#IndustryInnovation

Explore tagged Tumblr posts

Text

🚀 TURN YOUR IDEAS INTO REALITY WITH OUR EXPERT SOLUTIONS!

At Speeler Technologies, we specialize in transforming concepts into success stories. Whether you need digital marketing, web design, app development, or branding, our dedicated team is here to help your business thrive.

🌟 Why Choose Us?

Expertise: Years of experience and a passion for innovation.

Custom Solutions: Tailored strategies to meet your unique goals.

Proven Results: Real success stories from satisfied clients.

🔍 Curious to Learn More? Wondering how we can bring success to your next project? Contact us today and let’s discuss how we can turn your ideas into reality.

WhatsApp: https://wa.me/918985992323

#clientsuccess#projectshowcase#industryinnovation#expertiseshowcase#businessachievement#speelertechnologies#speeler

2 notes

·

View notes

Text

Don’t get left behind! v4holt is revolutionizing industries worldwide. 🔥 Find out how you can embrace this change and skyrocket your success.

#v4holt#IndustryInnovation#TechTrends#BusinessGrowth#FutureOfWork#BusinessRevolution#IndustrySolutions#EmergingTech#DigitalInnovation

0 notes

Text

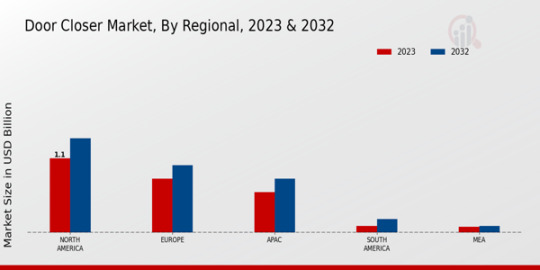

🌍🚪 Global Door Closer Market: Rising Trends & Future Prospects 📈

The global door closer market is witnessing steady growth due to rising demand for security and accessibility solutions in residential, commercial, and industrial spaces. The increasing focus on energy efficiency and compliance with safety regulations is further fueling market expansion.

Door closers play a crucial role in ensuring controlled door movements, preventing unauthorized access, and enhancing convenience in high-traffic areas.

Key Market Drivers

Growing Demand for Safety and Security Solutions: With increasing concerns over security in both residential and commercial buildings, the adoption of door closers has become essential. These devices contribute to controlled access, fire safety, and enhanced building security.

Expansion in Construction and Infrastructure Development: The rapid rise in urbanization and infrastructure development has led to increased installations of door closers. New commercial and residential projects require advanced door-closing mechanisms, driving market growth.

Technological Advancements: Innovations in door closer mechanisms, including automatic and smart door closers integrated with IoT, are gaining traction. These advancements offer convenience, remote control functionality, and energy-efficient operations.

Emphasis on Energy Efficiency: Door closers contribute to energy conservation by ensuring that doors close properly, reducing air leakage and maintaining indoor temperature control. This aligns with the increasing preference for sustainable building solutions.

Stringent Regulatory Standards: Government regulations regarding fire safety, accessibility, and building codes mandate the installation of door closers in various commercial and institutional settings. Compliance with these regulations is a significant market driver.

Market Trends

Integration of Smart Technologies: The incorporation of smart sensors and automation in door closers is becoming increasingly popular. These innovations allow for remote monitoring, automatic adjustments, and improved security features.

Customization and Aesthetic Appeal: Consumers are seeking door closers that match interior aesthetics while maintaining functionality. Manufacturers are focusing on offering customizable finishes, designs, and compact solutions.

Growth of E-Commerce Platforms: The availability of door closers through online platforms has increased market accessibility. Customers can now compare products, read reviews, and make informed purchasing decisions more conveniently.

Increasing Adoption in Specialized Sectors: The demand for door closers is rising in sectors such as healthcare, hospitality, and transportation, where controlled access and hygiene measures are critical.

🚀 Stay Ahead – Download the Full Report at Global Door Market Insight Segments !!

Key Market Players

ASSA ABLOY: A leading player known for its advanced door control solutions, focusing on innovation and smart technology integration.

DormaKaba: A major manufacturer providing a wide range of door closers with an emphasis on security and automation.

