#ControlSystem

Explore tagged Tumblr posts

Text

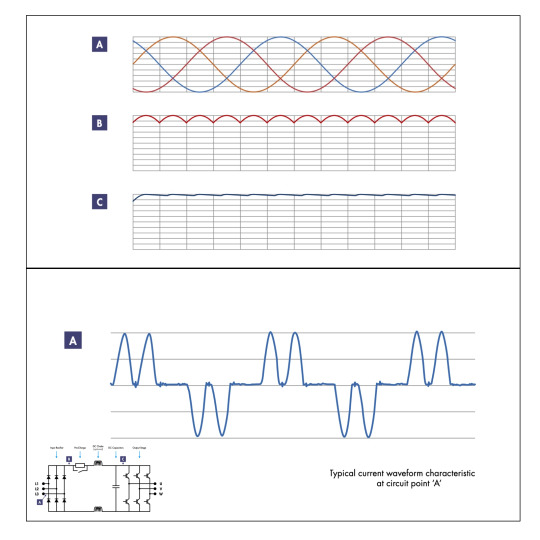

VFD Circuit Design (Continued) - Variable Frequency Drives

The VFD Exchange

#variablefrequencydrives#vfd#acdrives#industrial#controlsystem#acmotors#variablespeed#variabletorque#inverters#drives#electrical#engineering#automation#volts#amps#kilowatts#1phase#3phase#manufacturing#crushers#quarries#farms#agricultural#heating#ventilation#airconditioning#irrigationpump#watersupply#marine#ports

0 notes

Text

Autonomous Vehicle Control

July 18, 2024

by dorleco

with no comment

Autonomous Vehicle Technology

Edit

Introduction

Self-driving automobiles, sometimes referred to as autonomous vehicles, are a cutting-edge technological advancement that could revolutionize our daily lives and modes of transportation. These cars mimic a human driver’s decision-making process by using sensors, software, and control systems to make real-time decisions. They are designed to function alone and navigate. This introduction will examine the fundamental concepts and components of autonomous vehicle control.

1. Sensors

Lidar: Laser-based sensors that create accurate three-dimensional images of an object’s surroundings when it moves.

Radar: Radar uses radio waves to calculate the relative speed and distance of an object.

Cameras: Make use of cameras to capture images and videos that help identify lane markers, traffic signs, and other cars.

Ultrasonic sensors: Use them to find objects nearby to aid with parking and slow-moving situations.

GPS: Provides location information and facilitates navigation.

2. Control systems:

Autonomous Vehicle Control depends on sophisticated control systems to make decisions in real time. These systems perform control functions for the vehicle, including steering, braking, acceleration, and more, by analyzing sensor data. Safe and efficient driving is ensured by control algorithms, even in complex and dynamic environments.

3. Perception and Mapping:

Perception algorithms facilitate the car’s comprehension of its environment. They recognize objects, predict their movements, and assess the risks. Concurrently, mapping software creates up-to-date, precise maps of the road network to aid with vehicle navigation.

4. Place-Based:

Autonomous cars need to know where they are at all times. GPS alone is not sufficient for this. Advanced systems such as Simultaneous Localization and Mapping (SLAM) let vehicles maintain precise positioning by combining map information and sensor data.

5. Coming to a Decision:

The brain of the autonomous vehicle consists of its decision-making algorithms. They look at sensor data, traffic conditions, and route information to determine when to change lanes when to stop at a traffic signal, and how to avoid obstructions. These algorithms need to put safety first while accounting for other factors like passenger preferences and traffic laws.

6 . Redundancy and Safety:

Autonomous Vehicle Control safety is a critical concern. These vehicles are designed with multiple layers of redundancy, including backup sensors and control systems, to mitigate the consequences of component failures. To make sure they adhere to strict safety regulations, they also undergo extensive testing and validation.

7. Difficulties and Moral Issues:

The development and application of autonomous vehicles face several challenges, including ethical and legal ones. For example, figuring out who is at fault in an autonomous vehicle accident remains challenging. It is also debatable how, in morally questionable situations, these cars should put safety first.

