#Gondola Suspended Rope Platform Manufacturer

Explore tagged Tumblr posts

Text

Complete Manual on Hanging Scaffold Systems or Suspended Rope Platforms for plastering

In the realm of construction and maintenance tasks, there’s a stalwart ally that stands tall, quite literally. The Suspended Rope Platform (SRP), often recognized as a gondola or working platform, has become an indispensable tool for a spectrum of vertical endeavors. Specifically, in India, these platforms have etched their place firmly in various industries, revolutionizing the way projects are undertaken.

Evolution of Rope Suspended Platforms

Initially embraced primarily by major facade contractors, the trajectory of SRPs has undergone a significant shift. Over the past three years, a seismic shift has been witnessed, with the paint industry, spanning from manufacturers to applicators, showing an avid interest. This surge in demand has propelled manufacturers of these platforms to the forefront, dominating the market for close to a decade.

The utilization of Suspended Rope Platform isn’t confined to a singular purpose. From external wall plastering, painting high-rise structures, installing glass facades to the maintenance of expansive external surfaces, the applications are diverse and extensive. Even in scenarios necessitating alterations or demolition of buildings, these platforms emerge as indispensable temporary structures.

The Rise of Rope Suspended Platforms

What sets SRPs apart is their ascendance as the preferred mode of access across construction sites. Traditionally, scaffolding held sway, but the inherent advantages of SRPs, including efficiency and versatility, have prompted their ubiquitous presence in the construction landscape.

Quality and Innovation

Platforms like the hanging rope platform hoists from Jaypee India epitomize excellence, constructed meticulously using premium materials such as stainless steel and aluminum. The emphasis on stringent quality control ensures adherence to specified durability and reliability standards, ensuring that only the finest products reach customers.

Moreover, manufacturers of SRPs have undertaken a trajectory of innovation. Varied versions of these platforms cater to diverse job site specifications. Engineers have meticulously designed these platforms, integrating multiple safety measures to mitigate the inherent risks associated with erecting and maintaining tall structures.

Safety Features and Engineering Excellence

Safety stands paramount in the realm of suspended platforms. Manufacturers have embedded an array of safety features into their products to ensure secure operations:

Rope Failure Prevention: Incorporating locks to prevent tilting due to rope failure.

Advanced Technology: Integration of sophisticated mechanical and control electronics.

Quality Wire Ropes: Utilization of high-grade steel wire ropes to guarantee robustness.

Optional Overload Sensing: Offering the option for sensing overload, further enhancing safety.

Cable Locking Angle: Ensuring a secure cable locking angle of 3–8 degrees.

Superior Suspension Systems: Technologically superior suspension systems enhancing stability.

Durability: A testament to longevity, these platforms are engineered to withstand prolonged usage without succumbing to wear and tear.

Sturdy Construction: With a solid construction, these platforms exude reliability and stability.

Energy Efficiency: Notably, the energy requirements for operating these platforms are considerably lower compared to alternative access systems.

Proficient Management and Operations

One defining aspect of the Suspended Rope Platform (SRP),landscape in India is the involvement of extensively trained professionals overseeing the operation and maintenance of these platforms. Amidst a competitive market, manufacturers differentiate themselves by providing top-tier suspended platform services. These adept specialists, well-versed in every facet of access equipment, ensure superior maintenance and repair services right on the job site. From initial setup to operationalizing the platform, these professionals handle it all with finesse and expertise.

In conclusion, the evolution of suspended rope platforms for plastering and other vertical endeavors has heralded a paradigm shift in the construction and maintenance landscape. With an emphasis on safety, innovation, and efficiency, these platforms have become the linchpin in accessing vertical spaces, promising durability, reliability, and optimal performance. As the industry continues to evolve, these platforms are poised to remain at the vanguard, catering to the ever-expanding demands of vertical construction and maintenance tasks.

