#Batch Printing Machines Manufacturer

Explore tagged Tumblr posts

Text

Start Me Up: 30 years of Windows 95 - @commodorez and @ms-dos5

Okay, last batch of photos from our exhibit, and I wanted to highlight a few details because so much planning and preparation went into making this the ultimate Windows 95 exhibit. And now you all have to hear about it.

You'll note software boxes from both major versions of Windows 95 RTM (Release To Manufacturing, the original version from August 24, 1995): the standalone version "for PCs without Windows", and the Upgrade version "for users of Windows". We used both versions when setting up the machines you see here to show the variety of install types people performed. My grandpa's original set of install floppies was displayed in a little shadowbox, next to a CD version, and a TI 486DX2-66 microprocessor emblazoned with "Designed for Microsoft Windows 95".

The machines on display, from left to right include:

Chicago Beta 73g on a custom Pentium 1 baby AT tower

Windows 95 RTM on an AST Bravo LC 4/66d desktop

Windows 95 RTM on a (broken) Compaq LTE Elite 4/75cx laptop

Windows 95 OSR 1 on an Intertel Pentium 1 tower

Windows 95 OSR 1 on a VTEL Pentium 1 desktop

Windows 95 OSR 2 on a Toshiba Satellite T1960CT laptop

Windows 95 OSR 2 on a Toshiba Libretto 70CT subnotebook

Windows 95 OSR 2 on an IBM Thinkpad 760E laptop

Windows 95 OSR 2.5 on a custom Pentium II tower (Vega)

That's alot of machines that had to be prepared for the exhibit, so for all of them to work (minus the Compaq) was a relief. Something about the trip to NJ rendered the Compaq unstable, and it refused to boot consistently. I have no idea what happened because it failed in like 5 different steps of the process.

The SMC TigerHub TP6 nestled between the Intertel and VTEL served as the network backbone for the exhibit, allowing 6 machines to be connected over twisted pair with all the multicolored network cables. However, problems with PCMCIA drivers on the Thinkpad, and the Compaq being on the blink meant only 5 machines were networked. Vega was sporting a CanoScan FS2710 film scanner connected via SCSI, which I demonstrated like 9 times over the course of the weekend -- including to LGR!

Game controllers were attached to computers where possible, and everything with a sound card had a set of era-appropriate speakers. We even picked out a slew of mid-90s mouse pads, some of which were specifically Windows 95 themed. We had Zip disks, floppy disks, CDs full of software, and basically no extra room on the tables. Almost every machine had a different screensaver, desktop wallpaper, sound scheme, and UI theme, showing just how much was user customizable.

@ms-dos5 made a point to have a variety of versions of Microsoft Office products on the machines present, meaning we had everything from stand-alone copies of Word 95 and Excel 95, thru complete MS Office 95 packages (standard & professional), MS Office 97 (standard & professional), Publisher, Frontpage, & Encarta.

We brought a bunch of important books about 95 too:

The Windows Interface Guidelines for Software Design

Microsoft Windows 95 Resource Kit

Hardware Design Guide for Windows 95

Inside Windows 95 by Adrian King

Just off to the right, stacked on top of some boxes was an Epson LX-300+II dot matrix printer, which we used to create all of the decorative banners, and the computer description cards next to each machine. Fun fact -- those were designed to mimic the format and style of 95's printer test page! We also printed off drawings for a number of visitors, and ended up having more paper jams with the tractor feed mechanism than we had Blue Screen of Death instances.

In fact, we only had 3 BSOD's total, all weekend, one of which was expected, and another was intentional on the part of an attendee.

We also had one guy install some shovelware/garbageware on the AST, which caused all sorts of errors, that was funny!

Thanks for coming along on this ride, both @ms-dos5 and I appreciate everyone taking the time to enjoy our exhibit.

It's now safe to turn off your computer.

VCF East XX

#vcfexx#vcf east xx#vintage computer festival east xx#commodorez goes to vcfexx#windows 95#microsoft windows 95

221 notes

·

View notes

Note

Hi! I really like your worldbuilding and was wondering if you had any ideas for how their equivalents of a printing press would be considering that Firth mentions getting the paper and I imagine they have some type of reading material like books or scrolls.

Like if they use ink of some sort, the most obvious answer being from squids on some level or if they have a different form of manufacturing it as since squids are sapient here, they probably wouldn’t be too enthused about being mined for ink. Or it’s something like old thrown out paints, inks, and writing material from humans, though either way the question of how they would get certain materials to adhere underwater is questionable in itself. There are such things as waterproof paper and underwater writing utensils but I don’t imagine those would be common to come by nor do I think they would have that great of a ability really have much of the ability to manufacture them themselves on a large scale.

Or they just cut out the letters and symbols from stuff already printed by humans serial killer style, sort of like what the Bottom Feeders sign does

Hi, I wrote this one out in a doc to format it because i was thinking about so much information. This is going to be typed more formally than it would be otherwise because my program autocapitalizes lest i go insane. Its gonna be a little disjointed regardless. <3 giant wall of text under the cut im not subjecting anyones dash to this unprompted

As a preface: gonna assume paper, fabric, and other organic and/or delicate goods have a longer shelf life in this society, taking the same stance as for in-game props made of these materials. The cigarettes do not really dissolve and some paper can exist indefinitely, though it and cardboard are understood to be soggy. Whether this is due to sapient creature activity/preservation, or just due to the more cartoon logic of the setting and game design needs.

like this is just a good statement for my analysis and reads on this game's worldbuilding in general: there are a lot of things in crabgame that are not scientifically accurate and that is literally the most ok thing in the universe because of the needs of the gameplay, the story, just like ETC there is a lot of love for the real ocean in crabgame and thats what matters, and ill work around that. i, however, am also insane.

Also keep in mind that humans dont really do manufacturing and crafts underwater so while i’ve tried to keep water stuff in mind there is just not the info for how making oil based inks or individual batches of paper would work underwater yknow? Educated guesses. Wikipedia educated guesses.

Further assumption: Definitely agree with what u said about crabs not really having an ability to manufacture stuff on a large scale. I’m gonna assume factory work could definitely be a thing, but maybe not widespread like… industrialization. Industry is certainly a big and well-known thing in new-carcinia, and i don’t doubt that shellfish co. probably has some machine-powered factories, but most industry is probbbably going to be supplied through scavenging either way, even if it also includes craft and such.

Third assumption: easy answer is that due to the trash economy yeah a lot of paints and inks used in theoretical printing, writing, and art would probably be, and have been scavenged from trash for a long time, probably superceding any of the previously implied small factories or home production joints. This isnt to say that these production methods could not be adopted for the trash economy though. Ill get into it.

(clears throat) with all that said, through my basic research id have to say i think much manual writing and art, if made either through wholly original production or a mix of scavenging and refining, would be done through an equivalent to Grease Pencils, a wax writing tool which can make marks on hard and glossy surfaces, such as (relevant to crabs or other water critters) rock, ceramic, glass, metal, etc. there are many sources pigments for these writing implements could be derived from, like iron oxides (for use in reddish dyes), tyrian purple (there is actually a snail in the pacific that can be farmed for this dye without execution, Plicopurpura pansa iirc, who knew!) and carbon (ill return to this).

You mention the ethical concerns of farming sapient squids for their ink and I do agree with those, no matter how much ink cephalopods produce its still like… a resource made from a person and production cant exactly rise to demand without the horrors occurring. However, i’m mostly just skeptical of how useful squid ink would be for writing underwater. This ink is almost entirely melanin particles bound together with mucus, which does eventually disperse in water. Not to say it couldnt be collected, but i feel like underwater application would be kind of a fruitless task.

As an aside, with the general (really frightening (in a good way) to me) lack of molluscs we see in another crab’s treasure, tyrian purple or anything derived from molluscs would likely be largely out of the question. Some sea hares can also eject ink colored from the pigments they ingest from seaweed but also, this ink is toxic and… same mollusc problem. I guess people irl can eat sea hares so maybe with prep crabs could… who knows . Oh fuck pigments could be derived from seaweed and algae. Keep that in mind.

