#High speed Packaging Film

Explore tagged Tumblr posts

Text

ZDF01L High speed Packaging Film is a polyolefin heat shrinkable film produced by the double bubble process. It has the advantages of good transparency, good shrinkage, good toughness, good heat sealing, and good cold resistance.

Compared to other polyolefin shrink films, this film is especially suitable for high-speed pillow packaging, with good heat sealing and electrostatic sealing performance. The packaging effect is close to the body, and the maximum packaging speed exceeds 250 packages/minute. This film is mostly used in the form of a singlewound type, but there is no strict distinction between them, and it is determined according to the actual use.

Thickness: 10um, 11um, 15um, 19um, 25um.

https://en.zjzhongda.com/product/pof-shrink-film/zdf01l-high-speed-packaging-polyolefin-shrink-film-59.html

0 notes

Text

Athletes Go for the Gold with NASA Spinoffs

NASA technology tends to find its way into the sporting world more often than you’d expect. Fitness is important to the space program because astronauts must undergo the extreme g-forces of getting into space and endure the long-term effects of weightlessness on the human body. The agency’s engineering expertise also means that items like shoes and swimsuits can be improved with NASA know-how.

As the 2024 Olympics are in full swing in Paris, here are some of the many NASA-derived technologies that have helped competitive athletes train for the games and made sure they’re properly equipped to win.

The LZR Racer reduces skin friction drag by covering more skin than traditional swimsuits. Multiple pieces of the water-resistant and extremely lightweight LZR Pulse fabric connect at ultrasonically welded seams and incorporate extremely low-profile zippers to keep viscous drag to a minimum.

Swimsuits That Don’t Drag

When the swimsuit manufacturer Speedo wanted its LZR Racer suit to have as little drag as possible, the company turned to the experts at Langley Research Center to test its materials and design. The end result was that the new suit reduced drag by 24 percent compared to the prior generation of Speedo racing suit and broke 13 world records in 2008. While the original LZR Racer is no longer used in competition due to the advantage it gave wearers, its legacy lives on in derivatives still produced to this day.

Trilion Quality Systems worked with NASA’s Glenn Research Center to adapt existing stereo photogrammetry software to work with high-speed cameras. Now the company sells the package widely, and it is used to analyze stress and strain in everything from knee implants to running shoes and more.

High-Speed Cameras for High-Speed Shoes

After space shuttle Columbia, investigators needed to see how materials reacted during recreation tests with high-speed cameras, which involved working with industry to create a system that could analyze footage filmed at 30,000 frames per second. Engineers at Adidas used this system to analyze the behavior of Olympic marathoners' feet as they hit the ground and adjusted the design of the company’s high-performance footwear based on these observations.

Martial artist Barry French holds an Impax Body Shield while former European middle-weight kickboxing champion Daryl Tyler delivers an explosive jump side kick; the force of the impact is registered precisely and shown on the display panel of the electronic box French is wearing on his belt.

One-Thousandth-of-an-Inch Punch

In the 1980s, Olympic martial artists needed a way to measure the impact of their strikes to improve training for competition. Impulse Technology reached out to Glenn Research Center to create the Impax sensor, an ultra-thin film sensor which creates a small amount of voltage when struck. The more force applied, the more voltage it generates, enabling a computerized display to show how powerful a punch or kick was.

Astronaut Sunita Williams poses while using the Interim Resistive Exercise Device on the ISS. The cylinders at the base of each side house the SpiraFlex FlexPacks that inventor Paul Francis honed under NASA contracts. They would go on to power the Bowflex Revolution and other commercial exercise equipment.

Weight Training Without the Weight

Astronauts spending long periods of time in space needed a way to maintain muscle mass without the effect of gravity, but lifting free weights doesn’t work when you’re practically weightless. An exercise machine that uses elastic resistance to provide the same benefits as weightlifting went to the space station in the year 2000. That resistance technology was commercialized into the Bowflex Revolution home exercise equipment shortly afterwards.

Want to learn more about technologies made for space and used on Earth? Check out NASA Spinoff to find products and services that wouldn’t exist without space exploration.

Make sure to follow us on Tumblr for your regular dose of space!

2K notes

·

View notes

Text

Toy Story 2 | Still a perfect execution of a fantasy story

One of the things people uesd to complain about is that the cars in "Cars" did not need to be cars. As in, the fantastical element was not necessary to tell the story (which I wholeheartedly disagree with but that's not the point of this post). You could have told Finding Nemo with the fish as humans and have Nemo caught by... a traveling circus, or something, but to many, Cars was the damning example.

While Toy Story was the antithesis of Cars in every way.

Have not and will not see the fourth one but the first two films are perfect fantasy, and you don't immediately think of them as "fantasy".

I just rewatched TS 2 so it's fresh in my mind, and this story could not exist if these characters were not toys. Everything from the little details like the Etch-a-Sketch speed-drawing the map from the commercial to the "high stakes" rescue and escape that's only "high stakes" beacuse they're toys and not people and that one intersection is a death trap.

But the big thing is the main plot of the story: Woody is in the role of a has-been who wants to reclaim his glory days (like Mr. Incredible) but unlike a human, Woody himself was not part of those glory days, he's just one of many toys sold with the Woody's Roundup TV show, theoretically endlessly replacable, as all toys are. Unless you gave your hero amnesia, in no other storyline would this work with a human character, because Woody is both an outsider and the hero making his homecoming.

At the center of this trilogy is what it means to be a toy: A child's plaything. How each character relates to that fact is central to their arcs. The first movie tackled the divide between Woody's "I exist to be Andy's favorite toy" and Buzz's "I ain't no toy, I'm a Real Boy".

The second movie takes it one step further: Is a "toy" something you play with and inevitably ruin through playtime and the messy love of a child, or is a "toy" something you keep perfectly preserved in its packaging? And the consequences of being a toy when your human outgrows you, in Jessie's story, and is a valid point by Stinky Pete.

TS 3 takes the "what happens when the kid grows up" to its natural conclusion, with Andy going off to college. While I think it got a little carried away in spectacle and the incinerator scene, the endless replacability of a toy is Lotso's whole schtick.

