioning the Cylinder Head The cylinder head is a critical part of the engine that affects its overall performance. During the reconditioning process, the cylinder head is carefully restored to its original specifications. The head is machined, and components like valves, valve seats, and valve springs are inspected and reconditioned as necessary. Reseating the valves and ensuring the proper compression levels within the cylinder head is essential for efficient engine performance. This reconditioning ensures the engine operates smoothly without experiencing compression loss or other internal combustion issues. The cylinder head's reconditioning is often paired with engine replacement to provide the best performance possible. Crankshaft and Camshaft Reconditioning The crankshaft and camshaft play vital roles in an engine's function. These components are inspected for wear, stress fractures, or damage caused by heat and stress over time. If necessary, the crankshaft and camshaft are machined and polished to restore their surfaces. In severe cases, they are replaced with new components that meet the manufacturer’s specifications. Proper reconditioning or replacement of these shafts ensures that the engine’s moving parts function harmoniously, reducing the risk of vibrations or poor timing. This careful attention to the crankshaft and camshaft forms the backbone of a successful reconditioning service for any engine, including the Range Rover 2.0. Rebuilding and Reassembly of the Engine After reconditioning the engine’s components, the engine is meticulously rebuilt. Technicians carefully reassemble the engine, ensuring all parts are correctly installed, torqued to factory specifications, and lubricated. This includes installing the cylinder head, crankshaft, camshaft, pistons, and valves back into their respective places. During this phase, the new and restored parts are fitted with precision, ensuring the engine operates efficiently once back in the vehicle. The assembly process demands a high level of expertise, as even a small misalignment could affect the engine’s performance. The reassembly ensures that all components work together seamlessly, preparing the engine for its return to full operation. Testing and Tuning: Ensuring Optimal Performance Once the reassembly is complete, the engine is subjected to rigorous testing. These tests are designed to ensure that the engine performs as expected under various conditions. The engine is run on a test bench to evaluate factors such as fuel efficiency, power output, temperature regulation, and oil pressure. This phase also includes tuning the engine to meet optimal performance standards. Fine-tuning ensures that the engine runs smoothly with proper air-fuel mixtures, combustion efficiency, and timing. Any issues detected during testing are addressed immediately. These tests are critical to ensuring that the reconditioned engine meets or exceeds the original specifications. Installation and Final Checks The final step of the reconditioning service involves reinstalling the engine into the Range Rover. Once the engine is back in the vehicle, further checks are conducted to ensure everything is functioning correctly. Supply and fit services ensure that all components are installed accurately, including connections to the vehicle's fuel, exhaust, and cooling systems. Technicians run additional tests once the engine is in place to ensure there are no installation issues. This final phase guarantees that the engine performs to the required standards before it is handed back to the owner. This process ensures reliability, longevity, and optimal performance for the newly reconditioned Range Rover 2.0 engine. Read the full article

0 notes

Text

Global Top 13 Companies Accounted for 54% of total Axial Piston Hydraulic Motors and Pump market (QYResearch, 2021)

The Axial Piston Hydraulic Motors and Pumps industry can be broken down into several segments, Axial Piston Hydraulic Motors, Axial Piston Hydraulic Pumps, etc.

Across the world, the major players cover Bosch Rexroth Ltd., Bondioli & Pavesi SPA, etc.

An axial piston pump is a positive displacement pump that has a number of pistons in a circular array within a cylinder block. It can be used as a stand-alone pump, a hydraulic motor or an automotive air conditioning compressor. Axial piston motors are available in swash plate or bent axis design for medium- and high-pressure applications.

According to the new market research report “Global Axial Piston Hydraulic Motors and Pumps Market Report 2023-2029”, published by QYResearch, the global Axial Piston Hydraulic Motors and Pumps market size is projected to reach USD 2.29 billion by 2029, at a CAGR of 3.7% during the forecast period.

Figure. Global Axial Piston Hydraulic Motors and Pumps Market Size (US$ Million), 2018-2029

Figure. Global Axial Piston Hydraulic Motors and Pumps Top 13 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Axial Piston Hydraulic Motors and Pumps include Bosch Rexroth, Hengli, Danfoss Group, Linde Hydraulics, Bondioli & Pavesi SPA, Kawasaki, Eaton Corporation, Parker-Hannifin Corporation, Hydrosila, HAWE Hydraulik SE, etc. In 2021, the global top 10 players had a share approximately 54.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes