#Industrial Hoist Manufacturers

Explore tagged Tumblr posts

Text

Looking for Crane Hoist Manufacturers in India? Ailas Engineered is your trusted manufacturer and supplier, offering high-quality, heavy-duty crane hoists for all industrial applications.

#Electric Hoist Suppliers in India#Chain Hoist Manufacturers#Wire Rope Hoist Suppliers#Industrial Hoist Manufacturers#Heavy-Duty Hoists India#Custom Hoists for Cranes#Crane Hoist Manufacturers India#Ailas Engineered Hoist Solutions#Top Hoist Manufacturers in India#Reliable Crane Hoist Suppliers#Best Industrial Hoist Manufacturers

0 notes

Text

15 Ton Overhead Cranes For Steel Slabs Handling

IntroductionManufacturing Process of Double Girder Overhead CranesUtilization of Double Girder Overhead Cranes in the Steel IndustryHow to Determine the Price of Your Crane ProjectConclusion Introduction In the world of industrial logistics, efficiency, strength, and reliability are the key characteristics that dictate the quality of equipment. We’re excited to bring forth a prime illustration…

View On WordPress

#coil handling#coil industry cranes#coil lifting#coil loading cranes#coil transport#crane design#crane manufacturing#crane operations#crane safety#girder cranes#heavy-duty cranes#high-capacity crane#hoisting equipment#industrial cranes#load management#material handling#overhead cranes#steel coil production#steel coil storage#steel coils

2 notes

·

View notes

Text

The Ocean Sciences Building at the University of Washington in Seattle is a brightly modern, four-story structure, with large glass windows reflecting the bay across the street.

On the afternoon of July 7, 2016, it was being slowly locked down.

Red lights began flashing at the entrances as students and faculty filed out under overcast skies. Eventually, just a handful of people remained inside, preparing to unleash one of the most destructive forces in the natural world: the crushing weight of about 2½ miles of ocean water.

In the building’s high-pressure testing facility, a black, pill-shaped capsule hung from a hoist on the ceiling. About 3 feet long, it was a scale model of a submersible called Cyclops 2, developed by a local startup called OceanGate. The company’s CEO, Stockton Rush, had cofounded the company in 2009 as a sort of submarine charter service, anticipating a growing need for commercial and research trips to the ocean floor. At first, Rush acquired older, steel-hulled subs for expeditions, but in 2013 OceanGate had begun designing what the company called “a revolutionary new manned submersible.” Among the sub’s innovations were its lightweight hull, which was built from carbon fiber and could accommodate more passengers than the spherical cabins traditionally used in deep-sea diving. By 2016, Rush’s dream was to take paying customers down to the most famous shipwreck of them all: the Titanic, 3,800 meters below the surface of the Atlantic Ocean.

Engineers carefully lowered the Cyclops 2 model into the testing tank nose-first, like a bomb being loaded into a silo, and then screwed on the tank’s 3,600-pound lid. Then they began pumping in water, increasing the pressure to mimic a submersible’s dive. If you’re hanging out at sea level, the weight of the atmosphere above you exerts 14.7 pounds per square inch (psi). The deeper you go, the stronger that pressure; at the Titanic’s depth, the pressure is about 6,500 psi. Soon, the pressure gauge on UW’s test tank read 1,000 psi, and it kept ticking up—2,000 psi, 5,000 psi. At about the 73-minute mark, as the pressure in the tank reached 6,500 psi, there was a sudden roar and the tank shuddered violently.

“I felt it in my body,” an OceanGate employee wrote in an email later that night. “The building rocked, and my ears rang for a long time.”

“Scared the shit out of everyone,” he added.

The model had imploded thousands of meters short of the safety margin OceanGate had designed for.

In the high-stakes, high-cost world of crewed submersibles, most engineering teams would have gone back to the drawing board, or at least ordered more models to test. Rush’s company didn’t do either of those things. Instead, within months, OceanGate began building a full-scale Cyclops 2 based on the imploded model. This submersible design, later renamed Titan, eventually made it down to the Titanic in 2021. It even returned to the site for expeditions the next two years. But nearly one year ago, on June 18, 2023, Titan dove to the infamous wreck and imploded, instantly killing all five people onboard, including Rush himself.

The disaster captivated and horrified the world. Deep-sea experts criticized OceanGate’s choices, from Titan’s carbon-fiber construction to Rush’s public disdain for industry regulations, which he believed stifled innovation. Organizations that had worked with OceanGate, including the University of Washington as well as the Boeing Company, released statements denying that they contributed to Titan.

