#Industrial Chemical Storage Tanks.

Explore tagged Tumblr posts

Link

We are Chemical Storage Tanks Manufacturers, Suppliers in India. Contact us for HDPE Storage Tank & Industrial Chemical Storage Tanks.

0 notes

Text

Industrial Chemical Storage Tank Manufacturer - Step® Techno

Understanding the Importance of Chemical Storage Tanks

Chemical storage tanks are essential components in numerous industries, designed to safely store and handle chemical substances. These tanks ensure that chemicals are stored securely, preventing leaks and environmental contamination. A Chemical Storage Tank manufacturer has an essential role in providing high-quality tanks that meet the different demands of industries such as manufacturing, pharmaceuticals, and food processing.

Chemical storage tanks are widely used for storing acids, bases, and other chemicals required in industrial processes. These tanks come in various materials, such as stainless steel, fiberglass, and polyethylene, depending on the specific application.

Understanding Chemical Storage Tanks

The process of chemical storage involves carefully designed tanks that ensure the safe containment of hazardous substances. These tanks are equipped to handle extreme conditions, including high temperatures, pressure variations, and corrosive environments.

One important aspect of chemical storage tanks is their role in phosphating, a surface treatment process that improves corrosion resistance and enhances paint adhesion. This makes them vital for industries requiring high-quality surface finishes and extended equipment lifespan.

Applications of chemical storage tanks include:

Chemical Processing: Safely storing raw materials and intermediate products.

Water Treatment Plants: Containing chemicals used in water purification.

Pharmaceuticals: Safeguarding sensitive chemical compounds.

Food and Beverage: Ensuring hygiene and safety during chemical storage.

The Role of Industrial Chemical Storage Tanks

Industrial chemical storage tanks are specialized containers used to store large volumes of chemicals in industrial settings. These tanks ensure operational efficiency by maintaining the quality of stored substances and minimizing risks.

Functions of Industrial chemical storage tanks include:

Providing safe storage for hazardous and non-hazardous chemicals.

Protecting chemicals from environmental factors like UV radiation and moisture.

Ensuring compliance with safety and environmental regulations.

Industrial chemical storage tanks must be designed to meet stringent safety standards, making it essential to choose a reliable Industrial chemical storage tanks manufacturer for your requirements.

Key Features of Quality Industrial Chemical Storage Tanks

When selecting Industrial chemical storage tanks, there are several features to consider:

Material Durability: Tanks made from corrosion-resistant materials like stainless steel or high-grade plastic ensure longevity.

Leak-Proof Design: A well-sealed design prevents leaks and protects the environment.

Customization Options: Customizable features help meet specific industry needs, such as size, material, and fittings.

Safety Standards: Compliance with safety and environmental regulations is crucial.

Temperature Resistance: Tanks must withstand extreme temperatures, especially in industries dealing with heated chemicals.

Customization is a key factor in ensuring that the tank aligns perfectly with operational requirements, enhancing efficiency and reducing costs.

Overview of STEP® Techno Solutions LLP

STEP® Techno Solutions LLP is a leading Chemical Storage Tank manufacturer in India, known for its expertise in crafting high-quality industrial solutions. The company specializes in producing innovative Industrial chemical storage tanks designed to meet the diverse needs of industries.

With a strong commitment to quality and innovation, STEP® Techno Solutions LLP has become a trusted name in the industry. Their products are known for their durability, efficiency, and adherence to international safety standards. The company’s expertise ensures that clients receive tanks tailored to their specific requirements, ensuring optimal performance.

Advantages of Choosing a Top Industrial Chemical Storage Tank

A renowned industrial chemical storage tank manufacturer, offers various benefits:

Quality Assurance: Their products meet stringent quality standards, ensuring safety and durability.

Advanced Technology: The company uses cutting-edge manufacturing techniques to produce reliable solutions.

After-Sales Support: Comprehensive customer support ensures smooth operation and maintenance of tanks.

Cost-Effectiveness: High-quality products reduce the need for frequent replacements, lowering long-term costs.

Choosing a reputable Chemical Storage Tank manufacturer guarantees peace of mind and reliable performance in demanding industrial environments.

Customization Options for Industrial Chemical Storage Tanks

We offer customizable systems to meet specific client needs. From tank size and material selection to additional features like temperature control and agitation systems, customization ensures that the tanks align with operational requirements.

Customization enhances the functionality of Industrial chemical storage tanks by:

Allowing seamless integration into existing systems.

Improving operational efficiency by addressing unique challenges.

Extending the lifespan of the tanks with tailored features.

By opting for tailored solutions, industries can achieve optimal performance and cost savings.

Industry Trends and Innovations

The field of Industrial chemical storage tanks is constantly evolving, with new technologies and materials improving efficiency and safety. Current trends include:

Smart Tanks: Equipped with sensors to monitor temperature, pressure, and chemical levels in real time.

Eco-Friendly Materials: Increasing demand for sustainable and recyclable materials in tank manufacturing.

Modular Designs: Tanks that can be easily assembled or expanded to meet changing needs.

The future of Chemical Storage Tank manufacturer in India lies in continuous innovation, ensuring that industries have access to advanced solutions for their storage needs.

Conclusion

Industrial chemical storage tanks are indispensable for industries that require safe and efficient chemical storage. From ensuring safety and compliance to enhancing operational efficiency, these tanks play a pivotal role in modern industrial processes.

Choosing the right Industrial chemical storage tanks is critical for long-term reliability and performance. STEP® Techno Solutions LLP is a leading Chemical Storage Tank manufacturer, offers advanced, customizable solutions that cater to diverse industrial requirements.

STEP® Techno Solutions LLP is the #1 choice for reliable and innovative industrial chemical storage tanks. Their expertise, commitment to quality, and focus on innovation make them a trusted choice for industries across India. For more information visit our website, call +919898875757, or email at [email protected].

#Chemical Storage Tank manufacturer#Industrial chemical storage tanks#Industrial chemical storage tanks manufacturer#Chemical Storage Tank manufacturer in India

0 notes

Text

Reliable FRP Water Tank Manufacturer – Sagar FRP Industries

As a leading FRP water tank manufacturer, Sagar FRP Industries specializes in producing high-quality, corrosion-resistant fiberglass tanks. Our tanks are designed for maximum durability and safe, efficient water storage in any environment.

