#CNC Machine

Explore tagged Tumblr posts

Text

All CNC Machine Solution Under One Roof

Discover Sam Automation: Your one-stop Solution for All CNC Machine Needs - From Sale & Marketing to Installation, Training, Application Support, and Spares!

For more information contact us at +919872403386

#youtube#autocad#cnc solutions#lathe machine#cnc machine#cnc sparesmanufacturing#cnc spares#cnc parts#machine tools#probe

2 notes

·

View notes

Text

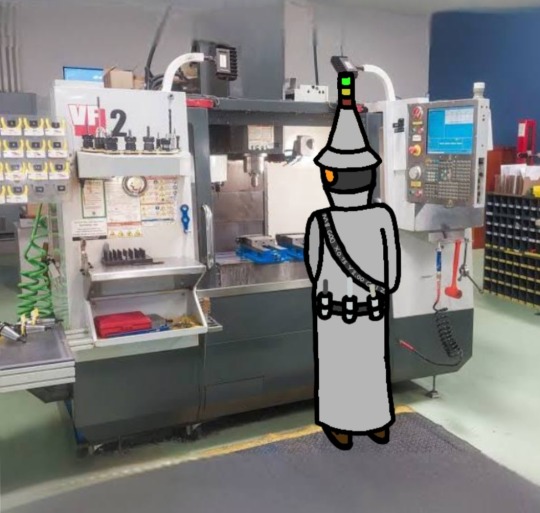

The Manufacturing Wizard inspects a CNC milling machine. His belt is similar to a chain-type automatic tool changer, and he uses it to hold a couple cutting tools.

#kuka haas#manufacturing wizard#my art#manufacturing#cnc machine#I put some G-code on the other belt

10 notes

·

View notes

Text

I was thinking about cognitive behavioral therapy and then I thought about something else so:

26 notes

·

View notes

Text

India's largest CNC machine tools group, Sahil Machines. Leading CNC machine manufacturers offering comprehensive machining centers both in India and overseas.

Established in 1968, Sahil Alloys & Machine Tools is a CNC machine manufacturer in India that has been innovating the manufacturing and CNC sectors since day one through our brand Suraj. By driving innovation, we strive to contribute to society and bring a positive impact on the global manufacturing and CNC industries.

#cnc machine#cnc machine operator#cnc router machine#cnc machine price#cnc machine price in india#cnc milling machine#cnc router machine price

2 notes

·

View notes

Text

Mistakes to avoid when buying a CNC machine

Embarking on the CNC machining path is akin to merging the meticulous world of technology with the time-honored tradition of craftsmanship. The decision to procure a CNC machine is a significant one, with each choice along the way shaping the trajectory of your craft. For more information, check this link: https://premierplasmacnc.com/.

2 notes

·

View notes

Text

CNC wood carving router machine manufacturers Chennai,CNC Engraving Machine Dealers in Chennai - Hiwin CNC Router

2 notes

·

View notes

Text

Applications of 3d Printing & CNC Machining

3D Printing Applications: Prosthetics, dental implants, and surgical instruments. Lightweight components and prototypes. Models, sculptures, and teaching tools. For more details visit here: https://www.pinterest.com/pin/922675042409536933

0 notes

Text

I think it's unreasonably funny when I see a robotic arm or cnc machine moving incredibly slowly when performing a delicate operation, before cautiously backing away from any obstacles. Then you can tell the exact moment the programmer went "fuck it we ball, machine rapid" and the robot rapidly accelerates to shoot through the air at the absolute maximum velocity it can achieve.

#wish I had a video of this#even then i dont know if anyone else would find it as funny as I do#robot#cnc machine#robotics

13 notes

·

View notes

Text

Success Technologies: Leading CNC Router Machine Manufacturer Industrial Routing Application

The CNC Router Machine has revolutionized industrial routing applications, offering unparalleled accuracy and productivity. As a leading CNC Router Machine Manufacturer in India, Success Technologies takes pride in providing cutting-edge solutions that cater to various industries, from woodworking and metal fabrication to signage and plastic processing.

What is a CNC Router Machine?

An intricate piece of equipment that automates drilling, engraving, carving, and cutting is a CNC (computer numerical control) router machine. Because it is computer-controlled and follows established protocols to perform specific actions, it is a crucial tool in industrial routing applications. Compared to existing manual routing techniques, CNC technology ensures high-quality outputs, significantly boosts efficiency, and reduces wasteful material usage.

Advantages of CNC Router Machines

1. Precision and Accuracy: A CNC router machine's ability to execute complex designs with outstanding precision is one of its most impressive features. The accuracy provided by these machines guarantees that there are few mistakes made when working with metal, plastic, or wood, allowing producers to create reliable and excellent goods.

2. Increased Efficiency and Productivity: Modern routing techniques frequently take a lot of time and work. Contrarily, CNC router machines run on their own, greatly cutting down on manufacturing time and boosting productivity. This is particularly useful for sectors that need to meet schedules and produce a great deal.

