Don't wanna be here? Send us removal request.

Text

Premium Jewellery Consumable Tools – High-Quality Supplies for Every Jeweler

Upgrade your jewelry-making process with our extensive collection of Jewellery Consumable Tools. We offer top-tier polishing materials, soldering essentials, abrasives, and cleaning solutions to help you create stunning jewelry pieces. Our tools are carefully selected to meet the needs of both professional goldsmiths and DIY enthusiasts, ensuring precision and efficiency in every project. Shop now for reliable and long-lasting consumables.

0 notes

Text

Jewellery Tools Manufacturers | WJT India – Excellence in Jewellery Crafting

WJT India stands out as a premier name among jewellery tools manufacturers, offering a comprehensive range of high-quality tools designed to elevate your craftsmanship. Our tools are meticulously engineered to provide precision, reliability, and durability for jewellers, goldsmiths, and artisans worldwide. Whether you require specialized pliers, hammers, engraving tools, or polishing solutions, WJT India delivers products that blend innovation with traditional expertise. Our commitment to superior craftsmanship ensures that every tool we offer enhances the beauty and intricacy of jewellery design. Trust WJT India for the finest tools to support your creative vision.

0 notes

Text

The Future of Jewellery Manufacturing with Advanced Jewellery Casting Machines

The jewellery industry has always been one of the most intricate and creative sectors in manufacturing, combining artistry with precision. As the demand for custom, high-quality jewellery pieces continues to grow, manufacturers are increasingly turning to innovative technologies to improve their production processes. One such breakthrough is the advanced jewellery casting machine, which is transforming the way jewellery is made. These machines have ushered in a new era of efficiency, accuracy, and design possibilities. But what does the future hold for jewellery manufacturing with the continued evolution of jewellery casting machines?

Revolutionizing Design Precision

In the past, creating fine jewellery often involved labor-intensive manual processes, with a significant degree of human error. While traditional casting methods such as lost wax casting are still used, advanced jewellery casting machines have taken precision to a whole new level. The machines now utilize state-of-the-art technology, such as computer numerical control (CNC) and 3D printing, to ensure that every detail of a design is captured with unmatched accuracy.

With these advanced casting machines, manufacturers can reproduce the most intricate and delicate designs with ease, ensuring flawless results. Complex patterns, fine engravings, and delicate textures that once required hours of manual work can now be produced in a fraction of the time. This revolution allows jewellery makers to expand their creativity, pushing the boundaries of design while maintaining the highest standards of quality.

Speeding Up the Production Process

The introduction of advanced jewellery casting machines has greatly improved the efficiency of jewellery production. Traditional casting methods often involved multiple stages of handcrafting, including mould making, pouring, and polishing, which could take a considerable amount of time. In contrast, modern jewellery casting machines streamline this process, allowing for faster production without compromising on quality.

Jewellery casting machines automate several key stages, such as wax injection, casting, and even some aspects of finishing, which results in significant time savings. Manufacturers can now produce large volumes of jewellery at a much faster rate, making them more competitive in the market. Additionally, these machines reduce the amount of waste, as the casting process is highly precise, which results in fewer defects and material losses.

Customization and Personalization

As customers increasingly seek personalised and one-of-a-kind jewellery pieces, the demand for customization has grown. Advanced jewellery casting machines are making it easier than ever for manufacturers to meet this demand. With the ability to create highly detailed and intricate designs through 3D modelling software, jewellers can now offer customized pieces with ease.

These machines can quickly adapt to a variety of designs, whether it's a unique engagement ring, a custom pendant, or an intricate bracelet. Through the use of digital technology, customers can now collaborate with jewellery designers to create a piece that reflects their personal style, preferences, and significance. This customization ability is not only a game-changer for the consumer market but also helps manufacturers stand out by offering truly bespoke services.

Sustainability and Material Efficiency

The jewellery industry is no stranger to the growing demand for sustainability, and advanced jewellery casting machines are helping meet these expectations. These machines are designed to use materials more efficiently, reducing waste during the casting process. In traditional jewellery casting, the process can produce a significant amount of scrap material, especially with precious metals like gold and platinum. However, modern casting machines are highly precise, ensuring that the exact amount of material is used for each cast, resulting in less waste.