#FRP tank manufacturers#FRP chemical storage tank manufacturer#FRP anti corrosive chemical tank manufacturer in Gurgaon#FRP fire fighting water tank manufacturer industry#FRP bottom storage tank manufacturer in Gurgaon#FRP feedwell manufacturers

0 notes

Text

Industrial Vessels in Different Industries

Industrial vessels are integral to numerous industries, providing crucial functions that enhance productivity, safety, and efficiency.

1. Pharmaceutical Industry

In the pharmaceutical sector, industrial vessels must adhere to stringent regulatory standards to ensure product quality and safety. Stainless steel is a common material for these vessels, as it resists corrosion and can withstand sterilization processes. Pharmaceutical-grade vessels include mixing tanks for compounding ingredients, reactor vessels for synthesizing active pharmaceutical ingredients (APIs), and storage tanks for purified water. Cleanability is a top priority, with vessels often equipped with CIP (Clean-in-Place) systems to maintain sterile conditions. By maintaining high standards of hygiene and precision, industrial vessels in this industry contribute to the safe production of medicines and other healthcare products.

2. Chemical Industry

The chemical industry heavily relies on industrial vessels for storing and processing volatile or hazardous substances. Reactor vessels enable controlled chemical reactions, while separation vessels play a role in refining raw materials. Materials like carbon steel and stainless steel are preferred due to their durability and resistance to chemicals. Tanks with advanced coatings are often used to handle corrosive chemicals, enhancing the lifespan of the equipment. Safety features, such as pressure-relief valves and fire-resistant designs, are crucial in this industry to prevent accidents and ensure compliance with safety regulations.

3. Food and Beverage Industry

Industrial vessels are essential in the food and beverage sector, where they are used to mix, process, and store ingredients under sanitary conditions. Stainless steel vessels are commonly employed, as they resist corrosion, are easy to clean, and do not react with food-grade ingredients. Mixing vessels help ensure uniformity in products like sauces, dairy, and beverages, while storage tanks are used to maintain the freshness of ingredients such as oils, syrups, and flavorings. Temperature-controlled tanks are often employed to keep perishable items fresh. Industrial vessels in this industry meet regulatory standards to maintain product quality and prevent contamination.

4. Oil and Gas Industry

Industrial vessels in the oil and gas sector must be robust and capable of withstanding harsh conditions. Storage tanks are essential for holding crude oil, refined fuels, and other hydrocarbons, while separation vessels are used in refining processes to separate oil, water, and gas. Spherical and cylindrical tanks are typical in this sector, with materials such as carbon steel and alloys used to handle high pressures and temperatures. Corrosion resistance and fire safety are critical in these vessels, as the materials stored are often flammable and subject to regulatory oversight. Industrial vessels in this industry are engineered to ensure safe handling and storage, protecting both personnel and the environment.

5. Water Treatment and Wastewater Management

In water treatment facilities, industrial vessels are used to store and process water at various stages of treatment. Stainless steel and fiberglass-reinforced plastic (FRP) are common materials, as they resist corrosion from chemicals used in purification processes. Storage tanks hold raw water, while mixing vessels add treatment chemicals. Clarifiers and sedimentation tanks remove solids, while holding tanks store treated water before distribution. Industrial vessels in this industry contribute to efficient water management, ensuring that clean, potable water is available for communities and industries.

Key Considerations for Selecting Industrial Vessels

When selecting industrial vessels, several factors are considered to ensure safety, compatibility, and efficiency.

Material Compatibility: Vessels must be made of materials compatible with the substances they will contain. For example, stainless steel is ideal for pharmaceutical and food applications, while FRP works well in water treatment.

Capacity and Size: Determining the right size and capacity is essential for optimizing production processes. Larger operations may require custom-sized vessels, while small-scale processes may benefit from compact designs.

Pressure and Temperature Resistance: High-pressure applications require reinforced vessels, while those exposed to varying temperatures must be designed to prevent structural damage. In chemical industries, vessels may be lined or coated to withstand corrosive environments.

Safety and Compliance: Industries dealing with hazardous or flammable substances must follow strict safety regulations. Pressure-relief valves, explosion-proof designs, and automated monitoring systems are often implemented to meet regulatory standards and protect workers.

Maintenance and Cleaning Requirements: Some applications, like pharmaceuticals and food processing, require frequent cleaning. CIP (Clean-in-Place) systems are integrated to allow for thorough cleaning without disassembling the vessel, ensuring hygiene and minimizing downtime.

Conclusion

Industrial vessels serve as the backbone of multiple industries, enabling efficient, safe, and compliant operations. Each industry relies on specialized vessels, tailored to meet specific needs while adhering to safety and regulatory standards. With innovations in materials and design, these vessels continue to evolve, offering increased durability, efficiency, and environmental sustainability.

#Industrial Vessels#storage vessels#inudstrial storage vessles#storage tanks#water treatment#chemical#cosmetic#food and beverage#paper and pulp industry#pharmaceutical water treatment#water solution#swjalprocess

0 notes

Text

SS Industrial Storage Tanks: The Backbone of Industrial Fluid Management

Stainless Steel (SS) industrial storage tanks play a critical role in the storage, handling, and transportation of liquids and gases across a wide range of industries. From food and beverage processing to chemical manufacturing and pharmaceuticals, these tanks offer unmatched durability, safety, and corrosion resistance. As industries continue to evolve and demand higher standards of material integrity and hygiene, SS storage tanks have become the preferred choice for businesses requiring reliable and efficient storage solutions.

What Are SS Industrial Storage Tanks?

SS industrial storage tanks are large containers designed to store various types of liquids, gases, and chemicals. These tanks are constructed from stainless steel, which is known for its corrosion resistance, strength, and ability to maintain the purity of stored substances.

Stainless steel, particularly grades like 304 and 316, is used because of its excellent performance in harsh environments where chemical reactivity, temperature fluctuations, and sanitation are key considerations. These tanks come in various sizes and configurations, from small tanks for specialty applications to massive vessels for industrial use.

