#electronicsmanufacturing

Explore tagged Tumblr posts

Text

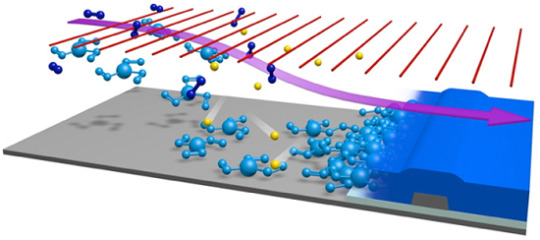

Selective soldering 🔧🔬🔥

Selective soldering involves attaching specific components to printed circuit boards (PCBs) and molded modules, a method particularly useful for items susceptible to heat damage from standard reflow ovens or wave soldering found in conventional surface-mount technology (SMT) or through-hole assembly techniques. Typically, this method is applied after an initial SMT oven reflow phase. The components targeted for selective soldering are often nestled among others already soldered via a surface-mount reflow method. This demands high precision in the selective soldering process to prevent damage to the surrounding elements.

#adafruit#selectivesoldering#pcbassembly#electronicsmanufacturing#surface-mount#throughhole#reflowprocess#precisionengineering#solderingtechnology#circuitboarddesign#manufacturinginnovation#techadvancements

5 notes

·

View notes

Text

#electronics#industry#manufacturing#quality#technology#electronicsmanufacturing#Electronic Manufacturing Services#Top EMS India

2 notes

·

View notes

Text

Why Aimtron is a Trusted Name in ESDM Services

In the rapidly evolving electronics industry, Electronics System Design & Manufacturing (ESDM) plays a crucial role in bringing innovative solutions to life. Companies seeking reliability, expertise, and cutting-edge technology turn to Aimtron, a name synonymous with excellence in electronics manufacturing. But what makes Aimtron stand out as a trusted provider of ESDM solutions? Let’s explore the key factors behind its reputation.

Commitment to High-Quality Electronics Design

Aimtron’s journey in electronics design has been defined by precision engineering and innovation. From conceptualization to prototyping, the company ensures that each design meets industry standards and client-specific requirements. Its expertise in electronic circuits, embedded systems, and component selection has made it a go-to choice for businesses seeking robust, scalable solutions.

Excellence in PCB Assembly Services

One of Aimtron’s core strengths lies in PCB assembly services, where it delivers highly reliable and efficient printed circuit boards for various applications. Using advanced manufacturing techniques, stringent quality control measures, and state-of-the-art equipment, Aimtron provides cost-effective yet high-performance PCB solutions tailored to industry needs.

End-to-End ESDM Solutions

What sets Aimtron apart is its ability to offer comprehensive ESDM solutions—from design and prototyping to manufacturing and testing. Clients benefit from an integrated approach that streamlines production, reduces costs, and ensures seamless functionality. Whether it’s for consumer electronics, automotive systems, industrial machinery, or medical devices, Aimtron guarantees top-tier manufacturing expertise.

Trusted by Industries Worldwide

With years of experience in electronics manufacturing, Aimtron has built strong relationships with global clients across diverse industries. Its reputation is backed by consistent delivery, cutting-edge technology, and an unwavering commitment to quality. By prioritizing customer satisfaction and continual improvement, Aimtron remains a trusted name in ESDM services.

Conclusion

In the competitive world of electronics, reliability and expertise make all the difference. Aimtron’s dedication to electronics design, PCB assembly services, and ESDM solutions solidifies its standing as a trusted partner for businesses seeking world-class manufacturing. With a focus on quality, innovation, and customer success, Aimtron continues to lead the way in modern electronics development.

0 notes

Text

Looking for cutting-edge microchips for your embedded systems or IoT devices? Discover precision-engineered microelectronics designed for speed, reliability, and compact integration. Ideal for industrial automation, healthcare tech, drones, and smart devices. Explore top-tier PCB design and custom electronics manufacturing services today.

