#ElectronicsManufacturing

Explore tagged Tumblr posts

Text

“Protect What Matters: Blast Without Damage”

When working with sensitive components, precision matters more than power.

🌿 Plastic Media brings the perfect touch for delicate surfaces: 📌 Soft-cutting action ideal for composite materials, plastics, and light metals. 📌 Won’t deform parts or create microfractures. 📌 Generates minimal dust—safe for both workers and the environment. 📌 Reusable over multiple cycles, reducing overall media cost. From aerospace maintenance to high-tech electronics, trust a media that treats your parts with care. 💬 Curious if Plastic Media is right for your line? We’d be happy to advise!

#PlasticMedia#SurfaceFinishing#PrecisionBlasting#EcoFriendlyAbrasive#AerospaceCleaning#ElectronicsManufacturing#DelicateSurfaceProtection

4 notes

·

View notes

Text

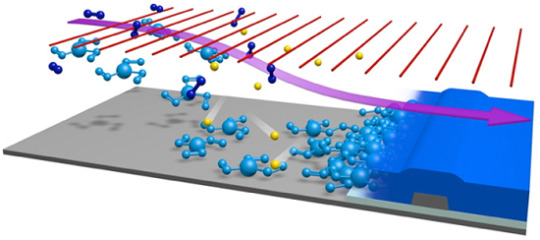

Selective soldering 🔧🔬🔥

Selective soldering involves attaching specific components to printed circuit boards (PCBs) and molded modules, a method particularly useful for items susceptible to heat damage from standard reflow ovens or wave soldering found in conventional surface-mount technology (SMT) or through-hole assembly techniques. Typically, this method is applied after an initial SMT oven reflow phase. The components targeted for selective soldering are often nestled among others already soldered via a surface-mount reflow method. This demands high precision in the selective soldering process to prevent damage to the surrounding elements.

#adafruit#selectivesoldering#pcbassembly#electronicsmanufacturing#surface-mount#throughhole#reflowprocess#precisionengineering#solderingtechnology#circuitboarddesign#manufacturinginnovation#techadvancements

5 notes

·

View notes

Text

#electronics#industry#manufacturing#quality#technology#electronicsmanufacturing#Electronic Manufacturing Services#Top EMS India

2 notes

·

View notes

Link

#ASEAN#DixonTechnologies#electronicsmanufacturing#India#NIELIT#PLIscheme#TataElectronics#US-Chinatrade

0 notes

Text

youtube

Modular Cleanroom Manufacturers in India | Experts in PUF Panel And Sandwich Partition Solutions

Did you know a single particle can cost a pharmaceutical company millions in product recalls?

That’s why industries across India trust modular cleanrooms—custom-built for hygiene, flexibility, and excellence. 💼✨

From pharmaceutical manufacturing to modular hospital theatres, electronics, food processing, cosmetics, and research labs—cleanrooms are transforming the future of precision industries. 🏭🔬

Discover why Polyurethane Foam panels, sandwich panels, air handling units, and laminar airflow systems are revolutionizing contamination control. 🌬️

Looking to upgrade your facility with a world-class modular cleanroom solution?

✅ Designed for speed, hygiene, and scalability ✅ Built with advanced, contamination-proof materials ✅ Ideal for industries where purity and compliance matter most

🔗 Visit www.aumindustriesmfg.com 📧 Email us: [email protected] 📞 Call: +91-9664808777 | +91-9722549868 | +91-9978629339

Let's build a cleaner, smarter, and safer tomorrow together! 🚀

#modularcleanrooms#cleanroommanufacturers#pufpanelsolutions#sandwichpanelexperts#pharmacleanroom#hospitalcleanroom#electronicsmanufacturing#foodprocessingindia#cosmeticsmanufacturing#contaminationcontrol#airhandlingunits#laminarairflow#cleanroomsolutions#industrialcleanrooms#madeinindia#futureready#aumindustries#cleanroomtechnology#healthcareinfrastructure#turnkeysolutions#precisionengineering#cleanenvironment#cleanroomdesign#cleanroomsetup#Youtube

0 notes

Text

Emerging Trends in Electrically Conductive Adhesives Market Transforming Global Manufacturing Landscape

The electrically conductive adhesives market is rapidly evolving, driven by technological advancements and the growing demand for efficient, eco-friendly alternatives to traditional soldering. These adhesives play a vital role in enabling electrical conductivity and mechanical bonding simultaneously, making them indispensable across numerous sectors including electronics, automotive, aerospace, healthcare, and renewable energy. As industry needs shift and technologies advance, emerging trends are reshaping this dynamic market and paving the way for broader adoption and innovation.

