#Gauge meter

Explore tagged Tumblr posts

Text

Kingdom Hearts Dream Drop Distance Commands - Break Time

#kingdom hearts dream drop distance#khddd#sora#commands#my gif#flashing#this is easily one of my all time favorite commands i love that it exists and that they brought it back for this game#BUT the devs are cowards for making this exclusive to sora#you guys are seriously not going to give us ballerina spinning riku?? shameful.#anyways sora has a chance of striking one of three poses while performing this command and each has a different effect#the first one fills up the link gauge with your dream eaters#the second one heals you and the last one resets your drop meter

199 notes

·

View notes

Text

"Mario! Thank goodness you're here!" The Toad exclaimed, hopping in place with a perpetual grin. "I was getting so nervous, sitting alone by myself in this corner here! I mean, it's all I ever do, but usually MIPS hops by to say hello every now and then, and I haven't seen him!"

"I'a tell you, Toad, there'a some pretty strange shenanigans'a happening around here, lately! Don'ta worry, Mario'a gonna handle it just'a like he'a handle Bowser!" The portly protagonist pat his chest with his blocky fist, doing his best to assure Toad that he wasn't scared.

"I should tell you, I've been seeing weird shadows dancing along my vision every now and then. And I heard a loud voice coming from the hallway with the Star Door! AND I lost my toothbrush this morning, so I had to resort to breathmints! I'm kinda freaking out, Mario!"

Mario put his hand to his chin, pantomiming thought. Toad's a great friend and a capable ally with info, but Mario was more than used to his solo adventure by now. The Star Door... the one by Dire Dire Docks? That could also be worth investigating. This was starting to seem kind of fun!

125 notes

·

View notes

Text

Thor: you're like a brother to me :) the person he's saying this to, who has seen the way he is with Loki: uhh, thanks?

#thorki#ish#thor might not be the best person to gauge the sibling-ness of a relationship#his meter is a bit off

46 notes

·

View notes

Text

Legend having purple eyes is a really popular headcanon, and so is the if Legend and Fable are siblings she has purple eyes too headcanon.

Purple can be wildly different hues based on how much red vs blue, so Fable would have more blue/purple eyes where Legend has more reddish/violet eyes.

Personal headcanon is that its because Fable is more naturally able to use magic so it didn't change hers nearly as much as Legend who isn't able to use magic as naturally but still uses an excess amount and thats why his eye color changed more pink.

based on this fanart

#me have headcanons??? ikr idk what happened#i know the actual magic meter is green#but i was kinda goin based on the energy gauge from albw and triforce heroes for this one#linked universe#lu headcanons#lu fable#lu legend#moon emissary thoughts

41 notes

·

View notes

Text

uhhhhhhh idk how to say this but the idea of you was….. fun and sexy!!!!! AND made me cry. you heard it here first

3 notes

·

View notes

Text

alcohol is just one of milou's biggest, if not THE coping mechanism for practically everything. she's well aware that it's not healthy but could give zero shits about it. she doesn't grow violent nor directly impacts other people around her — she really just wants to grow numb and for other people to mind their own business.

it doesn't concern them, so what gives them the right to dictate what she should and shouldn't do? usually, milou really does not care what others think about her, but this is different.

it takes a great amount of trust between her and another person to even hear them out and not grow hostile or outright lash out at them (both verbal and physical) if they try to intervene. weirdly enough though, her stoic demeanour persists if a complete stranger decides to comment on her habits. it's only when there's at least some rapport between her and the person in question that she grows increasingly hostile.

the sheer audacity that you think you're entitled to broach the topic of something that makes her feel so vulnerable — something that she thinks has become such an integral part of her by now.

#headcanons tbt.#anyway who's gonna be milou's 'i can fix her'#it's basically a fuck-around-and-find-out-meter to gauge your friendship lvl with milou#the more violent the less progress you have#the furthest point most people that even get that close to her#is when she just grows quiet / apathetic and shuts you out for a while#and if she actually decides to hear you out and consider your words?#man you are SPECIAL special#quite literally built diff fr#alcohol abuse tw#also though when she's still hostile towards you#her verbally lashing out will always be a part of it#but the more rapport there is#the less she's inclined and hesitates to literally beat the person up lol

11 notes

·

View notes

Text

one day i will read the second dmc novel..

