#Custom Hoists for Cranes

Explore tagged Tumblr posts

Text

Looking for Crane Hoist Manufacturers in India? Ailas Engineered is your trusted manufacturer and supplier, offering high-quality, heavy-duty crane hoists for all industrial applications.

#Electric Hoist Suppliers in India#Chain Hoist Manufacturers#Wire Rope Hoist Suppliers#Industrial Hoist Manufacturers#Heavy-Duty Hoists India#Custom Hoists for Cranes#Crane Hoist Manufacturers India#Ailas Engineered Hoist Solutions#Top Hoist Manufacturers in India#Reliable Crane Hoist Suppliers#Best Industrial Hoist Manufacturers

0 notes

Text

Wenn Ihr dieses Bild von mir seht, denkt Ihr wahrscheinlich: „Mann muss der sich auch noch so vollfressen so dick und rund wie er schon ist.“ Ja ich gleiche immer mehr einem menschlichen Schwein. Aber Ihr solltet meine Geschichte erfahren. Nach meinem ersten Semester in dem ich fünf Kilo zugenommen hatte und der Abgabe der Seminararbeit – nochmal zwei Kilo, bin ich drei Wochen in die Karibik gefahren um mich vom Stress zu erholen und da ich aufgrund von Krankheit keine Abifahrt machen konnte. Ich dachte ich gönne es mir mal. Natürlich habe ich mich fleißig am Buffet des Luxusressorts bedient. Ein Angestellter hat mich regelrecht animiert dazu. Doch danach wurde ich nicht zum Flughafen chauffiert, sondern zu einem Gebäude wo ich gewogen und an einen Kunden verkauft wurde. Ich hatte noch einmal achteinhalb Kilo zugelegt. Man pries mich als verfressen und faulen jungen Burschen an, der sich selbst gemästet hat. Man hat dort alle pummeligen Jungs, die dort im Hotel erfolgreich verführt worden sind, sich dicker zu futtern, verkauft. Wir wurden gefesselt auf ein Boot gehievt teilweise mit einem Kran. Wir wurde auf diese kleine Insel gebracht und leben ein Luxusleben solange wir uns ständig mit Essen vollstopfen und sonst meist nur schlafen. Falls nicht gibt es Elektroschläge. Ab und zu kommen zahlende Besucher die uns füttern, uns ins Ohr flüstern zu was für träge feiste Schweine wir uns doch gemästet haben und Sex mit uns haben. Einige die Monate vor uns oder gar ein ganzes Jahr zuvor auf diese Insel verschleppt wurden, sind mittlerweile so fett, dass sie sich nicht mehr bewegen können. Seid vorsichtig und fresst nicht so viel auch wenn Ihr im Urlaub seid!

When you see this picture of me, you probably think: “He's going to gorge himself as fat and round as he already is.” Yes, I look more and more like a human pig. But you should know my story. After my first semester in which I had gained five kilos and the submission of my seminar papers - another two kilos, I went to the Caribbean for three weeks to recover from the stress and because I couldn't go on a high school graduation trip due to illness. I thought I would treat myself. Of course, I diligently helped myself to the buffet at the luxury resort. An employee really encouraged me to do so. But afterwards I wasn't chauffeured to the airport, but to a building where I was weighed and sold to a customer. I had put on another eight and a half kilos. I was advertised as a greedy and lazy young lad who had fattened himself up. They sold all the chubby boys who had been successfully seduced in the hotel to put on weight. We were tied up and hoisted onto a boat, some of us with a crane. We were brought to this small island and live a life of luxury as long as we keep stuffing ourselves with food and otherwise mostly just sleep. If not, there are electric shocks. From time to time, paying visitors come to feed us, whisper in our ears about what lazy fatty pigs we have fattened ourselves up to be and have sex with us. Some of us who were dragged to this island months or even a whole year ago are now so fat that they can no longer move. Be careful and don't eat so much even if you are on vacation!

#ai generated#fatty piggy#fat gut#fatso#overfed#porky guy#greedy pig#forced fattening#fattened up#fat guy#gained weight

38 notes

·

View notes

Text

The Fox Says Nothing || Solo

TIMING: current LOCATION: the woods! PARTIES: @thunderstroked SUMMARY: mona gets hit with some pollen. CONTENT: none!

Mona hated the woods, and yet, she was supposed to be in them for the sake of a photoshoot she said yes to out of the kindness (not really) of her heart. It'd been because they were willing to pay more than average if the photos were done in the studio, and in an attempt to prove Siobhan wrong, Mona had been taking classes as well as trying out new things to enhance her picture taking.

Whether or not it was working was another thing.

The session had gone over the initial time limit, and she'd been assured that she would be compensated for such. She watched as the woman and her partner strolled off, heads together as they discussed the poses and how they were excited to see the final results. As they did so, Mona stared down at her view finder, frown pulling the sides of her mouth downward. The photos did look alright, and hopefully the time she'd been into photoshop editing would also be rewarding.

With a sigh, Mona began to pack her things. She was far from town, and it was unfortunate that she'd insisted on her own means of transportation instead of allowing the customers to drive her back in. The car that Edith had left behind was... a rust bucket, to say the least. The noises it made hurt Mona's ears, and she was almost positive that Edith knew that would be the case.

If she didn't have all of the equipment on her, she might shift and just run back to the car, but that wasn't feasible with the weight of the backpack. So instead, she hoisted it over her shoulder and ventured forward.

Before she could meet the halfway mark back to her car, she noticed something strange (which, in this town was saying a lot). A large root had burst through the ground, vines grappling the nearby trees. It stood taller than anything else in the vicinity. Mona stood off to the side, neck craned as she looked up at it with wide eyes. It felt very Beanstalk esque, aside from the pollen that began to dust overtop of her shoes. She took a small step back, looking up with distaste.

That had been the wrong call, because as soon as she tilted her face up to meet the onslaught of pollen, the ground beneath her had disappeared, and a plume of smoke pulled up around her. The backpack's crushing weight was hard to get from beneath, but she managed to scurry from under it. Shaking off the remainder of the pollen that was continuing to dust now, the fox looked up at it.

What the hell was that.

In an attempt to shift back, the fox anticipated the second plume of smoke, but was met with nothing. Again, and again-- three more times-- four, five-- and nothing. Exhausted from the labor of trying to shift, the fox realized now that she was stuck.

