#CollaborativeRobots

Explore tagged Tumblr posts

Text

Robotic Arms Market Future Trends Highlighting Automation, Industry 4.0, and Evolving Manufacturing Demands

The robotic arms market is undergoing a profound transformation, driven by automation, smart manufacturing, and the rising adoption of Industry 4.0 technologies. Once confined to heavy manufacturing plants, robotic arms are now expanding into new sectors and redefining how industries approach production, assembly, logistics, and even healthcare. As businesses prioritize efficiency and flexibility, the future of robotic arms lies in smarter, faster, and more collaborative systems designed to work seamlessly alongside humans.

Smart Manufacturing and Industrial Evolution

The integration of robotic arms into modern manufacturing systems is no longer a futuristic concept but a growing necessity. With smart factories becoming the new standard, robotic arms are at the center of digital transformation. Manufacturers are investing in robotics to improve accuracy, reduce downtime, and enhance productivity. This shift is also supported by a growing demand for high-quality, customized products with faster turnaround times.

Robotic arms, equipped with AI-powered sensors and machine learning algorithms, are enabling predictive maintenance, real-time process optimization, and autonomous decision-making. These innovations reduce operational costs and minimize human error, pushing the market toward increased adoption in sectors like automotive, electronics, and aerospace.

Collaborative Robots (Cobots) Gaining Traction

One of the key future trends shaping the robotic arms market is the rapid rise of collaborative robots, or "cobots." These systems are designed to safely operate alongside human workers, eliminating the need for safety cages and enabling direct interaction in shared workspaces. Their flexibility, affordability, and ease of programming make them ideal for small and medium enterprises (SMEs) seeking to automate without investing heavily in traditional industrial robots.

As cobots evolve, their applications are expanding into areas such as medical device assembly, packaging, inspection, and even food processing. Their ability to learn from human input and adapt to changing environments is setting the stage for a more inclusive and human-centered approach to industrial automation.

Miniaturization and Precision in Robotics

In addition to collaboration, the miniaturization of robotic arms is opening new possibilities in sectors that require precision and delicacy. Medical robotics, in particular, is benefiting from compact robotic arms that assist in minimally invasive surgeries, diagnostics, and rehabilitation. The increasing demand for medical automation and telehealth solutions is expected to boost the use of robotic arms in hospitals and clinics globally.

Similarly, in the electronics and semiconductor industries, micro-robotic arms are revolutionizing component placement, soldering, and quality control. The combination of speed and microscopic precision is allowing manufacturers to meet the growing demand for smaller, more powerful consumer electronics.

AI and Machine Learning Integration

Another transformative trend in the robotic arms market is the integration of artificial intelligence and machine learning. These technologies enable robotic arms to perform complex tasks without pre-programmed instructions, learning from their environment and improving over time. AI-powered vision systems, speech recognition, and decision-making capabilities are making robotic arms smarter and more autonomous.

This is especially relevant in sectors like logistics, where robotic arms are now capable of sorting, packing, and delivering goods with little human intervention. As e-commerce continues to boom, logistics firms are turning to robotics to enhance efficiency and meet rising consumer expectations.

Sustainability and Energy Efficiency

The future of the robotic arms market is also tied to global sustainability goals. Manufacturers are increasingly looking for energy-efficient solutions that reduce carbon footprints and lower waste. Robotic arms designed with lightweight materials, low-energy consumption motors, and smart power management systems are aligning with the green manufacturing movement.

Additionally, robotic arms are being used in recycling, waste management, and renewable energy industries. From sorting recyclable materials to assembling solar panels, these applications underscore the broader environmental role robotics can play in the future.

Challenges and Opportunities Ahead

While the robotic arms market is set for significant growth, it also faces challenges such as high upfront costs, cybersecurity concerns, and the need for skilled workers. However, advancements in plug-and-play robotics, cloud-based control systems, and remote diagnostics are gradually lowering these barriers.

Governments and private sectors are also investing in robotics training programs to address the skills gap and ensure a smooth transition toward automation. These initiatives will play a crucial role in shaping a workforce that’s ready to embrace and thrive alongside robotic technologies.

