#Industrial estimating software

Explore tagged Tumblr posts

Text

How Industrial Estimating Service Helps Control Costs in Manufacturing Plants

Cost control is a critical aspect of managing manufacturing plants. Whether you're dealing with production processes, equipment purchases, or labor management, maintaining financial discipline is essential for profitability and long-term success. One of the most effective ways to keep costs under control is through the use of industrial estimating services. These services provide accurate cost projections, which allow manufacturers to plan more effectively, avoid unnecessary expenses, and optimize resource usage.

This article explores how industrial estimating services help control costs in manufacturing plants, from production planning to resource allocation and everything in between.

1. Accurate Cost Estimation for Resource Allocation

Effective cost control starts with accurate estimates. Industrial estimating services use historical data, advanced software, and market analysis to provide precise cost forecasts for materials, labor, and overhead costs. These estimates enable manufacturing plants to allocate resources more efficiently, ensuring that production runs smoothly without overspending.

How It Helps:

Material Cost Management: Accurate estimation of raw material costs helps prevent overordering or underordering, both of which can lead to waste or shortages.

Labor Cost Planning: Estimating labor requirements allows for efficient workforce planning, ensuring that the plant has the right number of workers for each phase of production.

Overhead Cost Allocation: Estimating overheads accurately helps identify areas where expenses can be reduced, such as energy consumption or facility maintenance.

2. Budgeting and Financial Planning

Industrial estimating services provide a clear financial roadmap for manufacturing plants, offering detailed breakdowns of anticipated costs. This helps plant managers set realistic budgets and track expenses as the project progresses. A solid financial plan reduces the risk of cost overruns, allowing for better control of cash flow and working capital.

How It Helps:

Clear Budgeting: A detailed cost estimate provides an initial framework for budgeting, helping plants avoid financial surprises.

Tracking and Monitoring: With continuous tracking of actual costs against estimated costs, manufacturers can make adjustments in real-time to keep spending on track.

Contingency Planning: By including contingencies in the initial estimate, industrial estimating services help prepare plants for unforeseen costs, reducing the likelihood of financial strain.

3. Risk Mitigation and Cost Avoidance

Industrial projects often face unexpected risks such as supply chain disruptions, labor shortages, or regulatory changes that can escalate costs. Industrial estimating services can help identify and assess these risks early in the project, allowing plants to plan for potential cost increases and take preventative measures.

How It Helps:

Identifying Risks: Estimators use data analysis to foresee potential challenges, such as material price hikes or delays in supply chains, and account for these in the cost projections.

Preventative Measures: Based on risk assessments, plant managers can implement strategies to mitigate risks, such as sourcing alternative materials or adjusting production timelines.

Scenario Analysis: Estimating services can run different scenarios to show how various risks might impact costs, enabling manufacturers to develop contingency plans.

4. Optimizing Operational Efficiency

By analyzing the cost of labor, materials, and overhead, industrial estimating services can help manufacturers identify inefficiencies in their operations. Estimating tools can pinpoint areas where production processes may be too costly, helping manufacturers find ways to streamline operations and reduce waste.

How It Helps:

Process Optimization: Identifying high-cost areas in production helps manufacturers implement process improvements, such as adopting lean manufacturing principles or automation.

Waste Reduction: By analyzing material usage, estimating services can help manufacturers reduce scrap and rework, ultimately lowering production costs.

Equipment Utilization: Accurate cost estimates can also help ensure that equipment is being used effectively, reducing downtime and maximizing the return on investment in machinery.

5. Supporting Strategic Decision-Making

Industrial estimating services provide critical insights that support long-term strategic decision-making. Whether deciding to expand production capacity, invest in new technology, or make other large-scale financial commitments, having a reliable cost estimate helps ensure that decisions are made based on sound financial projections.

How It Helps:

Capital Investment Planning: When considering capital expenditures, industrial estimating services provide cost forecasts that guide investment decisions, ensuring they align with the plant’s financial capabilities.

Expansion Decisions: Cost estimates for new facilities or product lines help determine the feasibility of expansion and whether it will lead to profitable returns.

Technology Upgrades: Estimating services assess the costs and benefits of adopting new technologies, allowing manufacturers to invest in innovations that will drive long-term savings.

6. Enhancing Supply Chain Management

Effective supply chain management is essential for controlling costs in manufacturing. Industrial estimating services help evaluate the total cost of procurement, transportation, and inventory management. By analyzing supply chain variables, manufacturers can make more informed decisions about sourcing materials and managing stock levels.

How It Helps:

Supplier Evaluation: Estimating services provide insights into the cost-effectiveness of different suppliers, enabling manufacturers to choose the most cost-efficient options.

Transportation Cost Analysis: By factoring in transportation and logistics costs, industrial estimating services help manufacturers optimize supply chain routes and minimize delivery expenses.

Inventory Optimization: Accurate material cost estimation allows manufacturers to manage their inventory more effectively, ensuring that they don’t overstock or run out of essential materials.

7. Improving Project and Product Lifecycle Management

Managing the entire lifecycle of a manufacturing project, from planning to production and maintenance, requires careful cost control. Industrial estimating services help track costs throughout each phase of the project, enabling plant managers to stay on top of expenses and make adjustments as needed.