#Suspended rope platform for plastering#Suspended rope platform#Rope Suspended platform for plastering#Buy Suspended Rope Platform#Rope Suspended Platform (RSP)#Construction Equipment Manufacturer and Supplier in India#Construction Equipment#Facade cleaning system manufacturers in india#Gondola Suspended Rope Platform Manufacturer

3 notes

·

View notes

Text

3 Ways Suspended Platforms Increase Efficiency for Vertical-Vessel Maintenance

It’s time to upgrade maintenance practices for vertical vessels. Like any routine maintenance, inspecting, removing and replacing refractory in vertical vessels places a costly burden on facilities in terms of downtime and lost productivity. One of the main reasons for this is the traditional solution for accessing vertical surfaces – scaffolding – severely limits efficiency. It also increases safety risks for employees.

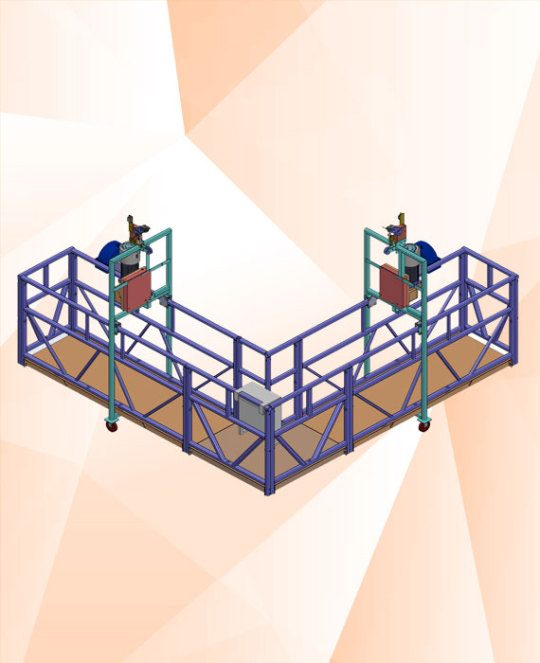

Processing facilities are taking action to reclaim maintenance productivity and safety by investing in custom-manufactured suspended platforms for vertical-vessel operations. These systems feature a lightweight, heavy-duty metal platform that is erected inside the vessel and raised or lowered using manual or electric hoists for hassle-free maintenance and relining applications.

Suspended platforms offer a number of benefits over scaffolding systems, starting with effectively eliminating the protracted setup times that dominate scaffolding-based maintenance schedules. Here’s how these customized systems can boost productivity and safety throughout the maintenance process.

Speedy Setup

The amount of time scaffolding systems take to erect is their biggest deterrent and the greatest drain on maintenance productivity. This is due in part to the sheer complexity of the operation, which includes juggling a variety of pipes, hardware, boards and other materials to create the structure. Erection times vary based on vessel size and configuration, but even with an experienced crew, scaffolding can take several shifts all the way up to an entire week to construct. This puts significant stress on maintenance budgets and timelines.

To simplify the process and decrease setup times, steel suspended platform implement a modular design and pin-together construction. This greatly reduces the number of components and tools required for erection and allows crews to complete setup in as little as two hours.

Modular components manufactured from high-strength 6061-T6 aluminum provide the same strength as steel at one-third of the weight. And, because vertical vessels often feature small access points, manufacturers limit the size of modular components. The resulting pieces are easy to maneuver, weighing 40 pounds (18 kg) or less, and fit through a 22-inch-diameter (560-mm-diameter) access hole. This provides a lighter, more easily maneuverable solution than scaffolding’s heavy wooden planks and steel pipes, some of which are up to 14 feet long.

In addition, pin connections allow for fast assembly and improve platform strength over welded connections by allowing for some flexibility while the platform is being raised or lowered. Welded joints are rigid, which increases stress on risers at platform joints. Pin-together joints are a better solution to help maintain safety and stability when dealing with varying speeds from the climbing hoists.