Stanley Black and Decker: A well-established company offering reliable and high-performance door closing systems.

GEZE: Specializing in smart and energy-efficient door control solutions tailored for modern building designs.

Allegion: A global leader in security solutions, offering high-quality door closers with enhanced safety features.

Rixson: A brand known for premium door control solutions, catering to both commercial and residential sectors.

Norton Door Controls: Offering innovative and durable door closer products designed for various applications.

Future Outlook

The global door closer market is expected to continue growing, driven by advancements in technology, increasing awareness of security and safety measures, and expanding construction activities.

0 notes

Text

Revolutionizing Industries with IoT Data Intelligence

From the healthcare sector to the industrial application sector, Bridgera's IoT analytics platform is setting the industries ablaze. Envision real-time monitoring, predictive maintenance, and streamlined official business operation thanks to management of IoT data that derive concrete results. Bridgera's IoT data intelligence is revolutionizing industries through predictive maintenance, real-time monitoring, and effective management of data; it opens the doors of innovation for enhancing operational performance.

Click here for more Info

0 notes

Text

Dynemech DLM/DLMS Series Mounts: Precision Vibration Damping for Industrial Applications

Reliable Stability & Vibration Control for Critical Machinery

Dynemech introduces the DLM/DLMS Series Mounts, made in steel and stainless steel for simple yet very effective vibration damping of machinery with base holes. These mounts ensure low-frequency attenuation for stable machine levelling and superior vibration reduction. Engineered for Versatile Applications Designed with the intent to perform well in diverse industrial environments, DLM (Steel) and DLMS (Stainless Steel) mounts are designed with enhanced durability, adaptability for uneven or sloping surfaces, and long-lasting vibration isolation.

✅ Key Features:

Vibration Attenuation: Well-reduces vibrations for enhancing machinery performance

Leveling Stabilization: Allows for excellent machine alignment

Adjustable Screw: Suitable even on unevenly sloped and rough surfaces without a hitch for installation

Stainless Steel- Corrosion Resistant (DLMS)-for pharmaceutical industries, food processing, beverage processes, medical machinery, and production of chemicals. Optimizing Performance Across Industries

The DLM/DLMS Series provides robust and reliable vibration control in sensitive environments where strict hygiene and operational efficiency are essential.

📢 Upgrade your machinery’s stability with Dynemech’s advanced damping solutions!

🔗 To learn more about our products: https://www.vibrationmountsindia.com/products/ 📞 Contact Us: +91-9810760131; +91-9911145131 📧 Email: [email protected] 🌐 Explore Our Solutions: vibrationmountsindia.com

#DynemechSolutions#VibrationControl#IndustrialAutomation#ManufacturingExcellence#MadeInIndia#IndustryInnovation#DynemechMounts

0 notes

Text

আপনার কারখানায় বা ব্যবসার জন্য প্রিমিয়াম ওয়েল্ডিং সল্যুশন খুঁজছেন? আপনার জন্য বাংলাদেশ সাপ্লাইয়ার্স নিয়ে এসেছে CEA Welding Machine! এই উচ্চমানের ওয়েল্ডিং মেশিনটি দিচ্ছে:

🔧 দীর্ঘস্থায়ী এবং শক্তিশালী পারফরম্যান্স ⚡ দ্রুত ও সঠিক ওয়েল্ডিং 💡 ইনোভেটিভ ডিজাইন 🌍 অত্যাধুনিক প্রযুক্তি 🛠️ সহজ ব্যবহারের সুবিধা

👉 আপনি যেকোনো শিল্পে কাজ করেন না কেন, CEA Welding Machine আপনার সেরা পছন্দ হতে পারে! এখনই আমাদের সঙ্গে যোগাযোগ করুন এবং আপনার ব্যবসার দক্ষতা আরও বাড়ান!

1 note

·

View note

Text

The Power of Cast Elastomers in Rugged Industries

In industries that operate under harsh conditions—such as Oil & Gas, Mining, Automotive, and heavy-duty manufacturing—finding materials that can endure relentless wear and tear is a critical challenge. Traditional materials often fall short, leading to frequent replacements, increased downtime, and higher operational costs. Enter cast elastomers: a versatile solution that combines durability, flexibility, and exceptional resistance to extreme environments. These materials are transforming how businesses approach efficiency and longevity, proving to be a game-changer across various sectors.

