#Electronics Manufacturing Services from India

Explore tagged Tumblr posts

Text

When electronics manufacturing took off in China in the 1980s, rural women who had just begun moving to the cities made up the majority of the factory workforce. They didn’t have many other options. Managers at companies like Foxconn preferred to hire women because they believed them to be more obedient, Jenny Chan, a sociologist at Hong Kong Polytechnic University who studies labor issues at Foxconn, told Rest of World. Over the past 30 years, that’s changed. Today, most of China’s iPhone workers are men; women have moved into less arduous service sector jobs. But in India, Foxconn and other electronics manufacturers are once again recruiting from a female workforce beginning to migrate for better jobs. Hiring a young, female workforce in India comes with its own requirements — which include reassuring doting parents about the safety of their daughters. The company offers workers free food, lodging, and buses to ensure a safe commute at all hours of the day. On days off, women who live in Foxconn hostels have a 6 p.m. curfew; permission is required to spend the night elsewhere. “[If] they go out and not return by a specific time, their parents would be informed,” a former Foxconn HR manager told Rest of World. “[That’s how] they offer trust to their parents.”

21 notes

·

View notes

Text

Rajasthan’s Journey to a 30 Lakh Crore Economy: A Vision for the Future

At the Rising Rajasthan Global Investment Summit 2024, Industry Minister Rajyavardhan Singh Rathore made a bold declaration about the state’s economic future. He highlighted the growth trajectory of Rajasthan’s economy, asserting that while the previous Congress government left behind a state economy worth ₹15 lakh crore, the current vision for the state will see it crossing the ₹30 lakh crore mark in just the next four years. This ambitious plan represents not only a doubling of the state’s economic size but also the transformation of Rajasthan into a major economic powerhouse in India.

This statement, made in the context of the Rising Rajasthan Summit, isn’t just a number. It reflects the aspirations of a state poised to redefine its place in India’s growth story. The summit, a significant platform for global investment, is seen as the starting point for this economic revolution. Let’s explore the key elements that are driving this vision for Rajasthan’s economic future.

From ₹15 Lakh Crore to ₹30 Lakh Crore: The Road Ahead

Rajyavardhan Singh Rathore, in his address at the summit, set the tone for Rajasthan’s ambitious growth plans. He stated that the previous Congress government left the state’s economy at ₹15 lakh crore, but the state is now targeting a bold and transformative leap to ₹30 lakh crore within the next four years. This growth is expected to come from a combination of factors, including a more business-friendly environment, focus on innovation, infrastructure development, and expanding the state’s industrial base.

The core of this vision is the recognition that Rajasthan is no longer just a state dependent on agriculture and mining. Over the past few years, it has rapidly diversified into other sectors, and the current government’s focus on boosting manufacturing, renewable energy, tourism, and technology is set to accelerate this growth.

Key Drivers of Rajasthan’s Economic Growth

1. Industrialization and Infrastructure Development

One of the primary drivers of Rajasthan’s economic growth is its increasing industrial output. The state has emerged as a major player in sectors like manufacturing, textiles, and electronics. With the government’s focus on improving infrastructure — especially transport, logistics, and industrial corridors — Rajasthan is becoming a hub for industries looking to tap into India’s growing demand for goods and services.

The development of the Delhi-Mumbai Industrial Corridor (DMIC) and other projects such as the Rajasthan Investment Promotion Scheme (RIPS) are opening up new opportunities for large-scale industrial growth. Rajasthan’s favorable policies and initiatives, including subsidies, tax breaks, and incentives for businesses, are attracting both domestic and foreign investments. These measures are expected to make the state a manufacturing powerhouse and increase its contribution to India’s overall GDP.

2. Renewable Energy Leadership

Rajasthan is already a leader in renewable energy, particularly in solar energy. The state boasts some of the best solar energy resources in India, making it a key player in the country’s transition to renewable energy. The government has set ambitious goals to expand solar energy capacity, with plans to increase renewable energy output significantly over the next few years.

By harnessing the power of the sun, Rajasthan aims to become a global leader in renewable energy, not just for domestic consumption but for export as well. This growth in renewable energy will not only generate power but also create jobs, drive investment, and make Rajasthan a key player in the global green energy revolution.

3. Tourism as a Growth Catalyst

Rajasthan is one of India’s most visited states, with its royal history, palaces, forts, and natural beauty attracting millions of tourists every year. The government has recognized the immense potential in expanding the tourism sector, especially eco-tourism, adventure tourism, and cultural tourism.

The Rising Rajasthan Summit also highlighted the opportunities in creating world-class infrastructure for tourists, developing new tourist circuits, and leveraging digital platforms for promoting tourism. By enhancing tourism infrastructure, Rajasthan can generate significant economic activity, create employment, and contribute to the overall growth of the state’s economy.

4. Skilled Workforce and Education

A critical component of Rajasthan’s economic future is its focus on skill development. The government is committed to improving education, providing job-specific training, and building a workforce that is capable of meeting the demands of a rapidly changing economy.

With an emphasis on sectors like information technology, engineering, healthcare, and tourism, the state is creating the necessary human capital to drive its ambitious growth targets. Skill development centers, vocational training institutes, and a focus on entrepreneurship are expected to empower the youth of Rajasthan to become contributors to the state’s economic growth.

The Role of the Rising Rajasthan Summit

The Rising Rajasthan Global Investment Summit 2024 was not just an event, but a significant milestone in the state’s journey towards achieving its economic goals. The summit served as a platform to showcase the state’s potential to global investors and business leaders, while also highlighting the government’s commitment to building an ecosystem that supports growth and innovation.

The summit emphasized the state’s readiness to embrace new technologies, foster innovation, and ensure that Rajasthan remains at the forefront of India’s industrial and economic transformation. From attracting foreign direct investment (FDI) to promoting local entrepreneurs, the summit is expected to catalyze the economic growth needed to reach the ₹30 lakh crore target.

Challenges and Opportunities

While Rajasthan’s growth prospects are incredibly promising, the journey to a ₹30 lakh crore economy will not be without its challenges. Issues such as improving infrastructure, ensuring sustainable growth, bridging the urban-rural divide, and promoting inclusive development need to be addressed. However, the government is aware of these challenges and is actively working towards overcoming them.

The vision of a ₹30 lakh crore economy by 2028 is ambitious, but with the right policies, leadership, and collaborations, it is achievable. The state’s vast resources, industrial potential, and commitment to innovation make it an exciting place to invest and do business.

Rajyavardhan Singh Rathore’s statement at the Rising Rajasthan Global Investment Summit 2024 marks the beginning of a bold new chapter for Rajasthan. With an economy poised to more than double in just four years, the state is entering a period of rapid transformation. The summit is a clear signal that Rajasthan is not only rising but is ready to become a key player in India’s economic future.

As the state continues to diversify its economy, attract global investments, and innovate across sectors, Rajasthan is setting itself on a trajectory of sustainable, inclusive, and dynamic growth. The next few years will define the state’s future, and if the ambitious vision laid out by the government is realized, Rajasthan will become one of the most powerful economic engines in India.

4 notes

·

View notes

Text

Preserving Assets: The Role of Corrosion Inhibitors in Industrial Maintenance

Corrosion is a persistent threat to industrial assets, causing billions of dollars in damages annually across various sectors. From oil and gas facilities to manufacturing plants, the impact of corrosion can be devastating, leading to equipment failures, production downtime, and costly repairs. However, with the right preventive measures in place, such as corrosion inhibitors, industrial facilities can effectively mitigate the risk of corrosion and prolong the lifespan of their assets. As a leading chemical company in Vadodara, Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) understands the critical role of corrosion inhibitors in industrial maintenance. In this blog post, we'll explore the importance of corrosion inhibitors, their applications, and the expertise of ICPL as a corrosion inhibitor manufacturer and exporter in India.

