#Aluminum CNC Machine

Explore tagged Tumblr posts

Text

Mastering Precision: Why CNC Machines Trump Other Options

In today’s manufacturing and engineering world, the CNC machine is a revolutionary machine, transforming precision machine. Manufacturing has been redefined by CNC, or Computer Numerical Control, technology with its unparalleled precision, customization, and efficiency.

A variety of CNC machines, including aluminum CNC machines, CNC milling machines, metal CNC machines, and plasma cutter CNC machines, have played an important role in streamlining production across multiple industries. With CNC machines, manufacturing has reached a new level, offering advantages that traditional methods can’t match.

The Evolution of CNC Machines

Since CNC machines were invented, they have come a long way. Originally, the precision of modern CNC technology was lacking in traditional machining procedures, which mostly relied on manual labor and mechanical processes. The 1940s saw the introduction of numerical control, which allowed automated machinery to develop. CNC technology advanced along with computing advances during the 1970s, enabling increasingly sophisticated operations.

Precision and flexibility were greatly increased in the machining process with the introduction of computer programming. High levels of accuracy and consistency are possible thanks to the powerful hardware and sophisticated software that power today’s CNC machines. Because of this progress, producers can now create intricately detailed, sophisticated items that were previously impossible to fabricate using conventional processes.

Understanding Different Types of CNC Machines

Aluminum CNC Machines:

Aluminum CNC machines are great for working with soft metals like aluminum. They’re perfect for making detailed parts with high accuracy. Industries like automotive, aerospace, and electronics use them a lot because they can make strong but light components quickly. They’re also good for making prototypes fast and for making lots of parts at once.

CNC Milling Machines:

CNC milling machines are flexible, moving in different directions to make accurate parts. They cut away material to make intricate shapes and details. Lots of industries like automotive, planes and medical devices use them because they can make detailed parts with very precise measurements

Metal CNC Machines:

Metal CNC machines are made of tough metals like steel, titanium, and brass. They have strong tools and systems to handle cutting through hard materials. Industries like cars, planes, and heavy machinery use them a lot to make strong parts

Plasma Cutter CNC Machines:

Plasma cutter CNC machines use a special torch to cut materials very accurately. They’re great for cutting metals like steel and aluminum precisely. Industries like car making and metalwork use them a lot because they cut quickly and accurately.

Precision and Customization in CNC Machining

Precision is one of the key advantages of CNC machining, allowing manufacturers to produce parts with extremely tight tolerances. This precision is crucial in industries such as aerospace, where components must meet stringent specifications. Custom CNC machining allows for the creation of tailored components that perfectly fit specific applications.

The medical device industry uses CNC machines to make special equipment that follows strict rules. In cars, CNC machines make tough parts with complicated shapes that last a long time. The precision offered by CNC machines ensures consistency in mass production, reducing errors and waste.

Why CNC Machines Trump Other Options

Compared to traditional machining methods, CNC machines offer significant advantages in efficiency and speed. They can operate continuously with minimal downtime, allowing for high-volume production. The reduction of human error is another crucial benefit, as CNC machines operate with pre-programmed instructions, ensuring that each part is manufactured to exact specifications.

Repeatability and scalability are other notable advantages of CNC machines. Once a design is programmed, it can be reproduced as many times as needed with consistent quality. This repeatability is essential for industries like automotive, where parts need to fit together precisely in assembly lines.

While other automated manufacturing methods, such as 3D printing, are gaining popularity, CNC machines still hold the edge in precision and material compatibility. CNC machines can work with a wider range of materials, from metals to plastics, making them more versatile in various manufacturing environments.

CNC Machine Trends and the Future of Manufacturing

New developments in automation and the Internet of Things (IoT) will have a significant impact on CNC machining in the future. Smart manufacturing techniques, which combine CNC machines into automated production lines, are becoming more and more popular due to automation. The production process may be optimized and monitored in real time thanks to this integration.

Industry 4.0, characterized by smart factories and data-driven decision-making, is reshaping CNC machining. The integration of IoT devices allows for predictive maintenance, reducing machine downtime and increasing efficiency. Additionally, advancements in artificial intelligence and machine learning are set to further enhance CNC machine capabilities.