I don’t… reject the possibility that crab society could have agricultural or dye farms but we only hear tell of like… One sardine farm and it is not sounding good for them. I don’t think these guys would really have any incentive to farm as little guys who can eat most things, one soldier in slacktide mentions scavenging heartkelp with their own claws. Probably some very small operations if any.

ASIDE OVER THAT WAS JUST PIGMENTS MOSTLY, to me the tricky part is what IS the waxy part. The grease. The thing that does not dissolve in water. Again, these component parts can probably be scavenged (and probably Have been scavenged since even before the trash economy, canisters of wax definitely fall overboard whaling ships and such) but i honestly can’t think of many ways a crab could make such a substance wholecloth. Perhaps creation of a quasi-inkstick with agar-agar or animal glue (fish glue/isinglass) and pigment? Which would naturally be a bit wet and wouldnt need an inkstone to gather the substance onto the printing apparatus.

For the stuff crabs actually write or print on, assuming a form of this is possible underwater i think pressed homemade paper would be a perfectly reasonable option for small-scale applications, though honestly imo “the paper” (newspaper) that firth mentions is probably printed on either re-used scavenged coated paper or scavenged/manually flattened thin plastic sheets. With access to machinery, shellfish co. would likely be able to manufacture thin plastic sheets, the npc LaTuna mentions her dress being created somehow by Shellfish co. and so i dont doubt that type of simple production is possible. We also see a lot of writing on cardboard so im gonna assume scavenged paints or these like. Agar inks and paint stamps will work on those? Maybe with some kind of sealant…

And of course as u mention bottomfeeders and shellfish desires both have signs that are made out of english letters that were pre-made, so thats probably a good option when applicable.

#crabgame#might expand on this later if i get the inkling to!#but yeah i think the biggest problem is a binding material for scavenged paints/inks#either manufactured by crabs or trash scavenged#or a bit of both#and like to expand more#like crabgame is a cartoon universe and i respect the choices made for it even if they fly in the face of realism because literally thats#like The World this is and its why i love it. however enough of this game's society and worldbuilding is also grounded enough i dont feel#unimaginably silly for speculating about the wider world and how it functions#theres a lot of care in portraying the world here#even when the gameplay and visual design and story take first priority as they should

8 notes

·

View notes

Text

North Carolina State University researchers have demonstrated a technique that allows people who manufacture metal machine parts with 3D printing technologies to conduct automated quality control of manufactured parts during the finishing process. The technique allows users to identify potential flaws without having to remove the parts from the manufacturing equipment, making production time more efficient. "One of the reasons people are attracted to 3D printing and other additive manufacturing technologies is that these technologies allow users to quickly replace critical machine components that are otherwise difficult to make outside of a factory," says Brandon McConnell, co-corresponding author of a paper on the work. "And additive manufacturing tools can do this as needed, rather than dealing with supply chains that can have long wait times. That usually means using 3D printing to create small batches of machine parts on demand." McConnell is an assistant research professor in NC State's Edward P. Fitts Department of Industrial and Systems Engineering.

Read more.

#Materials Science#Science#North Carolina State University#3D printing#Metals#Defects#Additive manufacturing

12 notes

·

View notes

Text

I have at least made a little progress in the salon today. Lots of ponies conditioned and processed into the next station. VERY many needing SunBox, and one batch in there already.

I've had to make a personal project soup to make room for work ponies, and those can sit with their hair set until I'm ready to work on them again. Will have good set with time.

I also got That Guy's and my laundry done today. I regret starting doing his laundry and I only did that because he paid for my medical bills. I'd rather he started doing it again since we're both working, now, though I am only working part time.

Very regret backing out of the Dollar Tree and Food Bank interviews, now. I had my eyes set on that mail room job too much. Granted, both of those jobs would be difficult for me to have done, too. The Dollar Tree is on the way of That Guy's work and if I could have gotten a 5am to 3pm shift on weekdays it would have been fine but they were only hiring part time. I could have walked to downtown after work, though.

The food bank IS downtown but like I'd gone over previously, I'd be dropped off around 5am and have to find somewhere safe to be between then and when stores and things started opening a few hours later, and also be stuck outside again from 1pm to about 3pm (or closer to 6pm on Son's theater rehearsal nights) waiting to be picked up.

Either way.

Tried looking for work again and I'm so despondent about it. I keep finding jobs I don't want to do but would just to be free and they all require experience that I don't have. It's not the kind of experience I can just say "I'll learn it on the fly" either, because it's things like "Must be familiar with siding extrusion machines" and "must have 1 year experience manufacturing printing plates because this isn't an entry level job, it's a job posting meant for advancement" and things like that. There's a customer service job at an insurance agency open. I don't know anything about insurance.

There's no work that I can do that is enough to support myself. Still.

And I'm struggling so badly with this gas station job.

7 notes

·

View notes

Text

Domino Presents New Monochrome Inkjet Printer at Labelexpo Southeast Asia 2025

Domino Printing Sciences (Domino) is pleased to announce the APAC launch of its new monochrome inkjet printer, the K300, at Labelexpo Southeast Asia. Building on the success of Domino’s K600i print bar, the K300 has been developed as a compact, flexible solution for converters looking to add variable data printing capabilities to analogue printing lines.

The K300 monochrome inkjet printer will be on display at the Nilpeter stand, booth F32, at Labelexpo Southeast Asia in Bangkok, Thailand from 8th–10th May 2025. The printer will form part of a Nilpeter FA-Line 17” hybrid label printing solution, providing consistent inline overprint of serialised 2D codes. A machine vision inspection system by Domino Company Lake Image Systems will validate each code to ensure reliable scanning by retailers and consumers whilst confirming unique code serialisation.

“The industry move to 2D codes at the point of sale has led to an increase in demand for variable data printing, with many brands looking to incorporate complex 2D codes, such as QR codes powered by GS1, into their packaging and label designs,” explains Alex Mountis, Senior Product Manager at Domino. “Packaging and label converters need a versatile, reliable, and compact digital printing solution to respond to these evolving market demands. We have developed the K300 with these variable data and 2D code printing opportunities in mind.”

The K300 monochrome inkjet printer can be incorporated into analogue printing lines to customise printed labels with variable data, such as best before dates, batch codes, serialised numbers, and 2D codes. The compact size of the 600dpi high-resolution printhead – 2.1″ / 54mm – offers enhanced flexibility with regards to positioning on the line, including the opportunity to combine two print stations across the web width to enable printing of two independent codes.

Operating at high speeds up to 250m / 820′ per minute, the K300 monochrome inkjet printer has been designed to match flexographic printing speeds. This means there is no need to slow down the line when adding variable data. Domino’s industry-leading ink delivery technology, including automatic ink recirculation and degassing, helps to ensure consistent performance and excellent reliability, while reducing downtime due to maintenance. The printer has been designed to be easy to use, with intuitive setup and operation via Domino’s smart user interface.

“The K300 will open up new opportunities for converters. They can support their brand customers with variable data 2D codes, enabling supply chain traceability, anti-counterfeiting, and consumer engagement campaigns,” adds Mountis. “The versatile printer can also print variable data onto labels, cartons, and flatpack packaging as part of an inline or near-line late-stage customisation process in a manufacturing facility, lowering inventory costs and reducing waste.”

Code verification is an integral part of any effective variable data printing process. A downstream machine vision inspection system, such as the Lake Image Systems’ model showcased alongside the K300, enables converters and brands who add 2D codes and serialisation to labels and packaging to validate each printed code.

Mark Herrtage, Asia Business Development Director, Domino, concludes: “We are committed to helping our customers stay ahead in a competitive market, and are continuously working to develop new products that will help them achieve their business objectives. Collaborating with Lake Image Systems enables us to deliver innovative, complete variable data printing and code verification solutions to meet converters’ needs. We are delighted to be able to showcase an example of this collaboration, featuring the .”