Understanding Corrosion Inhibitors

Corrosion inhibitors are chemical compounds designed to protect metal surfaces from the damaging effects of corrosion. By forming a protective barrier on the metal surface or altering the corrosion process, inhibitors prevent or slow down the oxidation and deterioration of metals in corrosive environments. Corrosion inhibitors are widely used in various industries, including oil and gas, petrochemicals, power generation, water treatment, and manufacturing, to safeguard critical assets and infrastructure from corrosion-related failures.

The Importance of Corrosion Inhibitors in Industrial Maintenance

1. Asset Protection: Industrial facilities rely heavily on equipment and infrastructure made of metal, such as pipelines, tanks, vessels, and machinery. Corrosion inhibitors play a crucial role in protecting these assets from corrosion, extending their service life and reducing the need for frequent repairs or replacements.

2. Cost Savings: Corrosion-related failures can result in significant financial losses due to equipment downtime, production disruptions, and repair expenses. By incorporating corrosion inhibitors into maintenance programs, industries can minimize the risk of corrosion-related failures and realize substantial cost savings in the long run.

3. Safety and Reliability: Corrosion compromises the structural integrity of industrial assets, posing safety hazards to personnel and the surrounding environment. Corrosion inhibitors help maintain the reliability and safety of critical infrastructure, reducing the likelihood of accidents, spills, and environmental contamination.

4. Environmental Protection: Corrosion-related leaks and spills can have detrimental environmental consequences, polluting soil, water bodies, and ecosystems. By preventing corrosion and minimizing the risk of leaks and spills, corrosion inhibitors contribute to environmental protection and sustainability efforts.

Applications of Corrosion Inhibitors

Corrosion inhibitors find applications across various industrial sectors, where metal components are exposed to corrosive environments. Some common applications of corrosion inhibitors include:

Oil and Gas Production: In the oil and gas industry, corrosion inhibitors are used to protect pipelines, well casings, and production equipment from corrosion caused by corrosive fluids, gases, and environmental conditions.

Water Treatment: Corrosion inhibitors are added to cooling water systems, boilers, and wastewater treatment facilities to prevent metal corrosion caused by dissolved oxygen, scale formation, and aggressive ions.

Manufacturing: In manufacturing processes involving metal components, such as automotive, aerospace, and electronics manufacturing, corrosion inhibitors are used to protect parts, components, and machinery from corrosion during production, storage, and transportation.

Marine and Offshore Structures: Corrosion inhibitors are applied to marine vessels, offshore platforms, and coastal structures to protect against corrosion in seawater environments.

ICPL: Your Trusted Corrosion Inhibitor Manufacturer and Exporter in India

As the best chemical company in Vadodara, ICPL is dedicated to delivering high-quality corrosion inhibitors tailored to the specific needs of industrial clients. Here's why ICPL is the preferred choice for corrosion inhibitors in India:

Expertise and Experience: With decades of experience in the chemical industry, ICPL possesses the expertise and technical know-how to develop and manufacture corrosion inhibitors that meet the highest quality standards and regulatory requirements.

State-of-the-Art Facilities: ICPL operates state-of-the-art manufacturing facilities equipped with advanced technologies and production processes to ensure the consistent quality and performance of its corrosion inhibitors.

Customized Solutions: ICPL offers customized corrosion inhibitor formulations tailored to the unique requirements and operating conditions of industrial applications. Our team of experts works closely with clients to develop solutions that address specific corrosion challenges and performance objectives.

Global Reach: As a corrosion inhibitor exporter in India, ICPL serves clients worldwide, exporting its products to diverse markets across Asia, Africa, the Middle East, and beyond. With a strong global presence and distribution network, ICPL delivers reliable corrosion protection solutions to industries around the globe.

Conclusion

In conclusion, corrosion inhibitors play a crucial role in industrial maintenance by protecting metal assets from the damaging effects of corrosion. As a leading corrosion inhibitor manufacturer and exporter in India, ICPL is committed to providing high-quality corrosion inhibitors that safeguard critical infrastructure, ensure operational reliability, and promote cost-effective maintenance practices. With ICPL's expertise, customized solutions, and global reach, industries can effectively mitigate the risk of corrosion and preserve the integrity of their assets for years to come. Contact ICPL today to learn more about our corrosion inhibitor products and solutions.

#Corrosion inhibitor Vadodara#Best chemical company in Vadodara#Corrosion Inhibitor exporter in India#Corrosion inhibitors manufacturer in India#Oxygen scavenger Chemical in Vadodara#Oxygen scavenger Chemical supplier in Gujarat#Oxygen scavenger Chemical Manufacture India#Oxygen scavenger Chemical exporter in Gujarat#Oil and gas industry#Oil and gas companies#Oil and gas pipelines#leading Oilfield Chemicals manufacturer and exporter in India

7 notes

·

View notes

Text

Digital Signature Certificate for Import-Export Code (IEC) Registration

The Import-Export Code (IEC) is a unique identification number required by businesses involved in the import or export of goods and services in India. One of the mandatory requirements for IEC registration is the submission of documents using a Digital Signature Certificate (DSC). This blog explains the importance of DSCs in the IEC registration process, how they are used, and why securing your DSC is crucial for your business’s growth in international trade.

What is the Import-Export Code (IEC)?

The Import-Export Code (IEC) is a key business identification number provided by the Directorate General of Foreign Trade (DGFT). It is mandatory for businesses wishing to engage in international trade activities. Whether you’re a manufacturer, wholesaler, or trader, an IEC is essential for clearing goods through customs, making payments for exports/imports, and availing other export benefits.

Why is a Digital Signature Certificate (DSC) Needed for IEC Registration?

E-Filing Requirement: The DGFT requires businesses to submit their IEC registration forms electronically via the DGFT portal. To sign and submit these online forms, you need a Digital Signature Certificate (DSC). This DSC ensures that the forms are validated and processed by the authorities without the risk of fraud.

Ensures Legal Validity: A DSC is recognized under the Information Technology Act, 2000, and serves as a legally valid electronic signature. This makes it possible for the IEC application to be processed legally, just like a traditional paper submission.

Prevents Tampering: The use of encryption technology in DSCs ensures that the information submitted for IEC registration cannot be altered once it’s been signed, thus preventing tampering or fraudulent modifications to the documents.

Faster Processing: Using a DSC speeds up the entire IEC registration process. Since the registration is done electronically, you can avoid delays associated with manual document submission and processing.

How to Apply for IEC Registration with a DSC

Obtain a Digital Signature Certificate (DSC): To apply for an IEC, you first need to obtain a DSC from a Certifying Authority (CA). You can choose between Class 2 and Class 3 DSCs, with Class 3 being the more secure option for business-related applications like IEC registration.

Prepare the Required Documents: The DGFT requires various documents for IEC registration, such as the PAN card, proof of address, bank certificate, and the identity of the applicant. Along with these documents, you will need your DSC to authenticate and sign the application.

Register on the DGFT Portal: Visit the DGFT’s official website and create an account. After registering, log in to complete the IEC application form online. During this process, you’ll be asked to upload your documents.

Attach the DSC: Once you’ve completed the form and uploaded all the necessary documents, you’ll need to sign the form using your DSC. This step ensures the authenticity of the registration application and validates your submission.

Submit the Application: After attaching your DSC, submit the application. The DGFT will process your application, and once it is approved, your IEC will be issued electronically.

Benefits of Using DSC for IEC Registration

Security: The encryption technology in DSCs secures your business’s data and ensures that sensitive information remains protected during the registration process.

Legitimacy: With a DSC, you can ensure that your IEC registration is legally valid, reducing the chances of rejection or delays due to discrepancies.

Efficiency: The use of DSC reduces the manual effort involved in IEC registration and ensures that your application is processed more quickly.

Reduced Fraud Risks: Since the DSC links your identity to the submitted documents, it prevents any fraudulent or unauthorized transactions, protecting your business from potential legal and financial issues.

