#Custom Carbon Steel Parts

Text

Stainless Steel Parts Manufacturer

CNC Parts4U is a leading copper, aluminium and Stainless Steel Parts Manufacturer Company in China that provides high-quality stainless steel parts and carbon steel parts etc. at reasonable price. Order online today!

0 notes

Text

National Knife Day

Grab or pull out your knives! Today we celebrate them, no matter their size, style, or brand! It is unknown who started National Knife Day or when they started it, but it was being celebrated by at least 2011. It is also unknown why the observance takes place on August 24, but one explanation appears to be that the date is connected to the Bowie knife. It was on this date in 1838 that Rezin Bowie, the brother of the knife’s namesake, wrote a letter to the Planters’ Advocate claiming he was the person who had created the knife.

One of the earliest tools known to humankind, the knife was present at the beginnings of the development of human civilization and came out of the need for survival. Early on, knives were used as primitive tools for digging and construction, as weapons, and to hunt, fish, and gather food. In contrast to today, almost everyone carried a knife. The first knives were made of stones which were cracked to make a sharp edge like a blade. Sharpened stone tools became more advanced during the late Lithic periods, and then even more so during the Copper and Bronze Ages. Metal blades appeared, which weren’t as sharp and didn’t stay sharp as long as the stone blades that preceded them. This led to the introduction of sharpening stones.

During the Iron age, tools became stronger and more durable. Iron knives came on the scene and stayed sharper longer. Steel blades followed iron ones, and not much has changed since then. Steel blades, which are made of an alloy of iron that has carbon, are the most common today and are known for being durable and efficient. Cobalt alloys and titanium are also used in knife making today.

Early knives didn’t have a separate handle and blade—they were all one piece. Eventually, handles began being made out of carved bone, wood, and metal, and then, rare materials like mother-of-pearl and tortoiseshell began being used. Today, wood is one of the most popular materials used for knife handles, and metals like stainless steel are also common. One other change besides that advent of a separate handle was the invention of the folding knife.

Knives have many different purposes in the present day, some of which are the same as they have been for thousands of years. Some ways they are used are to prepare food, as a utensil when eating food, by surgeons and medical professionals, to dress an animal, to fillet a fish, and for carving. There are various types of kitchen knives such as the chef’s, utility, paring, and bread knives. Most knives are affordable to just about anyone, but there are high-end custom knives such as Randall Made Knives, most of which sell for $400 of more. In many locations, there are laws that pertain to knives: ownership laws exist for certain types of knives, open and concealed carry laws apply to certain types of knives, and other types of laws exist, such as those that say a robbery is an “aggravated crime” with more severe punishment if a knife is involved. There also are certain areas where some types of knives are not permitted, such as at schools or on planes.

How to Observe

Knives should be used more today than on any other day of the year. Here are a few ideas on how to spend the day:

Do some knife throwing.

Do some whittling.

Prepare some food using a knife or multiple knives. It might be beneficial to first learn what type of knife is appropriate for different types of food.

Get a pocket knife, which has many uses.

Check for knife promotions such as giveaways and sales happening today. This is often a large part of the day.

Give someone a knife as a gift.

Clean, oil, and sharpen your knives.

Carry your knives around in a holster.

Cut a lot of things with your knives, such as food, paper, and rope.

Source

#National Knife Day#USA#Canada#Germany#Schnitzel-Himmel und Erde#food#restaurant#travel#vacation#original photography#Fire Jumper Burger#steak#filet#burger#bread#cookie#NationalKnifeDay#24 August#Jacobs & Co. Steakhouse#Louis M. Martini Winery#St. Francis Winery & Vineyards#Hess Persson Estates#Fried Green Tomatoes

6 notes

·

View notes

Text

WHATEVER HAPPENED TO LIMB STEEL?

A continuation of the story "Extension" uploaded in April 2022. Years pass, men mature, the house evolves.

legbry.blogspot.com/2024/07/whatever-happened-to-limb-steel.html

Here's an excerpt:

Limb had not ridden his Night Rod for several months. He descended to the garage and pulled the custom cover off the bike. He touched the handlebar and the electromechanical adaptations which allowed a quadruple amputee to ride a low heavy motorcycle. His hooks appeared too delicate for the job. He would exchange them before Saturday for his rubber claws which could be adjusted to a crushing grip. His unique bike was still his prize possession. It was unfortunate that it was so inconvenient to mount and dismount. His artificial legs afforded none of the lower body control which was such an integral part of riding such a machine. Instead, he found it necessary to keep his speed down and to concentrate on his precarious balance. He would take the bike out to test it later in the week and if he was confident in his ability, he would turn up at the leather dungeon riding it, dressed in full leathers artfully concealing his prosthetic limbs.

Zero later summoned Nub and instructed him to fetch Mylo. Zero intended interviewing the steelpunk whom Stub had mentioned and wanted the man to attend as soon as possible. He was as impatient as ever and saw no reason why he should wait on other people’s convenience. He heard Mylo and Nub approaching several minutes later, Mylo’s stubbies beating a regular rhythm on the naked wooden floor accompanied by Nub’s steel cleat on the heel of his boot. Mylo rapped on the door with a hook.

Zero was wearing his artificial stumps and sat on his trolley, identical to the ones which the torsos used daily for their excursions to the kitchen for breakfast. His stumps were glossy black carbon fibre and they provided a physical advantage in improving the torso’s balance and a psychological advantage in reassuring Zero that he still possessed leg stumps, albeit facsimiles. He wore his longest artificial arms and Limb had fitted his husband’s motorcycle jacket onto the torso and placed his most expensive officer’s cap at exactly the correct angle. Zero heaved his shoulders to force his mechanical elbows to lock at ninety degrees and faced the door.

3 notes

·

View notes

Text

Mens Wedding Bands: 6 Essential Tips for Choosing Your Perfect Match

Shopping for a mens wedding band can be just as exciting as picking out an engagement ring — especially when you find a trusted fine jewelry brand that’s dedicated to offering you a personalized experience. While there are many options out there and a lot of factors to consider, finding a band that reflects your style and personality doesn’t have to be difficult. Consider these six essential tips as you reflect on the perfect mens wedding band for you.

Start with a Budget

There are rings for men in every price range, so starting with a budget can help narrow down the field. Style, metal, and finish all affect the price of this important investment. There are no rules on how much you have to spend on the ring; it’s whatever you (and potentially your partner) are comfortable with spending on the ring.

