#industry40

Explore tagged Tumblr posts

Text

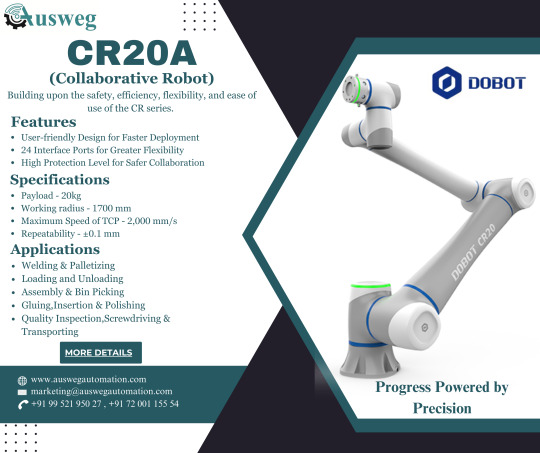

DOBOT CR20A Performance Unleashed With High Payload and Wide Radius

www.auswegautomation.com [email protected] +91 99 521 950 27, +91 72 001 155 54

#cobots#collabrativerobots#automation#industry40#robotics#manufacturing#ai#roboticstechno#digitaltransformation#innovation#techtrends#futureofwork#smartfactory#industrialautomation#productivity#workplacesafety#efficiency#humanrobotcollabration#roboticsindustry#advancedmanufacturing

2 notes

·

View notes

Text

Innovations in Manufacturing: Smart Factory Technology at the Forefront

Are you ready to take your manufacturing process to the next level? Look no further than iPlus MOBOT's innovative Smart Factory Technology. With IPLUSMOBOT ‘s Smart Factory Technology, you can streamline your manufacturing process, reduce downtime, and increase productivity. Our technology allows for real-time data monitoring and analysis, enabling you to make informed decisions and optimize your operations. iPlus MOBOT's Smart Factory Technology is at the forefront of the manufacturing industry, utilizing cutting-edge technology such as the Internet of Things (IoT), artificial intelligence (AI), and machine learning (ML). With our technology, you can automate routine tasks, reduce errors, and enhance quality control.

#SmartFactoryTechnology#ManufacturingInnovations#Industry40#DigitalManufacturing#AutomatedManufacturing#IoTinManufacturing#AIinManufacturing

2 notes

·

View notes

Photo

Robotics System Toolbox helps to design, simulate, and test manipulators, mobile robots, and humanoid robots in a single integrated design environment. #roboticautomation #robots #armrobots #automation #automationsystems #enstein_project #manufacturingindustry #productdesign #prototyping #fabrication #innovation #technology #enstein #industry40 #industrial_automation #industrialdesign #robotics #manufacturingprocess #roboticsengineering (at Enstein-Robots & Automations Pvt Ltd.) https://www.instagram.com/p/CpUW5ujLD0i/?igshid=NGJjMDIxMWI=

#roboticautomation#robots#armrobots#automation#automationsystems#enstein_project#manufacturingindustry#productdesign#prototyping#fabrication#innovation#technology#enstein#industry40#industrial_automation#industrialdesign#robotics#manufacturingprocess#roboticsengineering

2 notes

·

View notes

Text

#Biesse#precision#INDIAWOOD2025#WoodworkingTech#SmartManufacturing#Automation#Industry40#SustainableWoodworking#Innovation#powerelectronics#powermanagement#powersemiconductor

0 notes

Text

Manufacturing ERP Software: The Ultimate Solution for Growth & Efficiency

Looking to streamline your production process? Manufacturing ERP Software is the answer to streamlining production, lowering costs, and making things more efficient. From real-time inventory management to workflows in automation, a strong ERP for manufacturing assists companies in expanding faster with improved resource planning and data-driven decision-making. Make productivity better, reduce waste, and lead the market with the appropriate ERP solution. Don't hold back—improve your business today!

#ManufacturingERP#ERPSoftware#ERPforManufacturing#BusinessAutomation#Industry40#SmartManufacturing#ProductionManagement#SupplyChainManagement#EnterpriseSoftware#ManufacturingSolutions#CostEfficiency#WorkflowAutomation#DigitalTransformation#FactoryManagement#ProcessOptimization

0 notes

Text

A Smart Manufacturing Certificate from NAMTECH empowers you with cutting-edge skills in automation, AI, IoT, and data analytics, preparing you for high-demand roles in Industry 4.0. Gain industry-recognized expertise, enhance your career prospects, and stay ahead in the future of advanced manufacturing.