Types of SS Industrial Storage Tanks

Vertical Storage Tanks:

Designed to stand upright, these tanks are often used in industries that require storage for large quantities of fluids.

Vertical tanks are space-efficient, making them ideal for facilities with limited floor space.

Horizontal Storage Tanks:

These tanks lie on their side and are typically used for underground or above-ground storage.

Horizontal tanks are commonly used for storing fuel, water, and other liquids that need constant access.

Jacketed Tanks:

These tanks feature a secondary layer or "jacket" around the main body to control the temperature of the stored substance.

Jacketed SS tanks are widely used in the food, beverage, and pharmaceutical industries for processes like fermentation, pasteurization, and temperature-sensitive chemical reactions.

Pressure Vessels:

Pressure vessels are tanks designed to hold gases or liquids at pressures significantly different from ambient pressure.

These tanks are often used in industries like petrochemicals, oil and gas, and chemical manufacturing.

Mixing Tanks:

These tanks come with built-in mixing mechanisms such as agitators or impellers, used to blend, mix, or homogenize liquids or powders.

SS mixing tanks are frequently used in the food processing, pharmaceutical, and cosmetic industries for producing liquids, creams, and pastes.

Double-Walled Tanks:

Constructed with two layers of stainless steel, double-walled tanks provide added protection and are ideal for storing hazardous materials.

These tanks are used in applications where leakage prevention and environmental protection are critical.

Benefits of SS Industrial Storage Tanks

Corrosion Resistance: One of the primary reasons industries choose SS storage tanks is their excellent resistance to corrosion. Unlike other materials, stainless steel does not react with most chemicals, ensuring that the tank’s integrity is maintained over time, even when storing highly acidic or alkaline substances.

Durability and Longevity: Stainless steel tanks are known for their robustness and long lifespan. They can withstand high pressures and extreme temperatures without degrading, making them a suitable choice for a wide range of industrial environments. This longevity helps companies save on long-term maintenance and replacement costs.

Hygiene and Cleanliness: SS tanks are easy to clean and sanitize, making them essential in industries that prioritize cleanliness, such as food and beverage, pharmaceuticals, and water treatment.

Recyclability: Stainless steel is 100% recyclable, making SS industrial storage tanks an eco-friendly option. At the end of their service life, these tanks can be recycled without losing any of their original properties, contributing to a more sustainable industrial ecosystem.

Temperature and Pressure Tolerance: SS tanks can endure high-pressure applications and extreme temperatures, both hot and cold. This makes them suitable for industries like petrochemical refining, where materials are stored at high pressures, or in food processing, where temperature control is crucial.

Versatility: SS industrial tanks are versatile and can be customized for different applications. They can be designed with various features such as heating or cooling jackets, insulation, or specialized coatings to meet the unique needs of different industries.

Aesthetic and Structural Integrity: The clean and polished appearance of stainless steel also gives these tanks an aesthetic advantage, especially for industries that require visibility or public exposure, such as breweries or food production plants. SS tanks maintain their structural integrity and appearance for years without rusting, cracking, or staining.

Applications of SS Industrial Storage Tanks

Food and Beverage Industry: SS tanks are widely used for the storage of liquids like milk, juices, and alcoholic beverages, as well as for processes such as fermentation and pasteurization. The hygiene and non-reactivity of stainless steel are crucial for preserving the taste and safety of food products.

Pharmaceutical and Chemical Manufacturing: In the pharmaceutical industry, Chemical Storage tanks are used to store chemicals, water, and pharmaceutical products. Their non-reactive nature ensures that there is no contamination of sensitive products. In chemical manufacturing, SS tanks are employed to store and mix corrosive chemicals safely.

Oil and Gas: The oil and gas industry uses SS pressure vessels and storage tanks for holding petroleum products, LNG (liquefied natural gas), and other hazardous chemicals. These tanks must withstand high pressures and corrosive environments, making stainless steel the material of choice.

Water Treatment: SS tanks are used in water treatment plants for storing both potable and wastewater. They are preferred for their corrosion resistance and durability, particularly in environments that involve chlorine, saltwater, or other potentially corrosive substances.

Cosmetics and Personal Care: The cosmetic industry uses SS mixing and storage tanks to produce creams, lotions, and other personal care products. The smooth surface of stainless steel ensures that the ingredients do not stick or react with the tank, maintaining product quality.

Key Considerations for Choosing SS Industrial Storage Tanks

Material Grade: Depending on the application, different grades of stainless steel may be required. Grade 304 is the most common for general storage applications, while Grade 316 offers superior corrosion resistance for more demanding environments, such as those involving seawater or harsh chemicals.

Tank Size and Capacity: The size and capacity of the tank should be chosen based on the volume of material you need to store. Tanks can be custom-built to meet the specific requirements of your facility or operation.

Compliance with Regulations: Many industries, such as pharmaceuticals, food and beverage, and chemicals, must adhere to strict safety and hygiene regulations. SS storage tanks should comply with local and international standards, such as FDA, USDA, and ASME certifications, depending on the application.

Design Features: Depending on your needs, you may require tanks with additional features like heating or cooling jackets, agitators for mixing, or insulation to maintain temperature. Customizable features ensure the tank fits seamlessly into your operation.

Conclusion:

MS SS Tanks provide a reliable, durable, and eco-friendly solution for fluid and gas storage across multiple industries. With their excellent corrosion resistance, hygiene, and versatility, they stand as the backbone of modern industrial fluid management. Whether in the food, chemical, or oil and gas sectors, these tanks offer long-term cost savings, operational efficiency, and peace of mind, making them the smart choice for any business seeking an effective storage solution.

0 notes

Text

Industrial Tanks

Introducing Avon Engineering range of versatile Industrial Tanks – a hallmark of innovation in storage and processing solutions. These is redefine the concept of efficient storage and handling, offering a seamless blend of versatility, customization, durability, and compliance with industry standards for a wide range of industrial applications.

