#RFID Garments Tags

Explore tagged Tumblr posts

Text

The Benefits of Using Washable RFID Tags on Clothes

As technology evolves, the retail and textile industries are constantly seeking innovative ways to improve efficiency and customer experience. One such advancement is using washable RFID (Radio Frequency Identification) tags on clothing. These tags offer numerous benefits, from streamlined inventory management to enhanced customer satisfaction. We are exploring the advantages of washable RFID tags, especially in the realm of clothing and textile applications.

What is RFID Technology?

RFID technology works by using electromagnetic fields to automatically identify and track tags attached to objects. These tags contain electronically stored information that can be read by an RFID reader from a distance, without needing a direct line-of-sight scan. RFID technology is widely used in different industries for tasks like managing inventory, tracking assets, and controlling access.

What are the Uses and Benefits of Washable RFID Tags on Clothes?

Washable RFID tags are designed to withstand the rigors of laundering and are ideal for tracking garments throughout their lifecycle. They offer several advantages:

Washable RFID Tags for Tracking Clothes: These tags are embedded in garments to provide real-time tracking and monitoring. This is particularly useful in retail environments, where inventory management is crucial. Retailers can easily track stock levels, monitor the movement of items, and prevent theft. Additionally, RFID tags provide valuable data on consumer behavior, helping businesses optimize their inventory and marketing strategies.

Laundry Tags for Linen Tracking: In the hospitality and healthcare industries, tracking linens and uniforms is a significant challenge. Washable RFID tags are an effective solution to this problem. They allow for efficient inventory management, ensuring that linens are tracked through each stage of the laundry process. This not only reduces loss and theft but also helps in maintaining hygiene standards by ensuring that linens are properly cleaned and rotated.

Fabric Laundry Tags for Garment Tracking: These tags are made of soft, durable materials that can withstand multiple wash cycles without degrading. They are ideal for use in various settings, including hotels, hospitals, and sports clubs, where garments are frequently washed and need to be tracked accurately. Fabric laundry tags help organizations manage their garment inventories more efficiently, reducing the costs associated with lost or misplaced items.

RFID Silicone Laundry Tags: Silicone laundry tags are known for their durability and flexibility. They can withstand high temperatures and harsh chemical environments, making them suitable for industrial laundry applications. These tags are commonly used to track uniforms, workwear, and other textiles that require frequent laundering. By using RFID silicone laundry tags, organizations can streamline their laundry processes, reduce labor costs, and ensure accurate inventory counts.

RFID Non-Woven Fabric Laundry Tags: Non-woven fabric laundry tags offer a lightweight and versatile solution for tracking garments and linens. These tags are particularly useful in settings where the tags need to be discreet and unobtrusive, such as in high-end fashion or specialty uniforms. RFID non-woven fabric laundry tags help businesses maintain a seamless tracking system without compromising the comfort or appearance of the garments.

PPS Button Laundry Tag: PPS (Polyphenylene Sulphide) button laundry tags are small, durable, and resistant to high temperatures and chemicals. They are often used in applications where the tag needs to be securely attached to a garment, such as in military or industrial uniforms. PPS button laundry tags provide a reliable and long-lasting solution for garment tracking, ensuring that each item can be accurately identified and accounted for throughout its lifecycle.

Conclusion

The adoption of washable RFID tags in the clothing and textile industries offers numerous benefits, from improved inventory management to enhanced customer satisfaction. These tags provide a durable and reliable solution for tracking garments, linens, and other textiles, helping businesses streamline their operations and reduce costs. Whether used in retail, hospitality, healthcare, or industrial settings, washable RFID tags represent a significant advancement in the way we manage and track clothing and textile products.

As technology continues to evolve, the use of RFID tags is likely to become even more widespread, offering new opportunities for innovation and efficiency in various industries. Businesses that invest in this technology can expect to see improvements in inventory accuracy, reduced losses, and a better understanding of consumer behavior, ultimately leading to a more successful and profitable operation.

0 notes

Text

RFID Retail Solutions: Streamlining Inventory Management for Success

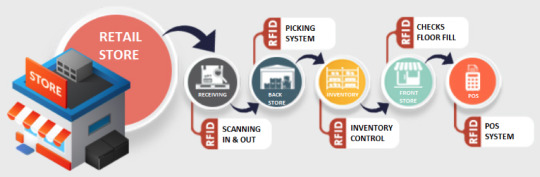

RFID is gaining widespread adoption in the retail sector. When Radio-Frequency Identification (RFID) technology was introduced over 70 years ago, it promised significant advancements, particularly in the retail industry, which demands precise inventory management. With a high volume of items moving quickly in and out of the premises and a plethora of sizes, colors, and designs requiring high selectivity, the chances of inventory loss, errors, and inefficiency are high. Utilizing RFID Technology in inventory management addresses these challenges effectively. According to recent studies, 58% of warehouse decision-makers have plans to implement RFID technology by the year 2028. While implementing RFID technology may take months, the initial efforts are already showing results, with billions saved annually in shrinkage (inventory losses).

Inventory management in retail is crucial for saving time, ensuring accuracy, and satisfying customers. Each item is equipped with an RFID Tag, and fixed RFID Readers are strategically placed to automate stock checks without manual intervention in warehouses or retail stores. This ensures 24/7 inventory counts, preventing shrinkage loss, inventory misplacement, and other errors. Handheld RFID readers complement fixed RFID readers, providing real-time updates and enabling rapid inventory checks to enhance overall efficiency. RFID technology enables various applications, including inventory picking, shipment verification, stock in/stock out, and locating lost items.