Moreover, many advanced jewellery casting machines are now designed to work with recycled materials, which supports the move toward more sustainable jewellery production. This is an important step towards reducing the environmental impact of the jewellery industry, as it allows manufacturers to reuse valuable metals rather than relying on new, mined materials. These practices not only contribute to environmental conservation but also help jewellery businesses reduce costs and maintain ethical sourcing standards.

The Integration of Artificial Intelligence and Automation

Looking further ahead, the future of jewellery manufacturing will likely see even more integration of artificial intelligence (AI) and automation. AI can be used to optimize the casting process by learning from past production data, predicting potential issues, and adjusting parameters for optimal results. These advanced systems could also enable jewellery casting machines to become more autonomous, requiring less human intervention during production.

Additionally, AI could help improve quality control by analyzing each piece as it is being cast, ensuring that any imperfections are caught early in the process. This level of automation will reduce the need for manual oversight, allowing manufacturers to focus on innovation and creativity.

Conclusion

The future of jewellery manufacturing is undeniably intertwined with the continued development of advanced jewellery casting machines. These machines have already revolutionized the industry by offering faster, more precise, and sustainable methods of production. As technology continues to evolve, we can expect even more breakthroughs in design, efficiency, and sustainability, making jewellery creation faster, more customizable, and more environmentally friendly.

For manufacturers, investing in an advanced jewellery casting machine is no longer just an option—it is a necessity for staying competitive in a rapidly changing market. As the demand for unique, high-quality pieces continues to rise, these machines will play a pivotal role in shaping the future of jewellery manufacturing, driving innovation and transforming the industry for years to come.

0 notes

Text

Best Practices for Using a Jewellery Cleaner Machine on Gemstones

Gemstones are prized for their brilliance and allure, making them a timeless addition to any jewelry collection. However, over time, dirt, oils, and grime can accumulate on their surfaces, dulling their sparkle. A jewellery cleaner machine can be an excellent tool to restore your gemstones’ radiance, but improper use can potentially damage delicate stones. To ensure your precious gemstones remain in pristine condition, it is essential to follow these best practices when using a jewellery cleaner machine.

1. Understand the Type of Gemstone

Not all gemstones are created equal, and their physical and chemical properties vary widely. Some stones, such as diamonds, sapphires, and rubies, are hard and durable, making them suitable for most jewellery cleaner machines. Others, like emeralds, opals, pearls, and turquoise, are softer or more porous and require extra care. Before using a jewellery cleaner machine, research the specific care requirements of your gemstones to avoid accidental damage.

2. Choose the Right Cleaning Machine

Jewellery cleaner machines come in various types, with ultrasonic cleaners being the most common. Ultrasonic machines use high-frequency sound waves to create microscopic bubbles that dislodge dirt and grime. While effective, these machines may not be suitable for fragile gemstones. If your collection includes delicate stones, opt for a machine with adjustable settings or consider a steam cleaner, which uses gentle steam to clean jewelry safely.

3. Inspect Your Jewelry Before Cleaning

Before placing your jewelry in a cleaner machine, inspect each piece carefully. Check for loose settings, cracks, or any visible damage. Ultrasonic vibrations or steam pressure can exacerbate these issues, potentially causing further harm to the gemstone or its setting. If you find any damage, consult a professional jeweler before cleaning.

4. Use the Appropriate Cleaning Solution

The cleaning solution used in the machine is just as important as the machine itself. Avoid harsh chemicals or abrasive cleaners, as they can damage certain gemstones. Opt for a gentle, non-toxic solution specifically formulated for jewelry cleaning. Always dilute the solution as directed by the manufacturer, and never use ammonia or bleach-based products, which can harm gemstones and metal settings.

5. Limit Cleaning Time

Overexposure to cleaning processes can weaken some gemstones or their settings. Follow the manufacturer’s instructions for the recommended cleaning duration, typically ranging from 3 to 5 minutes. For more delicate gemstones, limit the cleaning time to reduce the risk of damage. If a piece is heavily soiled, it’s better to repeat shorter cleaning cycles rather than extending one session.

