#CNC cutting machines

Explore tagged Tumblr posts

Text

Elevate Your Craft: A Deep Dive into CNC Cutting Machines

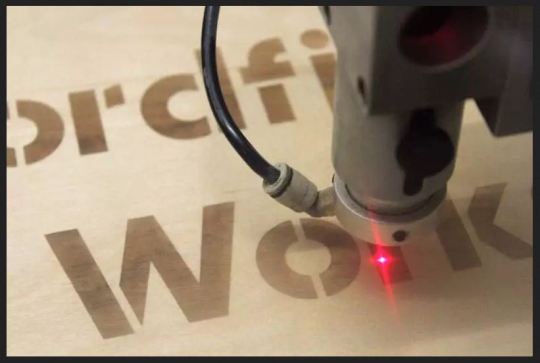

Unlock the potential of CNC cutting machines in your workshop. This article provides an overview of the technology, highlighting its versatility and efficiency across materials like wood, metal, and plastics. Learn how to assess your cutting needs, choose the right machine, and implement best practices for operation. Perfect for both professionals and DIY enthusiasts, this guide equips you with the knowledge to maximize your cutting capabilities and improve project outcomes.

0 notes

Link

#market research future#cnc cutting machines market#cnc cutting machine#cnc cutting machines#cnc cutting machines industry

0 notes

Text

Precision and Efficiency in CNC Metal Cutting with Fuson Precision Machining

In modern manufacturing, achieving precision and efficiency is critical to producing high-quality components. CNC metal cutting is a pivotal process that allows industries to create intricate metal parts with exceptional accuracy. Fuson Precision Machining is at the forefront of providing superior CNC metal cutting services. In this blog, we will explore the importance of CNC metal cutting, the benefits it offers, and why Fuson Precision Machining should be your go-to choice for this essential service.

Understanding CNC Metal Cutting

CNC (Computer Numerical Control) metal cutting is a manufacturing process that uses computer-controlled machines to remove material from a metal workpiece, creating precise shapes and designs. The process involves programming the desired dimensions into the CNC machine, which then guides cutting tools to perform precise cuts on the metal. This method ensures high levels of accuracy, repeatability, and efficiency, making it ideal for producing complex metal parts.

The Importance of CNC Metal Cutting

1. Precision and Accuracy

One of the key advantages of CNC metal cutting is its ability to achieve extremely tight tolerances. This precision is crucial in industries such as aerospace, automotive, and medical, where even the slightest deviation can lead to significant issues. With CNC metal cutting, manufacturers can produce parts that meet exact specifications, ensuring the highest levels of quality and reliability.

2. Efficiency and Productivity

CNC metal cutting is highly efficient, allowing for rapid production of metal components. The automation of the process reduces the need for manual intervention, minimizing errors and increasing productivity. This efficiency translates into faster turnaround times and cost savings for manufacturers, making CNC metal cutting an essential part of modern production.

3. Versatility

CNC metal cutting is versatile and can handle a wide range of metals, including steel, aluminum, brass, and titanium. This flexibility makes it suitable for producing a variety of components, from simple parts to complex geometries. Whether you need prototypes or high-volume production, CNC metal cutting can accommodate your needs.

Benefits of Choosing Fuson Precision Machining for CNC Metal Cutting

1. Expertise and Experience

Fuson Precision Machining boasts extensive experience and expertise in the field of CNC metal cutting. Our skilled technicians and engineers are proficient in handling complex projects and delivering precise metal components that meet the highest standards of quality. With years of industry experience, we understand the nuances of CNC machining and are equipped to tackle any challenge.

2. State-of-the-Art Equipment

We invest in state-of-the-art CNC machines and technology to ensure the best results for our clients. Our advanced equipment enables us to produce CNC metal cutting components with unparalleled accuracy and consistency. By leveraging cutting-edge technology, we can handle intricate designs and tight tolerances with ease.

3. Quality Assurance

Quality is at the core of everything we do at Fuson Precision Machining. We adhere to stringent quality control processes to ensure that every CNC metal cutting component meets or exceeds client expectations. Our commitment to quality is reflected in our ISO certification and our reputation for delivering reliable and precise metal parts.