Growing Preference for Lead-Free and RoHS-Compliant Materials

One of the most prominent trends influencing the Electrically Conductive Adhesives Market is the global shift toward lead-free and environmentally friendly materials. Regulations such as the Restriction of Hazardous Substances (RoHS) directive are pushing manufacturers to eliminate toxic materials like lead from electronic products. Electrically conductive adhesives offer a compelling alternative to traditional soldering methods by providing a safe, lead-free bonding solution.

These adhesives contribute to sustainability goals and enhance worker safety, as they release fewer volatile organic compounds (VOCs) and reduce energy consumption during the curing process. This growing preference for green materials is expected to further boost the adoption of ECAs in environmentally conscious industries.

Miniaturization and Compact Design Requirements

The ongoing trend of device miniaturization is reshaping the electronics industry. From smartphones and wearables to medical implants and microelectronic components, modern devices are becoming smaller and more complex. Electrically conductive adhesives support this trend by offering precision bonding and reliable conductivity even in the most compact applications.

Traditional soldering can be challenging and damaging for tiny components, but ECAs provide a gentler and more flexible bonding method. They are especially useful in fine-pitch applications and offer excellent adhesion to diverse substrates, including glass, metal, and flexible materials. As the demand for sleek and compact electronics grows, so does the relevance of ECAs.

Rise in Demand from Electric Vehicles and Automotive Electronics

Another significant trend shaping the Electrically Conductive Adhesives Market is the rise of electric vehicles (EVs) and the increasing integration of electronic components in automobiles. ECAs are being used extensively for bonding sensors, control units, displays, lighting systems, and battery components.

Their resistance to vibrations, temperature changes, and harsh environments makes them suitable for automotive applications. Additionally, the demand for lightweight and durable solutions aligns with the use of conductive adhesives, which contribute to the overall energy efficiency and reliability of EV systems. As the automotive sector continues to evolve, ECAs will remain central to this transformation.

Advancements in Conductive Fillers and Polymer Matrices

Material innovation is a key trend in the Electrically Conductive Adhesives Market. Researchers and manufacturers are constantly exploring new fillers and resins to enhance the performance of ECAs. Traditional fillers such as silver are being complemented or replaced with advanced materials like carbon nanotubes, graphene, silver nanowires, and hybrid nanoparticles.

These next-generation materials offer improved conductivity, thermal stability, and mechanical strength, while also reducing costs and environmental impact. Similarly, advancements in polymer matrices allow for better adhesion, flexibility, and compatibility with sensitive electronic components. These innovations enable ECAs to meet the evolving needs of cutting-edge industries.

Flexible and Wearable Electronics on the Rise

The increasing popularity of flexible and wearable electronics is another driver of growth and innovation in the Electrically Conductive Adhesives Market. These devices require materials that can endure bending, stretching, and repeated mechanical stress while maintaining consistent electrical performance.

ECAs are uniquely suited to meet these challenges, offering excellent elasticity, conductivity, and adhesion on flexible substrates. They are now commonly used in fitness trackers, smartwatches, foldable smartphones, and smart textiles. As wearable technology becomes more mainstream, the demand for flexible conductive adhesives is expected to surge.

Integration in Medical and Healthcare Devices

The healthcare industry is also seeing growing integration of ECAs in medical electronics and diagnostic devices. From biosensors and ECG leads to hearing aids and portable monitors, ECAs enable compact and reliable connections. Their biocompatibility, safety, and ability to bond delicate materials without heat make them ideal for medical applications.

Additionally, the trend of remote patient monitoring and personalized healthcare technologies continues to fuel demand for sophisticated electronics, indirectly expanding the scope of the Electrically Conductive Adhesives Market within the medical sector.

Outlook and Future Opportunities

The Electrically Conductive Adhesives Market is poised for substantial growth, backed by trends in sustainability, miniaturization, flexible electronics, and EV innovation. As industries shift toward smarter, more efficient, and environmentally friendly solutions, ECAs are becoming more than just alternatives—they are essential enablers of modern manufacturing.