6. Separate Jewelry Pieces

To prevent scratches and damage during the cleaning process, avoid placing multiple pieces of jewelry in the cleaner at the same time. Gemstones can collide with one another or with metal parts, leading to scratches or chips. Clean each piece individually or use separate compartments if your machine is equipped with them.

7. Rinse and Dry Thoroughly

After cleaning, remove the jewelry from the machine and rinse it under lukewarm water to remove any remaining cleaning solution. This step is crucial, as residual solution can cause discoloration or buildup over time. Gently pat the jewelry dry with a soft, lint-free cloth, and allow it to air dry completely before storing or wearing.

8. Avoid Overuse

While a jewellery cleaner machine is convenient, frequent cleaning can take a toll on gemstones and their settings. Reserve deep cleaning for when your jewelry shows visible dirt or dullness. For regular maintenance, use a soft, damp cloth to gently wipe your gemstones and remove surface oils and dirt.

9. Store Your Jewelry Properly

Proper storage plays a significant role in keeping your gemstones clean and shiny. Store each piece in a separate compartment or a soft pouch to prevent scratches and tangles. Avoid exposing your jewelry to extreme temperatures, humidity, or direct sunlight, as these factors can affect the color and durability of certain gemstones.

10. Consult Professionals for Delicate Pieces

For gemstones that require extra care, such as emeralds, opals, or antique jewelry, professional cleaning may be the best option. Jewelers have the expertise and tools to clean delicate pieces safely, ensuring their longevity and beauty.

Conclusion

A jewellery cleaner machine can be a valuable asset for maintaining the brilliance of your gemstones, but it’s important to use it correctly. By understanding the unique needs of your gemstones, choosing the right cleaning equipment, and following these best practices, you can keep your jewelry looking its best without risking damage. Treat your treasures with care, and they will continue to shine for years to come.

0 notes

Text

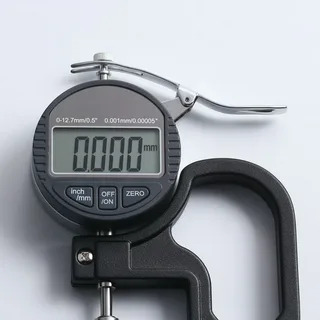

Ensuring Consistency in Jewelry Pieces with Thickness Gauge Meters

Creating jewelry that is both beautiful and functional requires meticulous attention to detail and precision. Every element, from the thickness of the metal to the placement of gemstones, must be carefully measured and controlled to achieve a perfect balance of aesthetics and durability. One essential tool that has revolutionized the jewelry-making process is the thickness gauge meter. This device ensures that every jewelry piece meets the highest standards of consistency and quality.

Importance of Consistency in Jewelry

Consistency is critical in the jewelry industry, whether you're crafting intricate custom pieces or producing designs in bulk. Inconsistent thickness in metal sheets or wires can lead to weak spots, structural flaws, and even customer dissatisfaction. For example, earrings that are too thin might bend easily, while bracelets with uneven thickness might feel uncomfortable to wear. By ensuring consistent measurements, jewelers can maintain their reputation for high-quality craftsmanship and durability.

The Role of a Thickness Gauge Meter

A thickness gauge meter is a specialized tool used to measure the thickness of materials with incredible accuracy. In jewelry making, it is primarily used for:

Metal Sheets and Wires: To ensure uniformity in gold, silver, platinum, or other precious metals used in crafting rings, necklaces, and bracelets.

Gem Settings: To confirm the precise depth and width of settings to securely hold gemstones.

Enamel and Coatings: To verify the thickness of applied coatings, such as rhodium plating, ensuring a flawless finish.

Benefits of Using a Thickness Gauge Meter in Jewelry

1. Enhanced Precision

A thickness gauge meter allows jewelers to measure even the thinnest layers of material with unparalleled precision. This accuracy ensures that every piece of jewelry is uniform, contributing to its aesthetic appeal and structural integrity.

2. Improved Quality Control

Consistency in material thickness is vital for quality control, especially in bulk production. With a thickness gauge meter, jewelers can identify discrepancies early in the process and make adjustments, reducing waste and ensuring every piece meets the required standards.

3. Cost Efficiency

Precious metals are expensive, and even minor variations in thickness can lead to material wastage or overuse. By using a thickness gauge meter, jewelers can optimize their use of materials, saving costs without compromising quality.

