#Certified Truck Mechanics

Explore tagged Tumblr posts

Text

Certified Mechanics for Commercial Truck Repairs and Maintenance

When your commercial truck or equipment needs repairs, Bayshore Truck Center has you covered. Our certified commercial truck mechanics are skilled in diagnosing and repairing all major gas and diesel engine issues, as well as other vehicle components. As a premier commercial truck repair shop, we service almost every make and model. If you need roadside assistance, towing, or in-shop repairs, our goal is to get you back on the road quickly and safely with minimal downtime.

#Ford Mobile Services#Commercial Truck Repair#Truck Maintenance#Roadside Assistance#Truck Towing Services#Certified Truck Mechanics#Vehicle Diagnostics

0 notes

Text

MORE OF THEM, FLESHING OUT THE TOWN!

Cody still has his siblings, and Frankie, so this town is just chalk full off smart ppl. Hes friends with Raf at school Carly works at the construction/paint store/ mechanics (this is a small town) Her and Miko bond over art, and she'll usually help Chrys pick paint colours out Spike works at the mechanics with his dad. he drives one of the only tow trucks in town and gets suckered into giving his friends free rides. Chip is a certified genius, and is taking college classes online. He wants to stay in town and investigate the weird happenings. He thinks its Aliens- Carly claims its ghosts, and Spike just wishes his friends would stop scaring him

#transformers#transformers fan continuity#transformers: hive#cody burns#carly transformers#spike witwicky#chip chase#tf g1#tf rescue bots

112 notes

·

View notes

Text

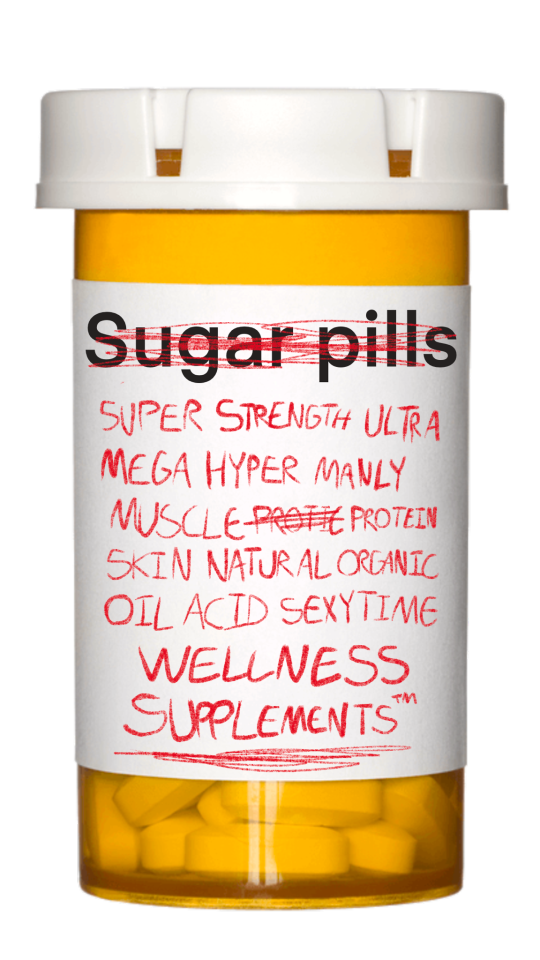

Reinvigoratize with this New Product™

Feel inadequate about your everything? Unable to satisfy the sexual partners you don’t have? Have problems in your life? This Product™ may be the thing for you!

I’ve used a fair share of health products like these over the years. Muscle enbiggeners, hairline unbaddifiers, virility virilinators, none of which ever worked as advertised. But this one is different, I promise!

See more info below!

This New Product™ is made exclusively with certified Real ingredients, making its effects twice as effective and its side effects thrice as side effective. Work these into your routine, and guaranteed, you will feel the effects!

Improvifized Strongitude

Have other people ever called you weak? Puny, perhaps? Scrawny, if you will? Perchance even a tad toothpickulous? Well after taking The Product™, your days of powerlessness will be over! Your lung capacity will double, your max bench weight will quadruple, your running speed will octuple! The ground will ripple under your every step! Weaklings will simply crumble from your sheer vigor! No one can or will stand in your way!

Decreasened Ugliness

Feel insecure about your appearance? No? Well you should, because you don’t use The Product™! Only users of The Product™ are able to attain true beauty, as verified by our patented beauty quantifying technology! Just one week of use, and people’s heads will turn in your presence, forming lines to witness the result of your metamorphosis journey!

Enhancicated Bedroom Performance

With The Product™, every night will be the best night of you and your partner’s lives! Intimate activities? Your pleasure will be amplified by magnitudes! Doing roleplay? Guaranteed to be twice as immersive! Literally just sleeping? That’s right, you will wake up better rested than ever, and with little to no chance of bizarre, disturbing nightmares! Everyone stands to improve their lives with the power of The Product™!

But why just take my word for it? Here’s some of what our customers are saying:

Customer Testimonies

“I knew that The Product™ would do a lot for my physical health, but no one ever told me about the mental health effects. I’ve been cheery all day, every day for the past month! I can’t remember what sadness feels like! I can’t remember what anger feels like! I can’t remember what fear feels like! I can’t remember what despair feels like! I can’t remember what despair feels like! I can’t remember what despair fe”

- Joy Glaggleburg, retail clerk, age 25

“The anti-aging properties of these things are unbelievable! I’ve only been taking these supplements for a week, and I already feel decades younger!”

- Lance DePeon, WWII veteran, age 4

“Product is…up to standard…contains…‘natural ingredients’…unknown origin. Effects may be…as advertised…benefits…likely caused by…product. May not be…obvious scam. Do…purchase or consume under any circumstances.”

- Sandia Natiolab, FDA product reviewer, age 49

“This ain’t like any of those WOKE supplements I keep seein’ ads for. These pills WORK. Since I started takin’ these, I’ve never spent a night without AT LEAST ten ladies in my bed, something always nice for a STRAIGHT MALE such as myself. But I also for some reason am NEVER ATTRACTED TO THEM so I just LEAVE. So then I sleep in my TRUCK. And then the ladies find my lack of interest in them disturbin’ so they then ALSO LEAVE. And then there’s MORE ladies the next evenin’. And they do THE SAME THING as the last batch. I can’t imagine life without this product! It’s almost better than garlic toast!”

- Chuck “Chuck” Chuckston, car mechanic, age 56

“why my doodoo yellow”

- Anonymous

For a limited time only, all of this can be yours for just $30,000 a month*! Just use code “PLEASEGODSOMEONEHELPME” at checkout, and the supplements will be on your way**!

—> —> —> —> —> Order here !! <— <— <— <— <—

*payment only accepted in form of bitcoin

**no refunds

64 notes

·

View notes

Note

U WANTED EIFFEL DISCUSSION okay uhh

what do you think he’d study if he went to uni/couldnt do radio?