A trove of tens of thousands of internal OceanGate emails, documents, and photographs provided exclusively to WIRED by anonymous sources sheds new light on Titan’s development, from its initial design and manufacture through its first deep-sea operations. The documents, validated by interviews with two third-party suppliers and several former OceanGate employees with intimate knowledge of Titan, reveal never-before-reported details about the design and testing of the submersible. They show that Boeing and the University of Washington were both involved in the early stages of OceanGate’s carbon-fiber sub project, although their work did not make it into the final Titan design. The trove also reveals a company culture in which employees who questioned their bosses’ high-speed approach and decisions were dismissed as overly cautious or even fired. (The former employees who spoke to WIRED have asked not to be named for fear of being sued by the families of those who died aboard the vessel.) Most of all, the documents show how Rush, blinkered by his own ambition to be the Elon Musk of the deep seas, repeatedly overstated OceanGate’s progress and, on at least one occasion, outright lied about significant problems with Titan’s hull, which has not been previously reported.

A representative for OceanGate, which ceased all operations last summer, declined to comment on WIRED’s findings.

5K notes

·

View notes

Text

One of the Greatest Inventions of All Time

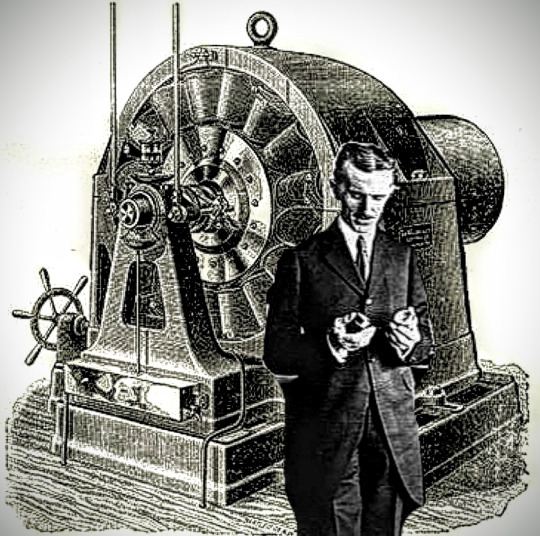

Nikola Tesla has many revolutionary inventions to his credit, but he is best known for his pioneering work in the development and promotion of alternating current (AC) electrical systems. Tesla's innovations in AC technology revolutionized the generation, transmission, and distribution of electrical power, becoming the foundation for the modern electrical power systems that we use today.

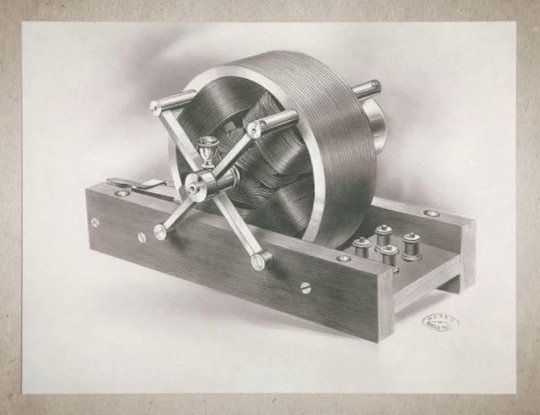

There is a common misconception made that Tesla was the first to invent, or discover, AC, but this is not true. It is well-known that Hippolyte Pixii was the first to discover AC in 1832. Pixii was an instrument maker from Paris who built an early form of an alternating current electrical generator (based on the principle of electromagnetic induction discovered by Michael Faraday), and thus started a new industry in power transmission. Tesla was not the first to discover or invent an AC motor, but he was the first to invent a practical AC induction motor with commercial value that could outperform all other motors. It must be noted that Italian inventor Galileo Ferraris also invented an induction motor similar to Tesla's, but it had no commercial value, and he even admitted himself that it was useless. Tesla's induction motor operates on the principle of electromagnetic induction, properly utilizing a rotating magnetic field that induces a current in a stationary conductor, resulting in rotational motion. The utilization of the rotating magnetic field makes the motor more simple, robust, versatile, efficient, and cost effective in that it has less moving parts reducing the likelihood of mechanical failure (as was common in other motors).

Tesla's induction motor became a fundamental component in the field of electrical engineering and is used today in various applications, being one of the most widely used devices in the world. The motors play a crucial role in transmitting electrical power to homes and businesses. They are commonly used in power generation plants to convert mechanical energy into electrical energy, which is then transmitted through the power grid for distribution to various locations. Induction motors are also widely employed in appliances and machinery within homes and businesses for various applications. These applications include conveyor systems, hoists, cranes, lifts, pumps, fans, ventilation systems, compressors, manufacturing machinery, wind turbines, washing machines, refrigerators, garbage disposals, microwaves, dishwashers, vacuums, air conditioners, robotics, electric vehicles, trains, power tools, printers, etc. Basically, anything that requires a spinning action for power.