To find more information about the K300 monochrome printer please visit: https://dmnoprnt.com/38tcze3r

#inkjet printer#variable data printing#biopharma packaging#glass pharmaceutical packaging#pharmaceutical packaging and labelling#Labelexpo Southeast Asi

2 notes

·

View notes

Text

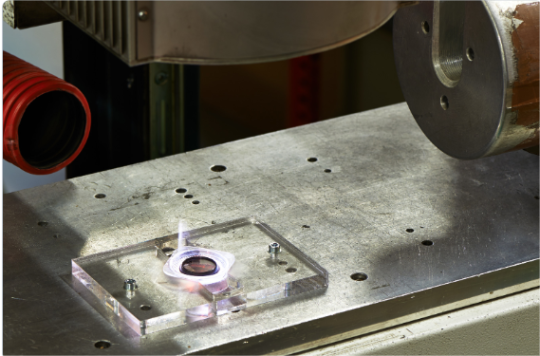

Applications & Precautions of CNC Machining Acrylic(PMMA)

Acrylic (PMMA) is a highly desirable material due to its strength, toughness and transparency. However, it may not be practical to rely on conventional processing to cut acrylic as the material is very fragile and any excessive force can lead to unwanted breakage.

Nevertheless, CNC machining offers a reliable method of manufacturing acrylic parts safely, with high precision and minimal waste of trim. CNC machining produces very few errors, allowing the manufacture of high quality acrylic parts and prototypes such as headlamps, housings, jewellery and more.

Advantages of Acrylic CNC Machining

As a CNC machined plastic, acrylic has many inherent advantages. Excellent transparency comparable to glass, Lighter weight than glass, Excellent dimensional stability, Good tensile and flexural strength, Good insulation level, Anti-wear, Anti-UV & sunlight, Good biocompatibility, Relatively low cost, Can be solvent bonded, Easy to polish, Available in a wide range of colours, Recyclable.

Choosing CNC machined acrylic over molding or 3D printing can bring additional benefits, some of the main advantages of machined acrylic include:

1.Material compatibility Acrylic is a thermoplastic that is malleable when heated, making it ideal for CNC machining. This inherent property makes it easy to fabricate and shape acrylic using this precise and efficient process.

2.Manufacture of High-Precision parts CNC machines offer extremely high cutting accuracy with tolerances down to thousandths of an inch. This level of high accuracy is particularly important when working with materials such as acrylic, where the need for neat edges and dimensional accuracy is critical.

3.Increasing productivity CNC machining is one of the most efficient ways to manufacture acrylic materials, especially when producing small batches of acrylic parts. The process allows for faster production speeds compared to manual methods, resulting in increased efficiency and productivity in acrylic manufacturing.

4.Reducing waste Thanks to its precise manufacturing method, the CNC machining is able to cut acrylics with optimum force, avoiding irreversible damage. This enables fast and efficient production of acrylic components with precise shapes and sizes. Using CNC machining increases accuracy and minimises waste in the manufacturing process.

5.Achieve high repeatability The automated CNC process ensures consistency across multiple parts or batches, thus ensuring consistent reproduction accuracy for each part. This reliability is a key benefit of CNC machining, especially in maintaining uniformity and accuracy in the production of acrylic parts.

6.Saving on manufacturing costs CNC machining can provide significant manufacturing cost savings due to reduced material waste, increased efficiency and lower labour costs. The precision and automation of CNC helps to achieve a leaner, more cost-effective production process.

Applications of Acrylic CNC Machining

CNC machined acrylic has many industrial uses, with the material being most widely used in the optical and automotive industries.

Alternatives to Glass

Due to its excellent transparency and clarity, acrylic is used as a replacement for shatterproof glass in many industries, including automotive, aerospace and optical.

Acrylic is commonly used as a glass replacement for window structures in aquariums, submarines, and hockey arenas. It is also used in the manufacture of lighting components such as headlights in the automotive industry. However, lights used in optical and automotive applications often have complex shapes and may also require very tight tolerances to provide optimal performance.

Medical and Dental

Due to its good biocompatibility, acrylic can be used in a variety of medical applications, including cosmetic surgery, where it can be used as a dermal filler. Acrylic can also be used as a bone cement in orthopaedic surgery (often used in fracture repair, joint replacement surgery or in vertebroplasty to fix the vertebrae, stabilize the spine and alleviate pain), as well as in dentistry for a variety of purposes (e.g. dentures).

Consumer goods

The aesthetics of acrylic make it suitable for a wide range of consumer products from furniture to consumer electronics to musical instruments.

Precautions When Machining Acrylic

Acrylic is a useful and versatile material, but it usually fails when subjected to compressive and tensile forces. This means that machining the desired shapes and cavities into acrylic panels requires care and attention.

However, the digital precision of CNC machining greatly simplifies this task. It also greatly increases the speed of acrylic machining and allows input parameters to be programmed to meet a wide range of needs.

Workpiece clamping

Plastics and metals have different workpiece clamping requirements, and acrylic is no exception in this regard. All areas of the material must be clamped using jigs and vises (smaller parts) or using adhesives to secure the entire part to the table (larger parts). If budget allows, a vacuum table is best suited for acrylic machining because it can effectively clamp and unclamp the material without damaging it.

Machining

CNC machining of acrylic typically requires a steady feed rate. Feed rates that are too low can lead to heat build-up and chips sticking back to the part, which can greatly reduce the quality of the surface finish. Another way to prevent heat build-up is to pre-cool the acrylic material before machining begins to allow for better chip removal. During machining, it is best to use oil-free coolants as they do not react with the plastic.

Surface finishing

For an aesthetically pleasing product, acrylic needs to be polished after CNC machining to produce optimum clarity and light transmission in the part. This is usually done by using progressively finer grit sandpaper followed by hand polishing with a linen towel and polishing paste. For high-quality prototypes, such as automotive headlight lenses or taillight lenses, or windows for electronics, polishing must be done by hand, a job done by the most experienced and skilled employees.

To create a diffusion effect on acrylic parts, the surface can be sandblasted and textured, while milky white paint offers another aesthetic option. Or to colour the part while maintaining transparency, it can be painted and coloured after hand polishing.

Conclusion

Acrylic is widely used for its strength, toughness and transparency, and CNC machining provides a reliable method for manufacturing high-quality acrylic parts. Acrylic machining has a variety of industrial applications, such as optical, automotive, and medical, but requires care and attention to post-processing such as clamping and polishing. Benefits include good material compatibility, manufacturing high precision parts, increasing productivity, reducing waste, achieving high repeatability and saving manufacturing costs.

#prototyping#prototype#rapid prototyping#prototype machining#cnc machining#precision machining#machining parts#cnc machining service#cnc machining services#cnc machining plastic parts#cnc machining parts#plastic cnc#cnc plastic part#cnc plastic#cnc plastic machining#plastic cnc machining#acrylic machining#pmma cnc machining#acrylic

2 notes

·

View notes

Text

How Israeli Tech is Shaping the Future of Additive Manufacturing Worldwide

Overview of Israel’s Strategic Position in Additive Manufacturing

Israel has rapidly emerged as a global force in additive manufacturing (AM), fortified by a powerful high-tech ecosystem, robust government support, and a legacy of innovation in defense, aerospace, and medical technologies. With the Israel additive manufacturing market valued at USD 221.4 billion in 2024 and forecasted to exceed USD 280.3 billion by 2032, the nation is positioned to lead transformative advances in 3D printing technologies. The Israel additive manufacturing market compound annual growth rate (CAGR) of approximately 7% reflects both escalating domestic demand and global interest in Israeli AM innovation.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40589-israel-additive-manufacturing-market-research

Driving Forces of Growth in Israel's Additive Manufacturing Market

Innovation Across Key Industrial Verticals

Israel additive manufacturing market sector is evolving as a backbone for modernization in:

Aerospace and Defense: Lightweight components, complex geometries, and high-performance materials enable operational efficiency and reduced lead times.

Healthcare: Customized prosthetics, implants, bioprinting, and surgical models offer patient-centric care and improved clinical outcomes.

Automotive and Industrial Manufacturing: Rapid prototyping, tooling, and small-batch production optimize supply chains and cut production timelines.

These sectors benefit from the convergence of additive technologies with AI, machine learning, and advanced robotics, all core competencies of Israel's high-tech sector.

