#Inconel Prices

Explore tagged Tumblr posts

Text

Inconel Prices, News, Trend, Graph, Chart, Forecast and Historical

Inconel, a high-performance alloy primarily composed of nickel and chromium, is a critical material in industries such as aerospace, automotive, marine, and energy. Its exceptional resistance to corrosion, oxidation, and extreme temperatures makes it indispensable for applications where reliability under harsh conditions is paramount. The market for Inconel is influenced by various factors, including demand from end-use industries, raw material availability, production costs, and global economic trends. Over recent years, fluctuations in Inconel prices have been shaped by these dynamics, as well as by geopolitical factors and technological advancements.

One of the primary drivers of Inconel prices is the cost of its raw materials, particularly nickel. Nickel is a key component of Inconel alloys, and its price volatility on the global market has a direct impact on the pricing of Inconel products. Nickel prices can fluctuate due to factors such as supply disruptions, changes in mining output, and shifts in demand from other industries like stainless steel production. Furthermore, geopolitical tensions in major nickel-producing regions can exacerbate supply chain challenges, influencing Inconel prices. Similarly, the price of chromium, another critical element in Inconel alloys, plays a role in determining the overall cost structure of these materials.

Get Real time Prices for Inconel: https://www.chemanalyst.com/Pricing-data/inconel-1365

The demand for Inconel is closely tied to the health of the industries that rely on its unique properties. For example, the aerospace industry, a major consumer of Inconel, heavily influences market dynamics. The ongoing push for fuel efficiency and lightweight materials in aviation has increased the demand for high-temperature-resistant alloys like Inconel. Any slowdown in aerospace manufacturing or global travel can dampen demand, exerting downward pressure on prices. Conversely, periods of strong growth in aerospace activity tend to drive prices higher as manufacturers ramp up their procurement of Inconel components.

The energy sector is another significant driver of Inconel demand, particularly in applications involving extreme environments such as gas turbines and oil and gas extraction. The global transition towards cleaner energy sources and the development of advanced energy systems have also spurred the need for materials like Inconel, which can withstand demanding operational conditions. Additionally, innovations in nuclear energy and hydrogen production are expected to further enhance the demand for Inconel alloys, potentially impacting prices over the long term.

Technological advancements in manufacturing processes and recycling capabilities are also influencing Inconel prices. Improved production techniques can lead to cost efficiencies, making Inconel more accessible to a broader range of applications. At the same time, the recycling of nickel-based alloys has emerged as a viable option to reduce dependency on primary raw materials. This recycling trend has the potential to stabilize Inconel prices by alleviating some of the pressure on raw material supply chains.

The regional distribution of production and consumption further adds complexity to the Inconel market. Major producers of Inconel alloys are concentrated in regions with advanced metallurgical capabilities, such as North America, Europe, and parts of Asia. However, the demand is global, driven by industries operating in both developed and developing economies. Emerging markets in Asia-Pacific, particularly China and India, are witnessing increased industrial activity, which is expected to bolster the demand for Inconel. This regional demand-supply interplay can create disparities in pricing across different markets.

The environmental impact of Inconel production is gaining attention, as sustainability becomes a growing concern across industries. The energy-intensive processes involved in producing nickel and chromium raise questions about the carbon footprint of Inconel alloys. As industries strive to meet stricter environmental regulations and adopt greener practices, the cost of compliance may influence Inconel pricing. Additionally, the development of alternative alloys and materials with comparable properties may introduce competition, potentially affecting market dynamics.

Market speculation and investor sentiment also play a role in influencing Inconel prices. The commodity nature of its key components, especially nickel, makes the Inconel market susceptible to price swings driven by speculative trading. This speculative activity can sometimes amplify the effects of underlying supply and demand factors, creating volatility in pricing.

In conclusion, the Inconel market is shaped by a complex interplay of raw material costs, industrial demand, technological innovations, and global economic trends. As industries continue to evolve and new applications for high-performance alloys emerge, the demand for Inconel is expected to remain robust. However, challenges such as raw material price volatility, geopolitical uncertainties, and environmental concerns will continue to influence pricing. Stakeholders in the Inconel market must navigate these factors strategically to ensure stability and capitalize on emerging opportunities. Maintaining a balance between supply chain resilience, sustainable practices, and technological advancements will be key to fostering growth in this vital market.