Benefits of Driverless Vehicles

Autonomous vehicle control has many potential benefits that could completely change our perspective on transportation. The following are a few of the primary advantages of autonomous vehicles:

Safety Improvement:

Autonomous cars have the potential to significantly reduce traffic accidents. The majority of accidents are the result of human error, such as inattentive driving or bad judgment. The capacity of autonomous automobiles to follow traffic laws and make decisions based on sensor data may make roads safer.

Reduction of Traffic Jams:

Enhanced fuel efficiency:

Autonomous vehicles consume less fuel overall because they can optimize their driving behaviors and speeds. By doing this, greenhouse gas emissions and the general harm that transportation does to the environment can be reduced.

Enhanced Mobility for the Elderly and Disabled:

Autonomous cars may provide a new level of mobility to people who are unable to drive because of age- or disability-related limitations. This could enhance their level of independence and well-being.

Enhanced Productivity and Leisure Time:

By enhancing their productivity and leisure time, passengers in autonomous vehicles can make better use of their travel time. The passengers can work, read, or have fun while the car is moving. This could increase overall productivity and reduce stress from the journey.

Decreased Parking Demand:

Autonomous vehicles’ capacity to pick up passengers and park in more convenient or far-off locales can reduce the demand for premium parking spots in urban areas. This could lead to a decreased requirement for parking infrastructure and improved area utilization.

Savings:

The cost of transportation as a whole could be reduced by autonomous vehicles. People can now choose on-demand transportation over owning a personal vehicle, saving money on expenses like fuel, insurance, and maintenance, thanks to autonomous ride-sharing services.

Drawbacks of Driverless Transportation

While there is much promise for autonomous car technology, there are several potential risks and challenges as well. Some disadvantages and problems with autonomous vehicle control are as follows:

Limitations of the technology:

Autonomous car technology is continuously evolving and not perfect. They might struggle to operate in inclement weather, deal with unforeseen situations, or recognize objects like bicyclists and pedestrians.

High Development Costs:

It will cost a lot of money to develop and test autonomous car technology. These costs could drive up the cost of vehicles by making the technology unaffordable for smaller enterprises.

Cyber security Risks:

Autonomous vehicles are susceptible to hacking and other internet threats because they rely so heavily on software and communication. A successful attack might compromise vehicle security and privacy.

Data privacy issues:

Autonomous vehicles gather a lot of information about their environment, passengers, and driving habits. There are worries about how this data is handled, used, and protected because it may violate people’s right to privacy.

Liability and Legal Concerns:

Establishing culpability in an autonomous vehicle collision can be challenging. Who is at fault — the vehicle’s manufacturer, the owner, or the software developer? Resolving these legal issues might be challenging.

Employment displacement:

As autonomous cars become more common, employment in transportation-related industries like trucking and taxi services may decline. There could be social and economic repercussions from this.

Ethical Conundrums:

Regulatory Difficulties:

Developing comprehensive legislation for autonomous vehicles is a challenging and drawn-out process. Varied regions and countries have varied rules and regulations, which could lead to discrepancies and possible adoption hurdles.

Conclusion:

In conclusion, the development of autonomous vehicle control has great promise for changing the way we think about transportation. The high level of autonomy that autonomous vehicles can operate at thanks to the integration of sensors, advanced software, and control systems presents several potential advantages. A few of these advantages are better safety, less traffic, more fuel efficiency, better mobility for the old and disabled, more productivity when traveling, and other economic and environmental savings.

Nonetheless, it’s critical to recognize the difficulties and worries related to autonomous vehicles. Technological constraints, exorbitant development expenses, cyber security threats, privacy issues regarding data, legal and liability complications, the possibility of job displacement, moral conundrums, and regulatory intricacies are all included in this list of challenges. In addition, discrepancies in accessibility, customer trust, and infrastructure adaption need to be taken into account.

It’s crucial to find a balance between tackling the problems that come with autonomous vehicles and maximizing their potential advantages as research and development go forward. To fully realize the potential of autonomous vehicle control, careful regulation, continuous research and development, and a strong commitment to safety and ethical issues are essential. Though the route to completely autonomous vehicles may be convoluted, it offers the prospect of future mobility that is safer, more effective, and more easily available.