How It Helps:

Lifecycle Cost Estimation: Estimating services provide a complete cost breakdown for each phase of the project, from design to commissioning, enabling better decision-making.

Maintenance Planning: For ongoing operations, industrial estimating services help plan for the cost of maintenance and repairs, reducing the risk of unexpected downtime.

Long-Term Profitability: By accurately forecasting costs over the long term, industrial estimating services help ensure that projects and products remain financially sustainable.

Conclusion

Industrial estimating services play a vital role in controlling costs within manufacturing plants. By providing accurate cost forecasts, identifying risks, optimizing resource allocation, and supporting decision-making, estimating services help manufacturers stay within budget and maximize efficiency. With the right estimating partner, manufacturers can reduce financial risks, improve operational performance, and enhance profitability, ensuring long-term success in a competitive industry.

#Industrial estimating service#cost control in manufacturing#manufacturing cost estimation#industrial project budgeting#resource allocation in manufacturing#accurate cost estimation#industrial cost forecasting#supply chain management in manufacturing#labor cost estimation#material cost forecasting#overhead cost management#manufacturing cost analysis#cost optimization in manufacturing#production cost estimation#financial planning for industrial projects#risk mitigation in manufacturing#operational efficiency in manufacturing#manufacturing plant budget planning#contingency planning in industrial projects#supply chain cost estimation#inventory management and cost control#lean manufacturing cost estimation#manufacturing process optimization#equipment cost estimation#industrial estimating software#predictive cost analysis#manufacturing project feasibility#material price forecasting#production planning and budgeting#cost management for manufacturing plants

0 notes

Text

Rethinking Estimations in the Age of AI

Rethinking estimations in AI-driven processes has become essential in the fast-paced world of IT and software development. Estimations shape project timelines, budgets, and expectations, yet traditional practices often lead to inefficiency and frustration. In a previous post, I explored the #NoEstimates movement and its call to move beyond traditional estimation techniques. Here, I’ll dive deeper…

#agile practices#AI#data-driven#Efficiency#estimations#historical data#IT industry#predictability#project planning#software development

0 notes

Text

Manufacturing Cost Estimating Software for Automotive Industry | Cost It Right

Explore the leading Manufacturing Cost Estimating Software for the Automotive Industry. Streamline cost tracking, improve accuracy, and optimize manufacturing processes with our tailored solutions. Get precise, real-time cost estimates for automotive production, helping you make informed decisions and boost profitability.

#Manufacturing Cost Estimating Software for Automotive Industry#best cost estimation software for manufacturer

0 notes

Text

#Saudi Arabia Marine Fleet Management Software Market#Market Size#Market Share#Market Trends#Market Analysis#Industry Survey#Market Demand#Top Major Key Player#Market Estimate#Market Segments#Industry Data

0 notes

Text

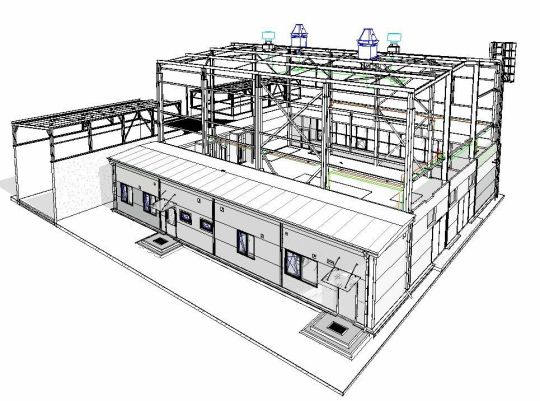

Exploring the Diverse Landscape of BIM Software in Construction: A Comprehensive Guide

Introduction: In the ever-evolving field of construction, Building Information Modeling (BIM) has emerged as a transformative technology that revolutionizes the way buildings are designed, constructed, and managed. BIM software plays a pivotal role in enhancing collaboration, improving efficiency, and minimizing errors throughout the construction process. This article delves into the various…

View On WordPress

#architectural design software#as-built documentation#BIM model accuracy#BIM software#Building Information Modeling#collaboration platforms#construction industry advancements#construction management software#construction project efficiency#Construction Technology#cost estimation tools#facility maintenance optimization#facility management solutions#laser scanning technology#LiDAR applications#MEP systems modeling#point cloud integration#project stakeholders collaboration#real-time coordination#structural engineering tools#sustainable building practices

0 notes

Text

#Construction Estimating#Construction Estimating Resources#Reliable Construction Cost Analysis#Professional Construction Estimator#Construction Estimating Techniques#Industrial Construction Estimates#Best Practices for Construction Estimating#Commercial Construction Cost Estimates#Construction Estimating Services#Accurate Construction Estimates#Cost Estimation for Construction Projects#Construction Cost Estimating Software#Construction Estimating Software#Construction Estimating Tools#Residential Construction Estimates#Construction Estimating Process#Construction Quantity Takeoff#Construction Budgeting and Estimating#Constructin Estimating Consultants#Construction Estimating Accuracy#Construction Estimates Templates#Construction Estimating Training#Construction Takeoff Software#Construction Estimate Comparison#Construction Bid Estimation#Construction Estimating Tips#e-procurement#Building Materials & Supplies#3D Renderings#Construction Spreadsheets