It is worth noting that suspended platforms require some initial site preparations. This can increase setup times the first go-round – sometimes up to a full shift for complicated systems. But in the long run, a suspended platform can save facilities significant time and effort with each use, leading to significant ROI potential.

For example, a copper plant replaced the scaffold system for their smelter with a custom suspended platform. This increased productivity and safety. Overall, the plant was able to save 320 man-hours per shutdown with the new system.

Room to Move

Even after the platform is assembled, the productivity benefits continue to add up. With scaffolding, tools and materials need to be hoisted up to working height a little at a time, often manually. This is a slow process with a heavy physical toll. It also limits productivity by restricting supply lines for materials, such as refractory brick, gunning equipment or other necessities.

A suspended platform, on the other hand, can easily transport up to 6,000 pounds (2,722 kg) up and down, and the open design provides ample space for personnel, tools and materials. This allows several workers to operate in the same area comfortably, as well as have everything they need close at hand for efficient maintenance. Crews simply load all necessary materials at the start of the shift while the platform is positioned at the vessel’s access point. When more brick or other supplies are required, the crew lowers the platform, loads the necessary materials and then easily returns to height. This saves considerable time and energy and can increase productivity by limiting the number of trips up and down.

The platform also provides more room and easier positioning for equipment such as gunning machines for shotcrete applications. Crews simply set up the machine directly on the platform and maneuver the entire system up and down, eliminating downtime from repositioning while maintaining an ideal distance from the vessel surface for proper adhesion. Using a suspended platform for this application also eliminates the physical toll and risk to crews from heavy hoses hanging from the scaffolding.

In addition, the open platform and electric hoist system allow for infinitely variable height, resulting in unrivaled access for inspection, removal and replacement of refractory materials.

Scaffolding is inherently rigid. It has to be to create a sturdy base of operations. However, this rigidity restricts crew access to the burn surface. Pipes inhibit visual inspection and make it difficult to work on the area directly behind them. The scaffolding structure can also obstruct small flaws, causing them to be overlooked. Crews must squat down or reach up high when working on surfaces in between 8-foot scaffolding stories.

Suspended platforms provide crews with 360-degree access at a comfortable working height, regardless of the task at hand. To optimize accessibility and productivity for a particular facility, manufacturers also customize designs to fit vessels up to 22 feet in diameter, so crews can get directly against the burn surface without risk of falling. This allows crews to inspect every inch, catching even the small flaws that could lead to bigger problems down the line if overlooked. Also, some suspended platforms allow crews to adjust the size of the platform by up to 3 feet while suspended by changing the outer panels. This results in better accessibility and easy transition between different widths of a vessel.

Ergonomics for Better Economics

It goes without saying that having a platform, rather than a narrow scaffold, increases worker safety.

Falls continue to rank number one in workplace injury reports, and refractory repair is not immune to tragic accidents. Recent U.S. Bureau of Labor Statistics data identified 338 fatal falls to the lower level among 1,038 total construction fatalities for the year. That same year, falls on the same level or to lower levels amounted to $17.1 billion (29.2%) of the nearly $60 billion spent by employers on serious, non-fatal workplace injuries.

A suspended platform replaces narrow wooden catwalks with an aluminum surface that spans the entire vessel, eliminating the risk of falls or dropped objects. It also eliminates the need for workers to climb up and down carrying small tools and the need to haul materials and larger equipment up to height, hand over hand, resulting in a much safer jobsite.

There are long-term safety benefits that go beyond this. From setup through all aspects of refractory maintenance, an aluminum suspended platform puts less physical strain on employees. The lightweight, modular components are less cumbersome than long poles and heavy wooden planks. Easy access to materials and tools reduces the risk of repetitive-motion injuries as well as minor cuts, bruises or scrapes that come with manually moving refractory materials. Being able to position the platform at the ideal working height for the job at hand limits bending or reaching, providing an ergonomic solution instead.

