#CompressionLoadCell

Explore tagged Tumblr posts

Text

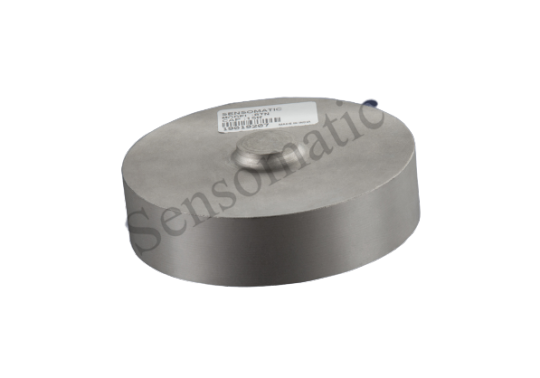

Compression Load Cell

Rudrra Sensor offers high-quality compression load cells with displays in India, providing precise measurements and real-time data for industrial applications. Contact us today to get a personalized quote for your requirements!

0 notes

Text

#load cell manufacturers in india#load cell suppliers#load cell suppliers in india#sensomaticloadcell#compressionloadcell#loadcellmanufacturersandsuppliersinindia#loadcellsuppliers#loadcellprice#sensomatic#stypeloadcell

0 notes

Text

We are the Top Load Cell Manufacturers and Suppliers in India. Sensomatic is one of the trusted and certified load cell suppliers in India.

0 notes

Text

How to Choose the Best Load Cells for Silos and Tank Weighing Systems

Introduction

Silos and tank weighing systems are integral to many industrial processes, especially in industries like agriculture, manufacturing, chemical processing, and mining. These systems provide accurate measurement of stored materials, whether solids or liquids, and play a crucial role in optimizing production and ensuring the consistency and quality of the final product. The accuracy of silo and tank weighing systems depends largely on the performance of the load cells used. A load cell is a sensor that converts force into an electrical signal, enabling precise measurement of the weight of materials stored in silos or tanks.

Choosing the right load cells for your silo and tank weighing system is paramount for ensuring that your operations run smoothly, efficiently, and safely. This guide will take you through the various factors to consider when selecting load cells for silo and tank weighing systems and highlight some of the most common types of load cells that are well-suited for such applications.

What Are Silo and Tank Weighing Systems?

Silo and tank weighing systems are used to measure the weight of materials stored in silos, tanks, or hoppers. These systems rely on load cells to detect any changes in weight, converting these measurements into electrical signals. These signals are then processed and displayed, allowing operators to monitor the amount of material in real-time.

The need for precise measurements is critical, especially in industries where the amount of material directly affects production processes, inventory control, and quality assurance. Whether you are measuring grain in an agricultural silos or chemicals in a processing tank, a reliable weighing system ensures the accuracy required for efficient operation.

Key Components of Silo and Tank Weighing Systems

Load Cells: Load Cells for Silos are the heart of any silo or tank weighing system. They measure the weight of the material stored within the silo or tank by converting the force exerted on them into an electrical signal.

Mounting Hardware: The Silo load cells are mounted securely within the silo or tank system using specialized hardware. This ensures that they function correctly and provide precise measurements.

Digital Indicators: These devices are used to display the weight readings provided by the load cells. They often come with digital readouts for easy interpretation of the data.

Controllers: The controllers manage the flow of data from the load cells to the digital indicators, automating the entire weighing process.

Understanding Load Cells for Silo and Tank Weighing Systems

Types of Load Cells Used in Silo and Tank Weighing Systems

Compression Load Cells: These load cells are the most commonly used type for silo and tank weighing systems. They are designed to bear compressive forces and ensure that weight is distributed evenly across the cell, leading to highly accurate measurements.

Pancake Load Cells: A specific type of compression load cell, pancake load cells have a low profile and are highly durable. They are ideal for applications where there is a need for minimal deflection and maximum accuracy.

Hydraulic Load Cells: Hydraulic load cells are used in applications that require heavy-duty weighing capabilities. These load cells provide reliable measurements and are particularly useful in environments where electrical power may not be available.

Strain Gauge Load Cells: These load cells use strain-sensitive materials to measure changes in force. They are highly accurate and are commonly used in applications that require precise measurements for both static and dynamic weighing.

