#Industry4_0

Explore tagged Tumblr posts

Text

Revolutionizing Cargo Handling with Self-Service Kiosk Machines

In the fast-paced world of maritime logistics, efficiency is everything.

Traditional cargo check-in and processing at ports often involve long queues, excessive paperwork, and time-consuming manual verifications. But with self-service kiosk machines, ports are stepping into a new era of automation and productivity.

🔹 Faster Cargo Processing – Self-service kiosks enable automated check-ins, reducing wait times and eliminating the need for manual paperwork. Cargo operators can quickly scan documents, input shipment details, and receive real-time status updates.

🔹 Improved Accuracy & Compliance – Human errors in cargo documentation can lead to delays and costly fines. Kiosks ensure compliance by cross-verifying data and generating digital records instantly, minimizing risks associated with incorrect filings.

🔹 24/7 Operations – Unlike manual check-in counters, self-service kiosks operate around the clock. This ensures smooth cargo movement even during non-peak hours, keeping supply chains active and efficient.

🔹 Enhanced Security – With integrated biometric authentication and RFID scanning, kiosks ensure secure access control, preventing unauthorized entries and enhancing overall port security.

By reducing bottlenecks and improving workflow automation, self-service kiosks are transforming ports into smarter, more efficient hubs for global trade. As the maritime industry embraces digital transformation, kiosks are proving to be a game-changer in cargo handling.

Are ports ready for a fully automated future? Let’s discuss!

#CargoHandling#SelfServiceKiosks#LogisticsInnovation#SupplyChainManagement#Automation#SmartLogistics#TechInTransport#FreightSolutions#DigitalTransformation#CargoTech#EfficiencyInLogistics#CustomerExperience#KioskTechnology#Industry4_0#TransportSolutions#FutureOfLogistics#SelfServiceSolutions#CargoManagement#LogisticsTech#InnovationInTransport#SeamlessShipping#SmartCargo#OperationalExcellence#KioskInnovation#LogisticsRevolution

1 note

·

View note

Text

The Future of Commercial IoT is Now!

Hello all, I've been exploring the realm of Commercial IoT, and it's incredible how companies are leveraging intelligent technology to increase efficiency, lower expenses, and improve security. From intelligent lighting and climate management to automated monitoring and asset tracking, IoT is revolutionizing industries.

One firm I discovered, MeshTek, has some neat commercial IoT solutions that keep companies connected and running at an optimal level.

What are your thoughts on the future of IoT in companies? Have you witnessed any practical implementations of how it's revolutionizing industries? Let's talk!

#commercial#SmartSolutions#commercialiot#SEOFriendly#SmartBusiness#ConnectedDevices#Industry4_0#iot development services#iotnbo#iot#web development#iotsolutions