4. Custom Solutions

We understand that each project is unique, and we offer customized solutions to meet specific requirements. Whether you need specialized materials, unique geometries, or specific finishes, we work closely with you to deliver CNC metal cutting components tailored to your needs. Our collaborative approach ensures that we provide solutions that align perfectly with your objectives.

Applications of CNC Metal Cutting

1. Aerospace Industry

In the aerospace industry, precision is critical. CNC metal cutting is used to produce components such as engine parts, landing gear components, and structural elements. The accuracy and reliability of these parts are essential for ensuring the safety and performance of aircraft.

2. Automotive Industry

The automotive industry relies on CNC metal cutting for the production of engine components, transmission parts, and various other critical elements. CNC metal cutting ensures that these parts meet the stringent standards required for vehicle performance and safety.

3. Medical Industry

In the medical field, CNC metal cutting is used to manufacture components for medical devices, implants, and surgical instruments. The precision and biocompatibility of these parts are vital for patient safety and effective medical treatment.

4. Electronics Industry

The electronics industry uses CNC metal cutting to create components for devices such as connectors, housings, and heat sinks. The ability to produce small, intricate parts with high precision is crucial for the functionality and reliability of electronic devices.

Success Stories: Fuson Precision Machining in Action

Client A: Aerospace Component Manufacturer

A leading aerospace component manufacturer turned to Fuson Precision Machining for the production of high-precision engine parts. Our expertise in CNC metal cutting enabled us to deliver components that met the stringent tolerances and quality standards required. The success of this project solidified our reputation as a reliable partner in the aerospace industry.

Client B: Medical Device Company

A medical device company required custom components for a new surgical instrument. Fuson Precision Machining provided tailored solutions, delivering precise CNC metal cutting components that ensured the instrument’s functionality and biocompatibility. Our collaborative approach and commitment to quality played a key role in the successful launch of the product.

Conclusion: Partner with Fuson Precision Machining for Superior CNC Metal Cutting

CNC metal cutting is essential for achieving precision, efficiency, and versatility in manufacturing. Fuson Precision Machining offers unparalleled expertise, state-of-the-art equipment, and a commitment to quality, making us the ideal partner for all your CNC metal cutting needs. Whether you operate in aerospace, automotive, medical, or electronics industries, we provide customized solutions that meet your specific requirements.

Contact Fuson Precision Machining today to learn more about our CNC metal cutting services and discover how we can help you achieve your manufacturing goals with precision and efficiency.

#CNC Metal Cutting#cnc metal fabrication#cnc metal process#CNC Work#prototype machining#cnc machining prototype

2 notes

·

View notes

Text

Best CNC laser cutting machine in India

As of my last knowledge update in January 2022, I don't have specific information on the latest CNC laser cutting machines available in India. However, I can provide you with some popular CNC laser cutting machine manufacturers that were well-regarded globally. It's important to note that advancements in technology and new models may have been introduced since then.

TRUMPF: TRUMPF is a globally recognized company for manufacturing high-quality CNC laser cutting machines. They offer a range of laser cutting solutions for various industries.

Amada: Amada is another well-known brand in the CNC machinery industry, including laser cutting machines. They have a reputation for producing reliable and efficient equipment.

Bystronic: Bystronic is a Swiss manufacturer known for its advanced laser cutting systems. They provide solutions for sheet metal processing and have a presence in India.

Mazak: Yamazaki Mazak Corporation, commonly known as Mazak, is a Japanese company that produces CNC laser cutting machines. They are known for their precision and innovation.

Han's Laser: Han's Laser is a Chinese company with a global presence, manufacturing laser cutting machines. They offer a variety of models suitable for different applications.

LVD: LVD is a Belgian company specializing in sheet metalworking equipment, including laser cutting machines. They are known for their innovative solutions.

When considering the best CNC laser cutting machine for your specific needs, factors such as the machine's power, cutting capabilities, ease of use, support services, and overall reputation of the manufacturer are important to consider.

To find the latest and best CNC laser cutting machines in India, it's recommended to check with local distributors, attend industry exhibitions, and explore online reviews and forums for updated information. Additionally, contacting the manufacturers directly or consulting with industry experts can help you make an informed decision based on your specific requirements.

