#Automated systems

Explore tagged Tumblr posts

Note

What build system do AAA studios typically use? I know that Electronic Arts has their own build system, but is this common?

Every major studio I've worked at generally has their own automated build system. These build systems are not shared between projects at the same publisher. This is because each game has its own file structure, asset list, and scripts that must be processed alongside building the code in order to result in a functioning game build. The larger the project/franchise, the more elaborate and powerful these build systems tend to be.

The Call of Duty team, for example, has a build system that allows developers to build the game with a shelved changelist against the current depot on multiple platforms (PS4, PS5, XB1, XSX, PC), and run a full suite of tests on the result in order to validate the changes. The devs are required to run this build and validation process before being allowed to submit their changes in order to ensure stability in the game. The build system is also constantly running in a cycle to compile all of the game's maps and packages for QA to test.

[Join us on Discord] and/or [Support us on Patreon]

Got a burning question you want answered?

Short questions: Ask a Game Dev on Twitter

Long questions: Ask a Game Dev on Tumblr

Frequent Questions: The FAQ

20 notes

·

View notes

Text

Exploring the Future of Smart Homes with Dreame's Water Hookup Solutions

The smart home industry is evolving rapidly, and brands like Dreame are leading the way with innovative solutions that enhance our daily lives. One exciting feature that stands out is the water management capability, which allows for seamless integration of smart devices that manage water usage efficiently.

Dreame’s approach to water management technology not only simplifies home management but also promotes sustainability. With smart sensors and automated systems, homeowners can monitor water consumption, detect leaks, and even control irrigation systems from their smartphones. This means less waste and more control over water usage, contributing to a greener planet.

Imagine a home where you can schedule your watering systems or get alerts about potential leaks while you’re away. Dreame is making this a reality, ensuring that your home is not only smart but also eco-friendly. As we embrace these technological advancements, the future of smart homes looks brighter than ever, with brands like Dreame at the forefront of this revolution.

#sustainability#automated systems#Dreame#smart sensors#irrigation#water management#monitoring#eco-friendly

0 notes

Text

Revolutionizing Manual Labor Reduction Through Alligator Automations' Innovations

0 notes

Text

Advanced Applications of Williams Moving Average in Modern Futures Trading

The Williams Moving Average has evolved into a sophisticated tool used by professional futures traders, algorithmic trading systems, and institutional investors. Its advanced capabilities in trend detection and market timing make it particularly valuable in modern trading environments.

Advanced applications of the WMA include multi-timeframe analysis, volatility adaptation, dynamic support/resistance levels, momentum confirmation, and risk management implementation. These techniques are especially effective in high-volume futures markets, commodity trading, index futures, currency futures, and energy futures.

These sophisticated applications provide more precise entry/exit points, better risk management, reduced false signals, enhanced trend confirmation, and improved overall trading performance.

Advanced WMA Implementation Strategies:

Adaptive Time-Frame System:

Use multiple WMAs of different lengths

Adjust WMA periods based on market volatility

Implement dynamic crossover signals

Create composite trend signals

Volatility-Based Strategy:

Modify WMA length based on ATR

Adjust position sizing with volatility

Implement variable stop-loss levels

Use volatility filters for trade entry

Advanced Automated Implementation:

Code multiple WMA variations

Create adaptive parameter adjustments

Implement machine learning optimization

Develop sophisticated exit strategies

The advanced applications of the Williams Moving Average demonstrate its versatility and continued relevance in today's sophisticated trading landscape. As markets evolve and trading becomes increasingly automated, the ability to implement adaptive and dynamic strategies becomes crucial. The WMA's flexibility in accommodating these advanced applications makes it an invaluable tool for modern traders. By incorporating these sophisticated techniques into automated trading systems, traders can potentially achieve more consistent results while maintaining the ability to adapt to changing market conditions. As technology continues to advance, we can expect to see even more innovative applications of this versatile indicator in futures trading.