Key Features:

Discover the efficiency of our Industrial Tanks, adept at providing storage, mixing, and processing solutions for liquids, chemicals, and materials. Moreover, these tanks optimize your operational processes by ensuring easy access and controlled distribution. Additionally, tailor your tank to suit your specific needs. Our Industrial Tanks come in a variety of sizes and configurations, enabling you to choose the perfect fit for your storage requirements and available space. Furthermore, crafted with durability in mind, our tanks feature robust construction that can withstand the demands of industrial environments. In addition, built with high-quality materials and engineering expertise, they ensure consistent performance and reliability over time. Lastly, our Industrial Tanks are designed to adhere to industry-specific standards and regulations, ensuring that your storage and processing activities are compliant and in line with safety protocols. @avonengineering

Experience Cutting-Edge Storage and Processing: Our Industrial product introduce a new dimension of efficiency in storage and processing. Whether for chemicals, liquids, or other materials, these tanks deliver reliable, customizable, and safe storage and handling solutions, optimizing your processes. They integrate technology, customization, durability, and compliance, offering a forward-focused solution that aligns with your storage and processing goals. Elevate your operational efficiency and invest in a product that ensures exceptional performance. Embrace a new era of storage and processing with our state-of-the-art Industrial products

#Industrial Tanks#Storage Tanks#Processing Tanks#Liquid Storage Solutions#Chemical Storage Tanks#Industrial Tank Manufacturers#Tank Solutions for Industries#Customizable Tank Configurations#High-Quality Tank Construction#Durable Industrial Tanks#Tank Systems for Various Materials#Industrial Tank Suppliers#Efficient Tank Solutions#Tank Solutions for Manufacturing#Tank Solutions for Chemical Processing

0 notes

Text

1 note

·

View note

Text

OMAKHEATERS - PLATİN

Omak Heaters: Your Trusted Partner in Heating Solutions

When it comes to reliable and efficient heating solutions for various industrial applications, Omak Heaters stands out as a leading provider of top-quality products. Specializing in IBS tank heaters, barrel heaters, filter heaters, satellite dish heaters, and more, Omak Heaters offers innovative and dependable heating solutions to meet the diverse needs of its customers.

IBC Tank Heaters:

Omak Heaters offers a wide range of IBC tank heaters designed to provide consistent and uniform heating for industrial storage tanks. Whether you need to maintain the temperature of liquids or chemicals stored in tanks, our IBC tank heaters ensure optimal heating performance, enhancing operational efficiency and productivity.

Barrel Heaters:

For heating applications involving barrels and drums, Omak Heaters offers high-performance barrel heaters engineered to deliver efficient and uniform heat distribution. Our barrel heaters are designed to withstand harsh industrial environments and provide reliable heating solutions for various applications, including oil and chemical processing.

Filter Heaters:

Omak Heaters also specializes in filter heaters designed to prevent freezing and maintain optimal operating temperatures for filtration systems. Our filter heaters are built to deliver consistent and reliable heating performance, ensuring uninterrupted operation and prolonging the lifespan of filtration equipment.

Omak Heaters Quality Assurance:

At Omak Heaters, quality and reliability are our top priorities. All our heaters are manufactured using premium-quality materials and advanced manufacturing techniques to ensure superior performance and durability. Our team of experienced engineers and technicians conducts rigorous quality control tests at every stage of production to guarantee the highest standards of quality and reliability.

Customer-Centric Approach:

Omak Heaters is committed to providing exceptional customer service and support. We work closely with our customers to understand their unique heating requirements and offer customized solutions tailored to their specific needs. From product selection to installation and ongoing technical support, our dedicated team is here to assist you every step of the way.

Contact Omak Heaters Today:

Whether you're in need of IBS tank heaters, barrel heaters, filter heaters, or satellite dish heaters, Omak Heaters has the expertise and products to meet your heating needs. Contact us today to learn more about our comprehensive range of heating solutions and discover how we can help optimize your industrial heating processes.

625 notes

·

View notes

Note

so like, they make these ionic membranes for dehumidifying 3d printer filament boxes... basically by turning water into hydrogen. they're really expensive tho.

we've been thinking if it's possible to make something significantly cheaper, and we think we have come up with something. it uses the same principle of electrolysis, but instead of a solid membrane, it uses a liquid. specifically, sulfuric acid is really good at pulling moisture out of the air, down to very low relative humidity, and it's also really good as an electrolyte for electrolysis of water, enabling you to do both processes simultaneously. and unlike the very expensive membranes, which fill the filament box with oxygen gas, you can pipe out both the oxygen and the hydrogen, reducing the risk of explosions and fire.

only problem it might react with the filament. someone would have to try it and find out. what do you think?

Most of the industrial sulphuric-acid based tank dryers are whole external systems that pipe air through the acid side in a separate container pretty far from the tank contents to reduce the opportunity for interaction between the tank contents and acid, so unless you do that it would probably be hard to get the concentration high enough without having loose acid vapour eat your filament.

If you're trying to avoid heat-based drying, I'm not sure this helps, I think the limiting factor on drying at room temperature is a migration rate for moisture out of the filament, not the dryness of the air being used for drying.

There's those solid-state dehumidifier elements which seem like a better idea if you are looking for a very reliable long-term dry holding system and you're willing to go through the equivalent rigamarole of a sulphuric acid dryer.

4 notes

·

View notes

Text

2024-12-24: Vermont (Hex 24)

The road meanders and weaves over rolling hills covered in forests. Beech, birch, and maple trees cling tightly to the cool ground; the forests conceal a variety of wildlife.

Notable Feature: The Lotus Eater Forest (Resource)

Consisting of several dozen acres of boreal forest on the edge of a lake, the Lotus Eater Forest is named after the lotophages in Homer’s Odyssey. Several of the trees here produce a chemical aura that is mostly imperceptible to humans but makes mammalian Beasts docile and unafraid of people. For every 4 hours a person waits in the forest near one of these trees, an animal native to the area wanders into the influence of the tree. Roll 1d12 and consult the table below to see what animal appears.