The induction motor is widely considered one of the most important inventions in the history of electrical engineering. Its importance lies in its transformative impact on industries, its efficiency and reliability, and its role in the broader electrification of society.

#nikola tesla#science#history#invention#discovery#induction motor#electricity#power#goat#ahead of his time#ahead of our time

152 notes

·

View notes

Note

You asked for more Mr. Cracker backstory, well here it is:

He and his cousin Dmitri were originally built for a store display featuring this brand new winter holiday hailing from the Emperor's homeworld, and when he gained sentience he decided to go out and search for a new job because making the same poses again and again and again in a window display is a fucking terrible job. They decided to call each other cousins because they were built by two different companies that work closely together.

Dmitri got a job working security at a shipping yard, but lost his leg when the hoist on the crane failed, dropping a shipping container onto his leg. The company that manufactured the hoist came under scrutiny by Imperial authorities, and was found to be pretty dang corrupt. The company was nationalized shortly thereafter, and thoroughly reorganized. Thankfully, single legs below the knee are a lot easier to replace than what was done to Pyotr or R3gg1e, so he's kind of got this mismatch in his industrial-looking prosthetic vs. the rest of him which looks like a tin soldier. Dmitri is a kind soul, if a little meek, and he's also a fan of classical music, but in his case it's Dmitri Shostakovich.

Thank you for going more in-depth on the characters. I am curious, since they are from Earth, whether technology-based sentient beings have legal rights on Earth, or if they had to leave first.

In order to get a job, they would need to have some form of socially recognized rights (they could be paid under the table if they are not legally recognized as beings by law). Without the law allowing them basic rights, they wouldn't be able to get bank accounts, houses, may not be able to pay for supplies (whatever they eat, replacement parts, etc.), or any legal documents.

Hmm.... that makes me curious about legal rights for non-humans in general across the DC universe. I believe some non-human entities try to disguise themselves as human in order to blend in. I wonder if there's also a legal aspect as well (especially at the beginning of the JL formation). Idk much about the world-building aspects as far as that :/

16 notes

·

View notes

Text

for any program of accumulation to preserve its legitimation and momentum, there must be an underlying mechanism of transmutation in its access and gestation of reception as communicable, socially commuting thought. in the absence of such transmutation, accumulative drives mutate into jarring and insular forms, a desire to hoard that gets vacuously jammed on one’s own onanistic satisfaction, meeting its final distribution in the hoarder’s death, where estate sales serve a function of proportional reuptake.

the intelligence base collectively entreated and honed with trade networks and uploads of impossibly rare media is one such means of resolving this legitimation crisis, or at least keeping the closed circuit from burning, without the intervention of more regulated organizational bodies. is there then a virginal, impervious stature to the dead hoarder, lost at the moment his collection, having absorbed him, is scattered like ashes?

the record, alongside the automobile, is the most archetypally modern luxury object, by the mechanical standardization of its manufacturing and universalizable symbolic structure, the capture and reproduction of presential contiguity through a chain of materials, plates dipped in candy baths of nickel and electromagnetically charged with potential to spark difference in emotional resonance and receptive experience, prolificity from the object’s own time slip as the durational index of concrescence at once sounded. this supplies provisions for a fantasy of consumption without loss. paradise of replica.

the void, the clearing for the flip, at the center of the disc grants it internal cohesion as a model for that passage, to be filled with a baton or a miraculous axial beacon for movements to the other side. in playback, you may find a beatrician glide of guidance in hearing from an openness to a stream of information, the substrate for its restructure. here the distant creed of an bygone online noosphere pierces our ear, information wants to be free. a pop astrologer would regard the record as the higher vibration of products to follow the second industrial revolution, cars are the lower vibration measured by content and consequences of inputs and outputs.

anything that is pure in a sense unweighted by absurdly constrictive and ostentatious ideological accoutrements, whether it is the material consolidation of expression or the will of an individual, should withstand the risk of diminution and obfuscation brought with a network of gemlike eyes laid upon it. nobue kawana is pure even if her index is spread thin by the thirst of those who are desperate to leap from the lure of a cover or an attractive backstory but remain stuck in the purgatory of incomplete reception and comprehension, no doubt mired by a misguided will for phenomenal intake, lost to the virality of epistemic fetishism. i am guilty of this myself! the identification of her as “pure” at this juncture, by a north american anglophone on a corporatized interface that is surveilled and datamined by design, is an affront to the opsec of her purity.

accumulation is not splendor without the haplotes of will and acumen to hoist it past the hypoxic raqia of its tests, higher into a communion of complete accordance, exaltation in the truth of its analytic coherence, losing any need to lathe its diadem down from the gleam of a nascent sighting. the totems of radical individualism are sent into a pyre that tyrannizes its pleasure in pursuit of mastery without masters, the manual for purification already torn. there is good in the world, good in its staging of returns, and good in the wear of its curtain. human creation attends its final callback with joyful abdication as it suffocates the last innocents.