We Provide:-

Best CNC laser cutting machine in India CNC punching services in pune Best MIG Welding Machine Pre-Treatment for Surface Preparation in pune Best CNC bending services India Best SS fabrication services in India Best spot welding services in pune Best tube, pipe, and angle cutting services in pune Best automotive manufacturers in pune Best manufacturing and assembly services

#best cnc laser cutting machine in india#CNC punching services in pune#best MIG Welding Machine#Pre-Treatment for Surface Preparation in pune#best CNC bending services india#best SS fabrication services in india#best spot welding services in pune#best tube#pipe#and angle cutting services in pune

2 notes

·

View notes

Text

https://berlin-machineries.com/

Buy Cnc fiber laser cutting machine, cnc edm wire cut machine, vertical turret milling machine, znc electric spark discharge machine, radial and pillar drill machine at best cost.

#CNC Fiber Laser Cutting Machine#CNC Fiber Laser Cutting Machine supplier#CNC Fiber Laser Cutting Machine Manufacturer#CNC Fiber Laser Cutting Machine supplier in pune#CNC Fiber Laser Cutting Machine Manufacturer in pune#Hydraulic Brake Press Machine#Hydraulic Brake Press Machine supplier#Hydraulic Brake Press Machine Manufacturer#Hydraulic Brake Press Machine supplier in pune#Hydraulic Brake Press Machine Manufacturer in pune#CNC EDM Wire Cut Machine#CNC EDM Wire Cut Machine supplier#CNC EDM Wire Cut Machine Manufacturer#CNC EDM Wire Cut Machine supplier in pune#CNC EDM Wire Cut Machine Manufacturer in pune#EDM Drilling Machine#EDM Drilling Machine supplier#EDM Drilling Machine Manufacturer#EDM Drilling Machine supplier in pune#EDM Drilling Machine Manufacturer in pune#ZNC Electric Spark Discharge Machine#ZNC Electric Spark Discharge Machine supplier#ZNC Electric Spark Discharge Machine Manufacturer#ZNC Electric Spark Discharge Machine supplier in pune#ZNC Electric Spark Discharge Machine Manufacturer in pune#Vertical Turret Milling Machine#Vertical Turret Milling Machine supplier#Vertical Turret Milling Machine Manufacturer#Vertical Turret Milling Machine supplier in pune#Vertical Turret Milling Machine Manufacturer in pune

3 notes

·

View notes

Text

High Quality Laser Cutting and Services in london

London, a hub of innovation and technology, has witnessed a surge in the utilization of laser cutting services across various industries. Laser cutting has revolutionized manufacturing processes, offering unparalleled precision, speed, and versatility. In this article, we will explore the significance of laser cutting services in London and delve into the benefits they bring to businesses and…

View On WordPress

#cnc cutting london#CNC cutting Shoreditch#CNC Machining London#CNC routing London#High Quality Laser Cutting Services#Laser cutting#Laser cutting east London#laser cutting london#laser cutting services#Laser Cutting Services in London#laser cutting shoreditch

3 notes

·

View notes

Text

It is our Pleasure to introduce our company HITZE ENGINEERING PVT LTD., Which has been incorporated as manufacturing of sheet metal components Since 2019.

6 notes

·

View notes

Text

Shaping the Road Ahead: 30 kW Lasers in Automotive Innovation

In recent years, 30 kW fiber laser cutting machines have emerged as a revolutionary technology in the automotive manufacturing industry. These machines utilize advanced fiber laser technology to achieve high-power cutting capabilities, enabling precise and efficient fabrication of automotive components. The impact of these machines on the industry has been profound, leading to improved productivity, cost-saving benefits, and enhanced customization opportunities.

Understanding Fiber Laser Cutting Machines

Fiber laser cutting machines are state-of-the-art tools that use fiber lasers to cut through various materials, including metals, with remarkable precision. The core of these machines is the fiber laser source, which generates an intense laser beam guided through an optical fiber. This highly focused and coherent laser beam is then directed onto the material to be cut, melting and vaporizing it with exceptional accuracy.