Animal Caught By The Trees (1d12)

Coyote (Use Hyena statblock)

Fox, Red or Gray (Use Jackal statblock)

Bobcat (Use Panther statblock)

Ermine, Weasel, or Mink (use Weasel statblock)

Mountain Lion (Use Panther statblock)

Otter (Use Giant Weasel statblock with a swim speed of 40)

Fisher or American Marten (Use Badger statblock)

Skunk (Use Troglodyte statblock with 4 HP and no chameleon skin)

Raccoon (Use Giant Rat statblock)

Black Bear

Deer

Moose/Elk (Use Elk statblock)

Animals found in this way can be easily captured in this stupefied state. Some people in other places would pay good money to have some of these creatures as exotic pets. The animal recovers from the effects of the trees after being out of their influence for 1d4 hours. Sticks and small branches taken from these trees can be placed near creatures to prolong the effects (useful for transporting creatures!), but will lose their potency after 12 hours.

Service Station: Unity Heating Distributors

A small office building and a gravel parking lot is surrounded by industrial-scale storage tanks that hold propane and heating oil. Unity Heating Distributors is not a traditional service station because its purpose is to supply rural Vermont households with the supplies they need to keep warm. However, gas and diesel is often hard to find out here, so the company installed a few gasoline and diesel tanks to top off their service vehicles. Locals and the occasional travelers passing through the area are welcome to fill up here, but it costs about twice as much as a regular gas station. Minor repairs and light engine work can be performed by the garage technicians on site, but they don’t usually keep the parts in stock for cars and light trucks and it’ll be a long wait to get them delivered out here. Those in search of food will need to settle for handfuls of candy from gumball style machines or a soda from a vending machine that hasn’t been refilled in a while.

Items From Other Hexes

Heloise Carter is a reporter for the Freedom Bell newspaper who specializes undercover investigative journalism. She is the contact of Will Karlsson (Hex 9) and is willing to help him cover the story, but she is in the middle of investigating a group of disappearances over the past few years that the police have attributed to hippie cults. Before she can help Will, she needs to finish her investigation on this story and the evidence is beginning to point toward corrupt cops inventing a story about hippie cults to hide murders of local counterculture figures who were openly critical of police actions.

3 notes

·

View notes

Text

Filling Line - End to End Packaging Solution

Company Overview: Shiv Shakti Machtech is a Manufacturer, Exporter, and Supplier of Filling Line - End to End Packaging Solution in Ahmedabad, Gujarat, India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. Filling lines are advanced, automated systems that optimize packaging efficiency for various industries, such as food and beverages, pharmaceuticals, chemicals, and cosmetics. From product filling to capping, labeling, and sealing, these systems provide a seamless, end-to-end packaging solution. Process of Filling Lines: Filling lines follow a systematic, step-by-step process to ensure efficient product packaging: Product Feeding: The raw material or liquid is fed into the system, often from bulk storage tanks. Filling: The system accurately measures and dispenses the product into containers or bottles. Capping: The system automatically places and tightens caps or lids onto the filled containers. Sealing: The system seals containers using heat or adhesives to ensure product integrity. Labeling: The system applies custom labels to containers for branding and regulatory compliance. Inspection: The system conducts quality checks to ensure that the packaging meets standards. Cartoning & Palletizing: The system groups, boxes, and prepares packaged items for shipping. Applications of Filling Lines: Food & Beverage Industry Pharmaceutical Industry Cosmetics & Personal Care Chemical Industry Agricultural Products What is a filling line? A filling line automates the process of filling containers with liquids, powders, or granules. It can include processes like capping, labeling, and packaging for a complete solution. What industries use filling lines? Industries like food and beverage, pharmaceuticals, cosmetics, and chemical manufacturing commonly use filling lines. Can a filling line handle multiple product types? Yes, our filling lines are versatile and can handle various product types, including liquids, semi-liquids, powders, and viscous materials. Shiv Shakti Machtech is a Filling Line - End to End Packaging Solution and an exporter worldwide, including to Algeria, Angola, Antigua, Barbuda, Argentina, Armenia, Australia, Austria, The Bahamas, Bahrain, Bangladesh, Belarus, Belgium, Belize, Benin, Bhutan, Bolivia, Botswana, Brazil, Brunei, Bulgaria, Burkina Faso, Cambodia, Cameroon, Canada, Central African Republic, Chad, Chile, Colombia, Congo, Democratic Republic of the Congo, Costa Rica, Cuba, Cyprus, Denmark, Dominica, Ecuador, Egypt, Guinea, Ethiopia, Fiji, Finland, France, The Gambia, Georgia, Germany, Ghana, Greece, Guyana, Hungary, Iceland, Indonesia, Iran, Iraq, Ireland, Israel, Italy, Jamaica, Japan, Jordan, Kazakhstan, Kenya, South Korea, North Korea, Kuwait, Kyrgyzstan, Laos, Latvia, Lebanon, Libya, Malawi, Malaysia, Maldives, Mali, Mauritania, Mauritius, Mexico, Moldova, Monaco, Mongolia, Morocco, Mozambique, Myanmar (Burma), Namibia, Nepal, Netherlands, New Zealand, Niger, Nigeria, Norway, Oman, Panama, Peru, Philippines, Poland, Portugal, Qatar, Romania, Russia, Rwanda, Saint Lucia, Saudi Arabia, Senegal, Serbia, Singapore, Slovakia, Somalia, South Africa, Spain, Sri Lanka, Sudan, South Sudan, Sweden, Switzerland, Syria, Taiwan, Tajikistan, Tanzania, Thailand, Togo, Tunisia, Turkey, Uganda, Ukraine, United Arab Emirates (UAE), United Kingdom, United States, Uruguay, Uzbekistan, Vanuatu, Vatican City, Venezuela, Vietnam, Yemen, Zambia, Zimbabwe. For further details or inquiries, feel free to reach out to us. View Product: Click Here Read the full article

#Ahmedabad#Algeria#Angola#Antigua#Argentina#Armenia#Australia#Austria#Bahrain#Bangladesh#Barbuda#Belarus#Belgium#Belize#Benin#Bhutan#Bolivia#Botswana#Brazil#Brunei#Bulgaria#BurkinaFaso#Cambodia#Cameroon#Canada#CentralAfricanRepublic#Chad#Chile#Colombia#Congo

2 notes

·

View notes

Text

Innovative Applications of Stainless Steel Plates in Various Industries

Stainless steel plates have become a cornerstone material in various industries, thanks to their remarkable properties such as corrosion resistance, strength, and versatility. These plates are used in a wide range of applications, from construction and manufacturing to food processing and energy production. Their ability to withstand extreme environments, coupled with low maintenance costs, makes them a go-to choice for engineers, designers, and manufacturers across the globe.