Conclusion

A Digital Signature Certificate (DSC) plays an integral role in securing and facilitating the Import-Export Code (IEC) registration process. By ensuring the authenticity of your online submission and protecting your business’s sensitive data, a DSC is essential for those seeking to engage in international trade. For a smooth IEC registration experience, consult with the Best CA Firm in Delhi, which can help you obtain a DSC and guide you through the entire registration process, ensuring your business is ready for global expansion.

2 notes

·

View notes

Text

A Comprehensive Guide to Company Formation Process in India with MAS LLP

Introduction: Forming a company in India is a significant step toward building a successful business. Whether you're a budding entrepreneur or an established business looking to expand, understanding the company formation process is crucial. MAS LLP offers expert guidance to help you navigate the complexities of establishing a company in India. In this blog, we'll walk you through the detailed steps involved in the company formation process and how MAS LLP can assist you every step of the way. Why Choose India for Company Formation? Growing Economy India's economy is one of the fastest-growing in the world, making it an attractive destination for business ventures. With a large consumer base and favorable government policies, India offers immense potential for growth and profitability. Ease of Doing Business The Indian government has undertaken several reforms to simplify the process of doing business. These include streamlined regulatory procedures, improved infrastructure, and various incentives for startups and foreign investors. Diverse Market India's diverse market provides opportunities across various sectors such as technology, manufacturing, retail, and services. This diversity allows businesses to explore multiple avenues for expansion and revenue generation. Steps in the Company Formation Process in India

Choose the Type of Company The first step is to decide the type of company you want to form. The most common types include: Private Limited Company: Ideal for small to medium-sized businesses. Public Limited Company: Suitable for large businesses looking to raise capital from the public. Limited Liability Partnership (LLP): Combines the benefits of a partnership and a company. One Person Company (OPC): Perfect for solo entrepreneurs.

Obtain Digital Signature Certificate (DSC) A Digital Signature Certificate is required for filing electronic documents with the Ministry of Corporate Affairs (MCA). Authorized directors must obtain their DSC from a certified agency.

Acquire Director Identification Number (DIN) Directors must apply for a Director Identification Number by submitting the necessary documents and forms to the MCA. DIN is a unique identifier for each director.

Name Approval Choose a unique name for your company and apply for name approval through the MCA portal. Ensure the name adheres to the naming guidelines set by the MCA.

Drafting of Incorporation Documents Prepare the necessary incorporation documents, including the Memorandum of Association (MOA) and Articles of Association (AOA). These documents outline the company's objectives, rules, and regulations.

Filing Incorporation Forms Submit the incorporation forms along with the required documents to the MCA. This includes Form SPICe (Simplified Proforma for Incorporating Company Electronically), MOA, AOA, and other relevant forms.

Payment of Fees Pay the registration fees and stamp duty as applicable. The fees vary based on the authorized capital of the company and the state in which it is being registered.

Certificate of Incorporation Once the MCA verifies the documents and approves the application, a Certificate of Incorporation is issued. This certificate signifies the legal existence of your company. How MAS LLP Can Assist You Expert Guidance MAS LLP offers expert advice and guidance throughout the company formation process. Our team of experienced professionals ensures that all legal requirements are met and that the process is smooth and hassle-free. Document Preparation We assist in preparing and filing all necessary documents, including DSC, DIN, MOA, and AOA. Our meticulous approach ensures accuracy and compliance with regulatory standards. Name Approval Assistance Choosing a unique and compliant company name can be challenging. MAS LLP helps you select and apply for a name that aligns with MCA guidelines and your business objectives. End-to-End Support From the initial consultation to obtaining the Certificate of Incorporation, MAS LLP provides end-to-end support. We handle all the paperwork, filings, and communications with the MCA on your behalf. Conclusion Forming a company in India involves several critical steps, each requiring careful attention to detail. With MAS LLP, you can navigate the company formation process with confidence and ease. Our comprehensive services ensure that your business is set up correctly and efficiently, allowing you to focus on your core business activities. Contact MAS LLP today to start your journey toward successful company formation in India.

#audit#accounting & bookkeeping services in india#income tax#ajsh#auditor#businessregistration#chartered accountant#foreign companies registration in india#taxation#ap management services

4 notes

·

View notes

Text

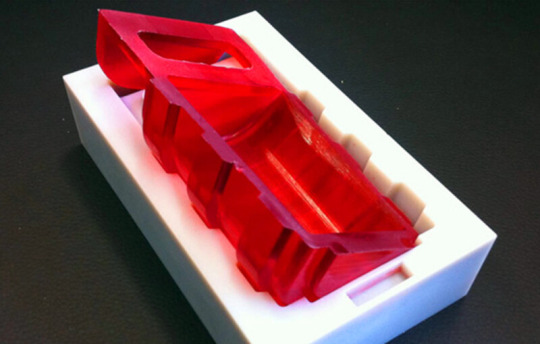

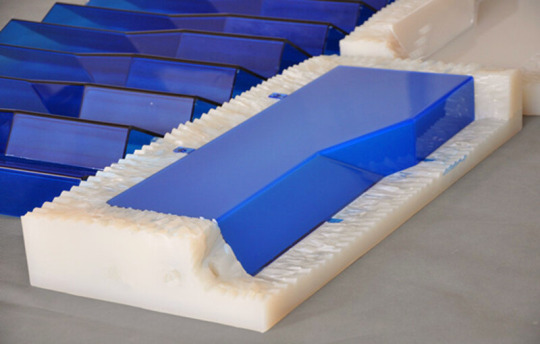

Working of Vacuum Casting and Its Multiple Uses

To make complicated components, a liquid substance is sucked into a silicone mold under vacuum. This method is known as vacuum casting. Rubber and plastic are examples of elastomers that are utilized as liquid materials in vacuum casting.

Since polyurethane resin, a kind of elastomer is employed as the casting medium, vacuum casting is also frequently referred to as polyurethane casting or urethane casting. When producing plastic components, vacuum casting is a more cost-effective method than injection molding because of its reduced manufacturing costs.

For batch manufacturing and other low-volume production tasks, vacuum casting is a great method of production. Vacuum casting is widely utilized in India's manufacturing of industrial electronics, FMCG, and consumer goods.

How do you work with vacuum casting?

Injection molding, in which cast material is poured into molds to create items, and vacuum casting services are very comparable processes. The kinds of molds used in injection molding and vacuum casting differ from one another.

Molds for injection molding might be formed of steel, aluminum, or other materials. Silicone molds are utilized in vacuum casting, nevertheless. This significantly lowers the mold-making cost because silicone is more affordable and has better durability.

Polyurethane is the most often utilized casting material in this procedure. The qualities of various polyurethanes vary, including good shock and temperature resistance, elasticity, flexibility, and structural stiffness. Thus, different polyurethanes may be employed depending on the kind of product being created.

Vacuum casting uses

Making complicated and sophisticated goods may be accomplished more cost-effectively and efficiently with vacuum casting as opposed to the conventional injection molding method.

Due to its efficient production process, vacuum casting finds widespread application in the fabrication of commercial items. The following are a few industries that employ vacuum casting:

Manufacturing of consumer goods

Vacuum casting is a more effective method of producing consumer goods including combs, hair brushes, makeup packaging, sunglasses, pens, and other stationery.

Industry of Food and Beverages

Vacuum casting is used to create food and beverage containers, bottles, cans, mugs, and glasses. Due to the process's great efficiency and ability to produce goods quickly, vacuum casting is widely utilized in various industries where rapid manufacture is essential.

Advanced industry

Excellent heat and shock resistance is a feature of polyurethanes. Therefore, the recommended production procedure for creating electrical device housings is vacuum casting by Vacuum Casting Manufacturer using polyurethanes.

Follow our Facebook and Twitter for more information about our product.