1 note

·

View note

Text

Maximizing Your Film's Financial Potential: A Complete Budgeting Handbook

🎥📊 Ready to take your film to the next level? Check out our new budgeting handbook to maximize your financial potential! 💰🤑 #filmfinance #budgetinghandbook #financialpotential

If you’re planning to create a film, it’s important to have a clear understanding of your finances. Budgeting is a crucial aspect of filmmaking, as it ensures that you have enough resources to bring your vision to life. With the right approach, you can maximize your film’s financial potential and create a masterpiece that captivates your audience. In this budgeting handbook, we’ll cover all the…

View On WordPress

#budget allocation#budget analysis#budget forecasting#budget management#budget planning#budget preparation#budget software#budget template#budgeting handbook#budgeting tips#cost estimation#cost management#expense tracking#film accounting#film budgeting#film finance#film funding#film industry#film production#filmmaking#financial control#financial planning#independent film#money management#movie budget#production budget#project budget

1 note

·

View note

Text

Common Pitfalls in Industrial Estimating Service and How to Avoid Them

Industrial estimating service is a crucial aspect of project planning, helping businesses determine accurate costs for materials, labor, equipment, and unforeseen expenses. However, even experienced estimators can make costly mistakes that lead to budget overruns, project delays, and financial losses. Understanding these pitfalls and how to avoid them can significantly improve the accuracy and reliability of cost estimates.

1. Inaccurate or Incomplete Project Data

One of the most common pitfalls in industrial estimating is relying on incomplete or outdated project data. Without accurate information on material costs, labor rates, and project specifications, estimators may produce unreliable cost estimates.

How to Avoid It:

Gather detailed project requirements, including material specifications, site conditions, and workforce needs.

Use up-to-date cost databases and historical project data to ensure accuracy.

Collaborate closely with engineers, contractors, and suppliers to obtain precise information.

2. Underestimating Material Costs

Material prices fluctuate due to market conditions, inflation, and supply chain disruptions. Underestimating these costs can lead to budget shortfalls and procurement issues.

How to Avoid It:

Monitor market trends and material price changes regularly.

Include a contingency budget to account for unexpected price increases.

Work with reliable suppliers to secure competitive pricing and reduce cost variations.

3. Overlooking Labor Productivity Rates

Failing to account for labor productivity variations can result in inaccurate labor cost estimates. Factors such as worker skill levels, site conditions, and project complexity affect productivity.

How to Avoid It:

Use industry benchmarks and historical data to estimate labor productivity accurately.

Adjust labor estimates based on the complexity and location of the project.

Consider potential delays caused by weather conditions, union regulations, and workforce availability.

4. Ignoring Project-Specific Risks

Every industrial project has unique risks, including regulatory compliance, environmental factors, and equipment failures. Ignoring these risks can lead to unexpected expenses.

How to Avoid It:

Conduct a thorough risk assessment before finalizing estimates.

Include contingency funds for unforeseen challenges.

Stay informed about industry regulations and environmental requirements.

5. Inconsistent Use of Estimating Software

Many companies rely on estimating software, but inconsistent or incorrect usage can lead to errors. Misinputted data or outdated software can affect cost projections.

How to Avoid It:

Ensure estimators are trained in using the latest estimating software.

Regularly update cost databases and software settings.

Cross-check manual calculations with software-generated estimates for accuracy.

6. Failure to Factor in Inflation and Supply Chain Disruptions

Inflation and supply chain issues can significantly impact industrial project costs. Overlooking these factors may result in underestimated budgets.

How to Avoid It:

Include an inflation adjustment factor in long-term projects.

Diversify supply chain options to mitigate material shortages.

Monitor global economic trends to anticipate cost fluctuations.

7. Not Revisiting and Updating Estimates

Cost estimates should not be treated as fixed numbers. Failing to revise estimates as the project progresses can lead to discrepancies between budgeted and actual costs.

How to Avoid It:

Conduct regular cost reviews throughout the project lifecycle.

Adjust estimates based on real-time project updates.

Maintain clear communication between project managers, estimators, and financial teams.

8. Overlooking Hidden Costs

Hidden costs, such as equipment maintenance, transportation, and compliance fees, can add up over time. Ignoring these expenses can cause financial strain.

How to Avoid It:

Break down estimates into detailed cost components, including indirect expenses.

Identify all potential cost factors, including permits, inspections, and logistics.

Account for additional site preparation or unforeseen environmental adjustments.

9. Lack of Collaboration Between Teams

Poor communication between estimators, engineers, contractors, and suppliers can lead to misunderstandings and inaccurate estimates.

How to Avoid It:

Foster collaboration between all project stakeholders.

Organize regular meetings to align expectations and verify data accuracy.

Encourage transparency in cost estimation processes.

10. Unrealistic Schedule Assumptions

Underestimating project timelines can result in rushed work, increased labor costs, and missed deadlines. Delays can further inflate costs due to extended equipment rentals and idle labor.

How to Avoid It:

Develop realistic timelines based on past project experiences.

Account for potential weather disruptions, permitting delays, and supply chain issues.

Plan schedules with buffer time to absorb unforeseen delays.