Rising Demand for Customization and Sustainability

The shift toward sustainable manufacturing and personalized solutions is fueling AM adoption. Israeli startups and research institutions are developing biocompatible, recyclable, and multi-material printing solutions that meet stringent regulatory and industry-specific standards.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40589-israel-additive-manufacturing-market-research

Technological Landscape of the Israeli Additive Manufacturing Ecosystem

Polymer-Based Additive Manufacturing

Valued at USD 306.31 million in 2024, this segment dominates due to its cost-effectiveness, versatility, and compatibility with lightweight, complex part production. With an expected CAGR of 17.3%, applications in consumer goods, automotive interiors, and medical devices continue to surge.

Metal-Based Additive Manufacturing

Growing at a robust 20.1% CAGR, metal AM is the cornerstone of defense and aerospace advancements. In 2024, it accounted for USD 180.86 million, projected to exceed USD 775.48 million by 2032. Israel’s focus on titanium, aluminum alloys, and nickel-based superalloys supports structural applications with high thermal and mechanical stability.

Hybrid Additive Manufacturing

By blending subtractive and additive processes, hybrid AM enhances surface finish and dimensional accuracy, critical in precision tooling, aerospace, and dental prosthetics. This segment is rapidly gaining traction due to its versatility and integration into smart manufacturing systems.

Segmental Breakdown of the Israel Additive Manufacturing Market

By Component

Hardware: Represents the largest share, valued at USD 1,137.28 million in 2024, supporting high-throughput production and industrial-scale fabrication.

Software: Fueled by AI-powered design, generative modeling, and process simulation, this segment is experiencing 19.9% CAGR, revolutionizing digital twin applications and real-time process monitoring.

Services: The on-demand printing ecosystem is expanding, empowering SMEs to access advanced AM capabilities with minimal capital expenditure.

By Deployment Model

In-House Manufacturing: With a Israel additive manufacturing market valuation of USD 317.09 million in 2024, large enterprises prefer internal AM operations for confidentiality and operational control.

Service-Based Models: Growing at 19.4% CAGR, third-party service bureaus are crucial in democratizing access to advanced AM technologies for startups and research institutions.

By Functionality

Prototyping: Dominates with USD 340.60 million in 2024, essential for R&D, iterative design, and proof-of-concept validation.

Production: The rising shift to end-use part manufacturing is catalyzing growth in this segment, valued at USD 197.73 million in 2024.

Tooling: Customized, high-durability tooling supports faster transitions from design to production across various industrial sectors.

By Printer Size

Small/Compact Printers: Most accessible and dominant segment, valued at USD 253.09 million in 2024, ideal for labs, healthcare, and educational institutions.

Medium and Large Printers: Increasingly adopted in industrial manufacturing, these enable batch production and larger component fabrication.

End-Use Industries Driving Adoption

Aerospace & Defense

USD 159.32 million in 2024, this sector prioritizes weight reduction, material performance, and supply chain agility. With Israel’s defense sector being R&D intensive, 3D printing significantly enhances manufacturing autonomy and mission-readiness.

Healthcare & Medical

USD 131.40 million in 2024, growing due to demand for patient-specific devices, bioprinted tissues, and anatomical models. With innovations in regenerative medicine, Israel is at the forefront of personalized healthcare.

Industrial & Automotive

Israel’s industrial ecosystem leverages AM for lightweighting, thermal management, and low-volume production, especially in EV components and robotics enclosures.

Strategic Movements and Competitive Intelligence

Leading Israel Additive Manufacturing Market Participants

Stratasys: A global pioneer, deeply rooted in Israel, with continuous development in multi-material, high-resolution systems.

XJet: Revolutionizing ceramic and metal printing with NanoParticle Jetting™ technology.

Nano Dimension: Innovator in multi-layer electronics and PCB printing, driving miniaturization and functional integration.

Recent Developments

XJet (June 2024): Launched new ceramic printers with applications in automotive and aerospace, enhancing resolution and mechanical strength.

Nano Dimension (Sept 2024): Acquired startups to advance multi-material electronics printing, expanding their capabilities in embedded sensor systems.

Challenges and Strategic Opportunities

Major Israel Additive Manufacturing Market Challenges

Capital Intensity: High upfront costs limit adoption, especially among SMEs.

Talent Gap: Scarcity of AM-trained professionals hampers rapid scaling.

Scaling Complexity: Transitioning from prototype to full production requires new QA methodologies and workflow optimization.

Strategic Israel Additive Manufacturing Market Opportunities

Workforce Development: Partnerships with universities and technical institutes to offer AM-centric curricula.

Material Innovation Hubs: Support from government and private sectors to develop high-strength composites, bioresorbable materials, and nanostructured alloys.

Sustainability Mandates: Incentives for closed-loop manufacturing systems, energy-efficient printers, and recyclable materials.

Future Outlook: Israel’s Role in Global Additive Manufacturing Leadership

Israel is poised to lead the next frontier of digital manufacturing, where data-driven fabrication, machine learning-enhanced design, and autonomous production lines define industry 4.0. With unmatched cross-sector collaboration between startups, research centers, and government agencies, the nation’s AM sector is evolving from rapid prototyping to full-fledged production infrastructure.

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40589-israel-additive-manufacturing-market-research

Conclusion

Israel additive manufacturing market is entering a golden era, driven by its technological prowess, strategic policy initiatives, and vibrant innovation culture. As the global demand for agile, sustainable, and customized manufacturing solutions intensifies, Israel is uniquely equipped to lead the charge. Enterprises, investors, and policy makers must align to fully harness this momentum and establish Israel as a global additive manufacturing powerhouse.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

#Israel#Additive Manufacturing#3D Printing#Israeli Tech#Advanced Manufacturing#Industrial 3D Printing#Aerospace#Medical Devices#Defense Technology#Innovation#Startups#Tel Aviv#Prototyping#Manufacturing Industry#AM Materials#Digital Manufacturing#Smart Manufacturing#High-Tech Industry#Metal 3D Printing#Polymer Printing#R&D#Technology Trends#Engineering#Robotics#Supply Chain#Product Development

1 note

·

View note

Text

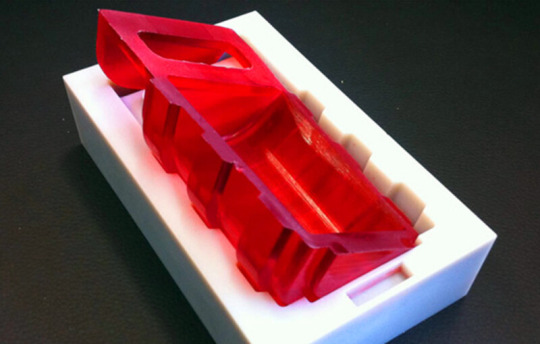

Learn About the Basics of Vacuum casting

Within the dynamic realm of production and prototyping, urethane casting is a unique technology that provides cost-effectiveness, accuracy, and diversity. Urethane casting has become the industry standard for a variety of applications, from complex prototypes to small-batch production runs, including consumer electronics, medical equipment, and the automotive and aerospace sectors.

Gratitude Casting of Urethane

The first step in the procedure is to create a master pattern, which is usually done via fast prototyping techniques like CNC machining or 3D printing. The silicone molds that are made from this master pattern are used to pour polyurethane resin into. The resin mimics the fine features of the master design once it has dried, producing pieces that are excellent and ready for manufacturing.

Flexibility throughout Sectors

The adaptability of urethane casting across sectors is one of its most noteworthy benefits. Urethane casting may be used for a variety of purposes, including the production of end-use components and prototypes for new product development. For instance, urethane casting makes it possible to quickly iterate ideas for dashboard panels, interior trim, and lighting fixtures in the car industry. Similar to this, urethane casting makes it easier and faster to produce unique medical device housings, surgical instruments, and prosthetic components in the medical profession. Vacuum casting also offers flexibility.

Benefits Compared to Conventional Approaches

When compared to conventional production techniques like CNC machining and injection molding, urethane casting has several significant benefits. The most important factor is cost-effectiveness. Because urethane casting requires less tooling up front, it's a great option for low-volume production runs if standard tooling costs are too high. Urethane casting also has a short turnaround time, which enables companies to quickly develop and refine ideas without having to wait for long lead periods.

Additionally, the design freedom provided by urethane casting makes it feasible to produce intricate surface details, undercuts, and complicated geometries that would be difficult or impossible to accomplish with alternative manufacturing processes. This versatility also applies to the choice of material, since a variety of polyurethane resins are available to satisfy certain performance needs, including those related to hardness, flexibility, and chemical resistance. You can Explore vacuum casting also.