Conclusion

The robotic arms market is entering an era defined by smart automation, human-machine collaboration, and sector-wide innovation. From manufacturing floors to operating rooms, robotic arms are transforming how tasks are performed, enhancing productivity, and opening doors to new opportunities. As technology continues to evolve, businesses that adopt and adapt to these trends will lead the future of industry.

0 notes

Text

#MISCO#CobotAutomation#USManufacturing#AudioEngineering#ReshoringInnovation#CollaborativeRobots#SmartManufacturing#MadeInUSA#electronicsnews#technologynews

0 notes

Text

Small but Mighty: The Gear Motor Changing the Robotics Game

Robots are becoming smarter, more compact, and more powerful than ever—and at the heart of this evolution is the compact gear motor. Just because it’s small doesn’t mean it lacks strength.

From collaborative robots to autonomous delivery bots and warehouse automation systems, compact drive technology is reshaping how robots move, work, and interact with the world. But what makes these small components such a big deal?

In our latest blog post, we break down the rising demand for compact gear motors in robotics and how BonSystems’ BSR reducers and BCSA smart actuators are pushing the boundaries of what's possible in tight spaces.

Curious how compact can still mean powerful? 🤖[Why the Robotics Industry Is Turning Its Eyes to Compact Gear Motors]

#Robotics#GearMotors#Automation#SmartActuators#CycloidalReducer#RobotDesign#AMR#AGV#CollaborativeRobots#BonSystems#FutureOfMotion

0 notes

Text

Simplify Fibre Inspection. Switch to EXFO’s FIP-500 fibre inspection scope. Damaged Multi-fibre Push On (MPO) connectors in data centres and Networking applications are the leading cause of network outages, needing precise inspections. We bring you the FIP 500 fibre inspection scope from EXFO for • Reliable results using zero-button testing and long-lasting (11 hrs. autonomy) Li-Po rechargeable battery • Precise inspections with on-board connector end face • High-clarity 2.4” Capacitive color touchscreen • Better visibility with built-in flashlight • Easy software updates over Wi-Fi With enhanced illumination and contrast from two Violet (415nm) LEDs, superior image quality from custom-carved lenses and a 1.4GHz dual-core CPU, it is truly world-class. Learn more here: https://zurl.co/h5xkp

#EXFO#FIP500#Networking#FiberInspection#melss#automatedtestequipmentmanufacturers#industrialiotsolutionsindia#collaborativerobots#industrialautomationandrobotics#electricvehicletestsolutions#endofarmtooling

0 notes

Text

Future of Collaborative Robots: Automation and AI Integration

The global collaborative robot market size is anticipated to reach USD 11.64 billion by 2030, exhibiting a CAGR of 31.6% over the forecast period, according to a new report published by Grand View Research, Inc. The growth can be credited to the growing inclination of industries toward collaborative robots or cobots to automate manufacturing processes.

Over the past few years, the growing interest in robot technology across various industries has positively impacted the collaborative robots industry. Unlike conventional industrial robots, cobots are developed to operate at par with their human counterparts. They are mobile and can be easily moved from one area of a manufacturing facility to another. Moreover, they can be programmed with ease, are more cost-effective than their fixed counterparts, and can be used in a wide range of low-speed, repetitive applications.

Collaborative Robot Market Report Highlights

By payload capacity, the up to 5kg segment accounted for the largest market share of over 43% in 2024. The growth is attributable to the increasing demand for enhanced in-building wireless connectivity catalyzed by the burgeoning number of smartphone users and data-intensive applications.

The assembly segment accounted for the largest market share in 2024, driven by the increasing adoption of collaborative robots (cobots) for tasks such as nut driving, bolting, and part fitting.

The automotive segment dominated the market in 2024, owing to its extensive adoption of automation technologies. Collaborative robots are particularly valuable in this sector for tasks such as assembly, welding, and painting, where they enhance productivity and ensure precision.

The European collaborative robots is expected to grow at the significant CAGR of over 30% from 2025 to 2030, driven by government initiatives promoting industrial automation and sustainability.

For More Details or Sample Copy please visit link @: Collaborative Robots Market Report

The increasing need for highly efficient and user-friendly robots that do not require highly skilled experts for deployment and functioning has created a significant demand for software platforms. These platforms allow the integration of robots, motion control, and the generation of an interface that enables the programming of such robots. For instance, Mitsubishi Electric Corporation has launched a cobot named MELFA ASSISTA equipped with RT VisualBox, the company’s engineering software. This software allows the intuitive creation of operating sequences by connecting block diagrams in a chain of events, including linking with other devices, such as cameras and the hands of the robot.