Conclusion

Industrial estimating service is a fundamental part of project planning, but common pitfalls can undermine its effectiveness. By ensuring accurate data collection, monitoring market trends, integrating risk management strategies, and improving collaboration, businesses can enhance the reliability of their cost estimates. Avoiding these pitfalls will lead to better financial control, improved project efficiency, and reduced risk of budget overruns.

#Industrial estimating service#industrial cost estimation#industrial project budgeting#industrial construction estimating#industrial cost forecasting#industrial estimating software#industrial estimating consultant#industrial infrastructure estimating#industrial project cost analysis#industrial material cost estimation#industrial labor cost analysis#industrial risk assessment#industrial estimating accuracy#industrial project feasibility study#industrial project scheduling#industrial cost control#industrial estimating best practices#industrial construction cost planning#industrial estimating service provider#industrial supply chain cost estimation#industrial energy sector estimating#industrial cost estimation challenges#industrial estimating technology#industrial cost optimization#industrial project financial planning#industrial contingency planning#industrial equipment cost analysis#industrial estimating trends#industrial estimating in manufacturing#industrial construction bid estimating

0 notes

Text

U.S. Copyright Office Presses 'Pause' on DMCA Exemption for Video Games

By Lydia Leung, LLB | Last updated on November 08, 2024

When we think of a library, we picture never-ending shelves of books; the world's knowledge available to us at the touch of a finger. But nowadays, it's not just physical records that libraries collect. Many now lend video games to their members, providing their local communities with entertainment while helping preserve the software for future generations.

The recent decision by the U.S. Copyright Office (USCO) to reject an exemption to the DMCA for video games in libraries' collections has put that practice into question. The decision prevents video games from being accessed remotely by researchers. While some in the games industry view this ruling as a win for rights holders, others see it as a major setback for arts research, especially compared to researchers in other fields with "routine and regular access" to digital archives.

What Is The DMCA?

Passed in 1998, the Digital Millennium Copyright Act (DMCA) brought the U.S. in line with treaties of the World Intellectual Property Organization (WIPO), updating copyright law for the digital age. Section 1201 of the DMCA criminalizes the "circumvention of copyright protection systems" that prevent unauthorized access to copyrighted works, such as reading encrypted optical discs or removing copy restrictions from electronic documents.

Exemptions are made for some uses, including for nonprofit libraries, archives and educational institutions (section 1201(d)), as long as a "good faith" determination is made. Libraries are permitted to create digital copies of obsolete works for purpose of preservation, but those works must not be commercially available for a "reasonable price" and can only be accessed onsite.

The Petition

The Video Game History Foundation (VGHF) has been working with the Software Preservation Network (SPN) since 2021 on a petition to the U.S. Copyright Office, proposing that the DMCA digital copying exemption be expanded to allow access to games outside of the physical premises of an institution. A study published by the VGHF in July 2023 estimated that 87% of video games released in the US before 2010 are "critically endangered" and inaccessible, being out of print in either physical or digital form. Options to play classic games are limited as many require vintage hardware or are no longer available on a digital storefront, potentially pushing consumers and researchers towards piracy as the most convenient means of access.

The petition's main argument is framed from the perspective of fair use: works kept by archives and collections are exempt from copyright infringement laws if they are used for purposes such as research or teaching. To enable this, the SPN proposed a system of user vetting and copyright notices, allowing institutions to restrict access only to users who submit a research request detailing the scope of their project and providing notices to remind them that their access is subject to copyright law.

The requirement of having to request specific access ensures that games are being used for research purposes, with the SPN citing "academic literacy" as a way of filtering out users planning to access them for entertainment. The USCO already allows institutions to lend other forms of media remotely, and the SPN argued that the DMCA's stringent rules around distribution of software programs places impediments on video game scholarship that are not present in other disciplines.

Arguments Against

The Entertainment Software Association (ESA), a trade association representing the U.S. video game industry, opposed the SPN petition, stating that the exemption would leave rights owners insufficiently protected and that the market for classic video games would be damaged. The SPN's proposed method of fair use vetting was dismissed by the ESA as "illusory", arguing that this was not enough justification for the breadth of use they would enable. It would be too difficult for libraries to supervise multiple users remotely accessing games, thus enabling usage for entertainment purposes.

Furthermore, the ESA contended that the market for classic video games is "vibrant and growing", citing the number of titles currently available on digital storefronts such as the Xbox Game Pass, not to mention frequent re-releases of individual titles on modern systems. That a game is "out of print" does not mean it is lost forever, only that the copyright owner decided not to put it on the market. Allowing widespread remote access to classic games would present a serious risk to the market and prevent copyright owners from enforcing their copyrights.

The USCO Ruling

The USCO observed that, for a fair use exemption, access to the games would have to be guarded against recreational use by containing "appropriately tailored restrictions". The view taken by the ESA on the SPN's proposed restrictions was echoed by the USCO, which ruled that they were not specific enough to prevent market harm and that the SPN had not met the burden of showing that allowing simultaneous remote access by multiple users was likely to be fair.