The nature of what a toy is is the whole point—a piece of wood or metal or plastic that is effectively immortal, but an immortal being forever in a place of willful servitude to children.

—

It seems rather obvious to give fantastical characters a fantastical story, but a lot of uninspired or forgettable fantasy takes a human plotline and just reskins it with fairies or animals and never takes full advantage of what the characters are.

When your fantastical elements and setting are just window dressing, like Avatar '09, a fancy backdrop for a bland story, why bother writing a fantasy story? Why waste all that worldbuilding and all that creativity? (I actually know the answer, Cameron got cold feet when his creative teams went all out to create something indeed alien, and kept nudging it back to something more friendly and recognizable until we got what we got).

Avatar '09 sure made a lot of money... and zero impact on our cultural memory. It's no one's favorite movie, no one's favorite retelling of Dances with Wolves. It's just pretty to look at.

You can write a retelling, a "modern take", a book of tropes and clichés, sure, but I'd encourage you to at least make one arc of your fantasy or sci-fi story only possible in your world, with your lore, with your characters. Otherwise, what's the point?

#writing#writeblr#writing a book#writing advice#writing resources#writing tools#writing tips#character development#character design#fantasy#toy story

17 notes

·

View notes

Text

🇺🇲 Let's delve into the captivating history and remarkable characteristics of the 1956 Plymouth Fury—an iconic automobile that made its mark during the golden age of American cars.

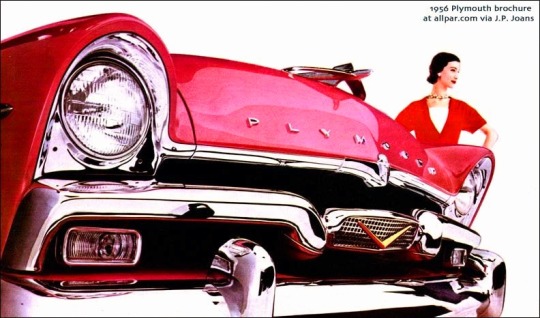

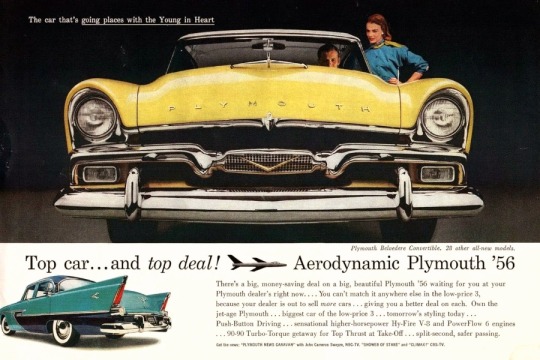

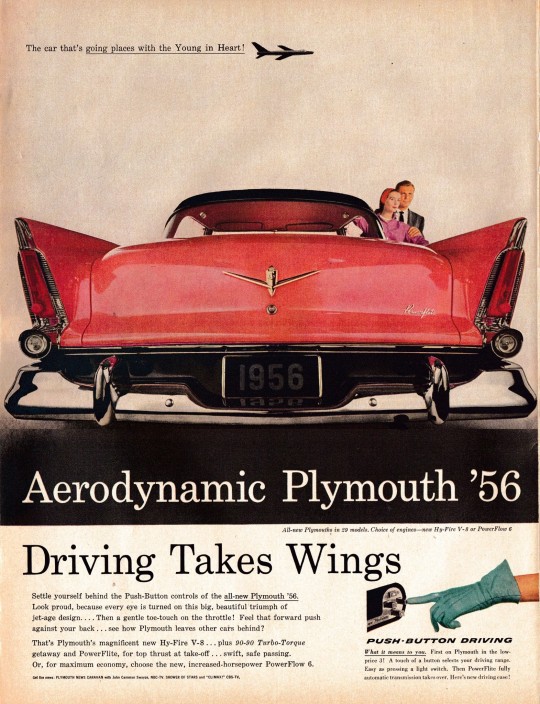

🚗 Introduced in 1956 as a top-of-the-line modelas (a sub-series of the Plymouth Belvedere), the Plymouth Fury embodied Chrysler's vision of luxury and performance within the "Forward Look" design era. It quickly gained acclaim for its distinctive appearance and powerful performance.

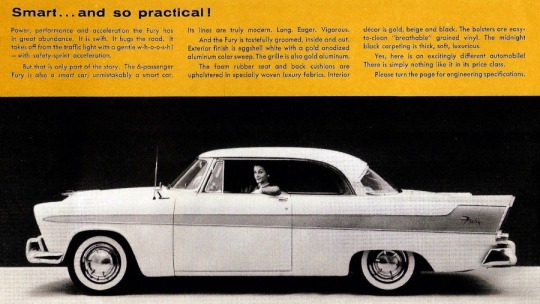

🌟 The 1956 Plymouth Fury boasted a sleek and aerodynamic profile, characterized by prominent tailfins, chrome accents, and dual headlights, setting it apart from its contemporaries.

⚙️ Under the hood, the Fury was equipped with Chrysler's FirePower V8 engine, delivering impressive horsepower and torque, making it a favorite among speed enthusiasts.

👑 Inside, the Plymouth Fury offered a plush and comfortable cabin adorned with premium materials and modern amenities, reflecting its upscale status.

🚀 The 1956 Fury introduced advanced features for its time, including power steering, power brakes, and push-button automatic transmission controls, enhancing the driving experience with added comfort and convenience.

🎬 The Plymouth Fury gained widespread fame as the primary vehicle in Stephen King's novel "Christine," later adapted into a popular horror film, showcasing the Fury's timeless allure and sinister reputation.

🏁 A formidable contender in NASCAR racing, the Fury demonstrated its performance capabilities on the track, solidifying its reputation as a high-performance vehicle.

👑 Despite its popularity, the 1956 Plymouth Fury was produced in limited numbers, becoming a rare and sought-after collector's item today. It represents an era of automotive innovation and artistic design, influencing subsequent generations of car enthusiasts and designers.

