#aerospaceengineering

Explore tagged Tumblr posts

Photo

#LockheedMartin #DarkStar #fighterjet seen in #TopGunMaverick as the successor to the iconic #SR71 #Blackbird by #SkunkWorks 🦨 #aircraft #planes #aerospace #TopGun #airplanephotos #planespotting #aircraftdesign #aerospaceengineering https://www.instagram.com/p/Cp6gAZfuxjO/?igshid=NGJjMDIxMWI=

#lockheedmartin#darkstar#fighterjet#topgunmaverick#sr71#blackbird#skunkworks#aircraft#planes#aerospace#topgun#airplanephotos#planespotting#aircraftdesign#aerospaceengineering

22 notes

·

View notes

Text

Explore the Skies with Aerospace Engineering!

Aerospace Engineering is the gateway to innovation in aviation and space exploration! From designing aircraft to developing spacecraft and satellites, this field pushes the boundaries of technology and human potential. Whether you're passionate about aerodynamics, propulsion, or space missions, Aerospace Engineering offers endless opportunities to soar high and dream big!

Start your journey today and be part of the future of flight and space exploration!

0 notes

Text

Engineering is evolving fast! The top fields of 2025 promise high salaries & global demand—but are you ready? 🌍💼

The right education matters! Studying abroad gives you the skills & exposure to stand out. Let Admissify help with admissions, visas & career placements! ✅

Tag a future engineer & drop a ⚙️ below! 👇

#engineering#mechanicalengineering#aerospaceengineering#civilengineering#chemicalengineering#ComputerScience

0 notes

Text

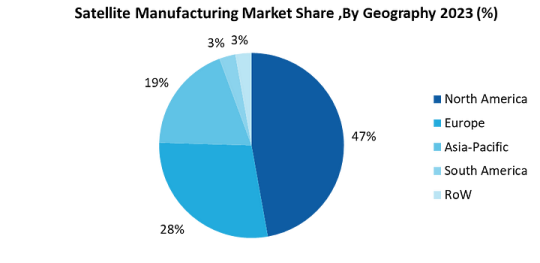

Satellite Manufacturing Market By Geography — Opportunity Analysis & Industry Forecast, 2024–2030

Satellite Manufacturing Market Overview:

Request sample:

Satellite manufacturing market is being reshaped by the Proliferation of Satellite Constellations and Miniaturisation of Satellite Technology. Next up is SpaceX’s Starlink project, which represents the rise of satellite constellations, with nearly 70 % of its 115 Falcon 9 launches in 2024 aimed at expanding its network. SpaceX launched 23 Starlink satellites on November 2024, 12 of which will have direct to smartphone connectivity and is pushing the boundaries of global connectivity to close the digital divide. On the other hand, the trend of miniaturisation is picking up, with Bengaluru based Pixxel achieving the milestone in July 2023. To develop compact satellites up to 150 kg in weight, with advanced technologies such as synthetic aperture radar and hyperspectral imaging, the company secured a multi-crore grant under the Ministry of Defence’s iDEX programme. These satellites, designed for the Indian Air Force, meet important defence and surveillance requirements and are part of the industry’s move toward smaller, cost-effective solutions with high impact capabilities.

Satellite Manufacturing Market- Report Coverage:

The “Satellite Manufacturing Market Report — Forecast (2024–2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Satellite Manufacturing Market.

AttributeSegment

By Solution

Hardware

Software

By Size

Small Satellites (up to 500kg)

Medium Satellites (500–1000kg)

Large Satellites (Above 1000kg)

By Range

Low Earth Orbit (LEO)

Medium Earth Orbit (MEO)

Sun Synchronous Orbit (SSO)

Geosynchronous Orbit (GEO)

By Application

Communication

Earth Observation & Remote Sensing

Research & Experiment

Reconnaissance

Mapping & Navigation

Others

By End User

Government

Defense

Commercial

Research Institutions

Maritime & Transportation

Academic

Others

By Geography

North America (U.S., Canada and Mexico)

Europe (Germany, UK, France, Italy, Spain, Netherlands and Rest of Europe)