6 notes

·

View notes

Text

''Mr. Plant has owed me a shoe since July 5, 1971." - Chapter IV.a - March 5th, 2024

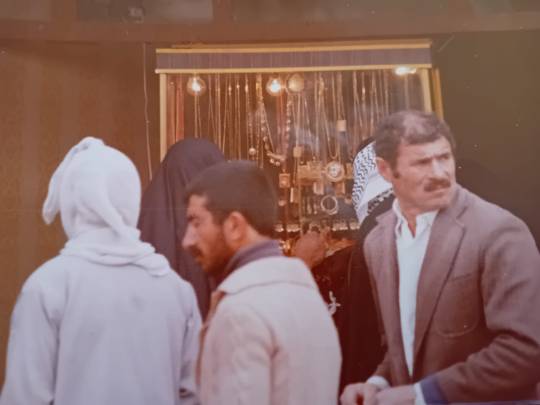

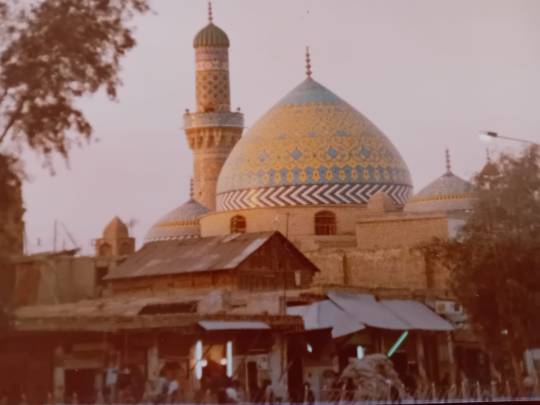

Some photos of Iraq I've taken on 1983. We can recognize Baghdad, - Nassiryah - Ur - Euphrates river.

IRAQ 1983 In January 1983 I was then informed that my new destination would be Nasiryah, Iraq. I left for Rome, and then in Fiumicino - late in the afternoon - I boarded an old Boing 707 of IRAQI Airways, the only company still serving Baghdad: the war with Iran was underway, and the international airlines had suspended flights to Iraq. Baghdad airport was only open at night, so we landed with the lights off, and when we began the descent towards the landing strip we were ordered to darken the windows. Having completed the customs and immigration procedures quite quickly (considering the fact of being in an Arab country and in a state of war) I went out into the deserted hall, where I easily saw the sign with my name hoisted by a local driver. He took me to a hotel on Sadoun street, in a ghostly Baghdad: all the lights were off, very few vehicles were circulating, security forces checkpoints at every intersection.

DEPARTURE FOR NASSIRYAH The next day the Project Manager – a tall, lanky Italian, with an unkempt beard – came to pick me up at the hotel. He told me to pack my bags, we would leave for Nassiryah immediately by car, since domestic flights were suspended due to the war. Our destination was 380 km away from Baghdad, and the highway was damaged by the continuous passage of military vehicles heading South, to the border with Iran. Just outside Baghdad, we passed alongside a high earth barrier, a couple of kilometers long: inside, it was explained to me, the Tammuz nuclear plant, destroyed by an Israeli air force incursion in June 1981. The journey was monotonous, and we only stopped once to refuel and eat shawarma. We arrived in Nasiryah in the late afternoon, and immediately checked into one of the two villas that VOLANI had rented for the expats. Here, towards the evening, I met my Italian colleagues: around ten people in total, which would soon be reduced to 5 given that the project was in the finishing phase.

THE PROJECT In essence it involved the rehabilitation of a plant for the production of electrical cables. When I arrived, in January 1983, the work was almost finished. All that was missing was the installation of a heavy overhead crane in the main warehouse, the completion of the new electrical system, the covering and infilling of some buildings. In consideration of the recent departures, and the fact that there were only 5 expatriates left, it was decided by the Management in Baghdad that we would leave one of the two rented villas, and concentrate on just one. I received the instruction from the Project Manager to rent couples of trailers locally, load the furniture and air conditioners owned by the Company present in villa No. 2, and ship everything to the warehouse in Baghdad. Having rented the trailers (far from a simple matter in a country in a state of war), they were accompanied to the villa and dismantling and loading operation began. I was at construction site, it was already a hot afternoon even though it was only the beginning of March, when I saw in distance a guy dressed in a Western style, jacket, white shirt and black tie. He was chatting with a local worker, who was nodding in my direction. When they got close, the guy – clearly a policeman – asked me:

Are you the boss here?

Yes – I replied – what do you need?

Come with me – he said in a tone that allowed no replies. I followed him in my pick up until we arrived in the parking lot of a low building, steel bars on the windows. The policeman motioned for me to follow him. We entered the building, there were cops everywhere, and photographs of bad guys sticked to the walls, with writings in Arabic indicating how much money the police would pay if information was given leading to their capture. I was taken to the office of the Commander, Mr. Abdul Karim Al Jalaani. The office was enormous, the Commander sat behind a large mahogany desk installed on a riser. I was made to sit on an Arab sofa, at the other end of the room, I was perhaps fifteen meters away from Major Al Jalaani. He looked at myself like you look at an insect, and then he said to me in English:

Are you the one who gave the order to vacate my villa that I rented there?

I organized the transport - I said - but the order left from Baghdad.

Good - he replied - I stopped the transport, come back here as soon as possible with your managers, the ones who gave you the order to vacate the house without my permission. Major's assistant, who had remained near the door, motioned for me to follow him. I went out into the street, breathing a sigh of relief: I had just entered and exited the headquarters of the so-called ''Mukabarat'' or Saddam Hussein's Secret Service, and I was still alive and in a good shapel! I went to the villa, and saw the trailers parked on the corner of the street - the watchman came to meet me:

Sir - he told me - we were loading the furniture, when a car with some policemen arrived - they stopped us and then asked what we were doing - I said that we were loading our furniture to send it to Baghdad - they ordered us to stop and they said:

''If one of these trucks dares to move we will arrest everyone''

Understood Sir?? We couldn't disobey, Sir – these people don't joke!

I understand, I understand, don't worry.

I went to the Central Post Office, I absolutely had to call the Baghdad office. In the old post office, a building with broken glass, dirty and with peeling walls, there was no one except the employees. I was able to get through the Baghdad office pretty quickly. I explained to the PM what had happened - he tried to reassure me, and I told him that I wasn't worried at all.