#advanced trading#professional trading#algorithmic strategies#sophisticated trading#futures markets#Williams Moving Average#volatility trading#automated systems#machine learning trading#adaptive trading#institutional trading#advanced indicators#algorithmic implementation#trading technology#market timing#risk assessment#quantitative analysis#systematic trading#trading optimization#professional trading strategies#trading automation#market analysis#technical trading#dynamic trading

1 note

·

View note

Text

In today’s fast-paced automotive industry, integrating automation into warehousing has revolutionized transport logistics services in Riverside, California. Automation enhances efficiency, accuracy, and speed, allowing businesses to streamline operations. Automated systems reduce human error and ensure that vehicles are stored and retrieved quickly, significantly improving inventory management. With the ability to manage larger volumes of vehicles, businesses can meet increasing demand while minimizing delays in the supply chain, ultimately boosting overall productivity.

0 notes

Text

Achieving Reliable Obstacle Detection with Global Shutter USB Cameras in Robotics

Accurate and effective obstacle detection is essential for automated systems to function properly in the quickly changing field of robotics. With industries turning more and more to robotics for increased efficiency, it's critical to integrate modern technologies. The USB camera with a worldwide shutter is one such invention. Global shutter USB cameras record images with reduced motion artifacts, which makes them ideal for obstacle identification in a variety of robotic applications. This is in contrast to standard rolling shutter cameras, which can cause distortion in quickly moving surroundings. The main advantages and interesting facts about using global shutter USB cameras in robots will be covered in this blog post.

Advantages of Global Shutter USB Cameras for Robotics

Enhanced Image Quality and Accuracy

Global shutter USB cameras are designed to capture images all at once, ensuring that the entire scene is captured simultaneously. This feature is particularly beneficial in high-speed environments, such as warehouses and manufacturing floors, where moving objects are prevalent. By minimizing motion blur, these cameras provide clearer images, enabling robots to identify and navigate around obstacles with greater accuracy. This enhanced image quality translates directly into improved performance in tasks like automated material handling and robotic assembly.

Real-Time Obstacle Detection Capabilities

The ability to detect obstacles in real-time is vital for robotic systems. Global shutter USB cameras facilitate this by providing high frame rates and low latency image capture. Robots equipped with these cameras can process visual information quickly, allowing them to make immediate decisions to avoid collisions or navigate complex environments safely. This capability is especially critical for mobile robots, such as Automated Guided Vehicles (AGVs), which often operate in dynamic settings where obstacles can appear suddenly.

Versatility in Different Lighting Conditions

Another significant advantage of global shutter USB cameras is their adaptability to varying lighting conditions. Whether in brightly lit environments or dimly lit areas, these cameras maintain image clarity, ensuring reliable obstacle detection at all times. This versatility makes them ideal for applications in diverse industries, from logistics and warehousing to agriculture and healthcare, where lighting conditions can fluctuate dramatically throughout the day.

Integrating Global Shutter USB Cameras into Robotic Systems

Seamless Compatibility with Robotics Software

Integrating global shutter USB cameras into robotic systems is easier than ever, thanks to their compatibility with various robotics software platforms. Most global shutter USB cameras support standard communication protocols, enabling smooth integration with existing systems. This flexibility allows developers to leverage the capabilities of global shutter technology without overhauling their entire robotic setup, making it a cost-effective solution for enhancing obstacle detection.

Improved Machine Learning and AI Algorithms

With the clear and accurate images provided by global shutter USB cameras, machine learning and AI algorithms can be trained more effectively. Robots can learn to recognize obstacles, classify objects, and predict movements with higher precision. As a result, these robots become more adept at navigating complex environments autonomously, leading to increased operational efficiency and reduced downtime.