Additionally, custom software enables item identification capabilities, allowing the system to identify and categorize items based on various attributes such as SKU, size, color, or location. This facilitates precise inventory tracking, enabling managers to quickly locate specific items, analyze stock movements, and optimize inventory levels. With item identification functionality, businesses can streamline their inventory management processes, reduce errors, and improve overall operational efficiency. Other features, such as notifications for removed items, real-time image capture, and item identification offer significant benefits, including improved inventory accuracy, enhanced transparency, and streamlined operations, ultimately leading to cost savings and better business outcomes.

Experts commonly cite inventory management as the primary use case for RFID technology, but its applications extend far beyond just that. RFID has proven its effectiveness in various areas, including omni-channel operations, smart fitting rooms, accelerated checkouts, and interactive displays. Over the past decade, RFID technology has made significant strides. Read accuracy has doubled, prices have dropped significantly, and the range has increased more than fivefold, leading to fewer devices required and better scanning capabilities. Today, RFID enables real-time visibility, enhanced accuracy, and increased automation, resulting in significantly improved operational efficiency, time and cost savings, and an enhanced overall customer experience.

#RFID Retail Solutions#RFID Garments Tags#RFID tags#Inventory Tracking#Inventory Management#RFID technology#RFID solutions#rfid reader

0 notes

Text

Foldable Container: Revolutionizing Logistics and Storage

In a world where efficiency and sustainability are key business drivers, the foldable container has emerged as a game-changing innovation in logistics and storage. These containers offer a smart alternative to traditional rigid packaging systems by combining durability with flexibility, making them ideal for a wide range of industries — from automotive and agriculture to retail and manufacturing.

What Is a Foldable Container?

A foldable container is a reusable storage and transportation solution designed to be collapsible when not in use. Typically made from high-quality plastic, metal, or hybrid materials, these containers can be folded flat, dramatically reducing the space they occupy during return transport or storage.

Unlike disposable or rigid bulk containers, foldable variants provide the same strength and protection during transit but with added benefits like space savings, ease of handling, and reduced environmental impact. They are used extensively for transporting bulk goods, small parts, and returnable packaging systems.

Key Features of Foldable Containers

The popularity of foldable containers can be attributed to their intelligent design and user-centric features. Here are some of the primary characteristics:

Collapsibility: These containers can be folded down to a fraction of their original volume, often saving up to 80% in storage space.

Stackability: Whether open or collapsed, foldable containers are designed to be stackable, allowing efficient use of vertical space in warehouses and transport vehicles.

Durability: Most foldable containers are manufactured using impact-resistant and weather-resistant materials, ensuring a long service life.

Ease of Use: Quick assembly and disassembly make them ideal for fast-paced operations.

Customization: Available in various sizes, with options for lids, doors, labels, and even tracking features like RFID tags.

Industries That Benefit from Foldable Containers

1. Automotive Industry

In automotive supply chains, where thousands of small and large components are moved between factories and suppliers, the foldable container proves invaluable. It helps streamline logistics by optimizing return trips and minimizing packaging waste.

2. Retail and E-commerce

Retailers often deal with seasonal inventory, which requires smart storage solutions. Foldable containers are ideal for temporary storage and transportation of goods, especially for reverse logistics.

3. Agriculture and Food Processing

These containers are frequently used to transport fresh produce, grains, and processed food. Their hygienic design, ease of cleaning, and collapsibility make them suitable for the food industry.

4. Pharmaceutical and Healthcare

In sectors where cleanliness, traceability, and transport efficiency are critical, foldable containers offer a sterile and manageable solution.

5. Textile and Garments

For transporting and storing bulk textiles, foldable containers reduce the need for disposable packaging and protect delicate fabrics from damage.

Environmental and Economic Advantages

Reduced Carbon Footprint

By enabling more containers to be transported in fewer trips, foldable containers help reduce fuel consumption and CO₂ emissions. A truckload of folded empty containers takes up far less space than rigid ones, minimizing the environmental cost of reverse logistics.

Cost Efficiency

While the initial investment in foldable containers may be higher than disposable options, they offer long-term savings through reuse, lower return transport costs, and minimized need for warehouse space.

Waste Reduction

One of the most significant benefits of foldable containers is the drastic reduction in single-use packaging waste. This supports corporate sustainability goals and aligns with increasing regulations aimed at reducing environmental impact.

Challenges and Considerations

Despite their advantages, foldable containers are not without challenges:

Initial Cost: The upfront cost may deter small businesses, although ROI is usually realized over time.

Maintenance: Reusable containers require periodic cleaning and inspection to ensure continued usability.

Compatibility: Not all existing racking or transport systems may be compatible with foldable designs.

However, these challenges are relatively minor when compared to the long-term value and efficiency they bring.

Innovations in Foldable Container Design

With the rise of automation and digital transformation in supply chains, foldable containers have also evolved. Some modern versions come with built-in sensors to monitor contents, temperature, or movement. Others are designed to be compatible with automated storage and retrieval systems (ASRS), offering enhanced functionality in smart warehouses.

Additionally, materials science has led to the development of ultra-light yet sturdy containers, further enhancing portability and performance.

Best Practices for Using Foldable Containers

To maximize the benefits of foldable containers, businesses should follow a few best practices:

Train Staff: Proper training ensures quick and safe handling, reducing wear and tear.

Track Usage: Implement tracking systems to monitor container life cycles and optimize usage.

Regular Inspection: Routine maintenance helps identify damages early and extends product life.

Plan Return Logistics: Efficient planning for return trips ensures containers are not left idle and return on investment is achieved faster.

The Future of Foldable Containers

The demand for flexible, reusable, and eco-friendly packaging solutions continues to grow across industries. As businesses aim to optimize logistics, reduce waste, and embrace sustainable practices, the foldable container is expected to play an increasingly pivotal role.

