#manufacturingprocess

Explore tagged Tumblr posts

Text

youtube

vertical lathe tooling,Double Helical Gear,rolling mill,3.5 ton Double Helical Gear, british vertical lathe, DoubleHelicalGear, helical gear manufacturing,double helical gear design,Lathe technique,metal turning,how to turn,3 ton complete process,Manufacturing process of Double Helical Gear,Metal turning / how to turn 3Ton Double Helical Gear smarter than others,craftsmanship,150yrs,manufacturing process,cutting edge engineering australia, how to make

Lathe technique making gear with a lathe Metal Turning /how to turn How to turn 3.5 ton double helical gear smarter than others Manufacturing process of Double Helical Gear 150yrs old British vertical lathe tooling - 3.5 ton Double Helical Gear for rolling mill how to make 150yrs old British vertical lathe tooling Complete Process of Machining & Tempering Double Helical Gear 3.5 ton Double Helical Gear for rolling mill 150yrs old British Workmanship vertical lathe tooling 3.5 ton Double Helical Gear for rolling mill Vintage Lathe Double Helical Gear Engineering Heritage Craftsmanship Industrial History restoration British Lathe precision machining helical gear manufacturing double helical gear design old school hack manufacturing process

#mechanical engineering#auto repairs#mechanical#monster engines#engines#manufacturingprocess#3.5tondoublehelicalgear#double helical gear design#double helical gear#rollingmill#Britishverticallathe#150yrs#doublehelicalgear#manufacturing process of double helical gear#Youtube

2 notes

·

View notes

Photo

Robotics System Toolbox helps to design, simulate, and test manipulators, mobile robots, and humanoid robots in a single integrated design environment. #roboticautomation #robots #armrobots #automation #automationsystems #enstein_project #manufacturingindustry #productdesign #prototyping #fabrication #innovation #technology #enstein #industry40 #industrial_automation #industrialdesign #robotics #manufacturingprocess #roboticsengineering (at Enstein-Robots & Automations Pvt Ltd.) https://www.instagram.com/p/CpUW5ujLD0i/?igshid=NGJjMDIxMWI=

#roboticautomation#robots#armrobots#automation#automationsystems#enstein_project#manufacturingindustry#productdesign#prototyping#fabrication#innovation#technology#enstein#industry40#industrial_automation#industrialdesign#robotics#manufacturingprocess#roboticsengineering

2 notes

·

View notes

Text

Every masterpiece begins with skilled hands and a passionate heart! ❤Experience true craftsmanship with DMAASA.

Want to see more behind-the-scenes? Follow us for more!

#Dmaasa#Dmaasain#wintercomforts#homedecor#beddingessentials#duvet#artisansofindia#behindthescenes#BTS#manufacturingprocess

0 notes

Text

The Manufacturing Process of High-Quality Stud Bolts Explained | Step-by-Step Guide

If you work in construction, oil and gas, or heavy machinery, you know that high-quality stud bolts are essential for structural integrity and durability. But have you ever wondered how these bolts are made?

Manufacturing industrial-grade stud bolts involves a step-by-step precision process that ensures strength, accuracy, and long-term performance. In this guide, I’ll walk you through the entire manufacturing process of high-quality stud bolts, from raw material selection to final inspection.

By the end, you’ll understand what makes a stud bolt reliable, corrosion-resistant, and fit for demanding environments. This knowledge will also help if you're sourcing other fasteners like foundation bolts, foundation J bolts, U bolts, or U clamps from a trusted anchor bolt manufacturer.

Raw Material Selection

The process starts with choosing the right raw material. The most common materials for stud bolts and foundation bolts include:

Carbon steel – Ideal for general applications requiring moderate strength.

Alloy steel – Provides higher strength and heat resistance, commonly used in oil and gas.

Stainless steel – Offers excellent corrosion resistance, perfect for marine and chemical environments.

The quality of the raw material directly affects the strength, durability, and load-bearing capacity of the stud bolt, foundation J bolts, and U bolts. Leading stainless steel U bolt manufacturers ensure that their products meet ASTM, ASME, or DIN standards, ensuring reliability in demanding conditions.