All of these small but significant safety benefits lead to long-term savings in the form of worker’s compensation claims and insurance premiums.

Making the switch to a ZLP500 rope suspended platform requires some initial planning, but positive returns are almost immediate. Facilities that have made the switch save tens of thousands of dollars with each maintenance cycle, providing a return on investment in one or two uses. The key is working with a reputable manufacturer that can provide a customized platform that fits a facility’s needs perfectly. Working together, these partners can revolutionize refractory maintenance in vertical vessels.

Mr. Jayesh Vadukiya, M.D, New Age Construction Equipment Engineering Company

New Age Construction Equipment Engineering Company is one of the leading manufacturers of construction equipment like Rope Suspended Working Platforms (Gondolas/ Cradles), Bar Bending Machines, Bar Cutting Machines, etc. The company is strictly complying with ISO 9001:2008 certification and its products have also received CE certificates. The stringent quality standards conforming to “OE” standards enable it to guarantee 100% satisfaction for the entire range of products.

New Age believes in innovation, technology, and customization of its products, based on market research and end-users’ expectations, and has a strong sales & service team of professionals. The company has many instances of innovation and customization, especially of its Rope Suspended Platforms (RSP) / Gondolas/ Cradles. Presenting here two success stories on customized RSP for Dam & Silo Project.

The job was to clean the wall of the dam. It was a very difficult job because of the wind pressure and the height of the wall. The width of the road on the dam was too short to fix a standard upper mechanism of RSP. Another problem was the customer’s requirement of designing the upper mechanism in such a way that vehicles should also pass through the upper mechanism and their movement should not be stopped during the cleaning.

Moreover, the upper mechanism was so heavy that it was next to impossible to shift it. The customer wanted to move the wall machine (upper mechanism + cradle) from one place to another in a short time, and we did that without the help of any laborers.

We designed the RSP in such a way that the client’s requirement was fulfilled, and work was done timely. We had also provided specially designed Motorized device for shifting of wall machine without any requirement of labor. With our vast experience of doing challenging projects, we are always ready to take new assignments and try to resolve all issues through our customized solutions.

0 notes

Photo

Rigid Machinery is a leading China based manufacturer and exporter of high quality height products, cradle, gondola, rope suspended platform, scaffold hoist platform, wire rope platform, swing stage platform, temporary suspended platform, window cleaning cradle, window cleaning gondola, and window glass cleaning machine at reasonable price.

#Height Products#Hoist Cradle#Motorized Gondola#Powered Platforms#Rope Suspended Platform#Scaffold Hoist Platform#Scaffolding Suspended Platform#Suspended Access Cradles#Suspended Access Platform#Suspended Platform Gondola#Suspended Platform Systems#Suspended Platforms

0 notes

Text

Suspended Rope Platforms and Traditional Scaffolding are evaluated to ascertain which offers greater advantages.

The debate between rope suspension platforms and traditional platforms in construction and maintenance has been going on for years. Both methods serve the purpose of safely moving workers to heights, but differ greatly in design, operation and suitability for different projects This blog post will explore the characteristics of rope suspended platforms and traditional scaffolding internally to identify different methods -may be better suited to different situations .

Custom scaffolding: a proven solution

One of the main advantages of traditional scaffolding is its stability and load-bearing capacity. It can support heavy loads, making it ideal for jobs that require a wide range of materials and equipment. Additionally, the scaffolding system is versatile and can be installed to different heights, allowing workers to safely access even tall buildings.