The increasing demand from industrial customers, researchers, and engineers further strengthens the outlook of the collaborative robots industry. These robots are being deployed across various industries and have been highly influential in addressing the challenges faced by the logistics sector, such as complex work processes, and managing several tasks in different combinations and compact spaces.

List of Key Players in Collaborative Robot Market

ABB Group

DENSO Corporation

Epson America Inc.

AUBO (BEIJING) ROBOTICS TECHNOLOGY CO., LTD

Comau S.p.A.

Energid Technologies Corporation

Fanuc Corporation

KUKA AG

Rethink Robotics GmbH

Robert Bosch GmbH

We have segmented the global collaborative robot market report based on payload capacity, application, industry vertical, and region

#CollaborativeRobots#Cobots#RoboticsMarket#Automation#IndustrialRobots#SmartManufacturing#AIinRobotics#CobotsIndustry#RobotAutomation#Industry40#ManufacturingTrends#RobotTechnology#FutureOfWork#IoTRobotics#GlobalMarket

0 notes

Text

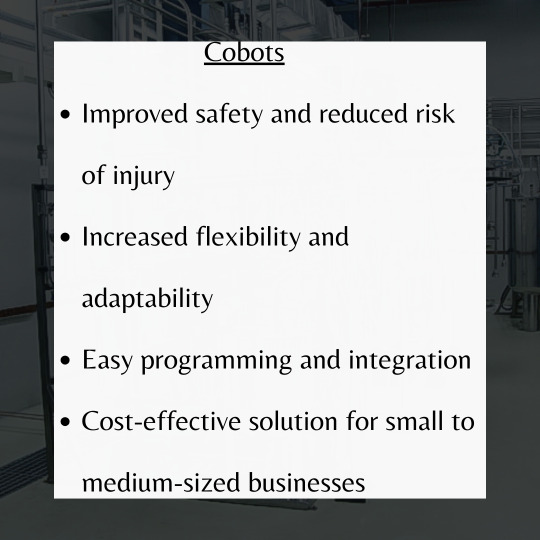

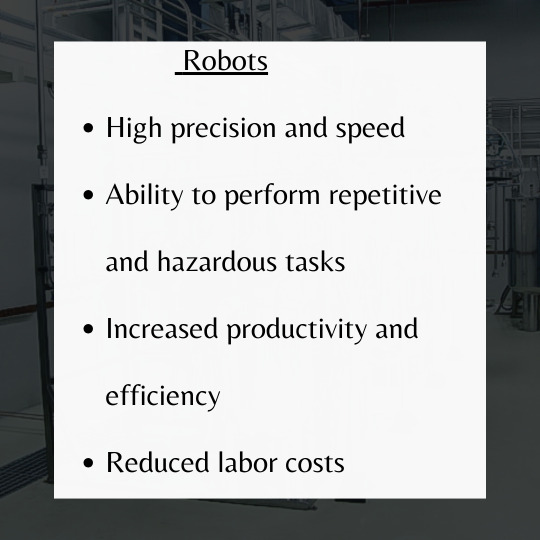

There are multiple differences between cobots and industrial robots and one may choose between them according to their own preferences. Patvin Engineering has been providing quality cobots and industrial robots for years. Visit our blog for more information.

#CobotsVsRobots#IndustrialAutomation#CollaborativeRobots#Robotics#AutomationTechnology#SmartManufacturing#Industry4_0

0 notes

Text

Motion Control Market: Trends to Watch in 2024 & Beyond

Motion control systems are pivotal components in automation, enabling the precise control of movements in machines across various industries. As industries increasingly lean towards automation, the global motion control market is projected to witness significant growth at a CAGR of 5.21% during 2024-2032, reaching $26,569.12 million by 2032. This substantial expansion is driven by the rising demand for motion control solutions and technologies, particularly in response to the growing adoption of robotics and automation technologies.