🦅 The Plymouth Fury 1956 embodies the spirit of American automotive excellence, blending style, power, and sophistication into an iconic package. Its enduring legacy continues to inspire admiration and nostalgia among car aficionados worldwide.

#brits and yanks on wheels#retro cars#transatlantic torque#vehicle#cars#old cars#brands#companies#automobile#american cars#chrysler#walter chrysler#plymouth#plymouth belvedere#plymouth fury#1950s cars#nascar#racing#race car#race#christine#novel#movie#american auto#automotive#stephen king#power steering#v8 engine#muscle car#luxury cars

17 notes

·

View notes

Text

03 ∙ the dark whimsicality of drifting: a visual analysis

[ ✼ part 3 of the self is not me, but us series ]

i was sooooo taken by drifting when i first heard it.

what a lovely and uplifting melody! what a whimsical and gorgeous and quaint little music video! 🥰 and in the teaser, hope fell asleep and woke up on this island so maybe this xz is a personification of hope and its place in his career!!!!!! 🥰🥰🥰

then the occupational hazard kicked in, and the thinking cap came on, and i had the time of my life proving myself wrong.

unlike the us mv, where the thrill was in trying to piece together the overarching story based on the visual cues we had, drifting was almost the opposite. the story was plain to see; as everyone has rightly pointed out, it's pretty apparent that the mv depicts — or at least has a striking, uncanny resemblance to — xz's journey from normalcy to celebrity.

what i enjoyed with this mv in particular was zhanzhan in wonderland’s outfits the search for the visual cues that they've slipped in and what (else) they could mean!!

i loved that they took so many creative liberties in the way they expressed the dark side of xz's celebrity, coating it in the same pretty, whimsical, wondrous sheen that so often packages the idea of stardom:

that although his dream of music was upheld and supported by his career as a designer, and although he probably did sleep on that call to join that audition programme, fame was a high-speed train that caught him unawares, sweeping him very abruptly away from a quaint little life where things were actually quite lovely in their ordinariness,

that he swung onto the entertainment scene but was left to fend for himself on the precipice of newfound fame; stakeholders wanting to control him under the pretense of guidance and insight, feeling like he was slipping away from the music or the films he wanted to make,

that sometimes he wakes up disoriented, constantly shuttled from hotel to hotel, bed to bed, depending where his schedules take him; bedtime (and his pillow!) the only reprieve,

that stardom is a labyrinth where the goalposts are constantly being moved, a large and intimidating and often lonely endeavour; that he has to fight an uphill battle and go out of his way for even a moment's comfort, without even the luxury of slipping out of the celebrity skin,

that fame is a terribly precarious thing, taking so long to scale and build yet able to fall apart in only a matter of moments; that he has to walk a tightrope to regain some semblance of control in his life, to light the way, to finally write his own story,

but… did he? has he really wrestled that control back for good?

or is it yet another loop like the start and end of the mv suggest — because to be a celebrity, even at his level, is to always be subject to the same, lonely tug-of-war? the invasions of privacy? the constant unrest? the risk of everything falling apart from one little move?

:)

something something i love bittersweet songs i learnt from the best ok

⋆

← prev ┊ part 2: the self is not me, but us → next ┊ part 4: why i say this album is xiao zhan in a bottle

4 notes

·

View notes

Text

Transform Packaging Efficiency with Film Lamination Adhesives

In today's fast-paced world, efficiency and sustainability are more important than ever. For film manufacturers, print industry professionals, and product packaging designers, finding ways to reduce waste while improving efficiency is crucial. Enter film lamination adhesives—a game-changing solution that can transform your packaging processes. This blog post explores how film lamination adhesives can help you achieve these goals, making your packaging not just better but also greener.

Understanding Film Lamination Adhesives

Film lamination adhesives are specialized compounds designed to bond layers of film together, creating a single, cohesive material. Used extensively in packaging, these adhesives offer numerous benefits, including enhanced durability and improved barrier properties.

Why Use Film Lamination Adhesives?

Film lamination adhesives are essential for creating multi-layered packaging that protects products effectively. They provide a strong bond between different types of films, ensuring that the final product is both durable and functional.

Types of Film Lamination Adhesives

There are several types of film lamination adhesives available, each designed for specific applications. These include water-based, solvent-based, and solvent-free adhesives. Each type has its own set of advantages, making them suitable for various packaging needs.

Applications in Packaging

Film lamination adhesives are used in a wide range of packaging applications. From seed and pesticide packaging to dairy products and vacuum pouches, these adhesives offer versatile solutions for various industries.

Benefits of Film Lamination Adhesives

Using film lamination adhesives in your packaging processes can significantly reduce waste and improve efficiency. Here are some key benefits:

Enhanced Durability

One of the primary advantages of film lamination adhesives is their ability to create highly durable packaging. This means your products are better protected, reducing the risk of damage during transit.

Improved Barrier Properties

Film lamination adhesives help enhance the barrier properties of packaging, making it more resistant to moisture, oxygen, and other external factors. This is particularly important for products like dairy and vacuum-sealed items.

Versatility

Film lamination adhesives are incredibly versatile, making them suitable for a wide range of applications. Whether you're packaging seeds, pesticides, or consumer goods, these adhesives can meet your needs.

Improving Efficiency in Packaging

Efficiency is key to staying competitive in the packaging industry. Film lamination adhesives can streamline your processes, making them more efficient and cost-effective.

Faster Production Times

Film lamination adhesives can significantly speed up production times. By creating strong bonds quickly, they allow for faster assembly of multi-layered packaging, increasing your overall output.

Reduced Downtime

Using high-quality film lamination adhesives can reduce downtime caused by equipment malfunctions or material failures. This ensures a smoother production process and higher efficiency.

Cost Savings

By minimizing waste and improving production efficiency, film lamination adhesives can lead to significant cost savings. This makes them a smart investment for any packaging operation.

The Future of Packaging with Film Lamination Adhesives

The packaging industry is constantly evolving, and film lamination adhesives are at the forefront of this evolution. By adopting these advanced adhesives, you can stay ahead of the curve and ensure your packaging processes are both efficient and sustainable.