Regarding the claims of market damage put forth by the ESA, the USCO acknowledged the evidence presented of a "substantial market" for classic video games, and the SPN's concession that the industry has made a greater effort in recent years to reissue older games. Considering these arguments, the Register ultimately rejected the petition, but recommended clarifying the wording used in the DMCA to reflect that a computer program may be accessed by as many individuals as the institution owns copies.

What Does This Mean?

As a newer form of digital media, U.S. law has yet to settle on a definitive classification of what copyrights arise from a video game. A common view is for games to be treated as computer software and for the source code to be considered a literary work. However, unlike "traditional" literary works such as books or newspapers, the interactive nature of a video game makes regulating access to it more complicated.

Games are often limited to their corresponding hardware, potentially leading to research costs going up as researchers may be forced to travel long distances or somehow purchase a retro console for themselves; not to mention potential consideration of extra-legal methods. Researchers are pushed into focusing on works that are easy to access rather than those they have a true interest in studying. Teaching is also affected: academics cannot assign their students games with historical or technological significance if they may not be able to access them (for example, the original Metroid Prime (2002), noted for its female protagonist and being the first game in the series to use 3D graphics, is only available on the GameCube). This curtails the growth of video game studies, introducing obstacles to a field with deepening cultural impact and technological advancement.

In their submission to the USCO, the SPN compared the rise of video games to the film industry, highlighting the creation of the National Film Preservation Board in 1988 as a way of recognizing that films are a part of cultural heritage, worthy of academic preservation and study. Whether games will ever reach that status remains uncertain: they make up a large part of our cultural and entertainment landscape today and it's clear that they are here to stay, but only time will tell whether the USCO's attitudes change.

Man, come the fuck on....

i think CEO's should be rounded up and shot personally

14 notes

·

View notes

Text

Before he was abruptly fired last month, Derek Copeland worked as a trainer at the US Department of Agriculture’s National Dog Detection Training Center, preparing beagles and Labrador retrievers to sniff out plants and animals that are invasive or vectors for zoonotic diseases, like swine flu. Copeland estimates the NDDTC lost about a fifth of its trainers and a number of other support staff when 6,000 employees were let go at the USDA in February as part of a government-wide purge orchestrated by the Trump administration and Elon Musk’s so-called Department of Government Efficiency (DOGE).

Before he received his termination notice, he says, Copeland had just spent several months training the only dog stationed in Florida capable of detecting the Giant African land snail, an invasive mollusk that poses a significant threat to Florida agriculture. “We have dogs for spotted and lantern flies, Asian longhorn beetles,” he says, referring to two other non-native species. “I don’t think the American people realize how much crap that people bring into the United States.”

Dog trainers are just one example of the kind of highly specialized USDA staff that have been removed from their stations in recent weeks. Teams devoted to inspecting plant and food imports have been hit especially hard by the recent cuts, including the Plant Protection and Quarantine program, which has lost hundreds of staffers alone.

“It’s causing problems left and right,” says one current USDA worker, who like other federal employees in this story asked to remain anonymous for fear of retaliation. “It’s basically a skeleton crew working now,” says another current USDA staffer, who noted that both they and most of their colleagues held advanced degrees and had many years of training to protect US food and agriculture supply chains from invasive pests. “It’s not something that is easily replaced by artificial intelligence.”

“These aren’t your average people,” says Mike Lahar, the regulatory affairs manager at US customs broker behemoth Deringer. “These were highly trained individuals—inspectors, entomologists, taxonomists.”

Lahar and other supply chain experts warn that the losses could cause food to go rotten while waiting in ports and could lead to even higher grocery prices, in addition to increasing the chances of potentially devastating invasive species getting into the country. These dangers are especially acute at a moment when US grocery supply chains are already reeling from other business disruptions such as bird flu and President Trump’s new tariffs.

“If we're inspecting less food, the first basic thing that happens is some amount of that food we don't inspect is likely to go bad. We're going to end up losing resources,” says supply chain industry veteran and software CEO Joe Hudicka.

The USDA cuts are being felt especially in coastal states home to major shipping ports. USDA sources who spoke to WIRED estimate that the Port of Los Angeles, one of the busiest in the US, lost around 35 percent of its total Plant Protection and Quarantine staff and 60 percent of its “smuggling and interdiction” employees, who are tasked with stopping illegal pests and goods from entering the country. The Port of Miami, which handles high volumes of US plant imports, lost about 35 percent of its plant inspectors.

Navigating the workforce cuts has “been absolute chaos,” says Armando Rosario-Lebrón, a vice president of the National Association of Agriculture Employees, which represents workers in Plant Protection and Quarantine program.

“These ports were already strained in how they process cargo, and now some of them have been completely decimated,” Rosario-Lebrón says. "We could be back to pandemic-level issues for some goods if we don't fix this."

The Department of Agriculture did not respond to a request for comment. Republican senator Joni Ernst, who has been a vocal backer of DOGE’s efforts, previously publicly supported the USDA’s dog training program and cosponsored legislation that would give it permanent funding. Her office declined to comment on cuts made to it.

Two federal judges and an independent agency that assesses government personnel decisions have already ordered that fired USDA employees be reinstated. Earlier this week, the USDA said that it was pausing the terminations for 45 days and would “develop a phased plan for return-to-duty.” But affected staff remain in the dark about their future, and the Trump administration has signaled it will fight court decisions to reinstate employees, with White House press secretary Karoline Leavitt calling one of the rulings “absurd and unconstitutional.”