1 note

·

View note

Text

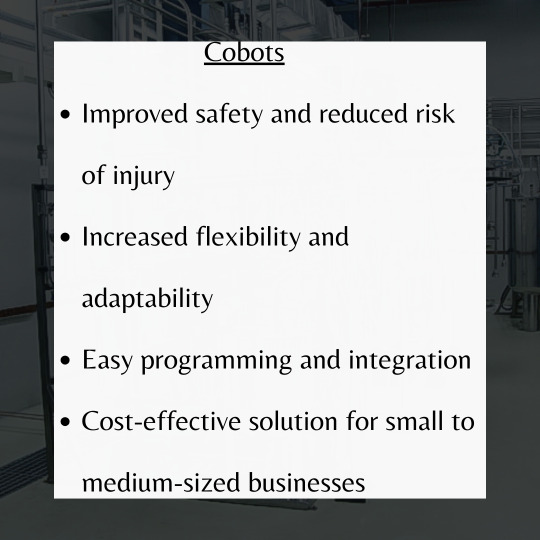

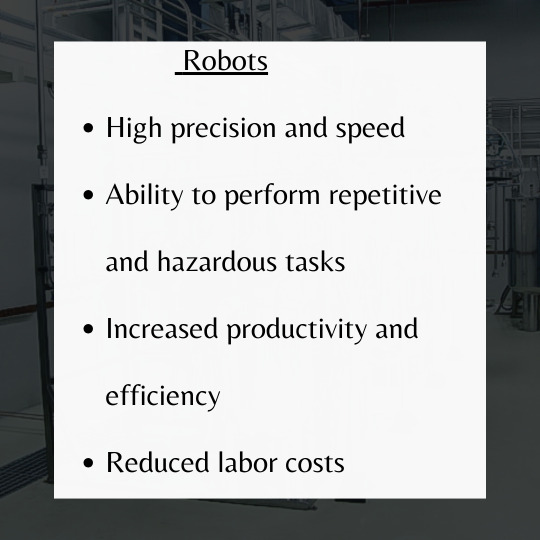

Cobot Applications Across Industries

Unlock the potential of your manufacturing processes with collaborative cobots of Patvinn Engineering. These innovative solutions enhance efficiency, improve safety, and adapt seamlessly across various industries! Visit our webpage to know more.

#CobotApplications#CollaborativeRobotics#Industry4_0#AutomationSolutions#SmartManufacturing#RoboticAutomation#CobotInnovation

0 notes

Text

Industry 4.0 Solutions

Interwork Software Solutions delivers advanced Industry 4.0 solutions, integrating IoT, AI, automation, and data analytics to revolutionize manufacturing and business processes. Our innovative technologies enable smart factories, optimize operations, enhance productivity, and drive digital transformation for businesses across industries, paving the way for a more connected and efficient future.

0 notes

Text

"Revolutionizing Industries: The Future Potential of Generative AI"https://www.blogger.com/blog/post/edit/3619939779363351777/2483200326677262814

#GenerativeAI#AIRevolution#FutureOfAI#AIinIndustries#TechInnovation#AITransformations#Industry4_0#AIAndBusiness#AIinHealthcare#AIinFinance#AIforGood#AIinManufacturing#NextGenAI#AIinCreativeFields#SmartTech#DigitalTransformation#AIApplications#AIImpact#TechTrends#InnovativeTech#MachineLearning

0 notes

Text

Exploring the future of connectivity! 🌐🚀 China’s IoT strategy is set to revolutionize industries. Are you ready to be part of the transformation? 💡🔌 #IoT #China #TechInnovation #SmartCities #FutureTech #Connectivity #Industry4_0

1 note

·

View note

Text

The sun rises over a sprawling oil rig, casting long shadows across a field where machines hum in synchronization, and teams work with precision. The industry, which has long been synonymous with manual effort and physical labor, has evolved. Automation has entered the picture, and the transformation is palpable. Today, what was once an industry dominated by human intuition and hands-on operation is increasingly being reshaped by technology—bringing efficiency, safety, and innovation to the forefront.

The Drive for Efficiency

For years, the oil and gas industry has been under immense pressure. Rising operational costs, fluctuating oil prices, increasing regulatory pressures, and the ever-growing demand for sustainability have all been hurdles that companies must navigate. The solution? Efficiency. And the key to unlocking greater efficiency in this industry lies in automation.

Historically, operations relied on human intervention for monitoring machinery, adjusting flow rates, performing routine checks, and troubleshooting equipment malfunctions. However, these methods were time-consuming, resource-intensive, and prone to human error. In the modern oil and gas landscape, automation has become the driving force behind a more efficient, more streamlined approach to operations.

The Power of Automation in the Field

On an offshore platform, an automated system monitors everything from the drilling process to environmental conditions. Sensors feed real-time data into control systems, alerting operators to any irregularities that may need attention. What was once a process involving constant manual oversight has now been replaced by intelligent systems that learn and adapt to conditions, making decisions in real time to optimize operations.

“We’ve gone from manual operations where everything had to be checked by hand to systems that provide us with up-to-the-minute data that we can act on immediately,” says Mark, a field technician. “It’s not just faster; it’s smarter. Automation helps us predict issues before they even happen.”

From predictive maintenance to remote monitoring, automation’s impact is profound. With the help of artificial intelligence (AI) and machine learning (ML), companies can predict when equipment is likely to fail, saving time and reducing costly downtime. Automatic systems can shut down or adjust operations to prevent equipment damage, which not only extends the life of machinery but also ensures smooth and uninterrupted production.

Efficiency in Every Corner of the Operation

Automation isn't limited to just the field or the platform. In fact, it permeates every aspect of the oil and gas value chain. Back in the office, real-time data streams are analyzed, and decisions are made instantaneously, enabling companies to react to market changes faster than ever before. Supply chains, once fragmented and slow-moving, are now seamlessly connected through automated systems that track inventory, forecast demand, and ensure timely deliveries.