Follow our Facebook and Twitter for more information about our product.

#vacuum casting#vacuum casting services#Urethane Casting#Explore vacuum casting#Custom Vacuum Casting Services

2 notes

·

View notes

Text

Automated 3D Printing Market Size Streamlining Additive Manufacturing with Smart Automation

The Automated 3D Printing Market Size is revolutionizing the future of manufacturing by integrating advanced automation with additive production processes. As industries seek faster prototyping, reduced labor costs, and 24/7 operational capabilities, the shift toward fully automated 3D printing ecosystems is gaining momentum. According to Market Size Research Future, the Market Size is projected to reach USD 9.3 billion by 2030, growing at a CAGR of 30.25% during the forecast period.

Market Size Overview

Automated 3D printing involves the use of robotics, software, sensors, and AI to manage the end-to-end additive manufacturing process—right from design, material loading, print initiation, part removal, post-processing, and quality inspection. This advancement eliminates the need for manual intervention, reduces production downtime, and enhances throughput.

Adoption is particularly strong in automotive, aerospace, healthcare, consumer goods, and industrial design, where batch production and precision are critical. As additive manufacturing matures from prototyping to full-scale production, automation becomes a key enabler of scalability and cost-efficiency.

Market Size Segmentation

By Component:

Hardware

Software

Services

By Process:

Material Handling

Automated Production

Part Handling

Post-Processing

Multiprocess Integration

By End-Use Industry:

Automotive

Aerospace & Defense

Healthcare

Consumer Products

Energy

Industrial Manufacturing

By Region:

North America

Europe

Asia-Pacific

Rest of the World

Key Market Size Trends

1. Rise in Lights-Out Manufacturing:

Fully automated 3D printing enables 'lights-out' factories—facilities that operate autonomously around the clock without human oversight. This is driving adoption in high-volume sectors like automotive and aerospace.

2. Integration of AI and Machine Vision:

AI-based software and vision systems are being incorporated to monitor print quality, detect anomalies, and trigger maintenance or adjustments automatically, reducing error rates and wastage.

3. Growth of Modular and Scalable Systems:

Manufacturers are adopting modular 3D printing cells that can scale linearly, allowing production capacity to grow alongside demand. These systems offer flexibility and reduce lead times.

4. Robotic Arm Integration:

Robotic arms are increasingly used for part removal, repositioning, cleaning, and packaging—streamlining post-processing workflows in multi-step additive manufacturing environments.

Segment Insights

Hardware Segment Leads the Market Size

The hardware segment, including 3D printers, robotic arms, sensors, and conveyors, dominates Market Size share due to rising installations of smart production units in manufacturing hubs globally.

Software Sees Accelerated Growth

Advanced software platforms manage job scheduling, material usage optimization, predictive maintenance, and digital twin simulations. Their role is becoming central to achieving full automation.

Aerospace & Healthcare Are Top Adopters

Aerospace companies use automated 3D printing to produce lightweight, complex parts with reduced assembly requirements. Healthcare providers use it for dental implants, surgical tools, and customized prosthetics—with automation boosting precision and regulatory compliance.

End-User Insights

Automotive Industry:

Automated 3D printing supports rapid prototyping, tooling, and production of complex parts such as intake manifolds, brackets, and custom components—delivering faster product development cycles.

Healthcare Sector:

Precision and biocompatibility are essential in medical applications. Automation ensures sterility, repeatability, and efficient batch production of medical devices and models.

Industrial Manufacturing:

Manufacturers leverage automation to reduce lead times for jigs, fixtures, and functional parts. Automated post-processing, including support removal and polishing, adds significant value.

Key Players in the Market Size

Leading companies are focused on end-to-end workflow automation, leveraging robotics, intelligent software, and cloud platforms. Key players include:

Stratasys Ltd.

3D Systems Corporation

Materialise NV

GE Additive

EOS GmbH

SLM Solutions

HP Inc.

Formlabs Inc.

Renishaw plc

Autodesk Inc.

These companies are investing in integrated ecosystems that combine design, simulation, production, and quality assurance in a seamless workflow, pushing the boundaries of what additive manufacturing can achieve.

Conclusion

Automated 3D printing is no longer a futuristic vision—it’s becoming a manufacturing standard. As businesses transition from R&D to full-scale production, automation will drive greater consistency, lower costs, and higher throughput. The convergence of robotics, AI, and additive technology is setting new benchmarks for speed, quality, and efficiency across industries. Organizations embracing this digital shift early will gain a competitive edge in the evolving global manufacturing landscape.

Trending Report Highlights

Explore related Market Sizes transforming automation and manufacturing efficiency:

Underfill Dispensers Market Size

Wet Chemicals Market Size

Taiwan Robotics Market Size

Automatic Elevator Inverter Market Size

Washdown Sensor Market Size

Electric Vehicle Capacitors Market Size

Fully Automatic Molding Machine Market Size

Industrial Automation Spares Market Size

North America Building Automation Systems (BAS) Market Size

Asia-Pacific Warehouse Automation Market Size

Thyristor Electric Power Controller Market Size

Wafer Level Packaging Market Size

0 notes

Text

3D Printers in India: A Complete 2025 Buying & Industry Guide

Introduction

The demand for 3D printers in India is growing rapidly as the technology becomes more accessible across industries such as education, healthcare, automotive, architecture, jewelry, and prototyping. From small-scale hobbyist printers to industrial-grade machines, India is embracing 3D printing as a powerful tool for innovation and manufacturing.

Whether you’re looking to buy a 3D printer in India or explore the best 3D printers available, this guide will help you make the right choice for your needs in 2025.

Why 3D Printing Is Booming in India

India’s additive manufacturing market is expected to surpass ₹3,000 crore by 2027, thanks to:

Government support through the “National Strategy on Additive Manufacturing.”

Educational integration in STEM and design programs.

Startups and SMEs utilizing 3D printing for prototyping and product development.

Affordable 3D printers now available across e-commerce platforms and local dealers.

As a result, 3D printing is no longer limited to big industries—it’s now accessible to individuals, educators, small businesses, and creators.

Types of 3D Printers in India

Before purchasing, it's essential to understand the types of 3D printers:

1. FDM (Fused Deposition Modeling) Printers

Best for: Beginners, prototyping, functional parts.

Material: PLA, ABS, PETG, TPU.

Popular models in India: Creality Ender 3 series, Anycubic Kobra, Prusa MK4.

2. Resin (SLA/MSLA) Printers

Best for: Jewelry, miniatures, dental models, highly detailed prints.

Material: Photopolymer resin.

Popular models: Elegoo Mars, Anycubic Photon Mono, Phrozen Sonic.

3. SLS & DMLS Printers

Best for: Industrial-grade applications like aerospace, automotive, and healthcare.

Material: Nylon powders, metal alloys.

Used by: Large manufacturing firms, research labs, and defense organizations.

Top 3D Printers in India (2025 Edition)

Here are some of the best 3D printers available in the Indian market:

1. Creality Ender 3 V3 KE

Type: FDM

Build Volume: 220 x 220 x 250 mm

Price: ₹20,000 – ₹25,000

Why it’s great: Affordable, customizable, ideal for beginners.

2. Anycubic Kobra 2 Max

Type: FDM

Build Volume: 420 x 420 x 500 mm

Price: ₹60,000 – ₹70,000

Best for: Large-format prints and fast output.

3. Elegoo Mars 4 Ultra

Type: Resin (MSLA)

Build Volume: 153 x 77 x 165 mm

Price: ₹22,000 – ₹28,000

Perfect for: Miniatures, jewelry casting, detailed models.

4. Raise3D Pro3 Plus

Type: Professional FDM

Build Volume: 300 x 300 x 605 mm

Price: ₹6,50,000+

Recommended for: Prototyping, batch production, engineering models.

Where to Buy 3D Printers in India

India has a well-established network of online and offline sellers. Here are the top options:

✅ Online Platforms

Amazon India – Wide range of FDM and resin printers with reviews.

Robu.in – Trusted tech supplier with accessories and spare parts.

3D Bazaar – Specializes in 3D printing equipment and services.