#vacuum casting#vacuum casting services#Explore vacuum casting#Vacuum Casting Services China#Vacuum Casting Manufacturer#Vacuum Casting supplier

2 notes

·

View notes

Text

Complete Manual on Hanging Scaffold Systems or Suspended Rope Platforms for plastering

In the realm of construction and maintenance tasks, there’s a stalwart ally that stands tall, quite literally. The Suspended Rope Platform (SRP), often recognized as a gondola or working platform, has become an indispensable tool for a spectrum of vertical endeavors. Specifically, in India, these platforms have etched their place firmly in various industries, revolutionizing the way projects are undertaken.

Evolution of Rope Suspended Platforms

Initially embraced primarily by major facade contractors, the trajectory of SRPs has undergone a significant shift. Over the past three years, a seismic shift has been witnessed, with the paint industry, spanning from manufacturers to applicators, showing an avid interest. This surge in demand has propelled manufacturers of these platforms to the forefront, dominating the market for close to a decade.

The utilization of Suspended Rope Platform isn’t confined to a singular purpose. From external wall plastering, painting high-rise structures, installing glass facades to the maintenance of expansive external surfaces, the applications are diverse and extensive. Even in scenarios necessitating alterations or demolition of buildings, these platforms emerge as indispensable temporary structures.

The Rise of Rope Suspended Platforms

What sets SRPs apart is their ascendance as the preferred mode of access across construction sites. Traditionally, scaffolding held sway, but the inherent advantages of SRPs, including efficiency and versatility, have prompted their ubiquitous presence in the construction landscape.

Quality and Innovation

Platforms like the hanging rope platform hoists from Jaypee India epitomize excellence, constructed meticulously using premium materials such as stainless steel and aluminum. The emphasis on stringent quality control ensures adherence to specified durability and reliability standards, ensuring that only the finest products reach customers.

Moreover, manufacturers of SRPs have undertaken a trajectory of innovation. Varied versions of these platforms cater to diverse job site specifications. Engineers have meticulously designed these platforms, integrating multiple safety measures to mitigate the inherent risks associated with erecting and maintaining tall structures.

Safety Features and Engineering Excellence

Safety stands paramount in the realm of suspended platforms. Manufacturers have embedded an array of safety features into their products to ensure secure operations:

Rope Failure Prevention: Incorporating locks to prevent tilting due to rope failure.

Advanced Technology: Integration of sophisticated mechanical and control electronics.

Quality Wire Ropes: Utilization of high-grade steel wire ropes to guarantee robustness.

Optional Overload Sensing: Offering the option for sensing overload, further enhancing safety.

Cable Locking Angle: Ensuring a secure cable locking angle of 3–8 degrees.

Superior Suspension Systems: Technologically superior suspension systems enhancing stability.

Durability: A testament to longevity, these platforms are engineered to withstand prolonged usage without succumbing to wear and tear.

Sturdy Construction: With a solid construction, these platforms exude reliability and stability.

Energy Efficiency: Notably, the energy requirements for operating these platforms are considerably lower compared to alternative access systems.

Proficient Management and Operations

One defining aspect of the Suspended Rope Platform (SRP),landscape in India is the involvement of extensively trained professionals overseeing the operation and maintenance of these platforms. Amidst a competitive market, manufacturers differentiate themselves by providing top-tier suspended platform services. These adept specialists, well-versed in every facet of access equipment, ensure superior maintenance and repair services right on the job site. From initial setup to operationalizing the platform, these professionals handle it all with finesse and expertise.

In conclusion, the evolution of suspended rope platforms for plastering and other vertical endeavors has heralded a paradigm shift in the construction and maintenance landscape. With an emphasis on safety, innovation, and efficiency, these platforms have become the linchpin in accessing vertical spaces, promising durability, reliability, and optimal performance. As the industry continues to evolve, these platforms are poised to remain at the vanguard, catering to the ever-expanding demands of vertical construction and maintenance tasks.

#Suspended rope platform for plastering#Suspended rope platform#Rope Suspended platform for plastering#Buy Suspended Rope Platform#Rope Suspended Platform (RSP)#Construction Equipment Manufacturer and Supplier in India#Construction Equipment#Facade cleaning system manufacturers in india#Gondola Suspended Rope Platform Manufacturer

3 notes

·

View notes

Text

BIS (Bureau of Indian Standards) certification is a mandatory quality and safety certification process in India that ensures products conform to specific standards and regulations set by the BIS. This certification is designed to guarantee that various products, ranging from electronics and appliances to industrial goods and food products, meet the established quality, performance, and reliability requirements. Manufacturers are required to obtain a BIS license, adhere to BIS standards, and label their products with the BIS mark, signifying compliance. BIS certification plays a critical role in consumer protection, product safety, and the promotion of quality standards within the Indian market, both for domestically manufactured and imported goods.

https://www.agileregulatory.com/service/bis-certification

#bis certification#bis certification for electronic products#bis hallmark certificate#bis certification list#bis registration#hallmark#fmcs#bisfmcs#bisforeignmanufacturer#bishallmark#isimark#Bisconsultant#bislicense#biscrs#bisisimark#bisforimport#biscertificationforimport

2 notes

·

View notes

Text

Ammonium Hepta Molybdate Innovations 2023: Trends Shaping the Industry

Ammonium hepta molybdate, a chemical molecule with a complex nomenclature, holds significant importance across diverse sectors. The year 2023 is anticipated to bring forth noteworthy advancements that will influence its trajectory going forward. From manufacturing to delivery, Palvi Chemicals – an excellent Ammonium Hepta Molybdate manufacturer in India prioritizes quality and service. Secure your Ammonium Hepta Molybdate supply with Palvi Chemicals for a seamless experience.

In this blog, we shall delve into the present patterns and progressions in the realm of Ammonium Hepta Molybdate, examining its importance in many industries.

Understanding Ammonium Hepta Molybdate:

To have a comprehensive understanding of Ammonium Hepta Molybdate, it is essential to begin with a foundational knowledge of its properties and characteristics. Ammonium hepta molybdate is a solid chemical with a crystalline structure, characterised by its white colour. It is formed of ions of molybdenum, oxygen, and ammonium. The chemical in question exhibits a wide range of uses spanning several industries, including agriculture, electronics, and metallurgy, hence conferring significant value in contemporary society.

Trends and Innovations in 2023:

· Sustainable Agriculture:

One of the prevailing trends observed in the year 2023 pertains to the escalated utilisation of Ammonium Hepta Molybdate within the realm of sustainable agricultural practices. In light of global concerns surrounding food security and environmental sustainability, it is becoming increasingly evident that this chemical plays a crucial role in contemporary agricultural practices.

The application of Ammonium Hepta Molybdate has been found to promote the growth of leguminous crops by its facilitation of nitrogen fixation, hence mitigating the reliance on synthetic fertilisers. This innovation not only enhances agricultural productivity but also mitigates the ecological footprint associated with farming practices. Ensure the quality and reliability of your chemicals. Choose Palvi Chemicals as your trusted Ammonium Hepta Molybdate exporter in UAE for your industrial needs!

· Advanced Electronics:

The utilisation of Ammonium Hepta Molybdate in cutting-edge technology has garnered significant attention within the electronics sector. The utilisation of this substance is prevalent in the manufacturing processes of sophisticated semiconductors and thin-film transistors. The increasing demand for smaller and more efficient electronic devices has underscored the significance of high-performance materials such as Ammonium Hepta Molybdate.

The year 2023 witnesses a concentrated effort towards enhancing production techniques and enhancing the electrical characteristics of materials based on Ammonium Hepta Molybdate. These advancements play a significant role in the advancement of quicker and more energy-efficient electronic devices.

· Metallurgy and Corrosion Protection:

Ammonium hepta molybdate has been widely employed as a corrosion inhibitor in diverse industrial sectors, such as the oil and gas, aerospace, and automotive industries. The advancements in the year 2023 primarily focus on enhancing the efficacy and longevity of corrosion protection measures for metal surfaces.

