#SupplyChainManagement

Explore tagged Tumblr posts

Text

🚛📱 Revolutionize your logistics business with cutting-edge mobile app solutions! From real-time tracking to AI-powered analytics, discover how technology can transform your operations, boost efficiency, and delight your customers. 🌟✨

📦 Why wait? Optimize your logistics today with Us. 🚛📦✨

Visit now.

#LogisticsApp#MobileAppDevelopment#TechInnovation#LogisticsSolutions#SSTechSystem#RealTimeTracking#AIinLogistics#SupplyChainManagement#BusinessGrowth#TechForBusiness#LogisticsIndustry#AI#analytics#technology#appsolutions#business#india#usa#australia#B2B#sstech system#flutter#webdevelopment#appdevelopment#appsdevelopment

3 notes

·

View notes

Text

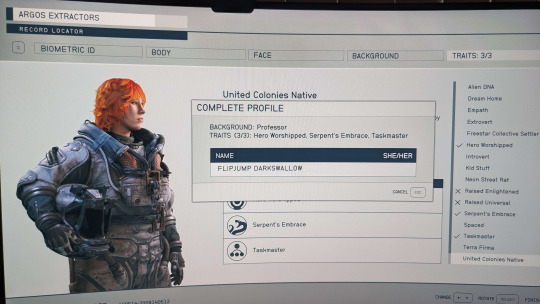

My review of a warehouse I found on Earth's Moon in the video game Starfield

I work at a cidery in the PNW. We have a pretty hefty canning line that can handle what I like to call a Solid Chunk of Volumetric Output. Our fulfillment and warehouse team touches several hundred pallets a day. We handle ingredients that come in drums, plastic IBC totes, 5 gallon buckets, and raw ingredients off the back of people’s Ford Raptors. We have pipes and valves and connectors. We talk about glycol and peracetic acid a lot. We have standard 4 level pallet racks, as well as push-back pallet racking and back-load pallet racking that maintains a First In First Out order.

I manage our Quality Assurance team, which means I spend most of my team at a desk or in a lab. I have driven our forklifts and our scissor lifts. I’ve blended our ingredients into our batching tanks. I verify our sanitation practices, and I help solve problems as needed. I spend a lot of my day staring at stainless steel pipes and mumbling about dissolved oxygen to myself.

That’s all to say, I’m not an expert. I would call myself a warehouse hobbyist and enthusiast. Not out loud to anyone, but when I play a video game that has a warehouse in it, I like to spend my time looking at how the warehouse is put together.

In addition to this, a note on Forklift Certification: It’s largely made up. There are some machines that require special licenses, and OSHA has classes you can take that probably look good on a resume, but if you look at the language that OSHA uses to define who is allowed to drive a forklift it only has two requirements. “Trained operators must know how to do the job properly and do it safely as demonstrated by workplace evaluation.” It’s up to the employer how that’s interpreted. My employer had me watch a forty five minute video and then someone watched as I drove around for thirty minutes saying “oh fuck oh fuck okay okay okay don’t hit anyone.”

I took my character, Dr. FLIPJUMP DARKSWALLOW, to the moon. I brought my companion Sarah with me, she said she wouldn’t mind a detour so that we could finally live out our shared dream of owning a pair of moon boots, so down we went to explore a seemingly abandoned lunar station. It seemed to be some kind of staging facility for receiving shipments, landing dock, staff kitchen and common area, but as far as I could tell there wasn’t anywhere within a kilometer or two to send the shipments once they arrived. Typical supply chain issues, major distro hub with nothing in site to distro to. But it did have a small on-site warehouse so Sarah and I both agreed to put a pause on our moon boots dream and explore.

This is called an IBC tote. You can fill these up through a big screw-top hole on the top, super easy to use, cheap ($275 new), universal. The most common versions I’ve seen have a galvanized steel cage and a galvanized steel pallet attached to the bottom so it can be universally picked up by a forklift. They typically have a 2” drain valve with a butterfly and a camlock. This is a pretty good example of an IBC tote! You can see how the galvanized steel was welded together at each intersection, bent into place and held there. The butterfly at the bottom has a cap in place, it has a pressure valve that’s clearly labeled. This looks pretty good!