3. Versatility Across Industries

A CNC Router Machine can be utilized in various sectors, including:

Woodworking: Furniture manufacturing, cabinetry, and decorative engravings.

Metal Fabrication: Cutting and engraving aluminum, brass, and other metals.

Signage Industry: Engraving letters and patterns for commercial signs.

Plastics & Composites: Creating precise cuts for industrial plastic applications.

4. Cost-Effectiveness

A CNC router machine could seem like a big investment at first, but the long-term advantages exceed the negative aspects. CNC technology's efficiency and automation safeguard labor costs, reduce material waste, and increase overall profitability.

5. User-Friendly Interface

Modern CNC Router Machines come equipped with advanced software interfaces that simplify programming and operation. Even with minimal technical knowledge, operators can quickly learn to use these machines effectively.

Choosing the Right CNC Router Machine Manufacturer in India

As businesses seek to upgrade their manufacturing processes, selecting a reliable CNC Router Machine Manufacturer in India becomes crucial. Success Technologies has emerged as a trusted name in the industry, offering state-of-the-art CNC routing solutions tailored to meet diverse industrial needs. Here’s why our machines stand out:

1. Advanced Technology Integration: We leverage the latest advancements in CNC technology, incorporating high-speed spindles, intelligent automation, and user-friendly software to ensure superior performance and ease of operation.

2. Customization and Flexibility: Different industries have different requirements. At Success Technologies, we provide customized CNC Router Machines designed to cater to specific applications, ensuring maximum productivity and efficiency.

3. Durability and Reliability: Our CNC router machines are built with premium parts and materials, ensuring stability over time and low maintenance needs. Our top priority is reliability so that companies can continue to produce.

4. Comprehensive Support and Training: Our commitment to customer satisfaction extends beyond machine delivery. We offer comprehensive training programs and after-sales support to help businesses maximize the potential of their CNC Router Machines.

Future of CNC Router Machines in Industrial Applications

The future of CNC Router Machines looks promising, with continuous advancements in artificial intelligence (AI), automation, and IoT integration. Smart CNC Router Machines with real-time monitoring capabilities will enhance productivity further, ensuring that industries stay ahead in the competitive manufacturing landscape.

The adoption of CNC Router Machines has transformed industrial routing applications, providing unmatched precision, efficiency, and versatility. As a leading CNC Router Machine Manufacturer in India, Success Technologies remains committed to delivering innovative solutions that empower industries to achieve operational excellence. Whether you are in woodworking, metal fabrication, or signage production, investing in a CNC Router Machine can be a game-changer for your business.

For additional information about our CNC router machines and to learn how we can assist you in streamlining your manufacturing processes, get in touch with Success Technologies.

Visit: https://www.successtechno.com/cnc-router-machine.html

E-mail ID: [email protected]

Phone: +91 9998961184 Location: 97, Barcelona Industrial Estate, Odhav Ring Road Circle, Ahmedabad, 382415

#CNC Router Machine#CNC Router Machine Manufacturer#CNC Machine#CNC Router Machine Manufacturer in India

0 notes

Text

Five-axis CNC online ‘cuts iron like mud’! ⚔️ Watch titanium alloy turn from scrap iron into aviation parts in 3 minutes! ✈️ 🔥If you dare to send the drawings, I dare to deliver in 3 days!

IndustrialHardWork #MetalTransformation #CNCCheat

0 notes

Text

Feed rate function

Feed rate is a critical parameter that dictates how efficiently and effectively a workpiece is transformed into a finished product, In the precision-driven world of CNC machining. Whether you’re optimizing for speed, surface finish, or tool longevity, understanding the feed rate function is essential. Let’s dive into what it means, why it matters, and how to leverage it for optimal results. What…

0 notes

Text

Revolutionizing Jewelry Design with Laser Welding and Engraving

The jewellery laser welding machine and UV laser engraving machine are revolutionizing the world of jewelry making. With accuracy, speed, and versatility, these technologies equip jewelers with the ability to produce beautiful work that meets their own creative visions. As technology continues to develop, incorporating these innovations will become the key to competitiveness and catering to demanding clientele. The jewelry-making future looks promising, and laser technology leads the way to this promising development. Overall, the incorporation of laser welding and engraving machines into the process of jewelry creation not only adds to the value of the finished product but also creates new possibilities for creativity and customization. Jewelers who incorporate these technologies into their business will be well-prepared to compete in a highly competitive market with distinctive and high-quality items that appeal to customers.

0 notes

Text

Optimising CNC Machining Design for Precision and Production Efficiency

Our top 4 Tips for Designing for Manufacturing

Designing for CNC machining requires precision and foresight to ensure components are not only manufacturable but also optimised for performance, durability, and cost-effectiveness. Key factors such as internal radii, hole design, wall thickness, and tolerance specifications play a crucial role in achieving high-quality, efficient CNC production.

In this blog, we explore four essential design strategies that enhance CNC machining efficiency, reduce production costs, and improve overall component quality.

To read more about visit here: https://issuu.com/ukquickparts/docs/optimising_cnc_machining_design_for_precision_and_

0 notes