Ongoing research efforts are focused on the development of advanced coatings and alloys that incorporate Ammonium Hepta Molybdate, with the aim of significantly prolonging the durability of crucial components and infrastructure. Not only does this result in cost savings in terms of maintenance, but it also contributes to the improvement of safety and reliability. Maximize your worldwide research and production efficiency with Ammonium Hepta Molybdate offered by one of the top Ammonium Hepta Molybdate traders in UAE – Palvi Chemicals. Explore the product range and place your order today.

· Healthcare and Pharmaceuticals:

In the field of healthcare and pharmaceuticals, Ammonium Hepta Molybdate is demonstrating potential as a catalyst and reagent in the synthesis of significant medications and pharmaceutical intermediates. The objective of advancements in this particular domain is to optimise production procedures and mitigate the ecological impact associated with the manufacturing of pharmaceuticals.

The distinctive characteristics of the molecule facilitate the development of medications that are more efficient and environmentally sustainable, hence leading to cost reductions and promoting environmental consciousness within the pharmaceutical sector.

· Energy Storage:

Ammonium hepta molybdate has gained significance in the renewable energy industry, specifically in the domain of energy storage systems. The growing use of solar and wind energy has led to a significant need for energy storage technologies that are both efficient and economically viable.

Scientists are currently investigating the possible applications of materials based on Ammonium Hepta Molybdate in the development of advanced batteries and supercapacitors for future generations. These technological advancements have the potential to greatly enhance the capacity and reliability of energy storage systems, thereby expediting the shift towards a more environmentally friendly energy framework. Rely on Palvi Chemicals - the most trusted Ammonium Hepta Molybdate supplier in UAE for consistent supply and top-notch quality products.

Final Thoughts:

The year 2023 marks a period of significant advancements in the field of Ammonium Hepta Molybdate, which are having a transformative impact on various industries like agriculture, electronics, metallurgy, healthcare, and energy. The wide range of applications and distinct characteristics of this asset render it highly helpful in tackling present-day concerns pertaining to sustainability and technological progress.

As the year progresses, it will be intriguing to observe the ongoing development and impact of these advances on the dynamic realms of research and industry, thereby reinforcing the pivotal role of Ammonium Hepta Molybdate in moulding our future. Please remain updated for additional advancements in this ever-evolving domain. Elevate your chemical research and production with one of the best Molybdenum chemicals manufacturers in India, Palvi Chemicals. Connect with the experts at Palvi Chemicals now to initiate a prosperous partnership!

#Ammonium Hepta Molybdate exporter in UAE#Ammonium Hepta Molybdate manufacturer in India#Ammonium Hepta Molybdate traders in UAE#Ammonium Hepta Molybdate supplier in UAE#Molybdenum chemicals manufacturers in India

5 notes

·

View notes

Text

CNC Laser Cutting Machine Price: A Comprehensive Guide

In today’s competitive industrial landscape, CNC laser cutting machines have revolutionized manufacturing, offering precision, speed, and cost-effectiveness. Businesses across sectors, including automotive, aerospace, metal fabrication, and signage, are leveraging these advanced machines to enhance productivity. However, one of the most crucial considerations for businesses is the CNC laser cutting machine price and its return on investment. In this guide, we will break down the cost factors, machine types, and how to choose the best CNC laser cutter for your needs.

Factors Affecting CNC Laser Cutting Machine Price

The price of a CNC laser cutting machine varies widely, depending on several key factors:

1. Laser Type

The type of laser source significantly impacts the cost. The three primary types are:

Fiber Laser Cutting Machines – High efficiency, best for cutting metals, and relatively higher in price.

CO2 Laser Cutting Machines – Suitable for non-metal materials like wood, acrylic, and plastics, usually more affordable than fiber lasers.

Diode Lasers – Typically used for engraving and small-scale applications.

2. Power Output (Wattage)

Higher wattage results in faster cutting speeds and the ability to cut thicker materials. However, it also increases the machine’s cost. CNC laser cutters range from 500W to 12kW, with higher power models priced significantly higher.

3. Cutting Bed Size

Larger working areas allow for cutting bigger sheets, making industrial-scale production more efficient. A larger bed size will add to the overall cost of the machine.

4. Brand and Manufacturer

Reputable brands like SLTL Group, known for innovation and reliability, may have higher upfront costs but ensure superior performance, durability, and after-sales support.

5. Additional Features & Automation

Modern CNC laser cutting machines come with features like auto-focus, AI-powered cutting path optimization, real-time monitoring, and safety enclosures, which can increase the price but improve efficiency and ease of use.

6. Maintenance and Operating Costs

Apart from the initial investment, factors such as power consumption, lens replacement, gas usage, and service costs contribute to the long-term expenses of owning a CNC laser cutter.

7. Software and Integration Capabilities

Many CNC laser cutting machines are integrated with CAD/CAM software, IoT-enabled remote monitoring, and automation features. These additions make the machines more efficient but also contribute to a higher cost.

8. Customization and Industry-Specific Requirements

Industries such as automotive, shipbuilding, and electronics may require customized CNC laser cutting solutions with specific automation, which impacts pricing.

CNC Laser Cutting Machine Price Range in India

While prices vary based on the factors above, here is an estimated price range:

Entry-Level CO2 Laser Cutting Machine – ₹5,00,000 to ₹15,00,000

Mid-Range Fiber Laser Cutting Machine (1kW – 3kW) – ₹20,00,000 to ₹50,00,000

High-End Industrial CNC Fiber Laser (4kW – 12kW) – ₹60,00,000 to ₹2,00,00,000

For an accurate quote, it is advisable to contact a reliable manufacturer like SLTL Group (www.sltl.com).

How to Choose the Right CNC Laser Cutting Machine?

Selecting the right CNC laser cutter depends on your specific needs and budget. Consider the following:

Material Type – Choose fiber laser for metals and CO2 laser for non-metals.

Production Volume – Industrial-scale businesses should invest in high-power fiber laser machines for bulk production.

Budget Constraints – Balance initial cost with long-term savings on maintenance and energy efficiency.

After-Sales Support – Opt for a manufacturer with a robust support system like SLTL Group to ensure smooth operations.

Ease of Use & Training – A user-friendly machine with proper training support ensures better productivity and less downtime.

Benefits of CNC Laser Cutting Machines

Investing in a CNC laser cutting machine comes with several advantages:

1. High Precision & Accuracy

CNC laser cutters offer exceptional cutting precision, ensuring intricate and detailed designs.

2. Faster Production Time

Automated laser cutters complete tasks much faster than traditional cutting methods, reducing production time.

3. Minimal Material Waste

Advanced laser technology ensures efficient use of materials, reducing overall waste and production costs.

4. Low Maintenance Costs

Compared to conventional cutting methods, CNC laser cutters require minimal maintenance, enhancing cost savings over time.

5. Versatility in Materials

These machines can cut a variety of materials, including metals, plastics, wood, and composites.

Why Choose SLTL Group for CNC Laser Cutting Machines?

SLTL Group is a pioneer in laser technology and offers a diverse range of CNC laser cutting machines that cater to different industrial needs. With cutting-edge innovation, superior precision, and a strong customer support network, SLTL is the go-to choice for businesses looking for high-quality laser cutters.

Key Benefits of SLTL Laser Cutting Machines:

Advanced fiber laser technology for high-speed precision cutting

Energy-efficient solutions to reduce operational costs

Customizable machines tailored to industry requirements

Strong after-sales service and maintenance support

IoT-enabled smart monitoring for real-time performance tracking

Compliance with international safety and quality standards

Final Thoughts

Investing in a CNC laser cutting machine is a strategic decision that requires careful consideration of price, performance, and long-term benefits. Whether you are a small business or a large-scale manufacturer, understanding the CNC laser cutting machine price and choosing the right machine will ensure maximum productivity and cost-efficiency.

