#Inventory Tracking

Explore tagged Tumblr posts

Text

Inventory Management Software Development Company - IBR Infotech

As a trusted inventory management software development company, we specialize in delivering high-quality, scalable solutions for businesses across various industries. Our custom-built inventory management software provides advanced features like multi-location management, real-time stock tracking, and integration with e-commerce and ERP platforms. We work closely with our clients to understand their inventory needs and deliver software that simplifies stock control, enhances operational efficiency, and improves decision-making. Our solutions are designed to help businesses reduce errors, cut costs, and boost productivity. Whether you run a retail business, manufacturing unit, or warehouse, we can help you manage your inventory with precision and efficiency. Let us help you build a robust inventory management system that drives growth and profitability.

#newyork#website design#app development#orlando web design#web developing company#inventorymanagement#inventory tracking#inventory management#inventory software#inventory#order management software#mobile app development#management courses

1 note

·

View note

Text

Are Your Warehouse Cameras Optimized for Inventory Tracking?

Do you know whether your existing camera system is assisting or impeding your inventory monitoring efforts in the chaotic world of warehouse management, where efficiency and accuracy are critical? Have you ever struggled with poor image quality, poor connectivity, or the inability to connect your inventory management system to your camera feeds? It could be time to assess your cameras, which are the central component of your surveillance system, if these issues seem familiar. More precisely, do your warehouse cameras perform as intended or do they have shortcomings that have an immediate effect on your profitability?

In this blog, we’ll explore how ONVIF PoE cameras could be the solution to your inventory tracking struggles, offering a seamless blend of performance, connectivity, and ease of use. By diving into common warehouse camera challenges, we’ll highlight how ONVIF PoE cameras are uniquely equipped to address your pain points and streamline your operations.

The Challenge: Inefficiencies in Inventory Tracking

Warehouse inventory tracking has evolved significantly with the rise of automation, barcoding, and advanced software systems. However, no matter how advanced your technology may be, there’s one critical piece of the puzzle that can’t be overlooked: your camera system. Poorly optimized cameras can severely limit the effectiveness of your inventory system and ultimately lead to costly errors and inefficiencies.

Here are a few pain points that many warehouses face:

Blurry or Low-Resolution Footage: Cameras with low resolution or poor image quality can make it difficult to identify inventory items, especially when it comes to smaller or complex labels.

Connectivity Issues: In many warehouses, networks are large and complex, and ensuring that all cameras are connected reliably can be a challenge. Connectivity issues often lead to missing footage or delayed updates, which means you might be relying on outdated or incomplete data.

Lack of Integration: Your camera system needs to work seamlessly with your warehouse management system (WMS). If your cameras don’t integrate well, you’ll face difficulties when it comes to tracking items in real-time or even viewing live footage of specific locations in your warehouse.

Limited Power Options: Traditional cameras might require separate power sources and complex wiring setups. This could create unnecessary installation costs and require frequent maintenance.

Scalability Concerns: As your warehouse grows, so does the need for more cameras. Some systems might struggle with scaling effectively or cause disruptions when new cameras are added.

The Solution: ONVIF PoE Cameras

So, how do you solve these challenges and optimize your warehouse for smoother inventory tracking? The answer lies in using the right type of camera—specifically, ONVIF PoE cameras.

What is an ONVIF PoE camera?

An ONVIF (Open Network Video Interface Forum) PoE (Power over Ethernet) camera is a surveillance camera that adheres to the ONVIF standard for video surveillance interoperability and connects to a network using Ethernet cables while also receiving power over the same cable. This unique combination ensures a stable connection and reduces the need for separate power cables.

Key Benefits of ONVIF PoE Cameras for Inventory Tracking

Let’s explore the top benefits of ONVIF PoE cameras and why they’re the optimal solution for warehouse inventory tracking.