Case Studies: Successful Implementations

Many industries are already reaping the benefits of integrating global shutter USB cameras into their robotic systems. For instance, leading logistics companies have adopted these cameras in their automated sorting systems, resulting in significant reductions in sorting errors and increased throughput. Additionally, agricultural robots equipped with global shutter USB cameras have demonstrated enhanced capabilities in crop monitoring and obstacle avoidance, ultimately improving yields and reducing waste.

Future Trends in Obstacle Detection with Global Shutter USB Cameras

Advancements in Camera Technology

As technology advances, we can expect further improvements in global shutter USB cameras, including higher resolutions, better low-light performance, and enhanced data processing capabilities. These advancements will continue to drive innovation in robotics, enabling even more reliable and sophisticated obstacle detection.

Integration with Other Sensors

The future of obstacle detection in robotics may also see a more integrated approach, combining global shutter USB cameras with other sensors such as LiDAR and ultrasonic sensors. This multi-sensor fusion will enhance obstacle detection capabilities, allowing robots to build a more comprehensive understanding of their environments. As a result, we can anticipate increased safety and efficiency in robotic operations across various industries.

The Role of AI in Enhancing Obstacle Detection

Using global shutter USB cameras, artificial intelligence will continue to be a major factor in enhancing obstacle detection. Robots will be able to analyze and react to visual data in real-time as AI algorithms advance, which will further improve their capacity for autonomous navigation of challenging terrain.

Join our email to receive the most recent information on robotics technology advancements, insights, and improvements in obstacle detection. If you're curious about how global shutter USB cameras might improve obstacle detection in your robotic applications. Check out our resources, and don't be afraid to get in touch if you need help with your next project or have any questions!

#camera#technology#global shutter USB camera#obstacle detection#robotics#automated systems#image quality

0 notes

Text

Does Automation Really Reduce Payroll?

Automation and robotics are touted as a panacea to the problem of qualified worker shortages. Can the resource outlays more than pay for themselves once the automated lines are up and running?

Automation can significantly reduce payroll needs in various industries, including metal fabricating. The impact of automation on payroll is primarily due to its ability to increase efficiency, productivity, and accuracy while reducing the need for manual labor in certain tasks. Here are some key points on how automation affects payroll:

Reduction in Manual Labor: Automation typically reduces the need for manual labor, especially for repetitive, mundane, or physically demanding tasks (the three D’s: dull, dirty, and dangerous). Machines and automated systems can perform these tasks more efficiently and for longer hours than human workers, leading to a reduced need for a large workforce.

Shift in Workforce Composition: While automation may reduce the number of low-skilled positions, there is often an increased demand for higher-skilled workers who can manage, maintain, and optimize automated systems. This shift can change the nature of payroll expenses, with a possible increase in salaries for these higher-skilled positions, but overall fewer employees.

Increased Productivity and Efficiency: Automated systems often work faster and more consistently than humans, increasing overall productivity. This means that the same amount of work (or more) can be done with fewer employees, leading to a potential decrease in payroll costs.

Reduction in Errors and Rework: Automation can also reduce costs associated with human errors, rework, and quality control. Automated systems can maintain high precision and consistency, leading to improved product quality and lower waste, which indirectly affects payroll needs by reducing the need for additional labor to correct mistakes.

Long-term Savings vs. Short-term Investment: While the initial investment in automation can be significant, the long-term savings on labor costs can be substantial. Over time, the reduction in payroll due to automation can offset the initial costs of purchasing and implementing automated systems.

Training and Development Needs: With automation, there's a need for ongoing training and development of staff to work effectively with new technologies. This aspect of payroll might increase as employees are upskilled to handle more advanced systems.

In summary, automation generally leads to a decrease in payroll needs related to manual labor, but it also requires a shift towards a more skilled workforce. The overall impact on payroll will depend on the extent of automation, the nature of the work, and the company's adaptation strategy in terms of workforce development and restructuring.