What Are Cast Elastomers?

Cast elastomers are a specialized type of polyurethane material created by combining polyols and isocyanates through a casting process. This method allows for precision customization, enabling manufacturers to tailor the material’s properties to meet specific requirements. Cast elastomers can be engineered for shock absorption, abrasion resistance, chemical durability, and more. They are designed to thrive in environments where traditional materials often fail, making them an ideal choice for industries that demand resilience and reliability.

Why Are Cast Elastomers

The global cast elastomer market was valued at USD 1.4 billion in 2023 and is projected to reach USD 1.8 billion in 2028, growing at 5.0% cagr from 2023 to 2028. The market is mainly led by the significant usage of cast elastomers in various end-use industries. The increasing industrialization and manufacturing activities in emerging economies coupled with the superior advantage of cast elastomers over conventional materials are driving the market for cast elastomers.

The significance of cast elastomers lies in their versatility and performance in extreme conditions. Let’s explore how they are making an impact across key sectors:

1. Oil & Gas: Built for the Tough Stuff

The Oil & Gas industry operates in some of the most punishing environments imaginable. Drilling rigs, pipelines, and offshore operations face high pressures, extreme temperatures, and corrosive chemicals daily. Cast elastomers are particularly suited for these applications due to their ability to withstand such harsh conditions.

Common uses include seals, gaskets, and pipeline linings—components that are critical for safety and operational efficiency. For instance, cast elastomers play a vital role in blowout preventers (BOPs), which are essential safety devices on oil rigs. Their durability ensures reliability under immense stress, leading to fewer breakdowns and enhanced safety measures. This translates to less downtime and significant cost savings for operators.

2. Mining: Taking a Beating Day After Day

Mining operations are synonymous with brute force and constant abrasion. Equipment like conveyor systems, slurry pumps, and screening machinery endure relentless wear as they process materials. Cast elastomers excel in this environment by offering exceptional resistance to wear and tear.

For mining companies, switching to cast elastomers often means fewer equipment replacements and reduced maintenance costs. These materials can absorb impacts and resist abrasions effectively, allowing them to take the beating that comes with heavy-duty operations. This durability not only saves money but also minimizes disruptions in production schedules.

3. Automotive & Transportation: Comfort Meets Strength

In the automotive industry, cast elastomers play a crucial role in enhancing vehicle performance and comfort. From suspension systems to engine seals, these materials contribute significantly to the overall functionality of vehicles.

Their shock-absorbing qualities improve ride comfort by reducing vibrations while driving. Additionally, cast elastomers resist oils, greases, and other fluids commonly encountered in automotive applications, ensuring that components last longer without degradation. Heavy-duty vehicles like trucks and buses particularly benefit from these properties as they endure constant vibrations and heavy loads without cracking or failing.

4. Industrial Manufacturing: Keeping the Line Moving

In manufacturing environments where efficiency is paramount, downtime can be detrimental. Cast elastomers help keep production lines running smoothly by powering conveyor belts, rollers, and wheels. Their ability to resist abrasion means less frequent repairs and maintenance.

Moreover, cast elastomers are used in vibration-dampening applications that protect expensive machinery from wear caused by constant motion. For industrial operations looking for reliability and cost-effectiveness, integrating cast elastomers into their processes is a strategic choice.

What Makes Cast Elastomers Stand Out?

Several key attributes set cast elastomers apart from traditional materials:

Unbeatable Durability: Designed to last in the most punishing environments.

Customizable Properties: Manufacturers can tailor hardness levels, softness, heat resistance, and other characteristics based on specific needs.

Chemical Resistance: They withstand exposure to oils, fuels, and harsh chemicals without degrading.

Cost-Effectiveness: Their longevity translates into savings on replacements and repairs.

Extreme Environment Ready: Capable of performing well in both scorching heat and freezing cold conditions.

The future looks promising for cast elastomers as manufacturers continue to innovate. There is a growing trend toward sustainable options such as bio-based elastomers to meet increasing environmental demands. Additionally, advancements in 3D printing technology may unlock new possibilities for precision manufacturing with cast elastomers.