With advancements in design, materials, and smart logistics, foldable containers are not just a trend but a necessity for modern-day supply chains. They align perfectly with the broader goals of circular economy models, making them a forward-thinking choice for businesses of all sizes.

Conclusion

The foldable container exemplifies how a simple yet thoughtful innovation can transform industrial practices. It’s a testament to how packaging solutions can evolve to meet modern demands for efficiency, sustainability, and cost-effectiveness. Whether you're managing a global supply chain or looking to streamline warehouse operations, foldable containers offer a practical and intelligent way forward.

0 notes

Text

Precision-Cut Garment Labels – Flawless Efficiency! ✂️

Witness our laser-cut labels – each piece trimmed to millimetric accuracy for seamless sewing!

✅ Kiss-cut tech – keeps backing intact ✅ Micro-perforated edges – prevents fraying ✅ Static-free stacking – easy handling ✅ Pre-notched corners – perfect alignment

Ideal for:

Woven care labels

Satin brand tags

RFID smart labels

🔥 Why choose us?

Zero-tolerance cutting – exact specs every time

72h sample service – fast turnaround

PrecisionLabels #GarmentTech #TextileManufacturing

(Ask about our low-melt adhesive option for no-sew applications!)

Optimized for:

Instagram/FB: Short + emoji highlights

YouTube: Add process timestamps in comments

Need a German/Spanish version? DM us!

0 notes

Text

Hospital Logistics 2.0: The Convergence of Scrub Vending Machines and Textile Tracking

If you’ve ever walked through the back corridors of a hospital—the ones staff use—you know it’s a world humming with precision and pressure. People rush between shifts, clean scrubs are a necessity, and logistics work silently to keep the whole system from falling apart. But behind the scenes, the management of those scrubs has long been an operational sore spot. Until now.

This post explores how hospitals are embracing a smarter, tech-powered future with Hospital Logistics 2.0. At the center of this transformation? Scrub vending machines and textile tracking technology.

A Brief History: From Manual Logs to Digital Threads

Uniform distribution wasn’t always complicated. But as hospitals grew, so did the uniform count—and the chance for mismanagement. Back then, staff queued for clean garments, inventories were tracked manually, and losses were chalked up to inevitability.

The first wave of improvement came with barcodes, which offered a glimpse of order. But it wasn’t until RFID tags and real-time tracking emerged that hospitals gained the ability to monitor garments across their entire lifecycle. That’s when textile logistics began evolving into something smarter—more connected, more transparent.

Scrub Vending Machines: Modern Access Meets Automation

Now, picture this: You’re a nurse finishing a 12-hour night shift. The last thing you want to do is wait in line for clean scrubs. Enter the scrub vending machine. Simple on the outside, but smart at its core.

With a quick ID scan, staff can access clean garments, correctly sized and ready to go. Every interaction is logged, inventory is updated automatically, and distribution becomes seamless. It's about minimizing friction, saving time, and maintaining accountability. These machines bring automation into an area of hospital life that previously relied on inefficient manual systems.

Textile Tracking: Making the Invisible, Visible

Beyond dispensing, how do hospitals know where garments are, how often they’re used, and when they need replacement? This is where RFID-based textile tracking shines.

Think of it as a digital map of every scrub set. From pick-up to laundry to return, each movement is logged in real time. This level of oversight means fewer lost items, better hygiene monitoring, and more strategic restocking. Hospitals can even use these insights to identify usage trends and tweak their supply accordingly.

Stitching It Together: An Ecosystem, Not a Gadget

What truly elevates Hospital Logistics 2.0 is the integration of vending machines and textile tracking into one intelligent system. When these two tools share data, they create a self-regulating feedback loop. The vending machine knows when to restock. The laundry knows when to prioritize a batch. The admin team sees it all live.

And this isn’t some future fantasy—it’s the now. Modern software platforms enable this integration through dashboards and mobile apps, ensuring all departments, from infection control to procurement, are on the same page. These tools aren’t just supporting staff—they’re enhancing care delivery.

Avoiding the Pitfalls: Implementation Matters

Rolling out any new system has its growing pains. Tech investment, training needs, and cultural adoption are all common challenges. But the benefits far outweigh the costs—provided implementation is handled with care.

Successful hospitals invest in user onboarding and select solutions with scalability and security at their core. Data privacy is non-negotiable, especially when systems track staff behavior. And future-proofing means choosing flexible platforms that adapt as needs evolve.

Benefits That Ripple Outward

The effects of better uniform logistics go far beyond cleaner scrubs. Staff satisfaction improves. Compliance becomes effortless. Costs drop. Sustainability goals become more attainable as garment life cycles are extended and waste is minimized.

Even reputation improves. Hospitals that adopt modern logistics signal professionalism and operational excellence—not just to patients and staff, but to regulators, insurers, and funding bodies.

Real Results: The Proof Is in the Data

One hospital, after integrating both scrub vending and RFID tracking, reported tangible wins: 40% fewer garment losses, 60% higher staff satisfaction with scrubs, and a 25% reduction in laundry operating costs. The system paid for itself—and then some.

Every garment in that facility became a data point. Every decision, a response to real-world usage. That’s the promise of smart logistics.

The Strategic Layer

To tie it all together, many institutions now rely on a centralized system for workwear managment. These platforms aren’t just about tracking—they’re about visibility, coordination, and long-term planning. They allow infection control officers, HR departments, and procurement teams to collaborate using shared data.

In this framework, the scrub vending machine becomes more than a convenience—it becomes a strategic tool. And when part of a larger uniform management system, it supports goals that span efficiency, compliance, and care quality.