0 notes

Text

AI Meets Automation: Transforming Industrial Productivity for the Future

Discover how AI-driven automation is revolutionizing industries, enhancing efficiency, reducing costs, and driving the future of smart manufacturing. Learn about predictive maintenance, quality control, IoT integration, and AI-powered robotics shaping Industry 4.0. Stay ahead with advanced Industrial Automation Solutions in Ahmedabad and Gujarat. 🚀 #IndustrialAutomation #AI #SmartFactories

#IndustrialAutomation#AIinManufacturing#AutomationSolutions#SmartFactories#Industry40#PredictiveMaintenance#AutomationGujarat#AhmedabadTechnology

0 notes

Text

Enterprise Energy Management: The Key to Smarter, Cost-Effective & Sustainable Manufacturing

In today's rapidly evolving industrial landscape, manufacturing enterprises are under increasing pressure to balance operational efficiency, cost-effectiveness, and sustainability. As energy consumption continues to rise, companies are turning to Enterprise Energy Management (EEM) as a strategic solution to meet these challenges head-on.

What is Enterprise Energy Management?

Enterprise Energy Management (EEM) involves the systematic approach to managing energy use across an entire organisation. By leveraging advanced technologies, data analytics, and real-time monitoring, businesses can optimise their energy consumption, reduce costs, and lower their environmental impact.

EEM integrates energy data with the broader operational framework of a company, enabling more informed decision-making at all levels of the organisation—from the factory floor to the boardroom. This holistic view allows businesses to identify inefficiencies, reduce waste, and unlock significant cost savings while contributing to sustainability goals.

The Benefits of Implementing EEM in Manufacturing

Cost Reduction: One of the most immediate advantages of EEM is its potential to reduce energy costs. By gaining a granular understanding of energy usage patterns and identifying areas of inefficiency, businesses can take proactive measures to optimise consumption, avoiding wasteful energy use. For example, automating energy-intensive processes during off-peak hours or adjusting equipment performance based on demand can result in significant savings.

Sustainability and Compliance: With growing global pressure to meet environmental regulations and corporate social responsibility (CSR) goals, EEM enables manufacturers to stay ahead of sustainability requirements. Through energy optimisation and the integration of renewable energy sources, businesses can reduce their carbon footprint, minimise resource consumption, and support green initiatives—fostering a positive corporate image and enhancing brand value.

Improved Operational Efficiency: EEM solutions provide real-time insights into energy consumption, empowering manufacturers to pinpoint inefficiencies and implement improvements swiftly. By integrating energy management with broader enterprise resource planning (ERP) systems, manufacturers can align their energy strategies with production schedules, machinery maintenance, and workforce planning, leading to smoother operations and enhanced productivity.

Enhanced Data-Driven Decision Making: EEM platforms utilise data analytics to deliver actionable insights into energy performance across the enterprise. By leveraging historical energy data and predictive analytics, companies can make more informed decisions about future energy investments and anticipate demand fluctuations. The ability to forecast energy needs with precision allows businesses to better manage energy procurement strategies and optimise pricing.

Key Technologies Supporting EEM

To unlock the full potential of EEM, manufacturers are turning to advanced technologies such as:

IoT (Internet of Things): Smart sensors embedded in machinery and equipment provide real-time data, allowing for continuous monitoring and analysis of energy consumption.

AI and Machine Learning: These technologies enable predictive analysis, helping manufacturers to optimise energy use proactively and automatically adjust operations to enhance efficiency.

Cloud Computing: Cloud-based platforms offer scalable solutions for managing vast amounts of energy data across multiple locations, giving manufacturers the flexibility to analyse and manage energy consumption from anywhere.

Automation and Smart Grids: Automation tools, coupled with intelligent grid systems, allow manufacturers to optimise energy distribution, automate energy-saving actions, and seamlessly integrate renewable energy sources into operations.

Challenges and Solutions in Implementing EEM

While the benefits of EEM are undeniable, its implementation can be complex. Challenges such as legacy infrastructure, data integration issues, and resistance to change can slow down the process. However, manufacturers can overcome these hurdles by taking a phased approach:

Start by integrating energy management with existing enterprise systems to avoid large-scale disruptions.