High Precision Load Cells: These load cells are designed to provide extreme accuracy and are often used in industries where tight measurement tolerances are critical.

Key Factors to Consider When Choosing Load Cells for Silos:

Accuracy Requirements: The accuracy of your silo or tank weighing system is essential for process optimization, quality control, and safety. High precision load cells are essential for applications where even minor inaccuracies can lead to significant operational issues.

Load Capacity: Choose a Load Cells for Silos that can accommodate the maximum load expected for the silo or tank. Load cells are designed to handle a certain weight capacity, so it is essential to select one that can handle both the empty container weight and the maximum material weight.

Environmental Conditions: The environment in which the load cells will operate significantly impacts their performance. Harsh environments with high levels of moisture, chemicals, or extreme temperatures require special types of load cells, such as waterproof, corrosion-resistant, or explosion-proof models.

Sensitivity: Sensitivity refers to the load cells ability to detect small changes in weight. For high-precision applications, load cells with high sensitivity are required to ensure accurate measurements.

Importance of Accuracy in Silo and Tank Weighing Systems

Process Optimization

In industries that deal with bulk materials, accurate measurements are vital for process optimization. When raw materials are added to or removed from silos or tanks, precise weight data is necessary to ensure the right quantities are used. This prevents overuse or underuse of raw materials, optimizing inventory and reducing waste.

Product Quality

Maintaining consistent product quality relies on accurate weighing of ingredients or raw materials. Whether it is for pharmaceutical manufacturing, food processing, or chemical production, an inaccurate measurement could compromise the final product’s quality.

Safety and Compliance

Accurate measurements also ensure that industrial processes comply with safety regulations. For example, overloading a silo and tank weighing systems could result in structural failure or spills. Therefore, load cells that can accurately measure and monitor weight are essential for preventing accidents and ensuring compliance with safety standards.

Silo Mount Assembly in Load Cells

The Silo Mount Assembly plays a crucial role in the accuracy and durability of load cells in silo and tank weighing systems. Proper mounting ensures that the load cells remain secure and function optimally, even under challenging conditions. A well-designed mounting system allows the load cells to measure weight accurately without risk of damage or distortion.

Steps in Silo Mount Assembly

Selection of Mounting Hardware: It’s important to choose mounting hardware that is compatible with the load cells and can withstand the environmental and operational stresses involved. This includes factors like temperature extremes, vibration, and the weight being measured.

Testing and Calibration: After mounting the load cells, it’s critical to test the system for high precision load cells and to ensure accurate digital readouts. Calibration is an essential step in this process, eliminating any potential errors and ensuring that the load cells provide accurate readings.

Installation: Installing the load cells with the proper alignment and avoiding damage is crucial. It is necessary to ensure that the weight is evenly distributed across all load cells for silos to obtain accurate measurements.

Applications of Silo and Tank Weighing Systems

Silo and tank weighing systems have a wide range of applications across multiple industries:

Agriculture: Used in grain silos load cells and feed storage systems to monitor and control the inventory levels, ensuring farmers maintain optimal stock levels.

Chemical Processing: These systems monitor liquid and chemical levels in storage tanks, ensuring materials are dispensed and handled safely.

Concrete and Cement: Load cells are used to measure raw materials such as sand, cement, and aggregates to ensure accurate batching for construction projects.

Pharmaceuticals: In the pharmaceutical industry, precise ingredient measurement is crucial for creating consistent and safe products.

Mining: Weighing systems are used to track ore and other materials, improving the efficiency and accuracy of extraction processes.

Sensomatic Load Cells for Silo and Tank Weighing Systems

Sensomatic offers a wide range of load cells specifically designed for silo and tank weighing systems. Sensomatic’s load cells are known for their durability, precision, and reliability. Whether you need a high precision load cell or a robust hydraulic load cell for harsh environments, Sensomatic has a solution that fits your needs.

Key Features of Sensomatic Load Cells

High Fatigue Resistance: Sensomatic load cells are designed to handle repetitive loads, making them suitable for long-term use in demanding applications.

Impact Resistance: These load cells can withstand sudden shocks or dynamic forces, ensuring their reliability in challenging environments.