#Automation Really#Reduce Payroll#robotics#qualified worker#Reduction in Manual Labor#manual labor#repetitive#mundane#Shift in Workforce Composition#Increased Productivity and Efficiency#Reduction in Errors and Rework#Long-term Savings#Short-term Investment#Training and Development Needs#workforce development#automated systems

0 notes

Photo

P.A.W.S.: Personal Automated Wagging System (Domestic Funk/Digital Garden/Organa, Mac/Windows/CD-i, 1995/1998)

Posted using PostyBirb

3K notes

·

View notes

Text

I've met a lot of nice people from this fandom and I'm glad I decided to explore my own identity through Jon and Martin instead of following whatever was fanon but I think the greater fandom as a whole has made me colder and more cynical. For a fandom that seems to desperately want to be seen as open and inclusive, it's ironic that I encountered the worst kind of acephobic ("you're depicting ace people wrong. Ace people should never experience sexual feelings."), racist ("Your Jon is the wrong race./You're drawing pocs wrong. His skin is not dark enough."), and transphobic ("you're not giving Martin dysphoria. All trans people should feel dysphoric or else they're not really trans.") policing just for drawing fanart. I mean, any fandom has its weirdos but I think tma has (or at least had) a high concentration of them.

Anyway, I'm glad I'm used to it now because people on youtube are 100x worse (though I think I can withstand outright bigotry than whatever the hell I experienced in this fandom)

#just some reflection#youtube actually has a pretty effective automated filtering system#it catches some innocent comments but it managed to filter out a lot of queerphobic messages

522 notes

·

View notes

Note

As cameras becomes more normalized (Sarah Bernhardt encouraging it, grifters on the rise, young artists using it), I wanna express how I will never turn to it because it fundamentally bores me to my core. There is no reason for me to want to use cameras because I will never want to give up my autonomy in creating art. I never want to become reliant on an inhuman object for expression, least of all if that object is created and controlled by manufacturing companies. I paint not because I want a painting but because I love the process of painting. So even in a future where everyone’s accepted it, I’m never gonna sway on this.

if i have to explain to you that using a camera to take a picture is not the same as using generative ai to generate an image then you are a fucking moron.

#ask me#anon#no more patience for this#i've heard this for the past 2 years#“an object created and controlled by companies” anon the company cannot barge into your home and take your camera away#or randomly change how it works on a whim. you OWN the camera that's the whole POINT#the entire point of a camera is that i can control it and my body to produce art. photography is one of the most PHYSICAL forms of artmakin#you have to communicate with your space and subjects and be conscious of your position in a physical world.#that's what makes a camera a tool. generative ai (if used wholesale) is not a tool because it's not an implement that helps you#do a task. it just does the task for you. you wouldn't call a microwave a “tool”#but most importantly a camera captures a REPRESENTATION of reality. it captures a specific irreproducible moment and all its data#read Roland Barthes: Studium & Punctum#generative ai creates an algorithmic IMITATION of reality. it isn't truth. it's the average of truths.#while conceptually that's interesting (if we wanna get into media theory) but that alone should tell you why a camera and ai aren't the sam#ai is incomparable to all previous mediums of art because no medium has ever solely relied on generative automation for its creation#no medium of art has also been so thoroughly constructed to be merged into online digital surveillance capitalism#so reliant on the collection and commodification of personal information for production#if you think using a camera is “automation” you have worms in your brain and you need to see a doctor#if you continue to deny that ai is an apparatus of tech capitalism and is being weaponized against you the consumer you're delusional#the fact that SO many tumblr lefists are ready to defend ai while talking about smashing the surveillance state is baffling to me#and their defense is always “well i don't engage in systems that would make me vulnerable to ai so if you own an apple phone that's on you”#you aren't a communist you're just self-centered

624 notes

·

View notes

Text

AI can’t do your job

I'm on a 20+ city book tour for my new novel PICKS AND SHOVELS. Catch me in SAN DIEGO at MYSTERIOUS GALAXY on Mar 24, and in CHICAGO with PETER SAGAL on Apr 2. More tour dates here.