Asia-Pacific (China, India, Japan, South Korea, Australia, New Zealand, and Rest of Asia-Pacific)

South America (Brazil, Argentina, Colombia, Chile and Rest of South America)

Rest of World (Middle East and Africa

Inquiry Before Buying:

COVID-19 / Ukraine Crisis — Impact Analysis:

The satellite manufacturing market was disrupted by the COVID-19 pandemic which led to delays in production and breaks in the supply chain. Labour shortages, delayed component deliveries, and deferred satellite launches were the result of lockdowns and restrictions. The pandemic saw communication and Earth observation satellite demand spike as remote connectivity and monitoring were relied on more, but manufacturers struggled to meet the demand in time.

The Russia Ukraine war had a significant impact on the satellite manufacturing market especially in terms of supply chain and geopolitical tensions. Russia is a major supplier of launch services and materials like titanium, propulsion systems, etc. At the outset of the war that disrupted access to the critical resources. sanctions on Russia added to difficulties, forcing manufacturers to look to alternative sources of supply. At the same time, the conflict drove up demand for military and reconnaissance satellites to track the situation in Ukraine and to maintain strategic communication.

Key Takeaways:

North America Dominates the Market

North America is the dominant region in the Satellite Manufacturing market largely due to the presence of players and substantial investments in the space sector. The United States, in particular, leads with companies such as SpaceX, RTX, Lockheed Martin and more which drive innovation in satellite manufacturing. Additionally, North America’s extensive launch infrastructure and high frequency of successful space missions support the demand for satellites. Additionally, the U.S government invests in satellites for surveillance, reconnaissance, and strategic defense applications which is driving the need for satellite manufacturing. In In November 2024, the Biden-Harris Administration announced CHIPS incentives awards to BAE Systems and Rocket Lab, underscoring North America’s leadership in the satellite manufacturing market. BAE Systems received $35.5 million to modernize its New Hampshire Microelectronics Center, significantly increasing production of critical MMIC chips for satellites and defense systems. Rocket Lab secured $23.9 million to expand its Albuquerque facility, boosting the production of space-grade solar cells essential for satellites and space programs like NASA’s Artemis. As the space economy continues to grow, including the need for satellite communications, Earth observation, and defense applications, North America’s robust framework positions it to retain its leading role in the global satellite manufacturing market.

Small Satellites Represent the Largest Segmen

In the Satellite Manufacturing market, small satellites are the dominant segment. Small satellites have revolutionized the satellite manufacturing landscape driven by their affordability, versatility and rapid development cycles. These satellites including nanosatellites and microsatellites are significantly cheaper to design, build and launch compared to traditional large satellites. Their compact size allows multiple small satellites to be launched on a single rocket reducing per-unit launch costs. Moreover, advances in miniaturized electronics and high-performance materials have enabled small satellites to perform complex tasks, from Earth observation and scientific research to navigation and defense. The rise of commercial constellations heavily relies on small satellite technology due to its scalability and ease of replacement. In May 2024, Revolv Space secured $27.33 million to enhance small satellite capabilities, highlighting growing demand in the segment.

Schedule A Call :

The funding will support the launch of its autonomous Solar Array Drive Assembly (SARA), designed to boost small satellite performance and meet the increasing needs of constellation operators. Additionally, research institutions leverage small satellites for educational purposes and low-cost experimentation further driving demand. All these factors combined with shorter production timelines and increasing innovation in modular designs position small satellites as a major segment in the satellite manufacturing industry.