As these legal and regulatory battles continue to play out, Hudicka says he anticipates a number of trickle-down effects to happen, such as local market wars over resources, which bigger cities and larger grocery chains will be better equipped for than mom-and-pops and rural communities. Hudicka says that allowing shipping containers to sit uninspected could also impact other sectors, as the delays will prevent them from being reused for other kinds of goods. “Those containers are supposed to be moving stuff every day, and now they’re just parked somewhere,” he says.

Kit Johnson, the director of trade compliance at the US customers broker John S. James, also predicts prices and waste to increase. But what raises the most alarms for him is the increased likelihood of invasive species slipping through inspection cracks. He says the price of missing a threatening pest is “wiping out an entire agricultural commodity,” an event that could have “not just economic but national security impacts.”

Decimating the Department of Agriculture could even have consequences for US Customs and Border Protection, which deploys the dogs trained by Copeland and other staffers at the National Dog Detection Training Center. CBP works closely with the USDA in other ways as well, particularly at points of entry. The two agencies run the Agricultural Quarantine Inspection program, but it’s funded by the USDA. Many Animal and Plant Health Inspection Service programs do not rely on taxpayer dollars to operate but instead collect fees from importers and other industry players. In this way, it subsidizes some of CBP’s agriculture-related activities. CBP did not respond to a request for comment.

As the fired USDA workers wait to hear whether their reinstatements will actually take place, ports are beginning to feel their absence. “There aren’t as many inspections being done, and it doesn’t just put us at risk,” says Lahar. “It puts our farmers and our food chains at risk.”

11 notes

·

View notes

Text

Top Manufacturing Cost Estimating Software for Automotive Industry | Cost Optimization Tools

Explore the best cost estimation software for manufacturers to enhance production accuracy and profitability. Leading solutions are designed to streamline cost estimation processes, reduce waste, and optimize resource allocation for automotive manufacturers.

1. Cost It Right

Cost It Right is an industry-leading Manufacturing Cost Estimating Software for automotive sector. With its advanced features, it allows manufacturers to streamline their cost estimation process, offering accurate cost breakdowns, labor, material, and overhead costs for each project. It leverages smart analytics to predict future costs, reduce wastage, and optimize resources. Its intuitive user interface, combined with powerful integration capabilities, ensures that automotive manufacturers can seamlessly incorporate it into their existing systems. Whether for new product designs or continuous improvement of production lines, Cost It Right provides the precision and scalability automotive manufacturers need to stay competitive.

2. Auto Estimator Pro

Auto Estimator Pro is another widely used software in the automotive industry, offering comprehensive cost estimation capabilities. It provides detailed project cost breakdowns and material requirements, which is particularly beneficial for manufacturers aiming to scale production without compromising on quality.

3. WinEstimator

WinEstimator is a cost estimation tool favored by automotive manufacturers for its detailed modeling of labor, material, and overhead expenses. Known for its robust reporting features, WinEstimator helps automotive companies analyze costs across different stages of production, offering valuable insights for decision-making.

4. ProEst

ProEst is a versatile cost estimating software that supports multiple industries, including automotive manufacturing. It is appreciated for its ability to provide real-time cost data and integrate seamlessly with other business systems, allowing automotive manufacturers to manage their operations more efficiently.

5. Estimator 360

Estimator 360 is designed to offer automotive manufacturers an all-in-one solution for estimating production costs. The software provides tools for labor cost estimation, material usage analysis, and overhead projections, making it a reliable tool for improving overall cost accuracy and decision-making.

Why Choose Cost It Right?

What makes Cost It Right stand out in the Manufacturing Cost Estimating Software landscape is its specialized focus on the automotive industry. Unlike generic solutions, it offers tailored tools to handle the unique complexities of automotive manufacturing. Its user-friendly interface, coupled with in-depth analytics and cost forecasting, ensures that automotive manufacturers can stay ahead of market trends, reduce unnecessary expenses, and optimize their operations for maximum profitability.

#best cost estimation software for manufacturer#Manufacturing Cost Estimating Software for Automotive Industry

0 notes

Text

#Saudi Arabia Marine Fleet Management Software Market#Market Size#Market Share#Market Trends#Market Analysis#Industry Survey#Market Demand#Top Major Key Player#Market Estimate#Market Segments#Industry Data

0 notes

Text

crowdstrike hot take 5: so who was incompetent, really?

OK so it's the first Monday after the incident. CrowdStrike (CS) is being tight-lipped about the actual cause of the incident, which Microsoft estimates to have affected 8.5 million devices.

Here's an unconfirmed rumor: CS has been firing a lot of QA people and replacing them with AI. I will not base this post on that rumor. But...

Here's a fact: wikipedia listed 8429 CS employees as of April 2024. Now the updated page says they have 7925 employees in their "Fiscal Year 2024".

Anyway. Here's a semi-technical video if you want to catch up on what bluescreen and kernel-mode drivers are in the contexts of the CS incident by a former microsoft engineer. He also briefly mentions WHQL certification - a quality assurance option provided by Microsoft for companies who want to make sure their kernel drivers are top-notch.