Discover more related topics here!

www.auckam.com

#EmbeddedSystems#MicrochipDesign#PCBA#ElectronicsManufacturing#IoTSolutions#PCBDesign#Semiconductor#TechInnovation#HardwareEngineering#IndustrialAutomation

0 notes

Text

Impact of Semiconductor and Electronics Industry on U.S. Chemical Vapor Deposition Market

The U.S. chemical vapor deposition market was valued at USD 4.15 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 8.6% from 2024 to 2030. This growth is attributed to technological advancements in the semiconductor industry, increasing demand for high-performance and energy-efficient devices, and the growing need for miniaturized semiconductor components are some of the key driving factors. Additionally, the rise in the adoption of CVD in various applications such as data storage, solar products, and cutting tools is also contributing to the market growth. However, the market’s expansion is not without challenges. Factors such as high equipment costs and the need for skilled labor can potentially hinder market growth.

For More Details or Sample Copy please visit link @: U.S. Chemical Vapor Deposition Market

The U.S. CVD market is characterized by rapid technological advancements and a high degree of innovation. Ongoing advancements in CVD techniques, such as plasma-enhanced CVD and atomic layer deposition, are driving the market. Significant research and development investments are being made by industry players and research institutions to develop innovative deposition processes, materials, and applications.

The chemical vapor deposition equipment segment dominated the U.S. market in 2023. This dominance can be attributed to the extensive use of CVD equipment in various industries, including semiconductors, electronics, and solar panels. The equipment is used to deposit thin films and coatings on substrates, which are essential in the manufacturing of semiconductors and other electronic components. The high demand for these components, driven by the growing electronics and semiconductor industries, has led to a significant market share of the CVD equipment segment.

The semiconductor & microelectronics segment dominated the U.S. market in 2023. The high market share is attributed to the increasing demand for high-quality and high-performance materials in the aerospace and defense sectors has been a significant driver for using CVD technology. Furthermore, in the U.S., rising demand for miniaturized and high-performance electronic devices has propelled the adoption of CVD for thin-film deposition of semiconductors and insulating materials.

Gain deeper insights on the market and receive your free copy with TOC now @: U.S. Chemical Vapor Deposition Market

List of key players in U.S. Chemical Vapor Deposition Market

Veeco Instruments Inc.

IHI Ionbond AG

Applied Materials Inc.

OC Oerlikon Corporation AG

ULVAC Inc.

CVD Equipment Corporation

Lam Research Corporation

#ChemicalVaporDeposition#CVDMarket#USMarketTrends#ThinFilmTechnology#AdvancedManufacturing#ElectronicsManufacturing#BiomedicalCoatings#AerospaceTechnology#RenewableEnergyTech#IndustrialCoatings

0 notes

Text

https://autoevtimes.com/government-slashes-import-duty-on-ev-battery-phone-parts/

#electronicsmanufacturing#EVbattery#mobilephone#EV#MakeInIndia#Electronics#Sustainability#electricvehiclesnews#evtimes#autoevtimes#evbusines

0 notes

Text

Hitech Circuits—Your Reliable Supplier for Premium PCB Assembly

At Hitech Circuits, we specialize in high-efficiency, high-precision surface mount technology (SMT) assembly, delivering unmatched capacity and quality for your PCB projects.

Our Capabilities:

1. Massive Daily Output

1 Million+ Components Placed Daily**: Powered by fully automated SMT lines (e.g., Fuji NXT, Siemens SIPLACE) and high-speed pick-and-place systems, we ensure rapid production scaling for both prototypes and bulk orders.

2. Advanced Packaging Expertise

QFN/BGA Mastery: Our precision equipment handles ultra-fine-pitch components, including QFN (0.3mm pitch) and BGA (down to 0.2mm ball diameter), with 99.99% placement accuracy.

X-Ray Inspection: 100% in-line X-ray verification for BGA solder joints, voids, and alignment defects, ensuring zero hidden faults.

3. End-to-End Quality Control

AOI + SPI Integration: Automated Optical Inspection (AOI) and Solder Paste Inspection (SPI) at every stage.

IPC-A-610/612 Compliance: Certified processes for mission-critical applications.

Why Choose Us?

