#Connectors

Explore tagged Tumblr posts

Text

Sunken USB Type C breakout 🔌🛠️🧩

Folks love our standard USB Type C breakout (https://www.adafruit.com/search?q=usb+type+c+breakout) - and we recently got a request to carry a 'sunken' Type C breakout - what's that mean? It looks like this! instead of sitting above the PCB the connector sits in the midline for a svelte look. this connector got our pick because it has four burly THM tabs to keep the connector from cracking at the contact pads.

#adafruit#usb#usbc#pcb#electronics#hardware#maker#diy#breakoutboard#connectors#tech#engineering#innovation#projects

22 notes

·

View notes

Text

2 notes

·

View notes

Text

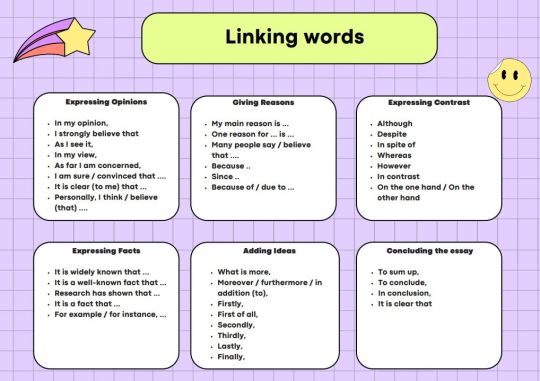

Don't know what type of linking words you should include in your argumentative essay? Check this lists

11 notes

·

View notes

Text

☝ High-quality solutions by DOIT-BI:

1. Help streamline workflows

2. Speed up data analysis

3. Improve overall productivity.

2 notes

·

View notes

Text

Socket Plug connectors, Receptacle Housing, cable connectors

DT Series Contact Size 16 3 Way Gray Receptacle Housing

#TE Connectivity#DT04-3P#Connectors#Tooling and Accessories#Cable compression tool#SAN#cable crimper#Tin Plated Contacts#f connector#Socket Plug connectors#Receptacle Housing#cable#Crimp Contact Socket#Ethernet crimping

2 notes

·

View notes

Text

from here (it's voice over though, we don't get to hear it):

youtube

It is an "IBM plug" on the ENIAC

These seem to have been normally used for connecting IBM reproducing punches, also called gang punches or summary punches to IBM accounting machine, descendants of the IBM tabulating machines.

However in this case on ENIAC, they seem to have it connected to the function table, per the description in the Wikipedia caption on this image:

So I that panel was doing some type of control on the function table I guess.

i wish usb ports were several magnitudes larger and made a hefty "kerchunk" sound when you plugged stuff in

14K notes

·

View notes

Text

What Are Automotive Connectors and Why Are They Essential in Modern Vehicles?

Automotive connectors may seem like small, insignificant parts, but their role in vehicle performance and safety is crucial. These connectors link various electrical components, ensuring your vehicle runs smoothly and efficiently. As vehicles become more sophisticated, the demand for high-quality automotive connectors continues to surge.

Understanding Automotive Connectors: What Are They Exactly?

Automotive connectors are specialized electrical connectors designed to withstand harsh automotive environments. They securely connect wires and components, ensuring uninterrupted power and data transmission throughout your vehicle's systems. Made to endure extreme temperatures, vibrations, and contaminants, they provide reliable connections crucial for modern vehicles.

Types of Automotive Connectors You Should Know

Automotive connectors come in diverse types, each serving unique purposes:

Wire-to-Wire Connectors: Connect wires directly, allowing electrical signals to flow efficiently.

Wire-to-Board Connectors: Link wiring harnesses to printed circuit boards (PCBs) to enable electronic control systems.

Board-to-Board Connectors: Connect multiple PCBs within advanced electronic systems.

Terminal Connectors: Securely terminate wire ends to ensure safe electrical contacts.

Why Are Automotive Connectors Crucial for Vehicle Performance?

Automotive connectors impact vehicle performance significantly by ensuring stable and continuous electrical connections. They influence:

Reliability: Robust connectors withstand harsh automotive conditions, reducing breakdown risks.

Safety: Quality connectors minimize short circuits and electrical faults, enhancing vehicle safety.

Efficiency: Reliable connections ensure optimal vehicle operation, improving fuel efficiency and emissions performance.

Key Features to Look for in High-Quality Automotive Connectors

Choosing the right automotive connectors is essential. High-quality connectors should feature:

Durability: Resistant to corrosion, abrasion, and vibration.

Weatherproofing: Ability to withstand moisture, dirt, and temperature fluctuations.

Ease of Installation: Simple assembly and disassembly for quick maintenance.

Conductivity: Excellent electrical conductivity ensuring optimal performance.

Applications of Automotive Connectors: Where Are They Used?

Automotive connectors find use in various vehicle systems, enhancing their functionality and reliability:

Engine Control Units (ECU): Connect sensors and actuators for engine management.

Safety Systems: Essential in airbags, ABS, and stability control systems.

Infotainment Systems: Ensure seamless connectivity for audio and navigation systems.