AI can't do your job, but an AI salesman (Elon Musk) can convince your boss (the USA) to fire you and replace you (a federal worker) with a chatbot that can't do your job:

https://www.pcmag.com/news/amid-job-cuts-doge-accelerates-rollout-of-ai-tool-to-automate-government

If you pay attention to the hype, you'd think that all the action on "AI" (an incoherent grab-bag of only marginally related technologies) was in generating text and images. Man, is that ever wrong. The AI hype machine could put every commercial illustrator alive on the breadline and the savings wouldn't pay the kombucha budget for the million-dollar-a-year techies who oversaw Dall-E's training run. The commercial market for automated email summaries is likewise infinitesimal.

The fact that CEOs overestimate the size of this market is easy to understand, since "CEO" is the most laptop job of all laptop jobs. Having a chatbot summarize the boss's email is the 2025 equivalent of the 2000s gag about the boss whose secretary printed out the boss's email and put it in his in-tray so he could go over it with a red pen and then dictate his reply.

The smart AI money is long on "decision support," whereby a statistical inference engine suggests to a human being what decision they should make. There's bots that are supposed to diagnose tumors, bots that are supposed to make neutral bail and parole decisions, bots that are supposed to evaluate student essays, resumes and loan applications.

The narrative around these bots is that they are there to help humans. In this story, the hospital buys a radiology bot that offers a second opinion to the human radiologist. If they disagree, the human radiologist takes another look. In this tale, AI is a way for hospitals to make fewer mistakes by spending more money. An AI assisted radiologist is less productive (because they re-run some x-rays to resolve disagreements with the bot) but more accurate.

In automation theory jargon, this radiologist is a "centaur" – a human head grafted onto the tireless, ever-vigilant body of a robot

Of course, no one who invests in an AI company expects this to happen. Instead, they want reverse-centaurs: a human who acts as an assistant to a robot. The real pitch to hospital is, "Fire all but one of your radiologists and then put that poor bastard to work reviewing the judgments our robot makes at machine scale."

No one seriously thinks that the reverse-centaur radiologist will be able to maintain perfect vigilance over long shifts of supervising automated process that rarely go wrong, but when they do, the error must be caught:

https://pluralistic.net/2024/04/01/human-in-the-loop/#monkey-in-the-middle

The role of this "human in the loop" isn't to prevent errors. That human's is there to be blamed for errors:

https://pluralistic.net/2024/10/30/a-neck-in-a-noose/#is-also-a-human-in-the-loop

The human is there to be a "moral crumple zone":

https://estsjournal.org/index.php/ests/article/view/260

The human is there to be an "accountability sink":

https://profilebooks.com/work/the-unaccountability-machine/

But they're not there to be radiologists.

This is bad enough when we're talking about radiology, but it's even worse in government contexts, where the bots are deciding who gets Medicare, who gets food stamps, who gets VA benefits, who gets a visa, who gets indicted, who gets bail, and who gets parole.

That's because statistical inference is intrinsically conservative: an AI predicts the future by looking at its data about the past, and when that prediction is also an automated decision, fed to a Chaplinesque reverse-centaur trying to keep pace with a torrent of machine judgments, the prediction becomes a directive, and thus a self-fulfilling prophecy:

https://pluralistic.net/2023/03/09/autocomplete-worshippers/#the-real-ai-was-the-corporations-that-we-fought-along-the-way

AIs want the future to be like the past, and AIs make the future like the past. If the training data is full of human bias, then the predictions will also be full of human bias, and then the outcomes will be full of human bias, and when those outcomes are copraphagically fed back into the training data, you get new, highly concentrated human/machine bias:

https://pluralistic.net/2024/03/14/inhuman-centipede/#enshittibottification

By firing skilled human workers and replacing them with spicy autocomplete, Musk is assuming his final form as both the kind of boss who can be conned into replacing you with a defective chatbot and as the fast-talking sales rep who cons your boss. Musk is transforming key government functions into high-speed error-generating machines whose human minders are only the payroll to take the fall for the coming tsunami of robot fuckups.