Now conceptually, there are two types of updates - updates to a software itself, and a definition update. For a videogame, the software update would be a new feature or bugfixes, and content update would add a new map or textures or something. (Realistically they come hand in hand anyway.) For an antivirus/antimalware, a definition update is basically a list of red flags - a custom format file that instructs the main software on how to find threats.

The video mentions an important thing about the faulty update: while many people say "actually it wasn't a software update that broke it, it was a definition file", it seems that CS Falcon downloads an update file and executes code inside that file - thus avoiding the lengthy re-certification by Microsoft while effectively updating the software.

Some background: On audits in software

A lot of software development is unregulated. You can make a website, deploy it, and whether you post puppy pictures or promote terrorism, there's no one reviewing and approving your change. Laws still apply - even the puppy pictures can be problematic if they include humans who did not consent to have their photos taken and published - but no one's stopping you immediately from publishing them.

And a lot of software development IS regulated - you cannot make software for cars without certifications, you cannot use certain programming languages when developing software for spaceships or MRIs. Many industries like online casinos are regulated - IF you want to operate legally in most countries, you need a license, and you need to implement certain features ("responsible gaming"), and you must submit the actual source code for reviews.

This varies country by country (and state by state, in USA, Canada, etc) and can mean things like "you pay $200 for each change you want to put to production*", or it can mean "you have to pay $40'000 if you make a lot of changes and want to get re-certified".

*production means "web servers or software that goes to end customers", as opposed to "dev environment", "developer's laptop", "QA environment" or "staging" or "test machines", "test VMs" or any of the other hundreds way to test things before they go live.

The certification, and regular audits, involves several things:

Testing the software from user's perspective

Validating the transactions are reported correctly (so that you're not avoiding taxes)

Checking for the user-protecting features, like being able to set a monthly limit on depositing money, etc

Checking the source code to make sure customers are not being ripped off

Validating security and permissions, so a janitor can't download or delete production databases

Validating that you have the work process that you said you would - that you have Jira (or similar) tickets for everything that gets done and put to production, etc, and

...that you have Quality Assurance process in place, and that every change that goes to production is tested and approved

You can see why I highlighted the last point, right.

Now, to my knowledge, security software doesn't have its own set of legal requirements - if I want to develop an antivirus, I don't need a special permission from my government, I can write code, not test it at all, and start selling it for, idk for example $185 per machine it gets deployed to.

And here's the thing - while there certainly is a level of corruption / nepotism / favoritism in the IT industry, I don't think CloudStrike became one of the biggest IT security providers in the world just by sweet talking companies. While there isn't any legal regulation, companies do choose carefully before investing into 3rd party solutions that drastically affect their whole IT. What I mean, CloudStrike probably wasn't always incompetent.

(Another rumor from youtube comments: A company with ~1000 employees was apparently pressured by an insurance company to use CrowdStrike - whether it's a genuine recommendation, an "affiliate link" or just plain old bribery... I do not know.)

WHY what happened is still very baffling

See, this is what would be the process if I was running a security solutions company:

a team is assigned a task. this task is documented

the team discusses the task if it's non-trivial, and they work on it together if possible

solo developer taking the task is not ideal, but very common, since you cannot parallelize (split it between several people) some tasks

while developing, ideally the developer can test everything from start to finish on their laptop. If doing it on their laptop isn't possible, then on a virtual machine (a computer that runs only inside software, and can be more or less stored in a file, duplicated, restored to a previous version, backed up, etc, just by copying that file)

in case of automated software updates, you would have "update channels". In this case it means... like if you have a main AO3 account where you put finished things, and then you'd have another AO3 account where you only put beta fics. So in my hypothetical company, you'd have a testing update channel for each developer or each team. The team would first publish their work only on their update channel, and then a separate QA team could test only their changes.

Either way, after maybe-mostly-finishing the task, the code changes would be bundled in something called a "pull request" or "PR" or "merge request". It's basically a web page that displays what was the code before and after. This PR would be reviewed by people who have NOT worked on the change, so they can check and potentially criticize the change. This is one of the most impactful things for software quality.

Either before or after the PR, the change would go to QA. First it would be tested just in the team's update channel. If it passes and no more development is needed on it, it would go to a QA update channel that joins all recent changes across all teams.

After that, it would be released to an early access or prerelease update channel, sometimes called a canary deploy. Generally, this would be either a limited amount - maybe 100 or 1000 computers, either used internally, or semi-randomly spread across real clients, or it could be as much as 10% of all customers' computers.

THEN YOU WAIT AND SEE IF THERE ARE NO ERROR REPORTS.

Basically ALL modern software (and websites! all the cookies!) collect "metrics" - like "how often each day is this running", or "did our application crash"

you absolute MUST have graphs (monitoring - sometimes this is a part of discipline called "reliability engineering") that show visually things like the number of users online, how many customers are lagging behind with updates, how many errors are reported, how many viruses are being caught by our software. If anything goes up or down too much, it's a cause for concern. If 10% of your customers are suddenly offline after a canary deploy is out, you're shitting your pants.

ONLY after waiting for a while to see everything is okay, you can push the update to ALL clients. It is unfathomable how anyone would do that straight away, or maybe how someone could do it without proper checks, or how the wrong thing got sent to the update.