By selecting a trusted and experienced manufacturer like SLTL Group, you can ensure that your investment in a laser cutting machine is cost-effective, reliable, and future-proof. SLTL’s advanced laser solutions, combined with superior customer service, make them a top choice for industries seeking high-quality laser cutting technology.

For the best CNC laser cutting machines in India, explore the advanced solutions offered by SLTL Group at www.sltl.com.

0 notes

Text

PSA Nitrogen Generator – Efficient, Cost-Effective, and High-Purity Nitrogen Supply

A PSA Nitrogen Generator is an advanced solution for producing high-purity nitrogen gas used in various industries. Using a Carbon Molecular Sieve (CMS) and a twin-tower system, this technology efficiently separates nitrogen from atmospheric air, ensuring a continuous supply of nitrogen without relying on external gas cylinders. With easy installation, low maintenance, and automatic operation, PSA nitrogen generators offer an energy-efficient and cost-effective alternative for industrial nitrogen production.

How Does a PSA Nitrogen Generator Work?

The PSA (Pressure Swing Adsorption) technology operates with two towers filled with Carbon Molecular Sieve (CMS). The process includes:

Air Compression & Filtration – Atmospheric air is compressed and passed through an air dryer and filters to remove moisture and impurities.

Separation Process – The twin-tower system alternates between adsorption and regeneration. One tower extracts oxygen and other gases, while the other regenerates for continuous operation.

Nitrogen Collection – The purified nitrogen is stored in a surge vessel and delivered to industrial applications.

Pressure Regulation – A Back Pressure Regulator (BPR) maintains the required pressure level for efficient gas flow.

Purity Control – An Online Oxygen Analyzer ensures the nitrogen meets the desired purity levels before being supplied for use.

This fully automated process eliminates the need for manual intervention, ensuring low operating costs and high efficiency.

Key Features of PSA Nitrogen Plants

✔ Air Compressor (Screw Type) – Supplies compressed air for nitrogen separation ✔ Air Dryer & Filters – Removes moisture, dust, and impurities ✔ Twin-Tower CMS System – Ensures maximum nitrogen purity ✔ Surge Vessel & Control Panels – Maintains stable pressure and gas flow ✔ Oxygen Analyzer & Rota Meter – Monitors purity and gas flow rates

Advantages of PSA Nitrogen Generators

✅ Cost-Effective & Energy Efficient – Produces nitrogen at a lower cost compared to traditional gas cylinders ✅ Eliminates Cylinder Dependency – No need to purchase, store, or transport nitrogen gas cylinders ✅ Compact & Space-Saving Design – Occupies minimal space in industrial setups ✅ Automatic Operation – Works on demand and stops when the required nitrogen level is reached ✅ Low Maintenance – Requires minimal servicing and has a long operational life ✅ Fast Installation & Service Support – Comes with quick after-sales service and a warranty

Technical Specifications

ParameterDetailsCapacity5 NM³ to 1000 NM³/HrMaterial of ConstructionMS/SS (Based on application)Nitrogen Purity95% to 99.999%OperationFully Automatic

Industries That Use PSA Nitrogen Generators

✔ Food & Beverage – Prevents oxidation and spoilage ✔ Pharmaceuticals – Used in drug manufacturing and packaging ✔ Electronics – Protects components from oxidation ✔ Chemical & Petrochemical – Essential for inerting and blanketing applications ✔ Metal Processing – Used in laser cutting and heat treatment

Why Choose Trimech India?

At Trimech India, we specialize in manufacturing high-quality PSA Nitrogen Generators designed to meet industry-specific requirements. Our products are known for their durability, efficiency, and advanced technology. We provide:

✔ Pre-installation consultation ✔ On-site installation & setup ✔ Comprehensive user training ✔ Quick 48-hour service response ✔ Warranty & free maintenance support

Contact Us Today!

📩 Email: [email protected] 📞 Phone: +91-79-25840557

0 notes

Text

Top DM Plant Manufacturers in Mumbai – Water Enviro Engineers

In today’s industrial landscape, the need for high-purity water is more critical than ever. Industries such as pharmaceuticals, chemicals, food processing, and power plants rely heavily on De-Mineralization (DM) plants to remove dissolved impurities and produce pure water. In Mumbai, several manufacturers offer cutting-edge DM plants, but Water Enviro Engineers stands out for its exceptional quality, advanced technology, and reliable services.

✅ About Water Enviro Engineers

Water Enviro Engineers is a renowned name in the water treatment industry, recognized for manufacturing and supplying DM plants in Mumbai and across India. With years of experience, the company offers customized solutions tailored to meet the specific water purification needs of various industries. Their DM plants are designed for maximum efficiency, ensuring the removal of dissolved solids, salts, and mineral ions, delivering high-purity water suitable for industrial applications.

🔹 Why Choose Water Enviro Engineers for DM Plants in Mumbai?

High-Quality Manufacturing Standards: Water Enviro Engineers follows stringent manufacturing processes, using high-grade materials and the latest technology. Their DM plants are designed to ensure optimal performance, longevity, and low maintenance.

Custom-Built DM Plants: Every industry has unique water purification needs. Water Enviro Engineers provides customized DM plants that meet the specific capacity, flow rate, and purity requirements of clients in Mumbai and across India.

Energy-Efficient and Cost-Effective: The company’s DM plants are engineered for energy efficiency, reducing operational costs while delivering consistent water quality. Their solutions help businesses maintain sustainable operations without excessive energy consumption.

Advanced Technology and Features: Water Enviro Engineers integrates cutting-edge technology in their DM plants, including multi-stage filtration, ion exchange resins, and automatic regeneration processes. This ensures effective demineralization and consistent water purity.

After-Sales Support and Service: One of the key strengths of Water Enviro Engineers is their dedicated customer support team. From installation and commissioning to maintenance and servicing, they offer end-to-end solutions, ensuring smooth operations for clients.

🔹 Applications of DM Plants in Mumbai Industries

Water Enviro Engineers caters to a diverse range of industries, providing DM plants for various applications, including:

Pharmaceuticals: Producing high-purity water for drug manufacturing.

Power Plants: Preventing scale formation and corrosion in boilers.

Food and Beverage: Ensuring clean, impurity-free water for production processes.

Chemical Industry: Delivering demineralized water for chemical processes.

Electronics Manufacturing: Purified water for cleaning and production.

🔹 Key Features of Water Enviro Engineers’ DM Plants

Two-Bed and Mixed-Bed DM Plants: Ideal for small- to large-scale water treatment needs.

Automatic and Manual Operation: Options for greater convenience and flexibility.

Durable Construction: Built with corrosion-resistant materials for long-lasting performance.

High Flow Rates: Suitable for industrial-scale applications.

Low Maintenance: Easy-to-operate systems with minimal maintenance requirements.

🔹 Contact Water Enviro Engineers

If you are looking for top DM plant manufacturers in Mumbai, Water Enviro Engineers is your trusted partner. With their expertise, high-quality products, and customer-centric approach, they deliver reliable and efficient DM plants to meet your industrial water treatment needs.

📞 Contact us today to learn more about their DM plant solutions and get a customized quote. 👉 Visit: https://www.waterenviroengineers.com/ 📩 Email: [email protected] 📱 Phone: +91- 97683 84367

🔹 Conclusion

When it comes to DM plant manufacturers in Mumbai, Water Enviro Engineers stands out for its superior quality, advanced technology, and excellent customer support. Their customized DM plant solutions cater to a wide range of industries, ensuring consistent water purity and efficient performance. For top-tier DM plants and expert water treatment services, contact Water Enviro Engineers today.