Invest in employee training to foster a culture of energy efficiency.

Collaborate with energy management solution providers to develop customised systems that align with business objectives and operational needs.

The Future of Enterprise Energy Management

As energy costs continue to rise and sustainability becomes an even greater priority, the future of EEM looks promising. The adoption of smart manufacturing technologies, such as the Industrial Internet of Things (IIoT) and predictive analytics, will provide manufacturers with more granular control over their energy usage, enabling further optimisations.

Moreover, with the increasing availability of green energy solutions, businesses will be able to power their operations more sustainably, reducing their reliance on non-renewable sources.

Conclusion

Enterprise Energy Management is more than just a cost-saving tool—it’s a key driver for smarter, more efficient, and sustainable manufacturing. By leveraging advanced technologies, data analytics, and automation, manufacturers can not only optimise their energy consumption but also contribute to a greener future. As the business world continues to embrace digital transformation, EEM stands out as a critical element for companies seeking to stay competitive, reduce costs, and achieve their sustainability goals.

Embracing EEM now can provide manufacturers with a strong foundation for the future—delivering long-term value, reduced operational costs, and a more sustainable business model.

#EnterpriseEnergyManagement#EnergyEfficiency#SustainableManufacturing#SmartManufacturing#GreenTech#Industry40#EnergyManagement#IoTInManufacturing#SmartFactories#CarbonFootprintReduction#SustainableBusiness#DigitalTransformation#ManufacturingTech#EcoFriendlyIndustry#SmartEnergySolutions#IndustrialIoT#FutureOfManufacturing

0 notes

Text

Unlock Precision with Dynalog’s Expert Robot TCP Calibration Services

In today’s fast-paced manufacturing world, precision is everything. That’s where Dynalog’s Robot TCP Calibration services come into play, ensuring your robotic systems operate with unmatched accuracy and efficiency. Let’s explore why Robot TCP (Tool Center Point) Calibration is vital and how Dynalog leads the industry with cutting-edge solutions.

📌 What is Robot TCP Calibration?

Robot TCP Calibration is the process of accurately identifying the tool center point—the exact position on the robot where tasks like welding, drilling, or assembly occur. A well-calibrated TCP allows robots to follow programmed paths precisely, reducing errors and improving performance.

⚙️ Why is Robot TCP Calibration Important?

✅ Increased Accuracy: Proper calibration ensures that robots perform tasks precisely without deviations.

✅ Improved Efficiency: Minimizes downtime caused by misalignment or rework.

✅ Longer Tool Life: Reduces wear and tear on robotic components.

✅ Consistent Quality: Maintains uniformity in production processes.

🛠️ How Dynalog Excels in Robot TCP Calibration

Dynalog is a trusted leader in the robotics industry, known for its advanced solutions in calibration and inspection. Here’s what sets us apart:

📊 1. Advanced Calibration Technology

We use state-of-the-art measurement systems and software to ensure your robots are calibrated with maximum precision. Our solutions are compatible with leading robot brands, ensuring seamless integration.

🧠 2. Expert Engineering Support

Our team of experienced engineers provides expert guidance throughout the calibration process. We don’t just fix issues—we prevent them.

🚀 3. Faster Turnaround Times

Time is money. Our efficient calibration process reduces downtime, keeping your operations running smoothly.

📈 4. Continuous Monitoring & Optimization

We don’t stop at calibration. Our solutions include tools for continuous performance monitoring and optimization to maintain peak efficiency.

💡 Industries That Benefit from Dynalog’s Robot TCP Calibration

Automotive: Ensure precise welding and assembly.

Aerospace: Achieve high accuracy in drilling and component fitting.

Electronics: Maintain quality during intricate assembly processes.

Medical Devices: Guarantee precision in delicate manufacturing tasks.

✅ The Dynalog Advantage in Robotic Calibration

Proven Expertise: 20+ years in robotic calibration and inspection.

Innovative Solutions: Cutting-edge technology for accurate results.

Customer-Centric Approach: Solutions tailored to your industry’s needs.

End-to-End Support: From consultation to implementation.

📞 Get Started with Dynalog Today

Ready to optimize your robotic operations with precise Robot TCP Calibration? Partner with Dynalog and experience the difference. Contact us for a consultation and discover how our solutions can drive your success.