Closing Thoughts

Hospital Logistics 2.0 isn’t just about technology—it’s about letting caregivers focus on care. It’s about modernizing systems that were long overdue for an upgrade. And ultimately, it’s about turning the behind-the-scenes hustle of clean scrubs into a seamless, silent support system for better health outcomes.

Thanks for reading. If you’ve got experience with hospital logistics—or questions about implementing these systems—drop a note or share this post. Let’s keep the conversation going.

0 notes

Text

The Hidden Heroes: Essential accessories for the garment industry

When it comes to fashion and garment manufacturing, the spotlight often shines on designers, fabrics, and finished products. Yet behind every perfectly tailored piece lies an unsung network of essential accessories and supplies that keep the industry running smoothly. Sri Lanka, as a global textile manufacturing hub, has developed a robust ecosystem of stationery suppliers in Sri Lanka who cater specifically to this sector's unique needs.

The journey of a garment from concept to consumer requires far more than just fabric and thread. Production floors depend on precise measurements, clear labelling, and consistent tracking systems. Quality garment accessories in Sri Lanka have become crucial differentiators in an increasingly competitive global market, where efficiency and presentation can make or break a brand's reputation.

Among the most indispensable items are the humble yet mighty tag pins. These seemingly simple fasteners secure price tags, size labels, and brand information to finished garments. The best tag pin and mobilon tape suppliers in Sri Lanka provide products that are secure enough to withstand shipping and handling, yet remove cleanly without damaging delicate fabrics—a critical balance in maintaining product integrity.

Beyond the production floor, administrative needs drive demand for specialised documentation. Office and stationery suppliers in Sri Lanka have evolved to offer customised solutions for the garment sector, including specialised order forms, quality control checklists, and logistics documentation that comply with international shipping standards.

Technology has transformed many aspects of garment production, but certain accessories remain irreplaceable. Pattern paper, fabric chalk, measuring tapes, and specialised scissors continue as staples in design rooms. Meanwhile, barcode systems, RFID tags, and digital inventory solutions have joined the essential toolkit for modern manufacturers.

The true value of these accessories lies not just in their function, but in how they connect various stages of production seamlessly. When properly selected and implemented, they enhance efficiency, reduce waste, and elevate the final product—proving that sometimes, the smallest components make the most significant difference in bringing fashion from imagination to reality.

#Stationery Suppliers in Sri Lanka#Office and stationery Suppliers in Sri Lanka#Garment Accessories in Sri Lanka#Tag Pin and Mobilon Tape Suppliers in Sri Lanka

0 notes

Text

Indore's Marks Print launches advanced RFID solutions

Marks Print, an Indore-based provider of tags and labels, has made a breakthrough with the launch of its advanced RFID (radio frequency identification) tags and labels. These innovative solutions are for diverse segments such as the garments, pharmaceuticals, cosmetics, and automotive industries. Established in 2007, the company has maintained a remarkable 20% annual growth rate.

Marks Print’s portfolio features a wide array of custom PS labels with multi-color designs and intricate embellishments along with variable data-printed labels and security labels tailored for a niche customer base. With the introduction of advanced RFID tags and labels, the company is set to elevate its offerings by delivering sophisticated, technology-driven solutions to existing and new clients, enabling them to thrive in competitive markets.

Marks Print has long been adopting cutting-edge technologies, leveraging multi-color flexo presses from Bobst and utilizing BST’s inspection systems. With its advanced RFID label and tag production line, complemented by data encoding and verification systems, Marks Print claims to be the sole provider of such comprehensive technologies in central India.

As a ZED Silver Certified Unit, Marks Print supplies specialized solutions to industries such as garments, FMCG, cosmetics, pharma, retail, automotive, and food and beverages. The company creates premium labels on diverse substrates, ensuring exceptional quality and decorative appeal.

Rawat says the label industry is undergoing a digital transformation with advanced technologies such as RFID reshaping the landscape. “RFID technology has become the cornerstone of modern labeling, offering unmatched benefits over traditional methods. Our track-and-trace solutions are tailored to meet industry demands, ensuring accurate tracking, inventory management, durability, versatility, and cost-effectiveness.”

Ankit Rawat, partner, whose focus remains on enhancing customer experience adds, “We are committed to providing solutions that combine innovation with practicality, ensuring our clients reap the benefits of cutting-edge technology while optimizing their operations.”

Marks Print continues to work towards labeling innovation, aiming to set new benchmarks in quality, technology, and customer satisfaction.

0 notes

Text

"You need to visit the store to get the full experience, but consider Burberry's use of RFID as one isolated element of the new technology it deployed to give the store the same feel as its website. It built RFID technology into the tags of many of its garments, enabling customers to pull clothing off the hanger, wave it in front of a nearby interactive mirror, and view footage of the artisan making the jacket. This helped customers find a 'rational' justification for what, given the prices, was ultimately an irrational purchase."

-Peter Sheahan, Matter (2016)

1 note

·

View note

Text

The Integration of NFC Clothes Tags in Smart Wardrobes

Fashion Meets Function: The Integration of NFC Clothes Tags in Smart Wardrobes

Enhancing User Experience with Xinye NFC Clothes Tags. Market Leader for RFID and NFC applications Xinye provides NFC clothes tags marrying very well with the futuristic closet systems. Wearable Nfc clothes tags are attached with Therefore, a digital identity is embedded or linked to a respective article of clothing or accessory. Users seek out further information about a garment by tapping their phone (or smart device) equipped with NFC technology against the tag and this can include instructions on maintenance, composition of the fabric and recommendations on that specific garment.Get more news about NFC Clothes Tags,you can vist our website!