#i think dante gives enzo one of his devil arms in it but enzo doesn't have the Fortitude to handle it + loses his arm as a result?#so that's what gioia's synch meter hinges on.. do you feel me.. it's the expression of how The Captain she Is...#the agathos wouldn't take her arm or what have you bc they lov her. But. the stronger her will is the better the agathos perform.. if she#bottomed out on will then i think the effects could be harmful to her!#meanwhile magdalena has the it's so joever -> we're so back gauge.. 😝#sriracha.txt#nero prime#💃🏻

4 notes

·

View notes

Note

everyone say thank you nat for bringing our christmas gift early (ps. it needs to include tissues)

askjhgsaskjgshd it's just a silly little thing,,,,, a silly little chapter i've finally picked up again

#tender curiosities baby!#asks#i am VERY bad at gauging the sadness meter of things i found out aksghaslkg

5 notes

·

View notes

Text

Ughh I hate that my city has a fanbase. I hate that the most important virtue here is being alert and cunning. I hate how this city is "the most hospitable and warm 😊", but only to people who fit right in.

I hate that I got snickered at the whole time at the market I was shopping at. And then they tried to make me pay more than what I owed. And I got catcalled but in a making fun of sort of way. All because I wore a too colorful shirt and don't have a nice haircut. They mistook me for a tourist, or just thought I was stupid. This happens to me very frequently, but when I voice my experiences I get scoffed at - except for the few weirdos I know who get exactly the same treatment.

And like, look. I could stick to the richest parts of my city that are streets of just cafes and restaurants and souvenir shops and bnbs and tourists. But what if I want to actually Live IN my city? I've been trying to understand how tf to fit in for 24 years here, I've been swindled and robbed and got laughed at while wearing anything from colorful patterned shirts on out of style pants to white t-shirts tucked in perfectly usual skinny jeans. I don't understand what is it that I give off that tells people "she's weird, she's foolish, she doesn't understand" but I hate that they take advantage of it. I want a city that is kinder.

#this is a naples hate blog#i have to like gauge my weirdness meter every day before walking out of the door#i seem to start with a negative amount of normalcy points no matter what i do#then. every pant thats not a skinny jeans is a -1#bright coloured shirts can be anything from -1 to -3#face mask is a solid -4 ALWAYS.#'what do you care what other people think!!' it's SO tiring to always feel like a clown or a stranger in my own home#and the 'weirder' i am perceived as the more alert i need to be bc I actively get people trying to swindle and rob me more often

6 notes

·

View notes

Text

An anthropomorphic cat that would emphatically state that they are not a cat.

Reblog and put the species of the nearest stuffed animal

#Niko#Oneshot#not a cat#2nd nearest is a walrus I made in middle school home ec#It was hard to gauge which was closer#until I realized I have a laser distance meter that just happens to be sitting on my desk#So I didn't even have to get up to verify this#Both are over 10 feet away but Niko is 3 inches closer#TECHNOLOGY!

82K notes

·

View notes

Text

20kg Mechanical Baby Scale Infant Weighing Scales in Uganda

Professional Infant Scale (removable tray)

The infant digital scale is gently curved to prevent infants from rolling off during weighing, and features excellent precision to accurately track babies' growth. It is compatible with infant length measurement devices, and features a removable tray for easy cleaning.

Infant Scale (removable tray) A baby scale is used to weigh newborns and very young children too young to stand. … Measuring the changing weight of an infant in the first few months of life cleaning Vibration-free weighing: vibrations are filtered out so that a stable weight is obtained, ideal for restless babies Backlit LCD display

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance. For inquiries on deliveries contact us

Office +256 (0) 705 577 823, +256 (0) 775 259 917

Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036

Email: [email protected]

#Crane (hanging) scales#Whole sale scales#Baby scales#Mini palm scales#Industrial platforms#assorted weighing brands including Avery#Salter#Health ( height and weight ) scales#Precision scales Analytical/Laboratory scales#Moisture meters#Temperature gauges#Pallet trolleys#kitchen scales#Animal scales#Bag closers-stitching machine#Plastic bag sealers#Plastic foot sealers#Batch sealers#Table top scales#Counter scales#Barcode readers/printer#Waterproof scales#Axle weigh bridge#Mini and full Weigh bridges among others.