Speed-to-Market: 48-hour prototype turnaround & 10-day mass production cycles.

Flexible MOQs: Support for small-batch R&D to 100k+ volume orders.

Global Material Sourcing: Access to a vetted network of component suppliers, reducing lead times.

Contact Us Today!

Let’s optimize your PCB assembly with speed, precision, and reliability.

Email:[email protected]

Tel & Whatsapp: +86-180333061378

Location: Building C, Suojia Technology Park, Hangcheng, Xixiang, Shenzhen, Guangdong, China

Authority certification: we're fully ISO9001:2015, ISO14001:2015 , UL (E354070) and RoHS certificated. You can reply on us for custom PCB production and Electronic assembly.

0 notes

Text

Best Fume Absorbers in India – Ascomp Inc.

Ensure a Safe and Clean Work Environment with High-Quality Fume Absorbers

In industrial workplaces, soldering stations, laboratories, and manufacturing units, toxic fumes and airborne contaminants pose serious health risks. Investing in a high-quality fume absorber in India is essential for maintaining a safe and healthy work environment. At Ascomp Inc., we offer advanced fume extraction solutions designed to eliminate harmful vapors and pollutants efficiently.

Why Do You Need a Fume Absorber?

✔ Removes Toxic Fumes – Protects workers from harmful gases, soldering smoke, and chemical vapors. ✔ Improves Air Quality – Ensures a clean and safe working atmosphere. ✔ Enhances Worker Safety – Prevents respiratory diseases and health hazards caused by prolonged fume exposure. ✔ Increases Productivity – Reduces discomfort and health risks, leading to better efficiency. ✔ Complies with Safety Regulations – Meets industrial air quality standards for fume control.

Types of Fume Absorbers Offered by Ascomp Inc.

1. Soldering Fume Absorbers

Designed for electronics and PCB soldering applications.

Equipped with high-efficiency carbon filters to remove harmful smoke.

Compact, portable, and easy to install on workbenches.

2. Industrial Fume Extractors

Ideal for heavy-duty manufacturing and welding operations.

High-power multi-stage filtration for superior air purification.

Suitable for factories, automotive workshops, and chemical labs.

3. Laser Fume Absorbers

Specially designed for laser cutting, engraving, and marking processes.

Effectively captures and filters out laser-generated fumes and dust particles.

Increases machine lifespan by preventing residue buildup.

4. Portable Fume Absorbers

Lightweight and compact for easy mobility.

Designed for small workshops, educational labs, and repair centers.

Energy-efficient with low power consumption.

5. Multi-Arm Fume Extraction Systems

Suitable for large-scale production units and industrial setups.

Comes with flexible arms for covering multiple workstations.

High-capacity filters for continuous air purification.

Industries That Need Fume Absorbers

✅ Electronics & PCB Soldering – Prevents exposure to soldering fumes and flux vapors. ✅ Welding & Metalworking – Eliminates toxic gases from welding and fabrication processes. ✅ Laser Cutting & Engraving – Controls dust and smoke generated during laser operations. ✅ Chemical & Pharmaceutical Industry – Ensures safe handling of volatile chemicals. ✅ Jewelry & Watchmaking – Protects workers from fine metal dust and polishing fumes.

Why Choose Ascomp Inc. for Fume Absorbers in India?

✔ High-Efficiency Filtration Technology ✔ Wide Range of Fume Absorption Solutions ✔ Durable and Energy-Efficient Designs ✔ Affordable Pricing with Bulk Order Options ✔ Reliable Customer Support & After-Sales Service

Order the Best Fume Absorber in India Today!

Keep your workplace safe, clean, and free from harmful fumes with Ascomp Inc.'s premium fume absorbers. Contact us now for expert advice and the best prices in India!

#FumeAbsorber#ESDSafety#IndustrialAirPurification#AscompInc#SolderingSafety#AirQualityControl#FumeExtractor#WorkplaceSafety#IndustrialEquipment#ElectronicsManufacturing

0 notes

Text

Electronic Chemicals and Materials Market Share by Region: Trends and Forecasts for 2032

The global electronic chemicals and materials market has been experiencing robust growth and is poised to continue its upward trajectory in the coming years. With technological advancements across various sectors, the demand for specialized chemicals and materials used in the manufacture of electronic devices is set to expand significantly. In this article, we explore the size, share, and growth analysis of the electronic chemicals and materials market through 2032.