LEO is the Largest Segment

In the Satellite Manufacturing market, Low Earth Orbit (LEO) has become the dominant segment due to its unique advantages and expanding applications. Satellites in LEO operate at altitudes between 500 and 2,000 km, allowing for lower latency in communications and higher-resolution imaging compared to higher orbits. This makes LEO ideal for Earth observation, remote sensing and real-time data transfer. Additionally, the reduced launch energy required to reach LEO contributes to lower overall mission costs makes it more viable for commercial ventures and smaller organizations. The growing trend of mega-constellations such as SpaceX’s Starlink and Amazon’s Kuiper relies on LEO for its ability to support large networks of interconnected satellites that provide global coverage. Furthermore, advancements in satellite design and propulsion systems enable efficient orbital deployment and maintenance within LEO. The World Economic Forum reckons that Earth observation data could add up to $700 billion in value by 2030, contributing $3.8 trillion to global GDP over that period. In addition, Earth observation can help to support policies and practices that could reduce over 2 billion tons of CO₂ emissions per year, making it an invaluable resource in the global sustainability field. With such a large economic and environmental influence, Low Earth Orbit observation is the largest application segment in the Satellite Manufacturing market. Additionally, the increasing private sector investments and evolving market demands ensure LEO’s continued dominance in satellite manufacturing.

Expansion of Satellite Constellations Boosts the Market

Expansion of satellite constellations is one of the major factors driving the Satellite Manufacturing Market, as can be seen from the recent growth of the European Galileo navigation system. Two more satellites were launched in September 2024, bringing the number of operational satellites to 32 in total. The placement of these satellites in medium Earth orbit at 23,222 km improves the constellation’s robustness and reliability. This expansion is crucial to guarantee the uninterrupted provision of high precision global navigation services, which Galileo intends to provide to more than two billion users around the globe. The demand for satellite manufacturing is still growing as more satellites are set to be deployed by 2026, and second-generation satellites are being developed. With countries and private companies investing in expanding their satellite networks for enhanced communication, navigation and data services, the opportunities to innovate and manufacture satellites more efficiently have never been higher. The growing need for satellite constellations is fueling the growth of the satellite manufacturing industry, which is accelerating advancements.

Buy Now:

High Cost of Materials to Hamper the Market

For more details on this report — Request for Sample

Key Market Players:

Product/Service launches, approvals, patents and events, acquisitions, partnerships, and collaborations are key strategies adopted by players in the Satellite Manufacturing Market. The top 10 companies in this industry are listed below:

L3Harris Technologies Inc.

SpaceX

Lockheed Martin Corporation

RTX

Airbus

Boeing

Thales

AAC Clyde Space, Inc.

Ariane Group

Sierra Nevada Corporation

#SatelliteManufacturing#AerospaceIndustry#SatelliteTechnology#SpaceInnovation#NewSpaceEconomy#SatelliteDevelopment#AerospaceEngineering#SpaceTech

0 notes

Text

Why Choose AME CEE 2025? Top Benefits of Taking the Exam!

If you’re interested in pursuing a career in aviation engineering, the AME

CEE (Aircraft Maintenance Engineering Common Entrance Exam) 2025 could be your gateway to a bright future. As the demand for skilled aviation professionals continues to soar, AME CEE 2025 offers numerous advantages for aspiring aircraft engineers.

Top Benefits of Taking the Exam: —

1. Access to Premier Institutes

The AME CEE 2025 exam is conducted to grant admission to some of the most reputed Aircraft Maintenance Engineering (AME) institutes across India. By qualifying for this entrance exam, you open the door to world-class facilities and expert training that will equip you with the technical know-how and hands-on experience required in the aviation sector. These institutes are recognized by the Directorate General of Civil Aviation (DGCA), which ensures that you receive a quality education recognized globally.

2. A Rewarding Career in Aviation

Aircraft maintenance engineers are in high demand due to the rapid growth of the aviation industry. By taking the AME CEE 2025 exam, you are positioning yourself for a rewarding career with opportunities in both private and government sectors. Aircraft engineers work on maintaining, repairing, and ensuring aircraft safety, making it a high-responsibility and high-salary profession. Choosing this career path through AME CEE 2025 means job security and the chance to work with cutting-edge technology.

3. Increased Job Stability and Growth

With the aviation industry witnessing consistent growth, the demand for aircraft maintenance engineers is on the rise. As an AME CEE 2025 graduate, you can rest assured that your career will have significant job stability. Airlines and aviation companies are always on the lookout for qualified engineers, making this one of the most secure career choices in the current job market.

4. Opportunities to Work Abroad

AME CEE 2025 doesn’t just offer domestic opportunities; it also paves the way for international prospects. With DGCA certification, you can work as an aircraft maintenance engineer anywhere in the world. Whether you’re dreaming of working with a global airline or in aviation hubs like Dubai, Singapore, or London, an AME CEE 2025 qualification will make you a globally recognized professional.