Select Your Ideal Style

There are a few styles to choose from when selecting your wedding band. The classic band is an all-metal band, sometimes with a bit of texture, but oftentimes smooth. You can also choose diamond accents for an extra pop, a single diamond, or a gemstone for some personality and color.

Determine Which Shape Is Right for You

Next, you need to choose the shape of the ring. This is wholly a personal choice, though some styles may be more comfortable for you to wear than others.

● Rounded inside and out rings are the classic and most common shape. They’re comfortable to wear and have a timeless look.

● Flat wedding bands have a flat exterior and a rounded or flat interior. They’re a contemporary choice, and the style is rising in popularity.

● D-shaped or domed wedding rings have a flat inside and rounded outside, which can help give a closer fit to the finger.

● Beveled rings are between flat and domed rings, with three facets instead of a continuous outer surface.

Choose a Metal to Rock

Choosing a metal may be the most important part of choosing a ring. Some popular choices include:

Precious Metals

● 14k White Gold

● 14k Yellow Gold

● 14k Rose Gold

● Platinum

Alternative

● Titanium

● Zirconium

● Cobalt

● Tantalum

Some fine jewelry brands may even offer exotic ring material choices such as meteorite, titanium, Damascus steel, or forged carbon fiber.

Finish It Off

Finally, choose a finish. High polish is common, giving your ring a highly reflective shine. A satin finish gives a similarly smooth surface but isn’t quite as reflective. You can also find other finishes, often textured, such as tree bark or sand. Hammered finishes make the ring look rugged, like it was forged with a hammer. Rock polishes are in the same vein but give more of a rocky appearance, which is less pronounced than a hammered appearance.

Customize It to You

You can choose a pre-made ring, or you can use all of the information above to create a custom ring that’s right for you. Choose whether you want gemstones or just metal, as well as your preferred style, materials, and more to make it truly unique. Find a trusted fine jewelry brand that can help you figure out what you want and what looks best, helping you get a fully customized ring you’ll love for a lifetime. Some of the best brands may even offer an online custom band builder to help you create a ring unique to you as you select the material, profile, dimension, finish, outside features, sleeves, and engraving.

About Shane Co.

Family-owned since 1929, Shane Co. makes expertly crafted fine jewelry to help everyone shine their brightest each day. Capture life’s most beautiful moments with jewelry designed in-house and hand-finished by on-site jewelers. You’ll discover truly unique pieces for a one-of-a-kind present, a milestone anniversary gift, a perfect engagement ring, or a beautiful gesture to yourself. Shane Co.’s passion for loose diamonds and colorful gemstones from around the world goes back four generations. The brand responsibly sources and hand-selects stones, cutting each to the highest standards. Their jewelry is not mass-produced and offers many options for customization, ensuring a truly personalized piece meant to last a lifetime. Shane Co. welcomes everyone and is proud to be your friend and jeweler.For jewelry crafted with the greatest care, including mens wedding bands, Shane Co. is your trusted source for fine jewelry.

Find the perfect mens wedding band for you or create your own at https://www.shaneco.com/

Original Source: https://bit.ly/4bt4qHK

2 notes

·

View notes

Text

Do you have any confusion about choosing the Steels and Materials?

Bridging the Gap Between Steel and Carbon Steel! … Remember, when it comes to steel, Virat Special Steels is your trusted guide!🔥

Steel:

Steel is an alloy primarily composed of iron, along with other elements such as carbon, silicon, and manganese. It contains carbon, silicon, and manganese in varying proportions.

Properties:

Steel has moderate strength. It is less hard compared to carbon steel. Steel is more ductile (can be shaped and bent). It is non-corrosive. Some types of steel (like nickel steel) are not magnetic. Steel can be alloyed with elements like chromium, nickel, and molybdenum to enhance specific properties.

Applications:

Used in construction, automobiles, airplane parts, and various industrial applications.

Global Production: The steel industry produces approximately 1.3 billion tons of steel annually.

Carbon Steel:

Carbon steel is a type of steel where carbon is the primary alloying element. It contains less than 2% carbon (without other noticeable alloying elements). As the carbon content increases, carbon steel becomes harder and stronger but less ductile and malleable.

Types:

- Mild Steel: Contains 0.05% to 0.29% carbon.

- Medium Carbon Steel: Contains 0.30% to 0.59% carbon.

- High Carbon Steel: Contains 0.60% to 0.99% carbon.

- Ultra Carbon Steel: Contains 1.00% to 2.00% carbon.

- Finish: Carbon steel usually has a lusterless finish.

In summary, steel is a broad category that includes carbon steel. Carbon steel, in turn, varies based on its carbon content and properties. It’s essential to choose the right type of steel for specific applications.

Virat Special Steels is one of the most reputable Tool Steel & Die Steel and Mold Steel Suppliers in India. Special steel is provided in all sizes and shapes (flat, round, and bars) depending on customer requirements. Based in #Gurgaon (Haryana) & #Ludhiana (Punjab) India.

Product List:

DIE STEELS ( HH 370 - 410 BHN ) DIN-1.2714 / AISI L6 )

HOT DIE STEELS (DIN 2343, 2344 / AISI H11, H13)

PLASTIC MOULD STEELS (DIN 2738, 2311 , AISI P 20 )

HIGH SPEED STEELS (DIN 3243 , 3343 / AISI M2 , M35)

HCHCr. (DIN 2379 , 2080 / AISI D2 , D3)

ALLOY STEELS, EN-SERIES ETC.