Get Real time Prices for Inconel: https://www.chemanalyst.com/Pricing-data/inconel-1365

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Inconel#Inconel Price#Inconel Prices#Inconel Pricing#Inconel News#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research#Canada#Japan#China

1 note

·

View note

Text

Inconel Material: Properties, Composition, and Grades

When thinking of materials for high performance in demanding applications, the name Inconel material automatically comes to mind. As the Inconel material is very expensive, the use is of a limited nature. Because of this Inconel material is generally less familiar as compared to Steel or Aluminum. In this article, we will explore some basics of this Inconel Material.

What is Inconel Material?

Inconel is a nickel-chromium-based super alloy that's known for its high strength, corrosion resistance, and ability to withstand extreme temperatures, pressure, or mechanical loads. Inconel Material alloys are oxidation- and corrosion-resistant. When heated, Inconel material forms a thick, stable, passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range and is attractive for high-temperature applications where aluminum and steel would come to creep as a result of thermally induced crystal vacancies. Inconel Material's high-temperature strength is developed by solid solution strengthening or precipitation hardening, depending on the alloy

Inconel Material Properties

Inconel is a nickel-chromium-based super alloy that's known for its high strength, corrosion resistance, and ability to withstand extreme temperatures, pressure, or mechanical loads. Inconel Material alloys are oxidation- and corrosion-resistant. When heated, Inconel material forms a thick, stable, passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range and is attractive for high-temperature applications where aluminum and steel would come to creep as a result of thermally induced crystal vacancies. Inconel Material's high-temperature strength is developed by solid solution strengthening or precipitation hardening, depending on the alloy

In addition to high-temperature performance, Inconel material has excellent strength properties at room temperature. The high amounts of chromium also give it superb corrosion resistance at room temperatures as well. The other alloys mentioned above in the composition section provide additional properties such as toughness and hardness. Several Inconel alloys, such as Inconel 718, are precipitated and hardened to increase strength even further.

Want to know more about Inconel material prices? Contact us today, and we'll provide you with competitive pricing and expert guidance. Inconel Material Grades

Inconel material has a variety of grades varying in composition and properties developed for specific applications. The common Inconel grades are as follows:

1. Inconel 600: Inconel material is the original alloy. It is heat- and corrosion-resistant, noted for elevated temperature corrosion/oxidation resistance, good hot and cold processing characteristics, good low-temperature strength, and both hot/cold fatigue properties. Inconel material has high strength under 650 °C, and it’s suitable for chemical-plant components.

2. Inconel 601: Inconel material has excellent oxidation resistance at elevated temperatures and high resistance to carburization. It is good for high-temperature organic-chemical plants. It resists oxidation from sulfur atmospheres and has good mechanical properties at room temperature and high temperature. It also has great stress corrosion crack resistance because of the low carbon content and fine grain structure. It has particularly good creep strength at elevated temperatures (above 500 °C, at which other alloys can fail). 601GC is the alloy's grain-controlled version, offering some properties enhancement over 601.

3. Inconel 625: Inconel material offers better corrosion resistance than 600 and 601. It has better performance in retaining strength and resisting creep from low temperatures up to a maximum service temperature of 980 °C

4. Inconel 718: Inconel material is suited to precipitation hardening. It offers good strength and toughness up to 650 °C and good general corrosion/oxidation resistance at all service temperatures. It is formulated for solution treatment or precipitation hardening.

5. Inconel X-750: Inconel material offers elevated corrosion resistance and oxidation resistance, as well as good strength below 980 °C. In addition, Inconel X-750 has good low-temperature performance and molding performance. It is mainly used for aerospace and industrial gas turbine components.