Electronic chemicals and materials encompass a broad range of substances and compounds used in the production of semiconductors, printed circuit boards (PCBs), flat panel displays, solar panels, and other electronic devices. These materials are crucial for the functioning of electronic products that we use every day, from smartphones and laptops to renewable energy technologies and automotive systems.

Request a Free Sample Copy - https://www.skyquestt.com/sample-request/electronic-chemicals-and-materials-market

The electronic chemicals and materials market includes components like:

- Semiconductor chemicals: Photoresists, etching chemicals, and others used in semiconductor fabrication.

- Printed circuit board materials: Copper foil, solder mask, and other materials essential for PCB manufacturing.

- Display materials: Polymers, liquid crystals, and other compounds vital for flat-panel displays.

- Solar materials: Silicon, substrates, and conductive materials used in the creation of solar panels.

- Battery chemicals: Materials used in the production of batteries for electronic devices and electric vehicles.

Market Size and Forecast

The global electronic chemicals and materials market was valued at USD 62.07 Billion in 2024 to USD 108.64 Billion by 2032 and is expected to grow at a compound annual growth rate (CAGR) of 7.24% between 2025 and 2032. This growth can be attributed to several factors:

1. Increasing demand for consumer electronics: With the rise in disposable income and changing consumer lifestyles, the demand for electronic products such as smartphones, wearables, and laptops is on the rise. This, in turn, is driving the need for electronic chemicals and materials.

2. Advancements in semiconductor technologies: As the world continues to rely more heavily on digital technologies, semiconductors remain at the heart of this growth. The increasing complexity of semiconductor devices and the push for smaller, faster, and more energy-efficient chips will require more advanced chemicals and materials.

3. Electrification of transportation: The rapid adoption of electric vehicles (EVs) has created a significant demand for battery materials. As EV manufacturers seek to enhance the energy density and charging speed of their batteries, there is a growing need for advanced battery chemicals.

4. Development of renewable energy sources: Solar power is a key contributor to the renewable energy sector. As countries strive to reduce their carbon footprint, the demand for solar panels—and consequently, the materials used to make them—is increasing. This will continue to boost the demand for electronic chemicals and materials over the coming years.

5. Global manufacturing expansion: In regions like Asia-Pacific, particularly China, South Korea, and Japan, the presence of major electronics manufacturers is driving demand for electronic chemicals and materials. Similarly, North America and Europe are also seeing an uptick in demand due to the rapid growth in electric vehicle production and semiconductor manufacturing.

Make an Inquiry to Address your Specific Business Needs - https://www.skyquestt.com/speak-with-analyst/electronic-chemicals-and-materials-market

Market Segmentation

The electronic chemicals and materials market can be segmented based on type, application, and region.

By Type

1. Semiconductor Chemicals: These materials are crucial in the production of semiconductors and integrated circuits (ICs). Semiconductors represent the largest share of the market due to their widespread application across electronics, automotive, and telecommunication industries.

2. PCB Materials: Printed circuit boards are an essential component of all electronic devices, ranging from consumer electronics to automotive systems. Materials such as copper, solder, and substrates make up a significant portion of the market.

3. Display Materials: Liquid crystals, polymer materials, and conductive films used in the creation of displays, particularly in flat-panel televisions, smartphones, and computer screens, are seeing significant growth.

4. Battery Chemicals: The production of lithium-ion batteries used in smartphones, laptops, and electric vehicles is fueling the demand for battery chemicals, such as lithium, cobalt, and nickel-based materials.

By Application

1. Consumer Electronics: Smartphones, laptops, tablets, and other devices are the largest consumers of electronic chemicals and materials.

2. Automotive: As electric vehicles (EVs) gain traction, the demand for specialized materials in battery technology, as well as advanced electronic components in automobiles, is rapidly increasing.