4. Customer Satisfaction

Customers expect their jewelry to be both visually appealing and long-lasting. Ensuring consistent thickness in each piece enhances its durability and comfort, leading to higher customer satisfaction and loyalty.

Types of Thickness Gauge Meters for Jewelers

Different types of thickness gauge meters are available to meet the specific needs of jewelry making:

Mechanical Thickness Gauges: Simple and reliable, these are ideal for measuring small pieces like metal sheets and wires.

Ultrasonic Thickness Gauges: These advanced devices use sound waves to measure the thickness of materials without causing any damage, making them perfect for delicate jewelry.

Digital Thickness Gauges: Equipped with digital displays, these meters offer precise readings and are user-friendly for jewelers of all skill levels.

How to Use a Thickness Gauge Meter in Jewelry Crafting

Calibrate the Device: Before using a thickness gauge meter, calibrate it according to the material you’re measuring to ensure accurate results.

Measure Consistently: For metal sheets, measure at multiple points to confirm uniformity across the surface.

Inspect Gem Settings: Use the gauge to verify the thickness of the metal around gem settings, ensuring they are secure without being overly thick.

Check Coatings: After plating or applying finishes, measure the coating’s thickness to ensure an even application.

Tips for Choosing the Right Thickness Gauge Meter

Consider the materials you work with most frequently, such as gold, silver, or enamel.

Look for a device that offers high precision and is easy to operate.

Opt for durable models, especially if you handle large production volumes.

Seek professional advice or reviews to ensure you invest in the best thickness gauge meter for your needs.

The Future of Thickness Gauge Meters in Jewelry

As technology advances, thickness gauge meters are becoming more sophisticated, offering features like real-time data analysis, wireless connectivity, and enhanced durability. These innovations make it easier than ever for jewelers to maintain consistency and improve efficiency in their processes.

Conclusion

Consistency is the hallmark of high-quality jewelry, and achieving it requires the right tools and techniques. A thickness gauge meter is an indispensable asset for jewelers, enabling them to craft pieces that are not only beautiful but also durable and reliable. By investing in this technology, jewelers in both custom and mass production settings can ensure every creation meets the highest standards, delivering unparalleled satisfaction to their customers. Whether you are a seasoned jeweler or just starting, incorporating a thickness gauge meter into your workflow is a step toward achieving precision and excellence in every piece.

0 notes

Text

Improving Productivity with Jewelry Laser Welding Machines

The jewelry industry thrives on precision, creativity, and efficiency. As demand for intricate and customized designs grows, artisans and manufacturers are turning to advanced technologies to enhance their productivity and maintain high-quality standards. One such revolutionary tool is the Jewelry Laser Welding Machine, a device that has transformed how jewelry is designed, repaired, and assembled.

What Is a Jewelry Laser Welding Machine?

A Jewelry Laser Welding Machine is a specialized device designed to join metals using a focused laser beam. Unlike traditional welding techniques that rely on heat and filler materials, this machine delivers pinpoint accuracy, making it ideal for delicate jewelry work. It is widely used for tasks such as soldering, repairing broken chains, resizing rings, and creating seamless designs.

How Jewelry Laser Welding Machines Enhance Productivity

1. Precision and Accuracy

One of the most significant advantages of using a Jewelry Laser Welding Machine is its unparalleled precision. The focused laser beam allows jewelers to work on minute areas without affecting the surrounding material. This accuracy ensures minimal wastage, leading to cost savings and faster project completion.

2. Reduced Downtime

Traditional welding methods often require extensive setup, heating, and cooling times. With a Jewelry Laser Welding Machine, the process is almost instantaneous. The machine can be operated continuously, reducing downtime and allowing jewelers to complete more tasks in a shorter period.

3. Versatility in Materials

Jewelry Laser Welding Machines are compatible with a wide range of metals, including gold, silver, platinum, and titanium. This versatility means that jewelers can handle various projects without needing multiple tools, further streamlining operations.

4. Enhanced Repair Capabilities

Repairs are a significant part of any jeweler’s workload. With a Jewelry Laser Welding Machine, fixing broken pieces, filling gaps, or resizing items becomes much faster and more efficient. The machine’s precision ensures that even the most delicate pieces can be restored without compromising their aesthetic or structural integrity.

