#ProgrammableVCU

Explore tagged Tumblr posts

Text

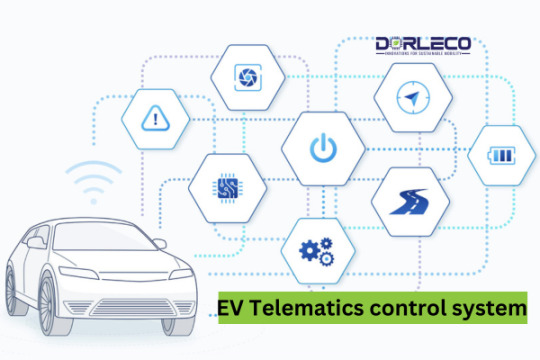

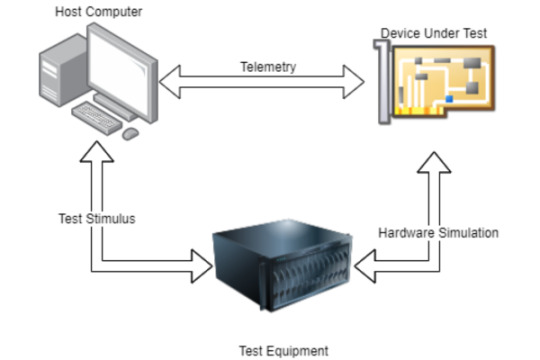

EV Telematics control system

September 9, 2024

by dorleco

with no comment

eMOBILITY CONTROLS

Edit

Introduction

The future of the automotive industry depends extensively on EV Telematics as it transitions towards electrification. This technology will be crucial in determining opportunities and obstacles and whether different strategies succeed or fail. Optimizing EV operations will require telematics’ valuable data on user behavior, energy economy, and vehicle performance. To properly utilize telematics as electrification advances, the sector must also solve obstacles like data security, infrastructure integration, and regulatory guidelines.

The increasing complexity associated with electric vehicle development will make telematics gathering data even more crucial in the future. Telematics systems will probably develop, gaining access to and using more data as the EV market steers the industry’s course. Telematics can add important context to the data collected and provide useful data about software and integrated technology systems when combined with a thorough analytics strategy. Telematics will continue to be a vital resource for the automotive industry as safety-optimized, technically advanced vehicles grow in capability.

Telematics in Automotive

Over the past few decades, telematics has been crucial to the automotive industry and is still an important part of product development. Telematics testing has been necessary for the correct validation of complex automotive systems and features in the integration of innovative technologies, such as advanced driver assistance systems (ADAS). Telematics goes beyond its conventional definition, which is the meeting point of information technology (IT) and telecommunications, encompassing data transmission, reception, and storage.

There are immediate obstacles, such range anxiety, to overcome before EV adoption becomes widely accepted. The ultimate goal is to lessen world reliance on foreign oil and improve the environment. Like many other areas of electrification, the optimization of EV telematics is strongly impacted by worries about battery life and constrained access to infrastructure for charging. Telematics is a useful tool that can help reduce range anxiety even though it can’t be removed because it offers immediate data on battery status, charging places, and the best routes. It’s critical to understand the overall operation of EV telematics before delving into the extra organizational advantages telematics can provide.

How does telematics work?

One of the benefits of telematics is that organizations have various platforms to choose from depending on their needs. Some teams may opt for Azure, while others may prefer Amazon Web Services. Regardless of the platform, the goal is to use a system that efficiently stores data points in the cloud. By presenting this data in charts or other visual formats, organizations can identify and extract valuable insights. This leads to thorough analytical evaluations, empowering them to make informed decisions. The telematics process follows a similar path for many, with information being gathered, stored, and transformed into actionable insights. This journey plays a key role in how organizations leverage telematics for product development, remaining an essential tool as OEMs continue to produce new EV models.

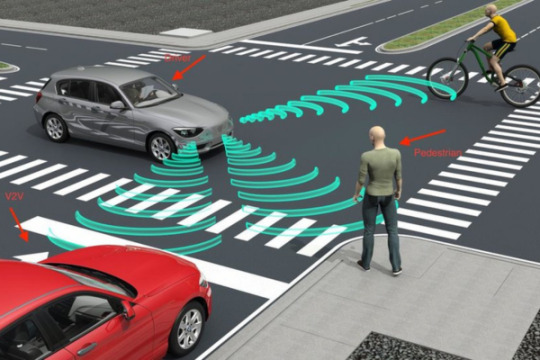

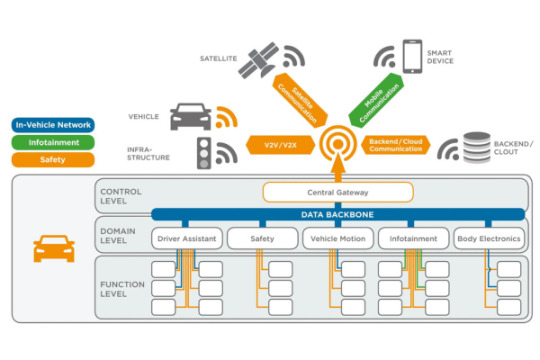

By connecting to the hardware and sensors of the car, the telematics device shows information about the battery life, the length and distance of the trip, the speed and acceleration, the GPS location, and vehicle maintenance. Additionally, telematics improves the effectiveness of subsystem interactions by directly connecting to EV subsystems.

For example, as infotainment subsystems grow in complexity to support more innovative technology, they will offer improved driver usability. Similarly, components like dash cameras, which assist drivers, are likely to become more common in future EV models. The CAN bus acts as a highway for all this information, enabling various components to communicate and transmit data seamlessly.

Important advantages telematics may offer to the development of EVs

The overall advantages that telematics brings to the advancement of EVs are as follows:

Transforms vehicle data into actionable assets: Transforms raw vehicle data into useful information that businesses may use to make decisions: Telematics transforms vehicle data into assets that can be used immediately.

Contextual evidence is offered for decision-making: Telematics data removes uncertainty and misunderstanding in the decision-making process by providing context, which supports decisions.

1. Monitor Driver Behaviour

Drivers are a valuable asset, but even one careless driver might put your company at serious risk. You can keep an eye on driver performance with EV telematics instead of depending on “How’s my driving?” hotline calls.

These solutions give fleet managers a thorough, up-to-date picture of driver behavior by continuously gathering data from fleet vehicles. Routes, distance traveled, driving time, average speed, incidences of severe braking or acceleration, and noteworthy occurrences like breakdowns or accidents are all included in the data that is recorded and easily accessed.

Fleet managers may intervene and rectify inefficient, careless, or risky driving with the use of this comprehensive understanding, which can reduce vehicle wear and tear, prevent accidents, prolong battery life, and eventually minimize insurance costs.

2. Monitor Vehicle Range in Real Time

There are some situations that even the best route planning cannot foresee. Unexpected circumstances may occur and force vehicles onto longer, less effective routes. This is not a big deal for a diesel fleet because drivers can fill up at the closest station. However, if there isn’t a proper charging station close by, it may be disastrous for an EV fleet.

For this reason, EV telematics is crucial for fleets that run on electricity. It gives fleet managers real-time information on the amount of remaining range in their vehicles, enabling them to swiftly adapt to unforeseen delays or detours by rerouting to incorporate adjacent charging stations as necessary.

3. Improve Routes Effectively

This supports proactive, data-driven route planning in addition to providing fleet managers with vital vehicle status updates and aiding in the prevention of theft. By planning routes that take into account the availability of charging infrastructure along the way, fleet managers can minimize problems like range anxiety and optimize battery efficiency.

Other benefits of real-time tracking include avoiding collisions, gridlock, and road construction. The majority of EV telematics packages frequently come with these features as standard.

4. Establish Charging Schedules and Alerts

One of the major challenges for fleet managers transitioning to electric vehicles is maintaining consistent vehicle charges. This requires careful coordination of schedules, routes, traffic conditions, and environmental factors such as elevation, weather, and temperature.

A robust EV telematics system like Trakm8 simplifies this process by leveraging real-time data from these and other factors. It offers continuous charging updates, allows fleet managers to prioritize vehicle recharging based on schedules and routes, and identifies available charging stations, enabling drivers to choose the optimal route for their current charging needs. If a vehicle’s battery reaches a critical level, fleet managers receive alerts to take immediate action.