Integration within Smart Wardrobes. Adding Xinye NFC Clothes Tags within smart wardrobes changes these pieces of furniture from a normal waste, designer a user sees to a smart container. When used in the smart wardrobe setup, NFC clothes tags power up the system to register new clothes in the wardrobe cabinet, monitor the motivation levels of the users.

Given the features of the items tagged, smart wardrobes with Xinye NFC Clothes Tags can provide customized wardrobe suggestions. For example, users of the NFC clothes tags system could be told how a certain suit would do for an evening event or what to wear for weather conditions.

When aesthetics meet utility, the assimilation of Xinye NFC Clothes Tags into smart wardrobes marks an advanced way of restoring order and enhancing efficiency in our ways of living. This technology aims at solving certain inconveniences that typically arise from the traditional management of clothing.

0 notes

Text

Discover the Best Machinery in Tirupur with Eagle Graphics 💼⚙️

In the heart of the bustling industrial hub of Tirupur, having the best machinery in Tirupur is key to staying competitive. At Eagle Graphics, we provide top-tier equipment, from RFID Machines to Printing Machines, ensuring your business operates at its best. Whether it's garment production, labeling, or cutting, we’ve got the best machinery in Tirupur to suit your needs. 🌟

Best RFID Machines in Tirupur 📡📦

When it comes to the best RFID Machines in Tirupur, Eagle Graphics leads the market with cutting-edge technology like RFID Tags, RFID Labels, and RFID Stickers. Our solutions ensure seamless operations for your tracking needs.

Best Label Printing Machines in Tirupur 🏷️🖨️

For those seeking the best label printing machines in Tirupur, our lineup includes the powerful HY Label Printing Machine and the precise VERTEX Ultrasonic Cutting Machine. These machines deliver unmatched quality and efficiency.

Best Printing Machines in Tirupur 🖨️🎨

Eagle Graphics offers the best printing machines in Tirupur, including Digital Printing Machines, Offset Printing Machines, and Screen Printing Machines. Whether you're printing textiles or paper, we have the solution.

Best T-shirt Printing Machines in Tirupur 👕🖌️

For garment makers, our best T-shirt printing machines in Tirupur provide vibrant, durable results. We offer Heat Transfer Printing Machines and Screen Printing Machines to elevate your production.

Best Cutting Machines in Tirupur ✂️🔪

Precision is vital in cutting, and Eagle Graphics delivers the best cutting machines in Tirupur, including Die Cut Machines, Laser Cutting Machines, and Hangtag Cutting Machines for flawless results.

Best Imported Machinery in Tirupur 🌍🚢

Looking for international quality? We provide the best imported machinery in Tirupur, featuring top-notch equipment like Cardboard Pasting Machines, Hy Folding Machines, and more to meet your production standards.

HY and VERTEX Machines in Tirupur 🛠️🏭

Our HY and VERTEX machines in Tirupur are designed to handle the most demanding tasks. From HY Label Printing Machines to VERTEX Encoding and Ultrasonic Cutting Machines, we offer robust, efficient solutions.

Conclusion 🎯

For the best machinery in Tirupur, trust Eagle Graphics to supply high-quality, reliable equipment. From RFID Machines and Printing Machines to Cutting Machines and Imported Machinery, we are your one-stop destination for all machinery needs. Contact us today to elevate your production! 🚀

1 note

·

View note

Text

TagMatiks RFID Laundry Tag

The power of TagMatiks RFID Laundry Tag for efficient and reliable tracking of linens and garments. Designed for durability, these tags withstand harsh laundry processes while providing real-time visibility and inventory management. Perfect for hospitality, healthcare, and commercial laundry services, they streamline operations and reduce losses. Elevate your laundry management with TagMatiks.

1 note

·

View note

Text

RFID Readers vs. Barcode Scanners: A Comparative Analysis

The debate between RFID (Radio Frequency Identification) and barcode technology revolves around their respective capabilities, limitations, and suitability for various applications in inventory management and tracking. While both technologies serve the common purpose of capturing data, they differ significantly in their operating principles, performance, and cost considerations. This debate has intensified as businesses seek to optimize their operations and leverage advancements in tracking and logistics technology.

RFID vs. Barcode: A Concise Comparison

Aspect -

Operating Principle

Data Capture Speed

Range and Flexibility

Durability

Cost Considerations

RFID Readers -

It uses radio waves to communicate with RFID tags.

High-speed data capture; reads multiple tags quickly.

Greater range and flexibility; reads tags remotely.

RFID tags are durable; RFID readers have fewer moving parts.

Higher upfront costs; ongoing expenses for tags.

Barcode Scanners -

It relies on optical scanning to read barcodes.

Slower data capture; reads one barcode at a time.

Limited range; requires direct line-of-sight.

Barcode labels can be damaged; scanners may require maintenance.

Lower initial investment: maintenance costs may accrue over time.

Higher upfront costs; ongoing expenses for tags.

Lower initial investment: maintenance costs may accrue over time.

Will RFID Replace Barcode?

The question of whether RFID will eventually replace barcode technology has puzzled experts and businesses alike. While RFID offers several advantages over traditional barcode scanners, like faster data capture, greater automation, and improved efficiency in inventory management, making RFID the go-to choice comes with its own set of challenges.

Cost is a big concern. RFID demands a hefty upfront investment in readers, tags, and infrastructure. For smaller businesses, these costs can be a barrier to adoption.

Compatibility is another issue. Many businesses have already heavily invested in barcode technology, with established systems and processes centered around barcode scanning. Shifting to RFID would mean significant changes to how things operate, which might not be practical or cost-effective in the short term.