5. Improved Consistency

Achieving consistent results is crucial in jewelry making. Manual welding methods often leave room for human error, resulting in uneven joins or visible marks. A Jewelry Laser Welding Machine eliminates these inconsistencies, delivering uniform results with every use.

Real-World Applications of Jewelry Laser Welding Machines

Custom Jewelry Design

The demand for personalized and intricate jewelry designs is rising. Jewelry Laser Welding Machines enable designers to create complex patterns and unique features that were previously challenging to achieve.

Mass Production

In a commercial setting, these machines significantly boost productivity by speeding up the production process. They allow manufacturers to produce large quantities of jewelry without compromising quality.

Jewelry Repairs

From resizing rings to repairing clasps, Jewelry Laser Welding Machines make repairs quick and straightforward. Their ability to work with various metals ensures versatility in addressing customer needs.

Prototyping and Experimentation

Designers often need to prototype new concepts before full-scale production. A Jewelry Laser Welding Machine provides the flexibility to experiment with different materials and designs, helping jewelers refine their ideas efficiently.

Tips for Maximizing Productivity with a Jewelry Laser Welding Machine

Regular Maintenance: Ensure that the machine is cleaned and serviced regularly to avoid technical issues.

Proper Training: Equip your staff with the necessary training to operate the machine efficiently.

High-Quality Materials: Use high-quality metals and consumables to achieve the best results.

Optimize Settings: Understand the machine’s features and customize its settings for different projects to maximize performance.

Monitor Output: Track the machine’s output and identify any bottlenecks in the workflow for continuous improvement.

The Future of Jewelry Manufacturing

As technology continues to evolve, tools like the Jewelry Laser Welding Machine are becoming indispensable in the jewelry industry. These machines not only improve productivity but also open up new possibilities for innovation and creativity. Their ability to handle delicate tasks with precision ensures that they remain a valuable asset for jewelers worldwide.

Conclusion

The Jewelry Laser Welding Machine is a game-changer for jewelers looking to boost productivity, maintain quality, and expand their creative horizons. Its precision, efficiency, and versatility make it an essential tool for modern jewelry-making processes. Whether you are a small artisan or a large-scale manufacturer, investing in this technology can significantly enhance your operations and give you a competitive edge in the market.

By integrating a Jewelry Laser Welding Machine into your workflow, you not only improve efficiency but also ensure that your designs meet the highest standards of craftsmanship, satisfying even the most discerning customers.

0 notes

Text

How Jewelry Laser Welding Machines Minimize Heat Damage on Precious Stones

In the intricate world of jewelry design and repair, preserving the integrity of precious stones is paramount. The introduction of Jewelry Laser Welding Machines has revolutionized how jewelers work, especially when dealing with delicate gemstones. Traditional welding and soldering methods often expose jewelry pieces to high levels of heat, which can lead to cracks, discoloration, or even complete loss of valuable stones. With laser welding technology, jewelers can now achieve seamless welds with minimal heat impact, safeguarding the beauty and quality of each piece.

Understanding Heat Sensitivity in Precious Stones

Many precious stones, including diamonds, emeralds, opals, and pearls, are highly sensitive to heat. Excessive temperatures can alter their physical appearance, affect their structural integrity, and even cause irreparable damage. Emeralds, for instance, often contain internal fissures that can expand under high heat, while pearls may discolor or lose their luster if exposed to direct heat. This presents a significant challenge for jewelers during repairs or customizations that require welding near stones.

The need for a precise, controlled welding solution that minimizes heat damage has led to the increased adoption of Jewelry Laser Welding Machines. These machines focus the energy into a small, pinpoint area, generating less overall heat compared to traditional methods and providing jewelers with the ability to weld in close proximity to heat-sensitive stones.

How Jewelry Laser Welding Machines Work

A Jewelry Laser Welding Machine operates by focusing a concentrated laser beam onto the metal, creating a localized heat zone that melts and fuses metals together. This highly controlled laser beam enables jewelers to make fine welds without spreading excess heat across the entire piece. Unlike flame-based or traditional torch welding, which generates substantial ambient heat, laser welding allows for precise control, producing only a narrow zone of thermal impact. This means jewelers can work within millimeters of precious stones without risking heat damage.