5. Receive Health Alerts

EV telematics systems equipped with sensors give fleet managers valuable insights into vehicle and overall fleet health, enabling predictive maintenance.

Conclusion:

EV telematics is anticipated to change the automobile industry over the next ten years. While precise dates and benchmarks are unknown, progress is unavoidable. The investigation of telematics and analytics for contemporary transportation has created an opportunity that is unlikely to close. Organizations should keep spending money on sophisticated telemetry solutions as the drive toward electrification increases, realizing that more data is always beneficial.

Three things can be counted on from an efficient telematics system: performance optimization, a strong security framework, and zero data loss. Particularly, performance needs to be considered a fine art since only select groups may truly recognize its worth. Telematics should be seen as a safety measure even by individuals who don’t rely on it significantly. Most businesses try to minimize operational uncertainty, and telematics offers vital visibility in situations where incomplete or ambiguous data could result in errors or failures. Product development will be becoming more complicated as the market moves toward EVs with cutting-edge technology and greater complexity. For these technologies to work as intended, telematics and data insights will be essential.

0 notes

Text

V-Model development techniques to design

August 1, 2024

by dorleco

with no comment

Control Systems

Edit

Introduction

The Verification and Validation Model, often known as the V-Model or the V-Cycle, is a software development methodology that prioritizes testing throughout the entire process. It’s a Waterfall approach modification that’s widely used in critical system development when thorough testing is necessary. The V-Model’s two main stages are completed in the following order:

1. Verification (left side of the V):

a. Analysis of requirements :

– Identify and document the client’s needs.

– Based on customer input, determine software and system requirements.

b. System Design:

Develop a high-level design specification by referring to the requirements.

– Explain the system’s overall architecture.

c. Architecture:

Create a comprehensive system architecture.

– Explain the interfaces that the system’s various components have with one another.

d. Module Design:

Break the system up into smaller, easier-to-manage parts.

– Clearly define each module’s requirements.

e. Implementation (Coding):

Write code according to the detailed module requirements.

1. Examining Units:

– Check that each module is accurate.

– Identify and fix module-level issues.

2. Validation (right side of the V):

a. Testing for integration:

To ensure that the modules work as a whole, integrate them and test them all together.

– Find and correct any errors in the modules’ interlobular communication.

b. Testing the system:

Test the system as a whole to make sure it meets the requirements.

Identify and fix issues at the system level.

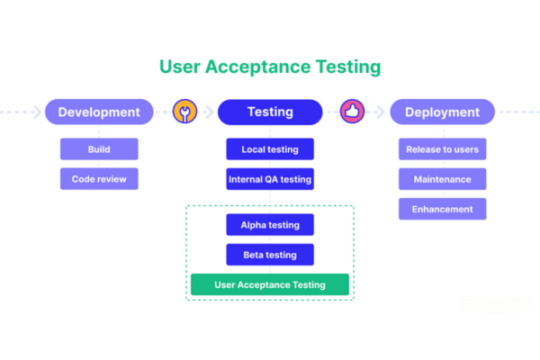

c. The user acceptance test, or UAT:

– Validate the solution by asking end users to attest that it meets their needs.

– Get user input and make necessary adjustments.

d. Initiation:

After testing is completed successfully, put the system into use.

Make sure that the necessary documentation has been completed.

1. Upkeep and Assistance: –

Assist continuously, fix issues that arise in the real-world setting, and implement any necessary improvements.

Important ideas and methods related to the V-Model:

The V-Model encompasses several fundamental concepts and techniques that guide its application in software development. The main concepts and techniques associated with the V-Model are as follows:

Initial Testing

Principle: Testing activities are initiated early in the development life cycle.

Technique: Unit testing is used in the early stages of test preparation and execution to guarantee that errors are identified and corrected as soon as practical.

2. An incremental and phased approach:

Principle: Development and testing have distinct periods.

Methodology: Testing is organized based on the stages that make up the development process. Systems that are only partially functional can be sent for testing and validation thanks to incremental development.

3. Trackability:

Principle: There should be a clear, traceable relationship between requirements and relevant tests.

Method: Make and maintain traceability matrices that link each requirement to the tests that verify its fulfilment. This ensures that all tests are covered thoroughly.

4. Loops of Feedback:

Principle: Continuous input is essential during the development and testing phases.

Methodology: As defects are found during testing, they are communicated to the development team for resolution. The quality of the software is improved by this loop of iterative feedback.

5. Record-keeping:

Concept: Extensive documentation is necessary at every stage of development and testing.

The method entails producing and maintaining current, comprehensive documentation for the design, requirements, test cases, and test plans. This documentation serves as a guide and comprehension tool for the duration of the system.

6. Testing and Development in Parallel:

Methodology: Testing for each phase is ongoing as the related development stage moves forward. Using a parallel approach reduces the likelihood that major defects will emerge later by allowing problems to be identified and solved sooner.

7. Well-defined positions and responsibilities:

It is important to specify the roles and duties of the development and testing teams.

Method: Assign specific duties to individuals or teams for each level of the V-Model. This establishes accountability and clarifies who is in control of what.

8. User Engagement:

Principle: User engagement is necessary for both validation and acceptance.

Method: Involve users in the User Acceptance Testing (UAT) stage to ensure the system meets their needs and expectations.

9. Management of Configurations:

Principle: Supervise and control changes made to the software and associated resources.

Technique: To keep version control, monitor changes, and ensure consistency between the development and testing processes, use configuration management procedures.

10. Comprehensive Testing:

Principle: All aspects of the system ought to be put to the test. Technique: Plan and execute a range of tests, including unit, integration, system, and user acceptance testing, to confirm the program’s accuracy and dependability.

Drawbacks of the main ideas and methods connected to the V-Model

Even while the V-Model offers a structured approach to software development with integrated testing, it is not without its drawbacks. The following are some limitations and drawbacks associated with the primary concepts and techniques of the V-Model:

1. Inflexibility and Rigidity:

Cons: When it comes to modifying needs, the V-Model could be less adaptable and more rigid. It makes the challenging assumption that needs are clear-cut and unchanging, which makes it challenging to adjust as the project develops.

2. System Visibility After Hours:

Cons: It takes a long time for the system to become fully visible during the development life cycle. This could lead to erroneous perceptions of user requirements or a delay in identifying design flaws, which makes problem-solving more challenging and costly.

3. Minimal User Engagement:

The only time consumers are often involved is during the User Acceptance Testing (UAT) phase. This could result in the discovery of significant issues or misunderstandings later on in the procedure when fixing them will be more expensive.

4. Dependency on Proactive Scheduling

Limitation: The effectiveness of the V-Model depends on having a firm understanding of the needs and starting early. If the needs change or the initial planning is flawed, delays and significant barriers could occur.

5. Nature in Sequence:

Cons: The V-Model follows a sequential path in which the completion of one phase depends on the success of the one before it. This could lead to a longer development timeframe, especially if changes are required after the project starts.

6. Insufficient Length for Iterative Development:

Cons: Iterative or incremental development approaches do not work well with the V-Model. It could not be compatible with modern agile methodologies, which strongly emphasize flexibility and quick reaction to changing requirements.

7. Excessive Focus on Testing

Cons: The V-Model may overemphasize testing as a stand-alone step, even though testing is crucial. This approach could not be effective for projects incorporating agile methodologies, which call for continuous testing and feedback

8. Presumption of Clearly Stated Needs:

Cons: The V-Model is based on the assumption that needs are precise and unchanging from the outset. As the project is being developed, adjustments may be necessary because needs often change.

9. Low Level of Client Involvement

Cons: User acceptability testing and requirements phases are usually the only times that customers or stakeholders are communicated with. This can result in a lack of ongoing contact and feedback throughout the development process.

10. Having Difficulties Handling Difficult Projects?

cons: The V-Model may face challenges when working on large, complicated projects with requirements that are not completely understood up front. An iterative and more flexible approach may be more appropriate in some circumstances.

Conclusion:

In summary, the V-Model’s core principles and techniques provide a structured, methodical approach to software development that emphasizes early testing and traceability. However, it’s crucial to consider both the benefits and drawbacks of the V-Model:

When choosing the V-Model, it’s critical to consider the project’s needs for stability, the organization’s overall development plan, and the project’s type. Though it might not be ideal for every project, the V-Model might be helpful in instances where a systematic, logical, and well-documented development process is required and if needs changes are either minor or properly managed. However, for projects that require more flexibility and adaptability, different methodologies like Agile may be more appropriate.