However, traditional scaffolding also has limitations. Scaffold installation and disassembly can be time-consuming, requiring skilled labor and specialized equipment. Additionally, structural buildings can obstruct pedestrian and vehicular traffic around the facility, causing infrastructure challenges, especially in urban areas

Rope suspension platforms: an easy option

Unlike traditional scaffolding, rope suspension platforms provide a flexible and flexible solution

Source- https://iriequipment.com/2024/03/21/suspended-rope-platforms-vs-traditional-scaffolding-which-is-better/

#construction equipment#suspended rope platform for plastering#suspended rope platform#buy suspended rope platform#zlp800 suspended platform#gondola suspended rope platform manufacturer#Traditional Scaffolding#Scaffolding

0 notes

Text

Optimizing Construction Efficiency via Suspended Rope Platforms

Easy Access

Normally, reaching high spots on a building during construction takes a lot of time and effort, like setting up scaffolding. But with suspended rope platforms, workers can quickly get to any part of the building without all that hassle.

Time Saver

Construction projects have tight schedules, and any delay can mess things up. Suspended rope platforms speed things up by letting different teams work on different parts of the building at the same time. This means less waiting around and faster progress.

Flexible

These platforms come in different shapes and sizes, so they can fit any building. Whether it’s a tall skyscraper or a shorter building, suspended rope platforms can be adjusted to work perfectly.

Safety First

Safety is a big deal in construction, especially when working high up. Suspended rope platforms have safety features like rails and harnesses to keep workers safe from falls. Plus, they’re regularly checked to make sure they’re in good shape.

Saves Money

While setting up suspended rope platforms may cost more at first, they end up saving money in the long run. They help finish projects faster, needing fewer workers and less downtime, which means big savings for construction companies.

Good for the Environment

Using suspended rope platforms instead of traditional scaffolding is also better for the environment. They use fewer materials and produce less waste. Plus, they’re more energy-efficient, which means less pollution.

In Conclusion

Suspended rope platforms are a game-changer in construction. They make it easier, faster, and safer to build tall buildings. With their help, construction projects can stay on schedule, save money, and be kinder to the environment. So, next time you see a skyscraper going up, remember the unsung heroes hanging from ropes, making it all happen.

Read this -https://iriequipment.wordpress.com/2023/11/20/the-art-of-connection/

#construction equipment#suspended rope platform for plastering#machine#buy suspended rope platform#suspended rope platform#zlp800 suspended platform#Gondola Suspended Rope Platform Manufacturer

0 notes

Text

Suspended Rope Platform: How to Use It Safely

Suspended rope platforms, also known as gondolas, play a pivotal role in construction, facilitating work at considerable heights while ensuring safety and efficiency. These platforms are essential equipment used for transporting workers and engineers during installations and maintenance work in various construction projects.

Understanding the Significance

Suspended rope platforms are advanced overhead operating equipment that serves as a viable alternative to traditional scaffolding systems. There are primarily two types available in the market: manual and electric. Their usage spans across high-rise building construction, curtain wall installations, and exterior wall maintenance and cleaning.

Advantages of Using Suspended Rope Platforms

The shift from conventional bamboo and metal scaffolding to suspended rope platforms is underpinned by multiple advantages:

Enhanced Safety Features: These platforms incorporate crucial safety elements like Digital Load Cells, Anti-Tilting mechanisms, and Anti-Sway Restriction Devices, ensuring a safer work environment.

Ease of Assembly and Transport: They are simple to assemble, disassemble, shift, and store, requiring minimal manpower. Installation typically takes only 1-2 days, contributing to operational efficiency.

Longevity and Maintenance: These platforms boast a long lifespan, are easy to maintain and repair, and retain a high resale or reuse value, making them a cost-effective investment.

Versatile Design: The flexibility and ample size of these platforms offer enhanced comfort to workers, promoting productivity and safety.

Safety Gadgets Integrated into Suspended Rope Platforms

Ensuring the safety of workers is a top priority in the design and implementation of suspended rope platforms. Some crucial safety devices incorporated into these platforms include:

· Centrifugal Speed Limiter

· Electromagnetic Brake with Manual Release

· Over Hoist/Top Limit Switch

· Anti-Tilting Cut-off Mechanism

· Anti-Sway Restriction Features

· Locking Arrangement for Upper Counterweights

· Hammer Weight for Wire Rope Locking

· Panelboard Lock & Key Mechanism

Ensuring Safe Usage

As esteemed suppliers of suspended rope platforms in Gujarat, ensuring the safe usage of gondolas is a primary responsibility. Accidents involving these platforms often stem from inadequate knowledge of their operation. Thus, it's imperative to highlight the necessary precautions for their safe utilization.