As ClownStrike is still silent about the actual cause of the issue, we can only make guesses about how much they circumvented their own Quality Assurance process to push the faulty update to millions of computers.

It gets worse

Here's the thing: CrowdStrike itself allows users to create computer groups and let them choose the update channel. You, as a business customer, can say

these 100 unimportant laptops will have the latest update

these important servers will have N-1 update (one version behind)

the rest of the company will have N-2 update (two update versions behind)

CrowdStrike has ignored those settings. According to some youtube comments, supposedly they pushed the update to "only" 25% of all devices - which is worrying to think this could have gone even worse.

Third time isn't the charm

And hey, do you know what happened two years before CrowdStrike was founded? The CEO George Kurtz was at the time, in 2010, the CTO of McAfee, the controversial / crappy security company (IMO offering one of the worst antivirus programs of all times, that was aggressively pushed through bundled OEM deals). In both 2009 and 2010 their enterprise software deleted a critical operating system file and bricked a lot of computers, possibly hundreds of thousands.

And yes, the trigger wasn't an update to the antivirus itself, but a faulty "definition update". Funny coincidence, huh.

12 notes

·

View notes

Text

All Cops Are Bastards... at least if you're Catholic

14 June 2024, 7:17 a.m. GMT

In an unscheduled announcement, Pope Francis, presumably in an effort to regain the trust of the historically anti-police LGBTQ+ community after being recorded using a homophobic slur, has declared that all marriages which resulted in a child who later became a police officer shall be annulled by the Catholic Church.

This latest papal decree comes as a shock to many clergy and laymen alike, but sources close the Pope say this has been at the forefront of his mind ever since a 2019 episode of Paw Patrol featuring a canine pope who made "undignified decisions" at the behest of the show's police dog, Chase. These decisions include using his forbidden powers to banish an unruly pigeon straight to hell after it tried eating a single grain of his holy kibble, using autotune software to exclude other animals from mass by saying prayers in a pitch so high only God and dogs can hear it, and ultimately destroying the fictional "pup mobile" in an effort to stop the mayor of Adventure Bay from codifying the Separation of Church and State.

In his statement, Francis said, "God, … in His infinite knowledge, knows which unions of Man and Woman will result in children who will later become police officers, and He does not recognize those unions in His Great Kingdom of Heaven."

The announcement may prove to be rather costly for the Church, as the Archdiocese of New York—which, since its elevation from diocese to archdiocese in 1850, has only ever had Irish-American leadership (we checked)—has released a statement claiming that, considering the long history of Irish-American police officers in New York City, the Church will have to do an intensive audit of its clergy to determine how many of them were unknowingly born out of wedlock, and thus falsely ordained. If this number proves large enough, it could lead to a significant portion of the Archdiocese's congregation learning that they, and their families, were never actually baptized. Religious scholars warn that this may lead to a schism or even the rise of seemingly oxymoronic "Irish-Protestantism," as some laymen would rather proclaim a false Pope than their own false baptism.

Francis has assured the press that he's "not worried about false baptisms at all," since baptisms within the Catholic Church need not be performed by a Catholic priest.

"The bigger concern is false marriages," says 52-year-old half-Italian professor of religious studies at Florida University College, Kingston whose name has been omitted as he asked to remain anonymous. "Think of how many people a single priest marries. Now imagine that priest's brother became a cop. Because of that brother's decision, now they're both the result of an illegitimate union, and all those people who think they've been married in the eyes of God have actually been living in sin this whole time, not to mention their children, who are illegitimate as well. It's really a cascading effect when you think about it. Our early calculations estimate that under this new rule, nearly one third of Catholics in the United States are bastards, and nearly one third of Catholic 'marriages' in the United States are illegitimate."

Some critics have drawn attention to the fact that this announcement comes just weeks after reports that the Church has purchased nearly $2.8 billion worth of stock in the U.S. wedding industry. When asked if the two events are related, the Vatican declined to comment.

17 notes

·

View notes

Note

So you've got a full time job in animation, right? PLEASE tell me (us, all of us) how long did it take to get in the industry, I'm personally having some PLANS, but I need some estimation ><

Yep, I’ve been working full-time as a 2D animator for a while now. But my personal experience can likely be not so helpful. Anyway. I would say it took me about one year from starting learning to job offer. Half a year - if we talk about serious interest to get a job in the field. I applied only to two vacancies in total, completed one test task for one of them (the first company didn’t send me one), and then my art director from my current job found me himself and offered me their test task. By that time I was already good at what I do, I think, so they liked my test task.

But here comes the list of buts (not butts, sorry!) - I do art professionally for years so I have a solid base in the field, animation stuff just layered on top. I often help junior artists as a teacher or mentor. Also my company and I match with our weird vibes of sort. Other people in animation called my pick of projects for my portfolio strange, sometimes disturbing, but my art director liked it.

Other things to mention is I’m 100% self taught and haven’t attended any courses or animation schools. LinkedIn Learning has several useful videos on the classic animation foundations, YouTube has tons of tutorial videos on the software, they’re my teachers.

Feel free to ask anything more specific.

10 notes

·

View notes