The future might not be about choosing one over the other but finding ways for RFID and barcode tech to work together. Hybrid systems that blend both technologies can offer the best of both worlds, letting businesses enjoy the perks of RFID while still relying on the trusty barcode when needed.

While RFID technology offers compelling advantages over traditional barcode systems, including faster data capture, greater automation, and improved efficiency, the widespread replacement of barcodes with RFID is unlikely to occur soon. Instead, businesses are likely to adopt a pragmatic approach, integrating RFID where it provides clear benefits while continuing to utilize barcode technology where it remains effective and cost-efficient. The future of tracking and logistics technology may thus be characterized by a hybrid approach that combines the strengths of RFID and barcode systems to meet the diverse needs of businesses across various industries.

#rfid solutions#rfid technology#rfid reader#rfid scanner#handheld scanner#inventory management#retail solutions#rfid garments tag#barcode scanner

0 notes

Text

The Unsung Heroes of Fashion: Hanger Manufacturers and Suppliers

In the bustling world of fashion retail, where every detail matters, hangers often go unnoticed. However, these seemingly insignificant items play a pivotal role in the presentation and preservation of garments. Hanger manufacturers and suppliers are the unsung heroes who ensure that clothing is displayed in the best possible way, enhancing both aesthetics and functionality. This blog delves into the crucial roles these professionals play and the innovations they bring to the industry.

The Importance of Hangers in Retail

A hanger's primary function is to support and display garments in a manner that maintains their shape and quality. In retail environments, where visual appeal can significantly impact sales, the right hanger can make all the difference. A well-designed hanger ensures that clothes are presented neatly and attractively, which encourages customers to take a closer look, try on, and ultimately purchase the items.

Evolution of Hanger Design

Over the years, hanger design has evolved significantly. Gone are the days when basic wire hangers were the norm. Today, hanger manufacturers produce a wide array of hangers tailored to specific garment types. Wooden hangers, for example, are ideal for heavy coats and suits, offering sturdy support and a touch of elegance. Velvet hangers, with their non-slip surface, are perfect for delicate fabrics and slippery materials. The diversity in hanger design reflects the varied needs of the fashion industry and the ongoing efforts to enhance garment care and presentation.

Customization for Brand Identity

In the competitive world of fashion, branding is everything. Hanger suppliers often work closely with high-end brands to create customized hangers that align with their identity. These bespoke hangers can feature brand logos, unique shapes, and specific colors, reinforcing the brand's image and creating a cohesive in-store experience. Custom hangers not only add a touch of luxury but also ensure that every detail, down to the hanger, reflects the brand's ethos.

Sustainable Practices in Hanger Manufacturing

As sustainability becomes a growing concern in the fashion industry, hanger manufacturers are also stepping up to the challenge. Eco-friendly hangers made from biodegradable materials like bamboo, recycled paper, and other sustainable sources are becoming increasingly popular. These hangers offer a green alternative to traditional plastic or metal hangers, reducing environmental impact. By opting for sustainable hangers, retailers can demonstrate their commitment to environmental responsibility, appealing to eco-conscious consumers.

The Role of Hanger Suppliers in the Supply Chain

Hanger suppliers are a crucial link in the fashion supply chain. They ensure that retailers have a consistent supply of high-quality hangers, which is essential for maintaining store aesthetics and functionality. This involves not only the production of hangers but also efficient logistics, storage, and distribution. A reliable hanger supplier can significantly enhance the operational efficiency of a retail business, ensuring that stores are always well-stocked and ready to display new collections.

Technological Innovations in Hanger Design

Innovation in hanger design extends beyond aesthetics and functionality. Technological advancements are paving the way for smart hangers equipped with RFID tags and other tracking technologies. These smart hangers can provide valuable data on inventory levels, customer preferences, and even security. By integrating technology into hanger design, manufacturers are helping retailers streamline operations, improve inventory management, and enhance the overall shopping experience.

Choosing the Right Hanger Manufacturer and Supplier

For retailers, selecting the right hanger manufacturer and supplier is a critical decision. Key factors to consider include the quality of materials, the range of available designs, customization options, and the manufacturer's commitment to sustainability. A reputable hanger supplier should be able to provide tailored solutions that meet the specific needs of the retailer, ensuring that every garment is displayed to its best advantage.

Conclusion

In conclusion, hanger manufacturers and suppliers play a vital yet often overlooked role in the fashion industry. Their work ensures that garments are not only displayed beautifully but also preserved in top condition. From innovative designs and customization to sustainable practices and technological advancements, these professionals are continually evolving to meet the demands of the fashion world. As the industry grows and changes, the importance of high-quality, well-designed hangers will only become more pronounced.

So, the next time you walk into a boutique and admire the perfectly presented clothing, remember the humble hanger and the dedicated professionals behind it. They are the unsung heroes who help fashion shine, one hanger at a time.

0 notes

Text

Intertextile Apparel to ‘capture opportunities of digital revolution’ with launch of Digital Solutions Zone

In the midst of the business world’s rapid adoption of new technology and the evolving environmental landscape, players across the wider textile industry are actively seeking innovative solutions for various sourcing, manufacturing, and retailing demands. Bidding to further cater to this need, the organizers have announced the debut of the Digital Solutions Zone at Intertextile Shanghai Apparel Fabrics – Autumn Edition 2024, taking place from 27 – 29 August at the National Exhibition and Convention Center. Coinciding with the fair’s 30th anniversary, the zone will give a dedicated platform to exhibitors specializing in solutions such as additive manufacturing, big data analytics, digital product passports, digital sustainability solutions, generative AI, personalized production, production technologies, virtual reality, wearable technologies, and more.