1. High-quality video for precise tracking

ONVIF PoE cameras are designed to deliver clear, high-definition footage, ensuring that every detail of your inventory is captured with precision. With high-resolution cameras, blurry or pixelated images become a thing of the past. You can clearly identify items, read labels, and track products in motion with sharp clarity—whether it’s through a live feed or recorded footage.

2. Reliable and Fast Connectivity

The main challenge with many camera systems is unreliable connectivity, especially in large warehouses where Wi-Fi signals can be weak. ONVIF PoE cameras use Ethernet cables to connect directly to your network, offering a more stable and faster connection compared to traditional wireless cameras. This reduces lag and minimizes the risk of dropped signals, ensuring you have constant, up-to-date footage of your warehouse.

3. Seamless Integration with Your WMS

One of the most powerful aspects of ONVIF PoE cameras is their ability to integrate smoothly with your existing warehouse management system (WMS). Whether you're using an off-the-shelf WMS or a custom-built solution, ONVIF cameras allow for easy integration, providing real-time video feeds that complement your inventory data. This seamless connection can trigger automatic updates in your WMS, reducing manual data entry and human errors.

4. Simplified Installation with PoE

When it comes to installation, ONVIF PoE cameras provide a hassle-free setup. Power over Ethernet means that both power and data are delivered through a single cable, making it easier to set up new cameras and reduce the need for complicated power installations. This can drastically reduce your upfront installation costs and make expansion simpler. Additionally, PoE cameras are less prone to power failures compared to traditional wireless options.

5. Scalability for Growing Warehouses

As your warehouse expands, so will your camera system. ONVIF PoE cameras are designed with scalability in mind. You can easily add additional cameras to your system without significant disruptions, ensuring that your inventory tracking capabilities grow alongside your operations. Their flexible design allows you to cover more ground without compromising quality or performance.

6. Cost-Effectiveness

While ONVIF PoE cameras might come with a higher initial cost compared to traditional CCTV cameras, their long-term benefits make them a cost-effective choice. With the ability to reduce installation complexity, improve efficiency, and lower maintenance costs, these cameras pay for themselves over time. Plus, their durability and ability to integrate with other systems help you avoid future expenses.

Why Your Warehouse Needs ONVIF PoE Cameras

When it comes to inventory tracking, every second and every detail counts. Poor camera systems can lead to missed opportunities, misplaced items, and incorrect data—all of which can impact your overall efficiency and bottom line. ONVIF PoE cameras offer the high-quality video, seamless integration, and reliability that your warehouse needs to keep operations running smoothly.

With their user-friendly features, scalability, and high-definition video capabilities, ONVIF PoE cameras make inventory management easier, faster, and more accurate. They help you get ahead of mistakes, track items in real time, and give you the peace of mind that your surveillance system is working as hard as you are.

Take Action Today

If you’re ready to optimize your warehouse camera system for better inventory tracking, it’s time to consider the powerful benefits of ONVIF PoE cameras. Stop relying on outdated, inefficient camera systems and start investing in technology that will future-proof your warehouse operations. With ONVIF PoE cameras, you can reduce human error, minimize downtime, and ensure the smooth operation of your business.

Want to learn more? Check out our range of ONVIF PoE cameras and get in touch with our team for tailored solutions to meet your warehouse’s unique needs.

0 notes

Text

Managing inventory efficiently is crucial for any business, and integrating modern shelving solutions can make a world of difference. At U R FIRST Logistics, we’re committed to helping you streamline your operations with cutting-edge shelving systems designed to enhance warehouse modernization.

0 notes

Text

Efficient inventory management is paramount for manufacturers in all industries. For Eco-Mix Materials Incorporated, a premier supplier of construction materials, it’s not just about keeping costs down; it’s about ensuring our commitment to responsible practices. One key area of focus is fly ash, a recycled material from coal combustion that offers significant environmental benefits in soil stabilization in Chicago, Illinois.

0 notes

Text

9 Inventory Management Tips to Help You Stay on Top of Your Stock

Owning a business requires you to deal with a seemingly never-ending array of challenges.