0 notes

Text

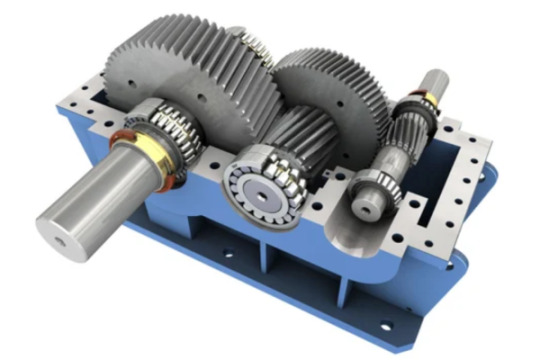

Transmission control systems

July 31, 2024

by dorleco

with no comment

Autonomous Vehicle Technology

Edit

Introduction

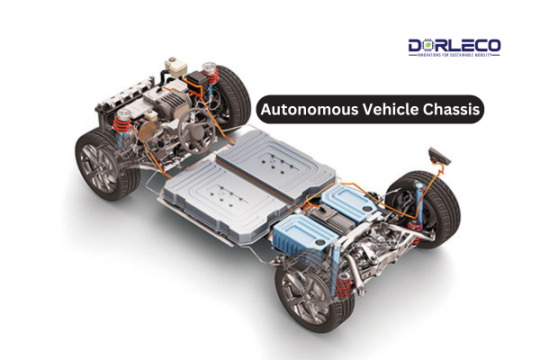

In the context of automotive technology, transmission control systems are the parts and systems that regulate how a car’s gearbox operates. An essential part of an automobile is the transmission, which directs engine power and distributes it to the wheels so the car can drive forward. Transmissions come in two primary varieties: automatic and manual.

These are a few crucial parts of the transmission control system.

1. Manual Transmission:

When using a manual gearbox, the driver engages and selects ratios manually using the clutch pedal and gear changer.

The clutch mechanism in a car with a manual gearbox is a component of the transmission control system; it releases the engine from the transmission to enable gear changes.

2. Gearbox Automation:

Gear shifts in an automatic transmission system are managed by the transmission control module (TCM) or transmission control unit (TCU) independently of the driver.

When determining when to shift gears, the TCM gathers data from sensors, such as throttle position and vehicle speed sensors.

3. DCT, or dual-clutch transmission:

Dual-clutch gears combine the best advantages of automatic and manual transmissions. By quickly engaging and pre-selecting gears with two clutches, they enable smoother and more efficient gear changes.

4. Transmission that Variably Capable (CVT):

By utilizing a belt, chain, and pulley system, CVTs provide an infinite number of gear ratios, allowing for smoother acceleration without the requirement for discrete gear shifts.

5. Electronic Control:

Modern transmission control systems require electrical components to function. The throttle position, load, engine speed, vehicle speed, and other variables are taken into account by the TCM or TCU while determining whether to shift gears.

6. Adaptive Transmission Control:

Some advanced transmission control systems are adaptive, meaning they may change their settings in response to evolving traffic conditions and driving patterns. By doing this, you can enhance driving performance, fuel efficiency, and enjoyment.

7. Torque Converter:

In automatic gearboxes, a torque converter is commonly utilized to transfer power from the engine to the transmission. It makes shifting gears easier and allows the engine to run even while the vehicle is not moving.

8. Shift Logic:

Certain shift logic algorithms are used by transmission control systems to decide when to upshift or downshift. These algorithms optimize fuel efficiency and performance by considering multiple parameters.

Transmission control systems’ advantages

Transmission control systems are quite helpful in terms of a vehicle’s overall driving pleasure, efficiency, and performance. Here are a few key advantages:

1. Enhanced Fuel Economy

Transmission control systems, especially in modern cars with electronic controls, can optimize gear ratios and shift points based on the driving conditions. This modification often leads to better fuel efficiency because it ensures the engine runs as effectively as possible.

2. Enhanced Capabilities:

Vehicle performance is improved by the use of transmission control systems, which offer more efficient gear shift management. Accurate and fast shifts can enhance acceleration, responsiveness, and general driving qualities in any type of transmission — manual, dual-clutch, or automatic.

3. More Livable Operations:

Especially automatic transmissions, which eliminate the need for manual gear changes, make driving more enjoyable. By ensuring that shifts occur smoothly and on time, modern control systems improve passenger comfort.

4. Flexibility in Driving Environments:

Many modern gearbox control systems are designed with adaptability in mind. These systems adjust shift patterns in response to factors including load, road conditions, and driver behavior to maximize performance in a range of scenarios.

5. Less fatigue among drivers:

Particularly when traveling long distances or through heavy traffic, automated gearboxes reduce driver fatigue. Removing the need to constantly engage the clutch and shift gears, allows drivers to focus more on the road.

6. Less fatigue among drivers:

Particularly when traveling long distances or through heavy traffic, automated gearboxes reduce driver fatigue. Removing the need to constantly engage the clutch and shift gears, allows drivers to focus more on the road.

7. Astute Gear Selection

Automatic transmissions have a transmission control system that can intelligently choose the appropriate gear based on the load, road conditions, and driver input. This ensures that the vehicle is always in the optimal gear for the conditions, improving efficiency and performance.

8. Smooth Stop-Start and Idle Engine Systems:

To guarantee a smooth engine idle, several transmission control systems can be paired with stop-start systems. By shutting off the engine while the automobile is stationary and starting it again when needed, these systems reduce the amount of gasoline used and pollutants produced when idling.

9. Decreased Pollution:

Transmission control systems can help cut emissions by improving engine performance and efficiency. Fuel consumption and pollutant emissions can be decreased with efficient gear shifts and improved engine control.

Transmission control system drawbacks

Transmission control systems offer numerous benefits, but they also have certain drawbacks. Here are a few potential drawbacks:

1. Cost and Complexity:

The control systems for modern gearboxes can be very complex, especially in vehicles with advanced electrical equipment. The intricacy of these systems sometimes leads to higher production costs, and because they require specialized knowledge and diagnosis, maintenance may be more expensive.

2. Upkeep and Restoration:

When a transmission control system malfunctions, fixing it can be costly and challenging. Not all repair businesses have the tools necessary to replace or reprogram electrical components, sensors, and control modules when these tasks become essential.

3. Issues with Reliability:

The electrical parts of transmission control systems are prone to mistakes or malfunctions. Reliability is crucial; any issues with the transmission control system could make driving challenging or possibly impossible, and possibly even cause the automobile to break down.

4. Restricted User Authority:

Certain contemporary automated transmissions are completely under the direction of the transmission control module (TCM). Giving up manual control may be irritating for some drivers, especially enthusiasts who prefer shifting gears themselves, even though it can lead to more effective and seamless working.

5. Drivers’ Learning Curve:

Certain drivers may have trouble acclimating to the behavior of specific transmission control systems, particularly if they are used to a different sort of transmission. For example, a continuous variable transmission (CVT) may require significant adjustment when transitioning from a standard automatic to one.

6. The risk of relying too much on electronics

The increasing reliance on transmission control systems on electronic components raises questions about the consequences of electrical breakdowns on vehicle operation. Without specialized equipment, operating the vehicle or diagnosing an electronic system issue could be more difficult.

7. Production of Heat:

Electronic components generate heat when they operate. Overheating in transmission control systems may lead to issues with the reliability and efficiency of electronic components. Adequate cooling systems must be used to prevent overheating issues.

8. Limited Aftermarket Modification Compatibility:

Certain aftermarket modifications, such as performance upgrades or custom tuning, might not function flawlessly with the original transmission control system. If this isn’t corrected, driving issues or even gearbox damage could result.

Conclusion:

In summary, transmission control systems are essential to contemporary cars, affecting things like performance, fuel economy, and overall driving pleasure. These systems have several advantages, regardless of whether they control continuously variable, dual-clutch, manual, or automatic transmissions.

The benefits include reduced driver fatigue, particularly with automatic transmissions, increased fuel efficiency through optimum gear ratios, improved vehicle performance with smoother and quicker changes, and adaptation to changing driving conditions. Reduction of pollutants improved towing capacity, and longer component life are further benefits of transmission control systems.