... you know, this is a tricky question because i just can't imagine eiffel going to college!! if he hadn't discovered his love for radio, he could've gotten certified as a mechanic, or an electrician, or he could've tried to get into music production, or he could've convinced himself that yeah, actually, he could totally handle being a truck driver, or he could've become one of those traffic control guys, but ultimately i think he would still have ended up working at pizza hut.

i don't say that to bring him down in any way. i like that he doesn't really have career ambitions. but he really doesn't. even his love of radio and his talent for that is like, yeah, he's good at it!! but if you ask him to do it as a job, it's still a job, and he hates being at work. i think that's difficult to apply to college because his whole worldview is antithetical to academia. even if he was interested in something in theory, they'd tell him to write one (1) essay and he'd be gone.

#like if he was forced to pick a college major umm. i feel like he'd probably go for film or something like that#but as soon as he realized he had to do more than just Watch Movies he'd be goneeeee.#he simply does not have a dream job and i respect him for that#thank you for the question!!#asks

11 notes

·

View notes

Text

nobody asked but here is some Random Crap about some OCs:

Despite his appearance, Jaro is physically affectionate with his minions and they all say he's a really good bossman. He'll hug them if they're in need of one. He and Sherman will sometimes go walking holding hands (they also hold hands whilst just chilling out together and Jaro is like reading a book or something and Sherman is just vibing to music). He's probably the most secure in his masculinity outside of issues stemming from his height in comparison to the others eijrfenrg

Sherman, in spite of his appearance, is more capable than he looks. Yes he's a cartoonish fiend who likes snorting radioactive substances and getting himself blown up... but he has created most of Marzon's mechanized military, has licenses for forklifts, trucks, fighter jets, mechas and tanks (he's working on getting certified as a train driver currently) and he's also able to make all kinds of explosives and chemicals. He's also a slimebeast and can become slime/transform his shape but this is kept as classified information. He was created by Jaro as a child after Jaro accidentally knocked over an oil drum full of spent rocket fuel, or so the story goes.

Finally, Sam loves cooking. He especially loves experimenting in the kitchen whilst drunk. The amount of times Cici has found him wearing only an apron and cut-off shorts with the kitchen on fire and him 15 bottles of drink in, she's lost count. Somehow, despite this chaos, his final dishes turn out pretty good and nobody knows why.

13 notes

·

View notes

Text

Entirely random head cannon about Chop Top- he's really good with cars. I would go so far as to say he's mechanically gifted/ skilled/ would be the type of guy to take a radio or tv remote apart then put it back together again for fun/ because he wants to see how it works. Seems kind of random/ maybe at odds with his character but I have actual reasoning for this one.

I am not a car guy at all but my friend who I inflicted TCM2 on is a certified car girl tm and when we watch it she always mentions how if Lefty's speed estimate is even remotely correct (90 mph) during the Rick the Prick and Buzz kill scene then Chop Top (who's presumably driving the truck) is a fantastic driver and the steering system (she always mentions a specific part I cannot remember for the life of me) of his truck is very well tuned. She also noted something similar about how well Drayton's chili truck maintains its path when he's on the phone, and she cringes when he makes that abrupt turn because it would fuck that up. Also in Texas Battleland they would need someone with at least some skill as an electrician to set up the lights in their "house" which is a skill neither Drayton nor Bubba have shown previously. Like all this could be Drayton or Bubba's doing but since these improvements align with Chop Top's return I like to think it's him.

10 notes

·

View notes

Text

Shingleback Bike Racks: Quality Bike Racks for Your Need

If you're a bike rider, you know how important it is to have the right equipment. But what if your bike rack isn't up to snuff? You could end up with a lot of problems like:

A squeaky rack that ruins the ride for everyone around you

A rack that rattles when it's not supposed to, making it hard for you to focus on your ride

A rack that makes noises every time you hit a bump in the road or take a turn too fast.

But don't worry, we've got your back! We've spent countless hours scouring the internet for the best bike racks on the market today. We've found one that really stands out from the crowd: The Shingleback Bike Rack. This thing is solid as a rock, easy to install and use, and has excellent features that make it perfect for any bike owner!

What is Shingleback Bike Rack?

Shingleback bike racks are manufactured by Shingleback Off Road Australia, which has been at the forefront of innovative engineering for bike racks.

The Shingleback bike rack makes it easy to transport bikes safely and take them wherever you go. It's compact and portable, perfect for many vehicles, from a common family car to trucks and camper trailers. And it comes in various models, so you can choose one that works best for your needs and style.

Shingleback racks have a sleek design and easily fit into many environments without being obtrusive. Plus, it’s strong to keep your bike safe while travelling on bumpy roads or through crowds at festivals!

Types of Shingleback Bike Racks

Shingleback bike racks are an excellent choice for avid bikers and adventurers. They're a great way to transport your bike, and they're great for people who dislike using their vehicle's trunk space to store bikes. Shingleback offers three different types of bike racks for your car or SUV to accommodate your unique needs:

Shingleback Lite Bike Rack

The Shingleback Lite bike rack is an excellent option for anyone looking to transport their bikes safely and securely. The rack has a ten-year guarantee, certified by independent parties to be safe, durable, and effective. In addition, it features a new foot-tilting latch to make loading and unloading easier than ever before.

This rack is compatible with Shingleback's extensive range of Sport and Boost accessories and their universal accessories. It packs a big punch with its cradle rotation/adjustment and is fully compatible with other racks in their line-up. It is perfect for mountain bikers, gravel grinders, roadies, or BMX'ers who need to transport their bikes safely from one place to another.

Shingleback Boost Bike Rack

This sleek and incredibly well-designed Shingleback Boost bike rack has maximum safety, durability, and effectiveness. It comes with an added Boost Link feature which provide tilting assistance even with a fully loaded rack.

This rack is compatible with Shingleback Boost accessories, which you can use to carry your bikes securely in your car or SUV. If you're an avid biker who must transport their bikes between different locations, this rack will help you do it easily and safely.

Shingleback Sport Bike Rack

Whether you're a professional cyclist or just a casual rider, Shingleback Sport bike rack will be right up your alley. It's made with a 10-year guarantee, so you can rest assured that it's safe and durable.

This rack is compatible with Shingleback's Sport accessories, so you can take your bike on any trip without worrying about how to transport it safely. Shingleback Sport bike rack is also effective for transporting bikes because it has a tilt mechanism that allows you to load your bike onto it quickly and easily.

Learn more about shingleback bike rack here

2 notes

·

View notes

Text

Winnipeg’s Best Truck Service Center: Reliable Repairs & Maintenance

Winnipeg’s Best Truck Service Center: Reliable Repairs & Maintenance

When it comes to keeping your truck in top condition, choosing the right service center is crucial. If you’re looking for the Winnipeg Best Truck Service Center, you need a place that offers reliability, efficiency, and expert care. That’s where Akal Truck & Trailer Centre Inc. comes in.