3. Renewable Energy: Solar panels, energy storage systems, and other clean technologies rely heavily on electronic materials, creating significant growth opportunities.

4. Telecommunication: The demand for high-performance electronic devices and components, driven by the proliferation of 5G networks, is contributing to the growth of the market.

Regional Analysis

The electronic chemicals and materials market is geographically diverse, with key regions including North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

- Asia-Pacific: This region holds the largest share of the market, primarily driven by the presence of leading electronics manufacturers in countries like China, South Korea, and Japan. Additionally, the region’s growing semiconductor industry and the widespread adoption of electric vehicles are contributing to the market’s growth.

- North America: The increasing demand for electronic materials in automotive applications (especially EVs) and the development of advanced semiconductor technologies are key growth drivers in North America.

- Europe: Similar to North America, Europe is witnessing a surge in demand for electric vehicles and renewable energy technologies, which in turn is bolstering the demand for electronic chemicals and materials.

Take Action Now: Secure Your Electronic Chemicals and Materials Market Today - https://www.skyquestt.com/buy-now/electronic-chemicals-and-materials-market

Market Trends and Drivers

1. Miniaturization of Electronic Devices: As devices become smaller and more powerful, there is an increasing need for specialized chemicals that can enable the production of smaller, more efficient components, such as transistors, capacitors, and resistors.

2. Focus on Sustainability: With growing environmental concerns, there is a greater emphasis on sustainable production methods for electronic materials. Innovations in recycling and the development of eco-friendly materials are gaining momentum.

3. Advancement in Semiconductor Fabrication: As the semiconductor industry moves towards more advanced technologies like 5G, AI, and quantum computing, there is a growing demand for specialized chemicals that can meet the stringent requirements of next-generation chips.

Electronic Chemicals and Materials Market Top Players Company Profiles

Shin-Etsu Chemical Co., Ltd. (Japan)

Linde Plc (England)

Fujifilm Corporation (Japan)

Resonac Holding Corporation (Japan)

Air Liquide (Paris)

Solvay (Belgium)

BASF SE(Germany)

Mitsui Chemicals America, Inc. (US)

Merck KGaA (Germany)

Covestro AG (Germany)

SUMCO Corp. (Japan)

Air Products & Chemicals, Inc. (US)

Songwon (South Korea)

Cabot Microelectronics Corporation

Dow Chemical Company

Honeywell International Inc.

Huntsman Corporation

Kanto Chemical Co., Inc.

Momentive Performance Materials Inc.

Samsung SDI Co., Ltd.

Challenges

Despite the strong growth prospects, the electronic chemicals and materials market faces some challenges:

- Supply Chain Issues: The market’s reliance on complex global supply chains for key materials such as rare earth elements and lithium can be impacted by geopolitical tensions and disruptions like those seen during the COVID-19 pandemic.

- Cost Volatility: The prices of raw materials, particularly those required for battery production, are subject to fluctuations, which can impact the overall cost of production.

Read Electronic Chemicals and Materials Market Report Today - https://www.skyquestt.com/report/electronic-chemicals-and-materials-market

The electronic chemicals and materials market is on a strong growth trajectory, driven by the ongoing advancements in consumer electronics, electric vehicles, semiconductor fabrication, and renewable energy technologies. With a projected market value of USD 108.64 billion by 2032, the sector offers abundant opportunities for innovation and expansion. Companies involved in the production of electronic chemicals and materials will continue to play a critical role in powering the next generation of technological advancements and addressing the challenges posed by a rapidly evolving global market.