It’s crucial to recognize a few disadvantages of transmission control systems, though. These include the systems’ expense and complexity, possible difficulties with upkeep and repairs, issues with dependability, and restrictions on user control, especially with some automatic transmissions. Other things to think about include potential incompatibilities with aftermarket modifications, a learning curve for drivers adjusting to new gearbox technologies, and issues with electronic component failures.

Despite these shortcomings, continuous technological developments seek to solve these issues and raise the general performance and dependability of transmission control systems. These systems will probably get more advanced as cars continue to develop, offering greater advantages while reducing some of the negatives that come with them.

Practically speaking, careful driving, following manufacturer instructions, and routine maintenance can help drivers get the most out of their transmission control systems. Even while there are disadvantages, they are surpassed by the benefits that well-thought-out and well-operating transmission control systems may offer in terms of effectiveness, performance, and general driving enjoyment.

0 notes

Text

AV Rescue Protocols of Autonomous Vehicles

July 29, 2024

by dorleco

with no comment

Autonomous Vehicle Technology

Edit

Introduction

Autonomous Vehicle Protocols AV Rescue Maintaining the security and dependability of self-driving cars requires protocols and emergency response. As autonomous vehicles become more prevalent on our roads, we must know how to respond to crises and accidents involving them. In this introduction, we will look at the key concepts and practices related to AV rescue and emergency response.

Gaining an Intense Knowledge of Self-Driving Cars: The advanced hardware, software, and sensor systems that autonomous cars are equipped with allow them to function independently. These vehicles use complex algorithms, sensors, cameras, radar, lidar, and radar to navigate and make driving decisions.

Different types of autonomous vehicles: Several kinds of self-driving car AVs are categorized using Levels 0 through 5 (full automation). The degree of automation in a car influences its capabilities and limitations, therefore emergency responders need to know.

Different Types of AV Emergencies: Autonomous vehicle emergencies might include medical crises, system malfunctions, accidents, and security breaches. Efficient emergency response is critical to mitigating hazards and ensuring everyone’s safety.

First Responder Training: Emergency responders, including firemen, paramedics, and law enforcement, should have specialized training to handle AV-related disasters. This training should include the unique challenges and safety issues of autonomous vehicles.

Communication with AVs: A lot of AVs have external communication systems that they can use to interact with first responders. These technologies can deliver vital information about the state of the vehicle and its occupants.

Vehicle Shutdown Protocols: First responders may need to disable the vehicle’s autonomous features to prevent more damage from being done. They ought to be able to safely disable an AV without jeopardizing their own or others’ safety.

Procedures for Passenger Autonomous Vehicle Rescues: Autonomous vehicles possess the capability to rescue passengers in need of assistance. In the case of an accident or medical emergency, AVs should have procedures in place that allow first responders to securely remove passengers.

Advantages Benefits of Autonomous Vehicle Rescue and AV Response Protocols

The effectiveness and safety of emergency response and autonomous vehicle rescue approaches are numerous for self-driving automobiles. These protocols are required to ensure a coordinated and effective response to emergencies as well as to address the unique challenges posed by autonomous vehicles. The following are some significant advantages of having emergency response and AV rescue processes established:

1. Enhanced Security

Cutting-edge safety features in self-driving cars, like collision avoidance systems, can mitigate the severity of collisions. Rescue protocols ensure that first responders can effectively communicate with these systems, possibly preventing more damage.

2. Swift Response:

Emergency responders can act quickly if they are aware of the established and acknowledged AV Rescue Protocols because they will know how to handle a problem and where to find the information they need. When there is a possibility of death, this is vital.

3. Particularized Instruction:

AV Rescue Protocols necessitate special training for first responders. They will be more equipped to manage AV-related scenarios and improve responders’ and passengers’ safety because of this training.

4. Interaction:

Numerous AVs are equipped with communication devices that let them tell emergency responders of information. This can include information about the kind of emergency, the health of the car’s occupants, and potential dangers, enabling a more thoughtful reaction.

Cutting-edge safety features in self-driving cars, like collision avoidance systems, can mitigate the severity of collisions. Rescue protocols ensure that first responders can effectively communicate with these systems, possibly preventing more damage.

5. Quick passenger rescue:

AV Rescue Protocols methods offer guidelines for safely extracting individuals from driverless autos. Responders can quickly attend to passenger needs in cases of accidents or medical emergencies.

5. Decreased risks:

Responders use AV Rescue Protocols to reduce the hazards involved in deactivating or stopping a vehicle’s autonomous systems. If the right methods are applied, there is a decreased chance that the rescue effort would unintentionally result in greater harm.

6. Working Together with Manufacturers:

Communication between AV manufacturers and emergency responders is facilitated by protocols. Together, we can better understand the technology and any shortcomings in the system, leading to more effective solutions.

Drawbacks of Autonomous Vehicle Rescue and Emergency Response Systems

While autonomous automobile emergency response and AV Rescue protocols offer numerous advantages, they also present a few challenges and disadvantages. It is essential to consider these limits to guarantee that protocols may be periodically improved to address future difficulties. The shortcomings and challenges associated with autonomous vehicle (AV) rescue and emergency response techniques are as follows:

1. Intricacy:

Because of how quickly technology is developing, it might be challenging to design and implement criteria for autonomous vehicles. It can be difficult to guarantee responders comprehend and adjust to the complex systems of AVs.

2. Cost and Requirements for Resources:

The infrastructure required to carry out AV Rescue Protocols and the training that emergency workers need can be expensive to put up. Smaller emergency response organizations may have financial constraints.

3. Various car capacities

Responders encounter varying degrees of automation, making it challenging to evaluate the potential and limitations of every autonomous vehicle they encounter. Protocols are required to address this variability.

4. Absence of Standardization

There are few recognized norms and practices across all fields and jurisdictions. Emergency response procedures can become complicated and unproductive when there is a lack of consistency.

5. Data Privacy Issues:

Handling and gaining access to data from autonomous vehicles (AVs), which can store sensitive passenger data, presents privacy concerns. A delicate balance must be struck between the need for data in accident investigations and individuals’ right to privacy.

6. Concerns About Liability

Determining culpability in accidents involving AV can be difficult. Legal problems could arise because AV Rescue Protocols do not always provide clear guidance on how to establish culpability.

7. Quick Development of Technology:

Because AV technology advances quickly, it is easy for AV Rescue Protocols to become outdated. It could be logistically challenging for first responders and regulatory entities to maintain protocols up to date with the latest advancements.

8. Sync Up Between Stakeholders:

An efficient catastrophe response often requires coordination amongst numerous parties, including government agencies, law enforcement, manufacturers, and insurance firms. Ensuring collaboration could prove to be challenging.

Conclusion:

To sum up, AV rescue and emergency response procedures for self-driving cars are crucial to guarantee the secure and efficient incorporation of these vehicles into our transportation networks. Although these procedures have a lot to offer in terms of efficiency, safety, and public trust, there are a few drawbacks and difficulties as well.

Notable hurdles that need to be addressed are the quick development of autonomous vehicle technology, the requirement for specialized training, worries about data privacy, and problems with standards and stakeholder coordination.

Nonetheless, the advantages of well-established protocols — such as improved safety, prompt action, effective passenger rescue, and unambiguous communication — far exceed the disadvantages. These obstacles can be met by continuing development of these procedures, cooperation from emergency responders, AV manufacturers, and regulatory agencies, as well as a dedication to staying up to date with technology improvements.

Emergency response and autonomous vehicle rescue techniques are essential in the rapidly evolving field of autonomous vehicles because they guarantee that the technology is used responsibly and safely by society. To satisfy the requirements of autonomous vehicles, these protocols will keep developing and changing, advancing efficiency, safety, and trust in the age of self-driving cars.

0 notes

Text

Electronic Stability Control: How Chassis Control Ensures Safety?