Accurate Digital Readouts: Sensomatic load cells provide precise, real-time weight measurements, ensuring your system is always providing accurate data.

Low Deflection: The low deflection design ensures that the load cells maintain structural integrity and measurement accuracy, even under heavy loads.

How to Choose the Best Load Cells for Silo and Tank Weighing Systems

Define Your Requirements

Before selecting a load cell, it’s essential to determine the type of material being measured (solid or liquid), the required load capacity, and the environmental conditions. If your application is in a harsh environment, you may need to consider specialized load cells that offer resistance to corrosion, temperature extremes, or other environmental factors.

Evaluate Load Cell Types

Choose load cells for silos based on your specific application needs. Compression load cells are suitable for general use, while hydraulic load cells may be better suited for heavy-duty or outdoor applications. Pancake load cells, on the other hand, are ideal for situations requiring low deflection and minimal space.

Consult with Experts

Selecting the right load cell is crucial, and working with a manufacturer or supplier can help you make the best choice. Reach out to load cell experts like Sensomatic, who can guide you in choosing the most suitable option based on your needs.

Conclusion

Choosing the right load cells for silo and tank weighing systems is essential for ensuring accurate measurements, system reliability, and process optimization. Understanding the various types of load cells, their applications, and the factors that affect their performance can help you make an informed decision. By selecting the best load cells for your silo and tank weighing systems, you ensure the continued efficiency, safety, and quality of your operations. Sensomatic’s range of high-quality load cells, including compression, pancake, and hydraulic load cells, provides the precision and reliability required for a variety of industrial applications. Invest in the right load cells to guarantee optimal performance and long-term success.

#load cell manufacturers in india#loadcellprice#loadcellsuppliers#sensomaticloadcell#compressionloadcell#stypeloadcell#loadcellmanufacturersandsuppliersinindia#load cell suppliers in india#load cell suppliers#sensomatic#SiloandTankweighingLoadCells#siloweighingScales#tankweighingscales#LoadCellforSiloandTankWeighing

0 notes

Text

#load cell suppliers#loadcellprice#sensomatic#compressionloadcell#stypeloadcell#loadcellsuppliers#load cell manufacturers in india#sensomaticloadcell#DoubleEndedShearBEamLoadCell#DeflectionBeamSensorLoadCell#Shearbeamloadcell#shearpinloadcell#Compactcompressionloadcell#singleendedshearbeamloadcell#singlepointloadcell

0 notes

Text

#load cell manufacturers in india#load cell suppliers#load cell suppliers in india#sensomatic#compressionloadcell#stypeloadcell#sensomaticloadcell#loadcellprice#loadcellmanufacturersandsuppliersinindia#UniversalLoadCell#HighSpeedSensor#SinglePOintLoadCell#BestLoadCellManufacturerinIndia

0 notes

Text

Best Load Cell Manufacturer in India - Precision, Reliability, and Innovation for Superior Weight Measurement Solutions Tailored to Your Industry Needs.

Introduction

In today's world, precision and accuracy are paramount in industries such as manufacturing, logistics, and engineering. Load cells, being vital tools for measuring force, weight, and tension, play a significant role in ensuring operational efficiency. But with so many manufacturers in the market, who stands out as the best load cell manufacturer in India? This article dives deep into what makes a load cell manufacturer exceptional, the advantages and disadvantages of search engine marketing (SEM), and how to choose the best partner for your needs.

Why Load Cells Are Crucial for Modern Industries

What Are Load Cells?

Load cells are transducers that converts Mechanical force into an electrical signal with digital outuput. They are integral to industries like:

Manufacturing: To ensure accurate weighing of raw materials.

Logistics: For monitoring cargo weight.

Construction: To measure tension in structural elements.

Applications of Load Cells in Various Industries

Aerospace: Ensuring precise weight measurement during assembly.

Automotive: Monitoring force in crash tests.

Healthcare: Utilized in patient lifts and medical scales.

Features of the Best Load Cell Manufacturer in India

Key Factors to Consider

Quality Assurance:

Adherence to international standards.

Use of high-quality materials.

Custom Solutions:

Load cells easy handed to customized the products

Flexibility in handling custom requirements.

Advanced Technology:

State-of-the-art manufacturing facilities.

Incorporation of modern innovations like wireless load cells.