#autonomousvehicle#controlsystem#VCU#VCUSupplier#Dorleco#Automation#Microcontrollers#programmableVCU

0 notes

Text

Static Test Bed Facility | Digilogic Systems

Digilogic Systems offers turnkey solutions for evaluating rocket/jet engine performance for Defense and Aerospace. Our solutions include Data Acquisition Systems designed to collect and analyze critical data from engine/motor tests. These Data Acquisition Systems for the test facility come in various types to handle specific data streams.

Various types of Data Acquisition Systems (DAS) include: MAIN DAS-1 MAIN DAS-2 High Bandwidth Data Recorder Real-Time Display DAS Flexi Nozzle Control DAS Temperature DAS-1 Temperature DAS-2 Strain DAS-1 Strain DAS-2 Vibration & Acoustic DAS-1 Vibration & Acoustic DAS-2

The collected data helps engineers to improve engine design, boost performance, and identify issues. With Digilogic's Static test bed facility, the defense and aerospace sectors benefit from advanced data collection and analysis, ensuring optimal engine performance and reliability.

If you would like more information (or) to request a quote, please feel free to contact us. Phone: Hyderabad: (+91) 40 4547 4601 Bengaluru: (+91) 80 4975 6034 Website: https://www.digilogicsystems.com/ Email: [email protected]

Please stay connected with us on our other social media channels for the latest updates!

Facebook: https://www.facebook.com/digilogicsystems LinkedIn: https://www.linkedin.com/company/digilogicsystems/ YouTube: https://www.youtube.com/@digilogicsystems/ Instagram: https://www.instagram.com/digilogic_systems/ Twitter: https://twitter.com/DigilogicSystem

#Statictest#DataAcquisitionSystem#performancetest#digilogicsystems#EngineOrientation#Actuators#FlightTesting#ControlSystem#Stabilization#rocketscience#engineering#TestEquipment#TestandMeasurement#defence#aerospace#aerospaceengineering

0 notes

Text

Fireye Sb560232Aa-120Vac5/10Tfi,Uv, No Purge | PartsHnC

The Fireye SB560232AA 120Vac5/10Tfi, UV, No Purge is an innovative safety control system for HVAC equipment. This gadget makes sure that heating and cooling systems run safely and effectively by utilizing cutting-edge technology. This functions by using its ultraviolet sensors to identify the presence of flames and then initiating the necessary actions to uphold safety regulations. This product enhances energy efficiency and lowers operating costs by providing dependable flame detection without requiring an exhaust cycle, making it compatible with a variety of HVAC equipment, including boilers and furnaces. The accurate detection abilities provide comfort by preventing any risks and enhancing HVAC system performance.

0 notes

Text

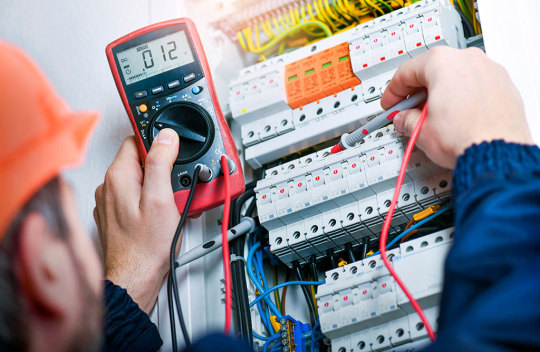

What Causes I/O Noise and Interference in PLC Systems? 8 Common Culprits Revealed!

Exploring Common Causes and Solutions for I/O Noise and Interference in PLC Systems

In the realm of industrial automation, PLC (Programmable Logic Controller) systems are indispensable, overseeing the operation of machinery and processes efficiently. However, they face a challenge: I/O (Input/Output) noise and interference. These disruptions can disrupt system stability, leading to malfunctions and downtime. In this comprehensive guide, we delve into the causes and solutions for I/O noise and interference in PLC systems, addressing 8 common culprits that engineers and technicians should understand well.

Understanding I/O Noise and Interference

Before delving into specific causes and solutions, it's crucial to understand the nature of I/O noise and interference. I/O noise refers to unwanted electrical signals or disturbances that corrupt intended signals in PLC systems. Interference includes external factors like electromagnetic radiation, radio frequency interference (RFI), and electromagnetic interference (EMI) disrupting communication between PLC components.