July 26, 2024

by dorleco

with no comment

eMOBILITY CONTROLS

Edit

Introduction

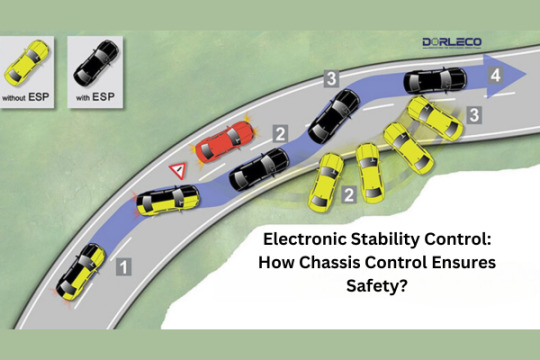

When it comes to automotive technology, safety is paramount. ESC, or electronic stability control, is one of the biggest advancements in automotive safety. This cutting-edge technology is designed to prevent skids and loss of control when driving in hazardous conditions or quickly. We will go over the concept of electronic stability control in this introduction, as well as how it effectively regulates a car’s chassis to ensure safety.

Understanding Electronic Stability Control (ESC)

Electronic stability control, sometimes referred to as ESC or ESP (Electronic Stability Program), is a state-of-the-art safety feature that is currently standard on most modern cars. Helping drivers maintain control of their vehicles is its main goal, particularly in challenging driving conditions.

Considering Vehicle Stability

Vehicle stability is necessary for safe driving. Vehicle instability can lead to hazardous situations like sliding, rollovers, or loss of control, especially in slick conditions like rain, snow, or uneven road surfaces. ESC was developed as a solution to these issues and significantly reduce the risk of accidents caused by instability.

How Electronic Stability Control Works

ESC uses a combination of sensors, microprocessors, and actuators to continuously analyze the vehicle’s behavior and adjust in real time to preserve stability. Here is how it works:

Sensor Inputs: The ESC gathers data on the mechanics of the vehicle from a range of sensors, including wheel speed, steering angle, yaw rate, and lateral acceleration. These sensors provide continuous feedback to the ESC system.

Microprocessor Analysis: The microprocessor of the ESC system continuously analyses the data from the sensors to determine whether the vehicle is deviating from the driver’s desired course. It compares the actual behavior of the vehicle with the driver’s inputs (such steering wheel position) and the planned trajectory.

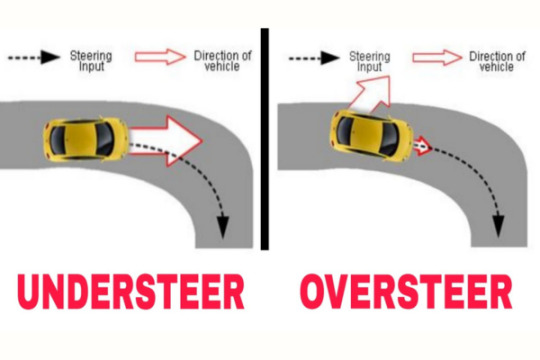

Actuator Response: If the system detects that the vehicle is beginning to skid, understeer — a situation in which the front wheels lose traction and push apart — or overseer — a situation in which the rear wheels lose traction and cause the vehicle to spin — it will take corrective action.

Restoration of Stability: ESC helps the car regain stability by adjusting the brake pressure and engine speed. This allows the driver to maintain control and steer clear of a potentially hazardous scenario. The changes occur almost instantaneously, and the driver is unaware of them.

Safety Guaranteed via Chassis Control

It takes electronic stability control to guarantee road safety. It is an essential component of the chassis control systems, which work together to provide a stable and predictable ride. The phrase “chassis control” describes a collection of technologies that help to keep drivers and passengers safe and avoid accidents, such as the Electronic Stability Control (ESC), the Traction Control System (TCS), and the Anti-lock Braking System (ABS).

Benefits of Electronic Stability Control: How Does Chassis Control Enhance Safety?

Electronic Stability Control (ESC), which has several significant advantages that improve road safety, is frequently a part of automobile chassis control systems. Some of the key advantages of ESC for ensuring safety are as follows:

Prevents Loss of Control: ESC is designed to identify and react to situations, such as sliding or skidding, where a car is in danger of losing control. By adjusting engine power and providing selective braking, ESC reduces the likelihood of accidents caused by a driver losing control of the vehicle.

Enhances Traction: On slick or uneven road surfaces, ESC can increase traction. By adjusting the engine output and braking pressure, it prevents wheel spin and holds the tires firmly on the ground. This comes in especially handy whether it’s icy, snowy, or pouring outside.

Minimizes Understeer and Oversteer: Understeer, or front-wheel slide, and oversteer, or rear-wheel skid, are common causes of accidents during rapid turns or unforeseen maneuvers. In these situations, ESC intervenes to assist the vehicle in maintaining a steady and predictable trajectory by applying the brakes to certain wheels.

Equivalents Additional Safety Systems: ESC works in tandem with Anti-lock Braking Systems (ABS) and Traction Control Systems (TCS) among other safety systems. When combined, these technologies provide extensive chassis control, making the vehicle responsive and stable in a range of driving conditions.

Reduces Rollover Risk: Electronic stability control (ESC) can also help to reduce the risk of rollovers in top-heavy vehicles such as trucks and SUVs. By preserving stability during quick turns or evasive maneuvers, ESC lowers the risk of the car overturning.

Boosts Driver Confidence: Knowing that the ESC is always monitoring and helping with vehicle stability helps boost driver confidence, especially in challenging driving circumstances. Driving habits could become safer because of this increased confidence.

Smoother Corrections: The vehicle’s behavior is rapidly and gently adjusted by the ESC. Unlike abrupt driver attempts, which can sometimes exacerbate a skid or slide, the ESC’s controlled interventions assist in preventing overcorrection and additional instability.

Electronic Stability Control Drawbacks: How Does Chassis Control Guarantee Safety?

While Electronic Stability Control (ESC) has significantly improved vehicle stability and reduced the risk of collisions, it is important to consider some of its possible limitations and drawbacks:

Cost: ESC is an expensive technology that requires certain actuators, sensors, and microprocessors. As a result, it might make producing and purchasing a car more expensive, which might raise the price of cars with ESC.

Maintenance costs: An ESC may need to be maintained and repaired on occasion, just like any other electrical device. The cost of identifying and fixing issues that develop from malfunctioning ESC system components may be substantial.

False Alarms: ESC systems can sometimes misinterpret the driving environment and initiate interventions when they are not necessary. These false alerts might irritate the motorist and cause a momentary loss of power or control.

Driver Overreliance: Some drivers may become too reliant on the ESC because they mistakenly believe that it will make up for unsafe driving habits. While ESC can sometimes alleviate some situations, driving must still be done with caution and attention.

Limited Effectiveness in Some Terrains: While ESC does a great job on standard highways, it might not work as well in off-road or difficult terrain. Drivers should proceed with caution in these circumstances as the ESC may struggle to keep control.

Tire Wear: ESC interventions may cause tires to wear down more quickly, especially when driving hard or regularly. The cost of operating the car may increase because of having to fix tires more frequently.

Not a Winter Tire Replacement: Not a Winter Tire Substitute Even though ESC can help with control in icy or snowy conditions, winter tires are still required. Nonetheless, drivers in regions with harsh winters should equip their vehicles with the appropriate tires for optimal safety.

Conclusion:

To sum up, Electronic Stability Control (ESC) is a significant technological development in the field of vehicle safety since it is essential to the way chassis control maintains road safety. This technology has completely changed how cars react to changing road conditions and handle them, greatly lowering the chance of collisions brought on by skidding, losing control, or bad weather. Many benefits are provided by ESC, such as preventing loss of control, improving traction, reducing oversteer and understeer, and coordinating with other safety systems.

The possible drawbacks and restrictions of ESC, such as expense, upkeep, sporadic false alarms, and the possibility of driver overreliance, must be acknowledged, though. Technology should be used sensibly and intelligently to mitigate these shortcomings.

Notwithstanding these factors, ESC continues to be a vital component of contemporary car safety, serving as an example of how advanced chassis control systems enhance traffic safety. ESC will surely continue to save lives and improve the safety of drivers, passengers, and pedestrians as it develops and becomes standard in a growing number of vehicles.

1 note

·

View note

Text

Predictive Maintenance and eMobility Controls

July 25, 2024

by dorleco

with no comment

eMOBILITY CONTROLS

Edit

Introduction

Predictive Maintenance:

Using data, advanced analytics, and machine learning, predictive maintenance is a proactive approach to equipment and machinery maintenance that foresees when repair is necessary before a failure occurs. It aims to minimize unplanned downtime, reduce maintenance costs, and optimize asset performance across a range of industries, including manufacturing, energy, transportation, and more.