6 notes

·

View notes

Note

“arp forklorp (alsarp callurp industreep treep lorp treep jitnarp hi-lurp farp trarp furp heep arp forklurp trarp eep urp powerorp industrarp trarp useep turp larp arp movorp materorp ovarp shorp distancurp Thurp forkleep warp developeep urp thurp earleep 20thurp centururp borp varurp companarp includeep Cleep wheep madurp transmissurp arp Yalorp &orp Townarp Manufacturarp whurp madorp harp”

- 🍌💜

(Translation: A forklift (also called industrial truck, lift truck, jitney, hi-lo, fork truck, fork hoist, and forklift truck) is a powered industrial truck used to lift and move materials over short distances. The forklift was developed in the early 20th century by various companies, including Clark, which made transmissions, and Yale & Towne Manufacturing, which made hoists.)

-> All four aliens just stare at you, unsure of what to say or think right now.

2 notes

·

View notes

Text

Complete Manual on Hanging Scaffold Systems or Suspended Rope Platforms for plastering

In the realm of construction and maintenance tasks, there’s a stalwart ally that stands tall, quite literally. The Suspended Rope Platform (SRP), often recognized as a gondola or working platform, has become an indispensable tool for a spectrum of vertical endeavors. Specifically, in India, these platforms have etched their place firmly in various industries, revolutionizing the way projects are undertaken.

Evolution of Rope Suspended Platforms

Initially embraced primarily by major facade contractors, the trajectory of SRPs has undergone a significant shift. Over the past three years, a seismic shift has been witnessed, with the paint industry, spanning from manufacturers to applicators, showing an avid interest. This surge in demand has propelled manufacturers of these platforms to the forefront, dominating the market for close to a decade.

The utilization of Suspended Rope Platform isn’t confined to a singular purpose. From external wall plastering, painting high-rise structures, installing glass facades to the maintenance of expansive external surfaces, the applications are diverse and extensive. Even in scenarios necessitating alterations or demolition of buildings, these platforms emerge as indispensable temporary structures.

The Rise of Rope Suspended Platforms

What sets SRPs apart is their ascendance as the preferred mode of access across construction sites. Traditionally, scaffolding held sway, but the inherent advantages of SRPs, including efficiency and versatility, have prompted their ubiquitous presence in the construction landscape.

Quality and Innovation

Platforms like the hanging rope platform hoists from Jaypee India epitomize excellence, constructed meticulously using premium materials such as stainless steel and aluminum. The emphasis on stringent quality control ensures adherence to specified durability and reliability standards, ensuring that only the finest products reach customers.

Moreover, manufacturers of SRPs have undertaken a trajectory of innovation. Varied versions of these platforms cater to diverse job site specifications. Engineers have meticulously designed these platforms, integrating multiple safety measures to mitigate the inherent risks associated with erecting and maintaining tall structures.

Safety Features and Engineering Excellence

Safety stands paramount in the realm of suspended platforms. Manufacturers have embedded an array of safety features into their products to ensure secure operations:

Rope Failure Prevention: Incorporating locks to prevent tilting due to rope failure.

Advanced Technology: Integration of sophisticated mechanical and control electronics.

Quality Wire Ropes: Utilization of high-grade steel wire ropes to guarantee robustness.

Optional Overload Sensing: Offering the option for sensing overload, further enhancing safety.

Cable Locking Angle: Ensuring a secure cable locking angle of 3–8 degrees.

Superior Suspension Systems: Technologically superior suspension systems enhancing stability.

Durability: A testament to longevity, these platforms are engineered to withstand prolonged usage without succumbing to wear and tear.

Sturdy Construction: With a solid construction, these platforms exude reliability and stability.

Energy Efficiency: Notably, the energy requirements for operating these platforms are considerably lower compared to alternative access systems.

Proficient Management and Operations

One defining aspect of the Suspended Rope Platform (SRP),landscape in India is the involvement of extensively trained professionals overseeing the operation and maintenance of these platforms. Amidst a competitive market, manufacturers differentiate themselves by providing top-tier suspended platform services. These adept specialists, well-versed in every facet of access equipment, ensure superior maintenance and repair services right on the job site. From initial setup to operationalizing the platform, these professionals handle it all with finesse and expertise.