The market will likely see continued investment in R&D to develop cost-effective, high-performance, and multifunctional adhesives. Collaborations between material scientists, electronics engineers, and manufacturers will shape the future of ECAs, making them integral to next-generation technologies across industries.

In conclusion, the Electrically Conductive Adhesives Market is undergoing a transformative phase, with emerging trends highlighting its growing importance in a technologically advanced and environmentally conscious world.

#ElectricallyConductiveAdhesives#ECAMarket#ElectronicsManufacturing#AutomotiveInnovation#SmartAdhesives#ConductiveAdhesives

0 notes

Text

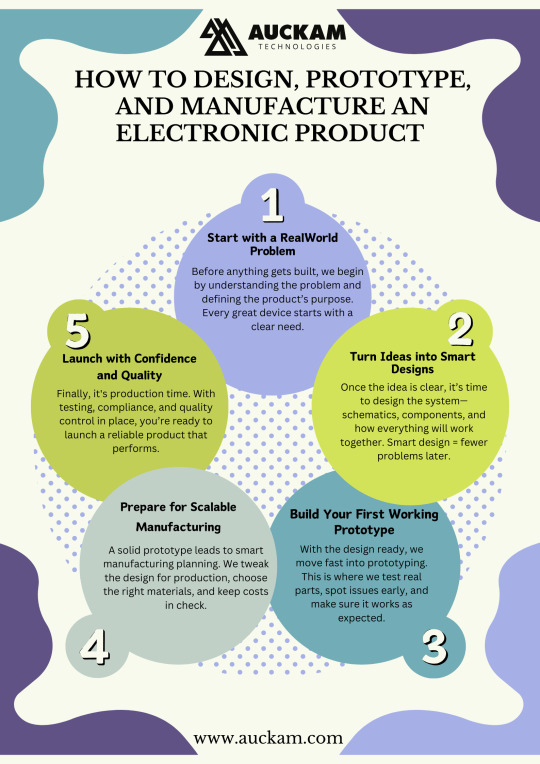

Learn how to design, prototype, and manufacture an electronic product step-by-step! This easy-to-follow guide shows how real-world problems turn into smart designs, working prototypes, and scalable manufacturing processes. Whether you're a startup, engineer, or product creator, mastering these stages is key to building successful electronics. Perfect for anyone passionate about product development, engineering, and innovation!

#ProductDesign#ElectronicsManufacturing#HardwareDevelopment#PrototypeDesign#InnovationEngineering#ManufacturingProcess#TechEntrepreneur#EngineeringDesign#ProductDevelopmentJourney#PCBDesign#IoTDevices#TechStartup#BuildAndLaunch#CADDesign#IndustrialDesign

1 note

·

View note

Text

Clean Air, Safe Workspaces: Fume Absorber and Extractors in India

In the modern industrial landscape, workplace safety is no longer optional—it’s a necessity. From electronics manufacturing and soldering stations to laser engraving and chemical labs, hazardous fumes are a common by-product of many essential operations. That’s where Fume Absorber and Extractors in India step in, ensuring that toxic particles, gases, and vapors are effectively removed from the working environment.

A Fume Absorber and Extractors in India is designed to capture airborne pollutants at the source, filtering them through activated carbon and HEPA filters before releasing clean air back into the workspace. These systems not only protect employees from exposure to harmful substances but also ensure compliance with occupational safety standards like OSHA and RoHS. This is especially important in sectors like electronics, where soldering generates smoke containing flux residues, lead, and other potentially harmful chemicals.

As India continues to expand its electronics and light manufacturing industries, the demand for high-performance fume extraction systems is growing. Companies like Ascomp Inc. are leading the charge by offering reliable and efficient Fume Absorber and Extractors in India that are suitable for a variety of applications. From compact desktop models for small workshops to high-capacity extractors for industrial-scale production lines, there's a solution available for every workspace.

One of the key benefits of these systems is their energy-efficient operation. Modern fume absorbers are designed with brushless motors, multi-layer filtration systems, and intelligent control panels that allow users to adjust airflow based on operational needs. This not only helps in maintaining clean air but also reduces power consumption and noise levels, creating a more pleasant and productive environment.