Customer Support:

24/7 technical assistance.

Comprehensive warranty policies.

Top Benefits of Choosing a Reputable Manufacturer

Enhanced operational accuracy.

Long-lasting and durable products.

Reduced downtime due to reliable performance.

How to Identify the Best Load Cell Manufacturer in India?

Questions to Ask Before Making a Decision

What industries does the manufacturer serve?

Do they provide custom load cell designs?

What certifications do they hold?

Are their products competitively priced?

Checklist for Evaluating Manufacturers

Years of experience in the field.

Range of products offered.

Client testimonials and reviews.

Types of Load Cells Offered by Top Manufacturers

Compression Load Cells

Used in applications where weight is applied vertically.

Tension Load Cells

Ideal for pulling force measurements, commonly used in cranes.

S-Type Load Cells

S- Type Load Cell is used in many industries.

Shear Beam Load Cells

Used in industrial weighing scales and tanks.

FAQs - Best Load Cell Manufacturer in India

1. Why a load cell manufacturer is the best in India?

A combination of high-quality products, customer-centric services, and advanced technology sets a manufacturer apart.

2. How do I choose the right load cell formy Industry?

Consider factors like capacity, environment, and the type of force measurement needed.

3. Are load cells expensive?

Prices vary based on type, capacity, and customization but are generally cost-effective for their applications.

Conclusion

Finding the best load cell manufacturer in India can make a significant difference in your business operations. Whether you need precision, durability, or innovative solutions, choosing the right partner ensures seamless performance and long-term reliability. With the insights provided, you are well-equipped to make an informed decision and invest in high-quality load cells tailored to your needs.

#StypeLoadCell#BestLoadCellManuacturersinIndia#SensomaticLoadCell#loadcellsuppliers#load cell suppliers in india#load cell manufacturers in india#LoadCellPrice#CompressionLoadCell#ShearbeamLoadCells#TensionLoadCell

0 notes

Text

Installing and Calibrating Compression Load Cells

🔹Unlock Precision with Our Compression Load Cells! 🔹

Looking for top-tier accuracy in measuring compression forces? Look no further! Our compression load cells are engineered to deliver unparalleled precision and reliability, ensuring your operations run seamlessly and efficiently.

#CompressionLoadCell#TensionandCompressionLoadCell#CompressionLoadCellPrice#TensionCompressionLoadCell#CompressionLoadCellWorkingPrinciple#HighCapacityCompressionLoadCell#MiniCompressionLoadCell#CompressionLoadCellDesign#DigitalCompressionLoadCell#InstallingandCalibratingCompressionLoadCells#LoadCells#SensomaticLoadCell

0 notes

Text

Advanced Silo Weighing System for Precise Inventory Management

A silo weighing system is a technology used to measure the weight of materials stored in a silo or other types of storage containers. This system is commonly employed in industries such as agriculture, manufacturing, and logistics where accurate monitoring of inventory and material usage is crucial.

The key components of a silo weighing system typically include load cells, which are sensors that measure the force exerted by the material within the silo. These load cells are strategically placed under the legs or supports of the silo to accurately gauge the weight.

Load Cells: Load cells are installed at various points beneath the silo to support its weight. These cells convert the force exerted by the material into an electrical signal. Signal Processing Unit: The electrical signals from the load cells are transmitted to a signal processing unit. This unit processes the signals to calculate the total weight of the material in the silo.

Display and Control Unit: The calculated weight data is then displayed on a control unit, often equipped with a digital display. This unit may also include controls for calibration, data logging, and other relevant functions.

#SiloWeighingSystem#WeighingSystem#LoadCell#LoadCells#SingleEndedShearBeamLoadCell#DoubleEndedShearBeamLoadCell#WeightMeasurement#UniversalLoadCell#WeighModules#CompressionLoadCell#SinglePointLoadCell#ShearBeamLoadCell#BeamLoadCell#SensomaticLoadCell#BallTypeLoadCell#TypesofLoadCells#Sensotech

0 notes

Text

Discover Reliable Compression Load Cells - Model BTN, BTS

A compression load cell is a type of sensor designed to measure force or load along a single axis, typically in a downward direction. It is used to quantify the compressive force applied to an object. On the other hand, a tension and compression load cell can measure both tension (pulling) and compression (pushing) forces.