From dealing with finances, to managing employees, ensuring compliance with regulations, and everything in between, today’s business owners have a million and one things to worry about.

And when you’re dealing with something with this many moving parts, it’s easy to overlook things.

But while you can get away with overlooking some things, inventory management is something you just can’t afford to mess up, or you could end up dealing with some severe financial consequences.

For example, according to estimates from a Coresight Research survey, poor inventory management accounts for 53% of unplanned markdowns for retailers, and in 2018, markdowns cost U.S. non-grocery retailers approximately $300 billion.

What’s more, 50% of survey respondents said “inventory misjudgments” act as a barrier to selling their products at full price.

As you can see, this is not something you can afford to overlook. But trying to wrap your head around inventory management can also be incredibly overwhelming.

With that in mind, we want to offer some inventory management tips so you can stay on top of your stock and avoid the pitfalls of poor inventory management.

So, if you’re dealing with issues related to your inventory, and you’re looking for some inventory management tips and tricks, then you’re going to want to keep reading.

What Are Some Common Inventory Management Issues?

Before we start offering inventory management tips, we also want to explore some of the most common inventory management challenges.

This knowledge will help put things in perspective for you and offer even greater context for how you can apply the advice we’re about to give.

Having said that, here are some of the most common inventory management issues:

Inaccurate Inventory Tracking

One of the most common inventory management issues is inaccurate tracking of stock levels.

Errors in data entry, miscounts during stock audits, and discrepancies between physical stock and recorded inventory are all too common.

These inaccuracies can lead to stockouts, where items are unavailable when customers want them, or overstocking, where excess inventory takes up valuable space and ties up capital.

Both scenarios are detrimental, as stockouts can result in lost sales, dissatisfied customers, and many other problems.

Overstocking and Stockouts

Overstocking occurs when a business orders more stock than necessary, which can lead to high storage costs and an increased risk of inventory becoming obsolete.

On the flip side, stockouts happen when inventory levels are too low to meet customer demand, and this can result in missed sales opportunities and damage to customer relationships.

Both of these situations are costly and highlight the importance of accurate demand forecasting and efficient inventory management practices.

Inefficient Supply Chain Management

As we’ve all learned over the last few years, supply chain disruptions can severely impact inventory management.

Things like delays in receiving goods and unreliable suppliers can all contribute to inventory shortages or excesses.

Inefficient communication between supply chain partners can further exacerbate these issues, making it difficult to forecast your inventory needs accurately.

This can lead to a situation where you either overstock to mitigate the risk of stockouts or understock due to uncertainty, both of which are certainly not ideal.

Poor Demand Forecasting

Poor demand forecasting can also lead to either overstocking or stockouts.

And without reliable demand forecasting, businesses risk either tying up too much capital in unsold inventory or losing sales due to insufficient stock.

That being said, accurately predicting consumer demand for the products you carry is vital for maintaining the right inventory levels.

But in order to do this, you’ve got to analyze historical sales data, market trends, and other relevant factors, otherwise you’ll be more likely to misjudge demand.

This issue is also particularly challenging in industries with seasonal fluctuations or rapidly changing consumer preferences.

Lack of Real-Time Data

The absence of real-time inventory data can leave businesses operating on outdated information, leading to poor decision-making when it comes to inventory management.

Without these real-time insights, businesses may struggle to respond quickly to changes in demand or supply chain disruptions, and this lag in information can result in missed opportunities for restocking or unnecessary purchases of slow-moving items.

With that in mind, implementing systems that provide real-time inventory tracking can help businesses make more informed decisions and improve their overall inventory management efficiency.

High Carrying Costs

Inventory carrying costs, which include expenses related to storage, insurance, and the risk of obsolescence, can significantly impact your business’ profitability.

If you overstock inventory or fail to move products quickly enough, you’ll face higher carrying costs, which are often compounded by the need to discount or write off obsolete inventory, and these issues can significantly reduce your profitability.

With that in mind, effective inventory management practices, such as just-in-time (JIT) inventory, can help minimize carrying costs by reducing the amount of inventory held at any given time.