Be sure - he said - tomorrow evening I will be in Nassiryah and we'll solve the problem.'' And so it was: in the evening the Project Manager arrived at the villa, accompanied by the head of our security service, a tall and large Iraqi, who had been a comrade in arms of the Major of Nassiryah Mukabarat. The next morning at 10.00 we were in the mega office of Major Al Jalaani. The meeting between the former comrades was warm: kisses on the cheeks, hugs, pats on the back, questions about the health of the family members, and then more hugs and then questions about the health of the family members all over again……Then we sat down on the usual sofa at 15 meters from the Major's desk, while the two old friends went on talking about old times, they exchanged phrases of which the PM and I understood nothing, and then burst into resounding laughter. All this for more than half an hour, then our Head of Security said, as if by chance:

Ahh sorry…Abdul Karim……by the way …I came to see you after so many years yes…but also for that stupid matter of the rented villa…you know…the one we want to leave…you know?

Abdul Karim as if falling from the clouds: ''Ah yes yes… I was informed by one of my collaborators that there were trailers ready to take away the furniture… but this is not done my friend… you should have warned, right?

You are perfectly right akooya (brother) but you know these Westerners don't always know what our customs are, so I ask you as the brother you are, to forgive them from the height of your goodness that everyone recognizes in you (How could he be the head of the Secret Services and being ''good'' no one has ever explained it to me)

Sure, sure - replied Abdul Karim - but you agree that there are conditions to be respected so that everything can be settled, right?

Of course akooya – said our Chief of Security.

Well - the Commander continued - come closer and I'll tell you what these conditions are (I didn't understand this, they could have continued to speak to each other ''remotely'' in Arabic, given that neither I nor the PM understood what they said to each other when they spoke their language)

The Head of Security sat down on a chair immediately prepared by the Major's attendent, and so began a dense exchange of sentences, which our friend only interspersed with ''naam…naam'' (yes…yes) Then it all ended, we got up and with big bows, touching our hearts with our right hand as a sign of ''how good of you to receive us and you didn't even let us get whipped'' we left the police station. In the car, our Head of Security informed us of the ''conditions'' posed by the Major to ''forget'' the nasty rudeness we had tried to do to him, taking away OUR furniture and OUR air conditioners from his villa, where we paid 6,000 USD /month rent + all expenses, including security. (We suspected that it was the watchman who alerted the police that the trailers had arrived for the move). Well for 4 additional months in cash, the complete re-painting of the house (exterior/interior/surrounding wall) and OUR air conditioners, the Commander would have forgiven our ''offence''. The PM muttered "WTF......" but we had to put on a good face because there were no alternatives. The next day - once all the furniture had been loaded onto the trailers - the painting work began, under the supervision of an Al Jalaani representative.

6 notes

·

View notes

Text

KRC: Elevating Excellence in Lifting Equipment

In the dynamic world of heavy industries and construction, the demand for reliable and efficient lifting equipment has never been higher. Companies operating in these sectors understand the critical role that high-quality lifting equipment plays in ensuring safety, productivity, and success. One company that stands out in this arena is KRC.

Elevating Safety Safety is paramount in any industrial setting, and KRC takes this responsibility seriously. With a history of providing top-tier lifting equipment, KRC has built a reputation for excellence in safety. Their commitment to adhering to international safety standards and rigorous quality control procedures ensures that every piece of equipment that bears the KRC name is designed and manufactured with safety as the top priority.

A Legacy of Innovation Innovation is the lifeblood of any industry, and KRC has a rich history of pioneering advancements in lifting equipment technology. Their team of engineers and designers are dedicated to developing cutting-edge solutions that make lifting operations safer and more efficient. From state-of-the-art cranes to precision-engineered hoists, KRC’s product range reflects their dedication to innovation.

Quality That Speaks for Itself The quality of lifting equipment can significantly impact the efficiency and longevity of any project. KRC understands this, and their commitment to quality is evident in every product they offer. Rigorous testing and quality assurance processes ensure that KRC’s equipment not only meets but often exceeds industry standards. This dedication to quality has earned KRC the trust of countless companies worldwide.

Global Reach, Local ExpertiseWith a global presence, KRC serves clients in various industries on a worldwide scale. However, what truly sets them apart is their local expertise. KRC’s regional teams understand the unique challenges and requirements of different markets, allowing them to provide tailored solutions that meet local regulations and standards. This combination of global reach and local expertise makes KRC a trusted partner for companies across the globe.

Beyond Products: Comprehensive SolutionsKRC doesn’t just offer lifting equipment; they provide comprehensive solutions. From initial consultations and equipment selection to installation, maintenance, and support, KRC is committed to being a partner throughout the entire project lifecycle. This approach not only ensures smooth operations but also maximizes the return on investment for their clients.

Conclusion In the world of lifting equipment, KRC stands as a beacon of excellence. Their unwavering commitment to safety, innovation, quality, and customer satisfaction has made them a trusted name in the industry. Whether you’re involved in construction, heavy industry, or any field that requires reliable lifting equipment, KRC is a name you can trust to elevate your operations to new heights.

If you’re seeking lifting solutions that prioritize safety, quality, and innovation, look no further than KRC. Your success is their mission, and they’re ready to help you reach it. Elevate your lifting operations with KRC today!

2 notes

·

View notes

Text

Lifting Machine Rental in Nashik

RMN Erectors is a marketplace chief within the discipline of Lifting Machine Rental in Nashik, India serving experts who work at heights in any kind of industry. We provide a huge variety of which includes, scissor lifts, Truck Mounted, Man Lift, Diesel Forklift. RMN Erectors make it hard for our clients, providing for Rental Lifting Machine, to work quickly and at any height. It's far from the main employer that surfaces in this context on a normal basis.

RMN Erectors company lives as long as the expectancy and offers its clients with a well-timed and effective lifter machine for rent service. All of our lift rentals equipment allows you to tackle anything the process throws at you with flexibility and confidence. The RMN Erectors Lifting Machine Rental in Nashik for having access to an effective and dependable system on demand, you benefit from the determination and technical capabilities of your nearby.

Rental Lifting Machine In Nashik

A rental lifting machine refers to a piece of equipment used for lifting heavy objects or materials to various heights. There are several types of lifting machines available for rent, depending on the specific requirements of the task at hand. Here are some common examples:

Forklift: Forklifts are versatile machines used for lifting and moving materials in warehouses, construction sites, and industrial settings. They have two forks at the front that can be raised and lowered to lift pallets or other heavy objects.

Boom Lift: Boom lifts, also known as cherry pickers, are used for elevated work tasks. They consist of a platform or bucket attached to a hydraulic arm (or boom), allowing workers to access elevated areas such as building exteriors, trees, or utility poles.

Scissor Lift: Scissor lifts are another type of aerial work platform that can be rented. They have a platform that moves vertically using a crisscrossing mechanism, which resembles a pair of scissors. Scissor lifts are commonly used for maintenance, construction, and installation tasks.