#ElectronicChemicals#SemiconductorMaterials#ElectronicMaterials#TechMaterials#MaterialScience#ElectronicsIndustry#Nanotechnology#TechInnovation#ElectronicsManufacturing#ChemicalsMarket#SustainableTech#AdvancedMaterials#SmartElectronics#ElectronicComponents#SemiconductorIndustry#HighTechMaterials#ElectronicsProduction#IndustrialChemicals#MaterialsScience#Nanomaterials

0 notes

Text

Address - 119, Shiv Shakti Industrial Estate, Lal Bahadur Shastri Rd, opp. Shantiniketan Hospital, Ghatkopar West, Mumbai, Maharashtra 400086 Phone - +91 8879359506 / +91 9920809230

#TouchSensorManufacturers#ProxSynergy#TouchTechnology#Innovation#ElectronicsManufacturing#SmartSensors#Automation#CapacitiveTouch#SensorSolutions#TechInnovation#ElectronicComponents#IndustrialAutomation#SmartDevices#MumbaiManufacturers#QualitySensors

0 notes

Text

Are you struggling with unstable PCB setups and inefficient workflows? The PAJ-450 is designed to bring precision, stability, and efficiency to your assembly process. Whether you're working on prototyping, R&D, or mass production, this modular jig is the ultimate game-changer!

💡 Why Choose PAJ-450? ✅ Modular & Reconfigurable – Easily adapt to different PCB sizes 🔄 ✅ Stable & Secure Holding – Spring-loaded system ensures precision 🎯 ✅ Dual Work Areas – Work on multiple projects simultaneously ⚡ ✅ Optimized Component Placement – Reduce errors and improve workflow 🛠️ ✅ Built to Last – High-quality SS304 steel construction 🏗️

🚀 Upgrade your PCB assembly process today! 🔗 Shop now – Link in bio!

#PCBAssembly #ElectronicsManufacturing #PCBDesign #Engineering #Innovation #TechTools #PCBTesting #ProductivityBoost #EstovirTechnologies #smtems #MadeInIndia

#estovirtechnologies#PCBAssembly#ElectronicsManufacturing#PCBDesign#Engineering#Innovation#TechTools#PCBTesting#ProductivityBoost#EstovirTechnologies#smtems#MadeInInd

0 notes

Text

Aimtron: A Name You Can Trust for PCB Assembly Manufacturing Services in Illinois

When it comes to PCB assembly manufacturing services, quality and reliability are paramount. With Aimtron, you can trust that you're working with a leader in the industry, providing top-notch services in Illinois and beyond. Our commitment to excellence and customer satisfaction has earned us a stellar reputation in the field of electronics manufacturing.

Unparalleled PCB Assembly Services

At Aimtron, we pride ourselves on offering comprehensive PCB assembly services tailored to meet the unique needs of our clients. Our state-of-the-art facility in Illinois is equipped with cutting-edge technology and staffed by highly skilled professionals. We handle everything from prototyping to full-scale production, ensuring your project is completed with precision and efficiency.

Expertise in PCB Design

In addition to our assembly services, Aimtron specializes in PCB design. Our team of experienced engineers works closely with clients to develop innovative and effective solutions. We understand that each project is different, and we customize our designs to meet your specific requirements. With our expertise, you can be confident that your PCB design will be optimized for performance and manufacturability.

Commitment to Quality

Quality is the cornerstone of Aimtron's PCB assembly manufacturing services. We adhere to strict industry standards and employ rigorous quality control measures throughout the production process. From the selection of raw materials to the final inspection, every step is meticulously monitored to ensure the highest level of quality and reliability. Our dedication to quality has earned us numerous certifications, including ISO 9001 and IPC-A-610.

Serving a Wide Range of Industries

Aimtron's PCB assembly services cater to a diverse array of industries, including telecommunications, medical devices, automotive, consumer electronics, and more. Our versatile capabilities and extensive experience allow us to handle projects of all sizes and complexities. Whether you need a small batch of prototypes or a large-scale production run, we have the expertise and resources to deliver exceptional results.

Customer-Centric Approach

At Aimtron, we believe in building strong, long-lasting relationships with our clients. Our customer-centric approach ensures that we understand your needs and provide personalized solutions that exceed your expectations. We are committed to delivering exceptional value, timely delivery, and unparalleled support throughout the entire project lifecycle.

Conclusion

When it comes to PCB assembly manufacturing services in Illinois, Aimtron is a name you can trust. With our expertise in PCB design, commitment to quality, and customer-centric approach, we are dedicated to helping you achieve success in your electronics manufacturing projects. Partner with Aimtron and experience the difference that a trusted industry leader can make.