6. Inconel 690: Inconel material offers greater resistance to chloride corrosion (e.g., salt water), high temperature/pressure water stress corrosion, strong oxidation environments, and fluorinated atmosphere attack. It is mainly applied in nitric acid environments, steam generators, and nuclear waste treatment plants.

Read More - Density of Inconel

2 notes

·

View notes

Text

Inconel 600 Alloy Scrap Supplier and dealer in India- Vardhman

Get high-quality Inconel 600 alloy scrap from trusted suppliers. Find competitive prices for Inconel scrap with assured quality and reliable service. Contact us today!

0 notes

Text

qrc coupling | camlock coupling manufacturer in india

Duplex and Super Duplex steels belong the family of stainless steels where the metallurgical structure consists of 2 Phase Viz Austenite and Ferrite, roughly in equal amounts.

They are designed to provide better corrosion resistance, particularly chloride stress corrosion and chloride pitting corrosion, and higher strength than standard stainless steel.

drnikhilpuri.com

#camlock coupling supplier in india#Camlock coupling supplier in india price#Super Duplex Camlock Manufacturer#Inconel Camlock Coupling manufacturer#Hastelloy Camlock Coupling Manufacturer

0 notes

Text

Reuse Nickel Materials with Our Experts

We utilize industry-leading retrieving and recycling methodologies to process a piece of recycling Nickel into new parts and equipment. Our team can help to protect the environment and safely reuse your particle.

#metal recycling#metal buyers#steel recycling#scrap steel prices#aluminum recycling#inconel recycling

0 notes

Text

In the US market, the Inconel Prices showcased a stagnancy in the price trend in the final quarter of 2022 owing to the fluctuating upstream Nickel prices and limited demand outlook. According to several market participants, nickel trading activity recovery depended on the market opening up to arbitrage trading. In November, the LME decided to keep things as they were. The supply of raw materials for moly ingot was insufficient; demand in China was extremely high, particularly in December. While there were some stocks of molybdenum oxide and Ferro molybdenum in Europe, due to these being more liquid markets with more trade, inventories of moly ingot in European warehouses remain critically low. There was a supply shortage in 2022, with downstream consumers reporting that there was less material available from China. Because there was no available material on the ground, some people flew material from China.

0 notes

Note

How significant is powder metallurgy for the use of bastardly-to-machine stuff like inconel these days? it's just i was checking out some quotes for DMLS printing recently and there wasn't *that* much of a price delta between alu and stuff like maraging steel and superalloys

I can’t speak to other industries, but in rocket engineering and fusion engineering it’s huge. Everybody loves to 3D print inconel, as well as funky copper alloys (shoutout to GRCop-84) and steel. It has terrific mechanical properties and you can make almost any arbitrary shape. The hot new thing to do is to 3D print as much of your rocket as possible.

HOWEVER, in nuclear fusion, inconel in general is kind of going out of fashion. For those of you in the room who aren't familiar, inconel refers to a class of "superalloys," structural metals that can retain their strength while very close to their melting point. One would think this would be a super useful property in a fusion reactor, and one would be absolutely correct. JET in the UK went hog-wild with inconel, as did TFTR at Princeton.

But, depending on the alloy, inconel is anywhere from 50% to 70% nickel. Nickel is particularly problematic in areas of high neutron flux (like, say, in a fusion reactor), where it captures neutrons and "activates." Almost every element does this to one extent or another, but it's real bad when it happens to nickel.

I'm not a neutronics person, but from what they tell me, the various transmutation reactions give you both radioactive byproducts with annoyingly long half-lives, and pockets of helium that lead to severe embrittlement. A nickel-rich alloy is just not going to have a good time in a fusion power plant, long term.

96 notes

·

View notes

Text

Is Monel similar to Inconel?

Many of our customers have such a question: Is Monel similar to Inconel? As a matter of fact, both Monel and Inconel are nickel-based alloys with exceptional corrosion resistance and high-temperature performance, but they differ significantly in composition, properties, and applications. In this article, let’s delve into the key aspects of these two alloys to understand their similarities and differences.

Is Monel similar to Inconel?