#RobotTCPCalibration#RoboticCalibration#Dynalog#IndustrialAutomation#Robotics#PrecisionEngineering#AutomationSolutions#SmartManufacturing#Industry40#RoboticsTechnology#ManufacturingInnovation

1 note

·

View note

Text

#Semiconductor_Manufacturing_Equipment is the backbone of modern technology, enabling the production of advanced microchips for electronics, AI, and automation. Precision, innovation, and efficiency drive the future of chipmaking.

#SemiconductorManufacturing#ChipMaking#TechInnovation#Semiconductors#AdvancedManufacturing#NanoTechnology#Electronics#Automation#FutureOfTech#Microchips#AI#SmartTechnology#Engineering#Industry40

0 notes

Text

Leading IoT Product Development Companies Driving Innovation

IoT product development companies are revolutionizing industries with cutting-edge smart solutions, integrating AI, cloud computing, and edge technologies. These companies specialize in designing and developing connected devices, ensuring seamless communication, security, and efficiency across various sectors like healthcare, automotive, industrial automation, and smart homes. Explore the top Top Hardware Design Companies in India firms that are transforming the future of connected technology with innovative hardware, software, and end-to-end IoT solutions.

#IoTIndia#TechInnovation#SmartSolutions#DigitalTransformation#AIoT#ConnectedDevices#Industry40#FutureTech#IoTStartups#SmartCities

0 notes

Text

Unlock Your Future in Smart Industries with IIoT!

The rapid advancement of technology has transformed industries across the globe, and the Industrial Internet of Things (IIoT) is at the forefront of this revolution. As industries move towards automation, smart factories, and real-time data-driven decision-making, IIoT is becoming an essential skill set for professionals.

Sharadha Skill Academy proudly presents an exclusive Industrial Internet of Things (IIoT) course designed to equip learners with hands-on experience, real-world applications, and industry-relevant knowledge. This comprehensive program will empower professionals and students alike to excel in the field of industrial automation and smart manufacturing.

Why Choose the IIoT Course at Sharadha Skill Academy?

✅ Practical Learning – Gain hands-on experience with IoT devices and industrial automation. ✅ Expert Guidance – Learn from industry professionals with years of experience. ✅ Career Advancement – Enhance your job prospects in the rapidly growing IoT sector. ✅ Affordable Fees – High-quality education at a reasonable cost. ✅ Limited Seats – Ensuring personalized attention and better learning outcomes.

Course Details

📅 Start Date: 3rd February 2025 ⏳ Duration: 5 Weeks 💰 Course Fee: ₹12,500

This course is meticulously designed to cover key aspects of IIoT, including:

Introduction to IIoT and Industry 4.0 – Understanding the evolution of industrial automation.

IoT Device Integration and Communication Protocols – Learning about MQTT, OPC UA, and Modbus.

Cloud Computing and Data Analytics in IIoT – Harnessing the power of cloud platforms.

Cybersecurity and Risk Management in Industrial Environments – Safeguarding industrial networks.

Who Should Enroll?

This course is perfect for:

Engineering students and graduates – Looking to build a strong foundation in IIoT.

Working professionals in manufacturing, IT, and automation sectors – Aiming for career growth and upskilling.

Entrepreneurs and business owners – Seeking to integrate IoT solutions in their operations.

What You Will Gain?

A deep understanding of IIoT concepts and their applications.

The ability to design and implement IIoT solutions for industries.

Hands-on experience with industry-grade IoT hardware and software.

Exposure to real-time industrial challenges and their solutions.

A certification that enhances your professional credentials.

The confidence to work in IIoT-related job roles and projects.

Enroll Now – Limited Seats Available!

Don’t miss out on this chance to upskill and future-proof your career in smart industries. With industries increasingly adopting IIoT for efficiency, sustainability, and automation, now is the perfect time to gain expertise in this transformative technology. Secure your seat today!

🌐 Website: sharadhaskillacademy.org 📞 Contact Us: +91 73977 88918 / 917 / 915 📍 Location: Sharadha Skill Academy, KG Garden City, Commercial Building 3rd Floor, Vedapatti, Via Nagarajapuram to Perur Road, Coimbatore – 641007, TN

Invest in your future – learn IIoT and take your career to the next level with Sharadha Skill Academy!