#pcbassembly#pcbassemblymanufacturer#pcbassemblyservices#pcbassemblyservice#electronicsmanufacturing#PCBassemblyManufacturingServicesinIllinois

0 notes

Text

Elevate Your Electronic Components with Custom-Machined Polypropylene Plastics! 🛠️✨

Discover how precision-engineered polypropylene components can enhance the performance and durability of your electronic products. Dive into our latest insights and see how our tailored solutions can meet your specific needs.

0 notes

Text

How Aimtron’s PCB Assembly Meets Industry Standards

In the fast-paced realm of electronics manufacturing, precision, reliability, and compliance are paramount. Aimtron, a trusted leader in the industry, sets itself apart by providing top-notch PCB Assembly Services that consistently meet and exceed industry standards. From meticulous craftsmanship to advanced technology, Aimtron demonstrates its commitment to excellence in PCB Assembly Solutions. Here’s a closer look at how Aimtron maintains its competitive edge while upholding the highest benchmarks in the industry.

Cutting-Edge Technology in PCB Assembly

Aimtron embraces state-of-the-art technology to ensure its PCB Assembly processes are efficient, precise, and scalable. With fully automated pick-and-place machines, in-line optical inspection systems, and advanced soldering techniques, Aimtron delivers unmatched quality in every project. The use of cutting-edge tools reduces errors and ensures that even the most complex assemblies meet stringent requirements.

Strict Adherence to Industry Standards

At Aimtron, compliance is more than a box to check—it's a core value. The company adheres to globally recognized standards, including ISO 9001 for quality management and IPC-A-610 for the acceptability of electronic assemblies. By aligning its Electronics Manufacturing processes with these benchmarks, Aimtron ensures that every product meets customer expectations for safety, reliability, and performance.

Tailored Solutions for Diverse Needs

No two projects are identical, and Aimtron understands the importance of customized PCB Assembly Solutions. Whether dealing with prototype development, low-volume production, or large-scale manufacturing, Aimtron adapts its approach to meet client-specific requirements. This flexibility allows the company to cater to industries such as automotive, healthcare, consumer electronics, and telecommunications.

End-to-End Services

Aimtron’s comprehensive PCB Assembly Services include design support, component sourcing, assembly, and rigorous quality control. This end-to-end approach ensures seamless project management and enables clients to focus on innovation while Aimtron handles the technical complexities of Electronics Manufacturing.

Sustainability and Innovation

In addition to meeting industry standards, Aimtron is committed to eco-friendly practices. The company minimizes waste, adheres to RoHS (Restriction of Hazardous Substances) directives, and optimizes energy consumption during PCB Assembly. This dedication to sustainability aligns with the growing demand for greener solutions in the electronics sector.

Conclusion

Aimtron’s unwavering commitment to quality, compliance, and innovation positions it as a leader in the PCB Assembly landscape. By delivering reliable PCB Assembly Services and customized PCB Assembly Solutions that meet industry standards, Aimtron continues to set the benchmark for excellence in Electronics Manufacturing. Whether you’re developing the next big tech innovation or streamlining an existing product, Aimtron is the partner you can trust for superior results.

0 notes

Text

A detailed view of a printed circuit board (PCB) with electronic components, transformers, and precision tools arranged on a white background—ideal for illustrating electronics manufacturing, PCB design, or hardware engineering processes.

Explore more content tailored for you

www.auckam.com

#PCBDesign#CircuitBoard#ElectronicsManufacturing#HardwareEngineering#TechAssembly#EmbeddedSystems#ElectronicComponents#SolderingStation#PCBTesting#IoTDevices

0 notes

Text

https://electronicsbuzz.in/posspole-partners-with-essci-to-boost-esdm-skill-development/

#POSSPOLE#ESDM#SkillDevelopment#ElectronicsManufacturing#MakeInIndia#WorkforceDevelopment#TechSkills#powerelectronics#powermanagement#powersemiconductor

0 notes