Laser welding technology uses adjustable settings for both the power and duration of each laser pulse. Jewelers can select the appropriate settings based on the type of metal and the stone’s heat tolerance. This level of customization further reduces the risk of damage to gemstones, ensuring they remain pristine while achieving a secure, clean weld.

The Benefits of Laser Welding for Stone-Sensitive Jewelry

One of the biggest advantages of using a Jewelry Laser Welding Machine is its ability to protect the unique characteristics of precious stones. Here’s how laser welding minimizes the risks associated with traditional methods:

Localized Heat Zone: Laser welding focuses heat energy directly on the metal, with minimal heat spreading to surrounding areas. This localized heat minimizes the risk of thermal shock to stones, making it ideal for jewelry pieces where gems are embedded close to welding areas.

Customizable Laser Power and Duration: Jewelry Laser Welding Machines allow jewelers to adjust the intensity and pulse duration of the laser. This means they can use lower power for heat-sensitive pieces, reducing the chances of stone damage and allowing for safe repairs and adjustments.

Reduced Need for Stone Removal: In traditional methods, jewelers often have to remove stones to protect them from heat. With laser welding, jewelers can complete their work without disturbing the placement of the gemstones. This saves time, reduces handling risks, and ensures the jewelry maintains its original look and integrity.

Precision in Fine Detail Work: Laser welding enables jewelers to perform intricate repairs and customizations with unmatched precision. Fine prongs, clasps, and settings can be welded accurately without affecting adjacent areas. For intricate, multi-stone settings, this precision is invaluable, allowing jewelers to work confidently without fear of damaging stones.

Real-World Applications of Laser Welding in Jewelry

Laser welding has proven essential for jewelers who specialize in high-value or heirloom pieces, where even minor damage to a gemstone can drastically affect its value. For example, an antique ring set with emeralds and pearls requires an extremely delicate approach to preserve both its historical integrity and the quality of each stone. A Jewelry Laser Welding Machine enables jewelers to address issues like cracked prongs, worn clasps, or broken links while keeping stones perfectly intact.

Additionally, jewelry laser welding is indispensable for customized designs, allowing jewelers to build unique settings and intricate patterns close to precious stones without compromising their color or quality. This technology offers a new level of creative freedom, empowering jewelers to innovate without the limitations imposed by traditional welding methods.

Conclusion: Elevating Jewelry Craftsmanship with Laser Welding

Jewelry Laser Welding Machines represent a significant leap forward in jewelry manufacturing and repair. By minimizing heat impact, these machines allow jewelers to work confidently around precious stones, ensuring each piece remains as beautiful and valuable as it was intended. Jewelers now have a powerful tool that enables them to provide exceptional craftsmanship while preserving the quality and appearance of sensitive gemstones. For anyone in the jewelry industry, adopting laser welding technology not only enhances productivity but also upholds the highest standards of care for every piece they work on.

0 notes

Text

How to Maintain and Calibrate Your Thickness Gauge Meter

A thickness gauge meter is an essential tool in many industries, from manufacturing and engineering to quality control and inspection. It ensures accurate measurement of material thickness, which is crucial for maintaining product quality and meeting industry standards. Regular maintenance and calibration are vital to ensuring that the thickness gauge meter continues to deliver precise measurements. In this guide, we’ll go over effective ways to maintain and calibrate your thickness gauge meter, ensuring it remains a reliable tool for years to come.

1. Why Maintenance and Calibration Matter

Over time, a thickness gauge meter can drift in accuracy due to factors like regular use, environmental conditions, and exposure to dust or moisture. Calibration helps restore the instrument's precision, ensuring it delivers consistent and accurate readings. Maintenance, on the other hand, prolongs the lifespan of the device, helping avoid costly repairs and downtime. Regular maintenance and calibration improve the tool’s reliability, help comply with industry regulations, and prevent product inconsistencies that could impact the final product quality.

2. Essential Maintenance Tips for Thickness Gauge Meters

Proper maintenance of a thickness gauge meter includes regular cleaning, handling, and storage practices. Here’s how to keep it in peak condition:

a. Clean the Sensor and Display

The sensor is the most critical part of a thickness gauge meter. Dirt, oil, or moisture on the sensor can lead to inaccurate readings. To clean it:

Use a soft, dry cloth to wipe down the sensor after each use.