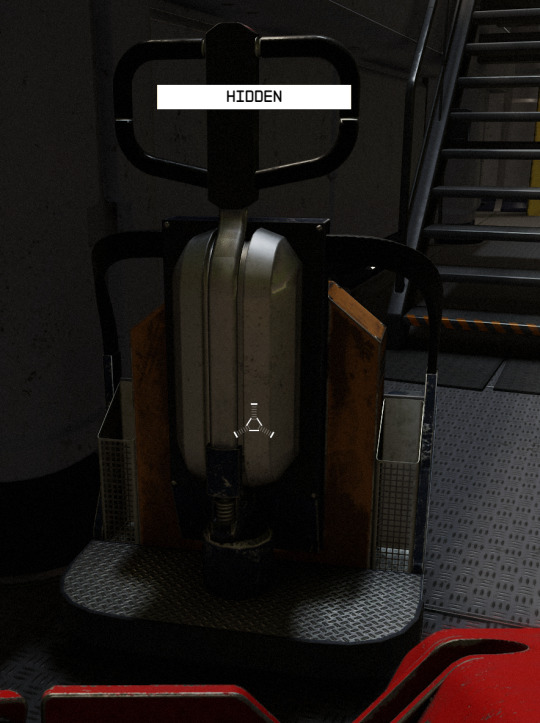

This is a pallet jack. On Earth in the present day, you roll it into the slats on a pallet, squeeze on a hand lever in the handle, and pump the handle bar up and down as it lifts. On the Moon in the future, it looks like it’s been upgraded for use in space with what I assume is probably some electric battery type of deal. Otherwise it’s very similar to a normal pallet jack! It even has the double wheels in the front, a detail I was very excited about. There doesn’t seem to be the hand lever though, or any buttons anywhere. I assume that’s because this model has a voice assistant like an Alexa in it.

It has a spring in the back as well, another neat little detail. I’d be curious to see how this works in action, there’s a decent number of mechanical parts on it for how futuristic it looks. There’s also two small… baskets, I guess? For paperwork maybe? On either end of the handle shaft. I made up the term handle shaft.

Here is what I assume is a future-forklift. And Sarah. Please ignore Sarah. I was required to take her on a mission early on, but she keeps saying things like “that’s not yours!” and “we should not break the law,” which has been definitely cramping Dr. DARKSWALLOW’s style. Anyway, this forklift is a far cry from the kinds we have in present day. Barely recognizable.

My best guess is that you stand on this platform to operate it. But there’s no buttons or levers again, no key ignition. Presumably this turns on somehow and that panel is a touchscreen, or maybe it’s another Alexa operated device. This whole thing seems pretty dangerous. There’s no roll cage. I guess maybe there’s no OSHA in the future? Or maybe this thing has a lot of safety tech built into it to protect the operator from making mistakes. Maybe it follows Asimov’s rules of robotics and can’t allow a human to come to harm, through action or inaction. But that seems like a lot of liability to pack into programming, and it seems expensive to attach a positronic brain to a forklift. I don’t know how it would anticipate other drivers doing things badly, knocking over pallets? It seems dicey.

I do like that the cabling looks like it’s painter’s taped onto the frame so it doesn’t get caught anywhere. That’s a great little detail, very much something a maintenance team might do in a pinch. A “short term hold” as they “work with supply chain details to implement a long term repair.”

I climbed up onto a pile of boxes to get this picture. It looks like they redesigned the forks in the future, kind of a high-heeled shoe thing going on at the ends there. And this forklift seems like it has reduced functionality from what forklifts here on Earth can do. Forklifts can usually do three things with the forks: lift up and down, pitch the forks back and forth, and spread the forks wider or narrower. I think this can only lift the forks up and down. There also seems to be a large orange ball on the bottom, but I don’t know what that’s used for. My best guess, given the short cylinder above it, is that the forks can control their yaw and rotate on a horizontal access? But they’re right up against the axle so I’m not sure how that would work. Maybe if you lift the forks up it’s able to rotate? But I don’t see much of an engine to ballast the center of gravity anywhere. Maybe the entire body is made with a very dense metal, it does seem to be pretty flush with the ground.

My biggest complaint is that this forklift doesn’t have any headlights or taillights. It’s important for forklifts to have a horn and bright lights to let other workers know there’s a forklift around, especially reverse lights. These might be taillights, if I’m giving some benefit here, but they’re so low to the ground I’m not sure how other drivers are going to be able to see them. But I’m not an expert in future light bulbs, maybe these work just fine.