The increasing focus on operational efficiency and accuracy fuels the need for advanced motion control products. Businesses are striving to optimize their operations and reduce labor costs, leading to a surge in demand for these systems. This trend is especially pronounced in fast-growing regions like Asia-Pacific, where motion control manufacturers and enterprises are rapidly expanding their offerings to meet the evolving needs of the industry.

Explore in detail about this market in our FREE sample

Automation, Robotics, and Industry 4.0: Driving Growth in the Motion Control Market

The rapid integration of automation, driven by Industry 4.0, has placed the motion control industry at the heart of technological transformation. Advanced robotics and automation are revolutionizing manufacturing processes globally. According to the International Federation of Robotics (IFR), global industrial robot installations rose by 10% in 2023, with the Asia-Pacific region dominating the landscape, accounting for nearly 70% of these installations.

China, in particular, has emerged as a leader in this domain. In 2023, 276,288 industrial robots were installed, representing 51% of global installations, marking the second-highest level ever recorded. Domestic manufacturers have significantly increased their market share, capturing 47% of the Chinese market. This growth reflects China’s strategic focus on enhancing its position as a global manufacturing powerhouse. The World Bank reports that manufacturing contributed 28% to China’s GDP in 2022, underscoring the importance of industrial automation in its economic framework.

The government has implemented policies aimed at fostering the adoption of automation technologies, with a particular focus on motion control systems. These systems ensure precision, efficiency, and scalability in production, key elements in the shift towards smart manufacturing under Industry 4.0. This substantially supports the fast growth of the Asia-Pacific motion control market.

Open-Loop vs. Closed-Loop Systems: The Backbone of Motion Control

In the motion control market, two dominant system types underpin industry operations: open-loop systems and closed-loop systems. Each system offers distinct advantages tailored to the application’s precision requirements and cost considerations.

Open-Loop Systems: Known for their simplicity and cost-effectiveness, open-loop systems operate without feedback mechanisms. The control signal sent to the motor remains unadjusted regardless of the outcome, making them ideal for applications where precision is not the top priority. While this lack of feedback limits accuracy, open-loop systems continue to be favored in cost-sensitive industries, where ease of maintenance and lower expenses outweigh the need for precise control.

Closed-Loop Systems: In contrast, closed-loop systems incorporate feedback loops that continuously adjust motor movements, ensuring superior accuracy and reliability. These systems are crucial in high-precision applications, such as robotics, CNC machinery, and advanced medical devices, where exact positioning and velocity control are essential. According to industry sources, the adoption of closed-loop systems is expected to grow, driven by the escalating demand for accuracy in automation processes.

Connect with our experts for a simplified analysis!

Recent Innovations by Key Players in Motion Control Technology

Latest advancements in motion control technologies have focused on enhancing performance, efficiency, and connectivity. Several leading manufacturers have introduced innovative products in 2023 and 2024, marking significant strides in the motion control market.

In March 2024, FANUC America unveiled its Power Motion i-MODEL A Plus (PMi-A Plus) at MODEX 2024. This PLC/CNC motion controller is designed to support general motion control equipment, expanding the versatility and functionality of FANUC’s product lineup.

In April 2024, Rockwell Automation Inc launched the FLEXLINE™ 3500, a low-voltage motor control center (MCC) for IEC markets. This solution enables manufacturers to unlock production data and improve productivity through smart, connected devices.

In November 2023, Siemens introduced the latest version of the Totally Integrated Automation (TIA) portal. This update simplifies motion control operations, offering flexible production solutions and addressing the skilled worker shortages prevalent in the industry.

Robert Bosch GmbH and Mazda collaborated in October 2023 to develop DSC-TRACK, ESP® control for motorsports, which features Vehicle Dynamics Control 2.0. This advanced system improves safety, agility, and comfort, providing enhanced performance for motorsport applications.

Future of Motion Control: AI, Cobots, and Industry Growth

The motion control market is set for transformative growth, driven by advancements in artificial intelligence (AI) and machine learning. AI-powered motion control systems will enable manufacturers to dynamically optimize processes, particularly benefiting precision-dependent industries like pharmaceuticals and electronics.

Additionally, the rise of collaborative robots (cobots), designed to work alongside humans, presents a major growth opportunity. With a projected CAGR of 31.13% through 2028, cobots are expected to become an essential component in manufacturing, boosting demand for motion control technologies.