#IIoT#IndustrialAutomation#SmartIndustries#IoT#Industry40#Automation#Technology#SkillDevelopment#CareerGrowth#SharadhaSkillAcademy#TechTraining#CyberSecurity#CloudComputing#PredictiveMaintenance#SCADA#PLC#EdgeComputing#AI#MachineLearning#DataAnalytics#SmartManufacturing#TechInnovation#FutureSkills#HandsOnTraining#ProfessionalCertification#IndustrialRevolution#IoTSolutions#Engineering#Entrepreneurship#IndustrialEngineers

0 notes

Text

The Future of Industrial Lubricants: Driving Efficiency and Sustainability in Modern Industries

In today’s industrial landscape, the role of industrial lubricants is more critical than ever. From towering manufacturing plants to high-precision automotive assembly lines, lubricants are the unsung heroes that keep machinery running smoothly, reduce wear and tear, and ensure operational efficiency. But as industries evolve, so do the demands placed on these essential fluids. The future of industrial lubricants is not just about reducing friction—it’s about driving sustainability, embracing innovation, and meeting the challenges of a rapidly changing world.

The Evolving Role of Industrial Lubricants

Industrial lubricants have come a long way from being simple oils and greases. Today, they are sophisticated formulations designed to meet the specific needs of modern machinery and processes. With industries increasingly adopting automation, IoT, and Industry 4.0 technologies, the demand for high-performance lubricants has surged. These advanced fluids are engineered to:

Minimize friction and heat generation in high-speed operations.

Extend equipment lifespan by reducing wear and corrosion.

Enhance energy efficiency by optimizing machinery performance.

But the story doesn’t end there. As global industries face mounting pressure to reduce their environmental footprint, lubricants are also evolving to support sustainability goals.

Key Trends Shaping the Industrial Lubricants Market

The global industrial lubricants market, valued at USD 63.9 billion in 2024, is expected to reach USD 74.3 billion by 2029, growing at a CAGR of 3.1%. This growth is driven by rising demand from industries like construction, mining, agriculture, and marine, as well as the increasing automation of manufacturing processes. Additionally, advancements in lubricant technology and the growing need for processed food are boosting market consumption, making the outlook for industrial lubricants highly promising.

1. Sustainability Takes Center Stage

The push for greener operations has led to the development of bio-based and eco-friendly lubricants. These products are derived from renewable resources and are biodegradable, making them a safer choice for the environment. For instance, industries are increasingly adopting vegetable oil-based lubricants and synthetic esters that offer superior performance while aligning with sustainability initiatives.

2. Smart Lubricants for Smart Factories

The rise of Industry 4.0 has ushered in a new era of smart manufacturing, where machinery is interconnected and data-driven. In this context, smart lubricants are emerging as a game-changer. These lubricants are embedded with sensors that monitor viscosity, temperature, and contamination levels in real-time, enabling predictive maintenance and reducing unplanned downtime.

3. High-Performance Solutions for Extreme Conditions

Industries such as energy, aerospace, and metals operate under extreme conditions, requiring lubricants that can withstand high temperatures, heavy loads, and corrosive environments. Advanced formulations like synthetic lubricants and solid-film lubricants are being developed to meet these challenges, ensuring reliability and performance even in the harshest conditions.

Real-World Applications Across Industries

Manufacturing

In manufacturing plants, lubricants play a crucial role in maintaining the efficiency of CNC machines, conveyors, and robotic arms. By reducing friction and wear, they help minimize downtime and improve productivity.

Automotive

The automotive industry relies on lubricants for everything from engine oils to transmission fluids. With the rise of electric vehicles (EVs), there’s a growing demand for specialized lubricants that can handle the unique requirements of EV components, such as batteries and electric motors.

Energy

In the energy sector, lubricants are essential for the smooth operation of wind turbines, gas compressors, and hydraulic systems. The shift toward renewable energy sources like wind and solar has further increased the need for high-performance lubricants that can operate efficiently in demanding environments.

Metals and Mining

The metals and mining industry faces some of the toughest operating conditions, with heavy machinery exposed to dust, heat, and moisture. Here, lubricants are critical for preventing equipment failure and ensuring safety.

Actionable Insights for Businesses

1. Choose the Right Lubricant

Not all lubricants are created equal. Businesses must select products that are tailored to their specific machinery and operating conditions. Consulting with lubricant experts can help identify the best solutions for your needs.