Cutting and Shaping the Stud Bolt

Once the raw material is selected, it is cut into precise lengths using:

Shearing machines for fast and efficient cutting.

Bandsaws or circular saws for more precise cuts, ensuring uniformity.

The cut metal pieces, also called billets, are then shaped to the required diameter and length based on the specifications of the stud bolt, foundation bolts, or U bolts.

Thread Rolling and Heat Treatment

Thread Rolling Process

The next critical step is creating precise, strong, and uniform threads on the stud bolts. Manufacturers use:

Thread rolling machines for cold-forming the threads, ensuring a stronger grain structure.

Cut threading for specialty foundation J bolts and U bolts where precise customization is needed.

Cold-rolled threads are preferred in high-performance applications because they increase fatigue resistance and durability.

Heat Treatment for Strength

To enhance mechanical properties, stud bolts, foundation bolts, and U bolts undergo heat treatment, which includes:

Hardening and tempering – Improves tensile strength and wear resistance.

Quenching and annealing – Reduces internal stresses, preventing cracks and failures.

Heat treatment plays a vital role in improving the overall toughness of the stud bolt, foundation J bolts, and U clamps, making them capable of withstanding extreme loads and temperatures.

Surface Coating and Finishing

To ensure corrosion resistance and longevity, the stud bolts, foundation bolts, and U bolts are coated using different protective finishes, such as:

Zinc plating – Prevents rust and oxidation in mild environments.

Hot-dip galvanizing – Ideal for outdoor and marine applications.

Teflon coating – Provides high resistance to chemicals and extreme temperatures.

Black oxide treatment – Enhances wear resistance and aesthetics.

The choice of coating depends on the application requirements, ensuring the stud bolts, foundation J bolts, and clamps can withstand harsh environments without degrading.

Quality Inspection and Testing

Before stud bolts, U bolts, and foundation bolts are shipped, they go through rigorous quality testing to meet industry standards. These tests include:

Dimensional accuracy check – Ensures the bolt meets exact length and diameter specifications.

Thread inspection – Verifies correct thread depth, pitch, and alignment.

Hardness and tensile strength testing – Confirms the bolt can handle required loads.

Corrosion resistance testing – Checks for durability in extreme conditions.

High-quality stud bolts, U bolts, and foundation J bolts must pass all these tests before they are approved for industrial use.

Packaging and Distribution

Once the stud bolts, foundation bolts, and U clamps pass quality control, they are carefully packaged and labeled to prevent damage during shipping.

Packaging options include:

Plastic-wrapped bundles for standard shipments.

Wooden crates for large, heavy-duty orders.

Vacuum-sealed bags for moisture-sensitive applications.

Reputable anchor bolt manufacturers ensure that their products reach customers with proper documentation, including material test reports (MTRs) and compliance certificates.

Conclusion

Manufacturing high-quality stud bolts involves multiple precision-driven steps, from selecting raw materials to applying protective coatings. Every stage—cutting, thread rolling, heat treatment, and testing—plays a vital role in ensuring durability and performance.

If you’re looking for industrial-grade stud bolts, foundation bolts, or U bolts, always choose a manufacturer that follows strict quality control measures and international standards. Leading stainless steel U bolt manufacturers and U clamp manufacturers ensure their products are built to last, even in harsh environments.

The right stud bolts and foundation J bolts can enhance safety, longevity, and reliability in demanding industries. Now that you understand the manufacturing process of high-quality stud bolts, you can make an informed decision when selecting bolts, clamps, and fasteners for your projects.

#StudBolts#ManufacturingProcess#IndustrialFasteners#BoltsAndNuts#PrecisionEngineering#MetalFabrication

0 notes

Text

Maximize your flow efficiency with our Gate Valves – designed to offer minimal resistance for unrestricted flow when fully open. These valves provide a tight seal to effectively stop fluid flow when closed, ensuring reliable performance in various applications. With options like wedge, parallel, and knife gate valves, there's a solution for every need, whether you're handling regular fluids or abrasive materials.