These look like future pallets! Pallets come in different materials, with wood or plastic as the most common, but they also come in standard sizes. But these pallets look like they’re way too small for the forklift to pick up. Maybe they’re just for the pallet jack? And big note here: I really hope for the sake of the warehouse manager in this facility that OSHA doesn’t exist, because each one of those pallets standing up on its side is going to be its own fine. Overall these pallets look pretty good, if small. And this disaster of a pile seems pretty true to form with how pallets are stored, no matter how many @everyone pings on Microsoft Teams you see get sent out about stacking pallets correctly.

I suspect everyone in the warehouse crew here hates their coworkers. They have four of these pallets in a square but are stacking things randomly on top of them. None of these things are strapped down, this black cube is on a pallet that’s a different size than the pallets underneath it. Just a bizarre move. I hope everyone’s doing okay.

And then on the other side is this: … Why? Why would anyone do this? You can’t pick those rolls up, the rest will roll right off the pallet. They’re not centered on the pallet so even if you did pick it up, you couldn’t put this onto pallet racking anywhere, it’s hanging off the edge.

This is pallet racking. It seems bolted together for some reason. I haven’t seen that before on this style of racking. It seems counter-intuitive; the whole point of this type is that it’s easy to put together, it’s modular. But if you bolt it together, it’s not modular anymore. Normally you just slot the pieces in, they fall into place and don’t require additional parts. Just welded steel with drop slots.

Oof. A dead body. I’m a little surprised there aren’t more of these here. It does feel a bit dangerous.

Here’s another pallet jack, but they aren’t using it correctly. The pallet goes into the forks, why did they put a pallet on top of the forks? Ridiculous. Now they’re just lifting things for no reason. A forklift put the pallet on, now a forklift has to take the pallet off? Why use the pallet jack at all?

And lastly: a propane cage! There’s no locks on it, the maintenance team is probably screaming at everyone to make sure they Lock Out/Tag Out their equipment, but I’ll give the benefit of the doubt and sign off on it because there’s no propane tanks inside the cage so maybe the locks just aren’t necessary. Hopefully it’s just in someone’s pocket while they’re going to refill the tanks.

Overall, this is a pretty dangerous looking facility but probably usable. I’d say they ought to start working towards shoring up some safety gaps here, maybe making more intentional decisions about purchases for a while so they have the equipment they need for their process flow instead of all this equipment that requires rework and multiple touches to get anything done. But a growing business sometimes has to take what’s available! Kudos to them for getting things up and running on the moon, not an easy feat.

47 notes

·

View notes

Text

Looking for a shipping ERP solution that streamlines your air, road, and sea freight operations? Magtec Business Solutions has got you covered! With instant freight quotations, accurate tax invoicing, and comprehensive job card management, our software is designed to make your shipping process seamless and efficient. Book a demo today! 🚀

#shippingerp#shippingmanagement#shippinglogistics#erp#shipping#freight#freightforwarding#logistics#supplychain#supplychainmanagement#business#businessmanagement#software#technology#innovation#solution#efficiency#streamline#automation#digital#digitaltransformation#magtecsolutions#bookademo#shippingindustry#shippingbusiness#shippingcompany#shippingandlogistics#shippinglife#shippingtips#magtec

2 notes

·

View notes

Text

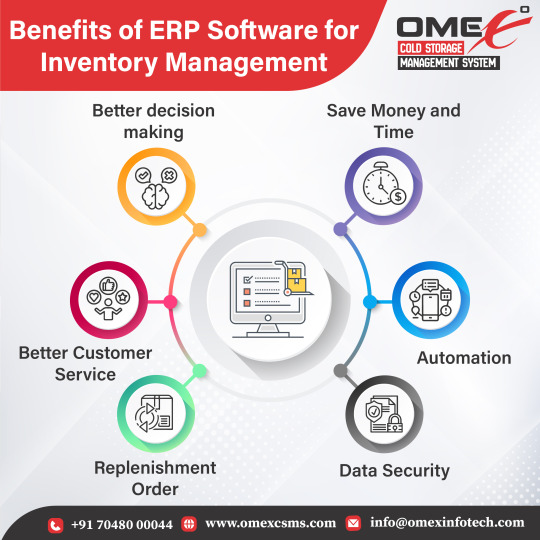

𝗘𝗻𝗵𝗮𝗻𝗰𝗲𝗱 𝗗𝗲𝗰𝗶𝘀𝗶𝗼𝗻-𝗠𝗮𝗸𝗶𝗻𝗴: Provides real-time insights that help in making informed decisions.