Composition:

Monel, also known as Monel alloy, is primarily a nickel-copper alloy, typically containing up to 67% nickel and 28% copper, with the remaining portion composed of iron, manganese, carbon, and silicon. This composition gives Monel its excellent corrosion resistance, particularly against acids and alkalies.

On the other hand, Inconel is a nickel-chromium alloy, with chromium content ranging from 15% to 25%, depending on the specific grade. Inconel alloys also contain significant amounts of other elements like iron, molybdenum, and titanium, which contribute to their high-temperature strength and oxidation resistance.

Properties:

Both Monel and Inconel exhibit excellent corrosion resistance, but the specific environments they thrive in differ. Monel’s corrosion resistance is particularly noteworthy in marine and chemical processing applications, where it can withstand the corrosive effects of saltwater and various acids.

Inconel, on the other hand, is renowned for its ability to maintain its mechanical properties at extremely high temperatures. It is often used in aerospace and power generation applications where materials must withstand extreme heat and pressure. Inconel’s chromium content also gives it superior resistance to oxidation and sulfidation at high temperatures.

When it comes to mechanical properties, Inconel generally offers higher strength and hardness compared to Monel. However, Monel has better formability and weldability, making it easier to shape and join into complex structures.

Applications:

The differences in composition and properties lead to distinct applications for Monel and Inconel. Monel is commonly used in the chemical processing, marine, and food processing industries due to its resistance to corrosion and ease of fabrication. Its ability to withstand the corrosive effects of saltwater makes it a popular choice for marine applications like shipbuilding and offshore drilling.

Inconel, on the other hand, finds its niche in high-temperature applications where strength and oxidation resistance are paramount. Aerospace, power generation, and petrochemical industries rely on Inconel alloys for components that must operate in extreme environments.

Conclusion:

While Monel and Inconel are both nickel-based alloys with exceptional corrosion resistance, they are not interchangeable. Each alloy has its unique composition, properties, and applications. Monel excels in corrosive environments and offers good formability and weldability, while Inconel is renowned for its high-temperature performance and oxidation resistance.

Thank you for reading our article and we hope it can help you to find the answer to the question: Is Monel similar to Inconel? If you are looking for Monel and Inconel suppliers and manufacturers online now, we would advise you to visit Huaxiao Alloy.

As a leading supplier of Monel and Inconel Alloys from Shanghai China, Huaxiao Alloy offers customers high-quality products such as Monel 400, Monel K500, Inconel 600, Inconel 601, Inconel 625, and Inconel 718 at a very competitive price.

2 notes

·

View notes

Text

Haynes 188 Sheet Suppliers in India

Haynes 188 Sheet in Mumbai, Haynes 188 Sheet Importers in Mumbai, Haynes 188 Sheet Suppliers in Mumbai, Haynes 188 Sheet Exporters in Mumbai, Haynes 188 Sheet Stockists in Mumbai.

HAYNES 188 Sheets is a cobalt-nickel-chromium-tungsten alloy that may be readily fabricated for aerospace and commercial gas turbine engine applications, including combustion cans, flame holders, liners, transition ducts, and afterburner parts. HAYNES 188 Coils is generally found in hot sections of engines in burner cans, ducting and afterburner components. In recent years, Udimet 188 Coils has been eclipsed by Alloy 230 for many applications due to improved properties. Udimet 188 Plates has good forming characteristics and is capable of being forged, hot worked or cold worked, although it does work-harden very rapidly so frequent intermediate annealing treatments are recommend for complex forming operations. Buy Alloy 188 Plates at reasonable price from us.

What are Haynes 188 Plates?

Haynes 188 Plate is a cobalt-based alloy that is composed of nickel, chromium, tungsten, and molybdenum, along with other elements. It is known for its excellent high-temperature strength, resistance to corrosion and oxidation, and good weldability.

What are the properties of Haynes 188 plates?

Haynes 188 plates have excellent high-temperature strength, good oxidation resistance, and good resistance to corrosion and erosion. They also have good weldability and formability, making them suitable for a wide range of industrial applications.

What are the applications of Haynes 188 plates?