Implementing a Safe Work System

Every operation involving a suspended working platform must adhere to a comprehensive safe work system. Project engineers, safety professionals, Jobsite staff, and building management should collaboratively establish and endorse safety protocols. A competent individual should oversee and supervise the implementation of this system, ensuring the safety of all personnel associated with the platform.

What is suspended rope platform?

A suspended rope platform, also known as a gondola, is a crucial construction tool for working at heights. It's an overhead operating equipment used to transport workers during installations and maintenance. With safety features like Anti-Tilting and Anti-Sway devices, it ensures safe, efficient work at elevated levels in construction projects.

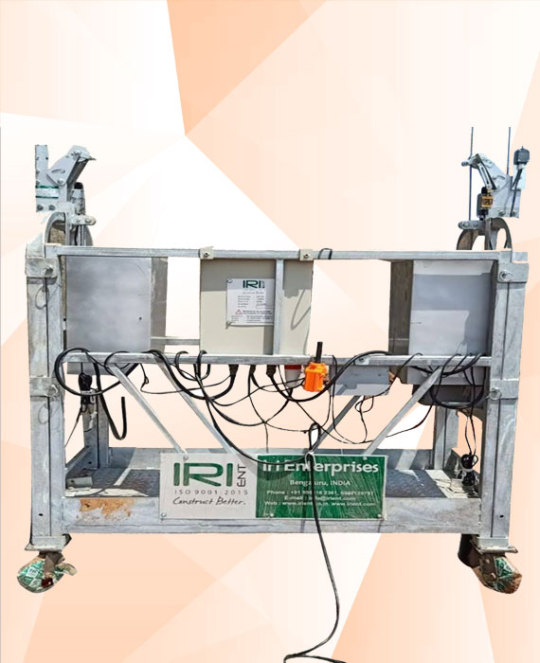

Rope Suspended Platform manufacturers in India

In India, several manufacturers specialize in rope suspended platforms. Irri Equipment one of them offering high-quality equipment for construction needs They manufacturers prioritize safety features and efficient design, catering to the diverse demands of the construction industry. They provide reliable solutions for working at heights with precision and safe.

Safety Protocols and Best Practices

To guarantee the safe operation of suspended rope platforms, adherence to strict safety protocols is crucial:

· Thorough Operational Planning: This involves selecting the appropriate platform for the job and evaluating the working environment.

· Secure Installation Methods: Employ tried-and-tested installation techniques to ensure stability.

· Regular Maintenance: Implement both on-site and periodic maintenance routines to keep the platform in optimal condition.

· Documentation and Certification: Maintain detailed operation and maintenance records, repair logs, and certificates of examination.

· Competent Personnel: Only qualified individuals should handle the installation, movement, and dismantling of these platforms.

· Avoiding Hazardous Conditions: Use of the platform should be prohibited in hazardous conditions to prevent potential risks.

· Continuous Supervision: Regular monitoring and supervision of safety measures should be in place to ensure ongoing compliance.

Prioritizing safety protocols and measures is pivotal for the seamless and secure operation of suspended rope platforms. At our company, we emphasize these precautions to safeguard the well-being of our customers and all involved in construction projects. Should you require further guidance or assistance in utilizing these platforms safely, our team of suspended rope platform suppliers is always available to offer support and expertise.

Source - https://iriequipment.com/

#Buy Suspended Rope Platform#Suspended Rope Platform#Rope Suspended Platform#Suspended rope platform for plastering#Bar bending machine#Construction Equipment Manufacturer and Supplier in India#Construction Equipment

1 note

·

View note