Another major advantage is the portability and ease of installation. Many units come with flexible extraction arms and wheels, allowing users to move the unit between different workstations with ease. This adaptability makes fume extractors ideal for dynamic production setups, research labs, and small manufacturing units where space and flexibility are crucial.

Maintenance of fume absorbers has also become simpler, with filter change alerts and quick-access panels making routine upkeep hassle-free. With local availability of replacement parts and support from providers like Ascomp Inc., businesses can ensure uninterrupted operation and long-term reliability of their air filtration systems.

In addition to health and safety, using fume extractors enhances product quality. Fumes and particles can contaminate sensitive components during soldering or coating processes. A clean, contaminant-free atmosphere minimizes product defects and ensures higher yield, ultimately contributing to customer satisfaction and brand credibility.

#FumeExtractor#AirPurification#AscompInc#IndustrialSafety#ElectronicsManufacturing#CleanAirSolutions#SolderingFumes#WorkplaceSafety#MakeInIndia#IndustrialAutomation

0 notes

Text

📢 PRODUCT SPOTLIGHT: Manual De-Taping Machine for Taped Radials – MAP 860 R When precision is non-negotiable, Estovir Technologies delivers. ⚙️ Up to 18,000 pcs/hr 📏 Ø 0.4 – 0.8 mm leads 📦 Portable & compact 📍 Made for PCB assembly lines, ECM, and training labs. ✅ High-accuracy manual mode 🇮🇳 Proudly Made in India

🔧 Built for techs who value control over chaos. 🌐 Learn more at smtems.com

#EstovirTechnologies#Smtems#ManualDetapingMachine#MadeInIndia#PCBTools#ComponentProcessing#ElectronicsManufacturing#TechGear

0 notes

Text

0 notes

Text

Why Aimtron is a Trusted Name in ESDM Services

In the rapidly evolving electronics industry, Electronics System Design & Manufacturing (ESDM) plays a crucial role in bringing innovative solutions to life. Companies seeking reliability, expertise, and cutting-edge technology turn to Aimtron, a name synonymous with excellence in electronics manufacturing. But what makes Aimtron stand out as a trusted provider of ESDM solutions? Let’s explore the key factors behind its reputation.

Commitment to High-Quality Electronics Design

Aimtron’s journey in electronics design has been defined by precision engineering and innovation. From conceptualization to prototyping, the company ensures that each design meets industry standards and client-specific requirements. Its expertise in electronic circuits, embedded systems, and component selection has made it a go-to choice for businesses seeking robust, scalable solutions.

Excellence in PCB Assembly Services

One of Aimtron’s core strengths lies in PCB assembly services, where it delivers highly reliable and efficient printed circuit boards for various applications. Using advanced manufacturing techniques, stringent quality control measures, and state-of-the-art equipment, Aimtron provides cost-effective yet high-performance PCB solutions tailored to industry needs.

End-to-End ESDM Solutions

What sets Aimtron apart is its ability to offer comprehensive ESDM solutions—from design and prototyping to manufacturing and testing. Clients benefit from an integrated approach that streamlines production, reduces costs, and ensures seamless functionality. Whether it’s for consumer electronics, automotive systems, industrial machinery, or medical devices, Aimtron guarantees top-tier manufacturing expertise.

Trusted by Industries Worldwide

With years of experience in electronics manufacturing, Aimtron has built strong relationships with global clients across diverse industries. Its reputation is backed by consistent delivery, cutting-edge technology, and an unwavering commitment to quality. By prioritizing customer satisfaction and continual improvement, Aimtron remains a trusted name in ESDM services.

Conclusion

In the competitive world of electronics, reliability and expertise make all the difference. Aimtron’s dedication to electronics design, PCB assembly services, and ESDM solutions solidifies its standing as a trusted partner for businesses seeking world-class manufacturing. With a focus on quality, innovation, and customer success, Aimtron continues to lead the way in modern electronics development.