For more information visit

https://www.viratsteels.com/

Watch now: https://www.youtube.com/watch?v=c4h5KqyzVd0

Any further queries feel free to contact us :

Email: [email protected] or Call: +91 98140 21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#steel#iso9001#SteelTrades#MetalIndustry#DieSteels#ToolSteel#HighSpeedSteels#PlasticMouldSteels#hot work steel#cold work steel#HCHCr#DB6Steel#H13Steel#H11Steel#P20Steel

2 notes

·

View notes

Text

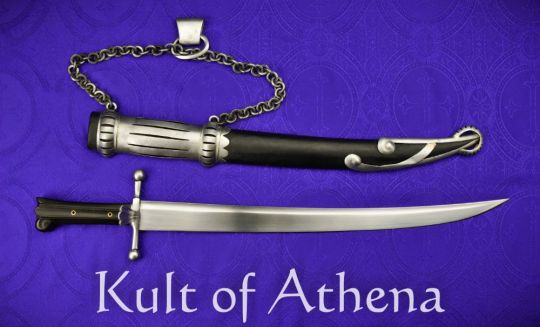

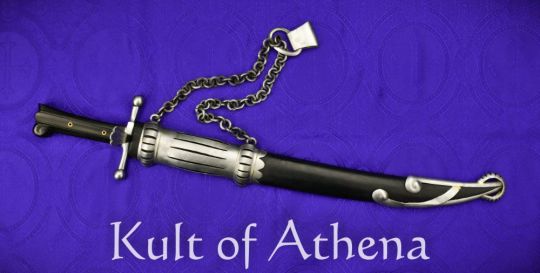

Ádám Bodorics – Ebony Grip Hidden Tang Messer

This beautifully balanced and custom-crafted Messer by specialist swordsmith Ádám Bodorics feels like a natural extension of the hand and its well-tempered and sharp blade slices quickly, cleanly and decisively. The guard and riveted nagel are of steel and the grip is finely carved from smoothly polished fine ebony wood which is directly riveted to the blade tang. The sword is matched with a wood-core scabbard which is lavishly embellished with steel fittings in a landsknecht inspired style. A hanging chain and belt loops allows for it to be worn on the belt. Below are Ádám’s own thoughts on his custom creation:

The large variance in Messers and related sidearms make them a great medium for experimentation and theoretical designs. With this ebony-hilted piece, I intended to create something completely new based on sources mainly from between 1520-1540. In the 16th century, knifelike sidearms undergo several changes, one of them being the increasing regularity of hidden tangs. Illustrations from the period sometimes show rather complex grip shapes that would be complicated with a full-tang construction, but a hidden or a frame tang makes them much more trivial. In this case, I went for a hidden tang and a one-piece ebony grip.

The light, curved blade is ground from 51crv4 high-carbon steel and is heat-treated to 50-52 HrC. While the shape favors cutting and slicing, the tip is subtly reinforced. The spine visibly thickens in the last few milimeters, and the edge angle gets a bit more obtuse. I spotted this detail first on a heavily curved Kriegsmesser from the Kunsthistorisches Museum, but I noticed it elsewhere as well since. The proper tang is relatively short, not an uncommon detail on 16th century specimens.

The short cross with it’s finials is based on a pair of illustrations by Monogramist HD from 1545, and so is the approximate shape of the Nagel. The cross is slid down along the blade and is affixed in place by

the triple-fullered, hand-forged and filed Nagel. The most striking part of the Messer is the grip carved and filed from a single piece of Gabon ebony including a shape following pommel type CC2. This is the most theoretical part as well. If we define CC2 pommels as having a complex bottom profile (as opposed to the simple curve of type CC1), then there are plenty of illustrations showing non-metal grip ends matching the type, from Dürer, Beham, etc. If we limit the definition to the somewhat architectural type done by Sumersperger and the makers of several early 16th century pieces, then we even have an existing piece where the shape is part of the organic grip, all the way back in the late 13th century (NDK-1123-2, shown in Cahiers LandArc 2017 N24, pg2). The swirl of the “beak” is present on several sources as well, from a very basic version by Hans Sebald Beham’s “Peasant at the marketplace” through a richly decorated swirl painted by Lucas Cranach the Elder in “Judith with the head of Holofernes” all the way to the dizzying all-metal Kriegsmesser by Melchior Diefstetter in Vienna. I aimed at a relatively simple shape that would be still above the one on

the Beham woodcut.

The scabbard is based on the already-mentioned illustrations by Monogramist HD. It has a wooden core, a black leather cover and several steel fittings. The largest of said fittings emulate the puff&slash fashion of the time. This detail is found on surviving scabbards of the period, not just in art. The suspension is by a length of handmade mild steel chain and a metal belt loop as in the inspiring illustration. Monogramist HD shows both Messers in a right-side, edge-up carry position – as this is without parallel in the period, I set the scabbard up for a more conventional, left-side, edge-down carry position.

#Kult of Athena#KultOfAthena#New item Wednesday#Ádám Bodorics#Adam Bodorics#Ebony Grip Hidden Tang Messer#Messers#sword#swords#weapon#weapons#blade#blades#European Swords#European Weapons#Medieval Swords#Medieval Weapons#Renaissance Swords#renaissance Weapons#16th century#6150 High Carbon Steel#Battle ready

8 notes

·

View notes

Text

Abrex 600 Sheet Plates

Since the fundamental limit of ABREX is to give assurance from scratched territory, in this way we try to manufacture precision fabricated Abrex 600 Plates, which are extensively known for their positive conditions like high insurance from effect, weld breaking point, handiness, and significantly more. One progressively included piece of breathing space that goes with the usage of ABREX 600 sheets and plates is that the greatness of the fundamental part reduces enormously, which shows to be of authentic help with truly grinding working conditions. This associates in growing the future of the mechanical parts related with these sheets and plates.

At Vandan Steel & Engg. co., we attempt to cling ourselves to all the fundamental worldwide models and benchmarks of collecting, to retreat the entire methodology. In addition, the amassing of Abrex 600 Abrasion Resistant Plates and Sheets, is done in proximity of all the skilled and experienced partners, who work relentlessly towards collecting the best grouping of things for our customers.

Our entire workplace is outfitted with the best extent of equipment and mechanical assembly, which makes the age of Abrex 600 Wear Resistant Plates and Sheets especially smooth and mix-up free. All these Abrex sheets and plates are caused available to our customers at a completely moderate an incentive to go.

Abrex 600 plates have a lot of characteristics given by solidified steel make it a convincing candidate in materials decisions. Solidified steel is subsequently low carbon steel which contains chromium at extra by weight. It is the extension of chromium that gives the steel of its novel flawless, spoil restricting properties.