In conclusion, the integration of automation, robotics, and AI is shaping the future of the motion control industry, opening new avenues for innovation and investment across sectors.

Explore Our Latest Release for the 2024-2032 Market Analysis

FAQs:

Q1) What is motor control in motion control systems?

Answer: Motor control refers to the methods and technologies used to regulate the movement of motors in a machine. In motion control systems, motor control ensures that motors function precisely to achieve the desired position, velocity, or torque.

Q2) What are the primary benefits of using motion control systems in automation?

Answer: Motion control systems offer improved precision, efficiency, and scalability in automation processes. They are critical for industries that require high-speed, accurate movements, such as automotive manufacturing, electronics assembly, and medical device production.

#motioncontrol#automation#industrialautomation#collaborativerobots#cuttingedgetechnology#machinelearning#industry40#marketresearch#tritonmarketresearch

0 notes

Link

#actuatorsinrobotics#AdvancedRoboticGrippers#AdvancedRoboticsEngineering#AutomationTechnology#collaborativerobots#CustomRoboticSolutions#EndEffectors#FlexibleRobotSystems#Grippertechnology#industrialrobots#KinematicsinRobotics#ManipulatorDynamics#MechanicalEngineering#MotionControl#PrecisionRobotics#ProgrammableManipulators#RobotManipulators#RoboticArmDesign#RoboticArms#RoboticAssemblyAutomation#RoboticAutomationSystems#RoboticControlSystems#RoboticEfficiencyEnhancement#RoboticManipulationTechniques#RoboticSystemIntegration

0 notes

Text

🤖 AI Manufacturing Automation Human‑Robot Synergy – Industry 5.0 Robotics Integration

AI manufacturing automation human robot synergy enhances Industry 5.0 collaboration between workers and intelligent robots for safer, smarter production processes. In modern factories, AI manufacturing automation human robot synergy combines artificial intelligence, collaborative robots, and skilled workers to foster Industry 5.0 innovation. This integration enhances productivity and worker…

0 notes

Link

#AI-DrivenManufacturing#collaborativerobotics#cross-bordertechtransfer#industrialautomation#nearshoringinnovation#PredictiveMaintenance#semiconductorrepositioning#supplychaindigitization

0 notes

Text

#MISCO#microspeaker#Energy#innovation#collaborativerobotics.#powerelectronics#powermanagement#powersemiconductor

0 notes

Text

Montreal/Berlin, September 10, 2024 – Vention, the company behind the cloud-based Manufacturing Automation Platform (MAP), announces its collaboration with ABB Robotics, confirming the compatibility between the Vention platform and the ABB GoFa™ family of cobots. Vention and ABB customers benefit from a seamless integration of both companies' technologies, from the design phase of the robot cells to the processes on the factory floor. As part of the Vention ecosystem, ABB will gain access to a wider range of do-it-yourself automation customers, while Vention will expand its offering with ABB's robotic solutions. The mutually beneficial relationship will expand market reach and innovation for both companies. Enhanced automation capabilities with the ABB GoFa™ CRB15000 Series The ABB GoFa™ robots, now available on the Vention marketplace, offer manufacturers proven cobots with a payload of 5 kg, 10 kg and 12 kg. Known for their safety, ease of use and performance, ABB GoFa™ robots are designed to work side-by-side with humans in various applications, from assembly and welding to material handling and inspection. ABB GoFa™ robots, enhanced by the power of the Vention Manufacturing Automation Platform ABB GoFa™ robots are now compatible with the entire Vention platform, including MachineBuilder (design), MachineLogic (robot programming), MachineAnalytics (operational monitoring and data) and Remote Support (on-demand support). This compatibility provides ABB customers with an intuitive user experience, from the design to the operation of robot cells. In addition, ABB GoFa™ robots will be available for Vention's innovative Rapid Series application line during 2025. "We are very pleased to welcome ABB to the Vention ecosystem. This collaboration enhances our ability to deliver democratized and powerful automation solutions" says Etienne Lacroix, Founder and CEO of Vention. "The partnership with Vention represents a significant step forward for both companies. This collaboration combines ABB's advanced cobot portfolio with Vention's expertise in application design and delivery. By bringing together our hardware and software capabilities, we're making robot automation more accessible and easier to integrate for businesses of all sizes. "Our joint efforts will address key industry trends and help companies improve their operations and make workplaces safer and more efficient," said Andrea Cassoni, Head of Collaborative Robotics at ABB Robotics. About Vention Vention helps companies automate their production areas in just a few days through a democratized user experience. Vention's digital manufacturing automation platform allows customers to design, automate, order, and deploy automated equipment directly from their web browser. Vention is headquartered in Montreal, Canada, with offices in Berlin and Boston. Its more than 300 employees serve more than 4,000 customers on five continents and in 25 manufacturing industries. For more information, see vention.com or follow us on LinkedIn. *MachineMotion, MachineLogic, MachineCloud and Vention are trademarks of Vention Inc. About ABB Robotics ABB (ABBN: SIX Swiss Ex) ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company's solutions combine technical expertise and software to optimize the manufacturing, movement, power, and operation of things. Building on more than 140 years of excellence, ABB's more than 105,000 employees are committed to driving innovation that accelerates industrial transformation. www.abb.com ABB Robotics & Discrete Automation, as one of the world's leading providers of robotics and machine automation, is the only company with a comprehensive and integrated portfolio that includes robots, autonomous mobile robots and machine automation solutions developed and orchestrated by our value-added software. We help companies of