2. Embrace Predictive Maintenance

By integrating IoT-enabled lubricants and monitoring systems, businesses can move from reactive to predictive maintenance. This approach not only reduces downtime but also lowers maintenance costs.

3. Prioritize Sustainability

Switching to eco-friendly lubricants can help businesses meet regulatory requirements and enhance their brand reputation. Look for products with certifications like ISO 14001 or Ecolabel.

The Road Ahead: A Greener, Smarter Future

As industries continue to evolve, so will the role of industrial lubricants. The future will see a greater emphasis on sustainability, innovation, and digital integration. Lubricants will no longer be just a maintenance tool—they will be a strategic asset that drives efficiency, reduces environmental impact, and supports the transition to smarter, more connected factories.

Download Sample Report : For businesses, staying ahead of these trends will be key to maintaining a competitive edge. By investing in the right lubricants and adopting advanced maintenance practices, industries can unlock new levels of performance and sustainability. The future of industrial lubricants is bright, and it’s time to embrace the change. After all, in the world of modern industry, every drop counts.

#IndustrialLubricants#Sustainability#Industry40#Efficiency#Manufacturing#Automotive Energy#FutureTech#PredictiveMaintenance#GreenSolutions

0 notes

Text

Manufacturing Software Development Company vs. In-House Development: Which is Better?

In the fast-evolving world of manufacturing, technology plays a crucial role in streamlining operations, improving productivity, and driving innovation. One critical decision businesses face is whether to partner with a manufacturing software development company or invest in building an in-house development team. Each approach has its merits and challenges, and the right choice depends on a company's goals, resources, and long-term strategy.

Understanding In-House Development

In-house development involves hiring manufacturing software developers, designers, and engineers who work exclusively on the company's software needs. This model offers the benefit of control and customization. Businesses can directly oversee the development process, ensuring that the software is tailored to their exact requirements.

However, building an in-house team comes with significant challenges:

High Costs: Recruiting skilled developers, training them, and providing the necessary infrastructure can be expensive. Ongoing costs such as salaries, benefits, and software tools add to the burden.

Time-Consuming: Assembling a team, defining the scope, and developing software from scratch is time-intensive, potentially delaying time-to-market.

Skill Gaps: Manufacturing requires niche expertise, and it might be challenging to find developers proficient in the specific technologies needed for industry-specific solutions.

The Case for Partnering with a Manufacturing Software Development Company

Collaborating with a manufacturing software development company has emerged as a preferred option for many manufacturers. These companies specialize in creating tailored solutions for the manufacturing sector, offering expertise and efficiency that in-house teams often lack.

Here are some compelling reasons to choose this route:

Cost-Effectiveness: Partnering with an external company eliminates the need for upfront investments in hiring, training, and infrastructure. Most firms offer flexible pricing models, allowing businesses to pay only for the services they need.

Access to Expertise: A manufacturing software development company employs professionals with extensive knowledge of manufacturing processes and the latest technologies. This ensures the development of solutions that align with industry best practices.

Faster Time-to-Market: With pre-existing tools, templates, and frameworks, these companies can accelerate the development process, giving manufacturers a competitive edge.

Scalability: As businesses grow, software needs may evolve. Development companies offer scalable solutions, allowing manufacturers to adapt without the hassle of restructuring an in-house team.

Key Factors to Consider

Choosing between in-house development and a manufacturing software development company depends on several factors:

Budget: Companies with limited budgets often find external development more cost-effective.

Project Complexity: For highly specialized or complex projects, the expertise of an external company is invaluable.

Long-Term Needs: Businesses with ongoing and diverse development requirements might benefit from an in-house team.

Conclusion

For most manufacturers, partnering with a manufacturing software development company offers unparalleled advantages in terms of cost, expertise, and speed. While in-house development provides control, it demands significant investment and resources. By leveraging the specialized knowledge and flexibility of external partners, manufacturers can focus on their core operations while staying ahead in the technological race.

0 notes

Text

https://electronicsbuzz.in/embedded-systems-in-manufacturing-powering-the-next-generation-of-smarttechnology/

#Embeddedsystems#automation#precision#and scalability.#SmartManufacturing#Industry40#Automation#AI#IoT#EdgeComputing#DigitalTransformation#powerelectronics#powermanagement#powersemiconductor

0 notes