These load cells are versatile and find applications in various industries, including manufacturing, construction, and materials testing.

The price of a compression load cell can vary based on factors such as capacity, precision, and the manufacturer. Higher capacity compression load cells, designed to handle heavier loads, may be more expensive than lower capacity ones. It's essential to consider your specific application requirements when choosing a load cell, as this will impact the overall cost.

The working principle of a compression load cell involves the deformation of a material, typically a strain gauge, when a force is applied. This deformation leads to changes in electrical resistance, which can be measured and correlated with the applied force. The load cell then provides an output signal that corresponds to the force being measured.

#DiscoverReliableCompressionLoadCells#CompressionLoadCell#TensionandCompressionLoadCell#CompressionLoadCellPrice#TensionCompressionLoadCell#CompressionLoadCellWorkingPrinciple#HighCapacityCompressionLoadCell#MiniCompressionLoadCell#CompressionLoadCellDesign#DigitalCompressionLoadCell#LoadCells

0 notes

Text

Sensomatic is one of the most reliable load cell manufacturers and suppliers in India. With over 20 years of experience, we are rated as the most preferred and trusted load cell manufacturer in India. We are India’s leading manufacturer and supplier of Universal Load Cell, Double Ended Shear Beam Load Cell, S Type Load Cell, Button Type Load Cell, High-Speed Load Sensor, Elevator Sensor, Cable Tension Load Cell, Bending Beam Load Cell, etc.

visit us

#sensomaticloadcell#sensomatic#loadcellsuppliers#compressionloadcell#singleendedshearbeamloadcell#stypeloadcell#loadcellmanufacturersinindia#loadcell#loadcells

0 notes

Text

Optimize Accuracy with Single Ended Shear Beam Load Cells

Choosing the right type and capacity of single ended shear beam load cells is critical for accuracy. Consideration should be given to factors such as load range, material, and application requirements.

Matching the load cell specifications to the specific needs of the weighing system contributes to optimal performance. A single ended shear beam load cell is a type of transducer used to measure force and weight in various industrial applications.

It is designed to convert mechanical force or load into an electrical signal that can be further processed to determine the weight of an object. Single ended shear beam load cells play a pivotal role in various industrial applications, serving as the backbone of weighing systems.

To ensure optimal accuracy in weight measurements, it is crucial to understand the working principles of these load cells and implement strategies to enhance their precision. This article explores the working principle of single-ended shear beam load cells and provides insights into optimizing their accuracy. The working principle of single-ended shear beam load cells is based on shear stress. When a force or load is applied to the load cell, shear stresses are induced within the material, leading to deformation.

#SingleEndedShearBeamLoadCell#ShearBeamLoadCell#BeamLoadCell#CompressionLoadCell#SinglePointLoadCellWorkingPrinciple#WhatareLoadCells#TypesofLoadCells#DoubleEndedShearBeamLoadCell#SensomaticLoadCell#BeamDeflectionSensor

0 notes

Text

Reliable Rocker Column Load Cells

Introducing our reliable Rocker Column Load Cells, the ideal choice for precise weight measurements in a wide range of industrial settings.

Our product line includes models CMP and CMP-SP, both designed to deliver accurate and consistent results, ensuring the utmost reliability in your weighing processes.

Key Features: Precision Engineering: Our Rocker Column Load Cells are meticulously engineered to provide high-precision weight measurements, meeting the stringent standards of various industries.

Versatility: Suitable for diverse industrial applications, these load cells are designed to excel in challenging environments, delivering accurate results across a spectrum of weights and conditions. Model Options: CMP: This model is crafted for general industrial weighing applications, offering a robust solution for a variety of setups. CMP-SP: Specially designed for applications requiring additional features or specifications, the CMP-SP model ensures top-notch performance in specialized scenarios.

Choose our Rocker Column Load Cells for a dependable solution that meets the rigorous demands of industrial weight measurement. Contact us today to discuss your specific requirements and discover how our products can elevate the accuracy and reliability of your weighing processes.