For more details, visit- https://www.primevalvesindia.com/products/gate-valve

#primeindustrialvalves#industrailvalve#gatevalves#gatevalve#industrialgatevalve#gatevalvemanufacturer#gatevalvesupplier#watersupplysystem#watertreatmentplant#oilindustry#GasIndustry#manufacturingprocess

0 notes

Text

🌟 Revolutionizing Manufacturing: The Power of Polyurethane Sheets! 🌟

🔧 Polyurethane sheets are transforming the manufacturing and processing industries with their exceptional versatility and durability. Our latest blog post delves into the diverse applications of PU sheets and how our custom processing services can meet your large-scale plastic procurement and OEM needs.

#polyurethane#manufacturingprocess#manufacturing#processingindustry#customsolutions#engineering#oem#plastic products#innovation#materialscience#industrial design#technology#futuretech#sustainability#ecoideas

1 note

·

View note

Text

Manufacturing Execution Systems: Revolutionizing the Manufacturing Industry

Efficiency, precision, and flexibility are essential for success. As technology continues to evolve, Manufacturing Execution Systems (MES) have emerged as a vital tool to streamline operations, improve productivity, and ensure product quality. These systems bridge the gap between the shop floor and the top-floor systems, such as Enterprise Resource Planning (ERP) solutions, enabling manufacturers to control and monitor the entire production process in real-time.

What Are Manufacturing Execution Systems?

A Manufacturing Execution System (MES) is a comprehensive software platform that manages and monitors the production floor in real-time. It serves as the nerve center of a manufacturing plant, tracking every detail of the production process from raw material acquisition to finished product delivery. By integrating MES with other systems, manufacturers gain deeper insights into production performance, enabling more informed decision-making and operational improvements.

Key functions of an MES include:

Production scheduling: Ensuring that production processes are optimized and executed on time.

Real-time monitoring: Offering visibility into all aspects of the manufacturing process, including machine performance, material flow, and labor efficiency.

Quality management: Ensuring that products meet required specifications and quality standards.

Data collection and reporting: Providing real-time data on production metrics, performance, and outcomes.

Traceability: Offering the ability to trace materials and components throughout the production cycle for compliance and quality assurance.

How Manufacturing Execution Systems Work

Manufacturing Execution Systems are designed to gather data from machines, production lines, and workers on the factory floor. This information is processed in real-time, providing manufacturers with a clear overview of the status of production, inventory levels, machine health, and operator performance. Through continuous monitoring and control, MES helps optimize every step of the production process.

Enterprise Resource Planning (ERP): Coordinating high-level business activities, such as procurement, inventory management, and customer order fulfillment.

Supervisory Control and Data Acquisition (SCADA): Controlling equipment and collecting data from industrial systems.

Product Lifecycle Management (PLM): Managing product development and design processes.

By linking these systems together, MES acts as the connective tissue that ensures smooth communication and coordination across the entire manufacturing enterprise.

The Benefits of Implementing MES:

The advantages of using Manufacturing Execution Systems are manifold, helping businesses maintain a competitive edge in the global marketplace:

1. Increased Efficiency and Productivity

With real-time data collection and automated decision-making, MES helps manufacturers reduce downtime and optimize machine utilization. It allows operators to identify production bottlenecks and adjust workflows in real-time, ensuring that production stays on track.

2. Enhanced Quality Control

Quality is paramount in manufacturing, and MES ensures that quality standards are met at every stage of production. By collecting detailed data, manufacturers can spot defects early, prevent costly rework, and maintain compliance with industry regulations.

3. Improved Traceability and Compliance

For industries with strict regulatory requirements, such as food, pharmaceuticals, or aerospace, traceability is critical. MES tracks every material, component, and production step, allowing for complete traceability and ensuring that manufacturers can meet regulatory demands.

4. Cost Reduction

By optimizing production processes, reducing waste, and minimizing machine downtime, MES contributes to significant cost savings. Additionally, better resource utilization and inventory management help manufacturers avoid excess inventory and reduce material costs.

5. Real-Time Visibility

With MES, manufacturers have real-time visibility into their operations. This allows decision-makers to act quickly, prevent disruptions, and ensure smooth production workflows.