In the control room, operators no longer need to manually adjust settings or manually check equipment. Instead, automated systems do the heavy lifting, adjusting pressure, temperature, and flow based on real-time inputs. This not only minimizes human error but also ensures consistency in production. The systems are constantly learning and adapting, fine-tuning processes to achieve the highest efficiency possible.

Cutting Costs While Increasing Output

Perhaps the most immediate benefit of automation in oil and gas is its ability to cut costs while simultaneously increasing output. Automation has proven to be a game-changer when it comes to reducing operational expenses. Tasks that once required large teams to complete—such as inspections, monitoring, and adjusting equipment—can now be performed by a few key systems and software, drastically reducing the need for human labor in some areas.

This shift is crucial in an industry where margins are razor-thin, and every dollar counts. Automation ensures that companies are not only able to keep costs down but also operate at peak efficiency, extracting the maximum possible value from every barrel of oil or cubic foot of gas produced.

More efficient operations also mean that companies can scale more quickly without sacrificing quality or safety. Automation enables them to do more with less, increasing output without the need for additional resources or manpower. It’s an ideal solution for companies seeking to boost production while keeping operational costs in check.

Improving Safety and Reducing Risk

Safety has always been a primary concern in oil and gas operations, particularly in hazardous environments like offshore rigs or Deepwater drilling sites. Automation has stepped in as a game-changer in this area as well. By deploying robots, drones, and other automated systems, companies can minimize human exposure to dangerous situations.

For instance, drones can be deployed to inspect pipelines and offshore platforms, collecting data from areas that would otherwise require workers to put themselves at risk. Sensors and automated safety systems can detect gas leaks, monitor pressure levels, and track environmental changes, automatically shutting down systems before a catastrophic failure can occur.

The safety benefits extend to employees too. With automation handling more of the high-risk tasks, workers can focus on strategic decision-making, troubleshooting, and overseeing operations from a safe distance. This shift not only ensures greater safety but also helps improve job satisfaction, as workers are less exposed to dangerous conditions and more involved in higher-level operational management.

Environmental Impact: Automation for Sustainability

Sustainability has become one of the most important drivers for change in the oil and gas industry. With automation, companies are making strides toward reducing their environmental footprint. Intelligent systems can optimize production rates, reduce waste, and ensure more sustainable energy consumption. Automation also plays a significant role in reducing emissions, as systems can adjust processes in real-time to prevent unnecessary energy use and gas flaring.

“We can now track our carbon emissions more accurately and make real-time adjustments to minimize waste,” explains James, a sustainability officer at a major oil company. “Automation allows us to be more precise and efficient in how we operate, which is key to reducing our impact on the environment.”

The Road Ahead

As the oil and gas industry continues to evolve, automation will undoubtedly play an even larger role in driving efficiencies and innovations. While there is still work to be done, the current advances are already transforming the sector, making operations more reliable, cost-effective, and sustainable. For industry leaders, embracing automation is no longer a choice—it’s a requirement for staying competitive and future-ready.

Looking to the future, companies will continue to refine their automation processes, leveraging data analytics and artificial intelligence to further improve decision-making and operational efficiency. But the fundamental shift has already taken place: oil and gas operations are no longer driven solely by human hands—they are powered by automation, intelligence, and the endless possibilities that come with it. The industry has stepped into a new era, one where operations are smarter, safer, and more efficient than ever before.

To learn more about these advancements and how they are shaping the future of oil and gas, join us at our Oil & Gas Automation and Digitalization Conference (https://ogad-conference.com/).

#AutomationInOilAndGas#DigitalTransformation#Industry4_0#AIinEnergy#SmartOperations#FutureEnergy#OilAndGasInnovation#SustainableEnergy#EnergyTech#OperationalExcellence

0 notes

Text

Discover the transformative power of AI across industries! From automating tedious tasks in finance to revolutionizing customer experiences in retail, AI is reshaping the world. In healthcare, it’s improving diagnostics and patient care, while in manufacturing, it’s driving efficiency with predictive maintenance. Even agriculture is getting smarter with precision farming. Curious about how AI is making waves in other sectors?

Read more about these game-changing applications and see how your industry can benefit!