These innovations mean even more opportunities for industries reliant on high-performance materials to maximize efficiency while reducing costs.

Download PDF Report Insights :

For businesses operating in Oil & Gas, Mining, Automotive, or Industrial sectors, investing in cast elastomers could be the upgrade you've been waiting for. These materials offer more than just durability; they provide solutions that can improve your bottom line by enhancing efficiency and extending equipment life.

In an era where every dollar counts, choosing a material as tough and reliable as cast elastomers makes perfect sense. By embracing these resilient powerhouses, you can tackle your toughest challenges head-on while future-proofing your business against the ever-changing demands of the industrial landscape.

In summary, while cast elastomers may not be the most glamorous material on the market, their impact across industries is undeniable. They deliver reliability and adaptability—exactly what is needed in demanding sectors like Oil & Gas, Mining, Automotive, and Industrial manufacturing—making them an essential consideration for any business looking to thrive in challenging environments.

#CastElastomers#IndustrialMaterials#DurableSolutions#OilAndGas#MiningIndustry#AutomotiveComponents#IndustrialApplications#MaterialScience#RuggedIndustries#WearResistance#PolyurethaneSolutions#EngineeringMaterials#HeavyDutyApplications#CustomElastomers#IndustryInnovation

0 notes

Text

Exploring the Role of Blockchain in Transforming Food Safety, Healthcare, and Pharma

Uncover the groundbreaking potential of Blockchain technology in reshaping industries like Food Safety, Healthcare, and Pharmaceuticals. This course delves into how blockchain ensures data integrity, boosts transparency, and fosters trust in sectors where security and authenticity are paramount. From enhancing supply chain efficiency to improving regulatory compliance, discover how blockchain is setting new standards for these essential industries and paving the way for a secure future.

0 notes

Text

Choosing the Right Storage and Process Tanks for Your Industry

Selecting the right storage and process tanks is crucial for the smooth operation of your business, whether you're handling liquids, chemicals, or other materials. From material compatibility to capacity, there are several factors to consider to ensure efficiency and safety.

In our latest blog, we dive deep into: ✔️ Material Compatibility ✔️ Tank Capacity ✔️ Durability and Lifespan ✔️ Design & Shape ✔️ Temperature & Pressure Control

Ready to make the right choice for your industry? Discover more and let ASK Enterprises help you find the perfect storage and process tanks that meet your needs.

👉 Read the full guide here: [Link to blog] 🌐 Visit us: https://bit.ly/4hpeJQ0

#StorageTanks#ProcessTanks#IndustrialTanks#TankSolutions#Manufacturing#ChemicalStorage#FoodProcessing#TankDesign#Durability#IndustryExperts#SafetyFirst#TankCapacity#ProcessOptimization#ASKEnterprises#Engineering#IndustrialEquipment#TechSolutions#BusinessEfficiency#StorageSolutions#ProcessManagement#CustomTanks#TanksForIndustry#QualityTanks#IndustryInnovation#TankSelection

0 notes

Text

1 note

·

View note

Text

#BusinessGrowth#DigitalTransformation#Dynamics365#EfficiencyUnlocked#SmartBusinessSolutions#InnovateYourBusiness#FutureOfWork#TechForGrowth#StreamlineSuccess#IndustryInnovation

0 notes

Text

🔋 Ukraine Cobalt Market Size: Growth, Challenges & Future Outlook 🚀

Market Overview

The Ukraine cobalt market is experiencing steady growth, driven by rising demand from industries such as electric vehicles (EVs), electronics, aerospace, and renewable energy. Cobalt, a crucial component in lithium-ion batteries, is witnessing increased adoption due to the global transition towards clean energy and sustainable technologies.

The country’s cobalt reserves and mining activities position it as an emerging player in the global supply chain.

The Ukraine cobalt market size was estimated at 7.06 (USD billion) in 2023. The Ukraine cobalt market is expected to grow from 7.42 (USD billion) in 2024 to 12.75 (USD billion) by 2035. The Ukraine cobalt market CAGR (growth rate) is expected to be around 5.05% during the forecast period (2025-2035).