𝗖𝗼𝘀𝘁 𝗮𝗻𝗱 𝗧𝗶𝗺𝗲 𝗦𝗮𝘃𝗶𝗻𝗴𝘀: Streamlines processes, reducing operational costs and time spent on manual tasks.

𝗜𝗺𝗽𝗿𝗼𝘃𝗲𝗱 𝗖𝘂𝘀𝘁𝗼𝗺𝗲𝗿 𝗦𝗲𝗿𝘃𝗶𝗰𝗲: Enhances responsiveness and accuracy, leading to better customer satisfaction.

𝗘𝗳𝗳𝗶𝗰𝗶𝗲𝗻𝘁 𝗥𝗲𝗽𝗹𝗲𝗻𝗶𝘀𝗵𝗺𝗲𝗻𝘁 𝗢𝗿𝗱𝗲𝗿𝘀: Automates inventory replenishment, ensuring optimal stock levels.

𝗗𝗮𝘁𝗮 𝗦𝗲𝗰𝘂𝗿𝗶𝘁𝘆: Protects sensitive information with robust security measures.

𝗔𝘂𝘁𝗼𝗺𝗮𝘁𝗶𝗼𝗻 𝗼𝗳 𝗣𝗿𝗼𝗰𝗲𝘀𝘀𝗲𝘀: Reduces manual effort through automated workflows, increasing efficiency.

#ERPSoftware#InventoryManagement#BusinessEfficiency#CostSavings#DataSecurity#CustomerSatisfaction#Automation#DecisionMaking#SupplyChainManagement#Replenishment

2 notes

·

View notes

Text

Merit Freight Systems Co LLC

Welcome Merit Freight Systems Co LLC to the TradersFind family!🎉We’re delighted to have you on our platform.

Find out their wide range of Clearing and Forwarding Agents, Freight Forwarding, Clearing and Forwarding Companies and many more at:

https://www.tradersfind.com/seller/merit-freight-systems-co-llc

#clearingandforwardingagents#freightforwarding#clearingandforwardingcompanies#logisticsservices#freightsolutions#shippingagents#cargohandling#supplychainmanagement#globallogistics#internationalfreight#freightforwardersuae#customsclearing#cargoforwarding#logisticsmanagement#transportationservices#exportandimport#freighttransport#shippingsolutions#uaelogistics#logisticsexperts#uae#uaebusiness#businessgrowth

4 notes

·

View notes

Text

A Beginner's Guide to Understanding Smart Contracts on the Blockchain

Smart contracts are a key feature of blockchain technology that allows for the creation of self-executing contracts. In this beginner's guide, we will explore what smart contracts are, how they work, and their potential applications.

What are Smart Contracts?

Smart contracts are self-executing contracts that are stored on a blockchain. They are computer programs that automatically execute the terms of a contract when certain conditions are met. For example, a smart contract could automatically transfer funds from one party to another when a specific condition is met, such as the completion of a task.

How do Smart Contracts Work?

Smart contracts are executed on a blockchain, which is a decentralized and distributed ledger. The code for the smart contract is stored on the blockchain, and the contract is executed when certain conditions are met. Once the conditions are met, the contract is automatically executed, and the results are recorded on the blockchain.

Applications of Smart Contracts

Smart contracts have many potential applications, including:

Financial Services

Smart contracts can be used in financial services to automate processes such as payments, settlements, and insurance claims. They can also be used to create decentralized financial products, such as decentralized exchanges and lending platforms.

Supply Chain Management

Smart contracts can be used in supply chain management to track the movement of goods and automate processes such as verification and payment. They can also be used to create more transparent and efficient supply chains.

Real Estate

Smart contracts can be used in real estate to automate processes such as property transfers and rental agreements. They can also be used to create more transparent and secure real estate transactions.

Conclusion

Smart contracts are a key feature of blockchain technology that allows for the creation of self-executing contracts. They are computer programs that automatically execute the terms of a contract when certain conditions are met. Smart contracts have many potential applications, including financial services, supply chain management, and real estate. As blockchain technology continues to evolve, we can expect to see increased use of smart contracts in a variety of industries.