In conclusion, the evolution of suspended rope platforms for plastering and other vertical endeavors has heralded a paradigm shift in the construction and maintenance landscape. With an emphasis on safety, innovation, and efficiency, these platforms have become the linchpin in accessing vertical spaces, promising durability, reliability, and optimal performance. As the industry continues to evolve, these platforms are poised to remain at the vanguard, catering to the ever-expanding demands of vertical construction and maintenance tasks.

#Suspended rope platform for plastering#Suspended rope platform#Rope Suspended platform for plastering#Buy Suspended Rope Platform#Rope Suspended Platform (RSP)#Construction Equipment Manufacturer and Supplier in India#Construction Equipment#Facade cleaning system manufacturers in india#Gondola Suspended Rope Platform Manufacturer

3 notes

·

View notes

Text

KRC: Elevating Excellence in Lifting Equipment

In the dynamic world of heavy industries and construction, the demand for reliable and efficient lifting equipment has never been higher. Companies operating in these sectors understand the critical role that high-quality lifting equipment plays in ensuring safety, productivity, and success. One company that stands out in this arena is KRC.

Elevating Safety Safety is paramount in any industrial setting, and KRC takes this responsibility seriously. With a history of providing top-tier lifting equipment, KRC has built a reputation for excellence in safety. Their commitment to adhering to international safety standards and rigorous quality control procedures ensures that every piece of equipment that bears the KRC name is designed and manufactured with safety as the top priority.

A Legacy of Innovation Innovation is the lifeblood of any industry, and KRC has a rich history of pioneering advancements in lifting equipment technology. Their team of engineers and designers are dedicated to developing cutting-edge solutions that make lifting operations safer and more efficient. From state-of-the-art cranes to precision-engineered hoists, KRC’s product range reflects their dedication to innovation.

Quality That Speaks for Itself The quality of lifting equipment can significantly impact the efficiency and longevity of any project. KRC understands this, and their commitment to quality is evident in every product they offer. Rigorous testing and quality assurance processes ensure that KRC’s equipment not only meets but often exceeds industry standards. This dedication to quality has earned KRC the trust of countless companies worldwide.

Global Reach, Local ExpertiseWith a global presence, KRC serves clients in various industries on a worldwide scale. However, what truly sets them apart is their local expertise. KRC’s regional teams understand the unique challenges and requirements of different markets, allowing them to provide tailored solutions that meet local regulations and standards. This combination of global reach and local expertise makes KRC a trusted partner for companies across the globe.

Beyond Products: Comprehensive SolutionsKRC doesn’t just offer lifting equipment; they provide comprehensive solutions. From initial consultations and equipment selection to installation, maintenance, and support, KRC is committed to being a partner throughout the entire project lifecycle. This approach not only ensures smooth operations but also maximizes the return on investment for their clients.

Conclusion In the world of lifting equipment, KRC stands as a beacon of excellence. Their unwavering commitment to safety, innovation, quality, and customer satisfaction has made them a trusted name in the industry. Whether you’re involved in construction, heavy industry, or any field that requires reliable lifting equipment, KRC is a name you can trust to elevate your operations to new heights.

If you’re seeking lifting solutions that prioritize safety, quality, and innovation, look no further than KRC. Your success is their mission, and they’re ready to help you reach it. Elevate your lifting operations with KRC today!

2 notes

·

View notes

Text

Leading Cranes & Hoists Manufacturer in Hyderabad – 18+ Years of Excellence

Sri Gajanana Cranes & Hoists is a leading manufacturer in Hyderabad with over 18 years of expertise in the industry. We specialize in designing, manufacturing, and supplying high-quality Cranes, Hoists, and Lifting Solutions tailored to meet diverse industrial needs. Our commitment to innovation, safety, and durability ensures efficient material handling for businesses across various sectors. Whether you need EOT Cranes, Goliath Cranes, Jib Cranes, or Custom Hoisting Solutions, we deliver reliable and cost-effective equipment to enhance productivity. Contact us today to explore our advanced lifting solutions and experience excellence in crane and hoist manufacturing.