In this blog, we will explore the innovative applications of stainless steel plates in different industries, highlighting how they contribute to improved efficiency and durability. ��As a trusted stainless steel plates dealer in Vadodara and Gujarat, Tube Trading takes pride in offering top-quality materials to meet the diverse needs of businesses across sectors.

Properties That Make Stainless Steel Plates Stand Out

Before diving into the various applications, it is essential to understand the key properties that make stainless steel plates such a valuable asset in industrial applications:

Corrosion Resistance: One of the most significant advantages of stainless steel is its ability to resist corrosion, even in harsh environments. This property is essential for industries such as marine, chemical processing, and food production, where materials are constantly exposed to moisture, chemicals, or salts.

Strength and Durability: Stainless steel plates offer exceptional strength, allowing them to withstand high-pressure environments and heavy loads. This makes them ideal for construction, infrastructure, and manufacturing industries.

Heat Resistance: Stainless steel can maintain its properties even at high temperatures, making it a preferred choice for applications in energy, aerospace, and automotive industries.

Aesthetic Appeal: The smooth, shiny surface of stainless steel plates gives them a modern, sleek look, which is often used in architectural applications and interior design.

Hygiene and Easy Maintenance: Stainless steel is easy to clean and maintain, making it a popular choice in the food, beverage, and pharmaceutical industries where hygiene is of utmost importance.

With these properties in mind, let us delve into the innovative applications of stainless steel plates in various industries.

1. Construction and Architecture

Stainless steel plates are a vital component in the construction industry due to their structural integrity and aesthetic appeal. In architectural design, stainless steel is often used in building facades, roofing, cladding, and interior décor. Its corrosion resistance ensures long-lasting durability in outdoor environments, while its sleek appearance adds a modern touch to buildings.

Additionally, stainless steel plates are used in the construction of bridges, tunnels, and other infrastructure projects. Their strength makes them ideal for load-bearing structures, while their resistance to rust ensures that they can withstand environmental exposure without degradation over time.

As a leading stainless steel plates dealer in Vadodara, Tube Trading has supplied high-quality stainless steel plates for numerous construction projects, ensuring the safety and longevity of these structures.

2. Food and Beverage Industry

The food and beverage industry requires materials that meet stringent hygiene standards. Stainless steel plates are widely used in this sector for the construction of food processing equipment, storage tanks, and countertops. Their non-porous surface prevents the buildup of bacteria, ensuring that food and beverages are processed in a clean and safe environment.

In addition to hygiene, stainless steel’s corrosion resistance is crucial when handling acidic or salty foods. For instance, in dairy processing or brewing, stainless steel ensures that equipment does not corrode or affect the taste and quality of the final product.

As a stainless steel plates supplier in Vadodara, Tube Trading works closely with food manufacturers to provide plates that meet industry standards for cleanliness, durability, and efficiency.

3. Chemical and Petrochemical Industries

In chemical and petrochemical industries, equipment is exposed to harsh chemicals, high temperatures, and corrosive environments. Stainless steel plates are used to construct reactors, storage tanks, pipelines, and other processing equipment. Their ability to resist chemical corrosion and withstand extreme temperatures makes them an ideal material for these applications.

Moreover, stainless steel's non-reactive properties ensure that it does not contaminate the chemicals being processed, maintaining the purity of the products.

In Gujarat, a hub for the chemical and petrochemical industries, Tube Trading stands as a reliable stainless steel plates supplier. Our stainless steel products are specifically designed to handle the rigorous demands of these industries, ensuring safety and operational efficiency.

4. Automotive and Transportation Industry

Stainless steel plates play a crucial role in the automotive and transportation industries due to their strength, durability, and ability to withstand impact. They are used in the construction of vehicle frames, exhaust systems, and various components that require resistance to heat and corrosion.

In addition to cars, stainless steel plates are essential in the railway and aerospace sectors, where safety and performance are critical. For example, stainless steel is used in the construction of airplane fuselages, train carriages, and ship hulls to ensure that these vehicles can handle extreme conditions without compromising safety.

As a stainless steel plates dealer in Gujarat, Tube Trading has a longstanding reputation for supplying top-quality materials to automotive and transportation manufacturers, helping them build safe, reliable, and efficient vehicles.

5. Energy and Power Generation

The energy sector, including oil and gas, nuclear, and renewable energy, requires materials that can withstand high temperatures, pressure, and corrosive environments. Stainless steel plates are used in the construction of pipelines, turbines, heat exchangers, and reactors.

In nuclear power plants, stainless steel is used to build containment vessels and other critical infrastructure that must remain operational under extreme conditions. In renewable energy projects, such as solar or wind power, stainless steel is employed in equipment that needs to be durable and weather-resistant.

In oil and gas refineries, stainless steel plates are essential for constructing equipment that handles corrosive materials and extreme temperatures, ensuring that operations run smoothly without frequent repairs or replacements.

Tube Trading supplies the stainless steel plates in Vadodara and Gujarat needed by power generation and energy companies to maintain efficient and safe operations.

6. Marine Industry

The marine industry is particularly challenging due to constant exposure to saltwater, which can rapidly corrode many metals. Stainless steel’s corrosion resistance makes it a preferred material for building ships, offshore platforms, and marine equipment.

In addition to corrosion resistance, stainless steel plates offer high strength, ensuring that marine structures can withstand the harsh conditions of the open sea. From ship hulls to underwater pipelines, stainless steel is a trusted material that guarantees long-lasting performance.

As a stainless steel plates supplier in Gujarat, Tube Trading caters to the unique needs of the marine industry, providing materials that perform reliably in saltwater environments.