#smartcontracts#blockchaintechnology#decentralization#FinancialServices#supplychainmanagement#realestate#Automation#transparency#efficiency#digitalcontracts

16 notes

·

View notes

Text

Sustainable Procurement: Unlocking Hidden Value in the Supply Chain

Sustainable procurement can be defined as the integration of environmental, social, and ethical considerations into the procurement process. It goes beyond traditional procurement practices focused solely on cost and quality, taking into account the entire life cycle of a product or service. This includes evaluating the environmental impact of raw material extraction, production processes, transportation, and disposal, as well as considering fair labor practices, human rights, and community engagement.

#sustainability#sustainable development#sustainable#sustainable living#ecofriendly#ecoconscious#Sustainable Procurement#supplychainmanagement#supplements#supplier

3 notes

·

View notes

Text

LAM India offers an MBA in Logistics and Supply Chain Management, providing comprehensive education in efficient management of supply chains. The program equips students with skills in logistics, transportation, and operations management. With a focus on industry-relevant curriculum and expert faculty, ILAM India prepares graduates for dynamic careers in the thriving logistics sector. https://www.ilamindia.in/mba-in-logistics-supply-chain-management.php

#ILAMIndiaMBA#LogisticsEducation#SupplyChainManagement#MBAProgram#LogisticsTraining#ILAMMBA#LogisticsSkills#SupplyChainEducation#MBAIndia

3 notes

·

View notes

Text

Invitation to Tender for Stationery Supply to Global Flex International!

Are you ready to embark on a journey of business excellence and growth? Global Flex International extends a cordial invitation to all prospective suppliers to participate in our invitation to tender for stationery supply. With the deadline set for April 30th, this is your chance to secure a lucrative contract with a globally recognized brand. Don't miss out on this incredible opportunity to become a valued partner in our mission to deliver top-quality stationery supplies to our clients worldwide.

**Online Tender for Stationery Supply:**

Our tender process is streamlined for efficiency and accessibility, offering an online platform for the submission of bids. No matter where you are located, you can easily access the tender documents and submit your bid with just a few clicks. Say goodbye to cumbersome paperwork and embrace the convenience of online tendering with Global Flex International.

**Tender Documents Available: **

To participate in the tender, interested suppliers can purchase the tender documents for a nominal fee of Kes 1,000. These documents provide comprehensive information about the scope of work, specifications, and evaluation criteria. By familiarizing yourself with the tender documents, you can ensure that your bid aligns perfectly with our requirements and expectations.

**Supply and Delivery of Stationery Tenders: **

Global Flex International operates on a global scale. We are seeking reliable suppliers who can fulfil the supply and delivery of stationery items. we encourage you to participate in our tender and become part of our supply chain network.

**Opportunity for Growth: **

Participating in our tender presents an excellent opportunity for suppliers to expand their business and reach new markets. Whether you specialize in office supplies, school stationery, or speciality items, there is a place for you in our supply chain. By winning a contract with Global Flex International, you can unlock new avenues for growth and prosperity for your business.

**Transparent and Fair Evaluation: **

We believe in conducting our tender process with transparency and fairness. Each bid will be evaluated objectively based on merit and suitability. We are committed to providing equal opportunities to all suppliers, regardless of size or scale of operations. At Global Flex International, we value integrity and professionalism in our business dealings.

**Inclusive Participation: **

Whether you're a large corporation or a small-scale enterprise, we welcome your participation in our tender. Our goal is to create a diverse and inclusive supplier base that reflects the rich tapestry of the global business community. Your unique offerings and capabilities are what make you stand out, and we encourage you to showcase them in your bid.

**Comprehensive Tender Notice: **

Our tender notice for the supply of stationery items covers a wide range of products, including office stationery, school supplies, and more. We invite suppliers to submit bids for the supply of stationery items that meet our quality standards and specifications. From pens and paper to folders and file organizers, we are looking for suppliers who can deliver excellence in every aspect of stationery supply.

**Act Now: **

The deadline for submission is fast approaching, so don't delay – purchase the tender documents today and start preparing your bid. This is your chance to make a lasting impression and secure a valuable contract with Global Flex International. We look forward to receiving your bid and potentially forging a successful partnership together.