ABREX 600 STEEL PLATE SPECIFICATION

Thickness : 5mm to 150mm

Width : 1,500mm to 2,500mm

Length : 6,000mm to 12,000mm

Heat Treatment : N, Q+T

Surface Paint : EP, PE, HDP, SMP, PVDF

Material : ABREX 600 Plate

APPLICATION

Machine building

Pylons and other architectural structures

Lifting and mobile equipment

Construction of bridges

Wearing plates

Framework structures

Crane booms, Rail cars

Stone or iron chutes

Truck frames, Containers

Vehicles and transport equipment

Anti drill plates such as security doors, shot blasting equipment and tumbling machine

For More Information :

Visit Our Website: http://wearplates.co.in/

Contact No: +91-8828813630

E-Mail ID: [email protected]

5 notes

·

View notes

Text

All-Steel Stress, Blast and Coating

All-Steel Stress, Blast & Coating is a subsidiary steel heating treating company under the All-Steel Brand. All-Steel Stress, Blast and Coating provides heat treatment of steel, thermal stress relieving, industrial sandblasting/steel shotblasting and steel coating of:

Fabricated weldments

Machined parts

Machine components

Dry Outs

Their Massachusetts Facility offers a 40 Ton lifting capacity, 20 Ton forklift capacity and a dedicated, professional staff with over 50 years of combined experience in thermal stress relieving, sandblasting and priming/painting.

Thermal Stress Relieving, also referred to as Stress Relieving, Heat Treating, Post Weld Heat Treating (PWHT) and can also be referred to as annealing.

In our new, state of the art industrial size stress relieving oven we can stress relieve:

Fabricated Weldments for post-weld heat treatment

Machined Parts

Metal Components

In addition, we provide dry-out services for paint and refractory process curing. Our furnace will operate between 250 degrees F and 1600 degrees F. We perform quality inspections during the stress relieving process and we can provide our customers with Certificates of Compliance and detailed Heat Charts when required.

Our Stress Oven can accommodate customer jobs that are 12’H x 11’ W x 31’L and our rail-car capacity is 54,000lbs.

We meet the following standards: ASME Section I: (900 – 1300F) Stress relieve /post -weld heat treat in accordance with ASME Sect. I, PW-39 for carbon steel weldments. ASME Section VIII: (900 – 1300F) Stress relieve/post-weld heat treat in accordance with ASME Sect. VIII, USC-56 for carbon steel weldments. AWS D1.1 (900-1200F): Stress relieve/post-weld heat treat in accordance with AWS D1.1, 5.8 for carbon steel weldments. Westinghouse 83030QA: (1175F +/- 25F) Westinghouse-approved stress relieve procedure for carbon steel welded structures. General Electric P8A-AG1, P10G-AL-0003 & 0004: (1125 – 1275F, 1125-1200F and 125-1300F) General Electric-approved stress relieve procedures for carbon steel. Standard Stress Relieve: (1100-1200F) Applied to ferrous materials to reduce residual stresses for improved dimensional stability or reduced risk of premature failure in service. Low Temperature Stress Relieve: (325-775F) Typically applied to stainless steel and aluminum welded fabrications to reduce residual stresses with little or no effect of the corrosion resistance and/or mechanical properties.

Industrial Sandblasting Services, also referred to as shot blasting can be done in our state-of-the-art facility in Central Massaschusetts. Our new, industrial-size facility provides our customers with sandblasting for:

Fabricated Weldments

Machined Parts

Metal Frames and Components

In our modern, clean blast room, our experienced blasters can accommodate the most specific blast media required for the job. We can blast customer jobs that are 16’H x 13’W x 30’L; and we have 40,000lbs rail-car capacity for our blasting facility.

Steel Coating Services: Industrial Priming, Painting and Coating for Steel and other Metals. Our new coating facility will be capable of providing priming/painting/coating services up to 16’H x 20’W x 50’L and weigh up to 80,000lbs. Our painters have extensive experience coating:

Fabricated Weldments

Industrial Machine Bases

Industrial Frames

Construction Equipment

Holding Tanks & Silos

Address:

84 Creeper Hill Road,North Grafton MA 01536

Phone:

(508) 839-4471

Our Social Pages:

facebook

twitter

linkedin

youtube

pinterest

3 notes

·

View notes

Text

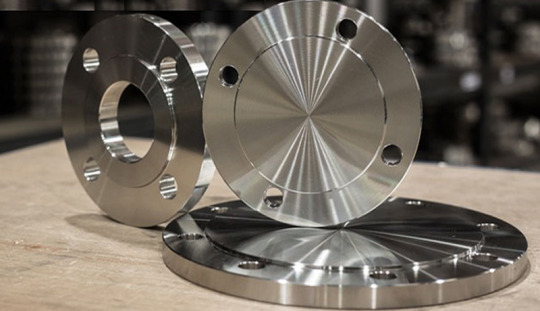

Types Of Flange & Flange Manufacturer in India

WHAT ARE FLANGES AND HOW DO THEY WORK?

Dalmine Flanges is a well-known Flange Manufacturer in India. A Flange is a forged or cast ring used to join sections of a pipe or any other machinery that requires a connection point in the middle. Stainless Steel Flange, Alloy Steel Flange, Carbon Steel Flange, and Nickel Alloy Flange are some of the most common types of flanges that are in high demand.

We are one of the largest Flange Suppliers in India. Flange comes in a variety of shapes, diameters, and thicknesses. Dalmine Flanges manufactures all products following international standards. Our business has been established a long time and has grown rapidly because of our customer service and the quality of products we provide.

Size, Standards, and Specifications for Flanges

A Flange is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Flanges are available in different sizes and standards, each with its specifications. We will explore flanges' size, bars, and specifications.

Flanges Type

Dalmine Flanges is a well-known Flanges supplier in India. They offer a wide range of flanges, including stainless steel flanges, carbon steel flanges, and alloy steel flanges. Their products are made to the highest quality standards and are backed by a 100% satisfaction guarantee.

Slip On Flanges

A Slip On Flanges is a type of gasket that is used in pipe fittings. It is a flat metal disk or other material placed between two parts to prevent leakage. Slip On Flanges are available in different sizes and standards, each with its specifications. we will explore flanges' size, bars, and specifications.

Blind Flanges

It is used to bring the end of a piping system to a close. The Blind Flange is essentially a flange without a hub or a drilled centre. Blind Flanges have the face thickness of a flange, a matching face type, and a bolting pattern that is identical to that of a flange. Blind Flanges can also be employed to seal a pressure vessel's nozzle opening.