#ReliableRockerColumnLoadCellsforWeightMeasurement#CompressionLoadCellPrice#TensionCompressionLoadCell#SensomaticLoadCell#RockerColumn#RockerColumnLoadCell#CompressionLoadCell#LoadCell

0 notes

Text

Optimize Accuracy with Single Ended Shear Beam Load Cells

Crafted with utmost precision, our Single Ended Shear Beam Load Cells are engineered to deliver superior accuracy in weight measurements.

These load cells are designed for reliability, ensuring consistent and trustworthy performance in various applications. Built to endure rigorous conditions, our Single Ended Shear Beam Load Cells go beyond mere accuracy; they embody durability and longevity. The robust construction ensures resilience in demanding environments, maintaining peak performance even under challenging circumstances.

Whether you're in manufacturing, logistics, or any industry requiring precise weight data, our load cells are built to meet your stringent requirements. Count on our technology to provide dependable results, contributing to the efficiency and accuracy of your processes.

Experience peace of mind knowing that our Single Ended Shear Beam Load Cells are not just instruments but partners in your pursuit of precision. Invest in quality, invest in accuracy – choose our Single Ended Shear Beam Load Cells for a seamless and reliable weight measurement experience.

#SingleEndedShearBeamLoadCell#ShearBeamLoadCell#BeamLoadCell#CompressionLoadCell#BeamDeflectionSensor#ShearPinLoadCell#LoadCellsWorkingPrinciple#WhatareLoadCells#TypesofLoadCells#DoubleEndedShearBeamLoadCell#LoadCellsSensor#LoadCells#StrainGaugeLoadCells#LoadCellsWorking

0 notes

Text

Reliable Tension Load Cells for Precise Measurement

When seeking reliable tension load cells for precise measurement, it's crucial to consider various factors to ensure accurate and consistent results. Tension load cells play a critical role in applications such as industrial weighing, force measurement, and material testing. Here are key aspects to focus on when selecting tension load cells:

Accuracy and Precision: Choose load cells with high accuracy and precision specifications to meet the required measurement tolerances. Consider load cells with low non-linearity and hysteresis for more reliable results.

Capacity and Range: Select load cells with an appropriate capacity that matches the expected load range of your application. Ensure the load cell's capacity exceeds the maximum load you anticipate to measure to prevent overloading.

Certifications and Compliance: Verify that the tension load cells comply with industry standards and regulations. Look for load cells that carry certifications from relevant authorities, ensuring they meet quality and safety standards.

#TensionLoadCells#PrecisionMeasurement#IndustrialWeighing#ReliableLoadCells#AccurateWeightMeasurement#ReliableTensionLoadCellsforPreciseMeasurement#loadcells#sensomaticloadcell#pancakeloadcell#stypeloadcell#Shearpinloadcell#Universalloadcell#Compressionloadcell#Buttontypeloadcell#LoadCells

0 notes

Text

Reliable Rocker Column Load Cells for Weight Measurement

Elevate Your Weighing Solutions with Our Reliable Rocker Column Load Cells!

Discover unparalleled precision and durability with our Compression Load Cell Model CMP, specially crafted for Monolith Construction. Engineered from high-nickel alloy steel, this load cell boasts a robust design that ensures accuracy even under angular loading conditions.

Why Choose CMP Load Cell?

Designed with ingenuity, our CMP load cell offers: ✅ Robust Construction: Built to withstand demanding environments, the CMP load cell guarantees reliable performance in any setting. ✅ Angular Loading Compatibility: The unique design allows for angular loading without compromising accuracy, providing flexibility in your weight measurement applications. ✅ IP68 Sealing: Trust in the resilience of our load cell, sealed to the IP68 standard, making it resistant to dust and water ingress for long-lasting functionality. ✅ Optimal Mounting Cups: The carefully crafted mounting cups, in combination with the ideal radius of the load cell, ensure precise and hassle-free installation, saving you time and effort. Applications: Whether you're in manufacturing, logistics, or any industry requiring precise weight measurements, our CMP load cell is your go-to solution.

#ReliableRockerColumnLoadCellsforWeightMeasurement#CompressionLoadCellPrice#TensionCompressionLoadCell#SensomaticLoadCell#RockerColumn#RockerColumnLoadCell#CompressionLoadCell#DigitalCompressionLoadCell#HighCapacityCompressionLoadCell#LoadCells

0 notes