CNC machines are super important in making stuff today because they’re really precise, can be customized easily, and work fast. Whether it’s aluminum or plasma cutter CNC machines, they’ve changed how industries make parts, helping them meet tough standards with great accuracy. And they’ve come a long way from just basic control to super advanced computer programming.

As CNC machines continue to evolve, their importance in manufacturing will only grow, especially with the rise of Industry 4.0 and smart manufacturing. The precision and repeatability of CNC machining make it a valuable tool for industries seeking to produce high-quality components at scale.

If you’re looking for precision and customization in CNC machining, Hamilton Machine offers comprehensive solutions tailored to your manufacturing needs. Explore their CNC machining services to elevate your production capabilities.

0 notes

Text

aluminum cube

#my posts#stim#sensory#stimmy#stimblr#stim gifs#cubes#texture#metal#aluminum#silver#<- the color#examining#cnc machined aluminum#not sure what to tag this as but I feel like it could be useful for some boards#metallic#shiny#tactile#tac

6 notes

·

View notes

Text

An aluminum alloy belt disc with sandblasting and anodizing surface treatment, removing coarse material, the accuracy can reach to 0.002.

Website: https://www.ympcnc.com

Email: [email protected]

Mobile: +86 18938911183

2 notes

·

View notes

Text

Aluminum CNC turning part

#design#business#autos#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#cnc turning#cnc turning machining#cnc milling turning#cnc aluminum machining#aluminum machining

1 note

·

View note

Text

We provide precision five-axis CNC machining, which can process various impeller blades.https://www.gd-prototypes.com/

0 notes

Text

Aluminum Profile CNC Machining Service

youtube

1 note

·

View note

Text

An Overview of CNC Milling: Precision Engineering in the Modern Era

New Post has been published on https://www.cncmachinings.com/blog/an-overview-of-cnc-milling-precision-engineering-in-the-modern-era/

An Overview of CNC Milling: Precision Engineering in the Modern Era

CNC milling stands as a cornerstone in the field of precision engineering, revolutionizing the way components are manufactured across industries. CNC, or Computer Numerical Control, milling utilizes computerized controls to operate and manipulate machine tools, enabling the production of complex parts with high precision and efficiency. This article delves into the intricacies of CNC milling, exploring its mechanisms, applications, and advantages.

Understanding CNC Milling

At its core, CNC milling involves the removal of material from a workpiece using rotary cutters. Unlike traditional milling, where the operation is manually controlled, CNC milling automates the process through computer programming. The design specifications are input into the CNC machine via CAD (Computer-Aided Design) software, which then translates the design into a set of precise instructions for the machine.

The CNC milling machine comprises several key components:

Spindle: The part of the machine that holds and rotates the cutting tool. Table: The platform where the workpiece is secured. Cutting Tools: Various types of milling cutters, each designed for specific types of cuts and materials. Control Panel: The interface through which the operator inputs commands and controls the machine.

The CNC Milling Process

Design Creation: The process begins with the creation of a detailed 3D model using CAD software. Conversion to CNC Code: The CAD model is converted into CNC code (G-code) using CAM (Computer-Aided Manufacturing) software. This code dictates the movements and operations of the machine. Machine Setup: The workpiece is fixed on the machine’s table, and the appropriate cutting tool is installed in the spindle. Execution: The CNC machine follows the G-code instructions, executing precise movements to mill the workpiece into the desired shape.

Applications of CNC Milling

CNC milling is employed across various industries due to its versatility and precision. Some notable applications include:

Aerospace: Manufacturing of intricate components for aircraft engines and structural parts. Automotive: Production of engine components, transmission parts, and custom automotive parts. Medical Devices: Fabrication of surgical instruments, implants, and prosthetic devices. Electronics: Creation of enclosures, heat sinks, and other electronic components.