Why ChooseAkal Truck & Trailer Centre Inc.?

Akal Truck & Trailer Centre Inc. is a trusted name in the trucking industry, known for its professional service and skilled mechanics. Whether you need routine maintenance, emergency repairs, or diagnostic services, this service center ensures your truck is road-ready in no time.

Services Offered

At Winnipeg Best Truck Service Center, you’ll find a comprehensive range of services, including:

Oil Changes & Lubrication – Keeping your engine running smoothly.

Brake Repairs & Inspection – Ensuring your safety on the road.

Engine Diagnostics & Repair – Identifying and fixing issues before they worsen.

Tire Inspection & Replacement – Enhancing road grip and fuel efficiency.

Transmission & Suspension Repair – Improving overall truck performance.

Fast & Efficient Repairs

Truck downtime means lost revenue. That’s why Akal Truck & Trailer Centre Inc. offers quick turnaround times without compromising on quality. Their team of certified technicians works diligently to get your truck back on the road as soon as possible.

Customer Satisfaction & Reliability

Customer trust is a priority at Winnipeg Best Truck Service Center. Akal Truck & Trailer Centre Inc. is committed to providing high-quality services at competitive prices, ensuring you receive the best care for your vehicle.

Visit Akal Truck & Trailer Centre Inc. Today!

If you’re searching for Winnipeg Best Truck Service Center, look no further than Akal Truck & Trailer Centre Inc. Conveniently located in Winnipeg, they offer top-notch truck maintenance and repair solutions to keep your fleet running smoothly. Visit today and experience superior truck service!

#AkalTruckRepairCentre#TruckRepairCentreInWinnipeg#TruckRepairShopwinnipeg#TruckMechanicWinnipeg#HeavyTruckRepairWinnipeg#winnipegtrucktrailerrepair#quicktruckandtrailerrepairwinnipeg#24hourtruckrepaircentrewinnipeg#reliabletruckmechanicinwinnipeg#commercialtruckrepairwinnipeg

0 notes

Text

Used Car Sales In Ontario CA – Best Deals on Quality Vehicles

If you're searching for the best used car sales in Ontario, CA, you're in the right place. Ontario, California, is a bustling hub for pre-owned vehicles, offering a wide range of choices for budget-conscious buyers. Whether you're looking for a fuel-efficient sedan, a rugged SUV, or a reliable truck, the used car market in Ontario, CA, has something for everyone.

Why Buy a Used Car in Ontario, CA?

1. Cost Savings

Buying a used car is a great way to save money. New cars depreciate quickly, losing a significant portion of their value within the first few years. A well-maintained used car offers the same reliability at a fraction of the cost.

2. Lower Insurance Rates

Since insurance premiums are based on the car's value, used cars generally have lower insurance costs compared to brand-new vehicles. This makes used cars a budget-friendly option.

3. Wide Selection

Ontario, CA, has a thriving used car market, including dealership-certified pre-owned (CPO) vehicles, private sales, and online marketplaces. With such variety, you can find a car that fits your needs and budget.

4. Reduced Depreciation

New cars depreciate rapidly in the first few years, but used cars have already undergone most of this depreciation. This means your investment holds its value better over time.

Best Places for Used Car Sales in Ontario, CA

1. Certified Dealerships

Many dealerships in Ontario offer certified pre-owned (CPO) vehicles that come with warranties, multi-point inspections, and added reliability. Some top dealerships in Ontario include:

Citrus Motors Ford

Ontario Hyundai

Empire Nissan

John Elway’s Claremont Chrysler Dodge Jeep Ram

2. Independent Used Car Dealers

Local independent dealerships often offer a wide range of vehicles at competitive prices. Some popular independent used car dealerships in Ontario, CA, include:

Rock Honda

STG Auto Group

Certified Auto Sales

3. Online Marketplaces

Websites like Craigslist, Facebook Marketplace, and AutoTrader provide extensive listings of used cars in Ontario, CA. Buyers can filter options by price, mileage, and features to find the best deals.

4. Car Auctions

For those looking for bargain deals, car auctions offer vehicles at lower-than-market prices. Government and police auctions in Ontario, CA, are excellent places to find well-maintained used cars at affordable rates.

Tips for Finding the Best Used Car Deals in Ontario, CA

1. Set a Budget

Before shopping, determine how much you can afford. Consider financing options, down payments, and monthly payments to ensure you stay within your budget.

2. Check Vehicle History Reports

Always request a vehicle history report (e.g., CARFAX or AutoCheck) to check for accidents, ownership history, and service records.

3. Inspect the Car Thoroughly

Inspect the car in person or hire a professional mechanic to check for any mechanical issues before finalizing your purchase.

4. Test Drive Before Buying

A test drive is crucial to ensure the vehicle meets your expectations. Check the brakes, acceleration, steering, and overall comfort.

5. Negotiate the Price

Don't be afraid to negotiate. Dealers and private sellers often have some flexibility on pricing, so make sure you get the best deal possible.

Conclusion

Finding the best used car sales in Ontario, CA requires research, patience, and a keen eye for quality vehicles. Whether you choose a dealership, independent seller, or an online marketplace, following the right strategies will help you drive away with a reliable and affordable used car. Start your search today and get the best deals in Ontario, CA!