0 notes

Text

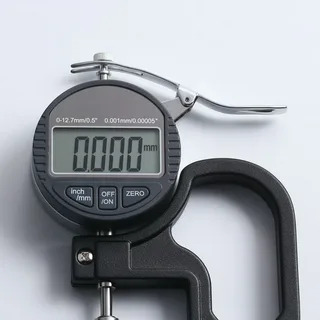

How to Maintain and Calibrate Your Thickness Gauge Meter

A thickness gauge meter is an essential tool in many industries, from manufacturing and engineering to quality control and inspection. It ensures accurate measurement of material thickness, which is crucial for maintaining product quality and meeting industry standards. Regular maintenance and calibration are vital to ensuring that the thickness gauge meter continues to deliver precise measurements. In this guide, we’ll go over effective ways to maintain and calibrate your thickness gauge meter, ensuring it remains a reliable tool for years to come.

1. Why Maintenance and Calibration Matter

Over time, a thickness gauge meter can drift in accuracy due to factors like regular use, environmental conditions, and exposure to dust or moisture. Calibration helps restore the instrument's precision, ensuring it delivers consistent and accurate readings. Maintenance, on the other hand, prolongs the lifespan of the device, helping avoid costly repairs and downtime. Regular maintenance and calibration improve the tool’s reliability, help comply with industry regulations, and prevent product inconsistencies that could impact the final product quality.

2. Essential Maintenance Tips for Thickness Gauge Meters

Proper maintenance of a thickness gauge meter includes regular cleaning, handling, and storage practices. Here’s how to keep it in peak condition:

a. Clean the Sensor and Display

The sensor is the most critical part of a thickness gauge meter. Dirt, oil, or moisture on the sensor can lead to inaccurate readings. To clean it:

Use a soft, dry cloth to wipe down the sensor after each use.

Avoid using harsh chemicals, as they may damage the sensor or other components.

Clean the display screen as well with a microfiber cloth to ensure clear readability.

b. Handle with Care

Avoid dropping or shaking the device, as this can dislodge internal components and affect its accuracy. When not in use, place the thickness gauge meter in its protective case to prevent accidental bumps or exposure to dust.

c. Store in a Controlled Environment

Moisture and extreme temperatures can degrade a thickness gauge meter over time. Store the device in a cool, dry place, ideally in a storage case, to protect it from environmental factors. Avoid leaving the device in direct sunlight, as prolonged exposure to UV light can damage sensitive components.

d. Regularly Check for Damage

Inspect the thickness gauge meter before each use for any signs of damage, such as cracks in the casing, loose buttons, or any signs of corrosion. Addressing minor issues early on can prevent more significant problems from developing.

3. How to Calibrate Your Thickness Gauge Meter

Calibration is the process of aligning the meter’s readings with a known standard to ensure accuracy. Calibration should be done regularly, depending on the frequency of use and the manufacturer’s recommendations. Here are the steps to calibrate your thickness gauge meter effectively:

a. Prepare the Calibration Standard

Before you begin, make sure you have calibration standards, which are materials with known thicknesses. Calibration standards should match the type of material you commonly measure. Most thickness gauge meters come with calibration blocks, but you can also purchase specialized calibration standards for more precise applications.

b. Follow the Manufacturer’s Instructions

Calibration procedures vary depending on the model and type of thickness gauge meter, so it’s essential to refer to the user manual. Each device has specific calibration instructions that are designed to ensure accuracy without damaging the instrument.

c. Zero the Gauge Meter

Many digital thickness gauge meters include a “zero” function. Start by setting the device to zero before measuring the calibration standard. This step is essential, as it aligns the device to measure correctly from the baseline of zero thickness.

d. Take Multiple Readings

To ensure accurate calibration, take several readings on the calibration standard, checking for consistency. If the device is reading higher or lower than the standard, make the necessary adjustments using the device’s calibration function until you achieve consistent accuracy.

e. Calibrate for Different Materials

If you measure materials of varying densities, recalibrate the thickness gauge meter for each type. Different materials may require adjustments to maintain accuracy. Most advanced meters offer options for different modes or presets based on material type, allowing you to switch between measurements efficiently.