Address: 325, Sarita, A-Wing, Prabhat Industrial Estate, near Dahisar Toll Naka, Diamond Industrial Estate, Dahisar East, Mumbai, Maharashtra 400068

#DMPlantManufacturers#WaterEnviroEngineers#DMPlantMumbai#WaterTreatmentSolutions#IndustrialWaterTreatment#PureWaterSolutions#DMPlantSuppliers#WaterPurification#WaterTreatmentExperts#DemineralizationPlant#MumbaiIndustries#IndustrialWaterSolutions#WaterPurificationSystems#DMPlantServices#WaterTreatmentPlants#PureWaterTechnology#WaterTreatmentMumbai#CustomDMPlants#EfficientWaterTreatment#ContactUs

0 notes

Text

Cas No: 107228-51-3 Manufacturers

Exploring CAS No: 107228-51-3 and its Manufacturers

CAS No: 107228-51-3 refers to a specific chemical compound widely used in various industries. Understanding the importance of the substance and the manufacturers that produce it is essential for businesses and researchers in sectors that rely on chemical products. However, instead of focusing on specific companies, this blog will delve into the general landscape of manufacturers involved in producing this compound, the industries that utilize it, and the market trends surrounding it.

What is CAS No: 107228-51-3?

CAS (Chemical Abstracts Service) numbers are unique identifiers assigned to specific chemicals. The number 107228-51-3 represents a particular compound that has various applications depending on its chemical structure and properties. Although the precise details of the compound’s use may vary, chemicals with this CAS number are typically involved in specialized applications, such as manufacturing intermediates, pharmaceutical formulations, or advanced materials.

The compound might not be as widely recognized as more common chemicals, but it plays a vital role in certain niche industries. These industries rely on suppliers who provide high-quality chemicals to meet precise regulatory and production standards.

Key Manufacturers in the Market

The production of chemicals like CAS No: 107228-51-3 typically involves a global network of manufacturers. These companies may vary in size from small specialized suppliers to large multinational corporations. Here’s an overview of the types of manufacturers you might encounter in the market:

Specialty Chemical Producers: These manufacturers often focus on creating chemicals in small to medium quantities, tailored for specific industries or applications. For example, they may produce CAS No: 107228-51-3 for use in pharmaceuticals, agrochemicals, or materials science. These companies may offer a range of chemicals that meet rigorous safety and purity standards and may even provide custom synthesis services for particular needs.

Bulk Chemical Suppliers: Larger companies that manufacture chemicals in bulk may also produce this compound. These manufacturers typically focus on providing cost-effective, high-volume production for industries such as automotive, construction, and electronics. Bulk suppliers tend to focus on economies of scale and logistical efficiency, making their products more accessible to a broad range of industries.

Contract Manufacturers: Some industries might choose to outsource the production of specific chemicals to contract manufacturers. These manufacturers provide specialized services, including formulation, blending, and packaging. They may produce CAS No: 107228-51-3 for clients in the pharmaceutical or specialty chemicals sectors, ensuring that the compound is produced to the exact specifications required.

Emerging Market Players: In recent years, new manufacturers have entered the market, especially in regions like China, India, and other parts of Asia. These companies are increasingly focusing on producing high-demand chemicals to cater to both local and international markets. With advancements in production techniques, these players can offer competitive prices and serve as important suppliers of specialty chemicals globally.

Industries That Utilize CAS No: 107228-51-3

The compound associated with CAS No: 107228-51-3 is used across several industries. Although its applications may vary depending on the precise nature of the chemical, the following sectors are likely to utilize this substance:

Pharmaceutical Industry: The pharmaceutical sector often uses specialized chemicals for drug development and formulation. If CAS No: 107228-51-3 is involved in any drug synthesis, it may be used as an intermediate or an active ingredient in certain formulations.

Agricultural Sector: Certain chemicals are used to produce pesticides, herbicides, and fungicides. If CAS No: 107228-51-3 falls into this category, it may be used to enhance crop protection or improve agricultural productivity.

Cosmetic and Personal Care Products: Specialty chemicals are often incorporated into cosmetics and personal care products for various benefits such as preservation, texture, or active skin-care properties. If the compound fits these requirements, it may be a part of the ingredient list in lotions, creams, and other personal care products.

Material Science: Chemical compounds are fundamental in the production of advanced materials, including polymers, coatings, and composites. If CAS No: 107228-51-3 is involved in this field, it could be used to create materials with enhanced durability, heat resistance, or other specialized properties.

Research and Development: Scientists and engineers in various research fields often rely on chemicals like CAS No: 107228-51-3 to conduct experiments, develop new technologies, or explore new materials. Chemical companies that specialize in custom synthesis and small-batch production are often the go-to suppliers for R&D departments.

Global Market Trends for CAS No: 107228-51-3

The demand for chemicals like CAS No: 107228-51-3 is influenced by several market trends, including:

Increasing Focus on Sustainability: As industries face growing pressure to reduce environmental impact, manufacturers are seeking more sustainable alternatives in chemical production. Companies that can provide eco-friendly chemicals or adopt greener manufacturing processes will likely stand out in the market.

Demand for Customization: Many industries are moving toward more specialized and customized products. Manufacturers that can provide tailored solutions for specific applications or regulatory requirements are in high demand. This trend is particularly relevant in pharmaceuticals and advanced material production.

Technological Advancements: New technologies are transforming the way chemicals are produced, making processes more efficient, cost-effective, and precise. Companies investing in cutting-edge research and development will remain competitive in a growing global market.

Growth in Emerging Markets: Manufacturers in emerging economies are playing an increasingly important role in the global supply chain. These companies benefit from lower production costs and are well-positioned to supply chemicals to industries in both developed and developing countries.

Conclusion

CAS No: 107228-51-3 is part of a dynamic and evolving chemical market. While it may not be a household name, the compound serves vital functions across a range of industries, from pharmaceuticals to agriculture and material science. Manufacturers of this compound come from various sectors, from small-scale specialty chemical suppliers to larger multinational corporations.

The key to navigating this market lies in understanding the applications of the compound, identifying reliable suppliers, and staying ahead of the trends that shape the industry. Whether you are sourcing chemicals for research, manufacturing, or product development, it's essential to partner with manufacturers that meet your quality standards and understand your specific requirements.

URL: For more information, visit Vasista Pharma : Cas No: 107228-51-3 Manufacturers

0 notes

Text

High Molecular Weight PIB: The Game-Changer in Lubricants, Sealants, and Beyond

The global polyisobutylene market size is anticipated to reach USD 3.42 billion by 2030, according to a new report by Grand View Research, Inc. The market is projected to grow at a CAGR of 7.3% from 2025 to 2030. The market is anticipated to expand in the years to come due to the growth of the automotive, electrical and electronics, food packaging, and building and construction industries across the globe.

Polyisobutylene exhibits low gas and moisture permeability, high thickening efficiency, good shear stability, good electrical insulation, adhesive, and tackifier properties, and resilience to UV. These properties make it suitable to manufacture filler compounds, adhesives, and sealants, tubeless tire inner lining, lubricants additives, fuel additives, wrap films, and cable insulation materials.

Major players are entering into partnerships to increase the polyisobutylene manufacturing capacity. For instance, in January 2019, Saudi Aramco and TotalEnergies entered into an agreement with Daelim Co., Ltd. to build a new polyisobutylene plant, which is expected to come on-stream in 2024. The facility will be located in Saudi Arabia and will give Daelim Co., Ltd. the opportunity to service customers in the Middle East and markets across Europe and Asia.

Polyisobutylene manufacturers are tapping the political scenarios in the region and engaging with governments to strengthen their foothold in the market. For instance, in March 2021, Kothari Petrochemicals received consent to operate for expansion from the Pollution Control Board in India. This expansion consent obtained from the government agency is expected to increase the production capacity of polybutylene.

Key polyisobutylene manufacturers are carrying out different marketing initiatives to increase their brand presence in the market. For instance, in August 2021, Chevron Oronite, a part of Chevron Corporation, sponsored and exhibited their products, including polyisobutylene, dispersants, PIBSA, and other products at the Specialty & Agro Chemicals America conference. Such initiatives are expected to result in promoting their brand in the market for polyisobutylene.