0 notes

Photo

Unlike houses built on-site using framed structures or prefab panels, modular buildings are constructed almost entirely in a factory. Volumetric "boxes" are built by skilled tradespeople and trucked to a prepared construction site, a process that proponents say reduces waste and deployment time. Even mega-landlord Greystar recently hopped on the modular bandwagon with several new multifamily residential projects, leading one to ask: Can modular help us end the housing crisis? Jon Hannah-Spacagna, the director of government affairs for the Modular Building Institute (MBI)—a trade association for allied professionals working in and around modular buildings—certainly thinks so. His role is to further MBI’s advocacy work, to collaborate with elected officials and government agencies, and educate the built environment sector on modular’s possibilities. Speaking with Dwell, Hannah-Spacagna explains the pros of building your house (or office) in a factory, dispels some rumors about code-related issues, and discusses what needs to change if cities want to rapidly make a dent in our country’s missing six million units of housing. Oaxaca Interests, a Texas real estate operator, developer, and investment firm, partnered with architecture firm Lake|Flato to create a modular home called the HiFAB.Dwell: For those unfamiliar with modular building, can you explain what it is?Jon Hannah-Spacagna: We’re not a product, we’re a process. A modular home is built to the same building codes as a site-built home—or whatever type of construction you want to think of. If we can build it modularly in a factory, it’s being built to those same standards that a site-built construction crew would build. It’s just simply that we build it in three dimensional, volumetric boxes, and then they are transported to the site and then craned into place.I’d love to hear a little bit about why modular building is a good process, or better than traditional building.We’ve had independent studies done that show our type of construction is greener, so there’s less waste and less emissions. Because we’re building a factory setting, we’re literally utilizing every piece of material that we procure for that project. And if there’s something that isn’t used, then it’s put to the side and used on the next project. The other part is the safety of the construction workers: If you went into any modular manufacturing facility, you’re not going to see any of those workers on scaffolding; they’re able to build these modules on a ground setting and move them from station to station. Everything from the exterior and floor construction to the mechanical, electrical, and plumbing that goes into them—even the furniture, in some cases—they’re built in a controlled setting, then trucked to the site. So it’s much safer for the employees.As I’ve toured many of our member factories, an interesting thing you see are people that you wouldn’t normally see on a construction site. You may see a disabled veteran in a wheelchair working at a modular construction station. You may see a lot more women in the workplace in a modular factory than you would on a construction site."It’s a matter of educating people on our industry, what we have to offer, and why modular is a good solution for housing." —Jon Hannah-Spacagna You say that modular buildings are built to the same standards as site-builds; what about the facilities themselves? How are they regulated?Facilities are inspected by state approved inspection agencies, and in some cases, the state actually sends their own people to inspect them. The factories have to be certified by the state that they're doing business in, in addition to each individual module being inspected and receiving a label from that state, if the state has a modular program. Some don’t, and those that don’t, then you work with the state building official to get those approved, but the factory has to submit their quality control manuals and get their own certification before they even start building a specific project.When did modular building become a widespread practice?Modular has been around since the old Sears catalog days; you could literally order a modular home in a Sears catalog back in the ’60s. [It’s resurgence] is due to a combination of [factors], from the marketing that we do out of our office, to the world of modular events in Las Vegas, which has been going on for many, many years. We continue to see record growth for that event year after year. I’m getting phone calls and emails almost on a daily basis—from government agencies, nonprofits that are building, housing developers wanting to learn more, investment companies that are looking to invest in modular construction and modular manufacturers. Once they have success with modular, they see the value of not only the quicker return on their investment, but also all the benefits that I’ve mentioned. And it really is a faster, greener, better way to build, and with the declining workforce that we have in the construction industry now—because we're not seeing kids coming out of school wanting to go into construction like they did 30 years ago—it’s going to have to be the way of the future for how construction is done.What are some of the biggest hurdles that the modular industry encounters?It’s a PR misunderstanding of what modular construction is. And that goes from the consumer, who may be looking to build their first home, to the developer who may be building 100 homes on a specific lot, to a governor or member of Congress who is looking for ways to solve our housing crisis. It’s a matter of educating them on our industry, what we have to offer, and why modular is a good solution for housing.But there are states that are taking that and running with it, like Colorado. We’ve worked with them for the past several years; they passed legislation a couple years ago that created $40 million in grants specifically to support the build of affordable housing using modular construction. And those grants were for existing modular manufacturers to expand their capacity and footprint and also to recruit new modular manufacturers to move to their state. They’ve also added low-income housing tax credits and other financial funding streams to support modular, and in the last three years, they’ve increased modular production by 687 percent. I would say 99 percent of that is focused on affordable housing.In Canada, we’ve seen great success: I worked with the Canadian Mortgage Housing Corporation right after the pandemic. They created what they called their rapid housing initiative. It started out as a $1.7 billion investment using only modular construction to build affordable housing, and in the first 24 months, they created 10,000 new housing units for those in need. So it’s a proof of concept that it works.Workers assemble a modular home in a factory for Inherent Homes, a Chicago prefab home builder.You work at a national level, so when you’re thinking about different cities, what are some of the most common code related challenges? Are there disparities around what could be built in Chicago, versus Denver, versus Atlanta?The easy answer is, that’s a misperception. We’re built to the same building codes as site-built construction. There are two code books that you reference—either the International Residential Code through the International Code Council, which is specifically for residential, single family residences, or the International Building Code through the International Code Council, which is specific to commercial or multi family modular construction. So every state in the U.S. adopts those building code standards. Most of them will have some amendments. It could be specific to wind, seismic, snow requirements. That’s what site-built contractors build to, and that's what our industry builds to. You won’t talk to pretty much anyone in our industry that says we want special or different building codes for modular—we can build to any building code in whatever state you want us to.Most of our manufacturers are regionally dispersed. For example, if they’re based in Texas, they could build for California, Colorado, and Louisiana; they can build anywhere as long as they know beforehand which state it’s going to and the building codes you need to comply with. We can do that. So that’s not a hurdle. It’s really the education piece to help people. We don’t have a building code problem and right now in both of those codes that I mentioned, the word modular does not exist. As an organization, we partnered with the International Code Council, and developed standards. So there’s ICC MBI standards, and not to get too far in the weeds and codes, but those were developed to help building officials understand our industry.We’re pro-anything that supports getting housing built faster. What are the possibilities for modular when it comes to fitting into existing or possible plans to remedy the housing crisis?For those that are wanting to really address housing, commit a set dollar amount and partner with the modular construction industry and modular manufacturers to say, "hey, for the next three years, five years, whatever it is, we want you to build X number of homes." We had manufacturers that just built 200 homes in Maui for FEMA as a part of the fire disaster relief. And they said, Okay, here are the designs. We want you to build one, two, and three bedroom homes. We need 200 of them. Here’s how many of each. And here’s the money. Our manufacturers built 200 homes in 60 days. They had all the means in place logistically. Some of these were constructed in Colorado, some in Idaho, and they were shipped or transported to the port in Seattle, loaded on a barge, transported to Maui, offloaded, and then set on site. They are beautiful one, two, and three bedroom homes. To me, it is what should be done, and how you’re going to maximize productivity.Top photo courtesy of MBI Source link