WOL3D – Offers domestic and imported 3D printers across categories.

Think3D – Caters to industrial, educational, and government clients.

✅ Offline Dealers

Located in major cities like Mumbai, Bangalore, Delhi, Pune, Hyderabad, etc.

Many stores provide demos, training, and post-sales support.

Look for authorized resellers to ensure warranty and service validity.

Industries Using 3D Printing in India

🔧 Manufacturing & Engineering

Used for rapid prototyping, tooling, jigs, and end-use parts.

Automotive and aerospace sectors use 3D printing to reduce lead time and material waste.

💎 Jewelry

3D printing is a game-changer for creating detailed wax/resin models for casting.

🦷 Healthcare & Dental

Customized prosthetics, dental aligners, surgical guides, and even bioprinting research.

🏫 Education

Schools, colleges, and IITs use 3D printers to teach design thinking and manufacturing.

🏗️ Architecture & Interior Design

Miniature models, scaled floor plans, and concept renders are easily produced.

Factors to Consider Before Buying a 3D Printer in India

1. Purpose

Are you buying for learning, business, industrial use, or personal projects?

2. Technology

Choose FDM for strength and affordability; Resin for high-detail work.

3. Build Volume

Larger volume means larger parts or batch printing, but also higher costs.

4. Material Compatibility

Ensure the printer supports your required filaments or resins.

5. Support & Warranty

Always buy from a dealer that provides installation, training, and customer service in India.

6. Price

Entry-level: ₹15,000 – ₹30,000

Mid-range: ₹30,000 – ₹1,00,000

Industrial: ₹2,00,000 – ₹15,00,000+

Cost of 3D Printing Services in India

If you’re not ready to buy, you can use local 3D printing services. Rates vary depending on size, material, and complexity:

FDM prints: ₹20–₹50 per gram

Resin prints: ₹40–₹100 per cubic cm

3D Scanning: ₹1,000–₹5,000 per object

Reverse Engineering & Modeling: ₹2,000–₹15,000+ based on project scope

Services are offered by platforms like Think3D, 3Ding, Proto3D, Imaginarium, and many city-based providers.

Future of 3D Printing in India

India is at the cusp of a 3D printing revolution:

Government adoption is increasing in railways, defense, and space.

Educational integration is creating a new generation of innovators.

Local manufacturing is reducing import dependency, especially for prototypes.

Bioprinting and construction-scale 3D printing are emerging technologies to watch.

As technology becomes cheaper and more efficient, 3D printing in India will expand into household and consumer applications as well.

Conclusion

The Indian market is ripe for the 3D printing boom—driven by accessibility, affordability, and awareness. From startups prototyping new ideas to students learning additive manufacturing, 3D printers are transforming how India builds.

Whether you’re searching for the best 3D printer in India, looking to buy online, or need local printing services, this is the best time to explore the possibilities.

Ready to start your 3D printing journey?

Choose the right technology, partner with trusted sellers, and join the community that’s shaping India’s future—layer by layer.

0 notes

Text

Bopp Tape Manufacturer - High-Quality Packaging Solutions | The Saga Enterprise

Introduction

In today’s fast-paced commercial world, packaging solutions are more than just boxes and labels, they’re essential tools that protect goods, build brand identity, and streamline logistics. At the heart of effective packaging lies something often overlooked but incredibly important: tape. Whether you're running an e-commerce store or a large-scale distribution center, the right tape can make or break your shipping process.

Enter The Saga Enterprise, a trusted Bopp tape manufacturer offering high-quality, durable, and cost-effective packaging solutions tailored for businesses of all sizes. With expertise in adhesive tape, stretch film, custom tape, and printed tape, we combine innovation with reliability to deliver what your business needs most: peace of mind with every package.

What is Bopp Tape?

Bopp stands for Biaxially Oriented Polypropylene, a material known for its excellent mechanical and optical properties. In simple terms, it’s a thin plastic film that’s stretched in two directions during production, giving it superior strength and flexibility.

Key Characteristics of Bopp Tape

High tensile strength

Resistant to moisture and chemicals

Excellent clarity and smooth surface

Good dimensional stability

Compared to other packaging tapes like PVC or masking tape, Bopp tape stands out for its durability, eco-friendliness, and suitability for automatic carton-sealing machines. It’s the go-to solution for e-commerce packaging, warehouse storage, and industrial shipments.

Why Choose Bopp Tape for Packaging?

Using the right packaging tape is not just about keeping boxes closed, it’s about protecting what's inside and promoting professionalism. Here's why Bopp tape should be your top pick:

1. Superior Adhesion

Bopp tape uses pressure-sensitive adhesives, such as acrylic or hot melt glue, ensuring long-lasting bonding even on rough surfaces.

2. Temperature and Moisture Resistance

Perfect for varied climates and long transit times, Bopp packaging tape holds strong without peeling or warping.

3. Lightweight and Cost-Effective

Despite its strength, Bopp tape is incredibly lightweight, reducing overall shipping weight and cost.

4. Versatile Applications

Ideal for industrial packaging, courier services, moving companies, FMCG businesses, and more.

When it comes to packaging security and efficiency, The Saga Enterprise’s Bopp tapes lead the way with precision and reliability.

The Manufacturing Process of Bopp Tape

Ever wondered how this miracle tape is made? Let’s break it down:

1. Raw Material Preparation

The base polymer (polypropylene) is melted and converted into a thin film via extrusion.

2. Biaxial Orientation

The film is stretched both lengthwise and widthwise, increasing strength and clarity.

3. Adhesive Coating

One side of the film is coated with a pressure-sensitive adhesive (like acrylic or hot melt).

4. Slitting and Rewinding

Large rolls are cut into smaller, customizable widths using precision slitters.

5. Quality Checks

Each batch undergoes strict quality control to test for:

Adhesive strength

Tensile strength

Film thickness

Resistance to UV, water, and chemicals

The Saga Enterprise ensures all tapes meet global packaging standards with ISO-certified production and eco-conscious practices.

Types of Adhesive Tapes Offered by The Saga Enterprise

We understand that one tape doesn’t fit all. That’s why we offer a wide array of adhesive tapes designed to fit diverse business needs:

1. General Packaging Tape

Clear and brown options

Available in multiple widths

Ideal for day-to-day packaging

2. Printed Tape

Brand your packages with company names, logos, or caution messages

Helps prevent tampering and increases visibility

3. Custom Tape

Choose your own design, width, color, and material

Perfect for brand recognition and professionalism

4. Specialty Tapes

Double-sided tape

Masking tape

Foam tape

Electrical tape

Each variant is developed with premium materials and tested adhesives, ensuring you always get top-notch performance.

Custom Tape Solutions for Brand Visibility

Let’s face it, first impressions matter. Custom packaging tape does more than just seal a box; it tells your story.

Why Custom Tape?

Build brand identity

Create customer loyalty

Deter tampering during transit

Stand out in crowded logistics chains

What Can Be Customized?

Logo or brand name

Text or tagline

Background color and finish (matte or gloss)

Tape width and length

With The Saga Enterprise, you get full creative freedom to design packaging tape that reflects your brand’s tone and values.

Stretch Film and Wrap Rolls: A Must-Have for Bulk Packaging

Beyond adhesive tape, stretch film is another unsung hero of the packaging world. Whether you’re bundling pallets or securing heavy items, our stretch wrap rolls have you covered.

Benefits of Stretch Film:

Protects goods from dust, moisture, and shifting during transit

Improves stability and load security

Reduces pilferage and tampering

Our Stretch Wrap Options:

Hand Roll: For manual application

Machine Roll: Compatible with stretch wrapping machines

Colored Films: For visual sorting and labeling

UV Resistant Films: For outdoor storage

All stretch films are designed to stretch up to 300%, reducing film usage and costs while enhancing load safety.

Benefits of Choosing The Saga Enterprise

There are countless tape manufacturers, but here's why our clients stick with us (pun intended):

1. Advanced Infrastructure

We operate with state-of-the-art machinery, capable of large-scale production with minimal waste.

2. Consistent Quality

Every product is QC tested, ensuring you receive uniform adhesive strength and film clarity.