#Cranes

#cranesandhoists

#MaterialHandling

#LiftingSolutions

#IndustrialCranes

#EOTCranes

#GoliathCranes

#JibCranes

#HeavyLifting

#Manufacturing

#HyderabadIndustry

#SriGajananaCranes

#sri gajanana cranes and hoists#Cranes#Hoists#Cranes and hoists#Cranes and hoists manufacturer in hyderabad#jib crane#Goliath cranes#stacker cranes#glantry cranes

0 notes

Text

20 Ton DG and Dual 16 Ton SG Overhead Cranes for Metal Factories

IntroductionManufacturing Process of the CranesThe 20 Ton Double Girder Overhead CraneThe 16 Ton Single Girder Overhead CranesUtilization of the Cranes in Metal Factories20 Ton Double Girder Overhead Crane Usage16 Ton Single Girder Overhead Crane UsageDetermining the Price of Your Crane Project Introduction Welcome to a fresh installment on our blog, where we highlight one of our eminent…

View On WordPress

#16 ton crane#20 ton crane#crane controls#crane installation#crane investment#crane maintenance#crane manufacturing#crane safety#double girder crane#heavy lifting solutions#hoist and trolley#industrial cranes#laser cutting#load bearing capacity#metal factories#metal twisting#overhead cranes#plasma cutting#single girder crane#wimac crane

0 notes

Text

Common Mistakes to Avoid When Using Drum Handling Equipment

Drum handling equipment plays a critical role in ensuring safe and efficient operations in various industries, particularly those involving hazardous or heavy materials. From transporting chemicals to managing bulk products, using drum handling equipment correctly can drastically improve productivity while preventing accidents. However, mistakes are often made during usage, leading to equipment damage or even personal injury. This article will highlight the common mistakes to avoid when using drum handling equipment.

Neglecting Regular Maintenance of Drum Handling Equipment

One of the most common mistakes businesses make is neglecting the regular maintenance of drum handling equipment. Like any other industrial equipment, drum handling systems require consistent upkeep to ensure they function properly and safely. Failing to perform regular inspections, lubrication, and part replacements can lead to premature wear and potential breakdowns. Develop a scheduled maintenance routine, check for rust, loose parts, and damage, and keep the equipment clean and lubricated to extend its lifespan.

Using Incorrect Drum Handling Equipment for Specific Tasks

Many industries use multiple types of drums (steel, plastic, fiber, etc.), and each type of drum has specific handling requirements. A common mistake is using the wrong drum handling equipment for a particular type of drum. For example, using a manual drum lifter designed for steel drums on plastic ones can cause damage to both the drum and the equipment. Ensure that the drum handling equipment is suitable for the type and weight of the drum. Manufacturers typically offer solutions designed for specific materials or drum sizes.

Overloading the Drum Handling Equipment

Overloading is another critical mistake when using drum handling equipment. Many operators assume that equipment can handle more weight than it is rated for, which can lead to equipment failure, accidents, and injuries. Overloading can also damage the drums and compromise the integrity of the contents inside. Always refer to the manufacturer's weight limits and never exceed the specified load capacity for your drum handling equipment. If necessary, use a piece of equipment with a higher weight tolerance.

Inadequate Operator Training

An untrained or inadequately trained operator is more likely to make mistakes when handling drum handling equipment. Mishandling, improper lifting techniques, or lack of awareness of safety protocols can result in injury or equipment damage. Ensure that all operators receive comprehensive training on the proper handling, safety, and maintenance procedures. Certification programs are available and should be considered for operators to enhance their skills and knowledge.

Ignoring Proper Safety Measures and PPE

Safety should always be a priority when using drum handling equipment, especially in environments where hazardous materials are being handled. Many workers neglect the importance of personal protective equipment (PPE) or fail to follow safety guidelines, putting themselves and others at risk. Enforce the use of appropriate PPE, such as gloves, helmets, and steel-toed boots, depending on the environment. Ensure that safety protocols and emergency procedures are clearly defined and followed.

Not Using the Right Drum Lifting Tools for Height and Reach

Improper lifting techniques or choosing the wrong lifting equipment for moving drums to higher shelves or tight spaces is another common mistake. Many workers use general lifting tools that aren't designed for high or awkward spaces, which can result in accidents or the equipment malfunctioning. Use equipment specifically designed for the job. For lifting drums to greater heights or over obstacles, ensure that you select tools like drum hoists or overhead cranes that are designed for such tasks.

Failing to Monitor Drum Condition During Handling

Another mistake is failing to check the condition of the drums before and during handling. Over time, drums can weaken due to wear, external damage, or the harsh nature of their contents. Using damaged drums can be hazardous. Inspect the drums before using them with drum handling equipment. Look for signs of cracks, rust, or any damage that could compromise their integrity during transportation or storage.

Conclusion

In conclusion, drum handling equipment is essential for ensuring smooth, safe, and efficient operations in various industries, particularly in those that require the transport of hazardous or heavy materials. If you’re in need of reliable and efficient drum handling equipment for your business, Meto Systems is a trusted name in providing top-quality industrial solutions. Their wide range of drum handling equipment ensures that you can safely and efficiently transport and store your materials, enhancing your workflow and minimizing risks. Choose Meto Systems for your drum handling needs, and take a step towards operational excellence today.