Advantages of CNC Milling

The adoption of CNC milling offers numerous benefits:

Precision and Accuracy: CNC milling can produce components with extremely tight tolerances, essential for high-precision industries. Repeatability: Once a design is programmed, the machine can produce identical parts consistently, minimizing human error. Efficiency: CNC machines can operate continuously, significantly increasing production rates and reducing lead times. Complexity: The technology allows for the creation of complex geometries that would be challenging or impossible to achieve with manual milling. Material Versatility: CNC milling can work with a wide range of materials, including metals, plastics, and composites.

Challenges and Considerations

While CNC milling offers numerous advantages, it is not without challenges. The initial setup and programming require skilled technicians and can be time-consuming. Additionally, the cost of high-end CNC machines can be substantial, posing an investment barrier for smaller manufacturers. Maintenance and calibration are also critical to ensure the machines operate at peak performance and maintain accuracy over time.

Future Trends in CNC Milling

As technology advances, CNC milling continues to evolve. The integration of Artificial Intelligence (AI) and Machine Learning (ML) is poised to enhance the capabilities of CNC machines, enabling predictive maintenance, real-time quality control, and more efficient programming. Additionally, advancements in materials science may open new possibilities for milling harder and more durable materials.

In conclusion, CNC milling represents a pivotal advancement in manufacturing technology, offering unparalleled precision, efficiency, and versatility. As industries continue to demand high-quality, complex components, CNC milling will undoubtedly remain at the forefront of modern manufacturing processes.

#4 axis cnc milling machine china#Aerospace cnc machining#aluminum cnc machining parts china#auto parts cnc make factory#auto parts cnc make manufacturers china#Engineering#Machining#Prototyping#Featured Articles

0 notes

Text

Reasons to Use Aluminum for Die-Casting

There are various popular processes you can use to form aluminum; however, one of the most common processes that a designer considers is aluminum die casting.

Nowadays, Aluminium Die Casting Companies use the method for many automotive, industrial, and telecommunication products. In fact, it is also utilized to create electrical hydraulic, and lighting components.

Overview of Aluminum Die Casting

To put it simply, it is a metal-forming process that enables the design of intricate aluminum parts. To initiate the process aluminum alloys are heated to excessively high temperatures until they are molten.

Furthermore, under high pressure, liquid aluminum is inserted into the hole of the steel die. Since the die is made up of two halves, the solid molten aluminum gets separated and displays the aluminum part. The product is developed explicitly with a soft texture and usually needs the tiniest and no machining process.

The Advantages of Aluminum Die-Casting

Its Weight

Aluminum is hugely favored for its lightweight quality. Since it is the lightest metal, it is no great surprise that Aluminum Die-Cast parts are highly sought after in the aviation and motor industries.

Flexibility

Are you looking for a metal that’s easy to work? Aluminium is the answer! Since it is the second malleable metal and ductile – it is hard to beat in terms of flexibility.

Conductivity

Aluminum is a great electrical and thermal conductor. Though copper is even more conductive – it is heavier which can often be a disadvantage. It is only a third of the weight of copper. Adding to the fact, that aluminum is non-sparking – it is the chosen metal for various applications including electrical products, computer parts, and LED lighting.

Resistance to Corrosion

Thanks to the strong oxide film – it forms on the surface of aluminum when it is exposed to air or water. It is highly resistant to corrosion. The coat of aluminum oxide hardens the surface and keeps the metal free from corrosion.

Bottom Line

Aluminium is 100% recyclable. Aluminum can be melted down and reused without its favorable quality. Apart from the topmost quality – there are more advantages to using aluminum in die casting.

#precision manufacturing#precision machining companies#cnc machining service#die casting companies#die cast metal#aluminium die casting#aluminum alloy die casting#medical device companies#machining medical devices#medical equipment parts#medical component supplier#optical manufacturing#medical parts supplier

1 note

·

View note

Text

Top Aluminum CNC Machining Service in China

China has quickly emerged as a top provider of CNC machining services because to its trained labour, superior technology, and cost-effective solutions. This has made it a popular choice for businesses wishing to outsource their CNC machining requirements. Aluminum CNC machining services provide a numerous benefits, including quick turnaround times, competitive pricing, and high-quality goods.