3. Competitive Pricing

Whether you’re a startup or enterprise, we offer flexible pricing models for small and bulk orders.

4. Quick Turnaround

Need a large custom order fast? Our streamlined processes and expert team ensure on-time delivery every time.

Applications Across Industries

Our tape and packaging products are trusted by a wide range of industries:

E-commerce & Courier Services: Durable tapes for high-volume packaging

Pharmaceuticals: Tamper-evident and hygienic stretch films

Food & Beverage: Custom tapes with branding and storage safety

Electronics: Static-resistant and secure sealing solutions

Retail & Supermarkets: Brand-enhancing tapes for point-of-sale packaging

With The Saga Enterprise, packaging is no longer an afterthought, it’s part of your brand strategy.

Innovations in Tape Manufacturing

We believe in staying ahead of the curve. Here’s how we keep innovating:

1. Water-Based Adhesives

Safer for the environment and workers, with the same superior grip.

2. Biodegradable Tapes

Made from recyclable or compostable materials, perfect for eco-conscious brands.

3. Smart Packaging

We’re exploring tapes embedded with QR codes, holograms, and RFID technology for intelligent tracking.

Sustainability and Eco-Friendly Packaging

As a responsible manufacturer, we’re committed to reducing our carbon footprint.

Recyclable Bopp tape options

Solvent-free adhesive choices

Eco-stretch films for responsible disposal

Participation in plastic offset programs

Our team can help you make sustainable packaging decisions without compromising strength or aesthetics.

How to Select the Right Tape for Your Packaging Needs

Choosing tape isn’t one-size-fits-all. Here's what to consider:

1. Tape Width & Thickness

Heavier loads need wider, thicker tape

40 microns is standard; 50+ microns for heavy-duty boxes

2. Adhesive Type

Hot Melt: Strong grip, fast tack

Acrylic: UV-resistant, suitable for long storage

Solvent-based: Best for extreme temperatures

3. Packaging Conditions

Cold storage

Rough handling

Long-distance transport

Need help picking? The Saga Enterprise team offers free consultations.

Global Market and Export Capabilities

Based in India, we proudly serve clients across the globe:

USA, UK, Australia, UAE, and Europe

Timely delivery through trusted logistics partners

Full export documentation and compliance support

Bulk order capacity with on-demand customization

With global packaging standards, we’re helping businesses expand with confidence.

FAQs

What is the minimum order quantity for custom tape?

Ans: The minimum order starts at 5,000 meters, but we can accommodate smaller test runs on request.

Can printed tape be made waterproof?

Ans: Yes! Our Bopp printed tapes come with water-resistant ink and film options.

What industries benefit the most from stretch wrap rolls?

Ans: Logistics, food storage, pharma, electronics, and agriculture use stretch film for securing large shipments.

How long does it take to manufacture custom packaging tape?

Ans: Standard turnaround is 7-10 business days, depending on design and volume.

Is Bopp tape recyclable?

Ans: Yes. Our Bopp tapes are made from recyclable polypropylene. Ask us about our eco-line.

Conclusion

At The Saga Enterprise, we know that packaging is more than just tape, it’s trust. With our extensive range of Bopp tape, adhesive tape, stretch film, and custom branding solutions, we’re helping businesses package smarter, safer, and stronger.

Need the perfect packaging solution? Let’s build it together.

0 notes

Text

Which Types of Bottom-Making Machines Are Best Suited for Paper Bag Production?

With the rising global demand for sustainable and eco-friendly packaging, paper bags have become the preferred alternative to plastic bags across multiple industries—from retail and food delivery to groceries and pharmaceuticals. However, for paper bags to be functional and durable, the quality of the bag bottom is critical. A strong, well-formed bottom ensures that the bag can hold weight without tearing or collapsing.

This is where bottom-making machines play a crucial role. But with various types of machines available in the market, choosing the right one for your specific application can be confusing. In this article, we’ll explore the main types of bottom-making machines used in paper bag production, their features, applications, and which one might be the best fit for your business.

Why Bottom Style Matters in Paper Bag Production

Before diving into machine types, it's important to understand how the style of the bottom influences the functionality and use case of a paper bag:

Square Bottom (Flat Bottom): Provides a wide base and upright structure. Ideal for shopping bags, grocery bags, food delivery, and luxury packaging.

V-Bottom (Sharp Bottom): Lightweight, simple structure, used for items like pharmacy bags, bakery goods, and small packaging needs.

Each bottom style requires a specific type of machine, built to handle the folding, gluing, and pressing operations for that bag format.

1. Square Bottom Paper Bag Making Machine

Overview:

A Square Bottom Paper Bag Making Machine is designed to manufacture bags with a flat base that can stand upright. These machines are highly versatile and commonly used for making medium- to large-sized bags.

Key Features:

Automatic tube forming, bottom folding, and gluing

Servo-based control for precision and speed

Handles both printed and non-printed paper rolls

Compatible with twisted/flat handle attachment units (optional)

Speed: Up to 120–200 bags per minute (depending on configuration)

Applications:

Shopping bags for retail and apparel stores

Grocery and food delivery bags

Luxury bags for gifts and branding

Bags for takeaways and cafes

Advantages:

Strong load-bearing capacity

Clean, professional look (suitable for branding)

Works well with kraft paper, laminated paper, and art paper

✅ Best suited for businesses producing high-end paper bags or bulk grocery/shopping bags.

2. V-Bottom Paper Bag Making Machine

Overview:

The V-Bottom Paper Bag Machine (also known as a sharp bottom or envelope bottom machine) produces bags with a pointed bottom shape. It is generally simpler in design and more economical, suitable for small bag production.

Key Features:

High-speed operation: up to 300–400 bags per minute

Compact and efficient design

Handles thinner paper materials

Easy to operate and maintain

Applications:

Bakery and confectionery bags

Medicine and pharmacy bags

Small packaging for retail

Lightweight product-carrying bags

Advantages:

Cost-effective

Ideal for low-weight applications

Low maintenance, compact footprint

✅ Perfect for entry-level manufacturers and businesses producing small, disposable paper bags.

3. Bottom Pasting Machines (Standalone Units)

Overview:

Standalone bottom-pasting or bottom-folding machines are designed to complete the final stage of bag production. These are typically used when the paper bag tube is formed manually or by another machine.

Key Features:

Manual or semi-automatic feeding

Adjustable for different bag sizes

Gluing, folding, and pressing in one cycle

Applications:

Custom paper bag producers

Small-scale units needing flexibility

Manual or semi-automatic production lines

Advantages:

Lower capital investment

Flexibility in operations

Can be integrated into existing setups

✅ Ideal for businesses with partial automation or customized small-batch production.

Why Choose Prakash Machineries Pvt Ltd for Paper Bag Machines?

At Prakash Machineries Pvt. Ltd., we offer advanced and reliable paper bag-making machines—including square-bottom, V-bottom, and bottom-pasting units. Our machines are built with

High-speed servo systems

User-friendly interfaces

Energy-efficient motors

Strong after-sales service and support

Whether you're just starting or scaling your paper bag production, we can help you choose the right solution tailored to your requirements and budget.

Final Thoughts

Bottom-making machines are essential to the structural integrity and market appeal of paper bags. Understanding the differences between square-bottom and V-bottom machines allows you to make smarter investment decisions. Each machine has its own strengths, depending on your industry, product type, and production scale.

If you're unsure which model suits your needs best, the team at Prakash Machineries Pvt. Ltd. is here to guide you. We’ve helped hundreds of businesses across India and beyond set up profitable and sustainable paper bag production lines. 🌐 Visit Prakash Machineries Pvt Ltd

#paper bag manufacturer#manufacturer#machines#square bottom#v bottom#paper#bagas#flexo#paper bag#alien stage#baking#cake#chris sturniolo#dan and phil#cooking#chocolate#critical role#delicious#breakfast

0 notes

Text

A Beginner’s Guide to Plastic Manufacturing Techniques and Technologies

Plastic manufacturing is a foundational part of modern industry, contributing to countless products we use daily from packaging and furniture to automotive parts and electronics. For beginners looking to understand how plastic products are made, it’s essential to get familiar with the various techniques and technologies that drive this vast and evolving industry.