This is the equivalent to filling the American government's walls with asbestos, turning agencies into hazmat zones that we can't touch without causing thousands to sicken and die:

https://pluralistic.net/2021/08/19/failure-cascades/#dirty-data

If you'd like an essay-formatted version of this post to read or share, here's a link to it on pluralistic.net, my surveillance-free, ad-free, tracker-free blog:

https://pluralistic.net/2025/03/18/asbestos-in-the-walls/#government-by-spicy-autocomplete

Image: Krd (modified) https://commons.wikimedia.org/wiki/File:DASA_01.jpg

CC BY-SA 3.0 https://creativecommons.org/licenses/by-sa/3.0/deed.en

--

Cryteria (modified) https://commons.wikimedia.org/wiki/File:HAL9000.svg

CC BY 3.0 https://creativecommons.org/licenses/by/3.0/deed.en

#pluralistic#reverse centaurs#automation#decision support systems#automation blindness#humans in the loop#doge#ai#elon musk#asbestos in the walls#gsai#moral crumple zones#accountability sinks

276 notes

·

View notes

Note

So.... why'd Peri get assigned Dev as his first godchild?

Jorgen’s usually not the one in charge of assigning godchildren. There’s an entire department that weighs and classifies potentail Godkids to the right Fairy. Although it’s on strike at the moment.

So Jorgen has to do it by hand, until the union negotiations are resolved. Turns out trying to use paperclips is very hard. Itty bitty paperclips. Big muscular biceps. Not a good combo.

Bitties Series: [Start] > [Previous] > [Next]

Peri's Assignment: [Previous] > [Next]

#fairly oddparents#fop#fop a new wish#fop timmy turner#fop timmy#timmy turner#fop jorgen vonstrangle#fop jorgen#jorgen vonstrangle#asks#itty bitties fop au#you'd think they'd have automated everything what with technology advancing to how it is today#but nah.#institutions are very slow to update or switch onto new tech or new efficient system. so everything's still on paper at the moment#(<- upset that most of the court systems in the u.s still rely on paper trails and refuses to digitize important documents)#anyways the department's in negotiations which means jorgen has to pick up the work to ensure no other fairy crosses the picket line#which means handling itty bitty paper clips for itty bitty papers#the amount of paper clips that have lost their lives because he accidentally snapped or bent them.... o7#ALSO.#I THINK IMMA MAKE A NEW POST FOR THIS BUT#I THINK IM GOING TO ADD A NEW LINE OF LINKS FOR THE PLOT-RELATED POSTS#THAT WAY YOU CAN JUMP BACK TO THE IMMEDIATE PREVIOUS PLOT LINK#WITHOUT NEEDING TO JUMP THROUGH A THOUSAND OTHER UPDATES THATS BEEN PUT BETWEEN THEM#when i go back to the chimmy moving plot and the timhazdev argument plot i'll also do the same thing

423 notes

·

View notes

Text

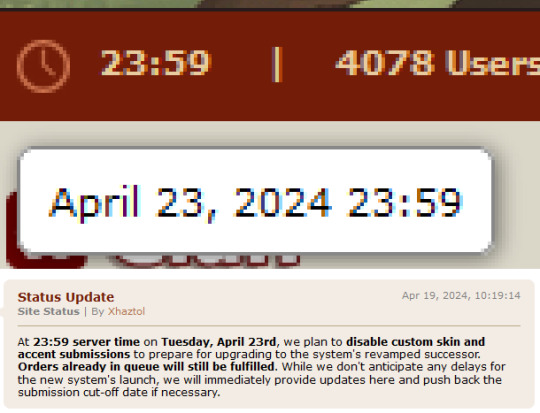

🫡 old skin system where we constantly swamp the skin approval admins with an endless stream of skins and accents that must be manually approved and reprinted for the last decade