all sizes and industries – from automotive to electronics to logistics – to become more resilient, flexible and efficient. ABB Robotics & Discrete Automation is helping customers transition to the connected and collaborative factory of the future. The business unit employs around 11,000 people at over 100 locations in around 53 countries. go.abb/robotics

#Cobots#Development#English#General#Hardware#IndustrialRobots#Programming#Software#ABB#ABBGoFa#ABBRobotics#Automation#Cobot#CollaborativeRobotics#CRB15000#MachineAnalytics#MachineBuilder#MachineLogic#ManufacturingAutomationPlatformMAP#Planning#Robotics#Robots#Vention

0 notes

Link

#agriculturalautonomy#agriculturalrobot#Agriculture&RoboticsSummit#AlleghenyConferenceforCommunityDevelopment#AltmanPlants#AWS#Burro#BurroGrande#CatalystInvestors#CibusCapital#collaborativerobot#F-PrimeCapital#FIRA#Formant#Futurride#harvest-assistcobot#InnovationWorks#Philadelphia#PittsburghRoboticsNetwork#S2GVentures#sustainablemobility#ToyotaVentures#TranslinkCapital#WalnutCapital

0 notes

Text

Robots on the Move: Understanding Autonomous Mobile Robots

In recent years, the landscape of logistics and industrial operations has witnessed a profound transformation with the advent of Autonomous Mobile Robots Market Share. Order fulfilment operations today face many new issues, such as growing labour costs, a declining supply of skilled personnel, and greater pressure for next, same-day, and two-hour delivery. These sophisticated robotic systems are revolutionizing the way businesses operate, streamlining processes, and enhancing overall efficiency.

Embracing new technology, procedures, and processes has always been a crucial component of the puzzle for distribution operations, which need to continuously modernise and adjust in order to be profitable and competitive in this new world. But with the speed at which technology is developing nowadays, it can be challenging to determine which automation solutions are most suited to your requirements. In this blog, we'll explore the dynamics of AMRs and delve into the insights provided by Quadrant Knowledge Solutions, a global advisory and consulting firm, through their comprehensive Market Intelligence Reports.

Understanding Autonomous Mobile Robots Market Forecast

AMRs represent a paradigm shift in automation, offering flexibility and adaptability in diverse environments. These intelligent robots utilize a combination of sensors, machine learning, and advanced algorithms to navigate autonomously, making them invaluable assets across industries. From warehouses to manufacturing floors, AMRs are on the move, enhancing productivity and reducing operational costs.

A market intelligence perspective involves recognizing the transformative impact these robots have on various industries. AMRs, characterized by their adaptability, leverage a blend of sensors, machine learning, and sophisticated algorithms to navigate autonomously. This technological convergence positions them as highly sought-after solutions in diverse environments, ranging from warehouses to manufacturing facilities.