5. High Earning Potential

One of the top reasons why students consider taking the AME CEE 2025 exam is the potential for high earnings. Aircraft maintenance engineers are well-compensated, with salaries ranging from impressive starting packages to higher pay scales with experience. Additionally, the aviation sector offers excellent perks, benefits, and growth opportunities for engineers as they advance in their careers.

6. Cutting-Edge Technology & Innovation

The aviation industry is at the forefront of technological advancements, and AME CEE 2025 provides an opportunity to be part of this innovation. As an aspiring AME student, you will be trained to work with the latest aircraft technologies, systems, and tools. This experience not only enhances your technical expertise but also allows you to be a part of an industry that is continuously evolving and pushing the boundaries of what’s possible in aviation.

7. Government Recognition and Certification

A major benefit of choosing AME CEE 2025 is that the exam leads to a government-recognized certification. The AME qualification granted through this exam is accredited by DGCA, ensuring that the certification holds value and is acknowledged by aviation industries globally. This recognition adds credibility to your qualifications and increases your chances of landing desirable roles in the aviation field.

8. Training for Real-World Challenges

Unlike other theoretical exams, AME CEE 2025 prepares students for real-world challenges. The exam’s curriculum is designed to provide both theoretical knowledge and practical skills, enabling students to gain hands-on experience in maintenance procedures, aircraft systems, and safety protocols. The focus on practical training ensures that AME CEE 2025 candidates are ready to take on the challenges of the aviation world right from day one.

Conclusion

Choosing to take the AME CEE 2025 exam is more than just an academic decision; it’s a strategic career move that sets you on the path to success in the dynamic and rewarding field of aviation. Whether you’re looking for access to top institutes, high earning potential, career growth, or the chance to work abroad, AME CEE 2025 offers it all. Don’t miss out on this opportunity to secure your future in one of the most sought-after industries today. Start your journey with AME CEE 2025 and take the first step toward a fulfilling career in aviation.

#AviationCareers#AviationEducation#aviationindustry#ameexam#aircraftmaintenanceengineering#AerospaceEngineering#AviationDreams#AviationJobs#FutureAviationLeaders

0 notes

Text

Aircraft Health Monitoring Systems Market — Forecast(2025–2031)

𝐓𝐡𝐞 𝐔𝐥𝐭𝐢𝐦𝐚𝐭𝐞 𝐆𝐮𝐢𝐝𝐞 𝐟𝐨𝐫 𝑨𝒊𝒓𝒄𝒓𝒂𝒇𝒕 𝑯𝒆𝒂𝒍𝒕𝒉 𝑴𝒐𝒏𝒊𝒕𝒐𝒓𝒊𝒏𝒈 𝑺𝒚𝒔𝒕𝒆𝒎 [𝐔𝐩𝐝𝐚𝐭𝐞𝐝 𝐈𝐧𝐟𝐨𝐫𝐦𝐚𝐭𝐢𝐨𝐧] | IndustryARC™

The Aircraft Health Monitoring Systems Market size is estimated to reach $12.7 Million by 2030, growing at a CAGR of 7.2% during the forecast period 2024–2030.

📊 𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐒𝐚𝐦𝐩𝐥𝐞

An #aircraft #health #monitoring system (#AHMS) is a software and hardware system that includes, sensors and other highly networked processing units for remote monitoring of #airplane data to assess its future or current serviceability and performance. These systems are also known as aircraft condition monitoring systems (#ACMS). An aircraft health monitoring system (AHMS) is directly related to the airline industry’s maintenance, repair, and overhaul (#MRO) segment. The use of an #AHMS decreases maintenance and operational costs while also improving an aircraft’s overall safety.

Increase in #demand for real-time problem management, custom alerting & analysis solutions, and rise in demand for performance #monitoring drive the #growth of the aircraft health monitoring system market. Furthermore, rise in aerospace IT investment in emerging economies and technical improvements for workflow optimization, increase the demand for advanced analytical systems, thus driving #market_growth.