Power Supply Issues: The Silent Saboteur

A stable power supply is crucial for any PLC system. However, fluctuations or disturbances can introduce noise, jeopardizing performance. Issues like voltage spikes, dips, and harmonics can arise, impacting power quality and increasing I/O noise.

Grounding Problems: Unearthing the Root Cause

Proper grounding is vital in mitigating I/O noise and interference. However, inadequate practices can amplify noise within the system. Ground loops and poor connections can create pathways for unwanted currents, resulting in signal distortion and ground noise.

Electromagnetic Interference (EMI): Taming the Invisible Beast

EMI originates from various sources like nearby motors and power lines, inducing unwanted voltages in nearby cables and components. Shielding cables, using twisted pair wiring, and relocating sensitive components can mitigate EMI.

Radio Frequency Interference (RFI): Navigating the Airwaves

RFI, found in industrial environments bustling with wireless devices, poses a threat to PLC systems. Employing frequency filtering techniques and shielding can mitigate RFI.

Crosstalk: When Signals Collide

Crosstalk occurs when adjacent conductors induce voltages in neighboring cables, leading to signal interference. Shielding, spacing, and wiring techniques can mitigate crosstalk.

Environmental Factors: Nature's Influence

External factors like temperature fluctuations and humidity can impact PLC systems. Extreme temperatures and humidity levels accelerate corrosion and compromise signal integrity, while contaminants can lead to short circuits.

Component Aging: The Silent Deterioration

Over time, components within PLC systems deteriorate, impacting performance and reliability. Regular maintenance and component inspection are essential to mitigate aging's impact.

FAQs (Frequently Asked Questions)

1. How do I identify I/O noise in PLC systems? Signal integrity tests using oscilloscopes help pinpoint irregularities in waveforms indicative of noise interference.

2. Can inadequate shielding contribute to I/O noise? Yes, it allows external electromagnetic fields to penetrate cables. Proper shielding minimizes noise ingress.

3. What role does firmware/software play in mitigating I/O noise? Updates may include optimizations or algorithms to filter noise, reducing its impact.

4. Are there industry standards for mitigating I/O noise? Yes, standards like IEC 61000 provide guidelines for EMC.

5. How can ground loops be prevented? Ensuring all ground connections are made at a single point eliminates potential differences and minimizes ground loop currents.

6. What measures mitigate environmental factors' impact? Installing PLCs in controlled environments and using protective enclosures safeguard components from environmental hazards. For more information visit here👉PujaControls

#PLCInterference#EMIandRFI#IndustrialAutomation#ElectricalNoise#PLCTroubleshooting#SignalInterference#ElectricalEngineering#AutomationTechnology#IndustrialControl#NoiseFiltering#ControlSystem#EMIProtection#RFISuppression#FactoryAutomation

0 notes

Text

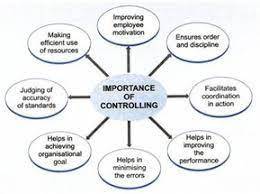

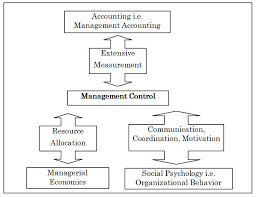

Control Mechanisms and Gaining a Competitive Advantage

The Importance of Control

Types of Controls

Control Systems in Operations

ORGANIZATIONAL CONTROL AND STEPS IN THE CONTROL PROCESS

1 note

·

View note

Text

youtube

I wrote a simple program for Scene2. I implemented states using a word in memory to hold the state id and then compare and movp to change between the states. I also added timers to each state to generate a fault if the state does not complete without the expected time specified. I did not create any logic to handle the error so for now the PLC just flags and continues. Next I would add the routines for error handling and also the EMO logic. I will leave it for now and continue to the next simulation.

https://href.li/?https://github.com/grimmonkey52/Mitsubishi_PLC_projects/blob/main/FIO_SCENE2/SCENE2.pdf

0 notes

Text

Delve into the Core Components of Dust Collection Systems. Discover the Power Source, Particle Separators (Vessels), and System Control, and Elevate Your Workplace Cleanliness to New Heights!