Growth Drivers

Increasing Demand for Electric Vehicles (EVs)

The shift towards green mobility has significantly boosted cobalt demand, as it plays a vital role in EV battery production. The rise in EV sales and supportive government policies for sustainable transportation contribute to market expansion.

Technological Advancements in Battery Production

Continuous research in battery chemistry and energy storage solutions is enhancing cobalt’s utility. While some manufacturers explore cobalt-free alternatives, the material remains essential for stability and energy density in high-performance batteries.

Growing Investments in Renewable Energy Storage

The expansion of wind and solar energy projects requires efficient energy storage solutions. Cobalt-based batteries are widely used for grid-scale energy storage, reinforcing the market's long-term potential.

Strategic Partnerships & Supply Chain Optimization

Companies are focusing on partnerships with local mining firms and adopting innovative extraction methods to enhance production capacity. Additionally, businesses are diversifying supply chains to reduce geopolitical risks and secure a stable cobalt supply.

Challenges & Restraints

Geopolitical Tensions & Supply Chain Disruptions

The ongoing Russia-Ukraine conflict has affected mining operations and trade routes, creating uncertainty in the cobalt supply chain. Import dependency and potential sanctions further complicate market dynamics.

Sustainability & Ethical Sourcing Concerns

There is growing pressure on companies to ensure responsible cobalt sourcing. Environmental regulations and ethical concerns surrounding mining practices are driving the need for greater transparency and recycling initiatives.

Volatility in Cobalt Prices

Fluctuations in cobalt prices due to global demand-supply imbalances pose a challenge for manufacturers and investors. Companies must adopt flexible sourcing strategies to mitigate price-related risks.

Market Opportunities

Expansion in Battery Recycling Technologies

With the push towards a circular economy, companies are investing in advanced recycling methods to extract cobalt from used batteries, reducing dependency on newly mined materials.

Rising Demand from Aerospace & Defense

Cobalt-based superalloys are widely used in aerospace applications due to their high strength and corrosion resistance. Growth in air travel and defense expenditures is expected to drive further demand.

Potential for Local Cobalt Refining & Processing

Ukraine can enhance its market position by investing in domestic refining and processing facilities. This would reduce reliance on imports and strengthen its role in the global cobalt supply chain.📩 Get Exclusive Insights on the Ukraine Cobalt Market! 🔍🚀

Stay ahead in the industry with in-depth market analysis, trends, and growth opportunities.

👉 Request a Free Sample Report Now at Ukraine Cobalt Market End Use Industry Insights 📊✅

Key Market Players

Several companies are actively shaping the Ukraine cobalt market through investments, partnerships, and technological advancements. Key players include:

SMM – A major player in cobalt extraction and processing, focusing on sustainable mining practices.

Harmony Cobalt – Engaged in cobalt mining and refining, with a strong emphasis on ethical sourcing.

Eramet – A global mining company involved in cobalt production and innovation.

Zaopin Mining – A key contributor to cobalt supply through its extensive mining operations.

GEM Co – Specializing in battery materials and cobalt recycling initiatives.

UMMC – A diversified mining company with cobalt production capabilities.

Glencore – One of the largest cobalt producers globally, supplying key industries.

BHP – A leading mining company expanding its footprint in cobalt and battery materials.

Tinci Materials Technology – A supplier of cobalt-based compounds used in battery production.

Freeport-McMoRan – A major mining company involved in cobalt extraction and refining.

Eurasian Resources Group – A significant player in the cobalt market with global operations.

Future Outlook

The Ukraine cobalt market is poised for growth due to increasing demand from the EV, energy storage, and electronics sectors. While geopolitical challenges and sustainability concerns pose risks, ongoing investments in refining, recycling, and responsible sourcing will help shape the market’s future. Companies focusing on innovation and supply chain resilience are likely to gain a competitive edge in the evolving cobalt landscape.

0 notes

Text

Choosing the Right Nozzle Manufacturer: What Every Business Should Know

In today’s competitive industrial landscape, selecting the right nozzle manufacturer can significantly impact your operations' efficiency, cost, and performance. Nozzles play a critical role across diverse industries, from agriculture to aerospace, making it vital to partner with a manufacturer who delivers precision, innovation, and reliability. This guide outlines the key factors businesses should consider when choosing a nozzle manufacturer and why making the right choice is crucial for success.