Innovations on the Horizon

Ongoing research and development in film lamination adhesives promise even more exciting innovations in the future. Stay tuned for new products and technologies that will further enhance your packaging capabilities.

Commitment to Sustainability

At [Your Company Name], we're committed to sustainability. Our film lamination adhesives are designed to minimize environmental impact while delivering superior performance. Join us in our mission to create a better, more sustainable future.

Taking the Next Step

Ready to revolutionize your packaging processes? Contact us today to learn more about our film lamination adhesives and how they can benefit your business. Our team of experts is here to help you find the perfect solution for your needs.

2 notes

·

View notes

Text

High Speed Mixer Machine Manufacturer

High Speed Mixer Machine https://www.invoitplast.com/granules-mixer-machine/plastic/high-speed-mixer-machine/ Application Of High Speed Mixer Machine: To manufacture any Plastic components or product it is must require that plastic raw material will be moisture free to eliminate the defects like black dots, pins, holes etc in final component or product. So to eliminate this problems we’ve designed the best solution for that which is High Speed Mixer machine.

It is also used to preheat the raw material like LD , PVC, EWA, HDPE etc before inserting into Extrusion process. Industries Cattered : Blown film plant, Lamination Plant, Packaging Industries, PVC pipe Plant, HDPE pipe Plant etc.

5 notes

·

View notes

Text

O.C. And Stiggs, Thieves Like Us coming to Blu-ray from Radiance!!!

Very exciting news today as the new UK-based boutique home video label Radiance has announced two new Altman releases coming in July! This marks O.C. And Stiggs’ first appearance in HD, and the Thieves disc is far more stacked with extras than the Kino release stateside was. Both are currently listed as Region B and will be available 7/17/23!

O.C. And Stiggs (1987)

BLU-RAY LIMITED EDITION SPECIAL FEATURES

High-Definition digital transfer

Uncompressed mono PCM audio

A new documentary featurette on the making of the film by critic Hunter Stephenson featuring new interviews with the cast and crew (2023) - more details to be confirmed

New interview with camera operator Robert Reed Altman (2023)

Altman on O.C. and Stiggs archival featurette (2005, 8 mins)

Trailer

Gallery of rare images

English subtitles for the deaf and hard of hearing

Reversible sleeve featuring original and new artwork by Time Tomorrow

Limited edition booklet featuring archival writings by Robert Altman about the film and his approaches to filmmaking

Limited edition of 3000 copies, presented in full-height Scanavo packaging with removable OBI strip leaving packaging free of certificates and markings

Extras subject to change

Thieves Like Us (1974)

BLU-RAY LIMITED EDITION SPECIAL FEATURES

High-Definition digital transfer

Original uncompressed mono PCM audio

Audio commentary by director Robert Altman

Brand new interview with co-screenwriter Joan Tewkesbury who discusses the film and her working relationship with Altman (2023)

Brand new interview with star Keith Carradine (2023)

Geoff Andrew on Thieves Like Us - the critic discusses the film and its place within Altman’s work

Two classic radio plays featured in the film - The Shadow written by and starring Orson Welles and Speed Gibson of the International Secret Police starring Ed Gardner

Trailer

Promotional image gallery

English subtitles for the deaf and hard of hearing

Reversible sleeve featuring designs based on original posters

Limited edition booklet featuring new writing by critic Pamela Hutchinson; archival writing by Robert Altman; and a piece looking at the script development from the novel by professor Alan Schroeder

Limited edition of 3000 copies, presented in full-height Scanavo packaging with removable OBI strip leaving packaging free of certificates and markings

Extras subject to change

#robert altman#oc and stiggs#thieves like us#blu ray#radiance#film#director#fuck yeah#home video#news

6 notes

·

View notes

Text

Albon admits to some head scratching at Williams after unexpected practice display at Silverstone

Williams drivers Alex Albon and Logan Sargeant expressed their surprise – and urged caution – over the Grove team’s high-flying performance on the opening day of practice for the British Grand Prix. Albon featured inside the top-three positions during both of Friday’s sessions at Silverstone, finishing behind only Max Verstappen’s Red Bull and Carlos Sainz’s Ferrari on the combined timesheets, while Sargeant joined him at the sharp end with a run to fifth in second practice. FP2: Verstappen tops second practice at Silverstone from Sainz and Albon as Leclerc hits trouble It comes after a raft of updates were applied the FW45, which aided Albon’s push for P7 in Canada – lifting Williams above AlphaTauri and off the foot of the F1 standings – and led to another competitive display in Austria. Speaking after hopping out of the car, Albon said: “It was a bit surprising in some ways. I have to say unexpected, you know. We’re not playing around doing weird things, it’s just a normal day for us. “Clearly, we crossed the line and we’re in the top three, so a bit of – in some ways – head scratching, but at the same time the car feels good. We’ve got an upgrade on the car that we’ve had for two races now. This feature is currently not available because you need to provide consent to functional cookies. Please update your cookie preferences FP2 Highlights: 2023 British Grand Prix “At least on the simulator it’s shown to be a bit more effective in the high-speed than the low-speed, and we haven’t really had too much high-speed tracks the last few races – Austria and Canada aren’t really that. “It’s the first time we’ve seen the package working on a quick circuit and it’s looking quite good. But we’ve got to keep ourselves grounded, it’s [about] chipping away. NEED TO KNOW: The most important facts, stats and trivia ahead of the 2023 British Grand Prix “The wind, the way that it is this weekend, it’s so strong, I think everyone… It doesn’t feel good around here, I think it feels terrible for everyone, but clearly less terrible for us than others, so let’s see.” As for where Williams might stack up on Saturday, Albon pointed to the mixed weather report, saying: “Tomorrow is going to be likely wet for a little bit. I hope it stays dry, I hope it’s similar weather to this, but let’s see what happens tomorrow. “But still the focus is on Sunday, because overtaking here is pretty easy, so you need a good race car. Our race pace was actually OK; it wasn’t amazing, but it wasn’t bad.” Albon placed third in both practice sessions at Silverstone on Friday Sargeant echoed Albon’s remarks as he looks to build on an encouraging weekend at the Red Bull Ring last time out and edge towards what would be a maiden F1 points finish. “It didn’t feel super smooth out there, to be honest,” he admitted. “This wind has been causing us a lot of issues, but I think it’s been the same for everyone, so [we’re] just trying to get on top of that. READ MORE: ‘It’s massively exciting’ – Hamilton shares more details on Apple’s F1 movie ahead of Silverstone filming “[There’s] still some stuff we can do better, for sure, heading into tomorrow. The weather looks a little bit tricky, but we’ll play it by ear. I think generally it was a solid start to the weekend and we’ll try and build off that. “Honestly, mine and Alex’s comments are pretty much in line, so that’s good. We can move in the same direction tomorrow as a team and hopefully the good pace continues.” Admitting that reaching Q2 would mark a “really good day”, Sargeant added: “I don’t think we’re getting too far ahead of ourselves yet. We’ll see tomorrow, we’ll see when quali comes around.” via Formula 1 News https://www.formula1.com