0 notes

Text

Impact of Semiconductor and Electronics Industry on U.S. Chemical Vapor Deposition Market

The U.S. chemical vapor deposition market was valued at USD 4.15 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 8.6% from 2024 to 2030. This growth is attributed to technological advancements in the semiconductor industry, increasing demand for high-performance and energy-efficient devices, and the growing need for miniaturized semiconductor components are some of the key driving factors. Additionally, the rise in the adoption of CVD in various applications such as data storage, solar products, and cutting tools is also contributing to the market growth. However, the market’s expansion is not without challenges. Factors such as high equipment costs and the need for skilled labor can potentially hinder market growth.

For More Details or Sample Copy please visit link @: U.S. Chemical Vapor Deposition Market

The U.S. CVD market is characterized by rapid technological advancements and a high degree of innovation. Ongoing advancements in CVD techniques, such as plasma-enhanced CVD and atomic layer deposition, are driving the market. Significant research and development investments are being made by industry players and research institutions to develop innovative deposition processes, materials, and applications.

The chemical vapor deposition equipment segment dominated the U.S. market in 2023. This dominance can be attributed to the extensive use of CVD equipment in various industries, including semiconductors, electronics, and solar panels. The equipment is used to deposit thin films and coatings on substrates, which are essential in the manufacturing of semiconductors and other electronic components. The high demand for these components, driven by the growing electronics and semiconductor industries, has led to a significant market share of the CVD equipment segment.

The semiconductor & microelectronics segment dominated the U.S. market in 2023. The high market share is attributed to the increasing demand for high-quality and high-performance materials in the aerospace and defense sectors has been a significant driver for using CVD technology. Furthermore, in the U.S., rising demand for miniaturized and high-performance electronic devices has propelled the adoption of CVD for thin-film deposition of semiconductors and insulating materials.

Gain deeper insights on the market and receive your free copy with TOC now @: U.S. Chemical Vapor Deposition Market

List of key players in U.S. Chemical Vapor Deposition Market

Veeco Instruments Inc.

IHI Ionbond AG

Applied Materials Inc.

OC Oerlikon Corporation AG

ULVAC Inc.

CVD Equipment Corporation

Lam Research Corporation

#ChemicalVaporDeposition#CVDMarket#USMarketTrends#ThinFilmTechnology#AdvancedManufacturing#ElectronicsManufacturing#BiomedicalCoatings#AerospaceTechnology#RenewableEnergyTech#IndustrialCoatings

0 notes

Text

https://autoevtimes.com/government-slashes-import-duty-on-ev-battery-phone-parts/

#electronicsmanufacturing#EVbattery#mobilephone#EV#MakeInIndia#Electronics#Sustainability#electricvehiclesnews#evtimes#autoevtimes#evbusines

0 notes

Link

#AIhardware#electronicsmanufacturing#PCBindustry#semiconductorindustry#SupplyChain#Taiwan#tradepolicy#US-Chinatariffs

0 notes

Text

Hitech Circuits—Your Reliable Supplier for Premium PCB Assembly

At Hitech Circuits, we specialize in high-efficiency, high-precision surface mount technology (SMT) assembly, delivering unmatched capacity and quality for your PCB projects.

Our Capabilities:

1. Massive Daily Output

1 Million+ Components Placed Daily**: Powered by fully automated SMT lines (e.g., Fuji NXT, Siemens SIPLACE) and high-speed pick-and-place systems, we ensure rapid production scaling for both prototypes and bulk orders.

2. Advanced Packaging Expertise

QFN/BGA Mastery: Our precision equipment handles ultra-fine-pitch components, including QFN (0.3mm pitch) and BGA (down to 0.2mm ball diameter), with 99.99% placement accuracy.

X-Ray Inspection: 100% in-line X-ray verification for BGA solder joints, voids, and alignment defects, ensuring zero hidden faults.

3. End-to-End Quality Control

AOI + SPI Integration: Automated Optical Inspection (AOI) and Solder Paste Inspection (SPI) at every stage.

IPC-A-610/612 Compliance: Certified processes for mission-critical applications.

Why Choose Us?

Speed-to-Market: 48-hour prototype turnaround & 10-day mass production cycles.

Flexible MOQs: Support for small-batch R&D to 100k+ volume orders.

Global Material Sourcing: Access to a vetted network of component suppliers, reducing lead times.

Contact Us Today!

Let’s optimize your PCB assembly with speed, precision, and reliability.