Haynes 188 plates are commonly used in high-temperature applications, such as gas turbine components, exhaust systems, and heat exchangers. They are also used in chemical processing, power generation, and aerospace applications.Specifications:AMS 5608 / AMS 5609Standard:AMS, AMS and APISpecialize:Shim Sheet, Perforated Sheet, B. Q. Profile.Size:0.5 MM TO 200 MM THICK IN 1000 MM TO 2500 MM WIDTH & 2500 MM TO 12500 MM LENGTHForm:Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange)Finish:Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)Hardness:Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc.Grade:Haynes 188 (UNS R30188)

Haynes 188 Plates Equivalent Grades

STANDARDWERKSTOFF NR.UNSHaynes 188–R30188

188 Haynes Plates Chemical Composition :

GradeCMnpSSiCrNiCoBFeLaWHaynes 18805-151.25 max020 max.015 max20-.5021.0 -23.020.0 -24.0Bal.015 max3.0 max03-1513.0 -15.0

Special Products

Haynes 188 Sheet

Alloy 188 Sheet

Conicro 4023 Sheet

2.4683 Sheet

Uns R30188 Sheet

Cobalt Alloy Haynes 188 Sheet

AMS 5772 Sheet

Cobalt Nickel 188 Sheet

Stellite 188 Sheet

Haynes 25 Sheet

L605 Sheet

Udimet L605 Sheet

Stellite 25 Sheet

UNS R30605 Sheet

2.4964 Sheet

AMS 5537 Sheet

Ams 5759 Sheet

HS25 Sheet

Cocr20w15ni Sheet

Cobalt Alloy Haynes 25 Sheet

Cobalt L605 Sheet

Inconel X750 Sheet

X750 Sheet

Haynes X750 Sheet

Nicrofer 7016 Sheet

Udimet X750 Sheet

Pyromet X750 Sheet

Superimphy 750 Sheet

2.4669 Sheet

UNS N07750 Sheet

Nickel Alloy X750 Sheet

NiCr15Fe7TiAl Sheet

Nickelvac X750 Sheet

AMS 5699 Sheet

Alloy X750 Sheet

Nimonic C263 Sheet

Nickel Alloy C263 Sheet

UNS N07263 Sheet

Haynes 263 Sheet

2.4650 Sheet

NiCo20Cr20MoTi Sheet

AMS 5872 Sheet

Hastelloy C263 Sheet

Nicrofer 5120 Coti Sheet

Nicrofer 5120 Coti Round Bar

Inconel 945 Round

Inconel 945 Bar

UNS N09945 Round

Inconel 945X Round

2 notes

·

View notes

Text

Inconel Price | Prices | Pricing | News | Database | Chart

Inconel, a family of nickel-chromium-based superalloys, has garnered significant attention in industries such as aerospace, automotive, oil and gas, and energy production, due to its extraordinary resistance to oxidation, corrosion, and heat. The price of Inconel, like many other specialized materials, is influenced by a variety of factors including raw material costs, market demand, geopolitical events, and production challenges. These alloys are composed predominantly of nickel and chromium, both of which are subject to volatile price fluctuations on global commodity markets. The cost of raw materials such as nickel is a significant component of Inconel's pricing structure, and even minor shifts in these raw material markets can have an outsized impact on the final price of the alloy.

Nickel, one of the key components of Inconel, is especially sensitive to supply disruptions. Any instability in major nickel-producing regions, such as Indonesia and the Philippines, can lead to a sudden spike in prices. Environmental regulations and government policies in these countries also influence the nickel market. The global demand for nickel has been on the rise due to its increased use in electric vehicle (EV) batteries, a factor that puts additional upward pressure on Inconel prices. As the EV industry continues to expand, the competition for nickel between the aerospace and automotive sectors could intensify, further contributing to pricing volatility.