Avoid using harsh chemicals, as they may damage the sensor or other components.

Clean the display screen as well with a microfiber cloth to ensure clear readability.

b. Handle with Care

Avoid dropping or shaking the device, as this can dislodge internal components and affect its accuracy. When not in use, place the thickness gauge meter in its protective case to prevent accidental bumps or exposure to dust.

c. Store in a Controlled Environment

Moisture and extreme temperatures can degrade a thickness gauge meter over time. Store the device in a cool, dry place, ideally in a storage case, to protect it from environmental factors. Avoid leaving the device in direct sunlight, as prolonged exposure to UV light can damage sensitive components.

d. Regularly Check for Damage

Inspect the thickness gauge meter before each use for any signs of damage, such as cracks in the casing, loose buttons, or any signs of corrosion. Addressing minor issues early on can prevent more significant problems from developing.

3. How to Calibrate Your Thickness Gauge Meter

Calibration is the process of aligning the meter’s readings with a known standard to ensure accuracy. Calibration should be done regularly, depending on the frequency of use and the manufacturer’s recommendations. Here are the steps to calibrate your thickness gauge meter effectively:

a. Prepare the Calibration Standard

Before you begin, make sure you have calibration standards, which are materials with known thicknesses. Calibration standards should match the type of material you commonly measure. Most thickness gauge meters come with calibration blocks, but you can also purchase specialized calibration standards for more precise applications.

b. Follow the Manufacturer’s Instructions

Calibration procedures vary depending on the model and type of thickness gauge meter, so it’s essential to refer to the user manual. Each device has specific calibration instructions that are designed to ensure accuracy without damaging the instrument.

c. Zero the Gauge Meter

Many digital thickness gauge meters include a “zero” function. Start by setting the device to zero before measuring the calibration standard. This step is essential, as it aligns the device to measure correctly from the baseline of zero thickness.

d. Take Multiple Readings

To ensure accurate calibration, take several readings on the calibration standard, checking for consistency. If the device is reading higher or lower than the standard, make the necessary adjustments using the device’s calibration function until you achieve consistent accuracy.

e. Calibrate for Different Materials

If you measure materials of varying densities, recalibrate the thickness gauge meter for each type. Different materials may require adjustments to maintain accuracy. Most advanced meters offer options for different modes or presets based on material type, allowing you to switch between measurements efficiently.

4. How Often Should You Calibrate?

The frequency of calibration depends on how frequently the device is used and the conditions it operates in. For heavily used devices, monthly calibration may be necessary. For tools used less often, calibrating every three to six months is typically sufficient. It’s also a good practice to calibrate the meter after any significant impact, exposure to extreme conditions, or if you notice inconsistent readings.

5. Signs That Your Gauge Needs Calibration

If you’re unsure when to calibrate, look for these signs:

Inconsistent Readings: If the thickness measurements vary despite measuring the same object multiple times, recalibration is needed.

Visible Damage: Physical damage can alter the gauge’s precision.

Frequent Use in Harsh Conditions: If your thickness gauge meter is used in environments with high temperatures, moisture, or chemicals, more frequent calibration is advisable.

6. Professional Calibration Services

For businesses requiring high-accuracy measurements, consider professional calibration services. Certified technicians have specialized equipment and can perform precise calibration to ensure compliance with industry standards. Many companies choose to have their devices professionally calibrated annually for added reliability.

Conclusion

Regular maintenance and calibration are essential to keep your thickness gauge meter performing at its best. By following these tips—cleaning and handling the device carefully, storing it properly, and calibrating it regularly—you ensure that your thickness gauge meter remains a reliable tool for quality control. Investing time in these steps pays off by prolonging the tool’s lifespan and enhancing the accuracy of your measurements, ultimately supporting better product quality and operational efficiency.

0 notes

Text

How Jewellery Consumable Tools Enhance Precision in Jewelry Making

Jewelry making is an art that demands high levels of skill, creativity, and precision. Whether creating delicate earrings or intricate necklaces, every tiny detail counts. Achieving this level of detail requires not just talent but also the right tools. Jewellery consumable tools play a vital role in ensuring that artisans can work with accuracy, consistency, and efficiency. With the help of modern tools, jewelry makers can produce high-quality designs that meet the demands of today's discerning customers.