Ineffective Inventory Management Systems

Many businesses today still rely on outdated or inadequate inventory management systems that lack the sophistication needed to handle modern inventory challenges.

These systems may not integrate well with other business processes or may require manual input, which increases the risk of errors.

In any case, a failure to modernize your inventory systems can lead to inefficiencies that hinder your business’ ability to compete.

Luckily, modern inventory management solutions, particularly those that leverage automation and real-time data, can significantly enhance your ability to efficiently manage your inventory.

Our Top Inventory Management Tips

As you can tell by now, there is no shortage of issues when it comes to inventory management.

These may not all apply to your business, but if you fail to address the challenges that do, it could have far-reaching consequences from which you may never recover.

Fortunately, below we’ve provided a comprehensive list of inventory management tips and tricks, so you can avoid falling prey to the pitfalls of poor inventory management.

1) Understand Your Inventory

One of the best inventory management tips we can offer is to make sure you have a solid understanding of your inventory.

This involves categorizing your inventory based on things like how quickly your company can sell a given item, along with its value, and how quickly people will be looking to replace that item.

Employing an ABC analysis is useful here, and this involves segmenting your inventory into A-items (high-value products with low sales frequency), B-items (moderate-value products with moderate sales frequency), and C-items (low-value products with high sales frequency).

This classification can help you evaluate your inventory and then concentrate your resources on the most impactful items.

2) Leverage Technology

Incorporating technology into your inventory management process through things like inventory management software can significantly streamline your operations.

These tools provide features like real-time tracking, automated reordering, and detailed analytics, among many other benefits.

What’s more, this kind of technology allows you to integrate your inventory system with other aspects of your business, like accounting, procurement, and sales, which helps to ensure the consistency of your data and the efficiency of your operations.

3) Optimize Your Inventory Levels

When it comes to inventory management, optimizing your inventory is arguably one of the toughest challenges you’ll face.

With that in mind, setting Periodic Automatic Replacement (PAR) levels is crucial for maintaining sufficient stock so you can meet demand without overstocking.

Setting PAR levels involves using software to set the minimum levels of inventory you need to fulfill demand for a specific product.

Once this is done, the software will then notify you of the need for the item to be reordered and can even be set to automatically reorder stock when the minimum level is reached.

Moreover, the Just-In-Time (JIT) inventory strategy can also be effective for optimizing your inventory levels, as it involves keeping minimal inventory on hand and ordering more only as needed.

However, while this strategy can help to reduce carrying costs, it requires accurate demand forecasting and reliable suppliers.

4) Improve Your Forecasting

Effective inventory management relies heavily on accurate forecasting, which you can do by using historical sales data and considering factors like seasonal fluctuations and market trends.

In any case, it’s essential to regularly update your forecasts based on new sales data and external factors, such as economic shifts or changes in consumer behaviour.

5) Manage Your Relationships

Developing strong relationships with your suppliers can help you negotiate better deals and help to improve the reliability of your supply chain.

And if you’re able to successfully negotiate better terms by leveraging volume, loyalty, and payment history, it can yield significant benefits, including discounts and priority delivery schedules.

6) Monitor and Audit

Regular audits can help you verify that your physical inventory matches your inventory records, allowing you to promptly address any discrepancies.

Making use of cycle counting, for instance, which involves counting a subset of inventory on a rotating schedule, may help you pinpoint issues more efficiently than a full inventory count.

7) Properly Train Your Staff

Properly and regularly training your staff in the best inventory management practices and how to operate the systems you’re using is crucial.

What’s more, encouraging accountability by implementing performance metrics and involving your staff in planning and decision-making processes can also help to improve your inventory management.

8) Optimize Your Storage

Designing an efficient warehouse layout allows you to easily access frequently picked items, ensuring smooth and unobstructed movement of goods.

Utilizing vertical space for storage by implementing a racking system, for instance, can also help by more efficiently using your space and decreasing rental costs.