Ms Wilmet Shea, General Manager of Messe Frankfurt (HK) Ltd, commented: “We are only beginning to understand the changes new technology will bring to the textile sector, but it’s clear there is huge potential in design, personalization, production, sustainability, traceability, and more. Intertextile Apparel prides itself on providing the right platforms within the fair to meet the market’s needs, and the Digital Solutions Zone will allow our exhibitors and visitors to capture the opportunities of the digital revolution. We have consistently provided education of this topic through our fringe program, and given a platform to several such exhibitors, but to expand and concentrate this offering into a dedicated zone is something we’ve been eager to realize.”

Innovations such as eco-design, product passports, and sustainable solutions for production are in high demand in China as EU regulations target the entire supply chain. Set to provide a unique opportunity for start-ups and emerging technology companies with potential textile industry applications, at the upcoming Autumn Edition the new zone will put these companies in front of thousands of international and domestic manufacturers looking to gain a technological edge in a competitive market. A unique, open booth design will help to facilitate discussions, while exhibitors will also be able to deliver seminars or product presentations for added engagement.

Textile-applicable digital highlights from previous Autumn Edition

Last year in August, various technology and solutions seminars featured in the Textile Industry Digital Application Forum and as standalone fringe events, while a number of companies made a technological impact, both as exhibitors and collaborators:

One key example was Shima Seiki, whose innovative fashion industry machinery and software solutions include knitting machines, design software, printing, CAD/CAM, and PLM. At the fair, they showcased their 3D fabric design solutions, said to greatly improve efficiency: from research and development to production.

Exhibiting at the same edition was Avery Dennison. Aiming to optimize labor and supply chain efficiency, reduce waste, advance sustainability, and connect brands and consumers, the multinational showcased its range of products and solutions, including labeling and functional materials, radio frequency identification (RFID) inlays and tags, software applications, branded packaging enhancements, and information display.

Providing a platform to nearly 4,000 exhibitors last autumn, the global apparel flagship welcomed 95,000 visitors from 117 countries and regions. Situated in the world’s textile manufacturing hub, regular buyers include garment manufacturers, global fashion brands, fashion designers, trading companies, retail chain stores, and many more.

Key zones at Intertextile Apparel this autumn

Located in the International Hall, the Digital Solutions Zone will be the latest addition to a number of product zones at the show, with others including:

Accessories Vision: for all garment and fashion accessories, including zippers, buttons, ribbons, lining, and much more.

Beyond Denim: fashionable, traditional, and innovational denim products, ranging from indigo-dyed cotton to bio-dyed viscose fabrics.

Digital Printing Zone: up-to-date digital printing solutions and an array of on-trend printed fabrics.

Econogy Hub (new): the new featured zone for sustainable textile products and services, taking the place of All About Sustainability.

Functional Lab: the go-to platform to cater to global demand for athleisure, sportswear, protective apparel, and more.

Premium Wool Zone: exclusive zone for high-end wool fabric suppliers of bespoke garments and suiting.

SalonEurope: featuring a variety of textile products, showcasing the best of European brands for the Asian market.

Verve for Design: dedicated zone for original pattern designs, with end-uses ranging from fashion to home furnishing.

Companies interested in contacting the organisers, to find out more about the new or existing zones, can click here.

The fair is co-organised by Messe Frankfurt (HK) Ltd; the Sub-Council of Textile Industry, CCPIT; and the China Textile Information Centre. It will take place alongside Yarn Expo Autumn, CHIC and PH Value at the National Exhibition and Convention Center (Shanghai), with the venue playing host to the entire apparel textile value chain. For more details on this fair, please visit: www.intertextileapparel.com.

Intertextile Shanghai Apparel Fabrics – Autumn Edition will be held from 27 – 29 August 2024.

0 notes

Text

The Journey of Clothing Labels: From Origins to Future Trends

The history of clothing labels is a fascinating journey that reflects the evolution of fashion and commerce. Name labels and clothing labels have become integral to the apparel industry, offering insights into a garment's origin, care instructions, and brand identity.

The origin of clothing labels can be traced back to the 19th century when the Industrial Revolution spurred mass production of garments. Before this, clothes were typically custom-made, and the need for labels was minimal. As ready-to-wear clothing became more common, manufacturers started using simple tags to distinguish their products from competitors. These early labels often included basic information such as the manufacturer’s name and location.

As the fashion industry grew, so did the complexity and importance of clothing labels. By the mid-20th century, labels had evolved to include not only the brand name but also care instructions, fabric content, and size information. This period also saw the introduction of standardised labels, which helped consumers make informed decisions about their purchases. Name labels became particularly popular for personalising children's clothing and school uniforms, ensuring that items could be easily identified and returned if lost.

In recent decades, technological advancements have further transformed clothing labels. The use of digital printing and advanced fabrics has allowed for more durable and detailed labels. Additionally, the rise of sustainable fashion has led to the development of eco-friendly labels made from recycled materials. Today, labels often include QR codes or RFID tags that provide consumers with extensive information about the garment’s production process, ethical standards, and even styling tips.

Looking ahead, the future of clothing labels is poised to embrace even more innovation. Smart labels equipped with NFC (Near Field Communication) technology could offer interactive experiences, such as virtual try-ons or direct links to purchase complementary items. Moreover, the emphasis on sustainability is likely to grow, with labels providing transparency about the environmental impact of garments and offering guidance on recycling or repurposing.

In conclusion, name labels and clothing labels have come a long way from their humble beginnings. They have evolved to become essential components of the fashion industry, offering valuable information and enhancing the consumer experience. As technology and sustainability continue to shape the industry, the future of clothing labels promises to be even more dynamic and informative.