Lighting Systems: Connect headlights, taillights, and interior lighting reliably.

Electric Vehicles (EV): Critical for battery management systems, motor controls, and charging connectors.

Emerging Trends in Automotive Connector Technology

As automotive technology evolves, connectors also adapt to meet emerging needs. Notable trends include:

Miniaturization: Smaller connectors accommodating compact vehicle designs without compromising performance.

Enhanced Durability: Improved materials resisting higher temperatures and extreme conditions.

Smart Connectors: Integrated sensors monitoring connector conditions and performance in real-time.

High-Speed Connectivity: Supporting advanced communication protocols for autonomous driving and vehicle-to-everything (V2X) communication.

How to Choose the Right Automotive Connectors for Your Vehicle?

Selecting suitable connectors ensures optimal performance and safety. Consider these factors:

Application Requirements: Match connectors to specific vehicle system needs.

Compatibility: Ensure connectors fit your existing vehicle systems.

Environmental Conditions: Choose connectors rated for your operating environment (temperature, moisture, vibration).

Industry Standards: Verify connectors comply with automotive industry standards like ISO, SAE, and IEC.

Benefits of Investing in Premium Automotive Connectors

Investing in premium automotive connectors brings long-term advantages, including:

Enhanced Vehicle Performance: Improved electrical reliability enhances overall vehicle efficiency.

Reduced Maintenance Costs: Durable connectors reduce frequent replacements, saving maintenance costs.

Improved Safety: Minimized electrical faults reduce safety risks, protecting passengers and vehicles.

Increased Vehicle Lifespan: Robust connectors extend the lifespan of vehicle systems by ensuring consistent performance.

Common Challenges with Automotive Connectors and How to Overcome Them

Despite their advantages, automotive connectors face challenges. Common issues include:

Corrosion: Regular inspections and using corrosion-resistant connectors mitigate this issue.

Wear and Tear: Regular maintenance and choosing high-quality, durable connectors can prevent premature failure.

Improper Installation: Proper training and using connectors designed for easy installation reduce installation errors.

The Future of Automotive Connectors: What Can We Expect?

The automotive connector industry will continue innovating, driven by advancements in electric and autonomous vehicles. Anticipate future developments such as:

Wireless Connectors: Eliminating physical connections, enhancing vehicle design flexibility.

Self-Diagnosing Connectors: Embedded diagnostics proactively identifying potential issues.

Advanced Materials: Innovations in materials further increasing durability and reducing weight.

In conclusion, automotive connectors are vital components in modern vehicles, significantly influencing performance, safety, and reliability. By understanding their importance, types, features, and emerging trends, vehicle manufacturers and consumers can make informed decisions, ensuring safer and more efficient vehicle operations.

0 notes

Text

#WealdElectronics#MILDTL26482#Connectors#UKManufactured#MilSpec#IndustrialHardware#DefenseTech#powerelectronics#powermanagement#powersemiconductor

0 notes

Text

Simplify Complex Integrations in Informatica IDMC

Don’t waste time building custom APIs. With Infometry’s 22+ native Informatica IDMC connectors, developers can instantly integrate platforms like Google Bigtable, Sheets, and Adaptive Insights — all while maintaining enterprise-grade security and scalability.

0 notes

Text

The Advantages of Oxygen-Free Copper in the Industrial Materials Industry

Hello, industry enthusiasts!

Today, I want to highlight the remarkable benefits of oxygen-free copper, particularly focusing on the brand Jingda, which is making waves in the Industrial Materials sector.

Oxygen-free copper is known for its exceptional electrical conductivity and resistance to corrosion. This makes it an ideal choice for various applications, including electrical wiring, connectors, and other components where reliability is crucial. Jingda has been at the forefront of supplying high-quality oxygen-free copper products that meet and exceed industry standards.

One of the standout advantages of using oxygen-free copper is its ability to enhance the performance of electronic devices. By reducing the risk of oxidation, Jingda's oxygen-free copper ensures a longer lifespan and improved efficiency in electrical systems. This is especially important in today's fast-paced technological world, where dependability is key.

Moreover, the manufacturing process of Jingda's oxygen-free copper adheres to strict quality controls, ensuring that customers receive only the best materials. With a focus on innovation and sustainability, Jingda is committed to providing solutions that not only meet current demands but also pave the way for future advancements.

In conclusion, if you're looking for reliability and performance in your industrial materials, consider the advantages of oxygen-free copper from Jingda. Embrace quality and innovation for a brighter, more efficient future!

Best wishes!

#reliability#corrosion resistance#industrial materials#sustainability#oxygen-free copper#connectors#electrical wiring

0 notes

Text

Buy UC 2510 Connector 4 Pin Online

Shop UC 2510 4-pin connector online at Tomson Electronics. Ideal for DIY, robotics, and electronic projects. Fast shipping & trusted quality.