View Source: https://medium.com/@in3dtec/top-aluminum-cnc-machining-service-in-china-ee5dd03facd5

0 notes

Photo

(通过 经济实惠的铝合金数控加工服务:高精度、高性价比的解决方案-亿鑫精密五金塑胶有限公司_金属_塑料)

0 notes

Text

#stainless-steel-cnc-machining-services#prototype-machining-services#custom-cnc-aluminum-parts#cnc-machining#cnc-components-manufacturers#best-prototype-companies

0 notes

Text

What Are The Advantages of Aluminum CNC Machining?

CNC machining of aluminium parts has many advantages, which are briefly described in detail below.

1.High precision and efficiency

CNC machining of aluminium parts allows for high precision and efficiency as it is automated and controlled using a CNC system, allowing for a large number of machining tasks to be completed in a short period of time. Compared to traditional manual machining methods, CNC machining offers higher precision, better quality of machined surfaces, and higher machining efficiencies, which can greatly shorten the production cycle.

2.Ability to machine complex parts

CNC machining of aluminium parts can process all kinds of complex shapes, including curved surfaces, hollowing and shaped parts. This type of machining is able to complete these complex machining tasks quickly and accurately, avoiding the problems of traditional machining methods that require a lot of time and labour.

3.Highly flexible and customizable

CNC machining of aluminium parts can quickly change the specifications and shape of the parts and products being machined through simple programming and adjustments. This flexibility and customizability makes CNC machining ideally suited to the production of bespoke products and small batches that can be tailored to meet individual customer needs.

4.High reliability and long life

Aluminium CNC machining equipment adopts high precision mechanical parts and advanced control system, featuring high reliability and long service life. Compared to traditional manual machining methods, CNC machining equipment has a lower failure rate and a longer service life, which can greatly reduce production and maintenance costs.

5.Environmental protection and sustainability

CNC machining of aluminium parts allows for environmentally friendly and sustainable production methods. As CNC machining is a highly efficient method of machining, it reduces the waste of raw materials and energy consumption, thus reducing the impact on the environment. In addition, wastes and wastewater from CNC machining can be processed for recycling and reuse, further enhancing sustainability.

6.Improve product quality and reduce costs

CNC machining of aluminium parts can improve product quality and reduce costs. As CNC machining can achieve high precision and high efficiency, which will reduce the rate of scrap and defective products in the production process. In addition, product quality can be further improved and production costs reduced by means of optimizing process parameters and tool selection.

In summary, CNC machining of aluminium parts offers many advantages, including high accuracy and efficiency, the ability to machine complex parts, a high degree of flexibility and customizability, high reliability and longevity, environmental friendliness and sustainability, as well as improved product quality and reduced costs. These advantages make CNC machining of aluminium parts more and more widely welcomed and applied in the manufacturing industry. With the continuous development of science and technology, aluminium CNC machining technology will continue to improve and enhance the development of the manufacturing industry to make greater contributions.

#design#autos#business#cnc machining#prototyping#precision machining#prototype#prototype machining#rapid prototyping#machining parts#cnc aluminum#aluminum machining#cnc aluminum machining#metal machining#cnc metal fabrication#cnc metal process