0 notes

Text

Ganesh Engineering is one of the trusted Wire Rope Hoist manufacturers in India. We offer the top-quality Wire Rope Hoist which is made of high-grade material and advanced level technology. Wire Rope Hoist makes construction work easier for workers. For more queries, reach us.

#WireRopeHoist#hoists#liftingequipment#WireRope#materialhandling#safety#industries#manufacturer#supplier#exporter#Ahmedabad#Gujarat#India#Ganeshcrane

0 notes

Text

What is Steel Wire Rope Used For?

Steel wire rope is an essential component in various industries due to its high strength, durability, and versatility. From construction and mining to maritime and adventure sports, steel wire ropes play a crucial role in ensuring safety and efficiency. In this blog, we will explore the numerous applications of steel wire rope and why it is a preferred choice across industries.

1. Construction and Infrastructure

Steel wire ropes are widely used in the construction industry for lifting, rigging, and hoisting applications. Tower cranes, elevators, and suspension bridges rely on high-quality wire ropes for stability and performance. Their ability to withstand heavy loads and harsh environments makes them indispensable in infrastructure projects.

2. Mining and Excavation

In the mining sector, steel wire ropes are used in hoisting systems, draglines, and underground mining operations. Their high tensile strength ensures safe and efficient transportation of minerals and materials from deep within the earth. Wire rope manufacturers in India supply specialized mining ropes designed for extreme conditions.

3. Oil and Gas Industry

The oil and gas industry requires robust and corrosion-resistant ropes for drilling, mooring, and lifting operations. Offshore drilling rigs and platforms depend on steel wire ropes to handle high loads in challenging marine environments. The use of galvanized and stainless-steel ropes enhances their longevity and performance.

4. Shipping and Maritime Applications

Ships, ports, and marine vessels extensively use steel wire ropes for mooring, towing, and anchoring. Their ability to withstand saltwater corrosion and extreme weather conditions makes them a reliable choice for maritime applications. Steel rope manufacturers in India produce high-quality ropes to meet the demanding requirements of the shipping industry.

5. Cranes and Material Handling

Steel wire ropes are the backbone of material handling equipment, including mobile cranes, overhead cranes, and forklifts. These ropes ensure safe and efficient lifting operations, reducing the risk of accidents and improving productivity.

6. Elevator and Escalator Systems

Passenger and freight elevators rely on steel wire ropes for smooth and safe movement between floors. The durability and flexibility of these ropes enhance the efficiency and reliability of modern vertical transportation systems.

7. Adventure Sports and Aerial Activities

Steel wire ropes are a crucial safety component in adventure sports such as zip-lining, bungee jumping, and rope courses. They provide secure anchoring and support for thrill-seekers, ensuring a safe experience.

8. Defense and Aerospace Industry

Military and aerospace applications require specialized steel wire ropes for aircraft controls, naval operations, and defense equipment. These ropes are engineered to withstand extreme stress and environmental conditions, making them suitable for critical missions.

9. Agriculture and Forestry

In the agricultural and forestry sectors, steel wire ropes are used for fencing, winching, and logging operations. Their high load-bearing capacity and durability make them ideal for securing and transporting heavy timber.

10. Structural and Safety Systems

Wire ropes are an integral part of structural and safety systems such as suspension bridges, stadium roofs, and industrial safety barriers. Their strength and flexibility allow for innovative architectural designs while maintaining safety standards.

Choosing the Right Wire Rope Manufacturer

When selecting a wire rope manufacturer, it is crucial to consider factors such as material quality, manufacturing standards, and customization options. Leading wire rope manufacturers in India offer a wide range of steel wire ropes tailored for specific industry needs, ensuring reliability and performance.

Conclusion

Steel wire ropes are a fundamental component in various industries, providing strength, safety, and efficiency in multiple applications. Whether for construction, mining, shipping, or adventure sports, high-quality steel wire ropes are essential for smooth operations. If you're looking for premium-grade steel wire ropes, trust Orion Ropes, a leading wire rope manufacturer committed to delivering top-quality products and excellent service.

0 notes

Text

Ensuring Safety and Efficiency with Lifting Equipment Inspection

Lifting equipment plays a critical role in many industries—from construction sites to manufacturing plants—where heavy loads must be moved safely and efficiently. Because the proper functioning of this equipment is essential to both productivity and safety, regular lifting equipment inspections are indispensable.

Why Lifting Equipment Inspections Matter

The primary purpose of a lifting equipment inspection is to ensure that all apparatus involved in hoisting or moving loads is in optimal condition. Over time, wear and tear, environmental factors, and even minor mishandling can lead to degradation. Without regular inspections, small defects can evolve into dangerous malfunctions, leading to accidents, injuries, or even fatalities. Furthermore, regulatory bodies mandate periodic inspections to ensure that companies adhere to strict safety standards.