0 notes

Photo

Unlike houses built on-site using framed structures or prefab panels, modular buildings are constructed almost entirely in a factory. Volumetric "boxes" are built by skilled tradespeople and trucked to a prepared construction site, a process that proponents say reduces waste and deployment time. Even mega-landlord Greystar recently hopped on the modular bandwagon with several new multifamily residential projects, leading one to ask: Can modular help us end the housing crisis? Jon Hannah-Spacagna, the director of government affairs for the Modular Building Institute (MBI)—a trade association for allied professionals working in and around modular buildings—certainly thinks so. His role is to further MBI’s advocacy work, to collaborate with elected officials and government agencies, and educate the built environment sector on modular’s possibilities. Speaking with Dwell, Hannah-Spacagna explains the pros of building your house (or office) in a factory, dispels some rumors about code-related issues, and discusses what needs to change if cities want to rapidly make a dent in our country’s missing six million units of housing. Oaxaca Interests, a Texas real estate operator, developer, and investment firm, partnered with architecture firm Lake|Flato to create a modular home called the HiFAB.Dwell: For those unfamiliar with modular building, can you explain what it is?Jon Hannah-Spacagna: We’re not a product, we’re a process. A modular home is built to the same building codes as a site-built home—or whatever type of construction you want to think of. If we can build it modularly in a factory, it’s being built to those same standards that a site-built construction crew would build. It’s just simply that we build it in three dimensional, volumetric boxes, and then they are transported to the site and then craned into place.I’d love to hear a little bit about why modular building is a good process, or better than traditional building.We’ve had independent studies done that show our type of construction is greener, so there’s less waste and less emissions. Because we’re building a factory setting, we’re literally utilizing every piece of material that we procure for that project. And if there’s something that isn’t used, then it’s put to the side and used on the next project. The other part is the safety of the construction workers: If you went into any modular manufacturing facility, you’re not going to see any of those workers on scaffolding; they’re able to build these modules on a ground setting and move them from station to station. Everything from the exterior and floor construction to the mechanical, electrical, and plumbing that goes into them—even the furniture, in some cases—they’re built in a controlled setting, then trucked to the site. So it’s much safer for the employees.As I’ve toured many of our member factories, an interesting thing you see are people that you wouldn’t normally see on a construction site. You may see a disabled veteran in a wheelchair working at a modular construction station. You may see a lot more women in the workplace in a modular factory than you would on a construction site."It’s a matter of educating people on our industry, what we have to offer, and why modular is a good solution for housing." —Jon Hannah-Spacagna You say that modular buildings are built to the same standards as site-builds; what about the facilities themselves? How are they regulated?Facilities are inspected by state approved inspection agencies, and in some cases, the state actually sends their own people to inspect them. The factories have to be certified by the state that they're doing business in, in addition to each individual module being inspected and receiving a label from that state, if the state has a modular program. Some don’t, and those that don’t, then you work with the state building official to get those approved, but the factory has to submit their quality control manuals and get their own certification before they even start building a specific project.When did modular building become a widespread practice?Modular has been around since the old Sears catalog days; you could literally order a modular home in a Sears catalog back in the ’60s. [It’s resurgence] is due to a combination of [factors], from the marketing that we do out of our office, to the world of modular events in Las Vegas, which has been going on for many, many years. We continue to see record growth for that event year after year. I’m getting phone calls and emails almost on a daily basis—from government agencies, nonprofits that are building, housing developers wanting to learn more, investment companies that are looking to invest in modular construction and modular manufacturers. Once they have success with modular, they see the value of not only the quicker return on their investment, but also all the benefits that I’ve mentioned. And it really is a faster, greener, better way to build, and with the declining workforce that we have in the construction industry now—because we're not seeing kids coming out of school wanting to go into construction like they did 30 years ago—it’s going to have to be the way of the future for how construction is done.What are some of the biggest hurdles that the modular industry encounters?It’s a PR misunderstanding of what modular construction is. And that goes from the consumer, who may be looking to build their first home, to the developer who may be building 100 homes on a specific lot, to a governor or member of Congress who is looking for ways to solve our housing crisis. It’s a matter of educating them on our industry, what we have to offer, and why modular is a good solution for housing.But there are states that are taking that and running with it, like Colorado. We’ve worked with them for the past several years; they passed legislation a couple years ago that created $40 million in grants specifically to support the build of affordable housing using modular construction. And those grants were for existing modular manufacturers to expand their capacity and footprint and also to recruit new modular manufacturers to move to their state. They’ve also added low-income housing tax credits and other financial funding streams to support modular, and in the last three years, they’ve increased modular production by 687 percent. I would say 99 percent of that is focused on affordable housing.In Canada, we’ve seen great success: I worked with the Canadian Mortgage Housing Corporation right after the pandemic. They created what they called their rapid housing initiative. It started out as a $1.7 billion investment using only modular construction to build affordable housing, and in the first 24 months, they created 10,000 new housing units for those in need. So it’s a proof of concept that it works.Workers assemble a modular home in a factory for Inherent Homes, a Chicago prefab home builder.You work at a national level, so when you’re thinking about different cities, what are some of the most common code related challenges? Are there disparities around what could be built in Chicago, versus Denver, versus Atlanta?The easy answer is, that’s a misperception. We’re built to the same building codes as site-built construction. There are two code books that you reference—either the International Residential Code through the International Code Council, which is specifically for residential, single family residences, or the International Building Code through the International Code Council, which is specific to commercial or multi family modular construction. So every state in the U.S. adopts those building code standards. Most of them will have some amendments. It could be specific to wind, seismic, snow requirements. That’s what site-built contractors build to, and that's what our industry builds to. You won’t talk to pretty much anyone in our industry that says we want special or different building codes for modular—we can build to any building code in whatever state you want us to.Most of our manufacturers are regionally dispersed. For example, if they’re based in Texas, they could build for California, Colorado, and Louisiana; they can build anywhere as long as they know beforehand which state it’s going to and the building codes you need to comply with. We can do that. So that’s not a hurdle. It’s really the education piece to help people. We don’t have a building code problem and right now in both of those codes that I mentioned, the word modular does not exist. As an organization, we partnered with the International Code Council, and developed standards. So there’s ICC MBI standards, and not to get too far in the weeds and codes, but those were developed to help building officials understand our industry.We’re pro-anything that supports getting housing built faster. What are the possibilities for modular when it comes to fitting into existing or possible plans to remedy the housing crisis?For those that are wanting to really address housing, commit a set dollar amount and partner with the modular construction industry and modular manufacturers to say, "hey, for the next three years, five years, whatever it is, we want you to build X number of homes." We had manufacturers that just built 200 homes in Maui for FEMA as a part of the fire disaster relief. And they said, Okay, here are the designs. We want you to build one, two, and three bedroom homes. We need 200 of them. Here’s how many of each. And here’s the money. Our manufacturers built 200 homes in 60 days. They had all the means in place logistically. Some of these were constructed in Colorado, some in Idaho, and they were shipped or transported to the port in Seattle, loaded on a barge, transported to Maui, offloaded, and then set on site. They are beautiful one, two, and three bedroom homes. To me, it is what should be done, and how you’re going to maximize productivity.Top photo courtesy of MBI Source link