For more details, visit- https://www.acmeairequipments.com/product/dust-collection-system/

0 notes

Text

PLC Programming Using CODESYS: An In-Depth Exploration

Programmable Logic Controllers (PLCs) are foundational to industrial automation, providing the control necessary for machinery and processes across various industries. Among the myriad of PLC programming environments available, CODESYS stands out as a versatile and powerful platform. This article delves into the intricacies of PLC programming using CODESYS, its adherence to the IEC 61131-3 standard, fieldbus support, IoT connectivity, and the services offered by Servotech Inc. in this domain.

Understanding CODESYS

CODESYS is a commercial PLC programming tool and real-time software platform designed for PLCs and embedded controllers. It offers a comprehensive suite of features that facilitate the development, testing, and deployment of control applications. One of its notable strengths is its manufacturer-independent nature, allowing engineers to program controllers from various vendors using a unified interface.

Adherence to IEC 61131-3 Standard

The IEC 61131-3 standard defines the programming languages and structures for PLCs, promoting consistency and interoperability across different systems. CODESYS supports all five languages outlined in this standard:

Instruction List (IL): An assembler-like language for low-level programming.

Structured Text (ST): A high-level, Pascal-like language suitable for complex algorithms.

Ladder Diagram (LD): A graphical language resembling electrical relay logic diagrams, widely used for its intuitive representation.

Function Block Diagram (FBD): A graphical language that uses blocks to represent functions and their interconnections.

Sequential Function Chart (SFC): A graphical language for depicting sequential control processes.

By adhering to this standard, CODESYS ensures that engineers can transition between different PLC hardware platforms without the need to learn new programming environments, thereby enhancing efficiency and reducing training costs.

Fieldbus Support in CODESYS

Fieldbus systems are critical for enabling communication between various components in an industrial setup. CODESYS provides extensive support for multiple fieldbus protocols, including:

EtherCAT: A high-performance Ethernet-based fieldbus system suitable for real-time control applications.

CAN Bus (CANopen, J1939): Widely used in automotive and industrial applications for robust communication.

Modbus: A serial communication protocol prevalent in connecting industrial electronic devices.

PROFIBUS: A standard for fieldbus communication in automation technology.

This extensive fieldbus support allows for seamless integration of various devices and systems, facilitating the development of complex automation solutions.

IoT Connectivity with CODESYS

In the era of Industry 4.0, the integration of IoT (Internet of Things) capabilities into industrial automation systems is paramount. CODESYS offers robust IoT connectivity features, enabling:

Remote Monitoring and Control: Access and control PLCs from remote locations, enhancing flexibility and responsiveness.

Data Logging and Analysis: Collect and analyze data from various sensors and devices to optimize processes and predict maintenance needs.

Cloud Integration: Seamlessly connect with cloud platforms for data storage, processing, and advanced analytics.

These IoT capabilities empower industries to implement smart manufacturing practices, leading to increased efficiency and reduced operational costs.

Servotech Inc.: Expertise in CODESYS PLC Programming

Servotech Inc. is a leading provider of PLC programming services utilizing the CODESYS platform. Their team of experienced engineers offers comprehensive solutions, including:

Custom PLC Application Development: Tailored solutions to meet specific automation requirements across various industries.

System Integration: Seamless integration of PLCs with existing hardware and software systems, ensuring optimal performance.

Training and Support: Providing clients with the knowledge and tools necessary to maintain and expand their automation systems effectively.

By leveraging CODESYS's versatile platform, Servotech Inc. delivers robust and scalable automation solutions that adhere to international standards.

Conclusion

PLC programming by Servotechinc using CODESYS offers a flexible and standardized approach to industrial automation. Its compliance with the IEC 61131-3 standard, extensive fieldbus support, and IoT connectivity make it a preferred choice for engineers and organizations aiming to develop sophisticated control systems. Servotech Inc.'s expertise in utilizing CODESYS further enhances the potential for creating customized, efficient, and future-ready automation solutions

#PLCProgramming#IndustrialAutomation#CODESYS#AutomationEngineering#SmartManufacturing#EmbeddedSystems#IndustrialControl#FactoryAutomation#IoTIntegration#ControlSystems

0 notes

Text

B.Tech - Mechatronics Engineering

B.Tech in Mechatronics Engineering is a multidisciplinary program that combines elements of Mechanical Engineering, Electronics, Computer Science, and Control Engineering. It aims to create engineers capable of designing and developing intelligent systems, robotics, automation, and advanced machinery. This program is perfect for students passionate about working with cutting-edge technologies such as robotics, AI, automation, and smart systems.