Key Features of Manufacturing Execution Systems

Several features define a robust and effective Manufacturing Execution System:

1. Production Monitoring and Control

MES monitors every detail of the production process, from machine performance to operator efficiency. It helps identify potential problems before they cause delays and offers solutions to improve overall productivity.

2. Inventory and Material Management

MES tracks inventory levels in real-time, ensuring that manufacturers have the materials they need when they need them. It also optimizes material flow and reduces waste, contributing to cost savings and improved efficiency.

3. Data Collection and Analysis

The data collected by MES provides valuable insights into production performance, machine efficiency, and quality control. Manufacturers can use this data to improve processes, reduce waste, and enhance product quality.

4. Workforce Management

MES offers tools for managing labor resources, tracking employee performance, and ensuring that workers are following standard operating procedures. It enables managers to allocate resources more effectively and optimize labor productivity.

5. Compliance and Reporting

MES provides real-time data for regulatory reporting, ensuring that manufacturers comply with industry standards. It also enables better traceability for quality assurance and recalls.

The Role of MES in Industry 4.0

The concept of Industry 4.0, also known as the Fourth Industrial Revolution, emphasizes the use of smart technologies, automation, and data exchange in manufacturing processes. Manufacturing Execution Systems play a critical role in this transformation by enabling manufacturers to embrace digitalization and automation.

MES systems facilitate the seamless integration of connected devices, IoT sensors, and automated systems into the production environment. This allows manufacturers to collect vast amounts of data, perform advanced analytics, and drive continuous improvement in their operations.

Additionally, MES enables the implementation of Smart Factories, where machines, systems, and humans interact seamlessly. In a smart factory, MES serves as the command center, coordinating activities, automating processes, and enabling real-time decision-making.

Choosing the Right MES for Your Business

https://enterprisechronicles.com/wp-content/uploads/2024/09/6.3-Choosing-the-Right-MES-for-Your-Business-Source-optiproerp.com_.jpg

Implementing the right Manufacturing Execution System can have a significant impact on your business’s success. When choosing an MES, it’s essential to consider factors such as scalability, ease of integration with existing systems, and industry-specific features.

Before investing in an MES solution, manufacturers should assess their current operations, identify areas for improvement, and establish clear goals for what they want the system to achieve. Working with experienced vendors who understand your industry is also crucial to ensuring a smooth implementation and maximizing the return on investment.

Conclusion

In conclusion, Manufacturing Execution Systems (MES) are essential tools for modern manufacturers looking to optimize their production processes, improve quality control, and enhance overall efficiency. With its real-time data collection, seamless integration with other systems, and robust reporting capabilities, MES helps manufacturers stay competitive in an ever-changing global marketplace. As industries continue to evolve toward Industry 4.0 and smart factories, the role of MES will only become more critical in driving innovation and operational success.

#manufacturing#engineering#manufacturingindustry#mechanicalengineering#manufacturer#manufacturingprocess#follow#industry#leanmanufacturing#manufacturingservices#americanmanufacturing#machining#gate#industrial

0 notes

Text

Call 9822619307 OR Get it here- https://www.pioneertapes.com/contact-us

#RenovationTips#SurfaceProtection#HomeImprovement#RenovationSafety#HomeRenovation#SurfaceProtectionTape#DamagePrevention#SurfaceProtectionSolutions#ManufacturingProcess#IndustryInnovation#IndustrialTape#TapeManufacturingSolutions#PackagingIndustry#TapeApplication#tapemanufacturer#logisticindustry#Pune#PioneerTapes

0 notes

Video

youtube

Welcome to KD Hardware!

At KD Hardware, we specialize in precision machining using state-of-the-art equipment, including automatic CNC lathes, turn-mill compound lathes, and Swiss-type CNC lathes.

No matter how complex your parts are—whether for prototyping or mass production—we ensure the best manufacturing process tailored to your needs. From metals to plastics and special materials, KD Hardware provides reliable machining services and solutions.

Got questions or specific requirements? Contact us today with your part specifications, and we'll respond promptly.

We look forward to working with you!