0 notes

Text

Will Self-Service Kiosk Machines Replace Human Jobs in the Future? 🤖💼

The rise of self-service kiosks has sparked a heated debate — will they take over human jobs? The short answer: not entirely! While kiosks are reshaping industries by automating routine tasks like ordering food, checking in at airports, and making payments, they are not here to eliminate jobs but rather to transform them.

Think about it — self-service kiosks handle repetitive, time-consuming tasks, allowing employees to focus on more meaningful and complex roles. In the hospitality industry, for example, kiosks speed up the check-in process, but human staff remain crucial for personalized guest experiences. In retail, automated checkout stations reduce wait times, yet employees are still needed for customer assistance, inventory management, and troubleshooting.

Instead of replacing human workers, kiosks enhance efficiency and productivity, enabling businesses to allocate their workforce more effectively. They also create new job opportunities in technology development, maintenance, and customer service support.

The future isn’t about machines vs. humans—it’s about collaboration. As self-service technology advances, the demand for human creativity, problem-solving, and emotional intelligence will only grow. The key is adapting and upskilling to work alongside technology rather than against it.

So, rather than fearing kiosks, let’s embrace them as tools that empower businesses and employees alike. What’s your take on the future of self-service technology? Let’s discuss in the comments! 👇

#SelfServiceKiosks#Automation#FutureOfWork#JobDisplacement#TechnologyTrends#WorkplaceInnovation#AI#CustomerExperience#DigitalTransformation#EmploymentFuture#KioskTechnology#HumanVsMachine#WorkforceDevelopment g#Industry4_0#BusinessStrategy#kiosk#kioskmachine#middleeastbusiness#gulfcountries#gcc#africa#MENA#UAE#Saudiarabia

1 note

·

View note

Text

Unlock the Power of Commercial IoT

Commercial IoT is transforming industries with smart automation, real-time monitoring, and seamless connectivity. From smart buildings to industrial automation, businesses use IoT to boost efficiency, reduce costs, and enhance decision-making. Ready to future-proof your operations? Commercial IoT is the key! 🚀

#commercial#SmartSolutions#commercialiot#SEOFriendly#SmartBusiness#ConnectedDevices#Industry4_0#iot applications#iotnbo#iot#bluetooth#software development#web development#iotsolutions#innovation#iot development services#iot platform

1 note

·

View note

Text

𝗝𝗼𝗶𝗻 𝘂𝘀 𝗮𝘁 𝗘𝗹𝗲𝗰𝘁𝗿𝗼𝗻𝗶𝗰𝗮 𝗜𝗻𝗱𝗶𝗮 2024! Discover cutting-edge EMS solutions and explore innovative technologies at our booth. Avalon Technologies is ready to showcase the future of Electronics Manufacturing Services. 𝗛𝗮𝗹𝗹: 15 𝗕𝗼𝗼𝘁𝗵: 𝗘65 𝗗𝗮𝘁𝗲: 11-13 𝗦𝗲𝗽𝘁𝗲𝗺𝗯𝗲𝗿 2024 𝗩𝗲𝗻𝘂𝗲: 𝗜𝗻𝗱𝗶𝗮 𝗘𝘅𝗽𝗼 𝗠𝗮𝗿𝘁 (𝗜𝗘𝗠𝗟), 𝗚𝗿𝗲𝗮𝘁𝗲𝗿 𝗡𝗼𝗶𝗱𝗮 We look forward to connecting with industry leaders and innovators. See you there! To know more: https://www.avalontec.com/ Avalon Technologies Limited Sienna Corporation Sienna ECAD Technologies Private Limited Manimozhi M

#ElectronicaIndia#EMSSolutions#Innovation#Technology#ElectronicsExpo#ElectronicsManufacturing#ManufacturingExcellence#CuttingEdgeTech#Industry4_0#Automation#PCBAssembly#SmartManufacturing#FutureOfElectronics#TechShowcase#ElectronicsIndustry#AvalonTechnologies#GreatNoida#IndianExpo#BusinessNetworking#EMSProviders#TechInnovation#EngineeringSolutions#ElectronicsInnovation

0 notes

Text

There are multiple differences between cobots and industrial robots and one may choose between them according to their own preferences. Patvin Engineering has been providing quality cobots and industrial robots for years. Visit our blog for more information.