Curriculum and Key Subjects:

The B.Tech program is typically a four-year course, divided into eight semesters, focusing on both theoretical and practical aspects. Some key subjects include:

Mechanical Design and Manufacturing

Control Systems and Automation

Electronics and Sensor Systems

Embedded Systems

Robotics and Intelligent Systems

AI and Machine Learning

Programming for Mechatronics Systems

The program also includes laboratory work, projects, and internships to help students gain hands-on experience in designing and integrating complex systems.

Career Opportunities:

Graduates of B.Tech Mechatronics Engineering can work in various industries like robotics, aerospace, automotive, manufacturing, healthcare, and consumer electronics. Some job roles include Robotics Engineer, Automation Engineer, Mechatronics Engineer, and Control Systems Engineer.

Conclusion:

B.Tech in Mechatronics Engineering provides a strong foundation for students to pursue exciting careers in high-tech industries, offering immense growth potential in the fields of robotics, automation, and AI-driven technologies.

#MechanicalEngineering#ElectronicsEngineering#ControlSystems#AIandRobotics#SmartMachines#EngineeringEducation#TechInnovation#EmbeddedSystems#IndustrialAutomation#FutureOfEngineering#MechatronicsDesign#RoboticSystems#EngineeringStudents#MechatronicsCareer#RoboticsAndAI

1 note

·

View note

Text

Motor control technology

July 16, 2024

by dorleco

with no comment

Autonomous Vehicle Technology

Edit

The application of different methods and technologies to coordinate and guide the operation of motors is known as motor control technology. Motors transform electrical energy into mechanical motion. They are extensively utilized in many different industries, including robotics, automotive systems, home appliances, and industrial gear. For motors to operate precisely, effectively, and safely in a variety of situations, motor control technology is essential. Several noteworthy facets of motor control technology include the following:

1. Motor controllers:

Microcontrollers and microprocessors, which execute control algorithms, interpret feedback, and generate signals that move the motor, are the brains behind motor control systems.

In motor control applications, digital signal processors, or DSPs, are widely used to interpret signals in real time and enable faster, more accurate control.

2. Algorithms for Control:

PID Management: A popular algorithm for controlling a motor’s speed, position, or torque is proportional-integral-derivative (PID) control. It adjusts control parameters based on the difference between the desired and actual values.

FOC, or field-oriented control: FOC is widely used in AC motor control to independently manage the torque and flux components to increase performance and efficiency.

3. Sensors:

· Encoders: These devices provide information about the motor’s location, allowing for precise position tracking and control.

· Hall Effect Sensors: These sensors monitor the position of the rotor and turn on the motor windings in brushless DC motors.

4. Electronic Drives:

· Inverters: These devices control the output voltage and frequency while transforming DC power into AC electricity for AC motors.

· Amplifiers: Increase the control signals from the controller to the power levels required by the motor.

5. Protocols for Communication:

· Ethernet and Wireless Communication: These technologies, which offer advantages like remote monitoring and control, enable communication in networked systems.

6. Power Electronics:

· Power Factor Correction (PFC): Improves the energy efficiency and power factor of the motor control system.

· Variable frequency drives (VFD) and soft starts: By enabling motors to accelerate and decelerate under control, VFDs and soft starters reduce mechanical stress and energy consumption.

7. Enhanced Features:

Regenerative braking allows the motor to act as a generator by recovering energy during braking and transferring it back into the power source.

By employing sensors and data analytics to detect possible motor breakdowns, predictive maintenance enables proactive maintenance.

8. Industry 4.0 integrating IoT:

· IoT Connectivity: By connecting motor control systems to the Internet of Things (IoT), it is possible to diagnose, monitor, and control them from a distance.