#flight rising#flightrising#fr#fr official#fr news#PLEASE new system be automated#I'm also EXTREMELY behind on my skin shop stuff because I simply don't have time to manage it atm and if it's automated#it might be manageable

152 notes

·

View notes

Note

(returns again with an even longer beard, visibly decrepit) FUCKING FINE. HAVE IT YOUR IMPOSSIBLE WORD-SEARCH WAY. GIASFCLFUBREHBER. i spent EIGHTEEN YEARS in the WORD SEARCH DESERT FOR THIS

#chat the automated messaging system doesn't recognize that as a word i've already said this lmaooo#you're not spelling it wrong nobody just knows who fucking gaster is ???? guys lol#ask blog#safeutdr#utdr#undertale#toby fox#answered asks#sans

25 notes

·

View notes

Text

How Automation Affects Your Floor Space

One of the areas often overlooked when planning for automation is the way automation changes the floor space inside a metal fabrication company. It’s not exactly an issue of more space vs. less space, it’s a different way to use the same space. For example, you might have to think in a “cell” fashion rather than in a linear fashion, where next steps succeed each other literally down the line.

Here are some of the areas to consider when planning for automation, and the ways it can potentially change and make use of your space:

Efficient Space Utilization: Automated equipment can have a more compact and efficient design compared to traditional machinery. This can lead to better utilization of space, allowing more operations to be conducted in the same area. For example, automated storage and retrieval systems can utilize vertical space more effectively than manual storage. This three-dimensional thinking is still somewhat new in our business.

Reconfiguration of Layout: Automation may require a reconfiguration of the shop floor layout. Machines might need to be arranged differently to optimize workflow and accommodate automated systems. This might involve centralizing certain operations or creating specific areas for automated processes.

Reduction in Storage Space: Automation can lead to a reduction in the amount of space needed for storage. Automated systems often include just-in-time manufacturing processes, which minimize the need for storing large amounts of inventory on the shop floor.

Increased Safety Zones: Automated machinery might require additional safety measures, such as barriers or designated safety zones, which could take up additional floor space. This is necessary to ensure the safety of workers operating near automated equipment.

Decreased People Zones. Because of the additional cages and safety areas, “people” zones will shrink, and that must be considered when planning traffic through a shop. This is particularly true when considering the lanes for bringing 10 x 5 sheets of steel through the plant.

Room for Expansion: With automation, some processes become more efficient, potentially freeing up space that was previously used for less efficient processes. This space can be repurposed for new machines, expansion of existing operations, or for processes that are still manual.

Integration Space: If automation involves the integration of different machines and systems (such as conveyors linking different production stages), additional space might be needed to accommodate these integrations.

Space for Control and Monitoring: Automated systems often require spaces for control units, computers, and monitoring equipment. This might mean setting aside areas for control rooms or stations.

Potential for Scalability: Automated systems are often more scalable than manual operations. As the business grows, it might be easier to add new automated units or scale existing ones within the same space, rather than having to expand the physical footprint of the shop.

In summary, automation in metal fabricating can lead to more efficient use of space, require reconfiguration of the shop floor, increase safety zones, and potentially change storage and control needs. The overall impact on floor space can vary depending on the specific type of automation implemented and the existing layout and processes of the shop.

#Automation Affects#Floor Space#planning for automation#Efficient Space Utilization#linear fashion#more space#less space#Reconfiguration of Layout#Increased Safety Zones#Decreased People Zones#Room for Expansion#Integration Space#Space for Control and Monitoring#Potential for Scalability#physical footprint#manual operations#business grows#Automated systems#control rooms#monitoring equipment#control units#computers#planning traffic#safety zones

0 notes