Not all businesses can afford to rent out warehouse space, but even if you’re storing your inventory in your garage, the same rules apply.

Whatever space you have should be used as efficiently as possible, and should allow for an easy flow of goods, particularly for your most popular items.

But if you are running out of room and you’re looking to scale without heavy investment in warehousing and distribution, outsourcing inventory management to a third-party logistics (3PL) provider can be advantageous, as it can help to reduce costs and improve operational efficiency.

9) Pick the Right Platform

Unfortunately, a lot of companies in our industry are still offering older payment terminals, most of which have no inventory management capabilities.

And if your device doesn’t offer these features, then you’re either going to have to have someone manage your inventory manually, which costs time and money, and can be subject to human error, or you’ll have to pay a third-party to take care of it for you, neither of which is ideal.

Fortunately, our platform offers online inventory management through an all-in-one, easy-to-use, centralized system that syncs with all your devices.

For example, if you do ten sales on your physical terminal, and five sales using your point-of-sale system, and then you log into our online platform, you’ll see all those sales in one place, and the products in question will immediately be deducted from your inventory.

So, ask yourself, when it comes to inventory management, is your payment processing platform working for you, or are you working for it?

Because if you are the one doing most of the work, then maybe it’s time for a change.

Searching for a payment processing platform that works as hard as you do? Why not contact us today and find out how we can help?

0 notes

Text

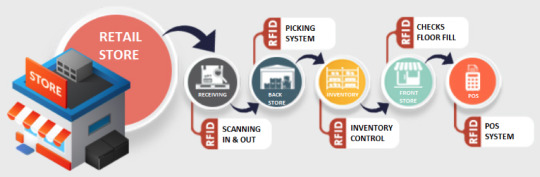

RFID inventory tracking software

Enhance your inventory management with RFID inventory tracking software. This advanced solution offers accurate tracking and efficient asset management. Ideal for warehouses, retail, and manufacturing, RFID inventory tracking software streamlines operations and reduces errors. Upgrade to our cutting-edge software for improved productivity and control over your inventory.

1 note

·

View note

Text

#Point-of-Sale System#Bars and Restaurants#Order Management#Streamlined Payments#Inventory Tracking#Customer Relationship Management#Employee Management#Menu Management

0 notes

Text

Reducing Operational Costs: The Financial Benefits of ERPNext in Retail by Sigzen

In the ever-evolving retail landscape, ERPNext Retail offers a comprehensive solution tailored to the unique challenges of the retail sectors. From inventory tracking and POS integration to automated reordering and CRM, ERPNext streamlines operations, enhances productivity, and significantly reduces operational costs. Its robust features, including e-commerce integration, dynamic pricing, and…

#CRM for Retail#ERPNext Retail#Inventory Tracking#Retail ERPSoftware#Retail Procurement#Retail Sales Management#Supplier Management

2 notes

·

View notes

Text

Efficient POS System for Bar and Grill | Streamline Operations & Boost Sales

Enhance your bar and grill operations with our efficient POS system. Streamline order management, inventory tracking, and customer service to boost sales and operational efficiency seamlessly. To Know pos system for bar and grill

0 notes

Text

Managing inventory effectively is crucial for businesses, especially those in the courier service in San Diego, California. In this bustling city, efficient inventory management can make all the difference in ensuring timely deliveries and satisfied customers. Whether you’re handling perishable goods or fragile items, implementing the right strategies can streamline operations and enhance customer satisfaction. By employing robust inventory management practices, courier services can stay ahead of the competition and meet the diverse needs of their clientele.

0 notes

Text

IBR Infotech offers custom pharmacy software solutions in New York, designed to streamline pharmacy operations and enhance patient care. Our solutions include prescription management, inventory tracking, automated billing, e-prescriptions, and compliance management to ensure smooth and efficient workflows. We integrate AI-powered analytics, telemedicine support, and multi-store management for modern pharmacies. Whether you're an independent pharmacy or a large healthcare provider, our secure and scalable software solutions help improve accuracy, reduce errors, and enhance customer experience. Optimize your pharmacy operations with IBR Infotech—contact us today!