Lap Joint Flanges

These Flanges can swivel flexibly around the pipe. This makes it easier to align opposing Flange bolt holes. Because Lap Joint Flanges Manufacturer are not in contact with the fluid inside the pipe, they are more durable. The Lap Joint Flanges in corroding or eroding pipe systems can be saved for re-use.

Threaded Flanges

Threaded Flanges are extremely robust and are made to accommodate a variety of pipe sizes. They are used as connectors in piping systems to link pipes to other pipes, tees, reducers, elbows, valves, and other piping equipment. We have cutting-edge facilities with the highest standards of technology, quality, and productivity at Dalmine Flanges.

We are one of the largest Flange Manufacturer in India These Gate Valves can be altered to meet the unique needs of our customers and are available in a variety of sizes, forms, and dimensions.

For more details

Website :dalmineflanges.com/

Source : Flange Manufacturer in India

9 notes

·

View notes

Text

Hi i put too much thought into EVERYTHING, This is a long post so beware

[the art is a bit off but i just needed to get this off brain]

App Δ. will be added at a later date

Casing for the Hydraulic Pump located on the shoulder part of the Lifter Class Robotic arm, Which will hence be called: LCR Arm. Casing is made of 1/4 of an inch Tempered steel, Bolts that affix on top of the Iron casing must be 1/2 of an inch at the bottom, and 3/4 of an inch, Bolts must be made of Carbonated Steel.

Hydraulic Pump. The Pump is used to siphon blood and mix with hydraulic compatible/ Troll Blood compatible (Compatible only with Fuchsias and Violets) Oi.

2a. Connectors to the Steel Plaque that holds the Hydraulic pump in place, Connectors are secured with a Grip, Recommendations are that they be soldered on if LCR arm is for Permanent or Semi-permanent Use.

2b. Oil Additive Tube, and Return Tube are located in the same 2 inch thick cylinder which pumps blood with the Added Blood Compative oil into the mechanism to make it's many functions work properly

Support beam located in the 'forearm' section of the LCR arm, It is made with a carbonated steel casing and Iron in the center, Able to support around 1000 kilograms before suffering breakage or bending.

Carbon Muscle fibers, Fibers made with plastic adjacent materials threaded within each other to resemble trollian muscular structure, it is able to contract and relax faster than any normal muscle could attempt without any breakage in the insides of the carbon fibers. 'Elbow' of the LCR arm is must have two 1/2, 3/4 bolts attaching the Support beam [See 3] to the rest of the LCR arm. Bolts must be made of Steel.

4a. Casing for the Arm's Central motor block [See 5] The casing is made of Ferroaluminum, and must be washed at the very least once a week due to the piston's it encases.

4b. Ball Joint Wrist functionality. A Ball joint is located at the "wrist" part of the LCR arm, it is able of 360 degrees of rotation, as well bending forwards and backwards without the assistance of the ball joint. Ball joints are made of Copper with Steel casings, Protecting the ball joints there are two Lock Casings made of Polymer to cushion blows from the Piston Punching Module [see 5a and App. Δ]

Custom Motorblock. A motor block that allows for 4 low action Variable Pistons. The pistons can be exchanged alongside the upper part of the motor block for the variability in the weaker hydraulic powered one or the stronger ignition powered one.

[Addendum. 5. Piston Punching Module]

As an additive, When the arm's sensors feel the bracing for a punch, Lift or general type of movement that would require force more than precision, it's pistons begin a low-regimen work, after 6 seconds the pistons will begin to move at normal pace and then it will be safe to utilize them.

Punching with the module will cause the forearm to extend 4 inches off of the elbow socket, It is held in place by Springs and two Heavy weight bolts so it wiill return to place, This causes the fist to move at a speed higher than the one of the punch, Allowing the "Piston Punching" to occur, This can be used to dig Railway nails to the ground, punching holes through rocks or exposing someone's insides to the outsides

[Addendum Finalized]

5a. Variable Pistons. The pistons have a rubber upper socket and must be made by vehicular specificity, The rubber cap is used to cushion blows to the Low Ceiling or the Motorblock. With that in mind it is warned that the motor block cap be changed every Two to three months.

#Long post#i'm not good at writing characters and such#but i think i'm pretty sweet at writing fake mechanicals stuff#long post#no one's gonna read this but i'm posting mostly for the#Worldbuilding#Aspect

5 notes

·

View notes

Text

Custom CNC Plastic Parts

Parts4U is a Custom CNC Plastic Parts manufacturer, provides best-quality CNC Parts such as milling plastic Parts etc. at the lowest price. Contact us: +86-13728800933

0 notes

Text

Leading Biogas Project Contractor: Professional Solutions by Shijiazhuang Zhengzhong Technology Co., Ltd

Leading Biogas Project Contractor: Professional Solutions by Shijiazhuang Zhengzhong Technology Co., Ltd

At Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel), we are proud to be a leading biogas project contractor, delivering comprehensive solutions for the design, construction, and operation of biogas projects worldwide. With over three decades of experience, our team has a strong foundation in wastewater treatment, biogas systems, and equipment manufacturing, making us a trusted partner in addressing complex environmental challenges.

Comprehensive Biogas Solutions for Diverse Industries

Center Enamel’s expertise spans multiple sectors, offering biogas project solutions tailored to the unique needs of industries such as agriculture, municipal wastewater, industrial wastewater, and high-concentration organic waste treatment. From the breeding industry to landfill leachate and kitchen waste, our biogas systems are designed to maximize energy efficiency, reduce waste, and promote sustainability.

We has developed a set of patented technologies for the biogas project, We collect, recycle and treat all kinds of organic waste from daily life, industry, agriculture, and animal husbandry in a scientific and environmentally friendly way. Using the mixed raw material fermentation technology that does not require the classification of raw materials and the maintenance-free super-large anaerobic reactor for waste heat insulation of biogas power generation, the gas production rate, and investment utilization ratio are effectively improved, and the sustainable and profitable commercial operation mode is realized in the biogas project.

We have a number of engineering design and construction cases for different raw materials such as livestock and poultry manure, crop straw, kitchen waste, high concentration organic wastewater. The self-developed high-efficiency anaerobic fermentation unit can fully mix the raw materials, solve the "capping phenomenon" on the liquid surface of the reactor, with a high volume gas production rate and stable operation. The self-developed anaerobic reactor heating system has the characteristics of instant automatic heating, low energy consumption and stable operation. The waste heat from biogas generation was used to heat the thermal insulation heating system outside the reactor, which greatly improved the gas production rate and investment utilization rate, and made the reactor work normally all year round.