Understanding the Role of Nozzles in Industrial Applications

Nozzles are indispensable components used for controlling flow, spray patterns, and atomization in various industrial applications. From irrigation systems in agriculture to combustion engines in aerospace, nozzles ensure precision and efficiency. Choosing a subpar manufacturer can lead to inefficiencies, increased downtime, and higher operational costs.

Key Applications of Nozzles

Agriculture: Irrigation systems, pesticide distribution, and crop spraying.

Manufacturing: Cooling, cleaning, and coating processes.

Aerospace: Fuel atomization and propulsion systems.

Oil & Gas: Spray nozzles for refining and cooling towers.

Healthcare: Medical devices and spray drug delivery systems.

Factors to Consider When Choosing a Nozzle Manufacturer

1. Industry Expertise and Experience

One of the first factors to evaluate is the manufacturer’s experience and track record in your specific industry. Manufacturers with a deep understanding of industry-specific requirements are better equipped to offer tailored solutions. Look for companies that have been in business for a significant period and can provide case studies or references from businesses in your sector.

2. Quality and Compliance Standards

The quality of nozzles is critical to achieving desired performance. Ensure the manufacturer adheres to global quality standards such as ISO 9001. Certifications indicate that the company maintains rigorous quality control processes. Additionally, inquire about compliance with industry-specific standards, such as FDA approval for healthcare applications or ASME standards for engineering.

3. Technological Capabilities

Technological innovation separates the top nozzle manufacturers from the rest. Assess whether the manufacturer uses advanced techniques such as 3D printing, laser drilling, or precision machining to produce nozzles. Cutting-edge technologies often lead to products with higher durability, precision, and performance.

4. Customization Options

Off-the-shelf solutions might not meet every business’s unique requirements. A reliable manufacturer should offer customized nozzle designs tailored to your needs, including specific flow rates, spray patterns, or materials. This ensures optimal performance for your application.

5. Material Expertise

The choice of material significantly impacts the nozzle’s longevity, corrosion resistance, and thermal stability. Leading manufacturers provide a range of materials, including:

Stainless Steel: Ideal for durability and corrosion resistance.

Brass: Cost-effective for low-pressure applications.

Ceramics: Best for high-wear environments.

Polymers: Lightweight and chemical-resistant options.

Ensure the manufacturer has expertise in recommending the right material for your specific use case.

6. Research and Development (R&D)

Manufacturers with a strong focus on R&D are more likely to innovate and stay ahead of industry trends. Ask if the company invests in developing new technologies or improving existing designs. This demonstrates their commitment to providing cutting-edge solutions.

7. Scalability and Production Capacity

For businesses planning to scale operations, it's crucial to partner with a manufacturer capable of meeting increased demand without compromising on quality. Evaluate the company's production capacity, lead times, and ability to handle bulk orders.

8. Customer Support and After-Sales Service

Responsive customer support ensures smooth communication and quick resolution of issues. A reliable manufacturer should provide:

Technical assistance during installation or troubleshooting.

Maintenance tips to extend nozzle life.

Replacement and warranty policies to minimize downtime.

The Importance of Testing and Validation

Before finalizing a manufacturer, ensure their products undergo rigorous testing for performance and durability. Testing methods may include:

Flow Rate Testing: Ensures consistent spray patterns.

Thermal Testing: Validates performance under extreme temperatures.

Corrosion Testing: Evaluates resistance to chemicals and environmental factors.

Request test reports or certifications to verify the product’s reliability.

Top Questions to Ask a Potential Nozzle Manufacturer

What industries do you specialize in?

Can you provide samples or prototypes for testing?

What materials do you offer, and how do you select the best material for specific applications?

Do you offer custom designs, and what is the typical lead time?

What are your quality control processes?

What after-sales support do you provide?

Benefits of Choosing the Right Nozzle Manufacturer

Partnering with a reputable manufacturer offers numerous benefits, including:

Improved Efficiency: High-quality nozzles optimize spray performance, reducing waste.

Cost Savings: Durable nozzles lower maintenance and replacement costs.

Enhanced Productivity: Reliable nozzles minimize downtime and maximize output.

Long-Term Partnerships: A reliable manufacturer provides consistent support and adapts to your growing needs.