Predictive maintenance’s essential elements include:

Data collection: Sensors, Internet of Things (IoT) devices, and other data sources capture real-time data about machinery and equipment, such as temperature, vibration, pressure, and usage trends.

Data analytics: To find patterns, anomalies, and potential problems in the gathered data, machine learning algorithms and advanced analytics technologies are employed. These algorithms can forecast when a piece of equipment will break or need maintenance.

Condition monitoring: By keeping a close eye on the equipment’s condition, maintenance personnel can spot problems early and take appropriate measures to prevent a breakdown.

Predictive alarms: Alerts and messages are sent out when analytics indicate that upkeep or repairs are necessary. These alerts can help with the prioritization and scheduling of maintenance tasks.

Maintenance Planning: By using forecasts and alerts, teams may schedule maintenance operations more efficiently, reducing downtime and avoiding costly emergency repairs.

Predictive maintenance advantages include:

Decreased Downtime: By resolving problems before they become failures, unexpected downtime is decreased. Improves maintenance schedules and lessens the need for needless planned maintenance. financial savings.

Extended Equipment Lifespan: Preventing problems before they get worse helps extend the life of equipment reduces the likelihood of device failure, improving safety.

Data-Driven Decision-Making: Makes data-driven decisions and resource allocation easier.

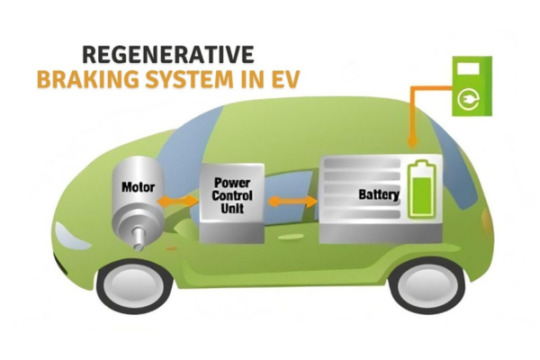

eMobility Controls:

In the realm of electric mobility, advanced electronic systems and software, also referred to as “eMobility controls,” oversee and regulate electric cars (EVs) and the infrastructure necessary for charging them. eMobility controls play a major role in the effective operation and pleasant user experience of electric cars and charging stations.

Important elements of eMobility controllers consist of:

Battery management involves keeping an eye on and controlling the battery’s health, temperature, and level of charge to get the most out of it and extend its life.

Infrastructure for managing the charging process, including grid integration, billing, and authentication, for fast chargers, home chargers, and public charging stations.

Energy Management: Energy management is the process of matching the grid’s capacity during periods of peak demand with the energy requirements of EVs.

Vehicle Control: Vehicle control refers to managing a vehicle’s torque and power distribution to improve efficiency, performance, and security.

User Interface: Using touchscreens or smartphone apps to provide drivers with simple interfaces to monitor and control charging, battery life, and other vehicle functions.

eMobility Controls Benefits:

Range optimization: Extends the driving range of electric cars through efficient energy management. Easy access to charging for electric vehicle owners is ensured by convenient charging.

Grid Integration: By incorporating EVs into the electrical system, grid stability is supported, and the overall carbon impact is reduced.

Savings: Reduces energy use and costs associated with charging for both car owners and chargers.

Environmental Benefits: Reduces greenhouse gas emissions by promoting the use of electric vehicles.

Predictive Maintenance Benefits:

Decreased Downtime: By foreseeing potential equipment problems before they arise, predictive maintenance helps to reduce unscheduled downtime. As a result, productivity and operational effectiveness increase.

Cost savings: By proactively addressing maintenance issues and avoiding emergency repairs, organizations can significantly reduce their maintenance expenses. Predictive maintenance optimizes maintenance schedules while reducing labor expenses and inventory of spare parts.

Extended Equipment Lifespan: Equipment and other assets can have their lives extended by timely maintenance and early problem detection. Consequently, companies may reap greater rewards from their financial investments.

Data-Driven Decision-Making: Predictive maintenance makes use of machine learning and data analytics to determine when and how to do maintenance. This data-driven approach results in the production of better plans. Because there are fewer unplanned breakdowns and more chances that the equipment will function when needed, equipment availability is raised and overall operational continuity is improved.

Improved Customer Satisfaction: In companies where downtime can affect customer services, predictive maintenance gives customers a more seamless and dependable experience.

Improved Resource Allocation: Maintenance teams can focus their resources more efficiently by focusing on the equipment that need maintenance the most, as opposed to following a standard plan for all assets.

Benefits of Electronic Mobility Controls:

Range Optimization: eMobility controls reduce “range anxiety” for drivers by enhancing energy efficiency and allowing electric vehicles (EVs) to travel farther between charges.

Convenient charging: With real-time status information, payment processing, and scheduling, the eMobility controls-managed charging infrastructure offers EV users a convenient and easy-to-use experience.

Grid Integration: Smart charging and load management for electric vehicles (EVs) are made possible by eMobility controllers, which facilitate the integration of EVs into the power grid. This balances energy consumption, lowers peak loads, and improves grid stability.

Savings: Compared to owners of traditional gasoline-powered cars, owners of electric vehicles can have lower running costs because of the lower cost of electricity and less maintenance requirements.

Environmental Benefits: Electric vehicles produce no exhaust emissions, which lowers air pollution and reduces their carbon footprint. This is made possible by contemporary eMobility technology.

Data insights: eMobility controls collect data on usage patterns, charging habits, and energy consumption. This information is then used by service providers and customers to optimize operations and make informed decisions.

Predictive maintenance’s drawbacks

Although predictive maintenance and eMobility controls offer numerous advantages, there may also be certain disadvantages and challenges. Some drawbacks of these technologies are as follows:

Cons of Predictive Maintenance:

Implementation Costs: Since deploying sensors, constructing a data gathering infrastructure, and developing predictive analytics skills are all necessary when putting up a predictive maintenance system, implementation costs might be substantial.

Data Availability and Accuracy: Timely and accurate data are necessary for predictive maintenance. Low data quality or limited data sources may make predictive maintenance less effective.

Training and Skill Requirements: For maintenance personnel to deploy predictive maintenance systems and correctly interpret the data, organizations must invest in their training and upskilling.

False Alarms: Predictive maintenance systems have the potential to generate erroneous forecasts or alerts, leading to unnecessary maintenance and related costs.

Integration challenges: It can be challenging to integrate predictive maintenance systems with existing equipment and practices, and it could be necessary to make significant changes to the way work is currently done.

Disadvantages of eMobility Controls:

Costs of Infrastructure: Infrastructure-related costs: Both the construction and upkeep of a public infrastructure and a fast-charging infrastructure for electric vehicles can be expensive.

Limited Infrastructure for Charging: In certain places, the scarcity of charging stations — especially fast chargers — may cause annoyances for electric vehicle (EV) owners.

Grid Load: In certain places, the quick uptake of EVs may impose undue strain on the grid, requiring costly adjustments to accommodate the growing demand.

Range Anxiety: Because certain electric vehicles have lesser ranges than cars with internal combustion engines, some drivers may still experience range anxiety even though eMobility features aid maximize energy use.

Limited Model Options: In certain markets, there may be fewer options for electric vehicle models than for conventional cars, which reduces buyer choice.

Energy Source: The environmental benefits of electric vehicles are influenced by the source of the electricity used for charging. If fossil fuels are used to create the electricity, the number of emissions that can be reduced could be limited.

Conclusion:

In conclusion, two revolutionary technologies that are changing how businesses manage assets, and the transportation sector functions are predictive maintenance and eMobility controls. While they both have a lot going for them, there are certain difficulties and things to keep in mind.

Utilizing data analytics and machine learning, predictive maintenance lowers downtime, saves money, and enhances safety by anticipating and averting equipment breakdowns. But in order to be successful, it needs competent staff and high-quality data, which can be expensive to deploy.

Future sustainable mobility and the shift to electric cars (EVs) depend heavily on eMobility controls. They provide advantages like lower operating costs and less environmental impact by optimizing range, charging convenience, and grid integration. However, there are still obstacles to overcome, such as the upfront cost of EVs, grid compatibility, and the expense of developing charging infrastructure.

Both technologies rely on advanced analytics and data to boost productivity, cut expenses, and boost overall performance. Additionally, they both aim to advance sustainability and lessen the environmental impact of transportation and industry.