Crane: Cranes are large machines equipped with a hoist, wire ropes or chains, and sheaves. They are used for heavy lifting in construction sites, shipping yards, and other industrial settings. Cranes come in various types, including tower cranes, mobile cranes, and overhead cranes.

Telehandler: A telehandler, or telescopic handler, combines the features of a forklift and a crane. It has a telescoping boom that can extend forward and upward, allowing it to lift and place loads with precision. Telehandlers are commonly used in construction and agriculture.

When renting a lifting machine, it's important to consider factors such as the required lifting capacity, reach, terrain conditions, and any specific attachments or accessories needed for the job. Rental companies typically offer different sizes and models of lifting machines to accommodate various project requirements.

Lifting Machine Hire In Nashik

Lifting machine hire refers to the service provided by equipment rental companies, where they offer various types of lifting machines or equipment for temporary use. Instead of purchasing a lifting machine outright, individuals or businesses can rent the equipment for a specific period of time to meet their lifting needs. Lifting machine hire is a cost-effective and convenient solution for those who require lifting equipment for short-term projects or occasional use.

The types of lifting machines available for hire can vary depending on the rental company and the specific requirements of the customer. Common examples of lifting machines that can be hired include forklifts, cranes, boom lifts, scissor lifts, telehandlers, and hoists.

When renting a lifting machine, customers typically have the flexibility to choose the specific model and size of the machine based on their lifting capacity and reach requirements. Rental periods can range from a few hours to several weeks or months, depending on the duration of the project.

Lifting machine hire services usually include delivery and pickup of the equipment to the customer's location. Some rental companies may also offer additional services such as equipment setup, maintenance, and operator training if required.

The rental rates for lifting machines are typically based on factors such as the type of equipment, rental duration, and any additional services requested. Rental companies may charge an hourly, daily, weekly, or monthly rate, depending on the terms of the rental agreement.

Overall, lifting machine hire provides a flexible and cost-effective solution for obtaining the necessary equipment to safely and efficiently perform lifting tasks without the need for long-term ownership.

Looking for an Lifting Machine Rental in Nashik? Then RMN Erectors is the best choice for you contact us at +91-9423969656 and visit our website

#Lifting Machine Rental in NashikRental Lifting Machine In Nashik#Lifter Machine For Rent In Nashik#Lifting Machine Hire In Nashik#Lifting Machine Rental In Nashik

2 notes

·

View notes

Text

Top EOT Crane Manufacturer in India | Gantry, Jib, and Wire Rope Hoist Solutions

SBE Crane is a leading EOT crane manufacturer in India, offering high-quality material handling solutions including gantry cranes, jib cranes, and electric wire rope hoists. Recognized as a trusted EOT crane manufacturer in Mumbai, Pune, Gujarat, and Chennai, we specialize in single girder and double girder EOT cranes to meet various industrial needs. As one of the top EOT crane suppliers and wire rope hoist manufacturers in India, SBE Crane delivers customized and durable lifting equipment for every sector. For more Visit

#eot crane manufacturer#eot crane supplier#eot crane manufacturer in pune#eot crane manufacturers in chennai

0 notes

Text

Overhead Crane for Sale: What You Need to Know Before You Buy

In industrial environments where heavy lifting is a daily task, having a reliable overhead crane can transform operations. If you're in the market for an overhead crane for sale, there are key factors to understand before making a decision. This guide explores what to look for, the different types available, and how to choose the right overhead crane supplier.

Understanding Overhead Cranes

An overhead crane, often referred to as a bridge crane, is used to move heavy materials across horizontal paths in warehouses, manufacturing units, and assembly lines. The system includes runways, a bridge, and a hoist, which allows for precise load control.

The two main components of the lifting mechanism are the overhead crane hoist and the bridge. The hoist is responsible for the vertical lift, while the bridge supports horizontal movement.

Types of Overhead Cranes and Hoists

There are several variations of overhead cranes and hoists, and your choice should depend on your workspace, load requirements, and frequency of use:

Single Girder Cranes: Ideal for lighter loads and smaller spans. They are cost-effective and easier to install.

Double Girder Cranes: Suitable for heavy-duty operations. They provide greater hook height and can handle larger capacities.

Top Running Cranes: Mounted above the runway beams. They offer maximum lifting height.

Under Running Cranes: Suspended from the building structure, they are better for lighter applications and environments with space constraints.

Choosing the Right Overhead Crane Supplier

The right overhead crane supplier is not just about selling equipment—it’s about long-term reliability, safety, and compliance. Look for suppliers who offer:

Custom engineering and design support

Load testing and compliance with safety standards

Maintenance and after-sales service

In-stock availability of replacement parts

Customer Testimonial:

"Our production efficiency improved significantly after sourcing from a reliable overhead crane supplier. The team helped us choose the right hoist and provided thorough training." — Facility Manager, Automotive Manufacturing Plant

Frequently Asked Questions (FAQs)

Q1: What is the lifespan of an overhead crane?

A well-maintained overhead crane can last 15-30 years depending on usage and environment.

Q2: How do I know which hoist I need?

The choice of overhead crane hoist depends on load weight, frequency of use, and required speed. A reputable supplier will assist with load calculations and suggest the best fit.

Q3: Do I need special training to operate overhead cranes?

Yes, operators must be trained and certified according to local regulations to ensure safe and efficient usage.

Q4: Are refurbished overhead cranes worth it?

Refurbished units can be cost-effective if inspected and certified by a trusted overhead crane supplier. Always request documentation on maintenance history and load tests.

Compliance and Safety First

Beyond performance, compliance with safety regulations is non-negotiable. Always verify that the crane and hoist meet ISO, OSHA, or local equivalent standards. Regular inspections, maintenance, and load testing are essential for workplace safety.

Final Thoughts

Purchasing an crane services isn’t just about price—it's about value, performance, and peace of mind. Collaborating with an experienced overhead crane supplier ensures you get the right solution tailored to your facility's needs.

0 notes

Text

Automated Material Handling Equipment Market: Innovations and Technological Advancements Reshaping Industries Worldwide

The Automated Material Handling Equipment (AMHE) market is experiencing significant growth, driven by advancements in technology and an increasing demand for efficient and cost-effective solutions in various industries. These systems are designed to automate processes such as the transportation, storage, and retrieval of materials in warehouses, manufacturing plants, distribution centers, and other industrial settings. AMHE includes a broad range of equipment, such as conveyors, automated guided vehicles (AGVs), cranes, robots, and sortation systems, all of which work together to streamline material flow and improve operational efficiency.