#mobile app development#app development#web developing company#web design services#orlando web design#web development company#webdevelopment#web design agency#website design#Pharmacy Software Solutions#custom pharmacy software solutions#pharmacy operations#inventory tracking#automated billing#e-prescriptions#website

0 notes

Text

How 2MP USB Cameras Are Revolutionizing Automated Stock Management

Effective stock management is more important than ever in the hectic retail and warehouse settings of today. Presenting the 2MP USB camera, a cutting-edge device that is revolutionizing how companies monitor stock levels and inventory. These cameras are a useful way to automate stock management procedures because of their excellent resolution and networking features. We'll look at how 2MP USB cameras are causing a stir in this industry and how they can help businesses in this blog post.

Enhancing Inventory Tracking with 2MP USB Cameras

One of the primary advantages of utilizing a 2MP USB camera is the enhanced inventory tracking it provides. These cameras can easily be integrated into existing inventory management systems, allowing for real-time monitoring of stock levels.

With a 2MP resolution, these cameras capture clear, detailed images of products, enabling businesses to conduct precise visual audits without the need for manual checks. This efficiency reduces human error and ensures that stock counts are accurate. By leveraging this technology, businesses can streamline their inventory processes, saving time and labor costs.

Streamlining stock replenishment processes

Another significant benefit of USB cameras with 2MP resolution is their ability to streamline stock replenishment. When integrated with inventory management software, these cameras can monitor product levels and automatically trigger replenishment alerts when stock runs low.

This automation not only minimizes the risk of stockouts but also helps in maintaining optimal inventory levels. Businesses can respond quickly to changes in demand, ensuring they always have the right products available for customers. By implementing 2MP USB cameras, companies can enhance their stock replenishment strategies and improve overall efficiency.

Increasing Operational Efficiency through Automated Data Capture

The adoption of 2MP USB cameras also leads to increased operational efficiency through automated data capture. These cameras can scan barcodes or QR codes, allowing for quick and accurate data entry into inventory systems.

By eliminating the need for manual data input, businesses can reduce the time spent on administrative tasks and focus on more strategic activities. This automation not only speeds up inventory management processes but also minimizes the likelihood of errors that can occur during manual entry. The result is a more efficient workflow that contributes to overall productivity.

Improving Security and Loss Prevention

Utilizing a 2MP USB camera in stock management can also enhance security measures and prevent loss. These cameras can be strategically placed throughout a warehouse or retail environment to monitor high-value stock areas.

With high-definition video capabilities, businesses can record real-time footage, providing valuable insights into stock movements and helping to identify potential theft or loss. Additionally, these cameras can be integrated with alarm systems, ensuring immediate alerts when unauthorized access occurs. Implementing 2MP USB cameras for security purposes adds an extra layer of protection for valuable inventory.

Optimizing Space Utilization in Warehouses

Effective stock management isn't just about tracking inventory; it's also about optimizing the space in which that inventory is stored. 2MP USB cameras can assist in monitoring stock levels across various storage areas, allowing for better space management.

By capturing images of inventory in real time, businesses can analyze which products are moving quickly and which are sitting idle. This data can inform decisions about stock placement and layout, ultimately leading to more efficient use of space. As a result, businesses can maximize their storage capabilities while minimizing clutter and disorganization.

Are you prepared to use a 2MP USB camera to revolutionize your stock management procedures? Examine the advantages of incorporating this cutting-edge technology into your business operations right now! These cameras provide solutions that are customized to meet your company's demands, whether you're looking to improve security, expedite inventory monitoring, or maximize warehouse space. For additional information on using technology to increase your operational efficiency, get in touch with us or sign up!