As part of our integrated service, we offer:

Engineering Design: Custom biogas project designs that cater to specific industry needs.

Equipment Manufacturing: Advanced biogas equipment with innovative features for optimal performance.

Engineering Construction: Turnkey solutions from project inception to completion, ensuring smooth and efficient operations.

Advanced Glass-Fused-to-Steel Tanks for Biogas Storage

At the core of our biogas solutions are our Glass-Fused-to-Steel (GFS) tanks, which are recognized for their superior durability, corrosion resistance, and ease of installation. These tanks are integral to the success of biogas projects, ensuring safe and reliable storage of biogas and related materials. With a focus on high-quality materials and precision engineering, our GFS tanks have gained a high market share and excellent reputation in the global industry.

Tailored Wastewater and Biogas Solutions

Our extensive knowledge of wastewater treatment allows us to offer integrated biogas solutions, combining wastewater treatment systems with biogas production. By leveraging biogas as a renewable energy source, industries can achieve energy savings, reduce carbon emissions, and contribute to a more sustainable future.

Our customized wastewater treatment processes cover a wide range of high-concentration organic wastewater treatment fields, including:

Medical Industry

Wine Industry

Paper Industry

Kitchen Waste Treatment

Landfill Leachate Management

By focusing on industry-specific challenges, we deliver tailored solutions that optimize biogas production while ensuring environmental compliance.

Pioneers in Wastewater and Biogas Technology

As a leader in both wastewater treatment and biogas project contracting, Shijiazhuang Zhengzhong Technology Co., Ltd continuously invests in research and development to remain at the forefront of innovation. Our commitment to technology advancement ensures that we provide the most efficient and sustainable solutions for industries seeking to reduce their environmental impact.

With our Glass-Fused-to-Steel tanks and modular equipment, we have developed a variety of product systems that deliver exceptional performance and value. Our solutions help industries achieve cost-effective biogas production while addressing wastewater treatment challenges.

Global Reach, Trusted Partner

With a presence in over 100 countries, Center Enamel is a trusted name in the biogas and wastewater treatment sectors. We have successfully completed numerous biogas projects across various industries, providing our clients with reliable, high-quality solutions that meet global standards. Our customers include major industries, municipalities, and agricultural businesses seeking to reduce waste and harness renewable energy.

Committed to Sustainability

At Center Enamel, sustainability is at the heart of what we do. Our biogas solutions not only help industries reduce their carbon footprint but also contribute to a circular economy by converting waste into valuable energy. We are committed to delivering biogas projects that benefit both our clients and the environment.

Why Choose Shijiazhuang Zhengzhong Technology Co., Ltd for Your Biogas Project?

Comprehensive Services: From engineering design to project construction and equipment manufacturing, we offer a full range of biogas solutions.

Innovative Technology: Our advanced Glass-Fused-to-Steel tanks and biogas systems provide reliable and efficient performance.

Tailored Solutions: We customize our biogas solutions to meet the unique requirements of each industry.

Global Expertise: With over 30 years of experience and a global presence, we are a trusted partner in the biogas industry.

As a leading biogas project contractor, Shijiazhuang Zhengzhong Technology Co., Ltd is committed to delivering sustainable, innovative, and efficient biogas solutions to meet the growing demands of the global market.

Contact us today to learn how we can help you harness the power of biogas and achieve your sustainability goals!

0 notes

Text

National Knife Day

Grab or pull out your knives! Today we celebrate them, no matter their size, style, or brand! It is unknown who started National Knife Day or when they started it, but it was being celebrated by at least 2011. It is also unknown why the observance takes place on August 24, but one explanation appears to be that the date is connected to the Bowie knife. It was on this date in 1838 that Rezin Bowie, the brother of the knife’s namesake, wrote a letter to the Planters’ Advocate claiming he was the person who had created the knife.

One of the earliest tools known to humankind, the knife was present at the beginnings of the development of human civilization and came out of the need for survival. Early on, knives were used as primitive tools for digging and construction, as weapons, and to hunt, fish, and gather food. In contrast to today, almost everyone carried a knife. The first knives were made of stones which were cracked to make a sharp edge like a blade. Sharpened stone tools became more advanced during the late Lithic periods, and then even more so during the Copper and Bronze Ages. Metal blades appeared, which weren’t as sharp and didn’t stay sharp as long as the stone blades that preceded them. This led to the introduction of sharpening stones.

During the Iron age, tools became stronger and more durable. Iron knives came on the scene and stayed sharper longer. Steel blades followed iron ones, and not much has changed since then. Steel blades, which are made of an alloy of iron that has carbon, are the most common today and are known for being durable and efficient. Cobalt alloys and titanium are also used in knife making today.

Early knives didn’t have a separate handle and blade—they were all one piece. Eventually, handles began being made out of carved bone, wood, and metal, and then, rare materials like mother-of-pearl and tortoiseshell began being used. Today, wood is one of the most popular materials used for knife handles, and metals like stainless steel are also common. One other change besides that advent of a separate handle was the invention of the folding knife.

Knives have many different purposes in the present day, some of which are the same as they have been for thousands of years. Some ways they are used are to prepare food, as a utensil when eating food, by surgeons and medical professionals, to dress an animal, to fillet a fish, and for carving. There are various types of kitchen knives such as the chef’s, utility, paring, and bread knives. Most knives are affordable to just about anyone, but there are high-end custom knives such as Randall Made Knives, most of which sell for $400 of more. In many locations, there are laws that pertain to knives: ownership laws exist for certain types of knives, open and concealed carry laws apply to certain types of knives, and other types of laws exist, such as those that say a robbery is an “aggravated crime” with more severe punishment if a knife is involved. There also are certain areas where some types of knives are not permitted, such as at schools or on planes.

How to Observe

Knives should be used more today than on any other day of the year. Here are a few ideas on how to spend the day:

Do some knife throwing.

Do some whittling.

Prepare some food using a knife or multiple knives. It might be beneficial to first learn what type of knife is appropriate for different types of food.

Get a pocket knife, which has many uses.

Check for knife promotions such as giveaways and sales happening today. This is often a large part of the day.

Give someone a knife as a gift.

Clean, oil, and sharpen your knives.