Advantages of fiber laser cutting machines over traditional cutting methods are numerous. Firstly, they offer higher cutting speeds and increased productivity, making them ideal for mass production in the automotive industry. Secondly, fiber lasers consume significantly less energy compared to CO2 lasers, reducing operating costs and environmental impact. Additionally, these machines are known for their excellent beam quality, resulting in smooth, burr-free cuts and minimizing post-processing requirements.

The key components of a fiber laser cutting machine include the laser source, optical fiber, cutting head, and CNC (Computer Numerical Control) system. The CNC system allows for precise control of the cutting process, ensuring accurate and repeatable results. The machine's software plays a crucial role in generating cutting patterns and nesting layouts to optimize material usage and minimize waste.

Transformation

The adoption of 30 kW fiber laser cutting machines has brought about a transformative impact on automotive manufacturing processes. One of the most significant advantages is the improved precision and speed of cutting operations. These machines can cut complex shapes and intricate patterns with unparalleled accuracy, leading to tighter tolerances and higher quality components. The enhanced speed allows for faster production cycles, reducing lead times and increasing overall manufacturing efficiency.

Moreover, fiber laser cutting machines offer exceptional versatility, capable of cutting a wide range of materials used in automotive manufacturing. From steel and aluminum to composites and plastics, these machines can handle various automotive-grade materials with ease, expanding the possibilities for design and innovation.

youtube

Benefits for Automotive Manufacturers

The utilization of 30 kW fiber laser cutting machines provides several compelling benefits for automotive manufacturers. One of the most notable advantages is cost-saving. Due to their high cutting speeds and reduced energy consumption, these machines lead to lower production costs, making them cost-effective for large-scale manufacturing.

Furthermore, fiber laser cutting machines result in minimal material waste. Their precise cutting abilities allow for optimized nesting layouts, maximizing material utilization and minimizing scrap. This reduction in waste not only saves costs but also contributes to a more sustainable and environmentally-friendly manufacturing process.

Another advantage is the level of customization and flexibility these machines offer. With their ability to cut intricate shapes and patterns, automotive manufacturers can cater to customer demands more effectively. Additionally, the adaptability of these machines enables rapid prototyping and quick design iterations, accelerating the product development cycle.

Several leading automotive manufacturers have successfully implemented 30 kW fiber laser cutting machines in their production processes. Hyundai Motor Company for instance, increased their production output by 40% after integrating fiber laser cutting machines into their assembly line. This efficiency gain allowed them to meet rising market demands while maintaining high product quality.

Another example is Volkswagen Group, which achieved significant cost savings by minimizing material waste through precise cutting patterns generated by fiber laser cutting machines. This reduced their overall material expenses and made their operations more sustainable.

In conclusion, 30 kW fiber laser cutting machines have revolutionized automotive manufacturing, offering increased precision, speed, and material versatility. These machines are driving the industry towards enhanced productivity, cost-effectiveness, and customization opportunities, making them a pivotal technology for automotive manufacturers in the 21st century.

2 notes

·

View notes

Video

youtube

STARMA cnc setting manual CCD camera of co2 laser cutting machine

#youtube#STARMA cnc setting manual CCD camera of co2 laser cutting machine This video to show how to setting the parameters of the CCD camera of Co2

2 notes

·

View notes

Text

The Future of Fabrication: Exploring CNC Cutting Machines

Discover how CNC cutting machines are transforming industries from woodworking to metal fabrication. This informative guide highlights their benefits, including improved efficiency and precision. Learn how to choose the right machine for your needs, explore innovative applications, and understand the technology behind these powerful tools. Whether you're upgrading your equipment or starting fresh, this resource provides essential insights for anyone looking to enhance their production capabilities.