Market Drivers

Several key factors are contributing to the rapid expansion of the Automated Material Handling Equipment market. One of the main drivers is the increasing demand for automation in industries such as manufacturing, logistics, e-commerce, and retail. The need for faster and more accurate material handling solutions, as well as the growing pressure to meet customer demands for quick deliveries, is pushing companies to adopt automation technologies.

The rising labor costs and the shortage of skilled labor are also influencing the market. Many businesses are turning to automated systems to reduce reliance on human labor, thereby lowering operational costs and improving productivity. Additionally, automated systems can work around the clock, ensuring higher efficiency and reducing the chances of human error. This results in enhanced throughput, better utilization of resources, and improved safety.

Technological advancements in robotics, artificial intelligence (AI), and the Internet of Things (IoT) are also playing a crucial role in the growth of the market. AMHE systems are becoming increasingly intelligent and capable of performing complex tasks, such as inventory management, predictive maintenance, and real-time data analysis. These innovations make automation systems more versatile and adaptable to a variety of industries, thus broadening their applications.

Market Segmentation

The Automated Material Handling Equipment market can be segmented based on the type of equipment, end-user industry, and region.

By Type of Equipment:

Conveyors: These are commonly used in manufacturing and distribution centers for transporting goods and materials. Conveyors offer an efficient means of material handling by reducing the need for manual labor and enhancing operational efficiency.

Automated Guided Vehicles (AGVs): AGVs are mobile robots used to transport materials within a facility. They follow pre-programmed paths and are equipped with sensors to avoid obstacles, improving the flow of materials while ensuring safety.

Robotic Systems: Robotic systems, such as robotic arms, are widely used in material handling for tasks such as sorting, picking, and packaging. They are often used in combination with other automated equipment to optimize processes.

Cranes and Hoists: These systems are used for lifting and transporting heavy materials in industrial settings. Cranes and hoists are vital in sectors such as construction and manufacturing.

Sortation Systems: These systems are designed to sort products based on predefined criteria such as size, color, or destination. They are typically used in warehouses and distribution centers for efficient order fulfillment.

By End-User Industry:

E-commerce and Retail: The e-commerce industry is one of the largest adopters of automated material handling systems. With the increase in online shopping, there is a growing need for efficient fulfillment centers that can handle large volumes of orders quickly and accurately.

Manufacturing: In manufacturing, AMHE systems are used to streamline processes such as assembly, packaging, and delivery. The automotive and electronics industries, in particular, rely heavily on automated material handling to improve production efficiency.

Logistics and Warehousing: The logistics industry is also a major consumer of AMHE, as it allows companies to optimize their supply chains, reduce transit times, and improve inventory management.

Food and Beverage: In the food and beverage sector, automated systems are used for tasks such as sorting, packaging, and palletizing. These systems ensure that products are handled hygienically and meet safety standards.

Pharmaceuticals: Automated systems in the pharmaceutical industry are crucial for ensuring the accuracy and safety of products. They help with tasks such as inventory management, sorting, and packaging of sensitive pharmaceutical products.

Regional Insights

The Automated Material Handling Equipment market is experiencing significant growth across various regions, with North America, Europe, and Asia Pacific being key players.

North America: North America, especially the United States, is one of the largest markets for AMHE, driven by the high adoption rate of advanced technologies in industries such as e-commerce, manufacturing, and logistics. The region's strong focus on research and development, along with the presence of several key market players, is also contributing to market growth.

Europe: Europe is another prominent region in the AMHE market, with countries like Germany, the UK, and France leading the way. The European market is characterized by a high demand for automation in manufacturing, logistics, and e-commerce, particularly in countries with strong industrial sectors.

Asia Pacific: The Asia Pacific region is expected to see the highest growth in the Automated Material Handling Equipment market. This can be attributed to the rapid industrialization in countries like China, Japan, and India. The increasing demand for automation in manufacturing and logistics, coupled with the region’s large population and growing e-commerce sector, is driving market expansion.

Challenges

Despite the significant growth potential, the AMHE market faces several challenges. One of the main obstacles is the high initial cost of implementing automated systems, which can be a barrier for small and medium-sized enterprises (SMEs). Additionally, the complexity of integrating new automated systems with existing infrastructure can lead to disruptions in operations.

Moreover, the rapid pace of technological advancements in automation means that businesses must constantly invest in upgrading their systems to remain competitive. This presents a challenge for companies in terms of budget allocation and resource management.

Conclusion

The Automated Material Handling Equipment market is poised for substantial growth, driven by the need for efficiency, cost reduction, and technological advancements. As industries continue to embrace automation to meet the demands of modern supply chains, the market for AMHE is expected to expand significantly in the coming years. However, businesses must carefully consider factors such as initial costs and system integration to ensure successful adoption.

0 notes

Text

Piano Movers Services in Clearwater

When it comes to moving a piano, you need a team of experienced professionals who understand the intricacies of handling such a delicate and valuable item. At Stars and Stripes Movers, we specialize in Piano Movers Services in Clearwater, offering expert care, precision, and the necessary equipment to ensure your piano reaches its destination safely. Whether you’re relocating across town or need to move your piano within Clearwater, our team is here to provide a seamless experience from start to finish.

Why Choose Stars and Stripes Movers for Your Piano Moving Needs?

Pianos are among the most challenging items to move, and at Stars and Stripes Movers, we’ve honed our skills to ensure your instrument is in the safest hands. Unlike standard furniture, pianos require careful disassembly, proper padding, and transport methods to prevent any damage. Our team is trained to handle a variety of pianos, including grand pianos, upright pianos, and baby grands. We use specialized tools and equipment to ensure a smooth transition from one location to another. Whether you’re moving your piano into a new home or preparing it for storage, Stars and Stripes Movers offers the peace of mind that comes with expert piano moving services in Clearwater.

Customized Piano Moving Solutions in Clearwater

The Right Equipment for Safe and Efficient Piano Moving

The proper equipment is essential when it comes to moving a piano safely. At Stars and Stripes Movers, we have invested in specialized equipment, including piano dollies, heavy-duty straps, and padding, to safeguard your instrument throughout the move. Our Piano Movers Services in Clearwater also include using ramps, hoisting techniques, and cranes when necessary to avoid any damage to your piano or your home. With the right tools, our team can handle the logistics of even the trickiest piano moves, whether it’s navigating narrow hallways or lifting a grand piano over stairs.