📊 𝐆𝐞𝐭 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭

The aircraft health monitoring system market is segmented on the basis of type, solution, end user, aircraft type and region. By type, the market is categorized into commercial aviation and #military_aviation. On the basis of solution, the market is divided into hardware, software, and services. On the basis of end user, the market is divided into OEMs, #MRO, and airlines. On the basis of aircraft type, it is categorized into fixed wing aircraft and helicopter. The market is analyzed based on four regions, namely North America, Europe, Asia-Pacific, and LAMEA.

New developments in aircraft health monitoring systems have generated complex systems. With the #aircraft_health_monitoring system market being in the growth stage of the product life cycle, there exists a lack of trained professionals that limits end users to invest in advanced solutions and services.

𝐁𝐲 𝐍𝐨𝐰 :

Airbus | Honeywell | FLYHT Aerospace Solutions Ltd. | GE | Meggitt | Rolls-Royce | RSL Electronics Israel | Raytheon Technologies | Teledyne Controls | Boeing | Naval Supply Systems Command (NAVSUP) | SHIMADZU CORPORATION | Asia Digital Engineering (ADE) | CAMP Systems International, Inc. | Controls and Data Services | Parker Meggitt |

#AircraftHealthMonitoring#AHMS#AerospaceTech#AircraftSafety#PredictiveMaintenance#AviationInnovation#FlightSafety#Avionics#SmartAviation#AerospaceEngineering#AircraftMonitoring#AviationTrends#MRO#DigitalAviation#AirlineTech

0 notes

Text

#AircraftMaintenanceEngineering#AME#AviationCareer#Vadodara#AerospaceEngineering#StudyAviation#AMELicensing

0 notes

Text

SAME is the leading name in aeronautical engineering, delivering cutting-edge innovations, advanced research, and top-tier education. We specialize in aircraft design, propulsion, avionics, and aerospace solutions, shaping the future of aviation with excellence and precision. Join us for pioneering advancements in aeronautics!

#aeronauticalengineering#Aerospaceengineering#aircraftcollege#aircraftcoursesinindia#aircraftengineeringcolleges#aircraftengineeringschool

0 notes

Text

youtube

Ever wondered what it takes to design cutting-edge systems that shape the world around us? From cars and airplanes to pipelines and air conditioning systems, CFD (Computational Fluid Dynamics) engineers play a pivotal role in solving real-world challenges involving fluid flow, heat transfer, and turbulence.

In this video, we dive into:

✅ The essential technical skills every CFD engineer needs—like proficiency in fluid mechanics, thermodynamics, and tools such as Ansys or OpenFOAM.

✅ How analytical expertise and attention to detail can transform designs and improve efficiency.

✅ Insights into industries like automotive, aerospace, and energy, where CFD engineers shine.

Learn how mastering differential equations, fluid dynamics, and thermodynamics can set you on the path to becoming a successful CFD engineer.

If you’re interested in speaking with our experts from Scania, Mercedes, and Nissan, and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/4gt2qC9

Don’t forget to like, share, and subscribe for more insights into the skills and tools driving innovation in engineering. 🚀

#CFDEngineering#FluidDynamics#EngineeringCareers#SimulationInnovation#Thermodynamics#AutomotiveDesign#AerospaceEngineering#SkillLync#youtube#mechanicalengineering#cad#Youtube

0 notes

Text

#Aviation#AvGeek#Aerospace#FlightSafety#PilotLife#AirTrafficControl#AircraftMaintenance#DroneTechnology#FlightSimulator#AviationPhotography#AirlineIndustry#AviationLovers#FlightTraining#AerospaceEngineering#AviationNews#FlightDeck#AirplaneMode#AviationHistory#AviationEnthusiast#FlightAttendantLife#AviationGeek#AviationDaily#AviationWorld#AviationCommunity#AviationLife#bird#Peregrine Falcon#Ostrich#Harpy Eagle#Budgerigar

0 notes

Text

Thus the Aeronautical engineering course involves designing, constructing, evaluating, and servicing flying machines. First, It works to expand the frontiers of aviation science, to make flying safer and more accustomed. Subcategories of aeronautical engineers include propulsion, aerodynamics, structures among others. Main distinction between Aeronautical Engineering and Aerospace Engineering is bound to the range of activities Aeronautical engineering is subfield of aerospace engineering. Whereas aeronautics mainly concerns itself with the engineering design of vehicles that sub-journey in and around the earth atmosphere, aerospace engineering encompasses the engineering of spacecraft and activities happening beyond the earth, space.