What Does a Lifting Equipment Inspection Involve?

A comprehensive lifting equipment inspection is a multi-step process that typically includes:

Visual Examination: Inspectors begin with a thorough visual check of all equipment components. This includes the structural framework, hooks, chains, ropes, and any other mechanical parts. Signs of corrosion, cracks, or deformities are noted.

Load Testing: In many cases, lifting equipment is subjected to controlled load tests to ensure it can safely handle its rated capacity. This test verifies that the equipment performs correctly under pressure.

Documentation Review: Maintenance logs, previous inspection reports, and repair records are reviewed to gain insight into the equipment’s history and identify recurring issues.

Functional Checks: Components such as brakes, gears, and control systems are tested to confirm that they operate within safe parameters.

Safety Feature Verification: Emergency stops, limit switches, and other critical safety features are verified to be fully operational. These features are essential in preventing accidents during unexpected situations.

Who Should Conduct These Inspections?

Lifting equipment inspections must be performed by qualified professionals. In many jurisdictions, certified inspectors are required to carry out these assessments. Their training ensures they are up-to-date on the latest safety standards and capable of identifying even the most subtle signs of wear or potential failure.

Preparing Your Equipment for Inspection

To ensure a smooth and efficient inspection process, preparation is key:

Keep Detailed Records: Maintain comprehensive logs of all maintenance, repairs, and previous inspections. This documentation not only helps the inspector but also enables your team to address issues proactively.

Perform Regular Self-Checks: Encourage your operators and maintenance team to perform daily or weekly visual checks. These routine inspections can catch issues early and minimize downtime.

Schedule Inspections Proactively: Rather than waiting for a problem to occur, schedule inspections at regular intervals as recommended by the manufacturer or regulatory guidelines.

The Benefits of Regular Inspections

Regular lifting equipment inspections offer numerous benefits:

Enhanced Safety: Identifying and addressing potential hazards before they escalate can prevent accidents and protect lives.

Operational Efficiency: Well-maintained equipment operates more efficiently, reducing the likelihood of unexpected breakdowns that can halt production.

Regulatory Compliance: Adhering to inspection schedules helps ensure compliance with legal and industry standards, minimizing the risk of penalties or shutdowns.

Cost Savings: Preventative maintenance is often far less expensive than emergency repairs or replacements following an accident.

Conclusion

In industries where lifting equipment is a workhorse, regular inspections are not just a regulatory requirement—they’re a critical component of operational safety and efficiency. By investing in professional, periodic lifting equipment inspections, you safeguard your workforce, ensure the longevity of your equipment, and maintain smooth, uninterrupted operations.

0 notes

Text

Reach Stacker Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Reach Stacker Market 2025 Size and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Reach Stacker Market scenario, and feasibility study are the important aspects analyzed in this report.

The Reach Stacker Market is experiencing robust growth driven by the expanding globally. The Reach Stacker Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Reach Stacker Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing.

In March 2022, Helm.ai (U.S.) collaborated with Ambarella (U.S.) and artificial intelligence vision Silicon Company to create a line of smart and cost-effective computer vision-based Advanced Driver Assistance Systems (ADAS) products for the global market.

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/106974

Key Strategies

Key strategies in the Reach Stacker Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Reach Stacker Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Reach Stacker Market.

Major Reach Stacker Market Manufacturers covered in the market report include:

CVS Ferrari SpA (Italy) Cargotec Corporation (Finland) Hoist Material Handling, Inc. (U.S.) Dalian Forklift Co., Ltd. (China) Liebherr Group (Switzerland) Konecranes (Finland) SANY Group (China) Terex Corporation (U.S.) Komatsu Ltd (Japan) Hoist Material Handling, Inc. (U.S.) Toyota Material Handling (Japan) Mitsubishi Heavy Industries, Ltd. (Japan) Taylor Machine Works, Inc. (U.S.)

The growing international seaborne trade activities and rising government expenditure on port infrastructure to promote safe & efficient commercial activities will support the demand for reach stacker over the forecast period

Trends Analysis

The Reach Stacker Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Reach Stacker Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Reach Stacker Market Solutions.

Regions Included in this Reach Stacker Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Reach Stacker Market.

- Changing the Reach Stacker Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Reach Stacker Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Reach Stacker Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global Reach Stacker Market?

► Who are the prominent players in the Global Reach Stacker Market?

► What is the consumer perspective in the Global Reach Stacker Market?

► What are the key demand-side and supply-side trends in the Global Reach Stacker Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Reach Stacker Market?

Table Of Contents:

1 Market Overview

1.1 Reach Stacker Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

0 notes