#F1#Albon admits to some ‘head scratching’ at Williams after ‘unexpected’ practice display at Silverstone#Formula 1

1 note

·

View note

Text

Top Benefits of Using Roll Packing Machines in Manufacturing

In the fast-paced world of manufacturing, efficiency and precision are key to staying competitive. A roll packing machine has become an essential tool, revolutionizing how products are packaged by streamlining processes, reducing costs, and ensuring product safety during transportation.

1. Enhanced Efficiency and Speed

A roll packing machine automates the packaging process, allowing manufacturers to handle large volumes of products quickly and efficiently. This reduces production time, meeting tight deadlines without compromising quality. Automated operations also minimize errors, ensuring consistent packaging across batches.

2. Cost-Effective Operations

By reducing the need for manual labor, roll packing machines lower labor costs significantly. Additionally, these machines optimize the use of packaging materials, cutting down on waste. Over time, the savings in labor and materials result in a substantial return on investment.

3. Improved Product Protection

Packaging is critical to ensuring that products reach their destination intact. A roll packing machine provides secure and uniform wrapping, protecting items from damage, dust, and moisture. This is particularly beneficial for delicate or high-value goods.

4. Customization and Versatility

Modern roll packing machines come with customizable settings to accommodate various product sizes and types. Whether packaging textiles, films, or industrial materials, these machines adapt to different requirements, making them versatile for diverse manufacturing needs.

5. Availability from Reliable Manufacturers

Choosing the right roll packing machine manufacturers is essential to ensure quality and reliability. Leading providers offer advanced machines that are durable, efficient, and equipped with the latest technology. For businesses looking for a roll packing machine in Delhi, options are available to meet local needs and specifications.

Conclusion

Integrating a roll packing machine into your manufacturing process enhances productivity, reduces costs, and ensures high-quality packaging. Terron India, a trusted name among roll packing machine manufacturers, offers state-of-the-art solutions tailored to the needs of modern manufacturers, ensuring efficiency and excellence.

#Pillow roll packing machine#roll packing machine#roll packing machine manufacturers#roll packing machine in delhi#roll packing machine manufacturers in delhi

0 notes

Text

Automatic Hologram Sticker Labeling Machine – Brothers.in

The LABELSTIK-300HG is an advanced automatic high-speed roll-to-roll hologram sticker labelling machine designed to apply promotional or security hologram stickers onto various types of labels or film rolls used in packaging industries. Incorporating a sophisticated microprocessor-controlled label dispensing system with a user-friendly sensing mechanism, this machine ensures precise and efficient labelling operations. Capable of labelling up to 300 labels per minute, the LABELSTIK-300HG accommodates label heights ranging from 8 mm to 50 mm and a minimum label length of 12 mm. It supports label rolls with a diameter of up to 400 mm and a core diameter of 75/76 mm, with a gap of approximately 3 mm or more between labels. Eliminates the need for manual data entry for different label sizes, streamlining the setup process. Allows seamless adjustment of labelling speed to match production requirements.

For More Details Clicks Here - https://www.brothers.in/labelstik-300hg.html

0 notes

Text

The Hidden Benefits of TV Antenna Installation Toowoomba: What You Didn’t Know You Needed

It was a sunny Saturday in Toowoomba when Sarah decided to host a family movie night. She had everything planned—popcorn, bean bags, and her grandmother’s favorite classic films. But as the evening rolled around, her streaming service buffered endlessly, ruining the mood. Frustrated, Sarah decided it was time to switch to a reliable option: a high-quality TV antenna installation Toowoomba service. What she discovered went far beyond buffering-free TV—it transformed her viewing experience and saved her money.

Why Australians Are Turning Back to TV Antennas

While streaming services have grown in popularity, a recent study revealed that 62% of Australians still tune in to free-to-air TV weekly. (Source: Roy Morgan). But why? For residents of Toowoomba, TV antenna installation isn’t just about enjoying local channels like 7, 9, and 10—it’s about reliability, cost savings, and unexpected perks.

Here’s what most websites won’t tell you:

1. Local Signal Boosts During Emergencies

Did you know that free-to-air TV often remains operational during power outages or internet blackouts? Unlike streaming services that rely on Wi-Fi, TV antennas provide a direct link to broadcasts. In Toowoomba, where storm seasons can occasionally disrupt connectivity, a reliable antenna ensures access to real-time weather updates and emergency broadcasts.

2. Better Picture Quality, No Buffering Required

While streaming services claim to offer HD, they rely heavily on your internet speed. Free-to-air TV, when paired with a professional antenna installation, delivers uncompressed high-definition broadcasts that outshine most streaming services. With a properly tuned antenna in Toowoomba, residents can enjoy crystal-clear visuals even during peak hours.

3. Cost Efficiency That Adds Up

Sarah’s decision to invest in a TV antenna wasn’t just about better reception—it was about cutting costs. Australians spend an average of $40 per month on streaming subscriptions. Over five years, that’s nearly $2,400. A one-time TV antenna installation in Toowoomba eliminates this recurring expense while delivering a lifetime of entertainment for free.