Visit Us :-

1 note

·

View note

Text

MP35N Excels in Aerospace Applications Worldwide

The aerospace industry demands materials that can withstand extreme conditions while ensuring unmatched performance and reliability. MP35N, a high-strength, corrosion-resistant alloy, has consistently proven its value in aerospace applications. From fasteners to engine components, MP35N excels where durability and strength are critical.

What Makes MP35N Stand Out?

MP35N’s unique composition of nickel, cobalt, chromium, and molybdenum imparts superior tensile strength, exceeding 300 ksi, along with excellent corrosion and fatigue resistance. These qualities make MP35N round bars and MP35N bars indispensable in crafting high-performance aerospace parts.

Key Aerospace Applications of MP35N

Landing Gear Components: MP35N rods are often used in landing gear systems for their ability to withstand high stress and fatigue cycles.

Engine Components: The heat resistance of MP35N bar stock ensures optimal performance in turbine blades and other engine parts exposed to extreme temperatures.

Fasteners and Bolts: MP35N bars are preferred for manufacturing aerospace fasteners and bolts due to their exceptional strength and corrosion resistance.

Springs and Seals: Flexible and robust MP35N rod materials are ideal for aerospace springs and seals that demand both flexibility and longevity.

Advantages Over Traditional Alloys

Compared to other materials like titanium or Inconel, MP35N provides:

Higher tensile strength.

Better corrosion resistance, including against hydrogen embrittlement.

Exceptional performance in marine and chemical environments.

Why Choose MP35N?

The versatility of MP35N bar stock makes it the material of choice for critical aerospace applications. Its ability to perform under extreme stress, temperature, and corrosive conditions ensures that MP35N rods remain a staple in high-performance designs.

Your Reliable MP35N Supplier

Amardeep Steel Centre LLP offers premium-quality MP35N round bars, MP35N bars, and MP35N rod materials tailored to your aerospace needs. Contact us today to source MP35N bar stock and elevate your projects with the industry’s leading high-strength alloy.

0 notes

Text

#PropulsionResearch#SpaceExploration#AerospaceInnovation#USAResearch#GravityManipulation#SpaceTravel#FuturisticTech#GravityControlPropulsion#USASpaceProgram#AerospaceEngineering#AdvancedTechnology#InterstellarTravel#SpaceTechnology#SpaceInnovation#doghealth#thinline#floydmayweather#day10#JamieFoxx#championsleague#reelsfbシ#reelstrending#reelsviralfb#reelschallenge#reelsinstagram#reelsviral#reelsvideo

0 notes

Text

Top Stories on the Latest Jet Fighters Revolutionizing Modern Warfare.

The latest jet fighters, like the F-35 and Su-57, redefine air combat with stealth technology, unmatched agility, and multi-role capabilities. These marvels of engineering push the boundaries of speed, precision, and innovation, making headlines globally. From cutting-edge avionics to advanced weaponry, their stories inspire awe and redefine military aviation.

For Details Watch Video: https://shorturl.at/eZRx4

#JetFighters#AviationInnovation#StealthTechnology#F35#Su57#AirCombat#MilitaryAviation#AerospaceEngineering#ModernWarfare#AviationEnthusiast

0 notes

Text

Why Titanium Sheets Are Essential in Aerospace Engineering

Why Titanium Sheets Are Essential in Aerospace Engineering

Titanium sheets, known for being strong, lightweight, and resistant to corrosion, are at the forefront of modern aerospace engineering. This silvery-gray metallic element has become indispensable for manufacturing aircraft, spacecraft, and critical components, delivering exceptional performance under the most extreme conditions.