0 notes

Link

A CNC plate drilling machine is a specialized tool used in the metalworking industry for drilling holes in large plates or sheets of metal. This machine incorporates computer numerical control (CNC) technology, which enables precise and automated drilling operations. CNC plate drilling machines are capable of drilling holes of various sizes and configurations, based on the programmed specifications. They offer high accuracy, efficiency, and repeatability, allowing for the production of complex hole patterns in a range of metal materials, including steel, aluminum, and stainless steel. These machines typically feature multiple drilling spindles and a movable worktable, enabling simultaneous drilling of multiple holes and efficient processing of large workpieces. CNC plate drilling machines are widely used in industries such as construction, shipbuilding, and manufacturing, where the accurate and efficient drilling of holes in metal plates is essential for structural integrity and component assembly. By utilizing CNC plate drilling machines, businesses can enhance productivity, reduce manual labor, and achieve precise hole drilling for their metal fabrication projects.

Read more about the top CNC plate Drilling machine in Dubai. Rockwood Machinery have their skilled team of welders, aluminium fabrication professionals, and installation crew, they collaborate with their suppliers and workers to assist produce and develop metal structures and systems on a big scale. Rockwood is the top CNC PIPE PROFILE CUTTING MACHINE in UAE.

2 notes

·

View notes

Text

#Fibre laser Cutting machine in mumbai#cnc laser router dealers in mira road#acrylic manufacturers in mira bhayandar#laser cutting machine suppliers in vasai#laser metal marking machine supplier in mumbai

2 notes

·

View notes

Text

2 notes

·

View notes

Text

CNC Fiber Laser Cutting Machine supplier | CNC Fiber Laser Cutting Machine Manufacturer in pune, India | CNC Fiber Laser Cut | Fiber Laser Cutting Machine

Best company for CNC Fiber Laser Cutting Machine supplier, CNC Fiber Laser Cutting Machine Manufacturer in pune, Mumbai, Delhi, India. Buy CNC Fiber Laser Cutting Machine at best cost only berlin-machineries.com

#CNC Fiber Laser Cutting Machine#CNC Fiber Laser Cutting Machine supplier#CNC Fiber Laser Cutting Machine Manufacturer

2 notes

·

View notes

Text

We are Direct Manufacturer & Supplier Of Fiber Laser Cutting Machines. Order Now . Email Us [email protected]

#Fiber Laser Cutting Machine#Laser Pipe Cutting Machine#Fiber Cutting Machine#Fiber Laser Cutter for Metal#Cnc Fiber Laser Cutting Machine Price#Fiber Optic Laser Cutting Machine#Co2 Fiber Laser#Fiber Laser Equipment#Fiber Laser Cutting Machine for Sale#Cnc Fiber Laser Cutting Machine

2 notes

·

View notes

Text

Buy Cnc fiber laser cutting machine, cnc edm wire cut machine, vertical turret milling machine, znc electric spark discharge machine, radial and pillar drill machine at best cost.

#CNC Fiber Laser Cutting Machine#CNC Fiber Laser Cutting Machine supplier#CNC Fiber Laser Cutting Machine Manufacturer#CNC Fiber Laser Cutting Machine supplier in pune#CNC Fiber Laser Cutting Machine Manufacturer in pune#Hydraulic Brake Press Machine#Hydraulic Brake Press Machine supplier#Hydraulic Brake Press Machine Manufacturer#Hydraulic Brake Press Machine supplier in pune#Hydraulic Brake Press Machine Manufacturer in pune#CNC EDM Wire Cut Machine#CNC EDM Wire Cut Machine supplier#CNC EDM Wire Cut Machine Manufacturer#CNC EDM Wire Cut Machine supplier in pune#CNC EDM Wire Cut Machine Manufacturer in pune#EDM Drilling Machine#EDM Drilling Machine supplier#EDM Drilling Machine Manufacturer#EDM Drilling Machine supplier in pune#EDM Drilling Machine Manufacturer in pune#ZNC Electric Spark Discharge Machine#ZNC Electric Spark Discharge Machine supplier#ZNC Electric Spark Discharge Machine Manufacturer#ZNC Electric Spark Discharge Machine supplier in pune#ZNC Electric Spark Discharge Machine Manufacturer in pune#Vertical Turret Milling Machine#Vertical Turret Milling Machine supplier#Vertical Turret Milling Machine Manufacturer#Vertical Turret Milling Machine supplier in pune#Vertical Turret Milling Machine Manufacturer in pune

3 notes

·

View notes