4. Eco-Friendly Entertainment

Few people realise that traditional antennas have a smaller carbon footprint than streaming services, which depend on energy-intensive data centers. For environmentally conscious Toowoomba residents, choosing an antenna is a step toward reducing digital energy consumption.

Finding the Right Installation Service

Here’s where it gets personal: choosing the right antenna service in Toowoomba makes all the difference. Sarah worked with a professional team that ensured her antenna was positioned perfectly to avoid interference from nearby hills and tall buildings. Their expertise also meant seamless integration with her existing TV setup.

If you’re considering TV antenna installation Toowoomba service, opt for a service that offers:

Expert knowledge of the local terrain

Comprehensive repair options for older antennas

Post-installation maintenance packages

How to Maintain Your Antenna for Longevity

Once installed, regular checks can prevent the need for frequent antenna repair. Here’s a simple checklist:

Clean your antenna annually to remove debris.

Inspect for loose cables or corroded connectors.

Schedule professional servicing every two years.

Final Thoughts

Switching to a TV antenna might seem like a small decision, but for residents of Toowoomba, it’s an investment in reliable, cost-effective, and eco-friendly entertainment. Whether you're drawn by the superior picture quality, the cost savings, or the security of uninterrupted broadcasts, one thing is certain: a TV antenna installation Toowoomba service is more than just a setup—it’s peace of mind.

If Sarah’s story resonates with you, perhaps it’s time to explore your options and experience the benefits firsthand.

(Sources: Roy Morgan, Clean Energy Council)

#tv antenna#tv antenna installation toowoomba#tv antenna toowoomba#antenna installation toowoomba#tv antenna installer#tv antenna installer toowoomba#tv antenna repair toowoomba#antenna repair toowoomba

0 notes

Text

Tray Sealing Machines Market Insights: Transforming Packaging with Automation

The tray sealing machines market is experiencing rapid growth as industries increasingly recognize the importance of effective, efficient, and sustainable packaging solutions. Tray sealing machines, which are used primarily for packaging food, pharmaceuticals, and consumer goods, are evolving due to advancements in technology, automation, and sustainability efforts. These machines play a critical role in preserving product quality, extending shelf life, and enhancing overall packaging efficiency. Here, we explore the key insights shaping the future of the tray sealing machines market.

1. The Growing Demand for Automation

One of the most prominent trends in the tray sealing machines market is the rising demand for automation. Automation offers several advantages, including increased production speed, reduced labor costs, and consistent, high-quality sealing. Automated tray sealing machines can process a high volume of products, making them particularly attractive to large-scale manufacturers in industries like food processing, pharmaceuticals, and retail. With automation, businesses can achieve better operational efficiency, minimize human error, and optimize their supply chain processes. As consumer demand for faster product delivery and high-quality packaging increases, the role of automation in tray sealing machines is becoming increasingly important.

2. Sustainability and Eco-Friendly Packaging

Sustainability has become a critical factor in the tray sealing machines market. With growing awareness of environmental issues and regulatory pressures on plastic waste, manufacturers are increasingly adopting eco-friendly packaging solutions. Tray sealing machines are now designed to handle biodegradable, recyclable, and compostable materials, enabling businesses to meet the rising demand for sustainable packaging. Innovations such as plant-based plastics, paper-based trays, and reusable materials are being integrated into packaging systems, reducing the environmental impact of packaging operations. This trend not only addresses consumer demand for sustainable practices but also aligns with global sustainability goals.

3. Advanced Sealing Technologies

As the need for packaging efficiency and product preservation increases, advanced sealing technologies are playing a pivotal role in the evolution of tray sealing machines. Modified atmosphere packaging and vacuum sealing are two major technologies being used in tray sealing to extend the shelf life of perishable products. MAP, which controls the composition of gases inside the packaging, helps preserve food freshness and quality. Additionally, skin packaging technology, which tightly seals the film to the product, is gaining traction in the market. These advanced sealing methods enhance the product’s appeal by maintaining its visual and sensory qualities for a longer time.

4. Customization and Flexibility in Packaging Solutions

Customization is becoming an essential feature in tray sealing machines. Consumers increasingly prefer tailored packaging solutions that suit their individual needs, whether it’s for portion control, easy-to-use formats, or personalized designs. Tray sealing machines are evolving to offer greater flexibility in terms of tray sizes, shapes, and materials. This customization is not limited to food packaging; non-food sectors such as cosmetics, pharmaceuticals, and electronics are also adopting flexible packaging formats. Businesses in these sectors can offer customized packaging that enhances the consumer experience while meeting specific regulatory requirements. The ability to adapt to diverse packaging needs is a significant factor driving growth in the tray sealing machines market.

5. Industry-Specific Applications

While tray sealing machines are traditionally associated with food packaging, their applications are expanding into other industries, such as pharmaceuticals, medical devices, and cosmetics. In the pharmaceutical industry, for instance, tray sealing machines are used to package drugs, medical equipment, and devices in sterile environments, ensuring that they remain secure and tamper-evident. Similarly, cosmetics companies use these machines to package beauty products, ensuring product integrity and aesthetics. This expansion across multiple industries is broadening the scope of tray sealing machines, providing manufacturers with more opportunities for growth and development in diverse markets.

6. Enhanced Product Quality and Safety

In packaging, the focus on product quality and safety is paramount. Tray sealing machines are designed to ensure that the products they seal remain fresh, secure, and free from contamination. By using technologies such as vacuum sealing and MAP, businesses can prevent spoilage and extend the shelf life of food products. Additionally, tray sealing machines contribute to tamper-evident packaging, which ensures that consumers receive products that are safe and unaltered. These capabilities are particularly important in the food and pharmaceutical sectors, where product safety is a primary concern.

7. Technological Integration and IoT

The integration of the Internet of Things into tray sealing machines is another emerging trend. IoT-enabled machines allow for real-time monitoring of the sealing process, offering businesses insights into performance, efficiency, and quality control. By tracking key parameters such as temperature, pressure, and sealing time, manufacturers can optimize their processes and ensure that they meet production standards. IoT integration also enables predictive maintenance, helping businesses reduce downtime and extend the life of their equipment. This technological advancement is making tray sealing machines smarter and more efficient, improving the overall packaging process.