Email:[email protected]

Tel & Whatsapp: +86-180333061378

Location: Building C, Suojia Technology Park, Hangcheng, Xixiang, Shenzhen, Guangdong, China

Authority certification: we're fully ISO9001:2015, ISO14001:2015 , UL (E354070) and RoHS certificated. You can reply on us for custom PCB production and Electronic assembly.

0 notes

Text

Electronic Chemicals and Materials Market Share by Region: Trends and Forecasts for 2032

The global electronic chemicals and materials market has been experiencing robust growth and is poised to continue its upward trajectory in the coming years. With technological advancements across various sectors, the demand for specialized chemicals and materials used in the manufacture of electronic devices is set to expand significantly. In this article, we explore the size, share, and growth analysis of the electronic chemicals and materials market through 2032.

Electronic chemicals and materials encompass a broad range of substances and compounds used in the production of semiconductors, printed circuit boards (PCBs), flat panel displays, solar panels, and other electronic devices. These materials are crucial for the functioning of electronic products that we use every day, from smartphones and laptops to renewable energy technologies and automotive systems.

Request a Free Sample Copy - https://www.skyquestt.com/sample-request/electronic-chemicals-and-materials-market

The electronic chemicals and materials market includes components like:

- Semiconductor chemicals: Photoresists, etching chemicals, and others used in semiconductor fabrication.

- Printed circuit board materials: Copper foil, solder mask, and other materials essential for PCB manufacturing.

- Display materials: Polymers, liquid crystals, and other compounds vital for flat-panel displays.

- Solar materials: Silicon, substrates, and conductive materials used in the creation of solar panels.

- Battery chemicals: Materials used in the production of batteries for electronic devices and electric vehicles.

Market Size and Forecast

The global electronic chemicals and materials market was valued at USD 62.07 Billion in 2024 to USD 108.64 Billion by 2032 and is expected to grow at a compound annual growth rate (CAGR) of 7.24% between 2025 and 2032. This growth can be attributed to several factors:

1. Increasing demand for consumer electronics: With the rise in disposable income and changing consumer lifestyles, the demand for electronic products such as smartphones, wearables, and laptops is on the rise. This, in turn, is driving the need for electronic chemicals and materials.

2. Advancements in semiconductor technologies: As the world continues to rely more heavily on digital technologies, semiconductors remain at the heart of this growth. The increasing complexity of semiconductor devices and the push for smaller, faster, and more energy-efficient chips will require more advanced chemicals and materials.

3. Electrification of transportation: The rapid adoption of electric vehicles (EVs) has created a significant demand for battery materials. As EV manufacturers seek to enhance the energy density and charging speed of their batteries, there is a growing need for advanced battery chemicals.

4. Development of renewable energy sources: Solar power is a key contributor to the renewable energy sector. As countries strive to reduce their carbon footprint, the demand for solar panels—and consequently, the materials used to make them—is increasing. This will continue to boost the demand for electronic chemicals and materials over the coming years.

5. Global manufacturing expansion: In regions like Asia-Pacific, particularly China, South Korea, and Japan, the presence of major electronics manufacturers is driving demand for electronic chemicals and materials. Similarly, North America and Europe are also seeing an uptick in demand due to the rapid growth in electric vehicle production and semiconductor manufacturing.

Make an Inquiry to Address your Specific Business Needs - https://www.skyquestt.com/speak-with-analyst/electronic-chemicals-and-materials-market

Market Segmentation

The electronic chemicals and materials market can be segmented based on type, application, and region.

By Type

1. Semiconductor Chemicals: These materials are crucial in the production of semiconductors and integrated circuits (ICs). Semiconductors represent the largest share of the market due to their widespread application across electronics, automotive, and telecommunication industries.

2. PCB Materials: Printed circuit boards are an essential component of all electronic devices, ranging from consumer electronics to automotive systems. Materials such as copper, solder, and substrates make up a significant portion of the market.

3. Display Materials: Liquid crystals, polymer materials, and conductive films used in the creation of displays, particularly in flat-panel televisions, smartphones, and computer screens, are seeing significant growth.

4. Battery Chemicals: The production of lithium-ion batteries used in smartphones, laptops, and electric vehicles is fueling the demand for battery chemicals, such as lithium, cobalt, and nickel-based materials.