Get Real Time Prices for Inconel: https://www.chemanalyst.com/Pricing-data/inconel-1365

The availability of chromium, another essential element in Inconel, can also impact the price of the alloy. Chromium is used for its anti-corrosive properties, and like nickel, it faces challenges related to supply chain disruptions. Chromium prices can fluctuate based on mining production levels and environmental policies in key producing countries such as South Africa and Kazakhstan. Changes in chromium pricing, while not as dramatic as those of nickel, still play a role in the overall cost of producing Inconel.

Another factor influencing Inconel prices is the complexity of the alloy's production process. Inconel alloys must meet exacting standards to ensure their performance in high-temperature and high-stress environments. These stringent production requirements necessitate advanced manufacturing technologies, highly skilled labor, and stringent quality control measures, all of which contribute to higher production costs. The use of specialized equipment and the precision required in the forging and machining of Inconel parts can drive up production expenses, which are then reflected in the price of the material.

The aerospace industry is one of the largest consumers of Inconel, and its demand for the alloy plays a crucial role in determining pricing trends. The need for high-performance materials that can withstand extreme temperatures and stresses in jet engines and gas turbines keeps demand for Inconel high. When aerospace production slows, as seen during economic downturns or industry-specific events like the COVID-19 pandemic, the demand for Inconel tends to decrease, which can lead to a temporary reduction in prices. However, as global travel and transportation recover, the aerospace industry is expected to drive a renewed demand for Inconel, potentially leading to price increases.

The oil and gas sector also has a significant impact on Inconel prices. Inconel's ability to resist corrosion in harsh environments makes it a popular choice for equipment used in offshore drilling and in the refining of petrochemical products. Fluctuations in the price of oil can influence the demand for Inconel, as companies in the oil and gas sector adjust their capital expenditures in response to changes in oil prices. When oil prices are high, investments in exploration and drilling increase, thereby boosting the demand for Inconel. Conversely, when oil prices fall, the demand for these materials may decline, leading to potential softening in Inconel prices.

Geopolitical events and trade policies also contribute to the overall pricing landscape for Inconel. Tariffs, trade restrictions, and political instability can disrupt the supply chain, causing delays in the production and delivery of raw materials, which, in turn, may increase the costs for manufacturers. For example, trade tensions between major economies such as the United States and China have, in the past, led to higher tariffs on raw materials, contributing to rising Inconel prices. Any changes in global trade dynamics can have a cascading effect on the cost structure of superalloys like Inconel.

Another important consideration is the growing emphasis on sustainability and the environmental impact of metal production. As industries and governments push for greener production processes, the cost of adhering to environmental standards can drive up the price of Inconel. Mining, refining, and manufacturing processes must meet increasingly stringent regulations related to carbon emissions, energy consumption, and waste disposal. These environmental compliance costs are often passed on to consumers in the form of higher material prices.

Additionally, the global supply chain's interconnected nature means that disruptions in one part of the world can ripple across markets, affecting Inconel prices globally. For example, natural disasters, labor strikes, or transportation bottlenecks in key manufacturing hubs can delay the delivery of raw materials or finished products, contributing to higher costs and supply shortages. In recent years, the COVID-19 pandemic exposed vulnerabilities in global supply chains, causing widespread delays and material shortages, including those affecting the production of superalloys like Inconel.

In summary, the price of Inconel is the result of a complex interplay of factors, ranging from raw material costs to market demand, geopolitical events, production challenges, and environmental regulations. As the demand for high-performance materials in industries like aerospace, oil and gas, and energy continues to rise, the pricing of Inconel is expected to remain volatile. Supply chain disruptions, coupled with increasing demand for nickel and chromium in other sectors, further contribute to the uncertainty surrounding Inconel prices. With its critical role in high-performance applications, the price of Inconel will likely continue to be a reflection of broader trends in the global economy, industrial growth, and technological advancements.