Unrivaled Strength-to-Weight Ratio

The aerospace industry prioritizes materials that offer high strength while minimizing weight, and titanium excels in meeting these demands. Comparable in strength to steel yet nearly half as heavy, this strong, lightweight metal reduces overall aircraft weight, improving fuel efficiency and payload capacity. These properties make it an ideal choice for fuselage panels, engine components, and landing gear.

Superior Corrosion and Heat Resistance

This lustrous, corrosion-resistant material exhibits exceptional durability in challenging environments, such as the salty, humid conditions encountered during oceanic flights. Its ability to withstand high temperatures without deformation makes it crucial for jet engines and exhaust systems, where thermal stress is significant.

Exceptional Durability and Longevity

Aircraft and spacecraft experience extreme mechanical stresses throughout their operation. Titanium sheets offer remarkable fatigue resistance, ensuring the structural integrity of key components over extended periods. This durability reduces the need for frequent replacements, providing significant cost savings over the lifespan of aerospace equipment.

Key Applications in Aerospace

Fuselage Panels: Titanium sheets enhance structural integrity while keeping the aircraft lightweight.

Engine Components: The metal’s high thermal tolerance ensures it performs reliably under extreme conditions.

Fasteners and Connectors: Its resistance to corrosion guarantees secure and long-lasting joints.

Spacecraft Shields: The strong, corrosion-resistant element protects against radiation and extreme temperature variations in outer space.

Q&A Section

Q: Why are titanium sheets preferred over aluminum in aerospace applications? A: While aluminum is lightweight and cost-effective, titanium sheets offer superior strength, corrosion resistance, and heat tolerance. These characteristics are critical for safety and performance in high-stakes aerospace environments.

Q: Is titanium recyclable in aerospace manufacturing? A: Absolutely. This lightweight, corrosion-resistant material is highly recyclable, aligning with the aerospace industry’s focus on sustainability and reducing environmental impact.

Conclusion

Titanium sheets play a vital role in aerospace engineering, offering an unmatched combination of lightweight strength, resistance to extreme environments, and exceptional durability. As engineers push the boundaries of innovation, this silvery-gray metallic element continues to drive advancements in aviation and space exploration, ensuring safer and more efficient operations.

0 notes

Text

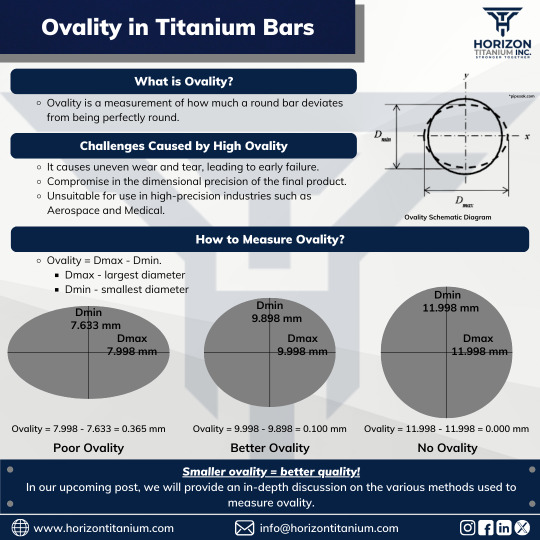

Understanding Ovality

In industries where precision is essential—like aerospace and medical devices—every millimeter plays a critical role. Ovality, the measure of roundness deviation, becomes a key factor in ensuring quality, reliability, and durability.

Even slight deviations in roundness can affect mechanical alignment, durability, and overall functionality. That’s why maintaining tight control over ovality is a priority in delivering reliable products.

Precision isn't just a goal; it’s a necessity for industries shaping the future. Let's continue to innovate with attention to detail and excellence in quality.

For more information, please write us at [email protected]

#KnowYourTitanium#Titanium#TitaniumRoundBars#Ovality#PrecisionMatters#Ti6Al4VELI#EngineeringExcellence#MaterialScience#QualityFocus#Quality#Reliability#Durability#Roundness#Dimensional#AerospaceEngineering#MedicalDevices#HorizonTitanium#StrongerTogether

0 notes