Polyisobutylene Market Report Highlights

The automotive rubber components application segment is expected to register the highest revenue-based CAGR over the forecast period. This is attributed to the use of polyisobutylene in the inner lining of tubeless tires, which is expected to be driven by the growing demand for passenger and commercial vehicles

By product, high molecular weight polyisobutylene dominated the market and accounted for more than 68.2% share of the overall revenue in 2024. This is attributed to its use in adhesives, fuel and lubricant additives, food-grade packaging films, and automotive rubber applications

The increasing demand for tubeless tires in the automotive industry and the rising demand for lubricant additives are expected to drive the market for polyisobutylene

Asia Pacific accounted for more than36.7% share of the overall revenue in 2024. This can be credited to the increasing demand for polyisobutylene from key industries, including automotive, construction, cosmetics, and aerospace, in emerging economies such as China and India

Curious about the Polyisobutylene Market? Get a FREE sample copy of the full report and gain valuable insights.

Polyisobutylene Market Segmentation

Grand View Research has segmented the global polyisobutylene industry report based on product, end-use, and region:

Polyisobutylene Product Outlook (Volume, Tons; Revenue, USD Million, 2018 - 2030)

High Molecular Weight

Medium Molecular Weight

Low Molecular Weight

Polyisobutylene End-use Outlook (Volume, Tons; Revenue, USD Million, 2018 - 2030)

Adhesives & Sealants

Automotive Rubber Components

Fuel Additives

Lubricant Additives

Others

Polyisobutylene Regional Outlook (Volume, Tons; Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Mexico

Europe

France

Italy

Asia Pacific

China

India

Latin America

Brazil

Middle East & Africa

Key Players in the Polyisobutylene Market

BASF SE

Daelim Co., Ltd.

TPC Group

INEOS

Kothari Petrochemicals Limited

Braskem

ENEOS Corporation

Zhejiang Shunda New Material Co., Ltd.

Shandong Hongrui New Material Technology Co., Ltd

Group of Companies «Titan»

Order a free sample PDF of the Polyisobutylene Market Intelligence Study, published by Grand View Research.

0 notes

Text

Wafer Cleaning Equipment Market set to hit $26.9 billion by 2035

Industry revenue for Wafer Cleaning Equipment is estimated to rise to $26.9 billion by 2035 from $9.3 billion of 2023. The revenue growth of market players is expected to average at 9.2% annually for the period 2023 to 2035.

Wafer Cleaning Equipment is critical across several key applications including memory, logic, mems and cis. The report unwinds growth & revenue expansion opportunities at Wafer Cleaning Equipment’s Type, Technology and Application including industry revenue forecast.

Industry Leadership and Competitive Landscape

The Wafer Cleaning Equipment market is characterized by intense competition, with a number of leading players such as SCREEN Semiconductor Solutions, Tokyo Electron, Lam Research, Applied Materials, Semes, Entegris, Veeco Instruments, PVA TePla, Akrion Systems, ACM Research, Modutek and MKS Instruments.

The Wafer Cleaning Equipment market is projected to expand substantially, driven by increasing demand for high-precision semiconductor devices and growth of iot and 5g technologies. This growth is expected to be further supported by Industry trends like Advances in Automotive Electronics.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/wafer-cleaning-equipment-market-research-report

Moreover, the key opportunities, such as expansion in emerging markets, development of eco-friendly cleaning solutions and integration of ai in wafer cleaning, are anticipated to create revenue pockets in major demand hubs including U.S., Japan, South Korea, Taiwan and Germany.

Regional Shifts and Evolving Supply Chains

North America and Asia-Pacific are the two most active and leading regions in the market. With challenges like high equipment and maintenance costs, stringent environmental regulations and technical complexity and skill requirement, Wafer Cleaning Equipment market’s supply chain from chemical supplier / equipment manufacturer / service provider to end-user is expected to evolve & expand further; and industry players will make strategic advancement in emerging markets including India, Brazil and France for revenue diversification and TAM expansion.

About DataString Consulting

DataString Consulting offers a complete range of market research and business intelligence solutions for both B2C and B2B markets all under one roof. We offer bespoke market research projects designed to meet the specific strategic objectives of the business. DataString’s leadership team has more than 30 years of combined experience in Market & business research and strategy advisory across the world. DataString Consulting’s data aggregators and Industry experts monitor high growth segments within more than 15 industries on an ongoing basis.

DataString Consulting is a professional market research company which aims at providing all the market & business research solutions under one roof. Get the right insights for your goals with our unique approach to market research and precisely tailored solutions. We offer services in strategy consulting, comprehensive opportunity assessment across various sectors, and solution-oriented approaches to solve business problems.

0 notes

Text

Enhance Heat Management with Thermally Conductive Adhesive from First Seal India

In industries where efficient heat dissipation is crucial, thermally conductive adhesives play a vital role. These specialized adhesives are designed to transfer heat between surfaces while providing strong bonding. First Seal India offers high-quality thermally conductive adhesives that ensure optimal thermal management for your applications, enhancing performance and longevity.

Why Choose First Seal India for Thermally Conductive Adhesive? First Seal India is committed to providing superior adhesive solutions that meet the highest industry standards. Our thermally conductive adhesives are engineered for reliability, efficiency, and safety, making us a trusted partner in various industrial sectors.

Key Features of Our Thermally Conductive Adhesive:

Excellent Thermal Conductivity: Efficient heat transfer reduces overheating and ensures optimal performance of electronic components.

Strong Bonding Strength: Provides durable adhesion between surfaces, ensuring structural integrity.

Electrical Insulation: Safeguards against electrical interference while maintaining heat transfer capabilities.

Chemical Resistance: Resistant to chemicals and environmental factors, ensuring long-term reliability.

Ease of Application: Available in various forms, including paste, film, and liquid, for convenient use.

Applications of Thermally Conductive Adhesive:

Electronics: Essential for bonding heat sinks to electronic components, ensuring efficient heat dissipation.

LED Lighting: Maintains temperature control in LED systems, enhancing performance and lifespan.

Automotive Industry: Used in electric vehicles and automotive electronics for effective thermal management.

Renewable Energy Systems: Enhances heat transfer in solar panels and wind turbine electronics.

Consumer Electronics: Keeps devices like laptops, smartphones, and gaming consoles cool during operation.

Advantages of Using Thermally Conductive Adhesive:

Improved Heat Dissipation: Protects sensitive components from overheating, reducing the risk of failure.

Enhanced Product Longevity: Prevents heat-related wear and tear, extending the life of components.

Energy Efficiency: Reduces energy consumption by maintaining optimal operating temperatures.

Versatility: Suitable for various materials, including metals, ceramics, and plastics.

Why First Seal India Leads the Way in Adhesive Solutions:

High-Quality Products: We use premium materials to ensure superior thermal conductivity and bonding strength.

Customized Solutions: Tailored adhesives to meet specific industry requirements.

Expert Support: Our technical team provides expert advice and support for your adhesive needs.

Timely Delivery: Reliable and efficient delivery services to keep your projects on schedule.

Competitive Pricing: High-quality adhesives at cost-effective prices, offering great value.

Customer Testimonials

“First Seal India’s thermally conductive adhesive has significantly improved our electronic components’ heat management. Highly recommend their products!” – Rohit Kumar, Electronics Manufacturer.

“The adhesive’s bonding strength and thermal conductivity are excellent. First Seal India delivers quality and reliability every time.” – Priya Desai, Automotive Parts Supplier.

Applications Across Industries From electronics and automotive to renewable energy and consumer goods, our thermally conductive adhesive solutions cater to a wide range of industries. We work closely with each client to provide customized solutions that meet their unique needs.

Conclusion Efficient heat management is essential for the performance and durability of your products. First Seal India’s thermally conductive adhesives offer the perfect balance of heat dissipation and strong adhesion. Visit First Seal India’s Thermally Conductive Adhesive Page to learn more about our products and enhance your thermal management solutions today!

0 notes