From an analyst standpoint, it's crucial to highlight the flexibility that AMRs bring to automation. Their ability to autonomously navigate through dynamic spaces not only streamlines operations but also enhances overall productivity. Industries adopting AMRs witness a reduction in operational costs, a key factor contributing to their widespread adoption. Exploring the nuanced applications of AMRs in different sectors becomes paramount. Understanding how these intelligent robots optimize logistics in warehouses, improve efficiency on manufacturing floors, and contribute to overall operational excellence provides valuable insights for businesses aiming to stay competitive.

A comprehensive market intelligence approach to AMRs involves delving into their technological intricacies, assessing their impact across industries, and recognizing the tangible benefits they offer. This multifaceted perspective and insightful analyses guide businesses in leveraging the potential of AMRs for sustained growth and efficiency gains.

Key Features of Autonomous Mobile Robots

Sensory Perception: AMRs are equipped with a range of sensors such as LiDAR, cameras, and ultrasonic devices, enabling them to perceive and navigate their surroundings with precision.

Adaptive Learning: Machine learning algorithms empower AMRs to adapt to changing environments, optimize routes, and learn from past experiences, improving efficiency over time.

Collaborative Operation: These robots can seamlessly collaborate with human workers, augmenting workforce capabilities and fostering a harmonious man-machine partnership.

To continue with the above mentioned market intelligence perspective, Quadrant Knowledge Solutions, a global advisory and consulting firm focused on helping clients in achieving business transformation goals with Strategic Business, and Growth Advisory Services, has provided invaluable insights into the AMR landscape through their Market Intelligence Reports (hyperlink). The latest data from 2022 reveals the current state of the global AMR market, while the forecast for 2027 paints a compelling picture of anticipated growth and industry evolution.

Talk With Us

Global Market Share (2022)

Quadrant's findings indicate a substantial market share for AMRs, with key players dominating the industry. Companies investing in cutting-edge technology and innovation are poised to lead, driving competition and fostering a dynamic market ecosystem.

Global Market Forecast (2027)

Looking ahead to 2027, the forecast suggests exponential growth in the Autonomous Mobile Robots market. Factors such as increased automation adoption, technological advancements, and the need for efficient supply chain management contribute to this projected surge. Businesses that strategically integrate AMRs into their operations stand to benefit from enhanced productivity and a competitive edge.

In conclusion, Autonomous Mobile Robots is not just a technological trend but a transformative force reshaping industries worldwide. As businesses embrace these robotic companions on their journey toward operational excellence, the insights provided by Quadrant Knowledge Solutions and other leading players in the market research field serve as a guiding light, illuminating the path to a future where autonomy and efficiency coexist seamlessly. Stay tuned for more updates on this dynamic and evolving field.

#AMRs#LogisticsTransformation#IndustrialOperations#SensorTechnology#MachineLearning#AdaptiveNavigation#CollaborativeRobotics#SupplyChainManagement

0 notes

Text

Is the efficiency of Device Programming bothering you? Not any more! We bring you BPM Microsystems latest 9th generation 2900L four socket manual device programmer to program high-density devices such as MCUs, managed NAND, and flash memory. Its Vector Engine Co-Processor accelerates flash memory waveforms during programming, achieving sp eeds of 12.8 GB per second through synchronous operations with zero dead waiting time between the DUT and the programmer, resulting in fast programming matching the silicon design. • Minimal operator fatigue due to integrated lever socket actuator • Extendable to 44 devices simultaneously • Mission-critical quality standards • BPWin and JobMaster for fast and easy production • Up to 52% faster programming For More Info: https://zurl.co/inrAZ

#melss#collaborativerobots#industrialiotsolutionsindia#industrialautomationandrobotics#automatedtestequipmentmanufacturers#electricvehicletestsolutions

0 notes

Text

#IndustrialEvolution hashtag#Mechanization hashtag#AutomationAge hashtag#GlobalizationTrends hashtag#DigitizationRevolution hashtag#Industry5Point0 hashtag#PersonalizationInnovation hashtag#TechTransformations hashtag#ManufacturingHistory hashtag#FutureOfWork hashtag#InnovativeTech hashtag#SmartManufacturing hashtag#CollaborativeRobots hashtag#MassCustomization hashtag#SustainableIndustry hashtag#HumanMachineCollaboration hashtag#IndustrialProgress hashtag#TechHistory

0 notes