0 notes

Text

RFID Retail Solutions: Streamlining Inventory Management for Success

RFID is gaining widespread adoption in the retail sector. When Radio-Frequency Identification (RFID) technology was introduced over 70 years ago, it promised significant advancements, particularly in the retail industry, which demands precise inventory management. With a high volume of items moving quickly in and out of the premises and a plethora of sizes, colors, and designs requiring high selectivity, the chances of inventory loss, errors, and inefficiency are high. Utilizing RFID Technology in inventory management addresses these challenges effectively. According to recent studies, 58% of warehouse decision-makers have plans to implement RFID technology by the year 2028. While implementing RFID technology may take months, the initial efforts are already showing results, with billions saved annually in shrinkage (inventory losses).

Inventory management in retail is crucial for saving time, ensuring accuracy, and satisfying customers. Each item is equipped with an RFID Tag, and fixed RFID Readers are strategically placed to automate stock checks without manual intervention in warehouses or retail stores. This ensures 24/7 inventory counts, preventing shrinkage loss, inventory misplacement, and other errors. Handheld RFID readers complement fixed RFID readers, providing real-time updates and enabling rapid inventory checks to enhance overall efficiency. RFID technology enables various applications, including inventory picking, shipment verification, stock in/stock out, and locating lost items.

Additionally, custom software enables item identification capabilities, allowing the system to identify and categorize items based on various attributes such as SKU, size, color, or location. This facilitates precise inventory tracking, enabling managers to quickly locate specific items, analyze stock movements, and optimize inventory levels. With item identification functionality, businesses can streamline their inventory management processes, reduce errors, and improve overall operational efficiency. Other features, such as notifications for removed items, real-time image capture, and item identification offer significant benefits, including improved inventory accuracy, enhanced transparency, and streamlined operations, ultimately leading to cost savings and better business outcomes.

Experts commonly cite inventory management as the primary use case for RFID technology, but its applications extend far beyond just that. RFID has proven its effectiveness in various areas, including omni-channel operations, smart fitting rooms, accelerated checkouts, and interactive displays. Over the past decade, RFID technology has made significant strides. Read accuracy has doubled, prices have dropped significantly, and the range has increased more than fivefold, leading to fewer devices required and better scanning capabilities. Today, RFID enables real-time visibility, enhanced accuracy, and increased automation, resulting in significantly improved operational efficiency, time and cost savings, and an enhanced overall customer experience.

#RFID Retail Solutions#RFID Garments Tags#RFID tags#Inventory Tracking#Inventory Management#RFID technology#RFID solutions#rfid reader

0 notes

Text

Warehouse management systems (WMS) are transforming the dynamics of freight forwarding by revolutionizing inventory control, optimizing logistics operations, and enhancing overall efficiency. Explore this article on how warehouse management systems are reshaping the freight forwarding landscape for valuable insights into modern warehouse management practices.

#logistics#supplychainmanagment#freightforwarding#import#export#AR#AP#inventory tracking#inventorymanagement#transportation

0 notes

Text

What Are the Key Features of Inventory Management Software?

Introduction

Inventory management software is a powerful tool designed to help businesses effectively track, manage, and control their inventory. In today's fast-paced business world, efficient inventory management is crucial for optimizing operations, reducing costs, and maximizing profitability. Whether you run a small retail shop or a large-scale manufacturing facility, having the right inventory management can make a significant difference in streamlining your processes and improving overall efficiency.

Key Features of Inventory Management Software

Inventory Tracking and Monitoring

One of the fundamental features of inventory management software is its ability to track and monitor inventory levels in real time. With this feature, businesses can easily keep track of stock quantities, locations, and movement within the warehouse or across multiple locations. This ensures that businesses always have a clear understanding of their current inventory status, helping to prevent stockouts, overstocking, and costly mistakes.

Automated Reordering

Automated reordering is another essential feature of inventory management software that helps businesses maintain optimal inventory levels without manual intervention. By setting up reorder points and preferred stock levels, businesses can automate the process of replenishing inventory whenever it falls below a certain threshold. This not only helps to prevent stockouts but also ensures that businesses avoid tying up capital in excess inventory.