By Application

1. Consumer Electronics: Smartphones, laptops, tablets, and other devices are the largest consumers of electronic chemicals and materials.

2. Automotive: As electric vehicles (EVs) gain traction, the demand for specialized materials in battery technology, as well as advanced electronic components in automobiles, is rapidly increasing.

3. Renewable Energy: Solar panels, energy storage systems, and other clean technologies rely heavily on electronic materials, creating significant growth opportunities.

4. Telecommunication: The demand for high-performance electronic devices and components, driven by the proliferation of 5G networks, is contributing to the growth of the market.

Regional Analysis

The electronic chemicals and materials market is geographically diverse, with key regions including North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

- Asia-Pacific: This region holds the largest share of the market, primarily driven by the presence of leading electronics manufacturers in countries like China, South Korea, and Japan. Additionally, the region’s growing semiconductor industry and the widespread adoption of electric vehicles are contributing to the market’s growth.

- North America: The increasing demand for electronic materials in automotive applications (especially EVs) and the development of advanced semiconductor technologies are key growth drivers in North America.

- Europe: Similar to North America, Europe is witnessing a surge in demand for electric vehicles and renewable energy technologies, which in turn is bolstering the demand for electronic chemicals and materials.

Take Action Now: Secure Your Electronic Chemicals and Materials Market Today - https://www.skyquestt.com/buy-now/electronic-chemicals-and-materials-market

Market Trends and Drivers

1. Miniaturization of Electronic Devices: As devices become smaller and more powerful, there is an increasing need for specialized chemicals that can enable the production of smaller, more efficient components, such as transistors, capacitors, and resistors.

2. Focus on Sustainability: With growing environmental concerns, there is a greater emphasis on sustainable production methods for electronic materials. Innovations in recycling and the development of eco-friendly materials are gaining momentum.

3. Advancement in Semiconductor Fabrication: As the semiconductor industry moves towards more advanced technologies like 5G, AI, and quantum computing, there is a growing demand for specialized chemicals that can meet the stringent requirements of next-generation chips.

Electronic Chemicals and Materials Market Top Players Company Profiles

Shin-Etsu Chemical Co., Ltd. (Japan)

Linde Plc (England)

Fujifilm Corporation (Japan)

Resonac Holding Corporation (Japan)

Air Liquide (Paris)

Solvay (Belgium)

BASF SE(Germany)

Mitsui Chemicals America, Inc. (US)

Merck KGaA (Germany)

Covestro AG (Germany)

SUMCO Corp. (Japan)

Air Products & Chemicals, Inc. (US)

Songwon (South Korea)

Cabot Microelectronics Corporation

Dow Chemical Company

Honeywell International Inc.

Huntsman Corporation

Kanto Chemical Co., Inc.

Momentive Performance Materials Inc.

Samsung SDI Co., Ltd.

Challenges

Despite the strong growth prospects, the electronic chemicals and materials market faces some challenges:

- Supply Chain Issues: The market’s reliance on complex global supply chains for key materials such as rare earth elements and lithium can be impacted by geopolitical tensions and disruptions like those seen during the COVID-19 pandemic.

- Cost Volatility: The prices of raw materials, particularly those required for battery production, are subject to fluctuations, which can impact the overall cost of production.

Read Electronic Chemicals and Materials Market Report Today - https://www.skyquestt.com/report/electronic-chemicals-and-materials-market

The electronic chemicals and materials market is on a strong growth trajectory, driven by the ongoing advancements in consumer electronics, electric vehicles, semiconductor fabrication, and renewable energy technologies. With a projected market value of USD 108.64 billion by 2032, the sector offers abundant opportunities for innovation and expansion. Companies involved in the production of electronic chemicals and materials will continue to play a critical role in powering the next generation of technological advancements and addressing the challenges posed by a rapidly evolving global market.

#ElectronicChemicals#SemiconductorMaterials#ElectronicMaterials#TechMaterials#MaterialScience#ElectronicsIndustry#Nanotechnology#TechInnovation#ElectronicsManufacturing#ChemicalsMarket#SustainableTech#AdvancedMaterials#SmartElectronics#ElectronicComponents#SemiconductorIndustry#HighTechMaterials#ElectronicsProduction#IndustrialChemicals#MaterialsScience#Nanomaterials

0 notes