#CobotsVsRobots#IndustrialAutomation#CollaborativeRobots#Robotics#AutomationTechnology#SmartManufacturing#Industry4_0

0 notes

Text

𝐂𝐞𝐫𝐚𝐦𝐢𝐜 𝐌𝐚𝐜𝐡𝐢𝐧𝐞𝐫𝐲 𝐌𝐚𝐫𝐤𝐞𝐭 𝐓𝐫𝐞𝐧𝐝𝐬 𝐚𝐧𝐝 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐅𝐑𝐄𝐄 𝐒𝐚𝐦𝐩𝐥𝐞: https://www.nextmsc.com/ceramic-machinery-market/request-sample

The 𝐂𝐞𝐫𝐚𝐦𝐢𝐜 𝐌𝐚𝐜𝐡𝐢𝐧𝐞𝐫𝐲 𝐌𝐚𝐫𝐤𝐞𝐭 is experiencing significant growth and innovation! As industries demand more advanced and efficient solutions, ceramic machinery is evolving to meet these needs.

𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬:

𝐓𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐢𝐜𝐚𝐥 𝐀𝐝𝐯𝐚𝐧𝐜𝐞𝐦𝐞𝐧𝐭𝐬: Cutting-edge technologies are driving efficiency and precision in ceramic manufacturing. Automation and smart machinery are setting new standards.

𝐆𝐫𝐨𝐰𝐢𝐧𝐠 𝐃𝐞𝐦𝐚𝐧𝐝: From construction to electronics, the demand for high-quality ceramic products is rising, creating opportunities for machinery suppliers.

𝐒𝐮𝐬𝐭𝐚𝐢𝐧𝐚𝐛𝐢𝐥𝐢𝐭𝐲: The focus on sustainable practices is leading to eco-friendly machinery and processes, aligning with global environmental goals.

𝐊𝐞𝐲 𝐓𝐫𝐞𝐧𝐝𝐬:

Increased investment in research and development to enhance machinery performance.

Expansion into emerging markets with growing infrastructure and industrial sectors.

Adoption of Industry 4.0 technologies for smarter and more connected manufacturing processes.

𝐊𝐞𝐲 𝐏𝐥𝐚𝐲𝐞𝐫𝐬:

Keda Industrial Company Limited

SACMI Imola S.C.

SITI B&T Group S.p.A.

Air Power Group S.p.A.

KERAjet S.A.

Mectiles Italia S.R.L.

Breton S.p.A.

Coesia S.p.A. (System Ceramics)

LB Technology

HÄNDLE GmbH

𝐀𝐜𝐜𝐞𝐬𝐬 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭: https://www.nextmsc.com/report/ceramic-machinery-market

The future of ceramic machinery looks promising with continuous advancements and increasing applications across various industries. Stay tuned for more updates and insights into this dynamic market!

#ceramicmachinery#markettrends#innovation#manufacturing#industry4_0#sustainability#techadvancements#marketinsights

0 notes

Text

#QualityManagement#ArtificialIntelligence#TechInnovation#ProfessionalDevelopment#ContinuousImprovement#EventAlert#Leadership#Industry4_0#DataDriven#MachineLearning#SmartSolutions#FutureTech#BusinessGrowth#QualityAssurance#SkillUp#TechTrends#InnovationHub#Conference2024#HeilbronnEvents#KnowledgeSharing

0 notes

Text

Industry 4.0 Software Solutions

Interwork Software Solutions provides cutting-edge Industry 4.0 software solutions, integrating IoT, AI, and automation to optimize processes, enhance productivity, and drive digital transformation for businesses across various industries.

#Industry4_0#DigitalTransformation#SmartManufacturing#IoT#TechInnovation#SmartFactories#DigitalSolutions

0 notes

Text

"Revolutionizing Industries: The Future Potential of Generative AI"https://www.blogger.com/blog/post/edit/3619939779363351777/2483200326677262814

#GenerativeAI#AIRevolution#FutureOfAI#AIinIndustries#TechInnovation#AITransformations#Industry4_0#AIAndBusiness#AIinHealthcare#AIinFinance#AIforGood#AIinManufacturing#NextGenAI#AIinCreativeFields#SmartTech#DigitalTransformation#AIApplications#AIImpact#TechTrends#InnovativeTech#MachineLearning

0 notes