The drawbacks of eMobility controls and predictive maintenance are anticipated to gradually lessen as governments, corporations, and consumers adopt these innovations and technology advances. In the end, these technologies are vital forces behind sustainability, efficiency, and safety, opening the door to a more intelligent, connected, and environmentally conscious future. When making choices about eMobility control systems and predictive maintenance, both individuals and organizations should weigh the advantages and disadvantages of these technologies.

#emobilitycontrols#predictivemaintenance#VCU#ProgrammableVCU#VCUSupplier#VCUServices#autonomousvehicle

0 notes

Text

Simulink-based software

July 22, 2024

by dorleco

with no comment

Control Systems

Edit

Introduction

Dynamic systems with various domains are modeled, simulated, and analyzed using the Simulink graphical programming environment. It is widely used for system design and simulation in numerous engineering disciplines, such as communications, signal processing, control systems, and more. Math Works creates it. Simulink-based software is highly popular in industries such as industrial automation, aerospace, and automotive.

Important characteristics of Simulink-based software are as follows:

Model-Based Design (MBD): Using Simulink’s model-based design technique, engineers can create a visual representation of the system they are building. This model could incorporate all of the system’s components, interactions, and operations.

Simulink uses a block diagram environment, where various system components are represented as blocks and the connections between the blocks explain how the blocks interact. Every block can represent a mathematical operation, a state machine, or a transfer function.

Library of Blocks: Users can drag and drop a sizable number of pre-made Simulink blocks into their models. The different mathematical processes, signals, sensors, actuators, and other parts that are frequently found in engineering systems are represented by these blocks.

Analysis and Simulation: With Simulink, users may simulate the behavior of their models in different situations. Before putting a design into hardware, engineers can assess how the system behaves, identify any issues, and improve the design. Simulink has an automatic code generation feature that lets users generate code in formats like as C or HDL directly from their models. This facilitates the transition from hardware platform implementation to simulation.

Integration with MATLAB: MathWorks also closely collaborated with Simulink to build MATLAB, a high-level programming language and environment. Users can use this interface to combine MATLAB’s computational capability and Simulink’s modeling features for mathematical calculations. Simulink enables engineers to link their models to hardware-in-the-loop (HIL) systems for testing and verification through real-time simulation.

Toolbox Support: Simulink-based software comes with several toolboxes that extend its capabilities for specific uses, such as image processing, control system design, signal processing, and more.

Customization and Extensibility: Users can construct their blocks and functions to customize Simulink’s functionality to meet their own needs. Modeling and simulation can therefore be extensively tailored.

Drawbacks of simulink-based software

While there are many advantages to utilizing Simulink for modeling and simulating dynamic systems, there can also be some drawbacks and challenges. When considering if Simulink is the ideal tool for a certain application, it’s important to consider the following factors:

Complexity and Learning Curve: Simulink could be hard for inexperienced users to understand, and there might be a learning curve to unlock all of its features. Users who are not familiar with the software may find it challenging to create and modify models effectively.

Resource-intensive: Large-scale, complex model simulation in Simulink can be a resource-intensive operation that requires a lot of RAM and computing resources. This may lead to longer simulation times and potential issues running simulations on less powerful systems.

Limited Support for Text-Based Programming: Simulink is a terrific tool for graphical modeling, but users who want a more text-based programming approach may find it to be less suitable than other options. The emphasis is on graphical modeling, however Simulink models can also be used in conjunction with MATLAB scripts.

Version Compatibility: Users may encounter compatibility issues when attempting to interact with models created in different Simulink versions. Ensuring that all team members are using the same or compatible version is essential to avoid compatibility problems.

Cost of Licenses: Simulink is a commercial program, and obtaining a license for both Simulink and MATLAB can be expensive. This cost component could be prohibitive, especially for new businesses, small enterprises, or budget-conscious educational institutions.

Problems with Code Generation: While code generated automatically is a useful tool, it may not always follow certain coding guidelines or may require further manual tweaks. To make sure that the final code meets project requirements, extra work could be needed.

Limited Hardware Support: Simulink enables hardware-in-the-loop (HIL) setups for real-time simulation, although it might only support a limited number of hardware platforms. Compatibility issues could arise with particular hardware. Modeling Some System Aspects Can Be Difficult: Simulink can be a modeling difficulty, especially when dealing with complex or non-linear behavior. Users may need to utilize other modeling methodologies or workarounds to resolve these concerns.

Model Maintenance: Large and complex models can become challenging to update and maintain over time. The model’s complexity needs to be carefully controlled because changes to one part could have unexpected consequences in other parts.

Conclusion:

To sum up, Simulink-based software provides a strong and adaptable platform for dynamic system modeling, simulation, and analysis in a variety of engineering areas. For engineers and researchers active in system design and analysis, its graphical block diagram approach, interaction with MATLAB, and a large library of preconfigured blocks make it a popular choice.

Model-based design, fast prototyping, automated code generation, and real-time simulation are some of Simulink’s advantages. The capacity to model intricate systems, model their behavior under many scenarios, and produce a code of production quality expedites the development process and promotes effective cooperation amongst interdisciplinary teams.

It’s crucial to take into account any potential disadvantages, though, like the learning curve for inexperienced users, simulations requiring a lot of resources, and possible difficulties with code development and model maintenance. In addition, while determining if Simulink is appropriate for a certain project, consideration should be given to the cost of licensing and the requirement for compatible software versions.

Notwithstanding these difficulties, Simulink is still a useful tool for many different kinds of applications, such as signal processing and control system design. Because of its adaptability, wide range of toolbox support, and customization possibilities, it is widely used in industry and academics for both practical engineering projects and educational purposes. Simulink-based software should ultimately be chosen after carefully weighing its advantages, disadvantages, and any restrictions on the demands of the particular project.

#autonomousvehicle#Simulink#Software#VCU#VCUSupplier#Dorleco#Automation#Microcontrollers#programmableVCU

1 note

·

View note

Text

What is the driving range of an electric vehicle on a single charge?

July 19, 2024

by dorleco

with no comment

Others

Edit

Introduction

Driving range of an electric vehicle

Electric vehicles (EVs) have become more and more popular in recent years due to their environmental friendliness and energy efficiency. Unlike traditional gasoline-powered vehicles, electric vehicles (EVs) employ battery-operated electric motors to generate power and propel the vehicle.

One of the most common concerns among potential EV buyers is an electric vehicle’s driving range or the distance an EV can travel on a single charge.

The driving range of an electric vehicle is mostly dependent on its specific brand and model as well as other factors including weather, driving conditions, and driving style.

This article’s objective is to examine the factors that affect an electric vehicle’s driving range.

How much distance can an electric vehicle cover on a single charge?

The driving range of an electric vehicle (EV) is determined by several factors, including the battery capacity, the kind of EV, topography, weather, and driving speed.

The battery capacity determines how much energy can be stored and used to power the vehicle. An electric vehicle’s driving range often grows as its battery capacity does.

The range of an electric automobile is affected by topography and driving speed since they change the amount of energy required to drive the vehicle. The driving range may be shortened by the energy needed for faster and hillier terrain.

The driving range of an electric vehicle is expanding due to advancements in battery technology and an increase in the number of charging stations. Considering that many contemporary EV vehicles can already go more than 200 miles between charges, long-distance driving is becoming more practical.

Variables That Could Impact the Range of an EV

Capacity of the battery: The size and capacity of the battery pack determine how much energy can be stored and used to power the vehicle. Longer driving ranges are usually found in EVs with larger battery packs.

Driving procedures: Frequently applying force when braking, accelerating rapidly, and driving aggressively can all reduce the range of an electric car. Regenerative braking can be used in conjunction with steady speed to extend the driving range.

Driving conditions: An EV’s range can be significantly impacted by several factors, including speed, topography, and weather. Extreme temperatures, steep terrain, and rapid speeds can all shorten the driving range.

Climate control: If an electric car relies on battery power to heat or cool the interior, its driving range may be reduced. Use the climate control sparingly to maximize the range.

Payload: Adding more weight to an electric vehicle (EV), such as passengers or freight, can reduce the vehicle’s operating range.

Route planning: By arranging the route and charging stations ahead of time, it is possible to guarantee that an EV will have enough range to arrive at its destination. By being informed of the locations and recharge periods of charging stations, range anxiety can be prevented.