· Data analytics: Motor performance optimization, efficiency increase, and predictive maintenance.

The advantages of motor control technology

Applications for motor control technology can be found in many different fields. The following are some of the main benefits:

1. Efficiency of Energy Use:

Motor speed, torque, and position can all be precisely controlled by motor control systems, which maximize energy consumption.

Power Factor Correction (PFC) and Variable Frequency Drives (VFDs) are two examples of energy-saving technologies that enhance power factor and adjust motor operation in response to demand.

2. Precision & Accuracy:

Advanced control algorithms such as PID and Field-Oriented Control (FOC) provide precise control over motor parameters, ensuring proper motion and placement in robotics and industrial processes.

3. Improved Results:

The performance of the system is enhanced overall because motor control technology enables smoother acceleration and deceleration and lessens wear and tear on mechanical components.

Faster reaction times and improved dynamic behavior are a result of strong motor control systems.

4. Lower Maintenance Expenses:

Predictive maintenance features, which save maintenance costs and downtime by identifying issues before they lead to equipment failure, are made possible by motor control technology.

Two more elements that increase equipment life and reduce maintenance requirements are soft starts and controlled acceleration and deceleration.

5. Adaptability and Flexibility:

Motor control systems can be employed in situations where the load needs fluctuate because of their flexibility.

Programmable controllers and flexible communication protocols enable easy integration into a wide range of automation systems.

Motor control technology can recover energy during braking and deceleration through the use of regenerative braking.

This feature can be particularly useful in situations where stopping is done frequently and contributes to greater energy efficiency.

7. Industry 4.0 Integration and Automation:

Motor control technology is a key component used in Industry 4.0 and smart factory implementations.

Modern communication protocols and data analytics integration assist data-driven decision-making and optimization.

8. Monitoring and Control at a Distance:

Integration with IoT and communication protocols enables remote monitoring and control of motorized systems, enabling real-time diagnostics and alterations.

Remote access facilitates troubleshooting and reduces the need for on-site interventions.

The motor control technology’s shortcomings

Motor control technology has many advantages, but it also has some disadvantages and challenges in its use. Among the principal downsides are the following ones:

1. Price and intricacy:

The intricacy of developing, putting into practice, and maintaining sophisticated motor control systems can lead to higher initial costs.

Because these systems are complex, specialized skills may be required for installation and troubleshooting.

2. Sensitivity to Environmental Conditions:

It is evident how sensitive motor control systems are to many environmental factors, such as temperature, humidity, and pollution. Weather extremes might affect performance and dependability.

3. Electromagnetic interference (EMI) compatibility:

Electromagnetic interference from motor control electronics may affect other nearby electronic devices. Appropriate shielding and filtering are required to lower EMI.

Compatibility issues may arise when integrating motor control systems with machinery or systems that are already in place.

4. Restricted Tolerance to Fault:

Although motor control systems are often equipped with safety safeguards, they may not be as fault-tolerant as they may be. Failed vital control systems may cause unexpected motor action and possibly cause damage.

5. Maintenance Difficulties

Predictive maintenance features do not guarantee against unexpected failures, thus prompt intervention is still necessary.

Certain applications may be concerned about downtime during maintenance, and certain skills may be required for maintenance.

6. Restricted Standardization

When attempting to mix parts from multiple manufacturers, integration challenges may come up.

7. The Learning Curve

when using new technologies or control algorithms, engineers and technicians may need to go through a learning curve to deploy and optimize motor control systems.

Conclusion:

To sum up, motor control technology is a revolutionary and transformative force that is reshaping various sectors by enabling us to operate motors more efficiently and intelligently. Automation and industrial processes have advanced greatly due to their many advantages, including improved safety, precision, and energy efficiency. When combined with predictive maintenance capabilities, the capability to remotely monitor and regulate motors lowers maintenance costs and downtime, promoting a more dependable and sustainable operating environment.

But it’s important to recognize the difficulties with motor control technologies. The intricacy of these systems, possible sensitivity to environmental factors, and compatibility and standards concerns highlight the necessity of meticulous preparation, execution, and continuous upkeep. To guarantee the integrity and security of these vital systems, the integration of motor control systems into the larger Industry 4.0 framework also presents cyber security issues that need to be resolved.