#swisscncmachining#manufacturingprocess#cncmachining#machiningprocess#swissscrewmachining#cncswissprecisionmachining#swissturnmachining

0 notes

Text

Tubular heater manufacturers specialize in producing durable, energy-efficient heating elements designed for a wide range of industrial and commercial applications. These heaters are crafted from high-quality materials to ensure optimal performance, reliability, and longevity. With expertise in customization, these manufacturers offer solutions tailored to specific needs, whether for process heating, freeze protection, or other specialized uses.

#TubularHeaters#IndustrialHeating#CommercialHeating#HeatingSolutions#EnergyEfficiency#ManufacturingProcess#CustomHeaters#QualityMaterials#HeaterManufacturers#EnergySavings#IndustrialTechnology

0 notes

Text

Gold Electroplating for Manufacturing Units.

See what our client says about us!

https://www.noblemetalcoating.com/

#goldelectroplating#electroplating#metalfinishing#surfacefinishing#metalcoating#manufacturingprocess#industrialprocess#qualitycontrol#precisionengineering

0 notes

Text

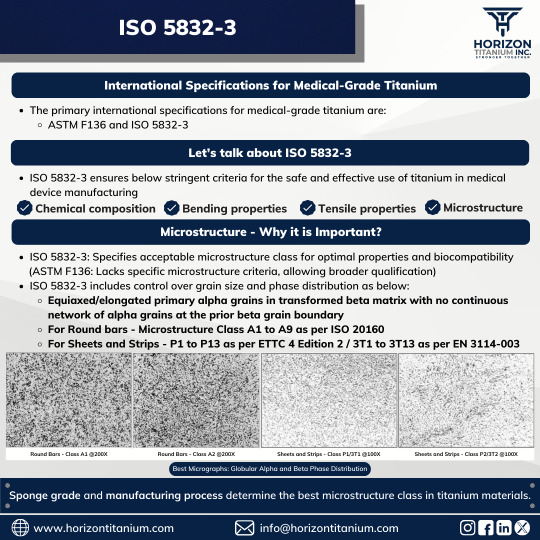

The properties of metals are determined by their metallurgy, and for applications such as medical use, these properties must be optimized. To achieve this, international standards specify the required microstructure. Two key standards for medical titanium materials are ASTM F136 and ISO 5832-3.

ISO 5832-3 defines microstructure classes with specific alpha and beta morphologies and phase distributions, detailed through micrographs. In contrast, ASTM F136 outlines microstructure requirements without specifying exact classes or providing micrographs, thus omitting precise details on alpha and beta phase distributions.

To illustrate this, consider the example of the color blue. ASTM F136 broadly accepts any shade of blue for medical applications. However, ISO 5832-3 specifies exact color codes, categorizing shades from Class Sr. No. A1 to A9, and thus sets rigorous microstructure requirements for medical grades. ASTM F136 lacks this level of detail and does not categorize shades of blue, merely stating that any blue is acceptable for medical use.

Therefore, adhering to the ISO 5832-3 standard is crucial for ensuring the precise microstructure requirements in Titanium materials needed for medical device manufacturing.

To know more about the importance of microstructure in titanium materials for medical applications, write us at [email protected]

#KnowYourTitanium#Titanium#Metallurgy#ISO5832_3#ASTMF136#Microstructure#MicrostructureClass#ISO20160#EN3114_003#SpongeGrade#TitaniumPurity#ManufacturingProcess#Biocompatibility#MaterialsScience#Standards#MedicalGradeTitanium#TitaniumImplants#PrecisionMicrostructure#MedicalDevices#HorizonTitanium#StrongerTogether

0 notes

Text

Understanding the Manufacturing Process of Stainless Steel U Bolts | Key Insights

Let’s briefly define stainless steel U bolts. These fasteners are shaped like the letter "U" with threads on both ends, designed for securing pipes, cables, or any rounded items to surfaces. The stainless steel material ensures strength, durability, and resistance to corrosion, making them ideal for both indoor and outdoor use, especially in environments prone to moisture, chemicals, or extreme temperatures.

Stainless steel U bolts are commonly used in applications such as:

Pipe support systems

Electrical wiring setups

Construction projects

Automotive industries

Marine equipment

With that said, let’s now look at the manufacturing process behind these indispensable components.