0 notes

Photo

Unlike houses built on-site using framed structures or prefab panels, modular buildings are constructed almost entirely in a factory. Volumetric "boxes" are built by skilled tradespeople and trucked to a prepared construction site, a process that proponents say reduces waste and deployment time. Even mega-landlord Greystar recently hopped on the modular bandwagon with several new multifamily residential projects, leading one to ask: Can modular help us end the housing crisis? Jon Hannah-Spacagna, the director of government affairs for the Modular Building Institute (MBI)—a trade association for allied professionals working in and around modular buildings—certainly thinks so. His role is to further MBI’s advocacy work, to collaborate with elected officials and government agencies, and educate the built environment sector on modular’s possibilities. Speaking with Dwell, Hannah-Spacagna explains the pros of building your house (or office) in a factory, dispels some rumors about code-related issues, and discusses what needs to change if cities want to rapidly make a dent in our country’s missing six million units of housing. Oaxaca Interests, a Texas real estate operator, developer, and investment firm, partnered with architecture firm Lake|Flato to create a modular home called the HiFAB.Dwell: For those unfamiliar with modular building, can you explain what it is?Jon Hannah-Spacagna: We’re not a product, we’re a process. A modular home is built to the same building codes as a site-built home—or whatever type of construction you want to think of. If we can build it modularly in a factory, it’s being built to those same standards that a site-built construction crew would build. It’s just simply that we build it in three dimensional, volumetric boxes, and then they are transported to the site and then craned into place.I’d love to hear a little bit about why modular building is a good process, or better than traditional building.We’ve had independent studies done that show our type of construction is greener, so there’s less waste and less emissions. Because we’re building a factory setting, we’re literally utilizing every piece of material that we procure for that project. And if there’s something that isn’t used, then it’s put to the side and used on the next project. The other part is the safety of the construction workers: If you went into any modular manufacturing facility, you’re not going to see any of those workers on scaffolding; they’re able to build these modules on a ground setting and move them from station to station. Everything from the exterior and floor construction to the mechanical, electrical, and plumbing that goes into them—even the furniture, in some cases—they’re built in a controlled setting, then trucked to the site. So it’s much safer for the employees.As I’ve toured many of our member factories, an interesting thing you see are people that you wouldn’t normally see on a construction site. You may see a disabled veteran in a wheelchair working at a modular construction station. You may see a lot more women in the workplace in a modular factory than you would on a construction site."It’s a matter of educating people on our industry, what we have to offer, and why modular is a good solution for housing." —Jon Hannah-Spacagna You say that modular buildings are built to the same standards as site-builds; what about the facilities themselves? How are they regulated?Facilities are inspected by state approved inspection agencies, and in some cases, the state actually sends their own people to inspect them. The factories have to be certified by the state that they're doing business in, in addition to each individual module being inspected and receiving a label from that state, if the state has a modular program. Some don’t, and those that don’t, then you work with the state building official to get those approved, but the factory has to submit their quality control manuals and get their own certification before they even start building a specific project.When did modular building become a widespread practice?Modular has been around since the old Sears catalog days; you could literally order a modular home in a Sears catalog back in the ’60s. [It’s resurgence] is due to a combination of [factors], from the marketing that we do out of our office, to the world of modular events in Las Vegas, which has been going on for many, many years. We continue to see record growth for that event year after year. I’m getting phone calls and emails almost on a daily basis—from government agencies, nonprofits that are building, housing developers wanting to learn more, investment companies that are looking to invest in modular construction and modular manufacturers. Once they have success with modular, they see the value of not only the quicker return on their investment, but also all the benefits that I’ve mentioned. And it really is a faster, greener, better way to build, and with the declining workforce that we have in the construction industry now—because we're not seeing kids coming out of school wanting to go into construction like they did 30 years ago—it’s going to have to be the way of the future for how construction is done.What are some of the biggest hurdles that the modular industry encounters?It’s a PR misunderstanding of what modular construction is. And that goes from the consumer, who may be looking to build their first home, to the developer who may be building 100 homes on a specific lot, to a governor or member of Congress who is looking for ways to solve our housing crisis. It’s a matter of educating them on our industry, what we have to offer, and why modular is a good solution for housing.But there are states that are taking that and running with it, like Colorado. We’ve worked with them for the past several years; they passed legislation a couple years ago that created $40 million in grants specifically to support the build of affordable housing using modular construction. And those grants were for existing modular manufacturers to expand their capacity and footprint and also to recruit new modular manufacturers to move to their state. They’ve also added low-income housing tax credits and other financial funding streams to support modular, and in the last three years, they’ve increased modular production by 687 percent. I would say 99 percent of that is focused on affordable housing.In Canada, we’ve seen great success: I worked with the Canadian Mortgage Housing Corporation right after the pandemic. They created what they called their rapid housing initiative. It started out as a $1.7 billion investment using only modular construction to build affordable housing, and in the first 24 months, they created 10,000 new housing units for those in need. So it’s a proof of concept that it works.Workers assemble a modular home in a factory for Inherent Homes, a Chicago prefab home builder.You work at a national level, so when you’re thinking about different cities, what are some of the most common code related challenges? Are there disparities around what could be built in Chicago, versus Denver, versus Atlanta?The easy answer is, that’s a misperception. We’re built to the same building codes as site-built construction. There are two code books that you reference—either the International Residential Code through the International Code Council, which is specifically for residential, single family residences, or the International Building Code through the International Code Council, which is specific to commercial or multi family modular construction. So every state in the U.S. adopts those building code standards. Most of them will have some amendments. It could be specific to wind, seismic, snow requirements. That’s what site-built contractors build to, and that's what our industry builds to. You won’t talk to pretty much anyone in our industry that says we want special or different building codes for modular—we can build to any building code in whatever state you want us to.Most of our manufacturers are regionally dispersed. For example, if they’re based in Texas, they could build for California, Colorado, and Louisiana; they can build anywhere as long as they know beforehand which state it’s going to and the building codes you need to comply with. We can do that. So that’s not a hurdle. It’s really the education piece to help people. We don’t have a building code problem and right now in both of those codes that I mentioned, the word modular does not exist. As an organization, we partnered with the International Code Council, and developed standards. So there’s ICC MBI standards, and not to get too far in the weeds and codes, but those were developed to help building officials understand our industry.We’re pro-anything that supports getting housing built faster. What are the possibilities for modular when it comes to fitting into existing or possible plans to remedy the housing crisis?For those that are wanting to really address housing, commit a set dollar amount and partner with the modular construction industry and modular manufacturers to say, "hey, for the next three years, five years, whatever it is, we want you to build X number of homes." We had manufacturers that just built 200 homes in Maui for FEMA as a part of the fire disaster relief. And they said, Okay, here are the designs. We want you to build one, two, and three bedroom homes. We need 200 of them. Here’s how many of each. And here’s the money. Our manufacturers built 200 homes in 60 days. They had all the means in place logistically. Some of these were constructed in Colorado, some in Idaho, and they were shipped or transported to the port in Seattle, loaded on a barge, transported to Maui, offloaded, and then set on site. They are beautiful one, two, and three bedroom homes. To me, it is what should be done, and how you’re going to maximize productivity.Top photo courtesy of MBI Source link