4. How Often Should You Calibrate?

The frequency of calibration depends on how frequently the device is used and the conditions it operates in. For heavily used devices, monthly calibration may be necessary. For tools used less often, calibrating every three to six months is typically sufficient. It’s also a good practice to calibrate the meter after any significant impact, exposure to extreme conditions, or if you notice inconsistent readings.

5. Signs That Your Gauge Needs Calibration

If you’re unsure when to calibrate, look for these signs:

Inconsistent Readings: If the thickness measurements vary despite measuring the same object multiple times, recalibration is needed.

Visible Damage: Physical damage can alter the gauge’s precision.

Frequent Use in Harsh Conditions: If your thickness gauge meter is used in environments with high temperatures, moisture, or chemicals, more frequent calibration is advisable.

6. Professional Calibration Services

For businesses requiring high-accuracy measurements, consider professional calibration services. Certified technicians have specialized equipment and can perform precise calibration to ensure compliance with industry standards. Many companies choose to have their devices professionally calibrated annually for added reliability.

Conclusion

Regular maintenance and calibration are essential to keep your thickness gauge meter performing at its best. By following these tips—cleaning and handling the device carefully, storing it properly, and calibrating it regularly—you ensure that your thickness gauge meter remains a reliable tool for quality control. Investing time in these steps pays off by prolonging the tool’s lifespan and enhancing the accuracy of your measurements, ultimately supporting better product quality and operational efficiency.

0 notes

Text

Almost...

#American dad#gif#odometer#meter#car#automobile#turning over#almost#so close#99999#gauge#numbers#expectations

0 notes

Text

Why Pressure Calibration Is Critical for The Oil and Gas Sector?

In the oil and gas industry, precision is paramount. Maintaining optimal pressure levels is not merely a technical requirement but a crucial aspect of ensuring safety, efficiency, and compliance.

Pressure calibration is essential in upholding these standards, as it directly impacts the integrity of equipment, the safety of personnel, and the overall efficiency of operations.

This blog explores why pressure calibration services is indispensable for the oil and gas sector and how it supports various critical aspects of the industry.

Ensuring Safety: The Cornerstone of Operations

Safety is the top priority in the oil and gas sector, where high-pressure systems are constantly at play. Even a minor deviation in pressure levels can have severe consequences, leading to leaks, equipment failures, or, in extreme cases, explosions.

Regular pressure calibration ensures that pressure-measuring instruments are accurate and reliable, functioning within their specified parameters.

By doing so, companies can minimise risks and prevent incidents that could compromise safety. Proper calibration is not just a precaution but a proactive measure protecting personnel and assets.

Enhancing Operational Efficiency and Productivity

Operational efficiency is vital to maintaining profitability in the oil and gas sector. Unplanned downtime due to equipment malfunctions can result in significant financial losses, while inefficiencies can hamper productivity.

Accurate pressure calibration maximises efficiency by ensuring that systems operate at their optimal capacity. Calibrated equipment helps maintain stability across various processes, reducing the likelihood of breakdowns and minimising wastage.

Companies can sustain consistent production rates by ensuring pressure instruments function accurately. This enhances productivity and reduces operational costs. In essence, pressure calibration is key to maintaining the smooth and efficient operation of oil and gas facilities.

Meeting Industry Standards and Regulatory Compliance

The oil and gas industry is highly regulated, with strict standards and guidelines that companies must adhere to for safety and quality assurance.

Regulatory bodies, such as ISO (International Organisation for Standardisation) and API (American Petroleum Institute), set stringent equipment maintenance and calibration requirements.

Compliance with these regulations is not optional; failure to meet these standards can result in fines, legal repercussions, and even the suspension of operations.