**Seize the Opportunity: **

In conclusion, the invitation to tender for stationery supply to Global Flex International is an opportunity not to be missed. With the deadline of April 30th looming, now is the time to act and position your business for success. Take the first step towards a bright future by participating in our tender process. We can't wait to welcome you into our network of trusted suppliers and embark on a journey of mutual growth and prosperity.

#stationery#supplychainmanagement#supplychainoptimization#procurement#invitation to tender#Supply and Delivery of Stationery Tenders#Supply Tenders in Kenya#Invitation To Submit A Bid#Tender Document

3 notes

·

View notes

Text

#AgricultureMarketing#FarmersMarket#Agribusiness#MarketAnalysis#DigitalMarketing#BrandPromotion#SupplyChainManagement#AgriInnovation#AgriculturalDevelopment#SustainableAgriculture#AgriConsulting#AgriEconomics#RuralMarketing#CropMarketing

2 notes

·

View notes

Text

Intrinseque Health - Clinical Supply Chain We Build and Execute Complex Clinical Supply Plans

Intrinseque Health is an EN ISO 13485 Certified Global clinical trial support services provider committed to the utmost in service delivery to drug development organizations (Pharmaceutical, Biotechnology, Medical Device & Contract Research Organizations (CROs)). Our team of industry professionals has over 300 years of combined experience supporting global clinical trials across a wide array of therapeutic areas. This vast experience enables us to empathize with our Customers while providing best-in-class solutions to overcome the hurdles and pain-points of conducting a clinical trial.

Regions & countries throughout the world will often present a unique set of regulatory and logistical challenges. It is our responsibility to understand and overcome these while ensuring that your products, supplies, equipment and services are available where needed to ensure study timelines are met. Intrinseque Health utilizes an operational methodology that is based on proven, cost-effective clinical supply chain strategy for each clinical trial. Our practice is to engage with our customers, early and often to ensure implementation of a robust clinical supply plan, resulting in the most successful study start-up and initiation.

#clinical supply#clinical trials#health#healthcare#supplychainmanagement#clinical supply chain#clinical supply chain management#drug development

2 notes

·

View notes

Text

PUSH AND PULL STRATEGY IN SUPPLY CHAIN

Grate to Learn

PUSH AND PULL STRATEGY IN SUPPLY CHAIN

#7 - Week 2

Hello everyone, today, I will bring you an interesting topic that I learned on Coursera: Supply Chain Management: Be Global by Dr. Mehrdokht Pournader from Macquarie University.

This series will last for 6 weeks corresponding to the content learned in the course. I will experience and write down what I learn through each subject bilingually. Hopefully, my sharing will help you, especially those interested in Supply Chain!

#7 - Week 2:

A good supply chain manager knows how to use different tactics and understand Trade-offs (lesson #6) in a certain supply chain to help the supply chain achieve balance in terms of value. cost efficiency and responsiveness at all times. One such effective strategy is: Pull and Push strategies focus on Demand Forecast and Align to customer preferences (Suitable to customer needs) through three application examples in the lesson.

Imagine, you are working near a shopping mall, you are on your lunch break and are planning to buy them, what are your options? First, if you are in a hurry, you will choose fast food like a sandwich from the nearest store. Second, if you want to eat more, you can choose to eat sushi at a food court. Third, you can choose a restaurant that you love and choose a plate of steak. As a supply chain manager, think about the differences between the three options above:

Which one has the most impact by logistics and strategies.

Which one belongs to the Market-responsive supply chain?

Which one belongs to the Physically-efficient supply chain?

For the sandwich supply chain, in the manufacturing plant, its production, packaging and distribution are calculated based on long-term forecast of demand. In short, sandwiches are pushed to market based on long-term forecasts. This is called Push strategy or called production method Make-to-stock strategy.

The advantage of this Push strategy is that logistics plans aim at cost efficiency and economies of scale such as purchasing (buying in large quantities will get discounts on products, pickles, side lettuce from farmers), produce and transport large quantities of inventory (full truckload), minimizing inbound and outbound transportation costs.