In this blog, we will explore how jewellery consumable tools enhance precision in jewelry making and how companies like WJTIndia Pvt. Ltd. are helping artisans create beautiful, flawless jewelry pieces.

The Role of Precision in Jewelry Making

Precision is one of the most critical aspects of jewelry making. Whether you are working with gemstones, precious metals, or intricate designs, every millimeter matters. A slight misstep can ruin an entire piece, leading to wasted materials and lost time. That’s why jewelers need tools that enable them to work with accuracy and finesse.

Jewelry consumable tools, such as saw blades, burs, files, and polishing compounds, are specifically designed to offer the kind of control needed for precision work. These tools allow artisans to shape, cut, and finish metals with minimal error, ensuring that each piece matches the original design perfectly. High-quality tools are critical for reducing variability and maintaining consistency across multiple pieces in a collection.

How Jewellery Consumable Tools Improve Accuracy

One of the main reasons that consumable tools are essential to precision in jewelry making is that they help artisans control every aspect of the process, from design to finishing. Let’s take a closer look at some of the ways these tools contribute to accuracy:

1. Cutting and Shaping

Precision starts with the initial cutting and shaping of raw materials. Jewelers use saw blades, burs, and other cutting tools to achieve clean, accurate cuts. Low-quality tools can create uneven cuts or cause materials to chip, which leads to inconsistency and may even ruin the piece. However, with the right jewellery consumable tools, jewelers can make fine, controlled cuts, resulting in a smooth and symmetrical design.

WJTIndia Pvt. Ltd. offers a wide range of high-performance saw blades and cutting tools that enable jewelers to execute precise cuts with ease, ensuring a polished outcome for each piece.

2. Filing and Smoothing

Once the basic shape of the jewelry is cut, the next step is filing and smoothing the surfaces. This step is crucial for eliminating rough edges and imperfections that may be left behind after cutting. Consumable tools such as files, abrasives, and sanding papers are indispensable for this task.

By using the right size and grade of files, jewelers can refine the shape and ensure a smooth finish. The high level of control offered by these tools allows artisans to enhance their designs without compromising accuracy. WJTIndia Pvt. Ltd. provides a wide selection of precision files and abrasives tailored for this purpose.

3. Polishing and Finishing

The final step in jewelry making is polishing and finishing, which gives the piece its shine and professional appearance. Polishing compounds, wheels, and buffing tools are essential consumables that help jewelers achieve the perfect finish. Without these tools, even the most well-designed piece can appear dull or incomplete.

Jewellers use polishing tools to remove any remaining imperfections, scratches, or marks left during earlier stages. This not only makes the jewelry more visually appealing but also enhances its durability. The finishing touch provided by high-quality consumable tools is what often sets professional jewelry apart from mass-produced items.

WJTIndia Pvt. Ltd. offers a range of advanced polishing tools that help artisans achieve that flawless final look, allowing each piece to truly stand out.

The Importance of High-Quality Consumable Tools

When it comes to enhancing precision in jewelry making, the quality of the tools being used cannot be overstated. High-quality consumable tools are built to last, provide consistent results, and allow artisans to work efficiently. Poor-quality tools, on the other hand, can lead to mistakes, wasted materials, and a lower-quality product.

At WJTIndia Pvt. Ltd., the focus is on delivering top-notch jewellery consumable tools that are designed to meet the needs of professional jewelers. From cutting to polishing, each tool is crafted with precision in mind, ensuring that artisans can produce high-quality pieces that meet customer expectations.

Conclusion

Precision is the cornerstone of exceptional jewelry making, and consumable tools play a key role in achieving that precision. By choosing high-quality jewellery consumable tools from trusted providers like WJTIndia Pvt. Ltd., artisans can enhance their craftsmanship, reduce errors, and create stunning pieces that stand the test of time.

Whether you are an experienced jeweler or just starting your journey, investing in the right tools is essential for success. With the help of the best consumable tools on the market, you can elevate your jewelry-making skills and bring your creative visions to life with flawless accuracy.

1 note

·

View note