Conclusion: A Dynamic Market

The tray sealing machines market is poised for significant growth, driven by technological advancements, automation, sustainability efforts, and industry-specific demands. As manufacturers continue to innovate and adapt to changing consumer expectations, the market will evolve to meet the need for more efficient, sustainable, and customized packaging solutions. From food and pharmaceuticals to consumer goods, tray sealing machines will remain a cornerstone of the packaging industry, ensuring product quality, safety, and environmental responsibility. With the continued integration of advanced technologies and a growing emphasis on sustainability, the future of tray sealing machines looks promising and full of potential.

#Tray Sealing Machines Market#Tray Sealing Machines Market trends#Tray Sealing Machines innovations#Tray Sealing Machines Market scopes#Tray Sealing Machines products

0 notes

Text

Fixing Color Registration and Alignment Issues in Flexographic Printing: An In-Depth Guide

Introduction Flexographic printing is renowned for its versatility and efficiency, making it a popular choice for printing on various substrates, including paper, plastic, and metallic films. However, achieving precise color registration and alignment can be challenging. Misregistration and color alignment issues can significantly affect print quality, leading to wasted materials and increased costs. This article examines the causes of color registration errors in flexographic printing and provides methods to control and optimize color alignment for superior print results. Understanding Color Registration and Alignment Issues Color registration refers to the accurate alignment of different color layers in a print job. When the colors do not align correctly, it leads to misregistration, resulting in blurred or double images. Several factors can contribute to these errors, including mechanical issues, improper press setup, and environmental conditions. Common Causes of Color Registration Errors - Mechanical Problems: - Plate Cylinder Issues: Worn or improperly mounted plate cylinders can cause misalignment. - Anilox Rollers: Damaged or inconsistent anilox rollers affect ink transfer and color consistency. - Gear Wear: Worn gears can lead to irregular movement, causing misregistration. - Improper Press Setup: - Incorrect Mounting: Incorrect mounting of printing plates can lead to skewed prints. - Tension Settings: Improper web tension can cause the substrate to stretch or shrink, affecting alignment. - Press Speed: Variations in press speed can lead to synchronization issues between different print stations. - Environmental Conditions: - Humidity and Temperature: Changes in humidity and temperature can affect the substrate's behavior, leading to alignment issues. - Static Electricity: Static buildup can cause the substrate to shift, resulting in misregistration. Methods for Controlling and Optimizing Color Alignment - Regular Maintenance: - Inspection and Replacement: Regularly inspect and replace worn or damaged components like plate cylinders, anilox rollers, and gears to ensure smooth operation. - Lubrication: Proper lubrication of moving parts can reduce wear and ensure consistent performance. - Accurate Press Setup: - Precise Plate Mounting: Use mounting systems that ensure accurate and consistent plate positioning. - Tension Control: Implement automated tension control systems to maintain consistent web tension throughout the printing process. - Speed Calibration: Calibrate press speeds to ensure synchronization between different print stations, reducing the risk of misregistration. - Environmental Control: - Climate Control: Maintain consistent temperature and humidity levels in the printing environment to minimize substrate expansion or contraction. - Static Elimination: Use anti-static devices to eliminate static buildup on substrates, ensuring stable and accurate alignment. - Advanced Monitoring Systems: - Registration Control Systems: Implement advanced registration control systems that use sensors to monitor and adjust the alignment of color layers in real-time. - Print Inspection Systems: Use automated print inspection systems to detect and correct misregistration issues during the printing process, ensuring high-quality output. - Operator Training: - Skill Development: Provide comprehensive training to operators on the importance of color registration and the methods to achieve precise alignment. - Best Practices: Encourage the adoption of best practices in press setup, maintenance, and environmental control to minimize errors. Case Study: Success in Improving Color Registration A leading packaging company experienced significant misregistration issues, resulting in wasted materials and customer dissatisfaction. By implementing a comprehensive maintenance program, upgrading to advanced registration control systems, and providing extensive operator training, they achieved a dramatic improvement in print quality. The company reported a 40% reduction in misregistration errors and increased customer satisfaction with the final product's quality. Conclusion Addressing color registration and alignment issues is crucial for achieving high-quality flexographic prints. By understanding the common causes of these errors and implementing precise control methods, printers can enhance print quality, reduce waste, and improve operational efficiency. Regular maintenance, accurate press setup, environmental control, advanced monitoring systems, and operator training are key strategies for optimizing color alignment in flexographic printing. With these measures in place, companies like Pasargad Iranian Ink can continue to deliver exceptional printing results and maintain their competitive edge in the industry. Read the full article

0 notes

Text

The Film Blowing Extruder: Revolutionizing Plastic Film Production

A Film Blowing Extruder is a machine that extrudes plastic material, typically polyethylene (PE) or other polymers, into a thin film. The process involves melting plastic pellets, extruding them into a tube of film, and then expanding the tube by blowing air into it, which forms a bubble. The bubble is then cooled and flattened into a thin film, ready for use in various industries like packaging, agricultural films, and more.

The Film Blowing Extruder Process

Feeding the Raw Material:

The first step in the process is the introduction of plastic pellets into the extruder barrel. These pellets are usually made from polyethylene (PE), polypropylene (PP), or other polymer materials that are suitable for film production.

Melting the Plastic:

The plastic pellets are subjected to heat within the barrel, where the screw gradually moves them forward, melting the plastic into a molten state. This is achieved through a combination of mechanical and thermal energy.

Extruding the Film:

Once the plastic is melted, it is forced through the die head, forming a tube of molten plastic. The die is designed to ensure a uniform thickness and smooth surface of the film.

Blowing the Bubble:

The molten plastic tube is inflated using compressed air, forming a bubble. The size and thickness of the bubble depend on the desired properties of the final film. The air pressure and speed of inflation play a crucial role in achieving consistent film thickness.