The manufacturing of stainless steel U bolts starts with the selection of raw materials. The most commonly used material is stainless steel, which is prized for its strength, resistance to corrosion, and long-lasting durability. The material used is typically a mix of iron, chromium, nickel, and other alloying elements that give the stainless steel its properties.

Common Types of Stainless Steel Used:

304 Stainless Steel: Known for its corrosion resistance and ease of welding, this grade is commonly used for general-purpose applications.

316 Stainless Steel: This grade is highly resistant to chloride corrosion and is ideal for marine and chemical processing environments.

430 Stainless Steel: Used in applications where high corrosion resistance is not a major concern, but strength is still required.

Once the material is chosen, the next step is to prepare the stainless steel for the forming process.

This article ensures that stainless steel U bolts meet industry standards is crucial for their functionality and longevity. Quality control measures include:

Dimensional checks: Verifying that the U bolt meets the required dimensions and tolerances.

Thread inspection: Ensuring that the threads are cut or rolled accurately and that they will accept nuts securely.

Surface finish: Checking that the surface is smooth, free of defects, and polished to the required standard.

Corrosion resistance testing: Ensuring that the bolts can withstand environmental factors like moisture, chemicals, and temperature fluctuations.

Here are the top benefits of using stainless steel U bolts in your projects:

Corrosion Resistance: Stainless steel’s resistance to corrosion makes U bolts perfect for outdoor, marine, or harsh environments.

Durability: The strength of stainless steel ensures that the U bolts last longer and can withstand significant mechanical stress.

Versatility: Stainless steel U bolts can be used across a wide range of industries, from automotive to construction to piping systems.

Ease of Installation: U bolts are relatively easy to install, saving time and labor costs in many applications.

Cost-Effective: While they may be slightly more expensive than other materials, stainless steel U bolts offer long-term savings due to their durability and corrosion resistance.

The manufacturing process of stainless steel U bolts involves several steps, each of which is critical in ensuring the final product is strong, durable, and suitable for a variety of applications. From raw material preparation to threading, finishing, and quality control, each stage ensures that the U bolts perform optimally in demanding environments.

By understanding how stainless steel U bolts are made, you can make better decisions when choosing these fasteners for your next project. Whether you are in construction, automotive, marine, or any other industry, U bolts made from stainless steel provide the strength, corrosion resistance, and durability you need to secure your equipment effectively.

This guide will equip you with the knowledge to take your garment construction skills to the next level and create clothes that look and feel truly professional.

Link

Understanding the Manufacturing Process of Stainless Steel U Bolts | Key Insights

#StainlessSteel#UBolts#ManufacturingProcess#EngineeringInsights#MetalFabrication#IndustrialFasteners

0 notes

Text

Peek into Lakhotia India’s manufacturing process. Quality craftsmanship meets cutting-edge technology. Get an exclusive look at how we craft precision-engineered conveyor belts and motor units, ensuring top-notch quality for your industrial needs. Read more: https://lakhotiaindia.in/ Contact us: +919025194360

#BehindTheScenes#LakhotiaIndia#ManufacturingProcess#QualityCraftsmanship#CuttingEdgeTechnology#PrecisionEngineering#ConveyorBelts#MotorUnits#IndustrialQuality#ExclusiveLook#TopNotchProducts

0 notes

Text

Explore how to manufacture high-quality fly ash bricks with our step-by-step guide. From sourcing materials to the final product, we demystify the process, ensuring efficiency and eco-friendliness. Ideal for builders and entrepreneurs seeking sustainable construction solutions. Explore our blog for comprehensive insights and expert tips.

#FlyAshBricks#ManufacturingProcess#SustainableConstruction#EcoFriendlyBuilding#BuildingMaterials#ConstructionTips

1 note

·

View note

Text

Crafting precision with CNC machining! 🏭✨ Watch as we transform polypropylene sheets into custom solutions for OEM clients. Perfect for large-scale orders and tailored designs. Let's build something amazing together! 🔧

#cncmachining#polypropylene#custommanufacturing#oemsolutions#oem#industrial design#precisionengineering#plasticfabrication#manufacturingprocess#innovation#factorylife#plastics

0 notes