Affordable and Reliable Piano Moving in Clearwater

At Stars and Stripes Movers, we know that moving a piano can be a significant investment, and we strive to offer competitive pricing for our Piano Movers Services in Clearwater. We believe that professional piano moving services shouldn’t break the bank, which is why we offer affordable rates without sacrificing quality or safety. We provide upfront pricing with no hidden fees, ensuring you can plan your move with confidence. Our team’s reliability and dedication to customer satisfaction mean you can trust us to handle your piano with the utmost care, all while staying within your budget.

Get in Touch with Stars and Stripes Movers for Piano Moving Services in Clearwater

If you’re ready to move your piano, look no further than Stars and Stripes Movers. Our Piano Movers Services in Clearwater are designed to provide a stress-free, reliable, and safe moving experience. We are committed to ensuring that your piano reaches its new location without any issues, allowing you to enjoy your music in your new space without a second thought. Contact us today for a consultation and discover how we can assist you with your next piano move!

1 note

·

View note

Text

Best Load Cell Manufacturer in India 2025 – A Deep Dive into Rudrra Sensor

In the fast-moving world of industrial technology, load cells are just as important to accuracy and dependability of weighing in various applications. As of 2025, Rudrra Sensor has emerged as a leading manufacturer of load cells in India, gaining recognition for its commitment to quality, innovation, and customer satisfaction. This article details the offerings, technological advancements, and other factors that make Rudrra Sensors the best among load cell manufacturers in India.

Understanding Load Cells

Load cells are sensors that translate force or weight into an electrical signal. Load cells are fundamental elements in scales, balancing equipment, and many industrial applications where precise weight measurement is important. Load cell performance and accuracy can substantially impact efficiency, safety, and adherence to industry standards.

Company Overview: Rudrra Sensor

Created to provide the best measurement solutions, Rudrra Sensor has established itself as a leading manufacturer of load cells. Located in Ahmedabad, Rudrra Sensor has utilized state-of-the-art technology and strict quality assurance to develop/load cells designed for various industrial applications.

Commitment to Quality

Rudrra Sensor is dedicated to quality. The company has a rigorous quality management system to ensure each load cell adheres to internationally-accepted norms. Rudrra Sensor's products use high-quality raw materials and manufacturing processes to achieve accuracy in extreme conditions.

Key Features of Rudrra Sensor Load Cells

1. Precision and Accuracy

Rudrra Sensor’s load cells are engineered for precision and accuracy, which are critical in applications such as manufacturing, logistics, and construction. Each load cell undergoes extensive testing to ensure it meets the required specifications, providing users with confidence in their measurements.

2. Versatile Product Range

One of the standout features of Rudrra Sensor is its diverse product range. The company offers various types of load cells, including:

Shear Beam Load Cells: Ideal for platform scales and industrial weighing applications, known for their stability and accuracy.

Tension Load Cells: Designed for applications requiring measurement of tensile forces, commonly used in cranes and hoisting equipment.

Compression Load Cells: Perfect for applications that involve compressive forces, such as industrial weighing systems.

This wide array of options allows businesses from different sectors to find the most suitable load cell for their specific requirements.

3. Robust Construction

Rudrra load cells are built with robust construction to ensure durability and longevity. They are engineered to withstand harsh environmental conditions, including temperature fluctuations, humidity, dust, and mechanical stress. This resilience is particularly important in industrial settings where load cells are subjected to rigorous use.

4. Advanced Technology

Rudrra Sensor applies advanced technologies in its manufacturing methods. Modern sensor technologies and advanced signal processing methods increase the capabilities of its load cells by ensuring fast response times and high accuracy. Rudrra Sensor is always working on research and development to keep the company on the cutting edge of current and future trends.

Advantages of Choosing Rudrra Sensor

1. Customization Options

Acknowledging that different applications have different requirements, Rudrra Sensor provides custom options for their load cells. Clients can specify features like load capacity, output signal type, or even protection from environmental conditions so that the load cells can be customized for their application.

2. Competitive Pricing

Rudrra Sensor has reasonable prices on their load cells, even if their products are high quality. This allows access to the load cells to a wider marketplace - especially small and medium enterprises - to benefit from quality measurement devices without breaking the bank.

3. Excellent Customer Support

Rudrra Sensor prides itself on delivering excellent customer support. Their dedicated team assists clients in selecting the right load cells for their applications and provides ongoing support to ensure optimal performance throughout the product’s lifecycle. This commitment to customer satisfaction fosters long-term relationships and trust.

Applications of Rudrra Load Cells

Rudrra Sensor’s load cells find a wide range of applications across various industries, including:

1. Manufacturing

In manufacturing environments, load cells are essential for quality control processes, ensuring that products meet weight specifications. Rudrra's load cells help manufacturers maintain consistency and reliability in their production lines.

2. Logistics and Warehousing

In logistics, accurate weight measurement is critical for inventory management and shipping. Rudrra load cells are utilized in weighbridges and conveyor systems to facilitate the efficient handling of goods.

3. Construction

The construction industry relies on load cells for weighing materials and ensuring structural integrity. Rudrra's tension and compression load cells are particularly useful in applications involving heavy lifting and material testing.

4. Food Industry

In the food industry, precision in ingredient measurement is vital for compliance with safety regulations and quality standards. Rudrra load cells are used in various food processing applications, from ingredient measurement to packaging.

Conclusion

As we look at the load cell manufacturing landscape in 2025, Rudrra Sensor emerges as a leader in the industry. Their unrelenting pursuit of quality, innovation, and service to the customer assistance place them as the foremost load cell manufacturer in the India marketplace. With their expansive range of load cells, advanced technology, and attention to detail, Rudrra Sensor fulfills the various needs of industries across the Country. If you are a business that needs a reliable, accurate load measurement solution,Rudrra Sensor is a name that stands out for its excellence and dependability.

#ShearBeamLoadCell#CompressionLoadCell#STypeLoadCell#WeightIndicatorLoadCell#DigitalLoadCell#HeavyDutyLoadCell#CustomLoadCell#SmartLoadCell

0 notes

Text

Warehouse Material Handling: Optimal Techniques for Effectiveness

Increasing productivity, reducing expenses, and maintaining a safe working environment all depend on effective warehouse material handling. Businesses can improve supply chain performance, minimize product damage, and streamline operations by implementing smart practices.

1. Improve the layout of the warehouse

Workflow and space utilization are improved by a thoughtful layout:

Zoning: Establish zones for shipping, packing, receiving, and storing.

Clear Pathways: To facilitate the movement of equipment, keep aisles open and free of obstructions.

High-Demand Items: Keep regularly used goods close to areas for dispatch.

Vertical Storage: To make the most of available space, use racks and shelves.