0 notes

Photo

Unlike houses built on-site using framed structures or prefab panels, modular buildings are constructed almost entirely in a factory. Volumetric "boxes" are built by skilled tradespeople and trucked to a prepared construction site, a process that proponents say reduces waste and deployment time. Even mega-landlord Greystar recently hopped on the modular bandwagon with several new multifamily residential projects, leading one to ask: Can modular help us end the housing crisis? Jon Hannah-Spacagna, the director of government affairs for the Modular Building Institute (MBI)—a trade association for allied professionals working in and around modular buildings—certainly thinks so. His role is to further MBI’s advocacy work, to collaborate with elected officials and government agencies, and educate the built environment sector on modular’s possibilities. Speaking with Dwell, Hannah-Spacagna explains the pros of building your house (or office) in a factory, dispels some rumors about code-related issues, and discusses what needs to change if cities want to rapidly make a dent in our country’s missing six million units of housing. Oaxaca Interests, a Texas real estate operator, developer, and investment firm, partnered with architecture firm Lake|Flato to create a modular home called the HiFAB.Dwell: For those unfamiliar with modular building, can you explain what it is?Jon Hannah-Spacagna: We’re not a product, we’re a process. A modular home is built to the same building codes as a site-built home—or whatever type of construction you want to think of. If we can build it modularly in a factory, it’s being built to those same standards that a site-built construction crew would build. It’s just simply that we build it in three dimensional, volumetric boxes, and then they are transported to the site and then craned into place.I’d love to hear a little bit about why modular building is a good process, or better than traditional building.We’ve had independent studies done that show our type of construction is greener, so there’s less waste and less emissions. Because we’re building a factory setting, we’re literally utilizing every piece of material that we procure for that project. And if there’s something that isn’t used, then it’s put to the side and used on the next project. The other part is the safety of the construction workers: If you went into any modular manufacturing facility, you’re not going to see any of those workers on scaffolding; they’re able to build these modules on a ground setting and move them from station to station. Everything from the exterior and floor construction to the mechanical, electrical, and plumbing that goes into them—even the furniture, in some cases—they’re built in a controlled setting, then trucked to the site. So it’s much safer for the employees.As I’ve toured many of our member factories, an interesting thing you see are people that you wouldn’t normally see on a construction site. You may see a disabled veteran in a wheelchair working at a modular construction station. You may see a lot more women in the workplace in a modular factory than you would on a construction site."It’s a matter of educating people on our industry, what we have to offer, and why modular is a good solution for housing." —Jon Hannah-Spacagna You say that modular buildings are built to the same standards as site-builds; what about the facilities themselves? How are they regulated?Facilities are inspected by state approved inspection agencies, and in some cases, the state actually sends their own people to inspect them. The factories have to be certified by the state that they're doing business in, in addition to each individual module being inspected and receiving a label from that state, if the state has a modular program. Some don’t, and those that don’t, then you work with the state building official to get those approved, but the factory has to submit their quality control manuals and get their own certification before they even start building a specific project.When did modular building become a widespread practice?Modular has been around since the old Sears catalog days; you could literally order a modular home in a Sears catalog back in the ’60s. [It’s resurgence] is due to a combination of [factors], from the marketing that we do out of our office, to the world of modular events in Las Vegas, which has been going on for many, many years. We continue to see record growth for that event year after year. I’m getting phone calls and emails almost on a daily basis—from government agencies, nonprofits that are building, housing developers wanting to learn more, investment companies that are looking to invest in modular construction and modular manufacturers. Once they have success with modular, they see the value of not only the quicker return on their investment, but also all the benefits that I’ve mentioned. And it really is a faster, greener, better way to build, and with the declining workforce that we have in the construction industry now—because we're not seeing kids coming out of school wanting to go into construction like they did 30 years ago—it’s going to have to be the way of the future for how construction is done.What are some of the biggest hurdles that the modular industry encounters?It’s a PR misunderstanding of what modular construction is. And that goes from the consumer, who may be looking to build their first home, to the developer who may be building 100 homes on a specific lot, to a governor or member of Congress who is looking for ways to solve our housing crisis. It’s a matter of educating them on our industry, what we have to offer, and why modular is a good solution for housing.But there are states that are taking that and running with it, like Colorado. We’ve worked with them for the past several years; they passed legislation a couple years ago that created $40 million in grants specifically to support the build of affordable housing using modular construction. And those grants were for existing modular manufacturers to expand their capacity and footprint and also to recruit new modular manufacturers to move to their state. They’ve also added low-income housing tax credits and other financial funding streams to support modular, and in the last three years, they’ve increased modular production by 687 percent. I would say 99 percent of that is focused on affordable housing.In Canada, we’ve seen great success: I worked with the Canadian Mortgage Housing Corporation right after the pandemic. They created what they called their rapid housing initiative. It started out as a $1.7 billion investment using only modular construction to build affordable housing, and in the first 24 months, they created 10,000 new housing units for those in need. So it’s a proof of concept that it works.Workers assemble a modular home in a factory for Inherent Homes, a Chicago prefab home builder.You work at a national level, so when you’re thinking about different cities, what are some of the most common code related challenges? Are there disparities around what could be built in Chicago, versus Denver, versus Atlanta?The easy answer is, that’s a misperception. We’re built to the same building codes as site-built construction. There are two code books that you reference—either the International Residential Code through the International Code Council, which is specifically for residential, single family residences, or the International Building Code through the International Code Council, which is specific to commercial or multi family modular construction. So every state in the U.S. adopts those building code standards. Most of them will have some amendments. It could be specific to wind, seismic, snow requirements. That’s what site-built contractors build to, and that's what our industry builds to. You won’t talk to pretty much anyone in our industry that says we want special or different building codes for modular—we can build to any building code in whatever state you want us to.Most of our manufacturers are regionally dispersed. For example, if they’re based in Texas, they could build for California, Colorado, and Louisiana; they can build anywhere as long as they know beforehand which state it’s going to and the building codes you need to comply with. We can do that. So that’s not a hurdle. It’s really the education piece to help people. We don’t have a building code problem and right now in both of those codes that I mentioned, the word modular does not exist. As an organization, we partnered with the International Code Council, and developed standards. So there’s ICC MBI standards, and not to get too far in the weeds and codes, but those were developed to help building officials understand our industry.We’re pro-anything that supports getting housing built faster. What are the possibilities for modular when it comes to fitting into existing or possible plans to remedy the housing crisis?For those that are wanting to really address housing, commit a set dollar amount and partner with the modular construction industry and modular manufacturers to say, "hey, for the next three years, five years, whatever it is, we want you to build X number of homes." We had manufacturers that just built 200 homes in Maui for FEMA as a part of the fire disaster relief. And they said, Okay, here are the designs. We want you to build one, two, and three bedroom homes. We need 200 of them. Here’s how many of each. And here’s the money. Our manufacturers built 200 homes in 60 days. They had all the means in place logistically. Some of these were constructed in Colorado, some in Idaho, and they were shipped or transported to the port in Seattle, loaded on a barge, transported to Maui, offloaded, and then set on site. They are beautiful one, two, and three bedroom homes. To me, it is what should be done, and how you’re going to maximize productivity.Top photo courtesy of MBI Source link