1 note

·

View note

Text

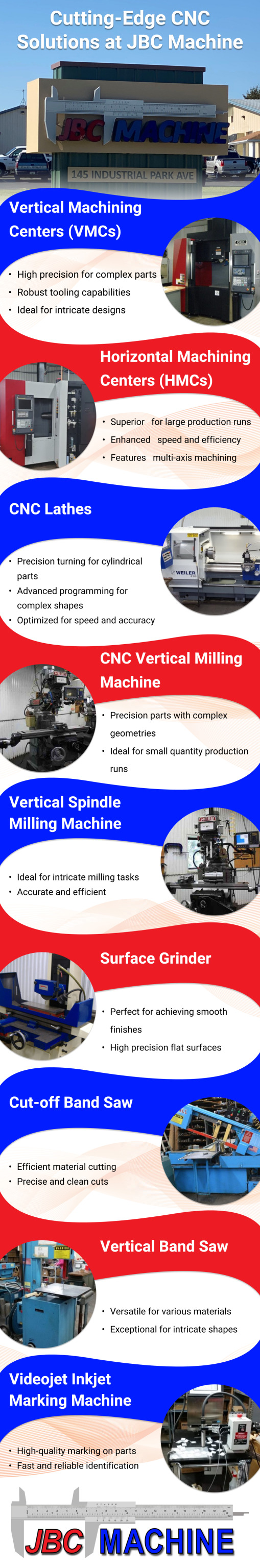

Precision CNC Machining & Custom Engineering Solutions at JBC Machine

https://jbcmachine.com/ - JBC Machine, Inc. offers advanced machining solutions with Vertical and Horizontal Machining Centers for precision and complex designs, ideal for intricate parts and large runs. Our CNC Lathes and Milling Machines excel in turning and milling precision parts, optimized for speed and accuracy. The facility also includes a Surface Grinder, Cut-off, and Vertical Band Saws for precise finishes and shapes, alongside a Videojet Inkjet Marking Machine for fast, reliable part identification. Call JBC Machine Inc. at 920-779-4075 for custom machining services.

JBC Machine, Inc.

145 Industrial Park Avenue, Hortonville, WI 54944

Phone: (920) 779-4075

E-mail: [email protected]

https://jbcmachine.com/

#CNC Plastic Machining#Plastic Machining#Aluminum Machining Custom Machine Shop#CNC Shaft Machining#Custom Machine Shop#CNC Drilling#CNC Drilling Services

0 notes

Text

Aluminium Profile 40X40

1 note

·

View note

Text

A Buyer's Guide to Choosing Custom CNC Machined Parts Manufacturers

In today's market, the demand for custom CNC machined parts is soaring across industries, including aluminum CNC turning parts. Selecting the perfect CNC machined components manufacturer is essential for quality and value. This article offers a concise guide to help you make an informed choice for your project.

Material Selection: Custom machined parts can be crafted from a variety of materials, including aluminum for CNC turning parts. Choose the right material based on your project's needs, properties, and cost, consulting your CNC machining parts factory for the best fit.

Assess Supplier Capabilities: Not all CNC machined components manufacturers are equal. Evaluate their expertise, experience, and equipment for the required machining processes and complexity, especially for aluminum CNC turning parts. Check their track record and references for reliability and quality.

Quality Control and Assurance: Ensure your chosen CNC machined components manufacturer follows stringent quality control processes, such as ISO 9001 certification, to guarantee precision and quality in your aluminum CNC turning parts.

Lead Time Management: Custom parts often have longer lead times. Understand your CNC machining parts factory's lead times to meet your project deadlines with effective communication & planning.

Pricing and Value: Compare quotes from multiple CNC machined components manufacturers, considering material and machining costs, along with additional services for aluminum CNC turning parts. Prioritize overall value and reliability over the cheapest option.

Effective Communication: Opt for a CNC machining parts manufacturer with strong communication skills. Clear and timely communication is vital for addressing questions or issues during production.

Post-Processing Services: Check if the manufacturer offers post-processing services such as deburring, polishing, anodizing, or painting, especially for aluminum CNC turning parts. Consolidating these services with one vendor can save time and effort.

Packaging and Shipping: Ensure the CNC machining parts factory can package and ship your parts securely to prevent transit damage, including your aluminum CNC turning parts. Confirm they can meet your specific shipping requirements.

Intellectual Property Protection: If your custom CNC machined parts involve proprietary designs or technology, ensure the manufacturer has policies to protect your intellectual property.

The right CNC machined parts manufacturer, including aluminum CNC turning parts, is crucial for your project's success. Considering these factors, you can make an informed decision and establish a productive partnership with a CNC machining parts factory that meets your quality, service, and value requirements.

#custom cnc turning parts#cnc parts manufacturer#cnc turned parts manufacturer#cnc machining parts manufacturer#small batch cnc machining#low volume cnc machining#machining components#machined plastic parts#aluminum parts machining#custom aluminum parts#prototype cnc machining#cnc precision parts

0 notes