Conclusion

Selecting the right nozzle manufacturer is a decision that can significantly impact your business's operational efficiency and overall success. By evaluating factors such as industry expertise, quality standards, technological capabilities, and customer support, you can ensure you partner with a manufacturer that meets your specific needs. Take the time to research, ask questions, and test products to make an informed decision.

#NozzleManufacturer#IndustrialNozzles#PrecisionEngineering#ManufacturingSolutions#NozzleTechnology#SprayNozzles#CustomNozzles#IndustrialEquipment#EngineeringExcellence#IndustryInnovation#EfficientOperations#NozzleDesign#MaterialEngineering#FlowControl#IndustrialAutomation#BusinessSolutions#QualityNozzles#NozzleIndustry#SmartManufacturing#NozzlePerformance

0 notes

Text

Discover how projection mapping, blends technology and creativity to create immersive experiences across industries.

#projectionmapping#ImmersiveExperience#TechAndCreativity#digitalart#interactivemedia#InnovationInArt#VisualStorytelling#ExperientialDesign#FutureOfMedicine#creativetechnology#IndustryInnovation#DynamicDisplays#techdriven#projectionart#TransformativeArt#BeyondTheScreen

0 notes

Text

Dynemech Compact Machinery Mounts: Precision Vibration Control for Heavy-Duty Applications

Optimizing Industrial Machinery Stability: Dynemech’s Compact Machinery Mounts Lead the Way in Vibration Control

As industries strive for superior Stability in Equipment Performance, Dynemech celebrates its commitment to Innovation with the release of Compact Machinery Mounts. These mounts are Engineered to provide precise Vibration Isolation for a Wide Range of Industrial Applications, offering a compact yet Highly Effective Solution for Controlling Vibrations and Maintaining Operational Efficiency.

Engineered to Perform Under Pressure Superior Load Management System Dynemech’s Compact Machinery Mounts Feature Advanced Rubber Components, strategically designed to operate under both compression and shear. These mounts are Engineered to maintain tight Tolerances on stiffness rates, Ensuring Optimal Vibration Control for Accurate Calculations in Demanding Applications.

Load range: 40 kg to 130 kg per piece

Designed for durability: Strong base Metal withstands high shock Loads without Deformation

Protection from contaminants: Domed shape cover to Safeguard against oil and contamination

Precision-Engineered for Tough Industrial Environments The architecture of the Compact Machinery Mounts includes:

Housing High-Performance Robust Rubber Components for Effective Vibration Isolation.

Lightweight and Compact Design suitable for Space-Constrained machines

Protection against all kinds of External Contaminants assures Long-Lasting Efficiency.

Revolutionizing Machinery Stability in Key Industries Ideal Applications in Heavy-Duty Machinery Dynemech Compact Machinery Mounts are a Revolution in the Heavy Machinery Industry and serve their Perfect Applications in the following Industries:

Diesel Engines & Compressors

Cooling Towers & Pumps

Industrial Generators & Marine Generators

ID & FD Fans

These Mounts give Stable, Reliable Performance even in the most demanding Environments, thus Ensuring that Industrial Equipment Operates at peak Efficiency. Dynemech's Commitment to Providing Superior vibration Control Solutions has shaped Industries and Created Stability, Optimizing Machine Performance for over 23 years.

To learn more about our products: https://www.vibrationmountsindia.com/products/ 📞 Contact Us: +91-9810760131; +91-9911145131 📧 Email: [email protected] 🌐 Explore Our Solutions: https://www.vibrationmountsindia.com/

#IMTEX2025#DynemechSolutions#VibrationControl#IndustrialAutomation#ManufacturingExcellence#MadeInIndia#IndustryInnovation#DynemechMounts

0 notes

Text

Discover the fascinating world of CNC Machining Applications in Industries! Learn about its history, types, and wide-ranging applications. Dive deeper with Alshurooq for more insights!

#CNCmachining#CNCtechnology#IndustrialMachining#ManufacturingTech#CNCapplications#Alshurooq#PrecisionMachining#MachiningSolutions#IndustryInnovation#EngineeringExcellence#ManufacturingIndustry#TechInIndustry

1 note

·

View note