0 notes

Text

How RFID and IoT Are Changing the Game in Uniform Management

Uniform management? Not exactly the most thrilling topic—until you realize how much of a headache it used to be. Lost uniforms, chaotic inventory, and constant reordering? Total nightmare. But with RFID (Radio Frequency Identification) and IoT (Internet of Things) stepping in, managing uniforms is starting to feel less like a chore and more like a well-oiled machine.

From healthcare to hospitality and manufacturing, businesses are swapping out old-school tracking methods for high-tech automation. RFID tags and IoT-powered systems are making uniform distribution smoother, cutting down on losses, keeping things hygienic, and—best of all—saving money. Let’s talk about how these innovations are totally reshaping uniform management software and what the future holds.

So, What’s the Big Deal with RFID and IoT?

RFID: The Ultimate Time-Saver

Think of RFID as a digital ID system for uniforms. Tiny tags embedded in garments send signals to RFID scanners, automatically logging every movement. No more manual scanning, no more guessing games—just instant tracking that makes sure uniforms don’t magically disappear into thin air.

IoT: The Smart Assistant You Never Knew You Needed

IoT kicks things up a notch by connecting RFID data to cloud-based systems. Now, businesses can track uniform usage in real time, automate restocking, and even analyze trends to stay ahead of demand. Plus, features like smart lockers mean employees can grab what they need without a middleman slowing things down.

Why RFID is a Total Game-Changer

No More Manual Tracking (Finally!)

Remember when uniform tracking meant clipboards, spreadsheets, and sheer frustration? RFID makes all that obsolete. Each time a uniform is issued, returned, or washed, the system records it instantly—no human intervention needed. That means fewer errors and way more efficiency.

Lost Uniforms? Not on RFID’s Watch

If missing uniforms are eating into your budget, RFID has your back. Every move a uniform makes is recorded, so if something goes missing, you’ll know exactly where it was last seen. Bonus: It also keeps employees accountable.

Smarter Laundry, Less Hassle

In industries like healthcare and food service, hygiene isn’t optional—it’s critical. RFID ensures that uniforms go through the right cleaning cycles and are returned to the right people, cutting down on contamination risks and mix-ups.

How IoT Is Taking Uniform Management to the Next Level

Smart Lockers: Grab and Go

IoT-powered smart lockers? Absolute game-changer. Employees scan an ID, grab their uniforms, and go—while the system keeps track of every transaction. No more wasted time, no more confusion.

Real-Time Inventory Updates

With IoT-powered uniform inventory management, managers always know what’s in stock and what’s running low. The system predicts shortages, reorders automatically, and ensures there’s never too much or too little on hand.

Predictive Analytics = Smarter Planning

IoT isn’t just about what’s happening now—it’s about anticipating what’s coming next. By analyzing uniform usage patterns, businesses can schedule replacements, optimize laundry cycles, and even adjust orders based on trends.

The Best Perks of RFID and IoT in Uniform Management

Supercharged Efficiency

No more bottlenecks, no more wasted time. RFID and IoT streamline every part of uniform management, making things run faster and smoother.

Cost Savings That Make a Difference

When uniforms aren’t getting lost, over-ordered, or underutilized, businesses save serious cash. RFID and IoT help cut unnecessary expenses while making sure resources are used wisely.

Hygiene You Can Actually Trust

For industries where cleanliness is king, RFID and IoT ensure uniforms are cleaned properly and swapped out at the right time. No more sketchy hygiene practices—just reliable, trackable sanitation.

The Challenges of Jumping on the RFID and IoT Train

The Price Tag

Yes, these systems are a smart investment, but they aren’t free. Businesses need to think about upfront costs and whether the long-term benefits justify the expense.

Integration Takes Work

Not every company has the latest tech infrastructure, which means rolling out RFID and IoT might take some adjustments. Compatibility with existing systems and staff training are key to making the transition smooth.

Data Security Concerns

Tracking uniforms digitally means storing sensitive data. Businesses need to lock down their systems with encryption and authentication to keep everything secure.

Who’s Already Using RFID and IoT Like a Pro?

Healthcare

Hospitals are using RFID to track scrubs, lab coats, and protective gear, ensuring strict hygiene compliance. IoT-powered smart lockers let medical staff grab clean uniforms without waiting in line.

Hospitality

Hotels and restaurants rely on RFID and IoT to keep uniforms available for housekeeping, kitchen, and front-desk employees. Automated tracking prevents shortages and keeps things running smoothly.

Manufacturing and Industrial Workplaces

In factories, workwear software helps track uniform usage, flagging items for replacement and ensuring compliance with safety standards.

What’s Next for RFID and IoT in Uniform Management?

AI + RFID + IoT = Next-Level Efficiency

Imagine a system that doesn’t just track uniforms but predicts what you’ll need before you do. AI-powered analytics will help businesses plan ahead, reduce waste, and keep everything running like clockwork.

Blockchain for Ultimate Security

Blockchain could make RFID tracking even more secure by ensuring data stays tamper-proof and accessible only to authorized users. More transparency, less risk.

Managing Uniforms Across Multiple Locations

As companies grow, keeping track of uniforms across different locations will get even easier with RFID and IoT. No matter where employees are, they’ll always have access to what they need.

The Bottom Line

RFID and IoT are totally transforming uniform management, making it faster, smarter, and more reliable. From automated tracking to predictive analytics, these innovations are turning an outdated process into a seamless experience.

If you’re looking to take uniform management to the next level, investing in uniform management software is a no-brainer. With RFID and IoT in the mix, the future of uniform tracking has never looked better.

0 notes