Barcode Scanning and RFID Integration

Many inventory management software solutions come equipped with barcode scanning and RFID integration capabilities, allowing businesses to easily identify and track individual items within their inventory. Barcode scanning enables quick and accurate data capture, while RFID technology provides real-time visibility into inventory movement and location. By leveraging these technologies, businesses can improve inventory accuracy, reduce errors, and streamline their operations.

Forecasting and Demand Planning

Effective inventory management requires businesses to anticipate future demand and plan accordingly. Inventory management software often includes forecasting and demand planning tools that analyze historical data, market trends, and other factors to predict future demand patterns. By accurately forecasting demand, businesses can optimize their inventory levels, minimize stockouts, and ensure that they have the right products available when customers need them.

Multi-Channel Selling and Integration

In today's omnichannel retail environment, businesses often sell their products through multiple channels, including brick-and-mortar stores, e-commerce platforms, and third-party marketplaces. Inventory management software with multi-channel selling and integration capabilities allows businesses to manage inventory across all channels from a single platform. This ensures that inventory levels are synchronized across all sales channels, preventing overselling and ensuring a seamless shopping experience for customers.

Warehouse Management

For businesses with large warehouses or distribution centers, warehouse management functionality is crucial for optimizing storage space, streamlining picking and packing processes, and improving overall efficiency. Inventory management software often includes warehouse management features such as bin location tracking, pick and pack workflows, and automated replenishment, allowing businesses to maximize the use of their warehouse space and minimize operational costs.

Reporting and Analytics

Data-driven decision-making is essential for effective inventory management. Inventory management software typically includes robust reporting and analytics capabilities that provide businesses with insights into key metrics such as inventory turnover, stock velocity, and carrying costs. By analyzing this data, businesses can identify trends, spot opportunities for improvement, and make informed decisions to optimize their inventory management processes.

Benefits of Inventory Management Software

Improved Efficiency and Productivity

By automating manual tasks, streamlining processes, and providing real-time visibility into inventory levels, inventory management software helps businesses improve efficiency and productivity across the organization. This allows employees to focus on more value-added tasks, such as serving customers and growing the business, rather than spending time on repetitive administrative tasks.

Cost Savings

Effective inventory management can result in significant cost savings for businesses. By minimizing stockouts, reducing excess inventory, and optimizing warehouse space, inventory management software helps businesses lower carrying costs, improve cash flow, and maximize profitability. Additionally, by accurately forecasting demand and optimizing inventory levels, businesses can reduce the risk of obsolescence and minimize write-offs.

Enhanced Customer Satisfaction

Inventory management software enables businesses to provide better service to their customers by ensuring that products are always available when needed. By preventing stockouts and minimizing order fulfillment times, businesses can improve customer satisfaction, build loyalty, and drive repeat business. Additionally, by providing accurate and up-to-date information on product availability, businesses can reduce the likelihood of backorders and order cancellations, further enhancing the customer experience.

Scalability and Growth

As businesses grow and expand, their inventory management needs evolve as well. Inventory management software provides scalability and flexibility to accommodate changing business requirements, whether it's adding new products, expanding into new markets, or scaling up operations. By providing a centralized platform for managing inventory across multiple locations and channels, inventory management software enables businesses to scale efficiently and effectively without outgrowing their systems.

Also Read:-

Tips for a Successful Billing Software Deployment

What security measures should be considered when using POS software?

Conclusion

Inventory management software is a valuable tool for businesses of all sizes and industries looking to optimize their inventory management processes, improve efficiency, and drive growth. With its comprehensive features and benefits, inventory management software enables businesses to track, manage, and control their inventory more effectively, ultimately leading to increased profitability and customer satisfaction. By investing in the right inventory management software solution, businesses can position themselves for success in today's competitive marketplace.

0 notes

Text

Warehousing storage involves the storage of goods and products within a specific facility. This facility strategically organizes and handles items to oversee and store them effectively until they are ready for shipment to their ultimate destination.

0 notes