Get Real Time Prices for Inconel: https://www.chemanalyst.com/Pricing-data/inconel-1365

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Inconel#Inconel Price#Inconel Prices#Inconel Pricing#Inconel News#Inconel Price Monitor#Inconel Database#Inconel Price Chart

0 notes

Text

🔥 Elevate Your Projects with Inconel 625 Sheets & Plates! 🔥

✨ Unleash the Power of Inconel 625: Exceptional Corrosion Resistance & High Strength! ✨

Looking for top-notch Inconel 625 Sheets & Plates? Look no further! We are your premier stockiest, providing quality materials for your most demanding applications. 🚀

⚙️ Key Features: 🔷 Superior Corrosion Resistance 🔷 High-Temperature Strength 🔷 Excellent Weldability & Formability 🔷 Versatility for Various Applications

🌐 Explore Our Inventory: ✅ Wide Range of Sizes ✅ Competitive Prices ✅ Premium Quality Guaranteed

🛠️ Perfect for: 👉 Aerospace Engineering 👉 Chemical Processing 👉 Marine Applications 👉 Oil & Gas Industry 👉 High-Performance Manufacturing

💡 Why Choose Us? 🌟 Trusted Supplier 🌟 Fast Delivery 🌟 Unparalleled Customer Service

📞 Contact us today to discuss your requirements and place your order! 📩

#Inconel625 #SheetsAndPlates #HighQualityMaterials #Engineering #Manufacturing #MetalSupplier #InnovationInMetals #ReliablePartner #IndustrialMaterials

2 notes

·

View notes

Text

Premium Inconel Scrap Importer in Saudi Arabia | Vardhman Ferro Alloys

Looking for a reliable and reputable Inconel scrap importer in Saudi Arabia? Look no further than Vardhman Ferro Alloys. We offer top-quality scrap at competitive prices, backed by years of experience and unwavering customer satisfaction. Partner with us and discover the benefits of our premium services and products.

0 notes

Text

#Camlock coupling supplier in india price#Super Duplex Camlock Manufacturer#Inconel Camlock Coupling manufacturer#Hastelloy Camlock Coupling Manufacturer

0 notes

Text

Make Carbide Scrap Recycling Easy

Carbide scrap that is not recycled properly may end up in a landfill. Instead of discarding this scrap and hoping someone else finds it, why not call us and we will take it off your hands and used to make new parts and equipment.

0 notes

Photo

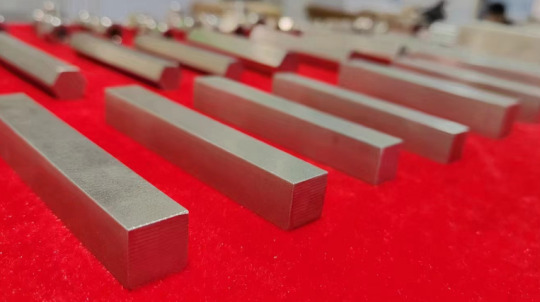

"Steel Manufacturer & Distributor - Inconel Alloys."

Inconel is a registered trademark of Special Metals Corporation for a family of austenitic nickel-chromium-based superalloys. Inconel alloys are oxidation-corrosion-resistant materials well suited for service in extreme environments subjected to pressure and heat. When heated, Inconel forms a thick, stable, passivating oxide layer protecting the surface from further attack. Inconel retains strength over a wide temperature range, attractive for high temperature applications where aluminum and steel would succumb to creep as a result of thermally induced crystal vacancies. Inconel’s high temperature strength is developed by solid solution strengthening or precipitation hardening, depending on the alloy.

#inconel 800 chemical composition#inconel 600 round bar#inconel 600 flanges#inconel 825 chemical composition#inconel 625 composition#inconel 625 round bar#inconel 825#inconel 825 price per kg#inconel 600#inconel 600 chemical composition

0 notes

Text

Leading Exporter of Inconel 625 Round Bars in Saudi Arabia - Metalforgeindia

MetalForgeIndia is a trusted name as the leading exporter of Inconel 625 round bars in Saudi Arabia. Known for their exceptional resistance to corrosion, oxidation, and high temperatures, these round bars are a preferred choice for industries such as aerospace, marine, and chemical processing.Our commitment to quality ensures that each product meets strict specifications, offering strength, durability, and reliability. we prioritize customer satisfaction through timely delivery, competitive pricing, and unmatched product quality. Choose the best product at metalforgeindia for your perfect need.

0 notes