Routine pressure calibration ensures that equipment remains compliant with industry standards and demonstrates that it functions within acceptable parameters.

By adhering to these calibration requirements, oil and gas companies can maintain their certifications, avoid penalties, and uphold their reputation for safety and reliability.

Protecting Valuable Equipment from Damage

Equipment used in the oil and gas industry represents a significant financial investment. The infrastructure is extensive and expensive, from pipelines and pumps to storage tanks and refineries.

Therefore, protecting this equipment from damage is a priority for every company in the sector. Regular pressure calibration is one of the most effective ways to achieve this.

Uncalibrated or improperly calibrated equipment can lead to over-pressurisation or under-pressurisation, which can damage components and cause costly maintenance issues.

Companies can detect discrepancies early, take preventive measures, calibrate pressure instruments, and avoid extensive damage. In doing so, they safeguard their assets, reduce repair costs, and extend the lifespan of critical equipment.

Facilitating Accurate Data Collection for Informed Decision-Making

The oil and gas sector relies heavily on data to make informed operational and strategic decisions. Accurate pressure readings are crucial for monitoring pipeline performance or ensuring storage conditions in refineries.

Pressure calibration ensures that these readings are precise, providing companies with reliable data to base their decisions.

When correctly calibrated, pressure instruments deliver accurate measurements, enabling operators to fine-tune processes, optimise production schedules, and maintain equipment effectively. This accuracy is essential for data-driven decision-making, leading to more efficient and cost-effective operations.

Conclusion: The Indispensable Role of Pressure Calibration

In an industry as complex and demanding as oil and gas, Industrial Automation is not just a technical requirement but a vital aspect of maintaining safety, efficiency, and compliance.

Regular calibration of pressure instruments ensures that equipment functions accurately, reducing risks, enhancing productivity, and protecting valuable assets.

By prioritising pressure calibration, oil and gas companies demonstrate their commitment to operational excellence, safety, and regulatory compliance.

It is an investment in the long-term success and sustainability of operations, underscoring precision's essential role in the sector.

#Pressure Calibration#Differential Pressure Calibration#Flow Meter Calibration#Industrial Automation#Industrial Automation Companies#Pressure Gauge Calibration

0 notes

Text

Are you on the hunt for reliable temperature detector suppliers in Iraq? In a country where industrial operations are booming, having the right suppliers for critical components like resistance temperature detectors (RTDs), temperature transmitters, globe valves, and check valves is paramount. Now will guide you through choosing the right Resistance Temperature Detector Suppliers in Iraq while introducing a new player in the market

Understanding the Need for Quality Suppliers

Before delving into the specifics of selecting the right temperature detector supplier, it’s essential to grasp why the choice matters. Industries across Iraq, whether oil and gas, manufacturing, or petrochemical, heavily rely on temperature detectors to monitor and control their processes. Any compromise in quality can lead to costly downtime, safety hazards, and operational inefficiencies.

Assessing Your Requirements

The first step in your quest for a reliable supplier is to assess your requirements. Do you need resistance temperature detectors (RTDs) with high accuracy in extreme conditions? Are you searching for temperature transmitters that ensure seamless data transmission for real-time monitoring? Or do you require globe valves and check valves to regulate fluid flow effectively?

Exploring the Options: RTD Suppliers

Now, let’s focus on resistance temperature detector suppliers in Iraq. These devices are crucial for precise temperature measurement, making them indispensable in various industries. When looking for an RTD supplier, consider factors such as:

#Pressure Gauges Suppliers In Iraq#Thermowells Suppliers in Iraq#Flow Meter Suppliers In Iraq#Pressure Switches Suppliers in Iraq#Check Valves Suppliers in Iraq

0 notes

Text

what do i do when i have the same dexcom sensor on my pump and my phone but they are showing completely different numbers lol

#i know the answer is test my blood. but i dont want tooooooo#my meter is downstairs and im so cosy in bed#my phone says 4.4 and going down. my pump says 10 and so it upped my basal#i dont have hypo unawareness its more like. theres other things wrong with me and those symptoms feel like hypos#so i feel like im low all the time#i cant really gauge my blood sugar by how i feel#debbie tees

0 notes