Carry your knives around in a holster.

Cut a lot of things with your knives, such as food, paper, and rope.

Source

#National Knife Day#USA#Canada#Germany#Schnitzel-Himmel und Erde#food#restaurant#travel#vacation#original photography#Fire Jumper Burger#steak#filet#burger#bread#cookie#NationalKnifeDay#24 August#Jacobs & Co. Steakhouse#Louis M. Martini Winery#St. Francis Winery & Vineyards

3 notes

·

View notes

Text

How Pipe Tees Work: A Crucial Component in Piping Systems

Pipe tees are essential components in piping systems, providing a means to create branches or connections between pipes. They play a vital role in various industries, including oil and gas, power generation, chemical processing, and construction.

Types of Pipe Tees

There are several types of pipe tees, each with its own unique characteristics and applications:

Equal Tee: This is the most common type of tee, with all three outlets having the same diameter.

Reducing Tee: A reducing tee has two outlets of the same diameter, and one outlet of a smaller diameter.

Branch Tee: A branch tee has a main outlet and a smaller branch outlet.

Lateral Tee: Similar to a branch tee, but with the branch outlet positioned at a specific angle.

Saddle Tee: A saddle tee is a specialized type of tee that is welded onto an existing pipe to create a branch connection.

How Pipe Tees Work

Pipe tees work by providing a junction point where two or more pipes can be connected. The flow of fluid or gas through the main outlet of the tee can be divided and directed into the branch outlet(s), allowing for the distribution of the fluid or gas to different parts of a system.

Key Factors Affecting Pipe Tee Performance

Several factors can influence the performance of pipe tees, including:

Pipe Size: The size of the pipe tee and its outlets will determine the flow capacity and pressure drop.

Material: The material of the pipe tee, such as stainless steel or carbon steel, will affect its durability and corrosion resistance.

Flow Direction: The direction of flow through the tee can impact the pressure distribution and turbulence.

Installation: Proper installation, including alignment and support, is essential for optimal performance.

Platinex Piping Solutions

Platinex is a renowned brand offering high-quality stainless steel piping solutions, including pipe tees. These fittings are manufactured by Ratnamani Metals and Tubes Limited (RMTL), a leading Indian stainless steel company.

Platinex pipe tees are ideal for various applications, including:

Oil and gas industry: For connecting pipelines and process equipment.

Power generation: For steam, water, and fuel lines.

Chemical processing: For handling corrosive and hazardous substances.

Construction: For plumbing systems and HVAC applications.

Platinex pipe tees offer several benefits, such as:

Corrosion resistance: Stainless steel provides excellent resistance to corrosion, ensuring long-term durability.

High-temperature resistance: Platinex fittings can withstand high temperatures, making them suitable for demanding applications.

Precision manufacturing: RMTL ensures precise dimensions and tolerances in Platinex fittings, guaranteeing proper fit and function.

Customizable solutions: Platinex can provide customized pipe tees to meet specific requirements.

Conclusion

Pipe tees are essential components in piping systems, providing a means to create branches or connections between pipes. By understanding the different types of pipe tees and their applications, you can select the appropriate fittings for your specific needs. Platinex piping solutions offer high-quality stainless steel pipe tees that are well-suited for a wide range of industries.

0 notes

Text

How Custom Sheet Metal Fabrication Boosts Manufacturing Efficiency?

Efficiency is key in manufacturing, and custom sheet metal fabrication plays a significant role in streamlining production processes. By allowing manufacturers to create parts and components that meet specific needs, this form of fabrication helps eliminate inefficiencies, reduce waste, and improve overall productivity. Custom sheet metal fabrication allows for precise cuts, bends, and welds, ensuring that each piece fits perfectly within a larger assembly. This precision reduces the likelihood of errors and rework, ultimately saving time and money. The integration of advanced technologies, such as CNC machining and laser cutting, further enhances the efficiency of custom sheet metal fabrication. These technologies enable the production of complex designs with high accuracy, making it easier to create intricate parts in large quantities without sacrificing quality. Moreover, the flexibility to work with various metals, including steel, aluminum, and copper, allows manufacturers to select materials that best suit the application, leading to better performance and longer-lasting products.

Custom Sheet Metal Fabrication for Architectural Projects

Architects often turn to custom sheet metal fabrication for creating unique, durable, and aesthetically pleasing structures. From decorative facades to intricate metal fixtures, custom fabrication allows for the design of elements that are both functional and artistic. Sheet metal can be manipulated into complex shapes and forms that are not achievable with other materials. This flexibility makes it ideal for custom projects where specific designs need to be brought to life. Fabricators can work closely with architects to ensure that the metal components are tailored to fit the project’s vision and specifications.

The Environmental Benefits of Custom Sheet Metal Fabrication

Custom sheet metal fabrication is not only a highly efficient process but also offers several environmental benefits. The precise nature of the fabrication process leads to minimal material waste, making it a more sustainable option. Many companies also recycle leftover metals, further reducing the environmental impact. Additionally, metals like aluminum and steel are inherently recyclable, meaning that parts created through custom sheet metal fabrication can be repurposed at the end of their life cycle. This contributes to a more eco-friendly manufacturing process and reduces the overall carbon footprint.

Custom Sheet Metal Fabrication for Automotive Parts

In the automotive industry, custom sheet metal fabrication plays a vital role in the creation of specialized parts. Whether for vintage car restorations or high-performance vehicles, fabricators can create custom metal components that meet specific requirements. Custom sheet metal parts offer improved fit and function, which can enhance the performance and longevity of a vehicle. From body panels to exhaust systems, the automotive industry relies on the precision and expertise of custom fabricators to produce parts that meet both performance and aesthetic standards.

Welding Techniques in Custom Sheet Metal Fabrication

Welding is a crucial component of custom sheet metal fabrication. Different welding techniques, such as MIG, TIG, and spot welding, are used depending on the type of metal and the specific requirements of the project. Skilled welders ensure that metal joints are strong, durable, and clean. Proper welding is essential for ensuring that the fabricated parts hold up under stress and are safe for their intended application. The expertise of the welder and the choice of welding technique can greatly impact the quality of the finished product.