7. Medical and Pharmaceutical Industry

In the medical and pharmaceutical industries, maintaining a sterile and clean environment is crucial. Stainless steel plates are widely used in the manufacture of surgical instruments, medical devices, and hospital equipment due to their easy-to-clean and non-reactive surfaces.

Moreover, stainless steel is essential in the construction of pharmaceutical processing equipment where contamination must be avoided. Its non-porous surface ensures that bacteria and other contaminants do not accumulate, ensuring the safety and efficacy of pharmaceutical products.

Tube Trading, a leading stainless steel plates dealer in Vadodara, supplies high-grade stainless steel to meet the strict hygiene and safety standards of the medical and pharmaceutical sectors.

Conclusion

Stainless steel plates have proven their versatility and durability across a wide array of industries. From construction and food processing to energy production and healthcare, the innovative applications of stainless steel plates continue to grow, driven by their corrosion resistance, strength, and ease of maintenance.

As a trusted stainless steel plates dealer in Gujarat and Vadodara, Tube Trading is proud to supply high-quality materials that meet the diverse needs of these industries. Our commitment to quality and customer satisfaction ensures that our clients receive the best possible products to enhance their operations, improve safety, and boost efficiency.

For businesses in need of durable and reliable stainless steel plates, Tube Trading is your go-to supplier in Gujarat. Whether you are in construction, automotive, or food processing, we provide solutions that cater to your specific requirements, ensuring long-term success and operational excellence.

#Stainless steel plates dealer in Vadodara#Stainless steel plates dealer in Gujarat#Stainless steel plates supplier in Vadodara#Stainless steel plates supplier in Gujarat

4 notes

·

View notes

Text

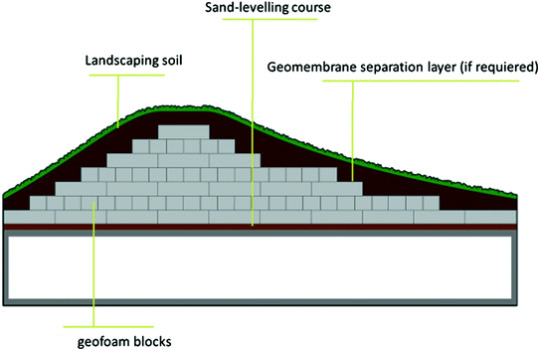

Unraveling the Growth Potential of the Geofoams Market: Global Outlook

The global geofoams market size is expected to reach USD 972.6 million by 2027, expanding at a CAGR of 2.7%, according to a new report by Grand View Research, Inc. Factors such as availability of geofoams at low cost coupled with its superior strength and durability are projected to fuel the market growth. Expansion of the construction industry across the globe coupled with the infrastructural developments in economies such as India, China, Brazil, Mexico, Saudi Arabia, and others is expected to propel the demand for geofoams over the forecast period. In addition, maintenance of the existing infrastructure in developed nations is likely to drive the growth of the market.

Geofoams Market Report Highlights

The expanded polystyrene geofoams segment accounted for USD 508.2 million in 2019 and is projected to expand at a CAGR of 3.1% from 2020 to 2027. The compatibility of the product has resulted in its increasing adoption for applications including roads and highway construction, building and infrastructure, and others

The road and highway construction application segment accounted for 38.07% of the total market and is projected to expand at a CAGR of 3.4% from 2020 to 2027 on account of the rising infrastructural growth across the developing economies including China, India, Brazil, UAE, Saudi Arabia, and others

Asia-Pacific accounted for USD 278.5 million in 2019 and is estimated to expand at a CAGR of 3.2% from 2020 to 2027 owing to the rising demand for road pavement, which is anticipated to further benefit the growth

China accounted for the highest market share in Asia Pacific on account of the rapidly expanding construction industry in the country

Europe market is estimated to expand at a CAGR of 2.8% owing to the rising number of construction and infrastructural activities in economies including Spain, Italy, and others

For More Details or Sample Copy please visit link @: Geofoams Market Report

Geofoams are increasingly used in the construction industry as it helps in suppressing the noise and vibrations. In addition, it is easy to handle and does not require any special equipment for installation. The product is increasingly used in the railway track systems, below the refrigerated storage buildings, storage tanks, and others to avoid ground freezing.

The geofoams undergo chemical changes when it comes in contact with petroleum solvents. It turns into a glue-type substance, thereby losing its strength. This factor is projected to limit the use of geofoams in the construction industry which is projected to restrict the industry growth over the forecast period.

#Geofoam#Expanded polystyrene (EPS)#Geofoam blocks#Construction materials#Road and highway construction#Retaining walls#Geotechnical engineering#Soil stabilization#Environmental protection#Earthquake resistance#Noise and vibration control#Water management#Hydrostatic pressure#Thermal insulation#Structural stability

10 notes

·

View notes

Text

SS Industrial Storage Tanks: Reliable Solutions for Every Industry

In industrial operations, storage solutions are critical for the safe and efficient handling of liquids, gases, and other materials. Stainless steel (SS) industrial storage tanks offer unmatched durability, resistance to corrosion, and versatility, making them the preferred choice across various industries. From chemical processing to food and beverage production, these tanks provide reliable storage solutions that meet stringent quality and safety standards.

What are SS Industrial Storage Tanks?

SS industrial storage tanks are containers made from high-grade stainless steel, designed to store a wide range of substances. These tanks come in various shapes and sizes, including cylindrical, rectangular, and custom designs, to accommodate specific industrial needs. Stainless steel's inherent properties—such as its resistance to corrosion, high tensile strength, and hygienic surface—make it an ideal material for industrial storage.

Key Benefits of SS Industrial Storage Tanks:

1. Durability and Longevity: Stainless steel tanks are known for their exceptional durability. They resist corrosion, rust, and chemical degradation, ensuring a long service life even in harsh industrial environments.

2. Hygiene and Cleanability: The smooth, non-porous surface of stainless steel prevents the buildup of contaminants and is easy to clean. This makes these tanks ideal for industries requiring strict hygiene standards, such as food and beverage and pharmaceuticals.