0 notes

Text

youtube

Desk of Ladyada - I2S DACs, Claude API, and Compute Module Backpack 🤖🎒🥧 https://youtu.be/XihMNhTyUlg

Ladyada explores I2S DACs, testing PCM51xx as a UDA1334A alternative. Work continues on the TLV320DAC3100, we test an AI API interface for setters/getters for Claude with pay per token. A new Pi Compute Module backpack is in progress - And we search for tall connectors for CM4/CM5.

#i2s#dac#raspberrypi#pcm5102#tlv320dac3100#compute#embedded#hardwaredesign#electronics#maker#opensource#adafruit#audiophile#tech#engineering#aiapi#claude#prototype#cm4#cm5#computemodule#raspberrypicm#pcbdesign#connectors#digikey#electronicsengineering#soldering#pcb#hardware#Youtube

4 notes

·

View notes

Text

Explore a wide selection of high-quality electronic and military connectors at Express Technology. As leading Electronic Connectors Suppliers and Military Connectors Suppliers, we offer durable, reliable, and customizable solutions tailored to your specific needs.

0 notes

Text

Heavy-Duty Connector Market Overview: Trends, Growth & Forecast

United States of America – The Insight Partners is honored to publish its new market study report: "HEAVY-DUTY CONNECTOR Market – Global Industry Trends, Share, Size, Growth, Opportunity, and Forecast Period." This in-depth report delivers a comprehensive analysis of the HEAVY-DUTY CONNECTOR market with insights into the present scenario, impending trends, growth factors, and possible constraints in the forecast period.

Overview

The HEAVY-DUTY CONNECTOR industry is under a dynamic transformation with changing industrial needs, technological breakthroughs, and increasing regulatory pressures. The connectors play a critical role in industries like manufacturing, energy, rail, and automation because they are capable of withstanding severe environments, mechanical stress, and high power requirements. The study discusses how such market drivers are propelling transformation in the industry and identifying challenges and opportunities in store.

Key Findings and Insights

Market Size and Growth

Historical Data & Forecast: Market size of heavy-duty connectors is expected to rise to US$ 5.31 billion by 2031 from US$ 3.31 billion in 2023. The market is estimated to record a CAGR of 6.08% in the forecast period.

Key Factors Influencing Market Growth:

Increasing use in robotics and factory automation.

Increased renewable energy projects expansion.

Industries development in rail and heavy machinery.

Need for high-performance, dependable, and customizable connectors.

Growing demand for high-performance and secure power/data transmission in rugged environments.

Get Sample Report: https://www.theinsightpartners.com/sample/TIPRE00008828

Market Segmentation

By Component

Hoods and Housings

Insert and Contact

Accessories

By Material

Metal

Plastic

By Termination Method

Crimp

Screw

By Application

Manufacturing

Power

Rail

Oil and Gas

Construction

Spotting Emerging Trends

Technological Advancements

Integration of IoT and Industry 4.0 solutions into connector systems.

Smart connectors with self-diagnosis abilities.

Application of cutting-edge materials for enhanced insulation and durability.

Miniaturization of connectors without reducing power capacity.

Changing Consumer Preferences

Greater preference for compact, easy-to-install connectors.

Increasing need for tailored, modular designs to suit industry-specific demands.

Transition towards using sustainable and recyclable connector materials.

Regulatory Developments

International standards (e.g., IEC, RoHS, REACH) tightening around material safety and environmental regulations.

Increased certification demands for connectors in transportation and energy applications.

Drive toward minimizing electromagnetic interference and enhancing data security.

Opportunity for Growth

Emerging Markets: Asia-Pacific, Latin America, and Africa's industrialization is driving demand for reliable electrical components.

Green Energy Projects: Renewable energy facilities such as wind and solar farms for secure power transmission.

Electric Vehicles: As the uptake of electric vehicles gains pace, so does demand for high-capacity connectors in charging points and vehicle systems.

Smart Manufacturing: Factories incorporating automation and data-driven manufacturing create a lucrative market for innovative heavy-duty connection solutions.

Defense and Aerospace: Continuous military modernization programs as well as growing aerospace spending drive demand for high-performance connectors.

Conclusion

"HEAVY-DUTY CONNECTOR Market – Global Industry Trends, Share, Size, Growth, Opportunity, and Forecast Period" offers precious insights for companies seeking to enter or grow their presence in this critical industry. Offering deep analysis of the most important market dynamics, the competitive landscape, and actionable tactics, the report gives stakeholders the power to make informed decisions and ride the waves of future opportunities.

About The Insight Partners

The Insight Partners is among the leading market research and consulting firms in the world. We take pride in delivering exclusive reports along with sophisticated strategic and tactical insights into the industry. Reports are generated through a combination of primary and secondary research, solely aimed at giving our clientele a knowledge-based insight into the market and domain. This is done to assist clients in making wiser business decisions. A holistic perspective in every study undertaken forms an integral part of our research methodology and makes the report unique and reliable.

0 notes

Text

#Automation#IndustrialIoT#Connectors#Robotics#PLC#Manufacturing#TEConnectivity#electronicsnews#technologynews

0 notes

Text

Glenair MWDM2L-25USP1,MWDM2L-37USP1 Micro-D connectors

0 notes