2. Make Use of the Proper Tools

Purchasing the right tools improves safety and productivity:

Pallet jacks and forklifts are perfect for moving large objects.

Conveyor Systems: Automate the movement of materials.

AS/RS: Reduce manual labor and improve inventory accuracy.

Handle large objects safely with cranes and hoists.

3. Put Safety First

Keeping the workplace safe safeguards both employees and inventory:

Instruction: Provide instruction on safe lifting and equipment use.

PPE: Offer safety shoes, gloves, and helmets.

Signage: Indicate walkways and potential hazards clearly.

Emergency Plans: Get ready for spills, fires, and medical emergencies.

4. Enhance Inventory Control

Errors and waste are decreased by efficient inventory control:

Use RFID or barcodes for real-time tracking.

FIFO/LIFO: Use the appropriate rotation techniques.

Verify physical stock counts through routine audits.

Inventory processes can be automated with WMS software.

5. Simplify the Picking and Packing Process

Delivery times are accelerated by faster processing:

Cut down on travel time with batch and zone picking.

Automation: Make packing and sorting faster.

Verify accuracy prior to shipping with quality checks.

6. Make Ergonomics Better

Encourage employee productivity and well-being:

Ergonomic Stations: Adjustable configurations lessen strain.

Lift Assists: Reduce the amount of manual lifting.

Training & Breaks: Keep employees informed and attentive.

7. Make Use of Technology

Smarter operations are driven by modern tools:

IoT & AI: Track conditions and forecast demand.

Reduce manual handling and increase inventory visibility with drones and AGVs.

8. Promote Ongoing Enhancement

Monitor KPIs, get input from staff, and keep up with developments in the field.

Concluding remarks

Material handling optimization improves customer satisfaction, safety, and warehouse performance. A tech-enabled, efficient strategy lays the groundwork for sustained operational success.

To get more information, please check out the link given below.

0 notes

Text

Professional Building Materials Lifting Service in CA – Call Today!

Regarding construction projects, having a reliable building materials lifting service in CA can make all the difference. Whether you're working on a residential or commercial site, efficient lifting solutions ensure safety, precision, and timely project completion. At REBCO Crane and Rigging, we specialize in providing top-quality lifting services for all your heavy material needs.

Why Choose Professional Building Materials Lifting Services?

Handling heavy construction materials requires expertise, precision, and the right equipment. Professional lifting services like REBCO Crane and Rigging help ensure:

Safety: Prevents injuries and damages by using proper lifting techniques.

Efficiency: It reduces manual labor and speeds up the process.

Precision: Ensures accurate placement of materials at the right location.

Cost-effectiveness: Minimizes project delays and labor costs.

Our Comprehensive Lifting Services

We offer specialized building materials lifting services in CA for various materials, including:

Steel beams and structures

Concrete panels and blocks

Wooden frameworks

Piping and industrial materials

Glass panels and facades

Advanced Lifting Equipment for Every Project

Having the right building material lifting equipment is crucial to ensure smooth operations. Our fleet includes advanced cranes, hoists, and rigging tools designed for heavy lifting, including:

Tower Cranes for high-rise construction

Mobile Cranes for flexible and quick lifting

Hydraulic Cranes for precise material handling

Boom Trucks for transporting and lifting materials

Enhancing Construction Efficiency

Using professional construction material lifting equipment significantly improves productivity and reduces downtime. Our team at REBCO Crane and Rigging ensures that all equipment is operated by certified professionals, ensuring smooth lifting operations for:

High-rise buildings

Bridges and road infrastructure

Warehouse and storage units

Industrial plants and factories

Efficient Construction Material Shifting Solutions

Apart from lifting, construction material shifting lift services are essential to safely transport heavy loads across job sites. We provide customized solutions for moving:

Pallets of bricks, cement, and stone

Heavy machinery and tools

Pre-fabricated structures

Roofing and insulation materials

Why REBCO Crane and Rigging?

Choosing REBCO Crane and Rigging means opting for reliability and expertise. Here’s what sets us apart:

State-of-the-art equipment: We use modern lifting technology to ensure precision and safety.

Experienced professionals: Our operators are highly trained and certified.

Customer-focused approach: We tailor our lifting services to fit your project requirements.

Safety compliance: We follow industry standards and regulations to ensure a secure work environment.

Contact Us Today!

If you need a trusted building materials lifting service in CA, look no further than REBCO Crane and Rigging. Whether it’s building material lifting equipment, construction material lifting equipment, or construction material shifting lift services, we have the expertise to handle it all. Contact us today for a consultation and get your project moving smoothly and safely!

#building material lifting equipment#building materials lifting service in ca#construction material lifting equipment#construction material shifting lift

0 notes

Text

Lifting Technology Solutions: Reliable Equipment for Every Need

Technologies Pod'yema is a prominent company specializing in the production and supply of lifting equipment. With years of experience in the industry, the company has earned a reputation for providing high-quality, reliable solutions to meet a wide range of lifting needs across various sectors.

The core of Technologies Pod'yema’s success lies in its commitment to innovation and the continuous improvement of its products. The company offers a diverse range of lifting equipment, including cranes, hoists, lifting platforms, and other essential machinery designed to enhance efficiency and safety in workplaces. By utilizing the latest technology and adhering to the highest manufacturing standards, Technologies Pod'yema ensures that all products are durable, safe, and capable of handling even the most demanding tasks.

One of the standout features of Technologies Pod'yema is its customer-focused approach. The company recognizes that each project may have specific requirements, which is why they offer customized solutions to meet the unique needs of their clients. Whether it's a small-scale lifting task or a complex industrial application, the company’s team of experts works closely with clients to design, manufacture, and supply the most suitable equipment.

Technologies Pod'yema is also dedicated to providing exceptional customer service. From initial consultation to post-purchase support, the company is committed to ensuring that its clients receive comprehensive assistance throughout the entire process. This approach not only helps clients select the right lifting equipment but also ensures smooth installation, ongoing maintenance, and timely repairs if needed.

In addition to high-quality products and services, Technologies Pod'yema adheres to strict safety protocols, ensuring that all equipment meets the necessary safety standards. This commitment to safety and quality is reflected in the company’s reputation, making it a trusted partner for businesses in need of reliable lifting equipment.

With a solid track record in the industry, Technologies Pod'yema continues to lead the way in the lifting equipment sector. Whether you're in construction, manufacturing, or any other industry requiring lifting solutions, the company is your go-to partner for cutting-edge technology and unmatched reliability.