Research and development efforts are being made to further improve the adaptability, robustness, and ease of integration of motor control technology, as well as to mitigate these issues as technology continues to evolve. The continued convergence of technology innovation and real-world application holds the potential to unleash even higher efficiency, opening the door to more intelligent, networked, and environmentally friendly industrial processes. A balanced strategy that takes into account both the benefits and drawbacks of motor control technology navigation will be essential for successful adoption and long-term gains.

#Autonomousvehicle#motorcontrol#technology#evcc#ccu#evse#ProgrammableVCU#embeddedsystem#Dorleco#VCUSupplier#VCU#Controlsystem

0 notes

Text

🚦 DIY Tower Light Installation – Step-by-Step Guide! ⚡🔧 #c3controls

💡 Light up your workspace with a Tower Light! Whether you're working in an industrial setting or upgrading your control panel, a properly installed tower light ensures safety, efficiency, and visibility.

In this quick DIY installation guide, we’ll show you how to: ✅ Mount & wire a c3controls Tower Light 🔌 ✅ Ensure a safe and efficient setup 🛠 ✅ Improve industrial automation & signaling 🚦

📽️ Watch the full installation guide here: 👉 https://youtu.be/LDuzPBAg7Q8?si=HFxC99WNi9mg3Rgm

🛒 Get your c3controls Tower Light today: 👉 https://www.c3controls.com/products/world-tower-lights/

#TowerLight#DIYInstallation#IndustrialAutomation#ElectricalEngineering#c3controls#FactorySafety#Automation#EngineeringLife#ElectricianTips#IndustrialDesign#ControlSystems

1 note

·

View note

Text

Revolutionizing Industries with Advanced Instrumentation & Control Automation

Are you looking for cutting-edge Instrumentation and Control Automation Engineering Services? At IPAC Automation, we specialize in delivering high-tech automation solutions tailored to your industry needs. From industrial automation to process control systems, we ensure seamless operations, improved efficiency, and reduced downtime.

Why Choose Us? ✔ Expertise in Industrial Automation ✔ Custom-Designed Control Systems ✔ Cutting-Edge Technology Implementation ✔ Proven Track Record in Multiple Industries

https://ipacautomation.com/

#Automation#IndustrialAutomation#ControlSystems#Instrumentation#Engineering#ProcessAutomation#ManufacturingTech#AutomationSolutions#SmartIndustry

0 notes

Text

Robotics and Automation in Mechanical Engineering Education

Explore the intersection of robotics and automation in Mechanical Engineering, preparing to shape the future of manufacturing and intelligent systems.

#best college of engineering in trichy#best autonomous college of engineering in trichy#krce the top engineering college in trichy#top college of engineering in trichy#krce the best college of engineering in trichy#college life stories#RoboticsandAutomation#Automation#MechanicalEngineering#SmartManufacturing#Mechatronics#ControlSystems#IndustrialInnovation#RoboticSystems#EngineeringExcellence#FutureOfManufacturing

0 notes

Text

Overload Relay for Motor: Why It’s Essential ⚡🔧

An overload relay is a crucial protective device that prevents electric motors from overheating and getting damaged due to excessive current. When a motor runs beyond its rated capacity, the overload relay detects the increased heat and automatically cuts off the power, protecting the motor from failure.

Types of Overload Relays:

🔹 Thermal Overload Relay – Uses heat-sensitive elements to trip the circuit. 🔹 Magnetic Overload Relay – Responds to sudden current spikes. 🔹 Electronic Overload Relay – Provides precise protection with adjustable settings.

Properly sizing and selecting an overload relay ensures your motor runs efficiently and lasts longer. Want to learn more? Check out our guide on Overload Relay for Motor! 🔥⚙️ For more related electrical engineering concepts visit Electrical Hub

#ElectricalEngineering#MotorProtection#Automation#PowerSystems#Circuits#Electronics#SmartGrid#RenewableEnergy#EmbeddedSystems#ElectricMotors#ControlSystems#Microcontrollers#PCBDesign#EnergyManagement#HighVoltage#ElectricalSafety

0 notes