Custom Sheet Metal Fabrication for Home Renovations

Homeowners and contractors often turn to custom sheet metal fabrication for unique home renovation projects. Custom metalwork can be used to create everything from kitchen backsplashes to roofing materials, ensuring that each element is both functional and aesthetically pleasing. Fabricators work with homeowners to design metal components that fit their specific needs, adding a personal touch to the project. Whether you’re looking for custom railings, countertops, or outdoor furniture, custom sheet metal fabrication provides a durable and stylish solution.

CNC Machines in Custom Sheet Metal Fabrication

CNC (Computer Numerical Control) machines have revolutionized custom sheet metal fabrication by offering precise and automated control over cutting and shaping processes. These machines are programmed using CAD software and can execute complex designs with incredible accuracy. CNC machines eliminate the risk of human error and significantly speed up production time. This technology allows fabricators to take on intricate and large-scale projects with consistent quality. By incorporating CNC technology, custom sheet metal fabrication has become more efficient and cost-effective.

Custom Sheet Metal Fabrication in Aerospace Industry

The aerospace industry depends on custom sheet metal fabrication for the production of high-performance components. Aerospace parts require extreme precision, as they must withstand high pressures, temperatures, and mechanical stress. Custom sheet metal fabricators create components such as engine parts, airframes, and structural supports that meet stringent industry standards. The ability to customize parts ensures that they fit perfectly within complex aerospace systems, helping to improve the safety and performance of aircraft. The use of lightweight metals like aluminum also contributes to fuel efficiency and overall aircraft performance.

Conclusion

Choosing custom sheet metal fabrication offers numerous benefits, including precision, durability, and customization. Whether you're working on an industrial, automotive, or architectural project, custom fabrication ensures that your metal components are designed to exact specifications, maximizing efficiency and performance. The use of modern tools and techniques, such as laser cutting and welding, guarantees high-quality results. In an age where unique designs and tailored solutions are increasingly important, investing in custom sheet metal fabrication can help you achieve superior outcomes that meet both functional and aesthetic goals.

0 notes

Text

Fasteners Manufacturers in India: A Growing Industry Powering Global Markets

Jinnox Bolt is one of the leading Fasteners Manufacturers in India. We supply fasteners made of different materials, including Stainless steel, Carbon steel, High tensile, Inconel, Monel, and Hastelloy. We are a top Fasteners Suppliers in India We also provide customized solutions to clients by delivering top-notch quality and other types of fasteners with specified qualities.

India’s fasteners manufacturing industry is one of the key sectors driving the nation's industrial growth. From automotive to construction, and from aerospace to infrastructure development, fasteners play a crucial role across a wide range of industries. The rise of Indian fasteners manufacturers over the years has been nothing short of remarkable, and today the country stands as a significant player in the global fasteners market.

Overview of the Fasteners Industry in India

Fasteners are components used to mechanically join two or more objects together. They include a variety of items like nuts, bolts, washers, rivets, screws, and specialized parts. In India, the fasteners industry can be broadly divided into two categories: industrial fasteners and automotive fasteners. The latter accounts for a significant share, driven by the growing demand from the automotive sector.

The Indian fasteners industry is currently valued at approximately $4 billion, and this figure is expected to grow significantly in the coming years. The reasons behind this growth are manifold – increasing infrastructure projects, growing domestic automotive production, and a surge in demand from overseas markets. Additionally, government initiatives like "Make in India" have further bolstered manufacturing capabilities, encouraging both domestic and foreign investments in this sector.

Major Hubs for Fasteners Manufacturing in India

India's Fastener Manufacturers are concentrated in a few key regions that have evolved into industrial hubs over the years. These include:

Ludhiana, Punjab: Known as the “fasteners capital” of India, Ludhiana houses a large number of small and medium enterprises (SMEs) involved in manufacturing fasteners. This region accounts for a significant share of the fasteners production in the country, especially for the automotive and bicycle industries.

Pune, Maharashtra: Pune is an important industrial hub, especially for automotive fasteners. The presence of major automobile companies in and around Pune has attracted many fasteners manufacturers to set up production facilities here.

Gurgaon, Haryana: Another key center for automotive fasteners, Gurgaon’s proximity to the National Capital Region (NCR) makes it an attractive location for fasteners manufacturers catering to the automotive and construction sectors.

Rajkot, Gujarat: Rajkot is emerging as a growing hub for fasteners, with manufacturers here focusing on producing precision fasteners that cater to both domestic and international markets.

Fasteners Products We Manufactured

Bolt Manufacturers in India

Nut Manufacturer in India

Washers Manufacturer in India

Threaded Rod Manufacturers in India

Screw Manufacturer in India

Coated Fasteners Manufacturer in India

Key Factors Driving the Growth of Fasteners Manufacturing in India

Several factors have contributed to the rapid growth of the Fastener Manufacturers in India:

Increased Demand from the Automotive Sector: India is one of the largest automobile manufacturers in the world. The demand for automotive fasteners has skyrocketed, especially with the rapid adoption of electric vehicles (EVs). Fasteners play a crucial role in EV assembly, and Indian manufacturers have stepped up to meet this demand.

Infrastructure Development: Massive infrastructure projects across the country, including highways, bridges, and metro systems, have significantly increased the demand for industrial fasteners. Fasteners are essential components in construction, and the ongoing urbanization and industrialization efforts in India are fueling this demand further.

Government Support and Initiatives: The Indian government’s focus on boosting manufacturing under the “Make in India” initiative has provided a boost to the fasteners sector. Policies promoting ease of doing business, tax benefits, and incentives for manufacturers have helped attract both domestic and foreign investment.

Export Growth: India has emerged as a key exporter of fasteners to markets in Europe, North America, and the Middle East. Indian manufacturers are recognized for producing high-quality fasteners at competitive prices, which has helped expand their footprint in global markets. Countries like the United States, Germany, and the UAE are some of the major importers of Indian fasteners.

Future Outlook

The future of Fasteners Suppliers in India looks promising. With continued investment in infrastructure, a robust automotive industry, and growing demand for exports, the industry is poised for sustained growth. Technological advancements and the adoption of Industry 4.0 practices will likely play a pivotal role in shaping the future of fasteners manufacturing in India.

In conclusion, the Fasteners Suppliers sector in India is not only an integral part of the country’s industrial ecosystem but also a growing player on the global stage. By addressing key challenges and capitalizing on emerging opportunities, Indian fasteners manufacturers are set to continue their growth trajectory in the years to come.

0 notes