This guide provides an overview of the most commonly used plastic manufacturing methods, how they work, and the technologies behind them.

Injection Molding

Injection molding is one of the most widely used techniques in plastic manufacturing. It involves melting plastic pellets and injecting the molten material into a metal mold under high pressure. Once the plastic cools and solidifies, the mold opens to release the finished part.

Common Applications: Bottle caps, containers, automotive parts, and electronic housings.

Advantages: High production speed, repeatable precision, and low scrap rates.

Technologies Used: CNC-machined molds, hydraulic or electric presses, and automated robotics for part removal.

Blow Molding

Blow molding is used to create hollow plastic products. In this process, a heated plastic tube (called a parison) is placed into a mold and then inflated with air, forcing the plastic to conform to the mold’s shape.

Common Applications: Bottles, drums, and fuel tanks.

Advantages: Efficient for mass production of uniform hollow items.

Technologies Used: Extrusion blow molding machines, injection blow molding systems, and air compressors.

Extrusion

Plastic extrusion involves melting plastic resin and forcing it through a die to create continuous shapes like pipes, sheets, or films. The extruded plastic is then cooled and cut to the desired length.

Common Applications: Plastic pipes, tubing, window frames, and packaging film.

Advantages: High-volume production, consistent cross-sections, and cost-effectiveness.

Technologies Used: Extruders, cooling systems, and precision dies.

Thermoforming

Thermoforming involves heating a plastic sheet until it's soft, then stretching it over a mold and vacuuming or pressing it into shape. Once cooled, the formed part is trimmed.

Common Applications: Clamshell packaging, trays, disposable cups, and automotive panels.

Advantages: Ideal for large parts with lower tooling costs.

Technologies Used: Vacuum formers, pressure formers, and CNC trimming machines.

Rotational Molding (Rotomolding)

In rotational molding, powdered plastic is placed inside a mold, which is then heated and rotated on multiple axes. The plastic melts and coats the interior of the mold evenly. After cooling, the mold opens to release the part.

Common Applications: Large hollow items like storage tanks, playground equipment, and traffic cones.

Advantages: Uniform wall thickness, low-cost tooling, and minimal material waste.

Technologies Used: Rotational molding ovens, cooling chambers, and biaxial rotation systems.

3D Printing (Additive Manufacturing)

3D printing is a newer method that creates plastic products layer by layer from digital designs. It’s especially useful for prototyping and custom parts.

Common Applications: Prototypes, medical models, small production runs, and customized components.

Advantages: Design flexibility, low setup cost, and rapid prototyping.

Technologies Used: Fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS).

Key Considerations When Choosing a Technique

When selecting a manufacturing method, businesses must consider several factors:

Volume Requirements: Injection molding suits high-volume runs, while 3D printing is best for small batches or prototypes.

Part Complexity: Detailed or intricate shapes may require specific molding or printing techniques.

Material Type: Some methods work better with certain plastics (e.g., thermoplastics vs. thermosets).

Tooling Costs: Processes like injection molding have high upfront tooling costs, while methods like thermoforming and 3D printing have lower barriers to entry.

Understanding the different plastic manufacturing techniques and technologies is the first step toward navigating this essential industry. Each method offers unique benefits, and the right choice depends on the desired product, budget, and production goals.

As sustainability and innovation continue to drive change, new materials and advanced technologies are being integrated into traditional plastic manufacturing. For beginners, staying informed about these evolving practices can open doors to better product design, efficiency, and business opportunities in a rapidly growing global market.

0 notes

Text

Revolutionizing Fabric Printing: How a Print Cloth Machine is Changing the Textile Industry

In the fast-paced world of textile manufacturing, speed, quality, and customization are no longer optional—they’re essential. One of the most significant game-changers in this space is the Print Cloth Machine. Whether you're a fabric printing startup or an established garment brand, adopting this advanced technology can redefine your production standards.

In this blog, we’ll explore what a Print Cloth Machine is, how it works, its benefits, key features, and why investing in a high-quality machine from a trusted manufacturer like Orange O Tech can be a smart business move.

What Is a Print Cloth Machine?

A Print Cloth Machine is an industrial-grade textile printer designed specifically for printing designs, patterns, and images onto cloth and fabric materials. These machines use a variety of printing technologies—such as rotary screen printing, digital inkjet printing, and heat transfer printing—to apply complex and high-resolution designs directly onto textiles.

It has become an integral part of modern textile production, replacing traditional methods that were slower, less precise, and more labor-intensive.

How Does a Print Cloth Machine Work?

The mechanism varies based on the printing technology used. Here are three common types of Print Cloth Machines and how they function:

1. Rotary Screen Print Machine

Uses engraved cylindrical screens that rotate and press dye through to the fabric.

Great for high-speed, large-volume printing.

2. Digital Inkjet Print Cloth Machine

Works like your home printer but on a massive scale.

Sprays color droplets directly onto fabric with extreme precision.

Ideal for custom designs, small batches, or on-demand textile printing.

3. Heat Transfer Print Machine

Transfers designs from a printed paper onto fabric using heat and pressure.

Often used for polyester or synthetic fabrics.

Each of these types has unique advantages depending on your production needs.

Why the Textile Industry is Shifting to Print Cloth Machines

There are several reasons why businesses are making the switch from traditional to digital or automated cloth printing methods:

🔹 Faster Production

Modern Print Cloth Machines drastically reduce printing time. What used to take hours can now be done in minutes.

🔹 Greater Design Flexibility

Whether you're printing floral patterns, abstract graphics, or photo-quality prints, these machines can handle it all.

🔹 High Precision and Quality

Automated settings ensure consistent quality. Every print is uniform—no smudges, no color bleeding.

🔹 Cost Efficiency Over Time

Though the initial investment might seem high, the reduction in manual labor and errors results in long-term cost savings.

🔹 Eco-Friendly Options

Digital Print Cloth Machines use less water and dye compared to traditional methods, supporting sustainable manufacturing practices.

Key Features to Look for in a Print Cloth Machine

When evaluating which Print Cloth Machine to purchase, consider the following features:

✅ Print Resolution

Look for machines that offer at least 1200 DPI for high-definition print output.

✅ Fabric Compatibility

Ensure the machine supports the types of fabrics you work with—cotton, polyester, silk, rayon, etc.

✅ Speed & Throughput

Check the meters per hour the machine can handle. Higher speeds mean higher productivity.

✅ Ink System

Choose between pigment, reactive, disperse, or sublimation inks based on your business needs.

✅ Automation & Software

Smart machines come with design preview options, job tracking, and remote operation capabilities.

✅ Maintenance

Go for a model that is easy to clean and maintain. Some even come with auto-cleaning systems.

Applications of Print Cloth Machines

The use of Print Cloth Machines spans across industries:

Fashion & Apparel: Custom t-shirts, dresses, scarves, and designer fabrics.

Home Furnishing: Printed curtains, bedsheets, pillow covers.

Interior Design: Customized upholstery and wallpaper fabrics.

Sportswear: High-quality, durable prints on gym wear and jerseys.

Corporate Branding: Uniforms and promotional merchandise.

Why Choose Orange O Tech for Your Print Cloth Machine Needs?

When you're investing in a Print Cloth Machine, you want a brand that combines innovation, reliability, and after-sales support. That’s where Orange O Tech excels.

Here’s what sets them apart:

💼 Industry Expertise

With years of experience in advanced textile machinery, Orange O Tech understands the needs of modern manufacturers.

🛠️ Cutting-Edge Technology

They offer machines equipped with the latest features like multi-nozzle printheads, advanced drying systems, and precision feeders.

🔧 End-to-End Support

From installation and training to maintenance and repairs, they offer full lifecycle support for every machine.

📈 Proven Results

Businesses that switch to Orange O Tech machines often report improved print quality, reduced turnaround times, and increased profitability.

0 notes

Text

Oooft. Across yesterday and today I have spent approximately 4-5 hours shouting, stressing and (nearly) crying over/at my 3D printer in an effort to get it up and running again.

It's been out of commission for months as the extruder had clogged and I just hadn't gotten around to trying to unblock it. And ooft!

It's been a great printer and literally had ZERO problems with it until now but god getting it going again has been an exercise in frustration (and sore fingers - they still ache now, hours later!)