The disadvantage of the Push strategy is that once customers change their tastes or some other factors change, affecting preferences or changing needs, the supply chain will be very slow to respond to those changes. That change causes significant damage

For the third option, fancy restaurant, preparation and delivery are done after you order from ingredients bought, order placed, prepared and food delivered. They are completely dependent on need,daily forecast and, they are demand-driven. This is called Pull Strategy or Make-to-order strategy.

The advantage of Pull strategy is that production and distribution are based on actual customer needs, final products or final services are personalized. Inventory or in this example other food waste is minimized. By personalizing, we improve quality and customer satisfaction.

The biggest disadvantage of the Pull strategy is that it is difficult to achieve economies of scale, and the cost to complete the final product is often quite high. The challenge is that the delivery speed (lead times) to the end user is often longer, causing customers to wait to get their food instead of choosing a sandwich with almost no wait.

Thus, Push strategy will be suitable for Physically-efficient supply chains and Pull Strategy will be suitable for Market-responsive supply chains.

The question is how can we take advantage of both Pull and Push strategies in the supply chain? The second example of sushi is a Push strategy, but the biggest difference is that you can choose multiple types of sushi, creating custom and delicious sushi plates of your choice according to a Pull strategy. A sushi restaurant needs to synthesize customer demand forecasts, then prepare a certain amount of sushi from each forecast (Aggregated demands). Aggregate forecasts are often more accurate than forecasts for each individual product or service. Sushi restaurants not only ensure and enhance customer satisfaction with personalized sushi plates, but also enjoy cost-effectiveness in aggregate forecasting and benefit from economies of scale. This is called Push Pull Strategy.

Supply chain managers are experts at drawing the line between two strategies based on the speed at which sushi is created and delivered to the final consumer in order to achieve cost-effective, increased responsiveness in the process. supply chain.

See you on topic Supply chain Terms will be very useful for your career in post #8.

Grate To Learn,

#supplychainmanagement#business#gratetolearn#supplychainsolutions#food supply#sushi#sandwich#supplychain

2 notes

·

View notes

Text

Hazmat (Hazardous Materials) Shipments

Hazmat (Hazardous Materials) shipments involve the transportation of potentially dangerous substances, requiring stringent regulations and safety measures to protect people, property, and the environment. Hazmat shipments are classified according to the type and level of hazard they pose, and proper labeling is crucial to ensure that all parties involved understand the risks and necessary precautions.

#freight broker#freight forwarding#logistics#transportation#air freight#transportservice#supplychainmanagement#sea freight#supplychainsolutions#shipping#hazmat#global shipping#self shipping#naruto shippuden#rw shipping#pro shipping#qsmp shipping#art#fanart

2 notes

·

View notes

Text

Elevate your business with Magtec ERP! 📈 Our tailored solutions can help you streamline operations, boost efficiency, and achieve your goals. Let's grow together! 💪

#magtec#magtecsolutions#magtecerp#erpsystem#businesssolutions#productivity#efficiency#automation#inventorymanagement#financialreporting#customerrelationshipmanagement#salesforceautomation#humanresources#supplychainmanagement#clouderp#softwaresolution#businessgrowth#digitaltransformation#technology#innovation#smallbusiness#mediumbusiness#enterprise#entrepreneur#businessowner#success#marketing#sales#finance#accounting

2 notes

·

View notes

Text

#supply chain#supplychainmanagement#experience supplying#supplychainsolutions#information technology#it services

2 notes

·

View notes

Text

Looking for reliable shipping partners? Explore our comprehensive list of trusted Shipping Companies in UAE. From sea to air, we connect you with the best services tailored to your needs. Save time and effort with TradersFind! 🚢✈️

🛠️ Connect with us on WhatsApp at +971 56 977 3623 to discuss your Shipping Companies

Visit TradersFind today to explore our directory of Shipping Companies in UAE🔗: https://www.tradersfind.com/category/shipping-companies

Shipping Companies In UAE

#shippingcompanies#uae#logisticssolutions#globalshipping#cargoservices#shippingindustry#exportandimport#freightforwarding#maritimeservices#supplychainmanagement#trustedpartners#efficientshipping#logisticsexperts#shippingworldwide#seamlessdelivery#customsclearance#internationaltrade#logisticsmanagement#shippingcontainers#reliableservices#doortodoordelivery#shippingbusiness#logisticssupport#shippingsolution#professionallogistics#worldwideshipping#connectwithus#tradersfind#b2binuae

2 notes

·

View notes