How Can the Range of an EV Be Determined?

One can compute the range of an electric vehicle (EV) using many techniques, including:

1. Manufacturer specifications: Occasionally, an estimate of an electric vehicle’s driving range on a single charge is mentioned in the manufacturer’s specifications. It’s important to keep in mind that this estimate may not precisely reflect driving conditions in the real world because it is typically based on standardized testing.

2. In-Car Display: A common feature of many electric cars is a display that shows the estimated range based on the driving circumstances at the time and the amount of battery charge left. To find out how long the automobile will run before needing to be recharged, can be a helpful tool.

3. Mobile Apps: Some EVs come with a smartphone app that provides owners with real-time information on the battery’s range, charge level, and nearby charging station locations.

4. Online Range Calculators: Several online range calculators that ask for information on temperature, terrain, and driving speed can be used to estimate an EV’s range in a variety of scenarios.

5. Test Drive: The best way to determine an EV’s range is to take it for a test drive. Throughout the test drive, you may monitor the battery’s remaining charge and estimate its range based on your driving style and the state of the road.

It’s important to keep in mind that an EV’s range may vary depending on several factors, including topography, driving style, weather, and more.

Understanding an EV’s range and limitations is essential to reducing range anxiety and ensuring the vehicle meets your needs when driving.

Is Driving an Electric Vehicle to Empty Safe?

While it is generally safe to drive an electric vehicle (EV) until the battery is very low or even empty, doing so regularly is not recommended. This explains why:

Battery Life: As long as the lithium-ion batteries in EVs are not completely exhausted, they should last longer. Driving an electric car frequently until the battery is almost depleted will limit its lifespan.

2. Range Anxiety: Those who frequently drive electric cars (EVs) until they are nearly empty suffer from this fear of not being able to get to a charging station before the battery runs completely flat.

3. Reduced Performance: When the battery is very low in charge, the EV’s acceleration and top speed may be impacted. This could be dangerous for your safety, especially in an emergency.

4. Electrical Components: An electric vehicle’s (EV) power electronics and motor may be subjected to additional strain when it is driven empty.

Conclusion:

In conclusion, a variety of factors, including the vehicle’s make and model, battery size and capacity, driving style, topography, environment, and more, may affect an electric vehicle’s operating range.

While some electric vehicles (EVs) may travel over 300 miles on a single charge, others have a range of less than 100 miles.

It is essential to understand the capabilities and range of an EV before making a purchase. To reduce range anxiety, you should also schedule your excursions to accommodate charging breaks.

Additionally, an EV battery’s lifespan will be shortened if it is routinely drained to extremely low levels, hence it is recommended to constantly keep the battery level above 20%.

As battery technology develops, it is expected that the range of EVs will increase, making them a more attractive and practical option for drivers.

FAQ:

1. How far does an ideal electric vehicle go?

The ideal driving range of an electric vehicle (EV) is greatly influenced by the needs and driving behaviors of the driver.

However many drivers consider a minimum of 200 miles on a single charge to be the ideal range because it allows for extended travel without the need to stop and recharge.

2. The increasing range of EVs

The driving range of an electric vehicle(EVs) has been steadily increasing in recent years; some versions can already travel over 300 miles on a single charge.

This trend is expected to continue as battery technology develops, increasing the attraction and viability of EVs as a vehicle option for drivers.

#autonomousvehicle#drivingrange#EVs#VCU#VCUSupplier#Dorleco#Automation#Microcontrollers#programmableVCU

0 notes

Text

Autonomous Vehicle Control

July 18, 2024

by dorleco

with no comment

Autonomous Vehicle Technology

Edit

Introduction

Self-driving automobiles, sometimes referred to as autonomous vehicles, are a cutting-edge technological advancement that could revolutionize our daily lives and modes of transportation. These cars mimic a human driver’s decision-making process by using sensors, software, and control systems to make real-time decisions. They are designed to function alone and navigate. This introduction will examine the fundamental concepts and components of autonomous vehicle control.

1. Sensors

Lidar: Laser-based sensors that create accurate three-dimensional images of an object’s surroundings when it moves.

Radar: Radar uses radio waves to calculate the relative speed and distance of an object.

Cameras: Make use of cameras to capture images and videos that help identify lane markers, traffic signs, and other cars.

Ultrasonic sensors: Use them to find objects nearby to aid with parking and slow-moving situations.

GPS: Provides location information and facilitates navigation.

2. Control systems:

Autonomous Vehicle Control depends on sophisticated control systems to make decisions in real time. These systems perform control functions for the vehicle, including steering, braking, acceleration, and more, by analyzing sensor data. Safe and efficient driving is ensured by control algorithms, even in complex and dynamic environments.

3. Perception and Mapping:

Perception algorithms facilitate the car’s comprehension of its environment. They recognize objects, predict their movements, and assess the risks. Concurrently, mapping software creates up-to-date, precise maps of the road network to aid with vehicle navigation.

4. Place-Based:

Autonomous cars need to know where they are at all times. GPS alone is not sufficient for this. Advanced systems such as Simultaneous Localization and Mapping (SLAM) let vehicles maintain precise positioning by combining map information and sensor data.

5. Coming to a Decision:

The brain of the autonomous vehicle consists of its decision-making algorithms. They look at sensor data, traffic conditions, and route information to determine when to change lanes when to stop at a traffic signal, and how to avoid obstructions. These algorithms need to put safety first while accounting for other factors like passenger preferences and traffic laws.

6 . Redundancy and Safety:

Autonomous Vehicle Control safety is a critical concern. These vehicles are designed with multiple layers of redundancy, including backup sensors and control systems, to mitigate the consequences of component failures. To make sure they adhere to strict safety regulations, they also undergo extensive testing and validation.

7. Difficulties and Moral Issues:

The development and application of autonomous vehicles face several challenges, including ethical and legal ones. For example, figuring out who is at fault in an autonomous vehicle accident remains challenging. It is also debatable how, in morally questionable situations, these cars should put safety first.

Benefits of Driverless Vehicles

Autonomous vehicle control has many potential benefits that could completely change our perspective on transportation. The following are a few of the primary advantages of autonomous vehicles:

Safety Improvement:

Autonomous cars have the potential to significantly reduce traffic accidents. The majority of accidents are the result of human error, such as inattentive driving or bad judgment. The capacity of autonomous automobiles to follow traffic laws and make decisions based on sensor data may make roads safer.

Reduction of Traffic Jams:

Enhanced fuel efficiency:

Autonomous vehicles consume less fuel overall because they can optimize their driving behaviors and speeds. By doing this, greenhouse gas emissions and the general harm that transportation does to the environment can be reduced.

Enhanced Mobility for the Elderly and Disabled:

Autonomous cars may provide a new level of mobility to people who are unable to drive because of age- or disability-related limitations. This could enhance their level of independence and well-being.

Enhanced Productivity and Leisure Time:

By enhancing their productivity and leisure time, passengers in autonomous vehicles can make better use of their travel time. The passengers can work, read, or have fun while the car is moving. This could increase overall productivity and reduce stress from the journey.

Decreased Parking Demand:

Autonomous vehicles’ capacity to pick up passengers and park in more convenient or far-off locales can reduce the demand for premium parking spots in urban areas. This could lead to a decreased requirement for parking infrastructure and improved area utilization.

Savings:

The cost of transportation as a whole could be reduced by autonomous vehicles. People can now choose on-demand transportation over owning a personal vehicle, saving money on expenses like fuel, insurance, and maintenance, thanks to autonomous ride-sharing services.

Drawbacks of Driverless Transportation

While there is much promise for autonomous car technology, there are several potential risks and challenges as well. Some disadvantages and problems with autonomous vehicle control are as follows:

Limitations of the technology:

Autonomous car technology is continuously evolving and not perfect. They might struggle to operate in inclement weather, deal with unforeseen situations, or recognize objects like bicyclists and pedestrians.

High Development Costs:

It will cost a lot of money to develop and test autonomous car technology. These costs could drive up the cost of vehicles by making the technology unaffordable for smaller enterprises.

Cyber security Risks:

Autonomous vehicles are susceptible to hacking and other internet threats because they rely so heavily on software and communication. A successful attack might compromise vehicle security and privacy.

Data privacy issues: