#Cable Assemblies Applications

Explore tagged Tumblr posts

Text

https://www.futureelectronics.com/p/interconnect--connectors-rectangular-plastic-industrial/776164-1-te-connectivity-2424471

Electrical connector, what is a data connector, electrical wire connectors

AMPSEAL 35 Position Latch Lock Crimp Terminal Free Hanging Plug Housing

#Connectors#Headers and Wire Housings#776164-1#TE Connectivity#Electrical#data#electrical wire#wire cable assembly#Cable Assemblies Applications#transmitting power#Ethernet crimping tool#mount socket#USB connectors

1 note

·

View note

Text

https://www.futureelectronics.com/p/interconnect--connector-tools-contacts-accessories/1060-20-0122-te-connectivity-4076061

Crimp wires, Cable Assemblies, crimping connectors, wire cable assembly

16 - 22 AWG Size 20 Male Crimp Pin for Automotive Connectors

#TE Connectivity#1060-20-0122#Connectors#Tooling and Accessories#applications#wires#plug housing#crimping tool#Cable Assemblies#crimping connectors#wire cable#coax assemblies#Micro plugs power connector#Male Crimp Pin

1 note

·

View note

Text

AHEAD OF THE United Nations Security Council action to consider the Palestinian Authority’s application to become a full member of the international body, the United States is lobbying nations to reject such membership, hoping to avoid an overt “veto” by Washington. The lobbying effort, revealed in copies of unclassified State Department cables obtained by The Intercept, is at odds with the Biden administration’s pledge to fully support a two-state solution. In 2012, the U.N. General Assembly passed a resolution granting Palestine the status of a non-member observer state. The diplomatic cables detail pressure being applied to members of the Security Council, including Malta, the rotating president of the council this month. Ecuador in particular is being asked to lobby Malta and other nations, including France, to oppose U.N. recognition. The State Department’s justification is that normalizing relations between Israel and Arab states is the fastest and most effective way to achieve an enduring and productive statehood. While clarifying that President Joe Biden has worked vigorously to support “Palestinian aspirations for statehood” within the context “of a comprehensive peace that would resolve the Israeli-Palestinian conflict,” a diplomatic cable dated April 12 details U.S. talking points against a U.N. vote for Palestinian statehood. The cable says that Security Council members must be persuaded to reject any proposal for Palestinian statehood — and thereby its recognition as a sovereign nation — before the council’s open debate on the Middle East, scheduled for April 18. “It remains the U.S. view that the most expeditious path toward a political horizon for the Palestinian people is in the context of a normalization agreement between Israel and its neighbors,” the cable reads. “We believe this approach can tangibly advance Palestinian goals in a meaningful and enduring way.” “We therefore urge you not to support any potential Security Council resolution recommending the admission of ‘Palestine’ as a U.N. member state, should such a resolution be presented to the Security Council for a decision in the coming days and weeks.”

#yemen#jerusalem#tel aviv#current events#palestine#free palestine#gaza#free gaza#news on gaza#palestine news#news update#war news#war on gaza#palestinian state#genocide joe#joe biden#united nations#security council#two state solution

6K notes

·

View notes

Note

Does your mom ever call you since you came to the campus

Sequal to https://www.tumblr.com/taintedpompom/766559252133314560/so-did-your-mom-go-to-this-school-too?source=share

"Mom I told you its fine." Rose moaned into the phone. She squrims on the kitchen highstool, feeling a bit... confined? With a sigh, Rose drags another stool over sighing in relief as she nestles herself between both seats. That felt right.

"But sweetie." Roxanne, her mother, muttered on the other end of the wire. Miles away, the doughy woman pouted, wrinkles crisscorssing her face. She had Rose when she was quite old, and frankly Rose was suprised she was had at all considering how low the woman's sex drive was. Even when Rose was (is?) a diehard rebel punk, her mother always chided her that her long blue jeans were torn maybe a bit TOO risqué? Honestly Rose wished her mother would loosen up. She always seemed so repressed, so... scared of the world.

And, Rose reminded herself, it was all a act. Meenah showed her those pictures, told her of her mothers secret past. She wasn't some old computer scientist still clattering away at assembly language. Well, actually Rose supposed she could still be doing that it's not like she understood computers that well. However she was ALSO some legendary cheerleader superstar. Or WAS, at least.

"I just think... aren't you going a bit TOO native?" Roxanne, who rarely listened to Rose's words much less her internal dialogue, was simply barreling through her sentence regardless of whatever revalations her dear daughter was trying to have. "I mean... what about Kanaya? You barely talk about her."

Rose bit her lip, both in frustration at her mother, and frustration at her self because now she was thinking about Kanaya. Darling, stacked, Kanaya. God, how did sex even get legs so long. Rose wasn't even sure HOW to talk to her, not without pushing her down the floor and pushing those fat fucklips of hers into her-

"And cheerleading?" Roxanne, who rarely listened to her Rose's words much less her internal dialogue, was simply barrelling through a perfectly good dream of Rose's and killing what Rose knew was going to be one of the better sonnets the muse ever foisted on her. Well a sonnet after some practical application of her fat, jiggling words to the muse's thick, bouncing inspriation. "Rose-"

Rose, who rarely listened to her mother's words on the best of times either, decided to barrel through her own sentence for once. "Oh what ABOUT cheerleading huh? Does the champion worry about me taking her place?"

"Rose Lacroix Lalonde!" Her mother gasped in shock. "What are you saying?"

"Don't play cute." Rose spat back, her rage manifesting from thin air at the thrill of a potential win. What mildly upset her before infuriated her, with the idea that her mother would try to trick her. To play HER for a fool. "You act like cheerleading is this lewd, dirty thing, but you've been doing it for years. You won RECORDS. You had movies.

"Ro, Rosie darling please believe me." Roxanne stammered, hurt in her voice. "I didn't"

There was a shift suddenly, a twist in the world as, whatever fantasy Meenah spun around Rose plunged through the phone lines, her lies twisting through cables and echoing in Roxannes ear, settling in her brain, her body, her past. It was slow, a gradual incursion that was stained in every post card sent, every text exchanged, every whispered word. Throughout the weeks, months it seemed, that Rose was away a silent pit of need bubbled away inside Roxanne, smaller then her daughters but no less intense, just waiting for a seed to sprout. And, when Rose shouted that false secret Meenah made up, that seed found fertile soil to sprout.

And, in a instant, it did that.

"I didn't mean to trick you dear." Roxanne purred through the phone, wrinkles smoothing away as the woman's voice went from hurt shock to sheepish grin. "I just wanted you to see your own talent. You always hated practice you know. You thought it was all nepotism."

Rose hushed, blinking in confusion. Practice? For what? Those violin classes, what did those suddenly she remembered, years of tantrums and bargaining as she was dragged to watch, and participate in her teacher's practice. All those runs, all those ballet classes. Of COURSE she knew her mom wasn't a cheerleader, who DIDN'T. What Rose didn't know was which school Roxanne got her big start in. "Mooom." She moaned, a large rattling sound on the other end as her Moms bosom probably flopped on a table, her mom knew she hated that. "It WAS nepotism, I didn't NEED your stupid trainers to cheerlead."

"Aw but babydoll..." Roxanne, Roxy, giggled, and a second giggle echoed off the phone, likely one of Roxy's old cheer partners who was visiting for one of their many reminisces. "Mommy's want what's best for their daugthers. Sure my little superstar could've made it without the gymnasium I bought you, or Joey's help... but then what could you thank me for in your little victory speech? Early adoption is key to these things." Ugh, Mom knew she loved it when she went all machevelli, she wasn't playing fair. "As for the secret, well, i had no choice!" Roxy giggled. "You wouldn't have gone to Sassys if you knew my trophy was on the wall. You always made ME play the princess you know. But Sassacare's is the best thing that ever happened to me. To US. I couldn't have you jepordize your future."

Rose sighed. Of course Mother was going to win. Mommy always won. Mommy knew best. It rankled at her. "So this was all some plot to trick me into following your footsteps. Well you won, happy?"

Mommy gave a muffled gasp. "Oh! Sorry dear I, um, started my aerobics class! Rest assured dear I am very, mmf, happy! Give Kanaya a kiss for me!"

The line went dead, letting Rose stew in her defeat, and Roxy, the biggest name in bounce, to fully pay attention to her cheerpartners face between her thighs. "Oh you horrible woman!" Roxy slapped Joey's face, the two laughing. "You almost got us caught."

Rose pouted on the other end, her face red with humiliation. She got tricked! To think all those teases from the Thorns calling her Daddy's princess weren't just mean boasts. It was true! Her mom was Queen of the school. Well fine then.

Roses belt buckle popped open as pounds popped into place on Rose's hips, her shirt riding up as the black shirt swapped colors with the pink skull emblazoned on it. Rose bit her lip, her thick, beautiful, princess lips. As Rose unknowingly rewired her mom's history, the present started to catch up. Not only in shaving Roxanne's own life down, cutting the 55 year old programmer down to a 43 year old celebrity with the biggest rack on television, but in Rose's own history. After all Rose was now the daughter of the hottest woman in the world (According to numerous online polls submitted one handed), and she always did resemble her mother. Rose didn't even notice her gait shifting, or the furniture growing heavier as a third chair slipped behind her. She was too busy being upset at her slut of a mom. A mom who, unknown to Rose, was only getting sluttier and sluttier with each phone call and fantasy Rose spun around the two. It was a vicious cycle.

One that was going to take Rose all the way to the top.

Not that she knew it of course.

5 notes

·

View notes

Text

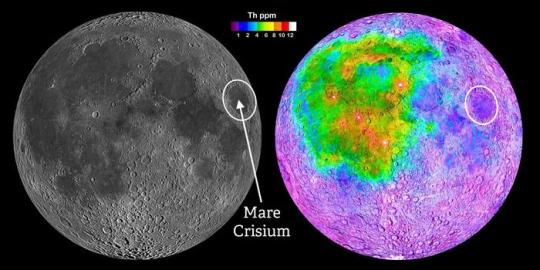

SwRI is sending its first instrument to the lunar surface to survey the Moon’s interior

LMS instrument aboard the Blue Ghost Lander heading to Mare Crisium in early 2025

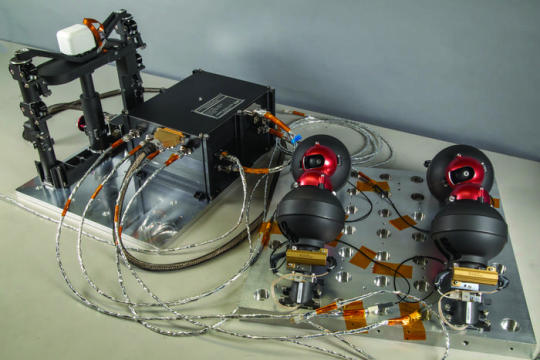

Through NASA’s Commercial Lunar Payload Services (CLPS) initiative, Southwest Research Institute developed the Lunar Magnetotelluric Sounder (LMS) to characterize the structure and composition of the Moon’s mantle by measuring electric and magnetic fields. The LMS instrument — manifested on the Blue Ghost lunar lander developed by Firefly Aerospace and targeted to launch on January 15, 2025 — will be the first SwRI instrument to touch the lunar surface. “For more than 50 years, scientists have used magnetotellurics on Earth for a wide variety of purposes, including to find oil, water, geothermal and mineral resources as well as to understand geologic processes such as the growth of continents,” said SwRI’s Dr. Robert Grimm, principal investigator of LMS. “The LMS instrument will be the first extraterrestrial application of magnetotellurics. NASA’s Artemis program is developing a series of increasingly complex missions to ultimately build a sustained human presence at the Moon for decades to come. To support these goals, LMS is part of a 14-day lunar lander mission to help understand the Moon’s subsurface in a previously unexplored location. Mare Crisium is an ancient, 350-mile-diameter impact basin that subsequently filled with lava, creating a dark spot visible to the naked eye on the Moon. Early astronomers who dubbed dark spots on the moon “maria,” Latin for seas, mistook them for actual seas. Mare Crisium stands apart from the large, connected areas of dark lava to the west where most of the Apollo missions landed. These vast, linked lava plains are now thought to be compositionally and structurally anomalous with respect to the rest of the Moon. From this separate vantage point, LMS may provide the first geophysical measurements representative of most of the Moon. Magnetotellurics uses natural variations in surface electric and magnetic fields to calculate how easily electricity flows in subsurface materials, which can reveal their composition and structure. LMS will allow scientists to probe the interior of the Moon to depths up to 700 miles or two-thirds of the lunar radius. The measurements will shed light on the material differentiation and thermal history of our Moon, a cornerstone to understanding the evolution of solid worlds. The LMS instrument ejects cables with electrodes at 90-degree angles to each other and distances up to 60 feet. The instrument measures voltages across opposite pairs of electrodes, much like the probes of a conventional voltmeter. The magnetometer is deployed via an extendable mast to reduce interference from the lander. The method reveals a vertical profile of the electrical conductivity, providing insight into the temperature and composition of the penetrated materials in the lunar interior. “The five individual subsystems of LMS, together with connecting cables, weigh about 14 pounds and consume about 11 watts of power,” Grimm said. “While stowed, each electrode is surrounded by a ‘yarn ball’ of cable, so the assembly is roughly spherical and the size of a softball.” The LMS payload was funded for delivery to the lunar surface through NASA’s CLPS initiative. SwRI designed the instrument, built the electronics box and leads the science investigation. Goddard Space Flight Center provided the LMS magnetometer to measure the magnetic fields, and Heliospace Corp. provided the magnetometer mast and four electrodes used to measure the electrical fields. Under the CLPS model, NASA is investing in commercial delivery services to the Moon to enable industry growth and support long-term lunar exploration. As a primary customer for CLPS deliveries, NASA aims to be one of many customers on future flights. NASA’s Marshall Space Flight Center in Huntsville, Alabama, manages the development of seven of the 10 CLPS payloads carried on Firefly’s Blue Ghost lunar lander.

TOP IMAGE: From within the Mare Crisium impact basin, the SwRI-led Lunar Magnetotelluric Sounder (LMS) may provide the first geophysical measurements representative of the bulk of the Moon. Most of the Apollo missions landed in the region of linked maria to the west (left image), whose crust was later shown to be compositionally distinct (right image) as exemplified by the concentration of the element thorium. Mare Crisium provides a smooth landing site on the near side of the Moon outside of this anomalous region. Credit NASA

LOWER IMAGE: LMSwRI led the development of the LMS instrument for the Mare Crisium lander mission, which includes (from left) a magnetometer, a central electronics box and four spring-launched electrodes. Credit Southwest Research Institute

6 notes

·

View notes

Text

The model of the Hussar "Gashal" was created in the middle of the war, by one of the engineers Jacob Farakaso, his work attracted the attention of the military due to the fact that the designer, even despite his injuries sustained in the war, had a very sad effect. The lower limbs lost their mobility, but by exerting strength, he managed to assemble a semblance of an endo-skeleton that allowed him to move as before, connected to the cervical region and stretched inside with fibers of synthetic flesh with nerve endings allowed him to return to service, but since he was commissioned. He spent some time with his family, learning about the applications of nutcrackers in the news and other sources, and seeing that they have their own weaknesses as flaws, the dying creature caused pity, because he also lost many comrades.

he began developing his own model that would allow the nutcrackers to be more protected and maneuverable, but for a long time he did not come up with engineering solutions, which depressed him. Except that the daughter had just brought a hussar figurine, its mechanics, although simple, but reliable, movable joints, a head that could be retracted into the shoulders, as if a soldier was hiding his head from the shots that came from an easel machine-gun pillbox.

sleepless nights spent at the table brought out a very effective model, his ideas on reinforced mechanical parts, as well as an ultra-sensitive hydraulic system capable of reacting much faster, like a powerful computer, it could protect its owner from a blow, from a shot from a heavy gun, give speed that was not a strong feature, jump over trenches, not fall into mud traps where so many wounded died, because such a simple trace from a shot by a large artillery shell collected water and blood inside itself, becoming quicksand

Sample number one: Hashal – passed the tests of basic motor skills based on computer modeling of the military and staff situation, tests without substance.

entry number 0-19/F-1:

the test revealed small failures in the body and joints of the cervical spine, yet it is very difficult to create a body for creatures when you do not have a sample, it cost a lot to establish system consumption, but a very impressive result. The chest opening was adjusted to the maximum, the spike was not so important, the magnetic belts turned out to be strong, but the check related to water turned out to be very unsuccessful, as well as for chemical reagents, some types of gas melt wires and their insulation, I do not have enough material to protect the cables.

Maybe I should turn to an old friend, he was sorting out the nutcrackers, maybe I can find the answer in them

Revision: this nutcracker took me a lot of time, I had to use ship cables with their insulation, but I had to look for details from undermined and faulty installations, tanks, and similar equipment, this made it easier for me to fuse some fragments, as well as microcircuits.

The control has improved, the balancing is almost calibrated, I made the inner ribs from titanium and aluminum, I had to melt a whole sheet of plate armor of the tank, oh gods, they will obviously kill me soon

Entry 0-20/F-2:

My fears were true, my adventures were noticed by those whom I clearly would not like to see in my house, they were looking for my prototype, the workshop was destroyed, I can't say how long I still have to live, they can kill my daughter, except for her I have no one left after that the case.. The projectile flew into our complex, damn freaks! So many civilians died then, and Jesse.. she was torn apart, the Collie was not sleeping then and did not let go of my hand: daddy, please.. Don't leave, there's a war! They're killing there! I'll work as long as I can, but how long will I last?

I don't remember how much time has passed since I finished it, it remains only to carry out the final touches, but how to carry them out without filling? Where will I get such a creature, even though such creatures could try to escape the same way, or have offspring, but here? How can this happen at all, especially here..

The Collie began to behave more closed, as if hiding, even though I said that secrets should only be told to those whom I am ready to entrust them, she is probably afraid to tell me about it, the main thing is that it does not attract too much attention to us.

entry number 1 from a personal notebook:

Well, still, these weasels watching my family noticed my daughter's behavior, they came with weapons to the complex! This is not acceptable! The rules do not give them the right to come here with weapons, with soldiers.. but among them I saw white coats, damn scientists, always climbing where they shouldn't and playing gods

Insomnia is killing me two or three months after people came to the complex, but I finally managed to get an answer from my daughter, damn it! She found the offspring of these creatures, even two, where should I put the other one? Of course, I can restore and upgrade the previously destroyed nutcracker, but how much will it be useful?

To the touch, these lumps of flesh are pleasant to the eyes, they are quite small, and so inquisitive, one of them with grayish-blue eyes constantly asks me, if I take it, he does not come off me all day. I feel like a mother to these creatures, if they can reproduce, then I can assume that two nutcrackers could have hidden them initially in our complex, but they could have got in other ways, they are difficult to see if they climb through the ventilation ducts. Collie became their babysitter, but they trust her more.

#The engineer's diary#lethal company art#sketch#lethal company nutcracker#my ocs#The writing of the lore is delayed#but there is a beginning

8 notes

·

View notes

Text

Leaked Cables Show “War Criminal White House” Opposes Palestinian Statehood

Despite Biden’s Pledge to Support a Two-State Solution, Cables Argue That Palestine Should Not Be Granted U.N. Member Status.

— Ken Klippenstein, Daniel Boguslaw | April 17, 2024 | The Intercept

An empty United Nations Security Council room ahead of a meeting on the situation in the Middle East, in NYC on April 14, 2024. Photo: Charly Triballeau/AFP via Getty Images

Ahead Of The United Nations Security Council action to consider the Palestinian Authority’s application to become a full member of the international body, the United States is lobbying nations to reject such membership, hoping to avoid an overt “veto” by Washington. The lobbying effort, revealed in copies of unclassified State Department cables obtained by The Intercept, is at odds with the Biden administration’s pledge to fully support a two-state solution.

In 2012, the U.N. General Assembly passed a resolution granting Palestine the status of a non-member observer state.

The diplomatic cables detail pressure being applied to members of the Security Council, including Malta, the rotating president of the council this month. Ecuador in particular is being asked to lobby Malta and other nations, including France, to oppose U.N. recognition. The State Department’s justification is that normalizing relations between Israel and Arab states is the fastest and most effective way to achieve an enduring and productive statehood.

While clarifying that President Joe Biden has worked vigorously to support “Palestinian aspirations for statehood” within the context “of a comprehensive peace that would resolve the Israeli-Palestinian conflict,” a diplomatic cable dated April 12 details U.S. talking points against a U.N. vote for Palestinian statehood. The cable says that Security Council members must be persuaded to reject any proposal for Palestinian statehood — and thereby its recognition as a sovereign nation — before the council’s open debate on the Middle East, scheduled for April 18.

“It remains the U.S. view that the most expeditious path toward a political horizon for the Palestinian people is in the context of a normalization agreement between Israel and its neighbors,” the cable reads. “We believe this approach can tangibly advance Palestinian goals in a meaningful and enduring way.”

“We therefore urge you not to support any potential Security Council resolution recommending the admission of ‘Palestine’ as a U.N. member state, should such a resolution be presented to the Security Council for a decision in the coming days and weeks.”

Experts say that without a unanimous Security Council vote, any vote from the U.N. General Assembly is largely symbolic.

“Like it or not, a General Assembly vote on this issue is of political rather than legal weight,” Richard Gowan, the International Crisis Group’s U.N. director, told The Intercept. “The Assembly can only accept a new state ‘on the recommendation’ of the Security Council.”

The diplomatic cable includes a rationale for the administration’s opposition to the vote, citing the risk of inflaming tensions, political backlash, and potentially leading to the U.S. Congress cutting U.N. funding.

“Premature actions at the UNSC, even with the best intentions, will achieve neither statehood nor self-determination for the Palestinian people. Such initiatives will instead endanger normalization efforts and drive the parties further apart, heighten the risk of violence on the ground that could claim innocent lives on both sides, and risk support for the new, reform government announced by President Abbas,” the cable says.

Asked about the cable and whether its opposition to U.N. recognition of Palestinian statehood contradicts the Biden administration’s position in support of a two-state solution, the State Department did not respond at the time of publication.

“The U.S. position is that the Palestinian state should be based on bilateral agreements between the Israelis and Palestinians,” Gowan said. “It does not believe that the UN can create the state by fiat.”

A second cable dated April 13 sent from the U.S. Embassy in Quito, Ecuador, relays Ecuadorian Foreign Minister Gabriela Sommerfeld’s agreement with the United States that Palestine should not be recognized for statehood. In cooperation with the United States, according to the cable, Sommerfeld instructed Ecuador’s permanent representative to the United Nations José De La Gasca to lobby Japan, Korea, and Malta (all rotating members of the Security Council) to reject the proposal. Lobbying of permanent member France is also mentioned.

Sommerfeld agreed, according to the cable, that “It was important any proposed resolution fail to achieve the necessary votes without a U.S. veto.” The cable says, “Ecuador would not want to appear isolated (alone with the United States) in its rejection of a ‘Palestine’ resolution (particularly at a time when the most UN member states are criticizing Ecuador over its April 5 incursion into Mexico’s embassy in Quito).” Ecuador finds itself in an escalating conflict with Mexico over its decision to arrest the former Ecuadorian vice president inside the Mexican Embassy.

Asked about the second cable, the State Department and the Ecuadorian Embassy in Washington did not respond to requests for comment.

With its yearlong seat on the powerful 15-member Security Council, Ecuador holds outsized influence to vote against the Palestinian proposal for recognition.

“This really shows the extent to which the [Ecuadorian President Daniel] Noboa administration is beholden to the United States,” Guillaume Long, senior fellow at the D.C.-based Center for Economic and Policy Research and former foreign minister of Ecuador, told The Intercept when shown the cable. “On top of this, it is quite shocking to see the United States, which condemned Ecuador’s April 5 storming of the Mexican embassy and its violation of international law … making the most of Ecuador’s isolation in the hemisphere to get it to do its bidding. Ecuador is just buying its way out of its crimes by committing more crimes. Truly shocking,” said Long, referring to Ecuador’s rejection of Palestinian membership in the U.N.

After the publication of this story, the Ecuadorian government released the following statement, which reads as translated: “Regarding the alleged leaks published by a digital portal, the Ecuadorian Foreign Ministry denies the veracity of its content. The foreign policy of the National Government, including its actions as a non-permanent member of the UN Security Council, is clear, adhered to the principles of international law, public and transparent, as is all participation of the country and its authorities in different international forums. Citizens are called to obtain information only through official means.”

Since 2011, the U.N. Security Council has rejected the Palestinian Authority’s request for full member status. On April 2, the Palestinian Observer Mission to the U.N. requested that the council once again take up consideration of its membership application. According to the first State Department cable, U.N. meetings since the beginning of April suggest that Algeria, China, Guyana, Mozambique, Russia, Slovenia, Sierra Leone, and Malta support granting Palestine full membership to the U.N. It also says that France, Japan, and Korea are undecided, while the United Kingdom will likely abstain from a vote.

“It is important that all Security Council members hear at this stage of the process that a number of members have questions that require further study about the Palestinian Authority’s formal request for UN membership through the Council, and that if a vote is forced on the issue, you will join the United States and not support approval of the application,” the cable reads.

#War Criminal | United States 🇺🇸#Leaked Cables | “War Criminal White House”#Opposes | Palestinian Statehood#— Ken Klippenstein | Daniel Boguslaw#Palestine 🇵🇸 | Should Not Be Granted | United Nations 🇺🇳 | Member Status

5 notes

·

View notes

Text

Are you searching a best 12 Fiber Pigtail

A 12-fiber pigtail refers to a fiber optic cable terminated on one end with a connector, typically used for splicing or connecting to other fiber optic cables or devices. In the case of a 12-fiber pigtail, it means that there are 12 individual optical fibers within the cable, each terminated with its connector.

Here are some key points about 12-fiber pigtails:

Number of Fibers: As the name suggests, a 12 fiber pigtail contains 12 individual optical fibers within a single cable assembly. These fibers are typically color-coded for identification purposes.

Connector Type: The connector termination at the end of the pigtail can vary depending on the application and compatibility requirements. Common connector types include LC, SC, ST, and MTP/MPO connectors.

Applications: 12 fiber pigtails are commonly used in data centers, telecommunications networks, and other fiber optic installations where high-density fiber connections are required. They are often used for splicing to distribution or breakout cables, connecting to patch panels, or interfacing with active network equipment.

Splicing: In many cases, the individual fibers within a 12 fiber pigtail are spliced to corresponding fibers in other cables or devices using fusion splicing or mechanical splicing techniques. This allows for the creation of permanent connections between fibers without the need for connectors.

Color Coding: Each fiber within the pigtail may be color-coded to facilitate identification and ensure proper alignment during splicing or connection. Common color codes include blue, orange, green, brown, gray, white, red, black, yellow, violet, rose, and aqua.

Jacketing and Protection: The fibers within the pigtail are typically enclosed in a protective jacket to provide mechanical protection and prevent damage to the individual fibers. The jacket may be made of materials such as PVC, LSZH (Low Smoke Zero Halogen), or plenum-rated materials for use in different environmental conditions.

Overall, 12 fiber pigtails provide a convenient and efficient solution for establishing multiple fiber connections in various fiber optic applications, offering high-density connectivity and reliable performance in optical networks.

Next: Buy Quality 12 LC Cable for Seamless Connectivity

2 notes

·

View notes

Text

Durkduct Flexible Air Ducting Solution for the Automotive Industry

Durkee textile air ductwork has been applied in the automotive plant since 2008, from industry benchmarks, foreign-invested factories to domestic-owned factories, and from OEM to other automotive accessories producers. So far, all major engineering projects or benchmark enterprises in automobile manufacturing plants have chosen Durkee flexible fabric air dispersion system. Durkee has a group of famous users worldwide, such as Volkswagen, General Motors, Ford, Renault, Fiat, Tesla, Toyota, Honda, Nissan, Audi, Mercedes-Benz, FAW, SAIC, GAC, Dongfeng, and Geely, etc.

By 2015, all automobile manufacturing industry projects only used Nanosox fabric ducts as the secondary air supply duct with unique properties, such as low space position line or spot air supply for energy-saving, environmental protection, easy installation, and oil resistance, etc. Since 2016, the insulated fabric air duct, which is the unique research and development of Durkee, has been fully promoted in the market.

It has been successfully applied as the primary air supply duct system for automobile manufacturing plants, including Jiangling, General Motors, Faurecia, FAW Toyota, BAIC, Ford, Dongfeng Honda, Geely, GAC Honda, and other projects.

Advantages of insulated fabric duct

Compared with commonly used traditional GI ducts, the advantages of the insulated fabric duct are more obvious:

Lightweight, faster installation

The insulated fabric ducting solution has a 100% factory prefabrication rate and on-site modular assembly, which is light in weight, requiring only slide bars or cable suspension, with zipper connection, greatly improving the quality of the project, shortening the construction period, and reducing the overall cost of the project.

Double insulation layer increases thermal insulation performance

The insulated fabric duct is composed of duct layer, an insulation layer, and an outer insulation layer, achieving a dual-layer insulation effect.

The integral composite insulation material has an infinite vapor resistance factor, which can effectively prevent water vapor penetration, maintain the initial thermal conductivity coefficient, and have a better insulation performance. The thermal resistance value is comprehensively improved. The Durkee fabric duct can effectively reduce cold and heat loss during the air transmission process.

High strength and pressure resistance performance

Different from the easy shearing and pressure deformation of rectangular metal ducts, the insulated fabric duct system adopts circular and elliptical shapes.

The insulated fabric duct can reasonably convert internal pressure into transverse tensile force on the duct wall, which can withstand 3000Pa-5000Pa or more pressure, far higher than the applicable range of traditional ducts below 2000Pa.

The insulated fabric duct system has been successfully applied in more and more primary air supply duct systems and return air duct systems. Durkee has become the leading supplier in the global fabric duct industry with a full range of professional solutions.

1 note

·

View note

Text

Life Cycle Management

Electronic Manufacturing Services Across the Product Life Cycle

Avalon the top-rated EMS companies in India renowned for their quality services, technical expertise, and customer satisfaction.

#Design For Excellence (DFX)#Return Merchandise Authorisation (RMA)#BOM Analysis#PLM Agile System For Program Management#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India#EMS#Life Cycle-Management

2 notes

·

View notes

Text

WHAT YOU NEED TO BUILD PC?

Title: Building a High-Performance PC: A Comprehensive Guide

Are you a tech enthusiast looking to embark on the journey of building your own high-performance PC? Whether you're a gamer, content creator, or simply seeking a custom computing experience, building your PC can be both rewarding and empowering. In this guide, we'll take you through the step-by-step process of assembling a powerful PC from scratch. Let's dive in!

1. Planning Your Build:

Before you dive into the build process, take some time to plan out your PC build. Define your use case – gaming, video editing, programming, etc. Set a budget, consider compatibility between components, and make a list of parts you'll need.

2. Selecting Components:

a. CPU (Central Processing Unit): Choose a CPU that matches your needs. Consider factors like core count, clock speed, and compatibility with your chosen motherboard.

b. Motherboard: Your motherboard choice affects compatibility and expansion options. Ensure it supports your CPU, has enough RAM slots, and the necessary connectors.

c. GPU (Graphics Processing Unit): For gaming or graphics-intensive tasks, invest in a powerful GPU. Research benchmarks and choose a card that meets your performance expectations.

d. RAM (Random Access Memory): Opt for sufficient RAM for multitasking and running applications smoothly. 16GB is a good starting point for most users.

e. Storage: Decide between SSDs (faster) and HDDs (more storage). Consider an SSD for your OS and frequently used software.

f. Power Supply: Choose a reliable PSU that provides enough power for your components. Ensure it's from a reputable brand and offers some headroom for future upgrades.

g. Cooling: Depending on your CPU choice, you may need an aftermarket cooler for efficient heat dissipation.

h. Case: Select a case that accommodates your components, offers good airflow, and has space for cable management.

3. Building Process:

a. Prepare Your Workspace: Clear a clean, well-lit area to assemble your PC. Have tools like screwdrivers ready.

b. Install CPU and Cooler: Follow your CPU manufacturer's instructions to install the CPU onto the motherboard. Apply thermal paste and attach the cooler.

c. Install RAM: Insert your RAM sticks into the designated slots on the motherboard.

d. Mount Motherboard: Secure the motherboard in the case, ensuring standoffs are correctly aligned.

e. Install Storage and GPU: Install your storage drives and GPU into their respective slots.

f. Connect Cables: Connect power cables, SATA cables, and data cables as needed. Route cables neatly to ensure good airflow.

g. Connect Case Fans: If your case includes case fans, connect them to appropriate headers on the motherboard.

h. Power Supply Connections: Connect the PSU cables to the motherboard, CPU, GPU, and storage drives.

4. First Boot and Testing:

a. Double-Check Connections: Before powering on, double-check all connections to ensure everything is properly connected.

b. Power On: Press the power button and check if all components light up and fans spin. If not, troubleshoot connections.

c. BIOS Setup: Enter the BIOS to configure boot order, RAM settings, and other necessary adjustments.

5. Software Installation:

a. Operating System: Install your chosen operating system using a USB drive or optical disc.

b. Drivers: Install motherboard, GPU, and other hardware drivers to ensure proper functionality.

c. Software and Updates: Install essential software and update your OS to the latest version.

6. Final Touches:

a. Cable Management: Neatly organize cables for better airflow and aesthetics.

b. System Monitoring: Install monitoring software to keep an eye on temperatures, performance, and other metrics.

c. Benchmarking: Run benchmark tests to ensure your PC is performing as expected.

Congratulations! You've successfully built your own high-performance PC. Remember that building a PC is a continuous learning experience. Stay updated on hardware trends, software updates, and potential upgrades to keep your system running smoothly and efficiently. Enjoy your custom-built powerhouse for years to come!

2 notes

·

View notes

Text

Wire Harness Components: Exploring the Building Blocks of Electrical Systems

In the realm of electrical engineering and connectivity, wire harnesses serve as unsung heroes, enabling the smooth transmission of power and signals across an array of industries. These vital components have become indispensable in modern applications, ensuring efficiency, reliability, and safety.

In this comprehensive guide, we delve into the world of wire harnesses, exploring their functionality, applications, and significance in various sectors.

For More Information Please visit, wiring harness manufacturers near me

What are Wire Harnesses?

A wire harness, also known as a cable harness or wiring assembly, is a bundled arrangement of multiple electrical wires or cables. These wires are bound together using various methods, such as tape, zip ties, or sleeves, to form a unified and organized unit. The purpose of a wire harness is to facilitate the efficient and tidy transmission of electrical signals, power, and data within complex systems.

Structure and Components:

Wire harnesses are designed to suit specific applications, and their structure can vary accordingly. Typically, a wire harness consists of the following components:

Wires/Cables: The core elements of a wire harness are the electrical wires or cables, which come in various gauges and types, depending on the application's requirements.

Connectors: Connectors are the crucial interface points that link the wire harness to other electrical components, devices, or systems.

Terminals: Terminals serve as the end points of individual wires, making electrical connections with connectors or other terminals.

Sleeves and Sheaths: To protect the wires from external elements and prevent damage, sleeves and sheaths are used as protective coverings.

Tapes and Labels: Tapes are utilized to bundle the wires together, while labels aid in identification and organization.

Applications in Different Industries:

Wire harnesses find extensive applications in numerous industries due to their efficiency and reliability. Some of the key sectors that heavily rely on wire harnesses include:

Automotive: In vehicles, wire harnesses are essential for transmitting electrical signals, power, and data to various components, such as engines, lights, sensors, and infotainment systems.

Aerospace: The aerospace industry uses wire harnesses to ensure secure and organized connectivity within aircraft, satellites, and spacecraft.

Electronics: From consumer electronics to industrial machinery, wire harnesses are crucial for connecting and powering electronic components.

Telecommunications: In the world of telecommunications, wire harnesses facilitate the smooth flow of data and power in network infrastructure.

Healthcare: Medical devices and equipment rely on wire harnesses to ensure precision and safety in their electrical connections.

Advantages of Using Wire Harnesses:

The adoption of wire harnesses brings forth several advantages:

Simplified Installation: Wire harnesses streamline the installation process by eliminating the need to deal with individual wires, reducing assembly time and errors.

Improved Reliability: Organized and secure connections enhance the overall reliability and performance of electrical systems.

Space-Efficient: Wire harnesses help conserve space, especially in compact devices and machinery.

Enhanced Safety: Properly insulated and protected wires reduce the risk of electrical hazards and ensure operator safety.

Conclusion:

Wire harnesses are the unsung heroes that play a vital role in ensuring seamless electrical connectivity across a myriad of industries. From automotive to aerospace, electronics to healthcare, these organized bundles of wires provide efficiency, reliability, and safety in diverse applications. As technology continues to advance, wire harnesses will remain a cornerstone of modern electrical engineering, contributing to innovation and progress across the globe.

2 notes

·

View notes

Text

EXPLORING THE 5 COOL PARTNER SELLER ELECTRONICS PRODUCTS-Part1

Exploring the 5 Cool Partner Seller Electronics Products

Prologue

Are you an electronics enthusiast looking to expand your electronics project repertoire? Want to take your skills to the next level by exploring new and exciting products? Look no further than our list of five cool electronics products from partner sellers!

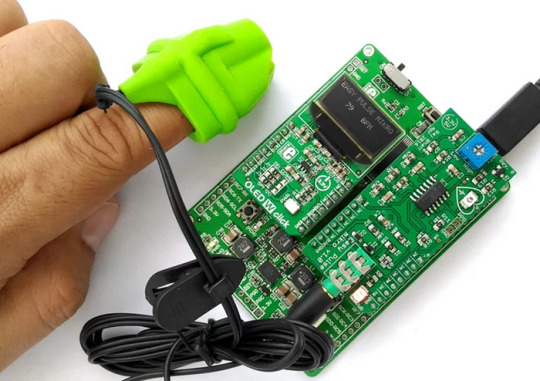

Whether you’re interested in building your own smart home devices, experimenting with sensors, or creating your own robot, these products are sure to inspire you. They cover a lot of application areas, from loop detectors used to monitor vehicle count in parking garages to Arduino CNC shields used in CNC machines, from simple pulse sensors used to detect cardiovascular pulse signals from fingertip to RGB LED panel light used in smart home, these products are unique, compact, and functional. Not only are these products fun to build and use but they’re also designed to help you learn new skills and techniques along the way.

What’s more, these products all come from trusted partner sellers who are committed to developing high-quality products. They’re happy to provide technical support for customers who have questions, so you can be sure you’re getting the best in electronics.

So get ready to dive into the world of electronics and explore these five cool partner seller products. You’re sure to find something that piques your interest and takes your own electronics projects to the next level.

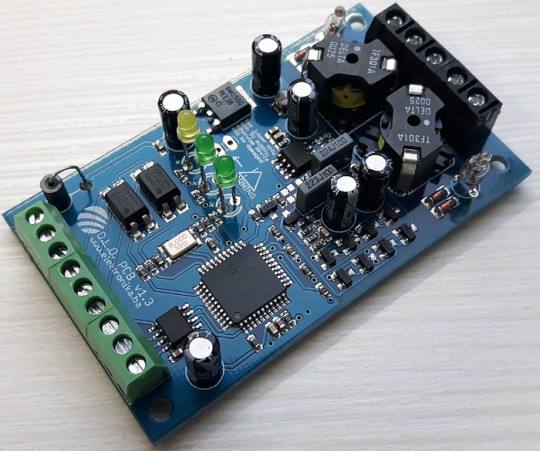

Inductive Loop Vehicle Detector by Elektronika-ba

Whether you need to monitor occupancy and count vehicles in parking garages, control vehicle access at door and barrier controls, or facilitate traffic light installations and traffic controllers, the inductive loop detector is the perfect solution. It can even detect the direction and speed of vehicle traffic, making it an invaluable tool for a variety of traffic-related applications. In addition, this device can function as a stand-alone speed trap and can be easily interfaced with Arduino.

We can also provide a pre-programmed PIC chip to meet your project requirements.

Specifications

Number of operating modes: 4

Tuning: Automatic

Detection type: Presence/Pulse

Presence time: Adjustable in 3 steps

Pulse duration: 250 ms / 500 ms

Signal filtering: Adjustable in 2 steps (NORMAL, HIGH)

Loop inductance: 20 uH — 1000 uH

Frequency range: 20 kHz — 145 kHz

Frequency selection: 2 combinations (LOW, HIGH)

Sensitivity: Maximum 0.0025% Δf/f, adjustable in 8 steps

Detection speed: 10 ms by default, adjustable

Start-up time: ~ 1 second per channel (or longer if the frequency is not stable)

Temperature range: -35°C — 120°C

Sensor protection: Galvanic isolation + gas discharge tube for lightning protection

Don’t settle for less — click here to learn more about the Inductive Loop Vehicle Detector and experience the compact, yet cool detector!

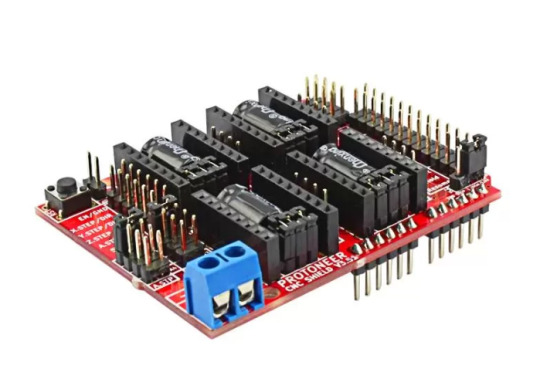

Arduino CNC Shield V3.51 by Protoneer

Designed by Protoneer, this kit is packed with features to ensure high precision control of your stepper motors, you can use it to easily build small CNC routers, DIY laser cutters, 3D printers, or any project that requires precise stepper motor control.

Our latest version 3.51 includes several enhancements to make assembly and installation even easier. We’ve added end-stop and probe signal filtering circuitry to eliminate false triggers and allow the use of unshielded cables for end-stops and probes. We’ve also increased the size of the solder pads for easier assembly and updated the probe pin labels to make installation a breeze.

With the Arduino CNC Shield Kit, you’ll have everything you need to build your own CNC router or mill with ease.

Features

Includes Noise Filers on all end stops and the probing pin. (New in V3.51)

GRBL 0.9 compatible. (Open source firmware that runs on an Arduino UNO that turns G-code commands into stepper signals https://github.com/grbl/grbl)

4-Axis support (X, Y, Z, A-Can duplicate X, Y, Z or do a full 4th axis with custom firmware using pins A4 and A3)

2 x End stops for each axis (6 in total)

Coolant enable

Uses removable Pololu A4988 compatible stepper drivers. (A4988, DRV8825 and others)(Not Included)

Jumpers to set the Micro-Stepping for the stepper drivers. (Some drivers like the DRV8825 can do up to 1/32 micro-stepping )

Compact design.

Stepper Motors can be connected with 4-pin molex connectors or soldered in place.

Runs on 12–36V DC. (At the moment only the Pololu DRV8825 drivers can handle up to 36V so please consider the operation voltage when powering the board.)

Don’t wait — click here to see more about the Arduino CNC Shield V3.51 and start your next project today!

Easy Pulse Mikro by Embedded Lab

What’s more, the Easy Pulse Mikro is designed in the convenient Mikro bus form factor, making it easy to integrate with a wide range of mikroElektronika’s development boards. With all necessary instrumentation and amplification built right in, this powerful sensor provides a clean and precise analog PPG waveform output that’s routed to the AN pin of the mikroBus connector.

Whether you’re a hobbyist, student, or professional developer, the Easy Pulse mikro is the perfect tool for monitoring heart rate and other vital signs.

Click here to see more about the Easy Pulse mikro.

Features

Compatible with mikroBus socket.

Filtered and amplified analog PPG signal output

On-board potentiometer for adjusting amplifier gain, if needed (rotate clock-wise for increasing gain)

Onboard LED for indicating heartbeat. It flashes synchronously with the heartbeat on detecting the pulse from the fingertip.

2 notes

·

View notes

Text

Aquatic Feed Ingredients and Products Market, Global Outlook and Forecast 2025-2032

The Latin America Wiring Harness in Military, Aerospace & Space Market refers to specialized electrical interconnection systems used in mission-critical applications. These wiring harnesses consist of complex assemblies of cables, connectors, and protective components designed to operate under extreme environmental conditions. They ensure power distribution, signal transmission, and data communication across various defense, aerospace, and space applications.

In military applications, wiring harnesses are integral to combat vehicles, radar systems, unmanned aerial vehicles (UAVs), and electronic warfare systems. In aerospace, they enable seamless operations in aircraft, helicopters, and avionics. The space segment relies on highly durable wiring harnesses for satellite systems, propulsion mechanisms, and onboard electronics.

These systems comply with rigorous industry standards, including MIL-STD (Military Standards), AS9100 (Aerospace Quality Standard), and NASA-STD (Space-Grade Specifications), ensuring high reliability and safety.

Download FREE Sample of this Report @ www.24chemicalresearch.com/download-sample/286455/latin-america-wiring-harnessmilitary-aerospace-space-market-2025-2032-898

The Latin America Wiring Harness in Military, Aerospace & Space Market was valued at US$ 412 million in 2024 and is projected to reach US$ 605 million by 2030, growing at a CAGR of 6.6% during the forecast period (2024-2030).

Key Market Insights:

Growing defense investments drive demand for military wiring harnesses in Latin America.

Expanding aerospace manufacturing hubs in Brazil and Mexico fuel market growth.

Rising satellite launches and space exploration projects create opportunities for space-grade harnesses.

Adoption of lightweight materials and fiber-optic technology enhances performance and efficiency.

The market’s upward trajectory is fueled by government initiatives in defense modernization, private sector investments, and technological advancements in wiring systems.

Market Dynamics

Drivers

Increasing Defense BudgetsCountries like Brazil, Mexico, and Argentina are expanding their military expenditures, leading to increased demand for advanced electrical interconnect solutions.

Aerospace Industry ExpansionBrazil’s Embraer S.A., one of the world’s leading aerospace manufacturers, is a key player in Latin America’s aerospace sector, creating consistent demand for wiring harnesses.

Rising Satellite and Space Exploration ProgramsLatin American space agencies and private firms are increasing investments in satellite programs, necessitating robust wiring solutions.

Technological AdvancementsThe introduction of smart wiring harnesses, AI-driven diagnostics, and fiber optics is revolutionizing military and aerospace connectivity.

Restraints

High Compliance and Certification Costs

Supply Chain Dependencies on Imported Components

Skilled Workforce Shortage for specialized wiring manufacturing

Opportunities

Expansion of Local Manufacturing to reduce import reliance

Strategic Collaborations with Latin America Aerospace Firms

Advancements in High-Temperature and EMI-Resistant Wiring Solutions

Challenges

Counterfeit Components impacting reliability

Political and Economic Uncertainties affecting defense budgets

Regional Analysis

Brazil

Leading aerospace manufacturing hub with companies like Embraer.

Government-backed defense initiatives boost military wiring harness demand.

Mexico

Major exporter of aerospace components, hosting Boeing, Airbus, and Bombardier facilities.

Expanding production capacity for military and aerospace electrical components.

Argentina

Investing in satellite technology and defense modernization.

FAdeA (Fábrica Argentina de Aviones) is a key industry player.

Others

Chile, Colombia, Peru, and Venezuela show emerging potential in military and aerospace applications.

Competitor Analysis

Major Market Players:

Embraer S.A. – Leading aerospace manufacturer

Latecoere – Specialized in aircraft electrical wiring

L3Harris Technologies – Advanced defense and aerospace components

TE Connectivity – High-performance connectors and cabling solutions

Carlisle Interconnect Technologies – Ruggedized cabling for extreme environments

Amphenol Corporation – Military and aerospace interconnect solutions

GKN Aerospace – Wiring solutions for aviation and defense

Market Segmentation (by Application)

Communication Systems – Used in military-grade radios, aircraft communication modules, and satellite networks.

Navigation Systems – Found in avionics, GPS systems, and UAV guidance systems.

Military Ground Equipment – Applied in armored vehicles, ground radar stations, and electronic warfare units.

Power Distribution – Used in aircraft electrical systems, satellites, and missile defense networks.

Others – Covers specialized applications such as drone wiring and space probes.

Market Segmentation (by Type)

Coaxial Wiring Harnesses – Used in high-frequency communication and radar systems.

Ribbon Wiring Harnesses – Applied in lightweight aerospace designs and avionics.

Twisted Pair Wiring Harnesses – Designed for EMI-resistant military and space applications.

Key Company

Embraer S.A.

Latecoere

L3Harris Technologies

TE Connectivity

Carlisle Interconnect Technologies

Amphenol Corporation

GKN Aerospace

Meneta

InterCon Systems

Saab AB

Geographic Segmentation

Brazil

Mexico

Argentina

Chile

Colombia

Peru

Venezuela

FAQ

What is the current market size of the Latin America Wiring Harness in Military, Aerospace & Space Market?

➣ The market was valued at US$ 412 million in 2024 and is projected to reach US$ 605 million by 2030, growing at a CAGR of 6.6%.

Which are the key companies operating in the Latin America Wiring Harness Market?

➣ Leading companies include Embraer S.A., L3Harris Technologies, TE Connectivity, Amphenol Corporation, and Carlisle Interconnect Technologies.

What are the key growth drivers in the Latin America Wiring Harness Market?

➣ Key drivers include rising defense budgets, aerospace expansion, satellite investments, and technological advancements.

Which regions dominate the Latin America Wiring Harness Market?

➣ Brazil (48%), Mexico (32%), and Argentina (12%) hold the largest market shares.

What are the emerging trends in the Latin America Wiring Harness Market?

➣ Emerging trends include lightweight materials, AI-driven diagnostics, local production expansion, and smart wiring systems.

Competitor Analysis

The report also provides analysis of leading market participants including:

Key companies Wiring Harness in Military, Aerospace & Space revenues in Latin America market, 2019-2024 (Estimated), ($ millions)

Key companies Wiring Harness in Military, Aerospace & Space revenues share in Latin America market, 2023 (%)

Key companies Wiring Harness in Military, Aerospace & Space sales in Latin America market, 2019-2024 (Estimated),

Key companies Wiring Harness in Military, Aerospace & Space sales share in Latin America market, 2023 (%)

Key Points of this Report:

The depth industry chain includes analysis value chain analysis, porter five forces model analysis and cost structure analysis

The report covers Latin America and country-wise market of Wiring Harness in Military, Aerospace & Space

It describes present situation, historical background and future forecast

Comprehensive data showing Wiring Harness in Military, Aerospace & Space capacities, production, consumption, trade statistics, and prices in the recent years are provided

The report indicates a wealth of information on Wiring Harness in Military, Aerospace & Space manufacturers

Wiring Harness in Military, Aerospace & Space forecast for next five years, including market volumes and prices is also provided

Raw Material Supply and Downstream Consumer Information is also included

Any other user's requirements which is feasible for us

Reasons to Purchase this Report:

Analyzing the outlook of the market with the recent trends and SWOT analysis

Market dynamics scenario, along with growth opportunities of the market in the years to come

Market segmentation analysis including qualitative and quantitative research incorporating the impact of economic and non-economic aspects

Regional and country level analysis integrating the demand and supply forces that are influencing the growth of the market.

Market value (USD Million) and volume (Units Million) data for each segment and sub-segment

Distribution Channel sales Analysis by Value

Competitive landscape involving the market share of major players, along with the new projects and strategies adopted by players in the past five years

Comprehensive company profiles covering the product offerings, key financial information, recent developments, SWOT analysis, and strategies employed by the major market players

1-year analyst support, along with the data support in excel format.

Download FREE Sample of this Report @ www.24chemicalresearch.com/download-sample/286455/latin-america-wiring-harnessmilitary-aerospace-space-market-2025-2032-898

0 notes

Text

Darshana Industries Bangalore, Trusted Supplier for Quality Engineering Products

When it comes to high-quality industrial hardware and engineering components, Darshana Industries Bangalore is a trusted name. As one of the leading manufacturers in the industry, Darshana Industries provides a wide range of innovative solutions, including Darshana hinges, industrial locks, handles, and sealing gaskets, catering to various industrial applications.

Your Reliable Dealer – Mapa Engineering Company

At Mapa Engineering Company, we take pride in being one of the top Darshana Industries dealers in Bangalore, offering genuine products at competitive prices. Our product range includes: ✅ Cable Ties – Durable and versatile for electrical, automotive, and industrial applications. ✅ Darshana Hinges – High-quality hinges for enclosures, cabinets, and industrial doors. ✅ Industrial Aluminium Profiles – Lightweight, corrosion-resistant solutions for modular assemblies and structures.

Why Choose Us?

✔ Authorized Dealer – We supply authentic Darshana Industries products. ✔ Wide Range of Products – From cable ties to industrial aluminium profiles, we offer a complete solution. ✔ Competitive Pricing & Bulk Supply – Get the best deals on industrial hardware. ✔ Expert Assistance – Our team provides guidance in selecting the right products for your needs.

If you’re looking for Darshana Industries Bangalore products, visit Mapa Engineering Company today for reliable service and quality engineering solutions!

#Cable Tie#darshana hinges#darshana industries#darshana industries bangalore#darshana industries dealers in bangalore#Industrial Aluminium Profiles

0 notes

Text

Crane Kits: A Comprehensive Guide to Building Your Own Crane System

If you’re in the world of construction or just a DIY enthusiast looking to tackle big lifting projects, a crane kit is a tool you should definitely consider. Whether you're working on a construction site, setting up heavy equipment, or even moving bulky items around in a workshop, a crane kit can help you get the job done safely and efficiently. This guide will walk you through what crane kit are, how they work, and why they could be the next essential addition to your toolkit.

What Is a Crane Kit?

A crane kit is essentially a set of components designed to help you build a crane. These kits typically come with all the essential parts you’ll need to assemble a functional crane, such as beams, pulleys, gears, and sometimes motors. Depending on the kit, you may receive a manual or online instructions to guide you through the assembly process. Some crane kits are designed to be mounted on trucks or trailers for portability, while others are stationary for use in factories or workshops.

Crane kits come in different sizes and designs, ranging from small, lightweight models suitable for personal or small business use to larger, heavy-duty models that can lift several tons of weight.

Types of Crane Kits

There are several types of crane kits, each designed for specific purposes:

Manual Crane Kits:

These cranes are usually powered by hand-operated winches or pulleys. They are ideal for smaller lifting tasks or when you don’t need to move massive loads.

Electric Crane Kits:

These kits come with an electric motor that makes lifting and lowering loads much faster and more efficient. Ideal for heavy lifting or frequent use in workshops or construction sites.

Hydraulic Crane Kits:

Hydraulic cranes use pressurized fluid to generate powerful lifting force. These are typically used in heavy-duty construction applications and are known for their reliability and power.

Overhead Crane Kits:

These kits allow for cranes to be installed above a workspace, providing overhead lifting power. They’re often used in industrial settings where lifting large, heavy objects is required in confined spaces.

Truck-Mounted Crane Kits:

These crane kits are designed to be mounted on trucks or trailers for portability. They’re great for jobs that require both mobility and lifting power.

Key Components of a Crane Kit

To build a crane from a kit, you'll typically find the following components included:

Base and Framework:

This is the structure of the crane, which supports the rest of the components. It may be made from steel, aluminum, or other durable materials.

Boom or Arm:

The boom is the long arm of the crane that extends outward to lift and move objects. It’s often adjustable, allowing you to extend or retract the length based on the task.

Hoist or Winch:

The hoist or winch is responsible for lifting and lowering loads. It is often powered by electricity, hydraulics, or manual operation.

Pulleys and Cables:

Pulleys are used to guide the lifting cables and reduce the force required to lift heavy loads. The cables themselves are typically made of steel for strength.

Counterweights:

These are used to balance the crane when lifting heavy objects. They prevent the crane from tipping over by offsetting the weight of the load being lifted.

Control Mechanism:

This can range from a simple hand lever to a complex electronic control panel, depending on the crane type. It allows the operator to control the movement and function of the crane.

Advantages of Using a Crane Kit

Cost-Effective:

Purchasing a crane kit is often more affordable than buying a fully assembled crane. You also save on labor costs because you can assemble the crane yourself.

Customization:

Many crane kits offer customization options so you can adjust the crane to suit your specific needs. Whether you need extra lifting power or a longer reach, crane kits can be tailored for different purposes.

Space-Saving:

If you don’t have a lot of space, some crane kits are designed to be compact and can be stored easily when not in use. The overhead crane kits, for example, don’t take up floor space, making them great for small workshops.

Increased Safety:

Cranes are designed to handle heavy lifting in a controlled, safe manner. A kit that includes quality components ensures your lifting tasks are done with minimal risk to both operators and the load.

Improved Efficiency:

With the right crane kit, you can lift heavy materials much faster than by manual labor. This helps boost productivity in construction or industrial settings.

Choosing the Right Crane Kit

When selecting a crane kit, you’ll want to consider several factors to ensure you’re getting the right one for your needs:

Weight Capacity: Make sure the crane is rated for the weight you plan to lift. Overloading a crane can result in dangerous accidents.

Reach: Consider how far the crane needs to extend. If you need to reach overhead or into a specific area, a crane with adjustable or extendable booms might be necessary.

Portability: Do you need the crane to be mobile? If you’re working on a job that requires frequent movement, look for truck-mounted or portable crane kits.

Assembly Difficulty: Some crane kits can be quite complex to assemble, while others are designed for easier setup. Choose a kit that fits your level of expertise.

Conclusion

Crane kits are a fantastic solution for anyone in need of lifting power on a budget. They provide all the necessary components to build a crane tailored to your specific needs, whether that be for construction, industrial, or DIY projects. By investing in a crane kit, you can handle heavy loads more efficiently, increase safety on the job site, and reduce labor costs.

Whether you're a seasoned professional or a hobbyist, choosing the right crane kit can make a significant difference in your operations. So, next time you’re planning a project that requires heavy lifting, consider how a crane kit might improve the process!

What do you think of crane kits—have you used one before, or are you considering getting one for a project?

0 notes