Cooling and Solidifying:

After the film blowing extruder is inflated, it is cooled quickly to solidify its structure. This cooling can be achieved either by water rings or air-cooling systems. Proper cooling ensures the film retains its integrity and flexibility.

Flattening the Film:

Once the film is cooled, it is flattened into a two-dimensional film using rollers or other flattening mechanisms. This process ensures that the film is smooth and uniform, with no wrinkles or defects.

Winding:

The flattened film is then wound onto a roll. This roll can be used for further processing, such as printing, cutting, or converting into bags or other packaging materials.

Advantages of Using Film Blowing Extruder

Cost-Effective Production: Film blowing is a continuous process, meaning that once the machine is set up, it can produce large quantities of film with minimal downtime, making it cost-effective.

High-Quality Films: The film blowing process ensures high-quality films with uniform thickness, smooth surfaces, and excellent mechanical properties. The ability to control film thickness during the inflation stage helps in producing films with consistent quality.

Flexibility: With the ability to produce different types of films—such as multilayer, stretchable, or biodegradable films—film blowing extruders offer flexibility to meet various market demands.

Environmental Sustainability: Advances in biodegradable plastics and multi-layer film technology have made it possible to produce more sustainable films. Film blowing extruders are now being used to produce eco-friendly alternatives that reduce the environmental impact of plastic packaging.

Conclusion

The film blowing extruder is an indispensable tool in modern manufacturing. It allows for the production of high-quality, versatile plastic films used in countless industries, from packaging to agriculture. With continued advancements in technology, these machines are becoming more energy-efficient, capable of producing multilayer films, and adaptable to new, eco-friendly materials. The role of the film blowing extruder in the modern world of plastic manufacturing cannot be overstated, as it continues to meet the growing demand for functional, cost-effective, and environmentally conscious plastic films.

0 notes

Text

Snack Food Packaging Market: Growth in Health-Conscious and Premium Products

The Snack Food Packaging Market is set to experience substantial growth due to increasing demand for convenience foods, innovative packaging solutions, and sustainability-focused initiatives. Rising consumer preference for on-the-go snacks and the need for extended product shelf life are key factors propelling market expansion.

Read Complete Report Details of Snack Food Packaging Market: https://www.snsinsider.com/reports/snack-food-packaging-market-2810

Market Segmentation

By Raw Material

Plastic

Description: Includes flexible films, rigid containers, and pouches.

Growth Drivers: Cost-effective, lightweight, and versatile properties.

Trends: Shift toward bio-based and recyclable plastics to reduce environmental impact.

Metal

Description: Primarily used in cans and tins for snacks.

Growth Drivers: High barrier properties for moisture and light protection.

Trends: Growing use in premium snack packaging for enhanced product preservation.

Paper

Description: Includes paperboard boxes, kraft paper pouches, and cartons.

Growth Drivers: Rising demand for biodegradable and eco-friendly materials.

Trends: Innovations in laminated and coated paper for improved durability.

Others

Description: Includes glass, bioplastics, and hybrid materials.

Trends: Adoption of alternative materials to meet niche market needs.

By Packaging Type

Rigid

Description: Includes containers, boxes, and trays.

Growth Drivers: Provides structural integrity and protection for fragile snacks.

Trends: Increased focus on reusable rigid packaging solutions.

Flexible

Description: Includes wraps, pouches, and bags.

Growth Drivers: Lightweight, cost-efficient, and suitable for a wide range of snacks.

Trends: Use of resealable and portion-control designs for consumer convenience.

By Application

Bakery Snacks

Growth Drivers: High demand for cookies, biscuits, and other bakery items requiring freshness retention.

Trends: Customizable packaging designs for improved brand visibility.

Candy & Confections

Growth Drivers: Need for aesthetic and protective packaging to maintain product appeal.

Trends: Adoption of metallized films and holographic designs.

Savory Snacks

Growth Drivers: Increasing consumption of chips, popcorn, and crackers worldwide.

Trends: Air-tight and nitrogen-flushed packaging for prolonged freshness.

Nuts & Dried Fruits

Growth Drivers: Rising health-conscious snacking trends.

Trends: Use of transparent packaging to showcase product quality.

Others

Description: Includes niche snack categories like protein bars and specialty snacks.

Trends: Growth in personalized and premium packaging solutions.

By Region

North America

Growth Drivers: Strong demand for convenience foods and innovative snack packaging.

Trends: Expansion of sustainable packaging solutions by leading manufacturers.

Europe

Growth Drivers: Increasing regulatory focus on eco-friendly packaging materials.

Trends: Growing preference for biodegradable and compostable packaging.

Asia-Pacific

Growth Drivers: Rapid urbanization and growing middle-class population boosting snack consumption.

Trends: Investments in automated and high-speed packaging technologies.

Latin America

Growth Drivers: Expansion of snack food markets in emerging economies.

Trends: Adoption of cost-effective packaging materials for mass markets.

Middle East & Africa

Growth Drivers: Rising snack food imports and investments in packaging infrastructure.

Trends: Increased focus on shelf-ready and export-friendly packaging.

Market Trends and Opportunities

Sustainability Initiatives: Growing emphasis on recyclable, biodegradable, and compostable materials.

Customization: Increased demand for packaging designs tailored to branding and consumer preferences.

Convenience Features: Innovations such as resealable packs, easy-to-open designs, and single-serve portions.

Smart Packaging: Incorporation of QR codes and NFC-enabled features for interactive consumer engagement.

Health Trends: Packaging innovations that highlight product transparency and nutritional information.

Market Outlook

The Snack Food Packaging Market is expected to grow steadily, supported by technological advancements, evolving consumer preferences, and regulatory changes promoting sustainable practices. Flexible packaging solutions are anticipated to dominate due to their versatility, while paper-based materials are likely to gain significant traction for their eco-friendliness. Emerging markets in Asia-Pacific and Latin America will be key contributors to market growth.

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions.

Contact Us:

Akash Anand – Head of Business Development & Strategy

Phone: +1-415-230-0044 (US) | +91-7798602273 (IND)

0 notes