3. Temperature Resistance: Stainless steel can withstand extreme temperatures, both hot and cold, making these tanks suitable for storing a variety of substances under different conditions.

4. Versatility: Stainless steel tanks can be used to store a wide range of materials, including chemicals, water, oils, and food products. They can also be customized with fittings, valves, and insulation to meet specific requirements.

5. Recyclability: At the end of their useful life, stainless steel tanks are fully recyclable, contributing to environmental sustainability and reducing waste.

Applications of SS Industrial Storage Tanks:

1. Chemical Industry: SS tanks are widely used in the chemical industry to store corrosive substances, acids, and solvents safely due to this chemical storage tanks Their resistance to chemical reactions ensures the integrity of stored materials.

2. Food and Beverage Industry: In the food and beverage sector, stainless steel tanks are essential for storing ingredients, intermediate products, and finished goods. Their hygienic properties ensure product safety and quality.

3. Pharmaceutical Industry: Stainless steel tanks are used to store pharmaceutical ingredients and finished products, ensuring contamination-free storage and adherence to stringent industry standards.

4. Water Treatment: SS tanks are employed in water treatment plants for storing and processing potable and non-potable water, leveraging their resistance to corrosion and bacterial growth.

5. Oil and Gas Industry: In the oil and gas sector, stainless steel tanks are used for storing crude oil, refined products, and other hydrocarbons, providing safe and durable storage solutions.

Why Choose Our SS Industrial Storage Tanks?

Partnering with us for your SS industrial storage tank needs means benefiting from superior quality and service.

Here’s what sets us apart:

1. High-Quality Materials: We use premium-grade stainless steel to manufacture our tanks, ensuring maximum durability and performance.

2. Customization Options: We offer custom design and fabrication services to meet your specific storage requirements, including size, shape, and additional features.

3. Advanced Manufacturing: Our state-of-the-art manufacturing facilities and experienced team ensure precision and quality in every tank we produce.

4. Compliance and Standards: Our tanks comply with industry standards and regulations, ensuring safety and reliability in all applications.

5. Comprehensive Support: From initial consultation to installation and maintenance, we provide comprehensive support to ensure your storage solution meets your needs.

Conclusion:

MS SS Tanks are an essential component in various industrial processes, offering unmatched reliability, durability, and versatility. By choosing our stainless steel tanks, you invest in a long-lasting, high-quality storage solution that supports efficient and safe operations across industries. Contact us today to learn more about our products and how we can meet your industrial storage needs.

0 notes

Text

Stainless Steel 304 Coils Stockists In India

Title: Exploring the Versatility of Stainless Steel 304 Coils: A Comprehensive Guide

Introduction: Stainless steel is a ubiquitous material known for its durability, corrosion resistance, and versatility in various applications. Among the numerous grades available, Stainless Steel 304 stands out as a popular choice for its excellent properties. This article delves into the world of Stainless Steel 304 Coils, examining their composition, characteristics, and diverse applications.

Section 1: Composition and Properties 1.1 Chemical Composition:

Breakdown of key elements in Stainless Steel 304 Coils.

Impact of chromium and nickel on corrosion resistance.

Other alloying elements and their contributions.

1.2 Mechanical Properties:

Tensile strength, yield strength, and elongation.

High-temperature performance.

Comparison with other stainless steel grades.

Section 2: Manufacturing Process 2.1 Hot vs. Cold Rolling:

Explanation of hot rolling and cold rolling processes.

Effects on coil thickness, surface finish, and mechanical properties.

2.2 Annealing Process:

Importance of annealing in enhancing corrosion resistance.

Annealing temperature and duration.

Section 3: Applications 3.1 Automotive Industry:

Use of Stainless Steel 304 Coils in exhaust systems and automotive components.

Corrosion resistance in harsh environmental conditions.

3.2 Construction Sector:

Applications in structural elements, facades, and roofing.

Aesthetics and durability in architectural designs.

3.3 Food and Beverage Industry:

Hygienic properties of Stainless Steel 304 Coils.

Common applications in food processing and storage.

3.4 Chemical and Petrochemical:

Resistance to corrosive chemicals and harsh environments.

Use in pipelines, tanks, and chemical processing equipment.

Section 4: Advantages and Challenges 4.1 Advantages:

Excellent corrosion resistance.

High strength and durability.

Ease of fabrication and maintenance.

4.2 Challenges:

Susceptibility to chloride-induced corrosion.

Cost considerations compared to other stainless steel grades.

Section 5: Maintenance and Care

Best practices for maintaining the integrity of Stainless Steel 304 Coils.

Cleaning methods and corrosion prevention.

Conclusion: In conclusion, Stainless Steel 304 Coils offer a compelling combination of corrosion resistance, mechanical strength, and versatility. Whether in automotive, construction, or food industries, these coils continue to play a crucial role in various applications. Understanding their composition, manufacturing process, and proper maintenance is key to unlocking their full potential in diverse settings.

2 notes

·

View notes

Text

Liquid Storage Tank Manufacturers in India

Find excellence in liquid storage with leading Liquid Storage Tank Manufacturers in India. From corrosive chemicals to potable water, tanks are engineered for durability and safety. With a commitment to superior craftsmanship, ensure compliance with industry standards and deliver innovative storage solutions. Expertise to provide customizable, efficient, and cost-effective liquid storage tanks that safeguard your valuable liquids. Elevate your storage capabilities with Bhupati Engineering's advanced solutions, setting new benchmarks for reliability and performance in the liquid storage industry.

#Liquid Storage Tank Manufacturers in India#Top Liquid Storage Tank Manufacturers in India#Best Liquid Storage Tank Manufacturers in India#Liquid Storage Tank Manufacturers#Liquid Storage Tanks#Liquid Storage Tank#Storage Solution Providers#Agricultural Storage Tanks#Material Handling Equipment Manufacturers & Suppliers#Grain Storage Silo Manufacturers in india#Industrial Material Handling Equipment Manufacturers in india#Vertical Bucket Elevator Manufacturers in India#"#Conveyor Belt Manufacturers in India

2 notes

·

View notes