0 notes

Text

Lifting Spreader Beam: Essential Equipment for Safe and Efficient Load Handling

Introduction

A lifting spreader beam is a crucial piece of equipment in material handling and heavy lifting operations. Designed to distribute weight evenly, it ensures stability and safety when hoisting large or awkwardly shaped loads. Unlike traditional lifting methods, which may place excessive stress on slings or chains, a spreader beam provides balanced support, reducing the risk of accidents and load damage.

This article explores the functions, types, benefits, and applications of lifting spreader beams, helping you understand why they are indispensable in industries such as construction, shipping, and manufacturing.

What Is a Lifting Spreader Beam?

A lifting spreader beam is a rigid structural bar used to stabilize and evenly distribute the weight of a load during lifting operations. It connects to the crane or hoist via lifting slings or chains, with attachment points for securing the load. The beam prevents load imbalance, minimizing the risk of tilting or swinging.

Key Components of a Spreader Beam

Main Beam – The primary load-bearing structure, typically made from high-strength steel or aluminum.

Lifting Lugs – Attachment points for connecting slings or hooks.

End Fittings – Adjustable or fixed connectors for securing the load.

Load Pads – Protective elements to prevent damage to delicate loads.

Types of Lifting Spreader Beams

Different lifting scenarios require specialized spreader beams. The most common types include:

1. Fixed-Length Spreader Beams

Pre-set length for consistent lifting applications.

Ideal for repetitive lifting tasks with uniform load sizes.

2. Adjustable Spreader Beams

Feature telescopic or modular designs for variable lengths.

Suitable for handling loads of different sizes without needing multiple beams.

3. Modular Spreader Beams

Composed of interchangeable sections for customization.

Used in complex lifting operations requiring precise adjustments.

4. Synthetic Spreader Beams

Made from high-strength synthetic materials for lightweight applications.

Often used in aerospace and marine industries where weight is a concern.

Benefits of Using a Lifting Spreader Beam

Incorporating a lifting spreader beam into your lifting operations offers several advantages:

1. Enhanced Load Stability

Prevents load swaying or tilting, ensuring safer lifts.

Distributes weight evenly across multiple attachment points.

2. Reduced Sling Stress

Minimizes the risk of sling failure by balancing tension.

Extends the lifespan of lifting slings and chains.

3. Improved Safety

Lowers the chance of accidents caused by unbalanced loads.

Complies with OSHA and ASME safety standards.

4. Versatility in Applications

Can handle various load shapes, including long, wide, or fragile items.

Adaptable to different industries, from construction to offshore rigging.

5. Cost Efficiency

Reduces equipment wear and tear, lowering maintenance costs.

Increases operational efficiency by enabling faster, more controlled lifts.

Applications of Lifting Spreader Beams

Lifting spreader beams are widely used across multiple industries due to their reliability and efficiency.

1. Construction Industry

Lifting prefabricated concrete panels, steel beams, and large construction modules.

Ensuring stability when moving heavy materials at height.

2. Shipping and Offshore Operations

Loading and unloading large cargo containers and ship components.

Used in offshore rigging for equipment installation and maintenance.

3. Manufacturing and Heavy Machinery

Transporting oversized machinery parts and assembly lines.

Facilitating precise positioning of heavy components during production.

4. Renewable Energy Sector

Installing wind turbine blades and generator components.

Handling large solar panel arrays safely.

5. Aerospace Industry

Moving aircraft parts and engine assemblies.

Ensuring delicate components are lifted without deformation.

Choosing the Right Lifting Spreader Beam

Selecting the appropriate spreader beam depends on several factors:

1. Load Capacity

Ensure the beam’s Working Load Limit (WLL) exceeds the maximum intended load.

2. Load Dimensions

The beam length should match the load’s width to prevent instability.

3. Material and Durability

Steel beams offer high strength, while aluminum and synthetic options provide lightweight solutions.

4. Adjustability Requirements

Fixed beams suit consistent loads, while adjustable beams offer flexibility.

5. Compliance with Safety Standards

Verify that the beam meets industry regulations (OSHA, ASME, EN).

Maintenance and Inspection of Spreader Beams

Regular maintenance ensures the longevity and safety of a lifting spreader beam.

1. Routine Inspections

Check for cracks, deformations, or corrosion.

Inspect lifting lugs and end fittings for wear.

2. Proper Storage

Store in a dry, clean environment to prevent rust and damage.

3. Load Testing

Conduct periodic load tests to confirm structural integrity.

4. Replacement of Worn Parts

Replace damaged slings, hooks, or load pads immediately.

Conclusion

A lifting spreader beam is an essential tool for safe and efficient load handling across various industries. By evenly distributing weight and enhancing stability, it minimizes risks and improves operational efficiency. Whether in construction, shipping, or manufacturing, choosing the right spreader beam ensures smoother, safer lifting operations.

Investing in a high-quality lifting spreader beam not only enhances workplace safety but also optimizes productivity, making it a valuable asset for any heavy lifting application.

1 note

·

View note

Text

Top EOT Crane Manufacturers in India: How to Choose the Right One

Selecting an EOT crane manufacturer in India requires careful consideration of several factors. Here’s what you should look for:

1. Industry Experience & Reputation

An established manufacturer with decades of experience is more likely to deliver high-quality and reliable products. Leading single girder EOT crane manufacturers in India have a strong reputation for providing durable and efficient cranes tailored to industrial needs.

2. Product Range & Customization Options

A good manufacturer should offer a variety of products, including gantry cranes, jib cranes, chain hoists, and wire rope hoists. Customization is also crucial—whether it’s adjusting load capacity, span, or operational features, the manufacturer should be flexible in meeting unique client demands.

3. Compliance with Safety Standards

Safety is a top priority in industrial lifting operations. The best EOT crane manufacturers in Mumbai, Gujarat, and Pune ensure their products meet IS (Indian Standards) and global safety certifications. Features like overload protection, emergency braking, and anti-collision systems enhance workplace safety.

4. Technological Advancements

Modern crane hoist manufacturers in India integrate smart automation and IoT-enabled monitoring systems into their cranes. Advanced features such as remote control operation, energy-efficient motors, and predictive maintenance tools improve efficiency and reduce downtime.

5. After-Sales Support & Maintenance

Even the best cranes require regular servicing. A reputable chain hoist manufacturer in India or wire rope hoist manufacturer in India should provide timely maintenance, spare parts availability, and 24/7 customer support to ensure uninterrupted operations. For more visit https://sbecrane.com/

#eot crane manufacturer in india#eot crane manufacturer in mumbai#eot crane manufacturer#eot crane supplier

0 notes