0 notes

Photo

Unlike houses built on-site using framed structures or prefab panels, modular buildings are constructed almost entirely in a factory. Volumetric "boxes" are built by skilled tradespeople and trucked to a prepared construction site, a process that proponents say reduces waste and deployment time. Even mega-landlord Greystar recently hopped on the modular bandwagon with several new multifamily residential projects, leading one to ask: Can modular help us end the housing crisis? Jon Hannah-Spacagna, the director of government affairs for the Modular Building Institute (MBI)—a trade association for allied professionals working in and around modular buildings—certainly thinks so. His role is to further MBI’s advocacy work, to collaborate with elected officials and government agencies, and educate the built environment sector on modular’s possibilities. Speaking with Dwell, Hannah-Spacagna explains the pros of building your house (or office) in a factory, dispels some rumors about code-related issues, and discusses what needs to change if cities want to rapidly make a dent in our country’s missing six million units of housing. Oaxaca Interests, a Texas real estate operator, developer, and investment firm, partnered with architecture firm Lake|Flato to create a modular home called the HiFAB.Dwell: For those unfamiliar with modular building, can you explain what it is?Jon Hannah-Spacagna: We’re not a product, we’re a process. A modular home is built to the same building codes as a site-built home—or whatever type of construction you want to think of. If we can build it modularly in a factory, it’s being built to those same standards that a site-built construction crew would build. It’s just simply that we build it in three dimensional, volumetric boxes, and then they are transported to the site and then craned into place.I’d love to hear a little bit about why modular building is a good process, or better than traditional building.We’ve had independent studies done that show our type of construction is greener, so there’s less waste and less emissions. Because we’re building a factory setting, we’re literally utilizing every piece of material that we procure for that project. And if there’s something that isn’t used, then it’s put to the side and used on the next project. The other part is the safety of the construction workers: If you went into any modular manufacturing facility, you’re not going to see any of those workers on scaffolding; they’re able to build these modules on a ground setting and move them from station to station. Everything from the exterior and floor construction to the mechanical, electrical, and plumbing that goes into them—even the furniture, in some cases—they’re built in a controlled setting, then trucked to the site. So it’s much safer for the employees.As I’ve toured many of our member factories, an interesting thing you see are people that you wouldn’t normally see on a construction site. You may see a disabled veteran in a wheelchair working at a modular construction station. You may see a lot more women in the workplace in a modular factory than you would on a construction site."It’s a matter of educating people on our industry, what we have to offer, and why modular is a good solution for housing." —Jon Hannah-Spacagna You say that modular buildings are built to the same standards as site-builds; what about the facilities themselves? How are they regulated?Facilities are inspected by state approved inspection agencies, and in some cases, the state actually sends their own people to inspect them. The factories have to be certified by the state that they're doing business in, in addition to each individual module being inspected and receiving a label from that state, if the state has a modular program. Some don’t, and those that don’t, then you work with the state building official to get those approved, but the factory has to submit their quality control manuals and get their own certification before they even start building a specific project.When did modular building become a widespread practice?Modular has been around since the old Sears catalog days; you could literally order a modular home in a Sears catalog back in the ’60s. [It’s resurgence] is due to a combination of [factors], from the marketing that we do out of our office, to the world of modular events in Las Vegas, which has been going on for many, many years. We continue to see record growth for that event year after year. I’m getting phone calls and emails almost on a daily basis—from government agencies, nonprofits that are building, housing developers wanting to learn more, investment companies that are looking to invest in modular construction and modular manufacturers. Once they have success with modular, they see the value of not only the quicker return on their investment, but also all the benefits that I’ve mentioned. And it really is a faster, greener, better way to build, and with the declining workforce that we have in the construction industry now—because we're not seeing kids coming out of school wanting to go into construction like they did 30 years ago—it’s going to have to be the way of the future for how construction is done.What are some of the biggest hurdles that the modular industry encounters?It’s a PR misunderstanding of what modular construction is. And that goes from the consumer, who may be looking to build their first home, to the developer who may be building 100 homes on a specific lot, to a governor or member of Congress who is looking for ways to solve our housing crisis. It’s a matter of educating them on our industry, what we have to offer, and why modular is a good solution for housing.But there are states that are taking that and running with it, like Colorado. We’ve worked with them for the past several years; they passed legislation a couple years ago that created $40 million in grants specifically to support the build of affordable housing using modular construction. And those grants were for existing modular manufacturers to expand their capacity and footprint and also to recruit new modular manufacturers to move to their state. They’ve also added low-income housing tax credits and other financial funding streams to support modular, and in the last three years, they’ve increased modular production by 687 percent. I would say 99 percent of that is focused on affordable housing.In Canada, we’ve seen great success: I worked with the Canadian Mortgage Housing Corporation right after the pandemic. They created what they called their rapid housing initiative. It started out as a $1.7 billion investment using only modular construction to build affordable housing, and in the first 24 months, they created 10,000 new housing units for those in need. So it’s a proof of concept that it works.Workers assemble a modular home in a factory for Inherent Homes, a Chicago prefab home builder.You work at a national level, so when you’re thinking about different cities, what are some of the most common code related challenges? Are there disparities around what could be built in Chicago, versus Denver, versus Atlanta?The easy answer is, that’s a misperception. We’re built to the same building codes as site-built construction. There are two code books that you reference—either the International Residential Code through the International Code Council, which is specifically for residential, single family residences, or the International Building Code through the International Code Council, which is specific to commercial or multi family modular construction. So every state in the U.S. adopts those building code standards. Most of them will have some amendments. It could be specific to wind, seismic, snow requirements. That’s what site-built contractors build to, and that's what our industry builds to. You won’t talk to pretty much anyone in our industry that says we want special or different building codes for modular—we can build to any building code in whatever state you want us to.Most of our manufacturers are regionally dispersed. For example, if they’re based in Texas, they could build for California, Colorado, and Louisiana; they can build anywhere as long as they know beforehand which state it’s going to and the building codes you need to comply with. We can do that. So that’s not a hurdle. It’s really the education piece to help people. We don’t have a building code problem and right now in both of those codes that I mentioned, the word modular does not exist. As an organization, we partnered with the International Code Council, and developed standards. So there’s ICC MBI standards, and not to get too far in the weeds and codes, but those were developed to help building officials understand our industry.We’re pro-anything that supports getting housing built faster. What are the possibilities for modular when it comes to fitting into existing or possible plans to remedy the housing crisis?For those that are wanting to really address housing, commit a set dollar amount and partner with the modular construction industry and modular manufacturers to say, "hey, for the next three years, five years, whatever it is, we want you to build X number of homes." We had manufacturers that just built 200 homes in Maui for FEMA as a part of the fire disaster relief. And they said, Okay, here are the designs. We want you to build one, two, and three bedroom homes. We need 200 of them. Here’s how many of each. And here’s the money. Our manufacturers built 200 homes in 60 days. They had all the means in place logistically. Some of these were constructed in Colorado, some in Idaho, and they were shipped or transported to the port in Seattle, loaded on a barge, transported to Maui, offloaded, and then set on site. They are beautiful one, two, and three bedroom homes. To me, it is what should be done, and how you’re going to maximize productivity.Top photo courtesy of MBI Source link

0 notes

Photo